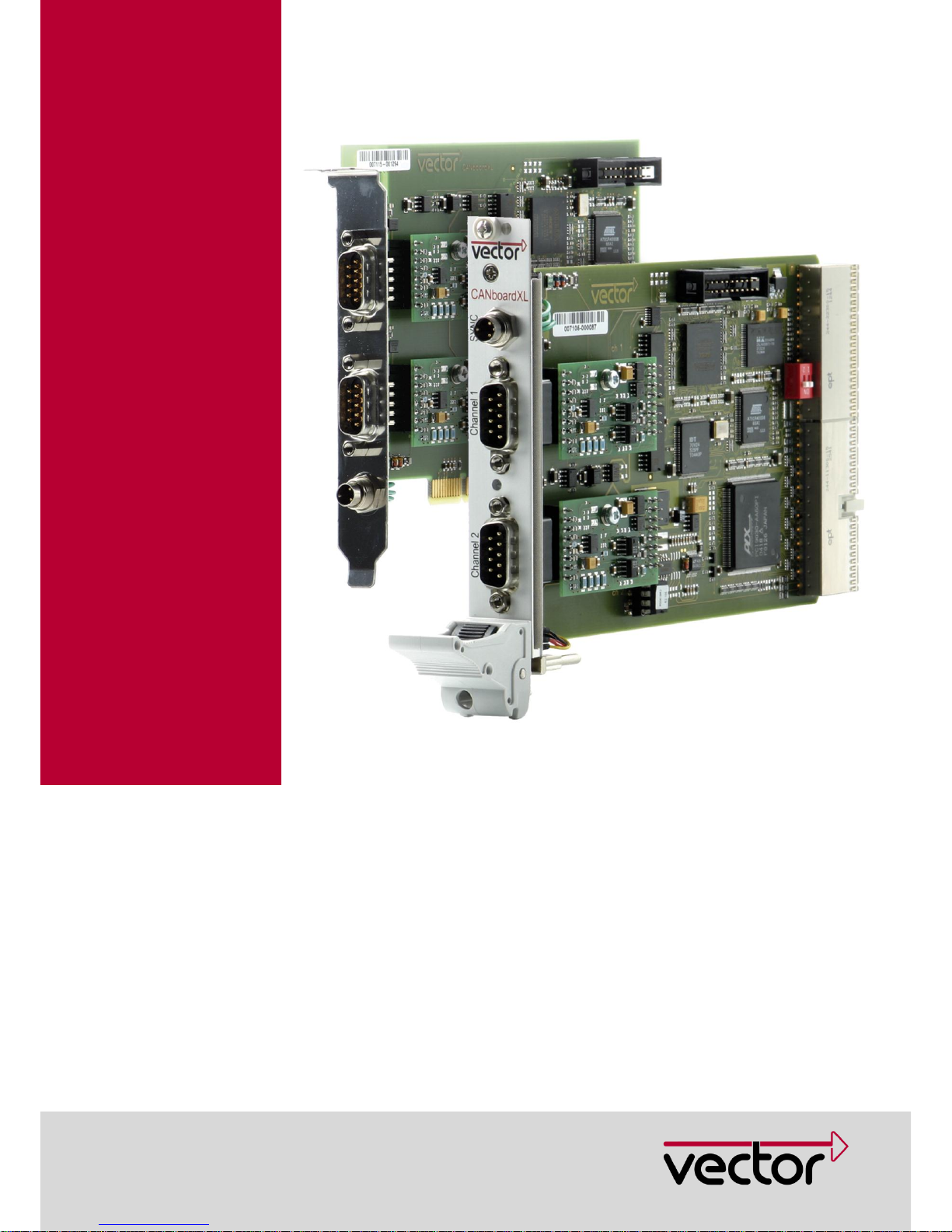

Page 1

Manual

CANboardXL Interface Family

Version 4.0

English

Page 2

Imprint

Vector Informatik GmbH

Ingersheimer Straße 24

D-70499 Stuttgart

The information and data given in this user manual can be changed without prior notice. No part of this manual may be reproduced in

any form or by any means without the written permission of the publisher, regardless of which method or which instruments, electronic

or mechanical, are used. All technical information, drafts, etc. are liable to law of copyright protection.

Copyright 2012, Vector Informatik GmbH. Printed in Germany.

All rights reserved.

Art. 80088

Page 3

Manual Table of contents

© Vector Informatik GmbH Version 4.0 - I -

Table of contents

1 Introduction 3

1.1 About this User Manual 4

1.1.1 Certification 5

1.1.2 Warranty 5

1.1.3 Support 5

1.1.4 Registered trademarks 5

2 CANboardXL Interface Family 7

2.1 Introduction 8

2.2 Driver Installation 8

2.3 Synchronization 9

2.3.1 Software Sync 9

2.3.2 Hardware Sync 9

2.4 Technical Data 11

3 Hardware Installation 13

3.1 General Notes 14

3.2 CANboardXL and CANboardXL PCIe 14

3.3 CANboardXL pxi 14

3.4 Replacing Piggybacks 15

4 CANboardXL Accessories 17

4.1 Accessories 18

5 Appendix A: Addresses 19

Page 4

Page 5

Manual Introduction

© Vector Informatik GmbH Version 4.0 - 3 -

1 Introduction

In this chapter you find the following information:

1.1 About this User Manual page 4

Certification

Warranty

Support

Registered trademarks

Page 6

Introduction Manual

- 4 - Version 4.0 © Vector Informatik GmbH

1.1 About this User Manual

To Find information

quickly

This user manual provides you with the following access help:

At the beginning of each chapter you will find a summary of the contents

In the header you can see in which chapter and paragraph you are

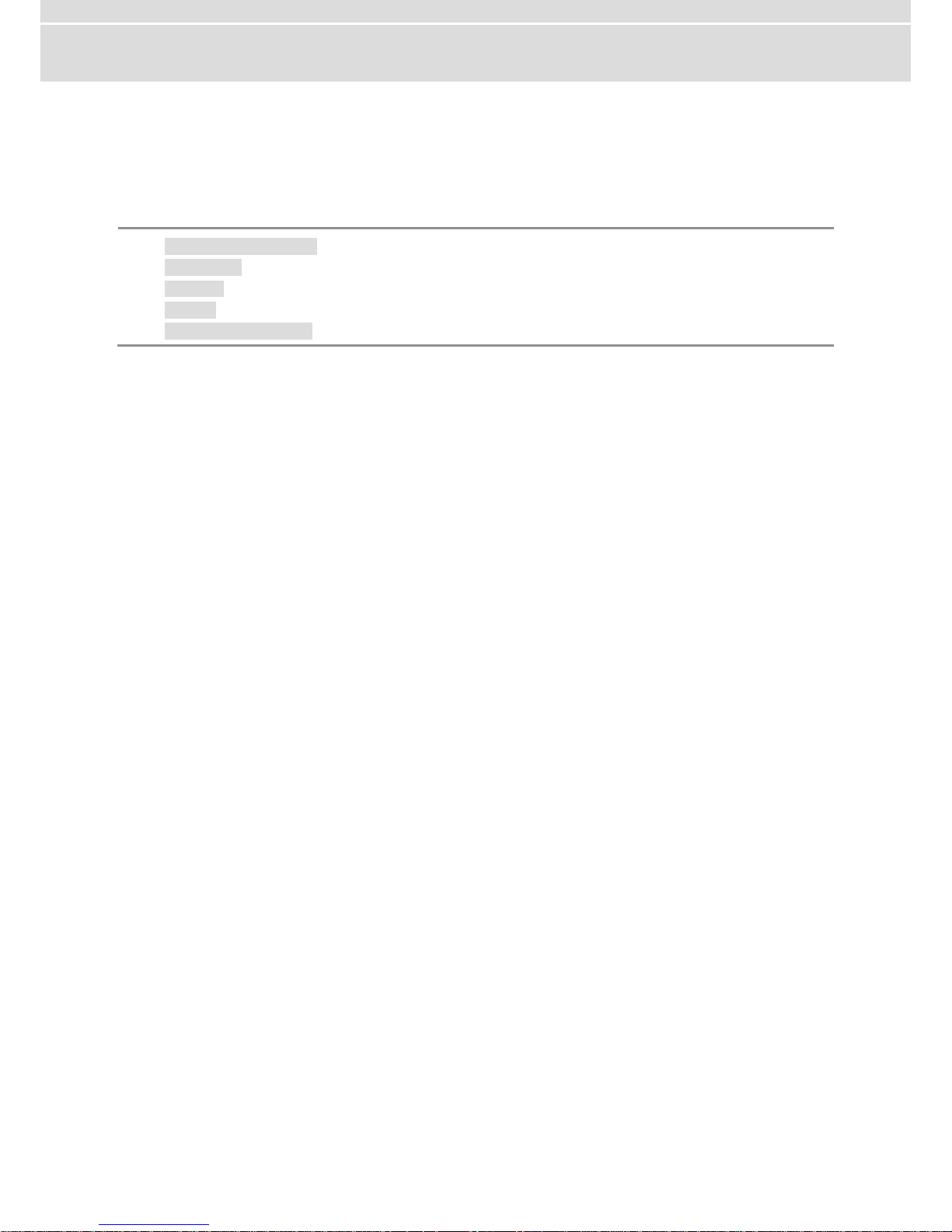

Conventions

In the two following charts you will find the conventions used in the user manual

regarding utilized spellings and symbols.

Style

Utilization

bold

Blocks, surface elements, window- and dialog names of the

software. Accentuation of warnings and advices.

[OK] Push buttons in brackets

File|Save Notation for menus and menu entries

Microsoft

Legally protected proper names and side notes.

Source Code

File name and source code.

Hyperlink

Hyperlinks and references.

<CTRL>+<S>

Notation for shortcuts.

Symbol

Utilization

Here you can obtain supplemental information.

This symbol calls your attention to warnings.

Here you can find additional information.

Here is an example that has been prepared for you.

Step-by-step instructions provide assistance at these points.

Instructions on editing files are found at these points.

This symbol warns you not to edit the specified file.

Page 7

Manual Introduction

© Vector Informatik GmbH Version 4.0 - 5 -

1.1.1 Certification

Certified Quality

Management System

Vector Informatik GmbH has ISO 9001:2008 certification. The ISO standard is a

globally recognized standard.

1.1.2 Warranty

Restriction of

warranty

We reserve the right to change the contents of the documentation and the software

without notice. Vector Informatik GmbH assumes no liability for correct contents or

damages which are resulted from the usage of the documentation. We are grateful for

references to mistakes or for suggestions for improvement to be able to offer you

even more efficient products in the future.

1.1.3 Support

You need support?

Please check the addresses at the end of this manual for your local support.

1.1.4 Registered trademarks

Registered

trademarks

All trademarks mentioned in this documentation and if necessary third party

registered are absolutely subject to the conditions of each valid label right and the

rights of particular registered proprietor. All trademarks, trade names or company

names are or can be trademarks or registered trademarks of their particular

proprietors. All rights which are not expressly allowed are reserved. If an explicit label

of trademarks, which are used in this documentation, fails, should not mean that a

name is free of third party rights.

Windows, Windows XP, Windows Vista, Windows 7 are trademarks of the

Microsoft Corporation.

Page 8

Page 9

Manual CANboardXL Interface Family

© Vector Informatik GmbH Version 4.0 - 7 -

2 CANboardXL Interface Family

In this chapter you find the following information:

2.1 Introduction page 8

2.2 Driver Installation page 8

2.3 Synchronization page 9

Software Sync

Hardware Sync

2.4 Technical Data page 11

Page 10

CANboardXL Interface Family Manual

- 8 - Version 4.0 © Vector Informatik GmbH

2.1 Introduction

CANboardXL for

PCI, PCIe und PXI

The CANboardXL is available in three variants that have identical functionalities

PCI card for installation in desktop PCs

PCI express card for installation in desktop PCs

Compact PCI/PXI backplane card for installation in industrial PCs

All cards contain a powerful 32 bit 64MHz microcontroller from ATMEL with ARM7

core and two SJA1000 CAN controllers from Philips. The SJA1000 handles CAN

messages with 11 bit as well as 29 bit identifiers. The reception and analysis of

remote frames is possible without restrictions. The CANboardXL is able to detect and

to generate error frames on the bus.

Configuration

The CANboardXL interface family can be configured with the Vector Hardware

Config tool (Windows | Start | Settings | Control Panel | Vector Hardware).

Further details about the tool can be found in the separate installation instructions at

the end of this manual.

Bus types

Various transceivers are available to interface the CANboardXL to a particular type of

bus. These CAN and LIN transceivers are available as plug-in boards (Piggybacks)

and can be mounted on the CANboardXL. For information on installing transceivers

please refer to chapter Replacing Piggybacks on page 15. A list of available

Piggybacks is included in the accessories manual on the driver CD:

\Documentation\Accessories_for_Network_Interfaces.pdf

Connectors

The CANboardXL has the following connectors:

Two D-SUB9 connectors for independent CAN and LIN operation

Binder connector (type 712) for synchronization

Internal sync connector (CANboardXL PCIe only)

Note: The pin assignments of the D-SUB9 connectors depend on the Piggybacks

being used. Further information can be found in the accessories manual on the driver

CD.

2.2 Driver Installation

Note: Information about the driver installation process can be found in the separate

installation instructions at the end of this manual.

Page 11

Manual CANboardXL Interface Family

© Vector Informatik GmbH Version 4.0 - 9 -

2.3 Synchronization

General information

Time stamps, which are created during a measurement by two or more devices of the

Vector interface family, can be synchronized by software or hardware.

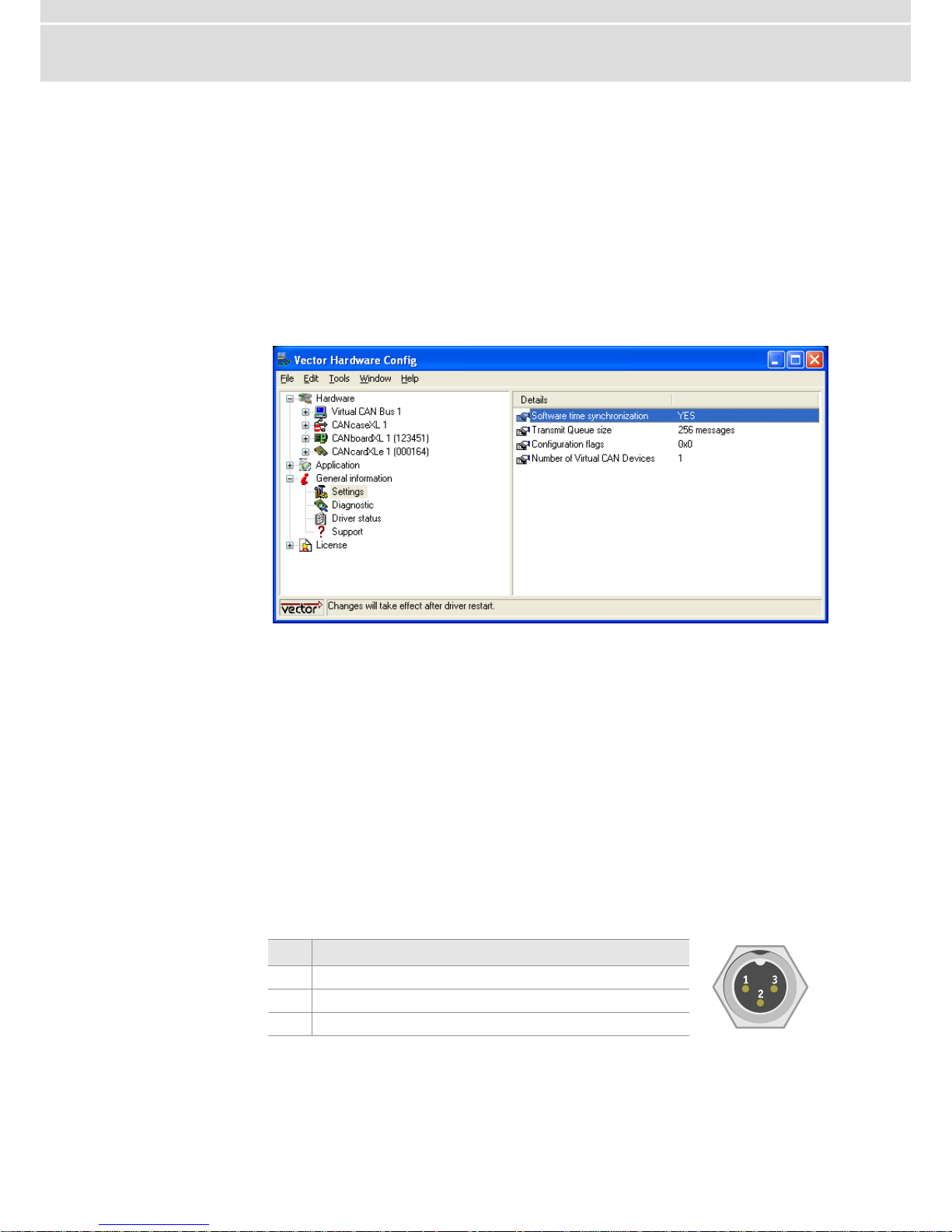

2.3.1 Software Sync

Synchronization

by software

The software synchronization is driver-based and available for all applications without

any restrictions. This kind of synchronization can be switched on in Vector Hardware

Config | General information | Settings | Software time synchronization.

Figure 1: Switching on the software synchronization.

The accuracy of the time stamp correction depends on the device and is typically

50 µs.

2.3.2 Hardware Sync

Synchronization

by hardware

A more precise synchronization of multiple devices is possible via the hardware

synchronization. The hardware synchronization with a maximum of four devices is

done with the SYNCcableXL (see accessories manual, article number 05018) and

has to be supported by the application. The accuracy of the time stamp correction

depends on the application and is typically 1 µs.

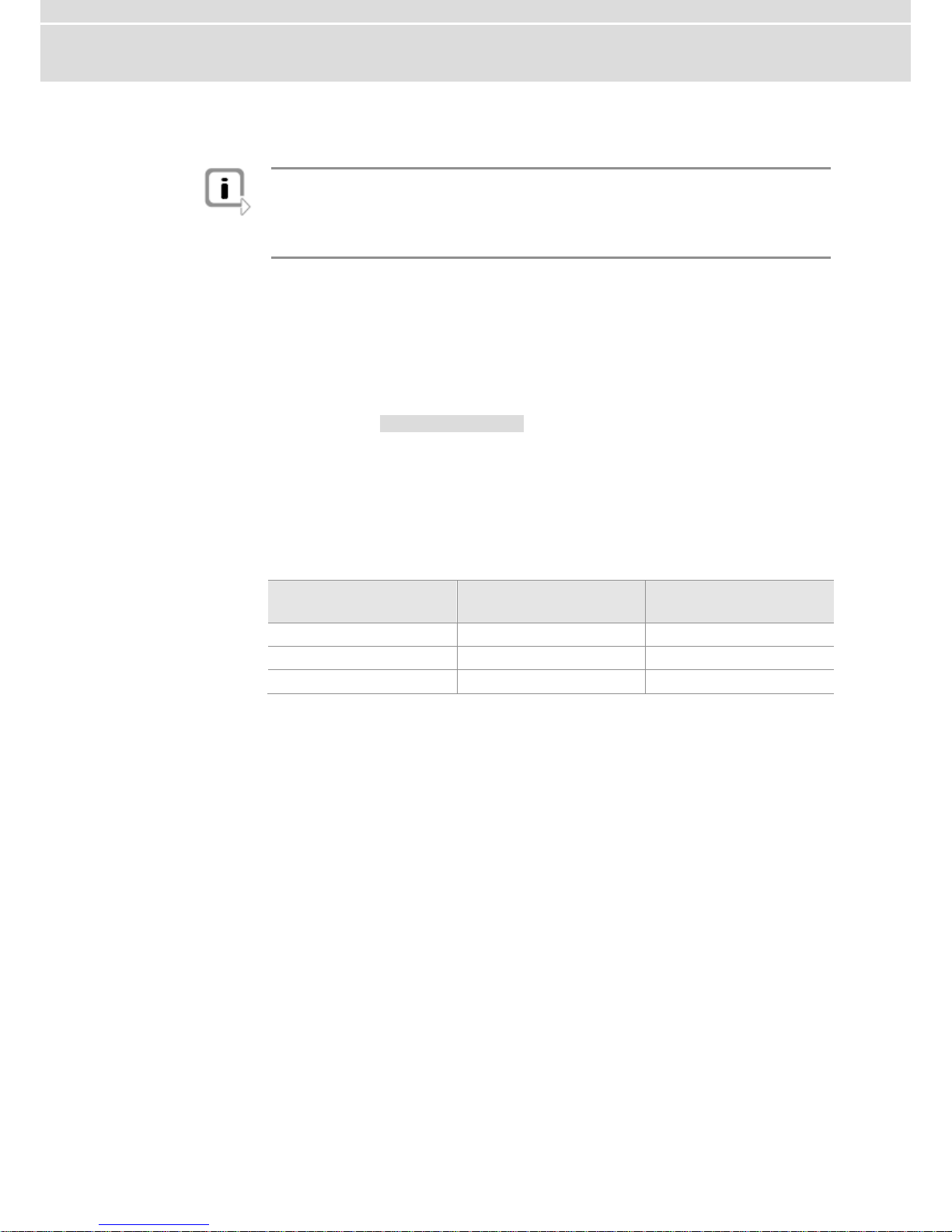

Functionality of

the hardware

synchronization

The devices to be synchronized must be interconnected by a two-wire bus (signals:

SYNC and GND). The devices have a 3-pin connector for this use case (Binder type

712).

Pin

Assignment

1

Not connected

2

Synchronization line

3

Ground

At each high-low edge of the sync line the CANboardXL generates a time stamp that

is provided to the application. This allows the application to synchronize the time

stamps of different devices to a common time base.

Page 12

CANboardXL Interface Family Manual

- 10 - Version 4.0 © Vector Informatik GmbH

The synchronization edges can be generated by the VN or the XL interface family.

Note: The hardware synchronization must be supported by the application. For

further information please refer to the relevant manual. Please note that the software

synchronization must be disabled (see Vector Hardware Config | General

information | Settings | Software time synchronization) if the hardware

synchronization is used.

Synchronization by

sync connector

(CANboardXL PCIe)

Multiple CANboardXL PCIe can be synchronized either by the Binder connector

outside the PC housing or by the internal sync connector. The internal sync connector

is a 10-pin connector (90° offset) and available next to the Piggyback slots. The

synchronization is done with a ribbon cable and a 10-pin standard socket.

Time synchronization

through

PXI backplane

Additional to the synchronization described above, the CANboardXL pxi supports time

synchronization through the PXI backplane.

In Figure 3 (see Replacing Piggybacks on page 15) you can see the switches (white

circle) that are used to control the synchronization between the cards.

In position ON, the synchronization is active. The right and left end of the

synchronization line, which is build with multiple CANboardXL pxi cards, has to be cut

off. The cut off of the right end is done with switch 2, the cut off of the left end with

switch 1.

Example

Time synchronization with three CANboardXL pxi:

CANboardXL pxi

Switch 1

Switch 2

1 (left)

OFF

ON

2 (middle)

ON

ON

3 (right)

ON

OFF

Page 13

Manual CANboardXL Interface Family

© Vector Informatik GmbH Version 4.0 - 11 -

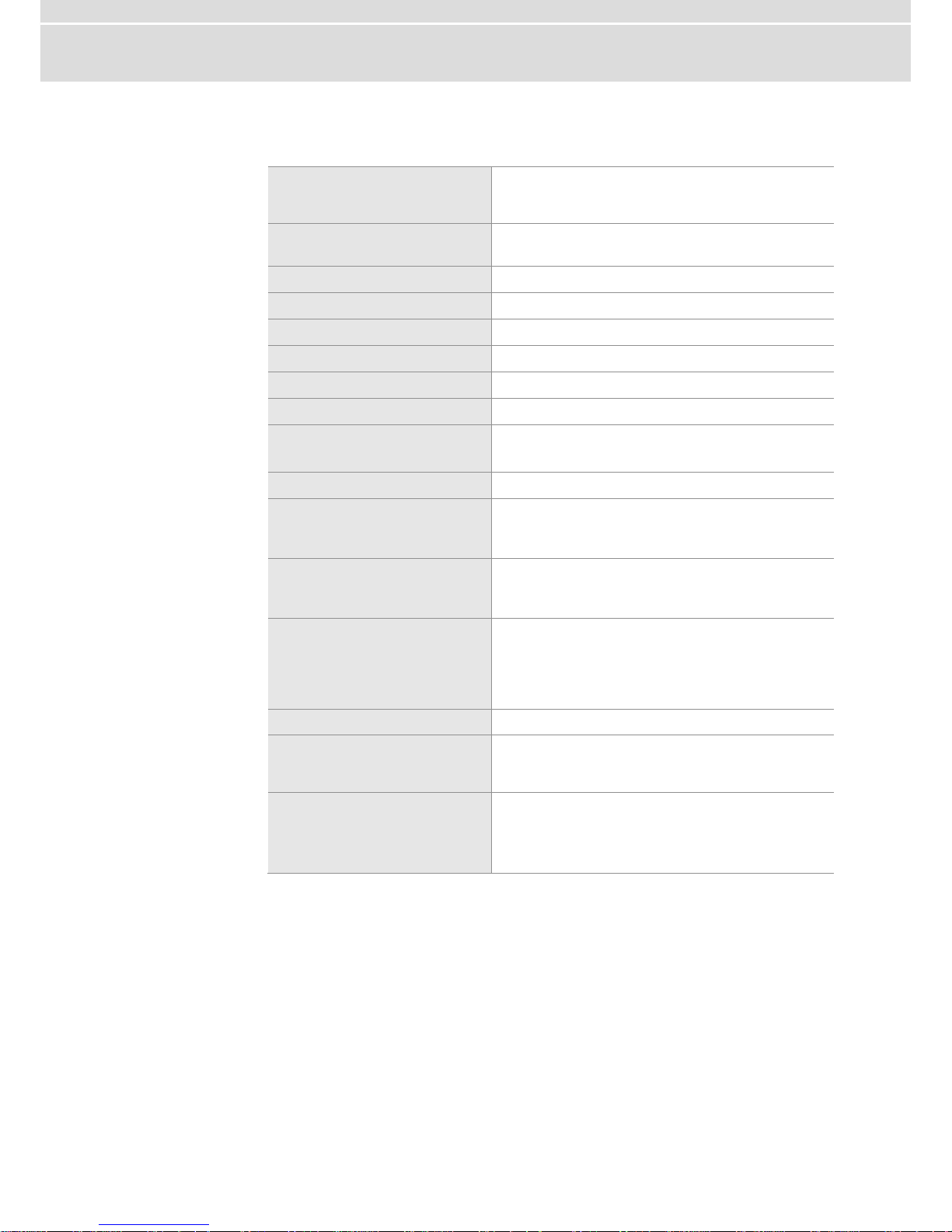

2.4 Technical Data

PC interface

CANboardXL : PCI

CANboardXL PCIe : PCI Express

CANboardXL pxi : Compact PCI / PXI

Channels

2 independent channels

for CAN, LIN and J1708

Transceiver

Piggybacks

CAN controller

2 Phillips SJA 1000

Microcontroller

ATMEL AT91R40008 32bit 64MHz

Max. baudrate

1 Mbit/s

Time stamp accuracy

1 µs

Error frame

Detection and generation

Power consumption

1W for CANboardXL/pxi without Piggybacks

2,5W for CANboardXL PCIe without Piggybacks

Configuration

Plug & Play

Dimensions

approx. 155 x 135 x 20 mm (PCI)

approx. 145 x 105 x 17 mm (PCIe)

approx. 210 x 135 x 20 mm (pxi)

Weight

approx. 210 g without Piggybacks (PCI)

approx. 210 g without Piggybacks (PCIe)

approx. 350 g without Piggybacks (pxi)

Temperature range

Operation: Standard -20...65 °C (PCI)

Operation: Standard 0...65 °C (PCIe)

Operation: Standard -20...75 °C (pxi)

Transport and storage: -40... 85 °C

Relative humidity

15 %...95 %, not condensing

Software requirements

Windows XP (SP3)

Windows Vista (SP1)

Windows 7

Hardware requirements

IBM PC AT or 100 % compatible;

Free PCI Slot (CANboardXL)

Free PCIe Slot (CANboardXL PCIe)

Free Compact PCI Slot (CANboardXL pxi)

Page 14

Page 15

Manual Hardware Installation

© Vector Informatik GmbH Version 4.0 - 13 -

3 Hardware Installation

In this chapter you find the following information:

3.1 General Notes page 14

3.2 CANboardXL and CANboardXL PCIe page 14

3.3 CANboardXL pxi page 14

3.4 Replacing Piggybacks page 15

Page 16

Hardware Installation Manual

- 14 - Version 4.0 © Vector Informatik GmbH

3.1 General Notes

Caution: Turn off the main power supply and disconnect your computer’s power cord.

Otherwise systems using an ATX power supply unit with soft power off may still be

powering the PCI slot. This can damage your PCI card when it is inserted into the slot

Caution: Do not force the CANboardXL into the slot. Make sure that the connectors

of the card’s PCI connector are aligned with the bus connector on the motherboard

before you insert the card into the slot. If it does not fit properly, gently remove it and

try again.

Note: Please observe all safety precautions prescribed by your PC manufacturer for

card installation!

Note: Do not touch the bottom and the topside of the PCBs (CANboardXL main

board and Piggybacks).

3.2 CANboardXL and CANboardXL PCIe

1. Turn off the computer and all peripheral devices. Unplug the power cord and

open the case.

2. Touch a metal plate on your computer to ground yourself and to discharge any

static electricity.

3. Remove the metal brackets from an unused slot.

4. Align the CANboardXL with the PCI/PCIe slot and press the card gently but firmly

into the slot.

5. Replace the computer cover.

6. Plug in the power cord.

3.3 CANboardXL pxi

1. Turn off the computer and all peripheral devices. Unplug the power cord and

open the case.

2. Touch a metal plate on your computer to ground yourself and to discharge any

static electricity.

3. Align the CANboardXL pxi with the slot and press the card gently but firmly into

the slot.

4. The CANboardXL pxi has to be fixed again with the screws.

Page 17

Manual Hardware Installation

© Vector Informatik GmbH Version 4.0 - 15 -

3.4 Replacing Piggybacks

1. Unplug the power cord and open the case.

2. Touch a metal plate on your computer to ground yourself and to discharge any

static electricity.

3. Unplug the CANboardXL.

Note: Each of the Piggybacks is fixed with a screw.

4. Detach the screw with the screw protection and remove the Piggyback carefully.

5. Plug in the alternative Piggyback.

CANboardXL

Figure 2: Channel 1 and 2 on CANboardXL.

CANboardXL pxi

Ch 1

Ch 2

Figure 3: Channel 1 and 2 on CANboardXL pxi.

Info: The two-row connector and the one-row connector must fit and must not be

displaced laterally.

Page 18

Hardware Installation Manual

- 16 - Version 4.0 © Vector Informatik GmbH

6. The Piggyback has to be fixed again with the screw and the screw protection.

7. Firmly insert the card into the selected slot. Push down to ensure the card is fully

seated.

8. Replace the computer cover.

9. Plug in the power cord.

Page 19

Manual CANboardXL Accessories

© Vector Informatik GmbH Version 4.0 - 17 -

4 CANboardXL Accessories

In this chapter you find the following information:

4.1 Accessories page 18

Page 20

CANboardXL Accessories Manual

- 18 - Version 4.0 © Vector Informatik GmbH

4.1 Accessories

Reference: Further information about the available accessories can be found in the

separate accessories manual on the driver CD:

\Documentation\Accessories_for_Network_Interfaces.pdf

Page 21

Manual Appendix A: Addresses

© Vector Informatik GmbH Version 4.0 - 19 -

5 Appendix A: Addresses

Vector Informatik

GmbH

Vector Informatik GmbH

Ingersheimer Str. 24

70499 Stuttgart

Germany

Support: +49 711 80670-200

Phone: +49 711 80670-0

Fax: +49 711 80670-111

mailto:info@de.vector.com

http://www.vector.com

Vector CANtech, Inc.

Vector CANtech, Inc.

39500 Orchard Hill Place

Suite 550

Novi, Mi 48375

USA

Support: +1 248 449 9290 Option 2

Phone: +1 248 449 9290

Fax: +1 248 449 9704

mailto:info@us.vector.com

http://www.vector.com

Vector Automotive

Technology

(Shanghai) Co., Ltd.

Vector Automotive Technology (Shanghai) Co., Ltd.

Sunyoung Center

Room 1701, No.398 Jiangsu Road

Changning District

Shanghai 200050

China

Phone: +86 21 6432 53530

Fax: +86 21 6432 5308

mailto:info@cn.vector.com

http://www.vector.com

Vector France SAS

Vector France SAS

168, Boulevard Camélinat

92240 Malakoff

France

Support: +33 1 4231 4010

Phone: +33 1 4231 4000

Fax: +33 1 4231 4009

mailto:information@fr.vector.com

http://www.vector.com

Page 22

Appendix A: Addresses Manual

- 20 - Version 4.0 © Vector Informatik GmbH

Vector GB Ltd.

Vector GB Ltd.

Rhodium

Central Boulevard

Blythe Valley Park

Solihull, Birmingham

West Midlands B90 8AS

United Kingdom

Support: +44 121 50681-77

Phone: +44 121 50681-50

mailto:info@uk.vector.com

http://www.vector.com

Vector Informatik

India Pvt. Ltd.

Vector Informatik India Pvt. Ltd.

Lokesh Madan

4/1/1/1, Sutar Icon, Sus Road

Pashan, Pune - 411 021

India

Phone: +91 20 2587 2023

Fax: +91 20 2587 2025

mailto:info@in.vector.com

http://www.vector.com

Vector Japan Co.,

Ltd.

Vector Japan Co., Ltd.

Seafort Square Center Bld.

18F, 2-3-12,

Higashi-shinagawa, Shinagawa-ku

Tokyo 140-0002

Japan

Support: +81 3 5769 7800

Phone: +81 3 5769 7800

Fax: +81 3 5769 6975

mailto:info@jp.vector.com

http://www.vector.com

Vector Korea IT Inc.

Vector Korea IT Inc.

#1406 Mario Tower

222-12 Guro-dong, Guro-gu

Seoul, 152-848

Republic of Korea

Support: : +82 2 807 0600 Ext.2

Phone: +82 2 807 0600

Fax: +82 2 8070601

mailto:info@kr.vector.com

http://www.vector.com

Page 23

Manual

© Vector Informatik GmbH Version 4.0 - 21 -

VecScan AB

VecScan AB

Theres Svenssons Gata 9

417 55 Göteborg

Sweden

Support: +46 (31) 764 76-00

Phone: +46 (31) 76476-00

Fax: +46 (31) 76476-19

mailto:info@se.vector.com

http://www.vector.com

Page 24

Page 25

Manual

Installation Instructions

Version 3.0

English

Page 26

Imprint

Vector Informatik GmbH

Ingersheimer Straße 24

D-70499 Stuttgart

The information and data given in this user manual can be changed without prior notice. No part of this manual may be reproduced in

any form or by any means without the written permission of the publisher, regardless of which method or which instruments, electronic

or mechanical, are used. All technical information, drafts, etc. are liable to law of copyright protection.

Copyright 2012, Vector Informatik GmbH. Printed in Germany.

All rights reserved.

Page 27

Manual Table of contents

© Vector Informatik GmbH Version 3.0 - I -

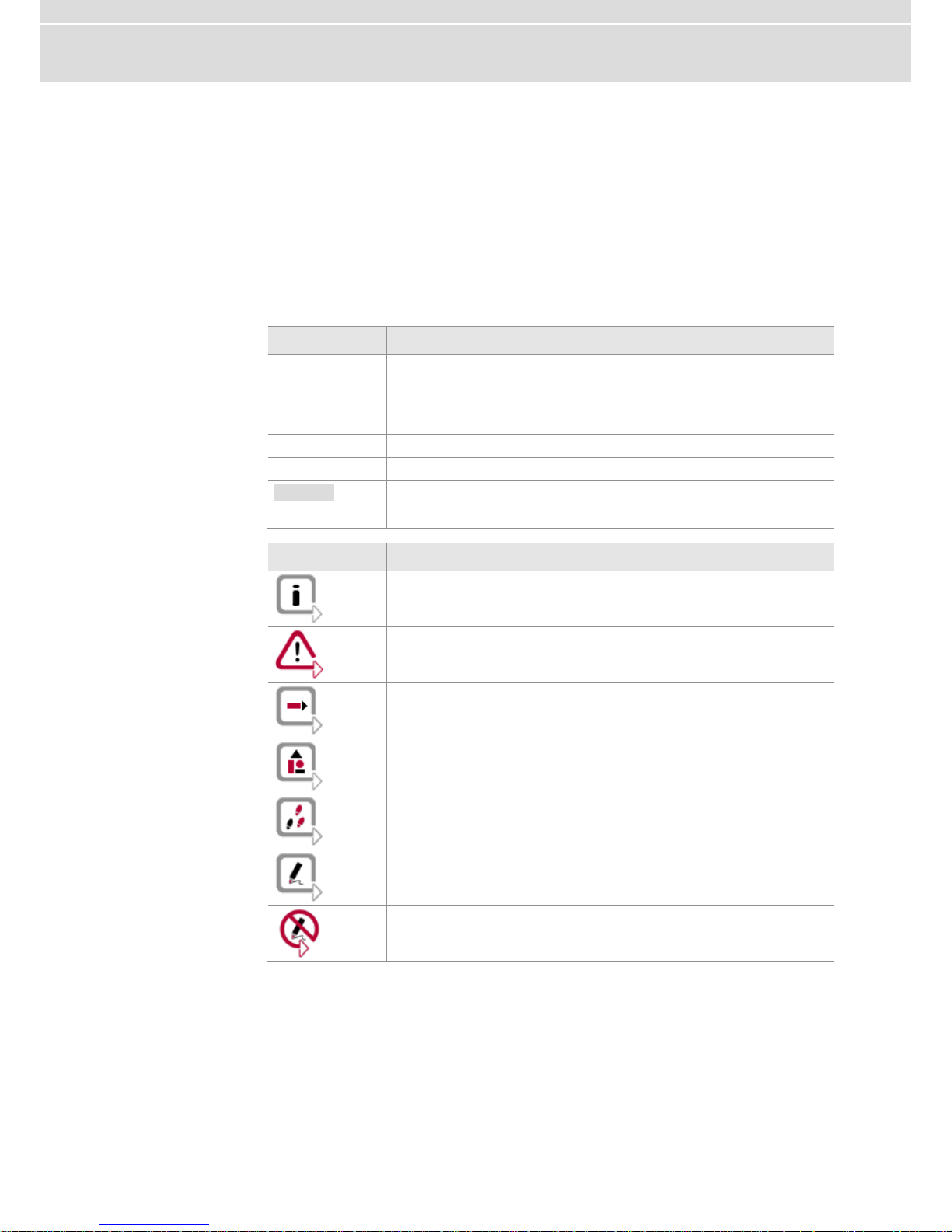

Table of contents

1 Introduction 3

1.1 About this User Manual 4

1.1.1 Certification 5

1.1.2 Warranty 5

1.1.3 Support 5

1.1.4 Registered Trademarks 5

2 Driver Installation 7

2.1 Minimum Requirements 8

2.2 Hints 8

2.3 Vector Driver Setup 9

2.4 Vector Hardware Configuration 11

3 Operating Test 13

3.1 Loop Test 14

3.1.1 CAN 14

3.1.2 FlexRay 16

3.1.3 MOST 17

4 Appendix A: Addresses 19

Page 28

Page 29

Manual Introduction

© Vector Informatik GmbH Version 3.0 - 3 -

1 Introduction

In this chapter you find the following information:

1.1 About this User Manual page 4

Certification

Warranty

Support

Registered Trademarks

Page 30

Introduction Manual

- 4 - Version 3.0 © Vector Informatik GmbH

1.1 About this User Manual

To find information

quickly

This user manual provides you with the following access help:

At the beginning of each chapter you will find a summary of the contents

In the header you can see in which chapter and paragraph you are

Conventions

In the two following charts you will find the conventions used in the user manual

regarding utilized spellings and symbols.

Style

Utilization

bold

Blocks, surface elements, window- and dialog names of the

software. Accentuation of warnings and advices.

[OK] Push buttons in brackets

File|Save Notation for menus and menu entries

Microsoft

Legally protected proper names and side notes.

Source Code

File name and source code.

Hyperlink

Hyperlinks and references.

<CTRL>+<S>

Notation for shortcuts.

Symbol

Utilization

Here you can obtain supplemental information.

This symbol calls your attention to warnings.

Here you can find additional information.

Here is an example that has been prepared for you.

Step-by-step instructions provide assistance at these points.

Instructions on editing files are found at these points.

This symbol warns you not to edit the specified file.

Page 31

Manual Introduction

© Vector Informatik GmbH Version 3.0 - 5 -

1.1.1 Certification

Certified Quality

Management System

Vector Informatik GmbH has ISO 9001:2008 certification. The ISO standard is a

globally recognized standard.

1.1.2 Warranty

Restriction

of warranty

We reserve the right to change the contents of the documentation and the software

without notice. Vector Informatik GmbH assumes no liability for correct contents or

damages which are resulted from the usage of the documentation. We are grateful for

references to mistakes or for suggestions for improvement to be able to offer you

even more efficient products in the future.

1.1.3 Support

You need support?

Please check the addresses at the end of this manual for your local support.

1.1.4 Registered Trademarks

Registered

trademarks

All trademarks mentioned in this documentation and if necessary third party

registered are absolutely subject to the conditions of each valid label right and the

rights of particular registered proprietor. All trademarks, trade names or company

names are or can be trademarks or registered trademarks of their particular

proprietors. All rights which are not expressly allowed are reserved. If an explicit label

of trademarks, which are used in this documentation, fails, should not mean that a

name is free of third party rights.

Windows, Windows XP, Windows Vista, Windows 7 are trademarks of the

Microsoft Corporation.

Page 32

Page 33

Manual Driver Installation

© Vector Informatik GmbH Version 3.0 - 7 -

2 Driver Installation

In this chapter you find the following information:

2.1 Minimum Requirements page 8

2.3 Vector Driver Setup page 9

2.4 Vector Hardware Configuration page 11

Page 34

Driver Installation Manual

- 8 - Version 3.0 © Vector Informatik GmbH

2.1 Minimum Requirements

Hardware

CPU

Pentium 4 or higher

Memory

512 MB or more

Network interface

CANcardXL : PCMCIA

CANcardXLe : ExpressCard 54

CANboardXL PCI : PCI

CANboardXL PCIe : PCI Express 1x

CANboardXL PXI : Compact PCI/PXI

CANcaseXL : USB

CANcaseXL log : USB

VN1610 : USB

VN1611 : USB

VN1630 : USB

VN2610 : USB

VN2640 : USB

VN3300 : PCI

VN3600 : USB

VN7600 : USB

VN8910 : USB

Software

Operating system

Windows XP SP3 (32 bit)

Windows Vista SP1 (32 bit)

Windows 7 (32/64 bit)

Driver version

8.x

Measurement

application

The devices can be run with several applications from Vector

(e. g. CANoe, CANalyzer) or with measurement applications

from other companies. Therefor the devices require a related

license. Applications based on the Vector XL Driver Library can

be run without a license.

2.2 Hints

Note: Many desktop PCs have power managers which block the CPU for a specific

time. This impairs accuracy of the time system. If your application has stringent timing

requirements (e. g. time-driven sending of messages or time-driven evaluations), you

have to deactivate these power managers. Power management settings may be con-

tained in the BIOS setup or on the Control Panel of Windows XP / Vista / Windows 7

(e. g. Power options).

No further mention will be made of the power manager in this document.

Info: Please note that you will need Administrator Rights for the following steps.

Page 35

Manual Driver Installation

© Vector Informatik GmbH Version 3.0 - 9 -

2.3 Vector Driver Setup

General information

The Vector Driver Disk offers a driver setup which allows the installation or the

removal of Vector devices.

1. Execute the driver setup from the autostart menu or directly from

\Drivers\Setup.exe before the device is inserted or connected to the PC with

the included USB cable.

If you have already inserted or connected the device to the PC, the Windows

found new Hardware wizard appears. Close this wizard and then execute the

driver setup.

2. Click [Next] in the driver setup dialog. The initialization process starts.

Page 36

Driver Installation Manual

- 10 - Version 3.0 © Vector Informatik GmbH

3. In the driver selection dialog select your devices to be installed (or to be

uninstalled).

4. Click [Install] to execute the driver installation, or [Uninstall] to remove existing

drivers.

5. A confirmation dialog appears. Click [Close] to exit.

If the driver has been properly installed, the device can be inserted or connected

to the PC with the included USB cable. The device is ready for operation now.

6. For Windows XP users only:

If the Windows found new Hardware wizard appears, select the option for auto-

matic driver search to complete the installation.

Page 37

Manual Driver Installation

© Vector Informatik GmbH Version 3.0 - 11 -

2.4 Vector Hardware Configuration

Executing Vector

Hardware Config

After the successful installation you will find the configuration application Vector

Hardware in the Control Panel (see below). The tool gives you information about the

connected and installed Vector devices. There are also several settings that can be

changed.

Control panel

Windows XP

Category view

Start | (Settings) | Control Panel, click in the left part of the window for further

Control Panel options followed by Vector Hardware.

Classic view

Start | (Settings) | Control Panel, click Vector Hardware in the list.

Control panel

Windows Vista

Category view

Start | (Settings) | Control Panel, click in the right part of the window for

Additional Options followed by Vector Hardware.

Classic view

Start | (Settings) | Control Panel, click Vector Hardware in the list.

Control panel

Windows 7

Category view

Start | Control Panel | Hardware and Sound, click Vector Hardware in the list.

Symbols view

Start | Control Panel, click Vector Hardware in the list.

The tool is split into two windows. The left window lets you access the installed Vector

devices, the right window displays the details of the selection. The following nodes

are available in the left window:

Hardware

Each installed Vector device is shown in Hardware. Additional details of available

channels are shown in a tree view. Status information on the device components and

the channels are also shown in this dialog.

Page 38

Driver Installation Manual

- 12 - Version 3.0 © Vector Informatik GmbH

Application

In Application all available applications are shown with their configured channels. If

you click on an application, all of its channels are displayed in the right pane on the

screen.

General information

The General information section contains general information on Vector devices and

applications.

License

The License section contains information on all currently valid licenses.

Note: You will find a detailed description of Vector Hardware Config in the online

help (Help | Contents).

Page 39

Manual Operating Test

© Vector Informatik GmbH Version 3.0 - 13 -

3 Operating Test

In this chapter you find the following information:

3.1 Loop Test page 14

CAN

FlexRay

MOST

Page 40

Operating Test Manual

- 14 - Version 3.0 © Vector Informatik GmbH

3.1 Loop Test

Operating test

The test described here can be performed to check the functional integrity of the

driver and the device. This test is identical for Windows XP, Windows Vista,

Windows 7 and independent of the application being used.

3.1.1 CAN

Device test

The operating test for CAN can be executed with the following devices:

CANcardXL

CANcardXLe

CANcaseXL

CANcaseXL log

CANboardXL Family

VN1610

VN1630

VN7600

Loop3.exe

Either two High-Speed or two Low-Speed transceivers are necessary for this

functional test:

1. Connect two CAN channels with a suitable cable. If two High-Speed transceivers

are being used, we recommend our CANcable 1 (CANcable 0 for Low-Speed

transceivers).

2. Start \Drivers\Common\Loop3.exe from the driver CD.

This program accesses the Vector devices and transmits CAN messages.

3. Select the connected CAN channels of the device(s) to be tested.

4. Set the appropriate baudrate depending on the transceiver being used (HighSpeed max. 1,000,000 Bd, Low-Speed max. 125,000 Bd).

5. Click [Start].

Page 41

Manual Operating Test

© Vector Informatik GmbH Version 3.0 - 15 -

6. You will see statistical data in the lower part of the window if the system has been

configured properly.

Loop3 application

7. The test procedure can be terminated with the [Stop] button.

An OK should appear in the upper part of the window.

Page 42

Operating Test Manual

- 16 - Version 3.0 © Vector Informatik GmbH

3.1.2 FlexRay

Device test

The operating test for FlexRay can be executed with the following devices:

VN3300

VN3600

VN7600

FRLoop.exe

This operating test requires an inserted FRpiggy.

1. Remove the FlexRay cable if it is connected.

2. Start \Drivers\Common\FRLoop.exe from the driver CD.

3. Execute the test.

4. If no error messages occur, the operating test was successful.

Page 43

Manual Operating Test

© Vector Informatik GmbH Version 3.0 - 17 -

3.1.3 MOST

Device test

The operating test for MOST can be executed with the following devices:

VN2610

VN2640

MLoop.exe

This functional test requires a MOST fiber optic cable and a fiber coupler for HFBR

connectors.

1. VN2610

Start \Drivers\Common\MLoop.exe from the driver CD

VN2640

Start \Drivers\Common\M150Loop.exe from the driver CD.

2. Select the VN2610/VN2640 to be tested from the list of detected devices.

3. Click [Twinkle] and check if the power LED of the VN2610/VN2640 is blinking at

least for one second.

4. Connect the MOST fiber optic cable with the VN2610/VN2640 device, select

Master mode and check if the program displays the status Unlock. Check if red

light comes out of the Tx fiber of the MOST fiber optic cable.

5. Connect both ends of the fiber with one fiber coupler to a ring and check if the

program displays the status Lock.

6. Close MLoop.exe with [Exit].

Page 44

Page 45

Manual Appendix A: Addresses

© Vector Informatik GmbH Version 3.0 - 19 -

4 Appendix A: Addresses

Vector Informatik

GmbH

Vector Informatik GmbH

Ingersheimer Str. 24

70499 Stuttgart

Germany

Support: +49 711 80670-200

Phone: +49 711 80670-0

Fax: +49 711 80670-111

mailto:info@de.vector.com

http://www.vector.com

Vector CANtech, Inc.

Vector CANtech, Inc.

39500 Orchard Hill Place

Suite 550

Novi, Mi 48375

USA

Support: +1 248 449 9290 Option 2

Phone: +1 248 449 9290

Fax: +1 248 449 9704

mailto:info@us.vector.com

http://www.vector.com

Vector Automotive

Technology

(Shanghai) Co., Ltd.

Vector Automotive Technology (Shanghai) Co., Ltd.

Sunyoung Center

Room 1701, No.398 Jiangsu Road

Changning District

Shanghai 200050

China

Phone: +86 21 6432 53530

Fax: +86 21 6432 5308

mailto:info@cn.vector.com

http://www.vector.com

Vector France SAS

Vector France SAS

168, Boulevard Camélinat

92240 Malakoff

France

Support: +33 1 4231 4010

Phone: +33 1 4231 4000

Fax: +33 1 4231 4009

mailto:information@fr.vector.com

http://www.vector.com

Page 46

Appendix A: Addresses Manual

- 20 - Version 3.0 © Vector Informatik GmbH

Vector GB Ltd.

Vector GB Ltd.

Rhodium

Central Boulevard

Blythe Valley Park

Solihull, Birmingham

West Midlands B90 8AS

United Kingdom

Support: +44 121 50681-77

Phone: +44 121 50681-50

mailto:info@uk.vector.com

http://www.vector.com

Vector Informatik

India Pvt. Ltd.

Vector Informatik India Pvt. Ltd.

Lokesh Madan

4/1/1/1, Sutar Icon, Sus Road

Pashan, Pune - 411 021

India

Phone: +91 20 2587 2023

Fax: +91 20 2587 2025

mailto:info@in.vector.com

http://www.vector.com

Vector Japan Co.,

Ltd.

Vector Japan Co., Ltd.

Seafort Square Center Bld.

18F, 2-3-12,

Higashi-shinagawa, Shinagawa-ku

Tokyo 140-0002

Japan

Support: +81 3 5769 7800

Phone: +81 3 5769 7800

Fax: +81 3 5769 6975

mailto:info@jp.vector.com

http://www.vector.com

Vector Korea IT Inc.

Vector Korea IT Inc.

#1406 Mario Tower

222-12 Guro-dong, Guro-gu

Seoul, 152-848

Republic of Korea

Support: : +82 2 807 0600 Ext.2

Phone: +82 2 807 0600

Fax: +82 2 8070601

mailto:info@kr.vector.com

http://www.vector.com

Page 47

Manual Appendix A: Addresses

© Vector Informatik GmbH Version 3.0 - 21 -

VecScan AB

VecScan AB

Theres Svenssons Gata 9

417 55 Göteborg

Sweden

Support: +46 (31) 764 76-00

Phone: +46 (31) 76476-00

Fax: +46 (31) 76476-19

mailto:info@se.vector.com

http://www.vector.com

Page 48

Get more Information!

Visit our Website for:

> News

> Products

> Demo Software

> Support

> Training Classes

> Addresses

www.vector.com

Loading...

Loading...