Page 1

BRICK CORE COM

Manual

Version 2.0n

Page 2

Imprint

Vector Informatik GmbH

Ingersheimer Straße 24

D-70499 Stuttgart

The information and data given in this user manual can be changed without prior notice. No part of this

manual may be reproduced in any form or by any means without the written permission of the

publisher, regardless of which method or which instruments, electronic or mechanical, are used. All

technical information, drafts, etc. are liable to law of copyright protection.

© Copyright 2019, Vector Informatik GmbH. All rights reserved.

Page 3

Contents

1 General Information ..................................................................................................................... 6

Important instructions .............................................................................................................. 6

Warranty and liability ............................................................................................................... 6

Trademarks .............................................................................................................................. 7

Used symbols and their meanings .......................................................................................... 7

2 Safety ........................................................................................................................................... 8

Proper Use and Intended Purpose .......................................................................................... 8

Hazards ................................................................................................................................... 8

Battery notice ........................................................................................................................... 8

Electrostatically Sensitive Components (ESD) ........................................................................ 9

Grounding practices............................................................................................................. 9

Warning of hot surface ............................................................................................................ 9

Disclaimer ................................................................................................................................ 9

3 System Configuration ................................................................................................................ 10

BRICK CORE COM computer core ....................................................................................... 11

Add-On BRICK CORE COM STORAGE BAY ...................................................................... 12

Add-On BRICK CORE COM PCIe ........................................................................................ 12

4 BRICK STORAGE ..................................................................................................................... 13

Lock / Unlock BRICK STORAGE cartridge ........................................................................... 13

BRICK STORAGE cartridge order Information ..................................................................... 13

5 Accessories ............................................................................................................................... 14

6 Product Identification ................................................................................................................. 15

Scope of delivery ................................................................................................................... 15

Type Plate .............................................................................................................................. 15

7 Technical Specification .............................................................................................................. 16

Technical Characteristics of BRICK CORE COM: ................................................................ 16

Environmental Characteristics and Conformity ..................................................................... 17

BRICK Temperature Management ........................................................................................ 17

BRICK System Critical Temperature warnings (absolute maximum rates) ....................... 17

BRICK STORAGE cartridge temperature warnings .......................................................... 18

Mechanical Details: ............................................................................................................... 19

BRICK CORE COM ........................................................................................................... 19

BRICK CORE COM with STORAGE BAY Add-on ............................................................ 20

BRICK CORE COM with STORAGE BAY and PCIe Add-ons .......................................... 21

8 Product Description ................................................................................................................... 22

BRICK CORE COM Computer Core ..................................................................................... 22

Front side BRICK CORE COM Computer core ................................................................. 22

Rear side BRICK CORE COM Computer core ................................................................. 23

BRICK CORE COM with STORAGE BAY ............................................................................ 24

Front side BRICK CORE COM with STORAGE BAY ....................................................... 24

9 Interfaces, Control Elements and Indicators ............................................................................. 25

Page 4

1GbE/TS 1/2/3/4 .................................................................................................................... 25

10GbE 1/2 .............................................................................................................................. 26

USB Client ............................................................................................................................. 26

DP (DisplayPort) .................................................................................................................... 27

2x Serial ATA (SATA) Port .................................................................................................... 28

USB3.0 Port 1/2/3/4 ............................................................................................................... 29

1GbE MGMT Port .................................................................................................................. 29

HMI Power ............................................................................................................................. 30

HMI Power button and LEDs ................................................................................................. 30

GPS SMA/F ........................................................................................................................... 31

SMA Port OPT1/2 .................................................................................................................. 31

SMA-RP WLAN 1/2 ............................................................................................................... 31

Microphone Input ................................................................................................................... 32

Headphones Output .............................................................................................................. 33

1GbE/802.1AS ....................................................................................................................... 34

CFast Slot .............................................................................................................................. 35

SYSCTRL (internal System Control) ..................................................................................... 36

GPIO General Purpose I/Os .................................................................................................. 37

Electrical characteristics Input/Output ........................................................................... 37

10 Typical Installation ..................................................................................................................... 38

Vehicle Power Wiring Diagram BRICK CORE COM and UPS (for reference only) .............. 38

11 BIOS/UEFI BRICK CORE COM 5700EQP616G ...................................................................... 39

Determination of the BIOS version ........................................................................................ 39

Operation ............................................................................................................................... 39

Advanced HDD Configuration ................................................................................... 40

Advanced South Bridge Configuration ...................................................................... 41

Advanced Onboard UART & CPLD Configuration .................................................... 42

12 Commissioning and Maintenance ............................................................................................. 43

Initial commissioning ............................................................................................................. 44

BRICK Core COM 5700EQP6 Operating system ......................................................... 46

Handling of internal components ........................................................................................... 47

Page 5

List of Figures

Figure 1: BRICK CORE COMplus ......................................................................................................... 11

Figure 2: BRICK CORE COMplus including STORAGE BAY attachment frame ................................. 12

Figure 3: BRICK CORE COMplus including STORAGE BAY and PCIe Add-on .................................. 12

Figure 4: BRICK CORE COM type plate (example) .............................................................................. 15

Figure 5: BRICK CORE COM mechanical drawing............................................................................... 19

Figure 6: BRICK CORE COM with STORAGE BAY mechanical drawing ............................................ 20

Figure 7: BRICK CORE COM with STORAGE BAY and PCIe mechanical drawing ............................ 21

Figure 8: BRICK CORE COMplus front view connectors ...................................................................... 22

Figure 9: BRICK CORE COMplus rear view connectors ...................................................................... 23

Figure 10: BRICK CORE COMplus front view STORAGE BAY connectors ......................................... 24

Figure 11: BRICK CORE COM STORAGE insert ................................................................................. 24

Figure 12: Pin assignment 1GbE/TS ..................................................................................................... 25

Figure 13: Pin assignment 10GbE/TS ................................................................................................... 26

Figure 14: Pin assignment USB Client .................................................................................................. 26

Figure 15: Pin assignment DisplayPort ................................................................................................. 27

Figure 16: Pin assignment mini SAS x4 ................................................................................................ 28

Figure 17: Pin assignment USB3.0 1/2/3/4 ........................................................................................... 29

Figure 18: Pin assignment 1GbE MGMT .............................................................................................. 29

Figure 19: Pin assignment HMI PWR .................................................................................................... 30

Figure 20: HMI Power button and LEDs ................................................................................................ 30

Figure 21: Pin assignment GPS ............................................................................................................ 31

Figure 22: Pin assignment OPT1/2 ....................................................................................................... 31

Figure 23: Pin assignment WLAN 1/2 ................................................................................................... 31

Figure 24: Pin assignment microphone ................................................................................................. 32

Figure 25: Pin assignment headphones ................................................................................................ 33

Figure 26: Pin assignment 1GbE 802.1AS ............................................................................................ 34

Figure 27: Pin assignment CFast .......................................................................................................... 35

Figure 28: Pin assignment SYSCTRL ................................................................................................... 36

Figure 29: Pin assignment GPIOs ......................................................................................................... 37

Figure 30: Power Wiring Diagram BRICK CORE COM and BRICK UPS ............................................. 38

Page 6

1 General Information

Important instructions

Prior to use of the unit it is essential to comply with the following instructions. As stipulated by law, we

are providing important safety information and advice how you can avoid damage to the device and

other fittings.

▪ Connection to the power supply must be carried out with correct polarity. Polarity reversal could

cause irreparable damages.

▪ The correct supply voltage is 12V or 24V DC

▪ Operation of the device is allowed only in circuits with safety low voltage within the admissible limit

values (SELV standard EN60950). This applies to all connections to the unit.

▪ The use of a power supply outside the limits defined above could cause damage or even destruction

of the device.

▪ It is forbidden to directly connect the unit to the 230 V mains voltage!

▪ Please avoid mechanical stresses when the device is installed.

▪ The unit has undergone a comprehensive final check to guarantee that it has left the facility in a

perfect condition. Prior to initial operation, the unit has to be examined for damage caused by

transport or inappropriate storage. If there is any damage to the unit it must not be taken into service.

▪ The unit must not be operated with defective safety equipment or with incorrectly mounted or

inoperable safety/protection devices.

▪ Prior to initial operation, please check the suitability of the unit for the specific application. Please

take special note of the admissible environmental and operating conditions specified in the data

sheet.

▪ Any removal of identification numbers, repair work by yourself or modification of the unit is forbidden.

▪ Prior to initial operation carefully read this user manual containing notes and warnings in order to

ensure safe operation.

▪ Unless specified differently, all technical data apply to an environmental temperature of 25°C. The

specified values are subject to the usual fluctuations.

▪ Stresses due to extreme environmental conditions (e.g. heat or cold) over a longer period of time

may influence reliability. Even under normal conditions of use within the admissible limits service

life may be reduced by permanent operation at the limits. Tolerance of the extreme values is subject

to the usual fluctuations.

Warranty and liability

We reserve the right to change the contents of the documentation and the software without notice.

Vector Informatik GmbH assumes no liability for correct contents or damages which are resulted from

the usage of the documentation. We are grateful for references to mistakes or for suggestions for

improvement to be able to offer you even more efficient products in the future.

Page 7

Trademarks

All trademarks mentioned in this documentation and if necessary third party registered are absolutely

subject to the conditions of each valid label right and the rights of particular registered proprietor. All

trademarks, trade names or company names are or can be trademarks or registered trademarks of their

particular pro- prietors. All rights which are not expressly allowed are reserved. If an explicit label of

trademarks, which are used in this documentation, fails, should not mean that a name is free of third party

rights.

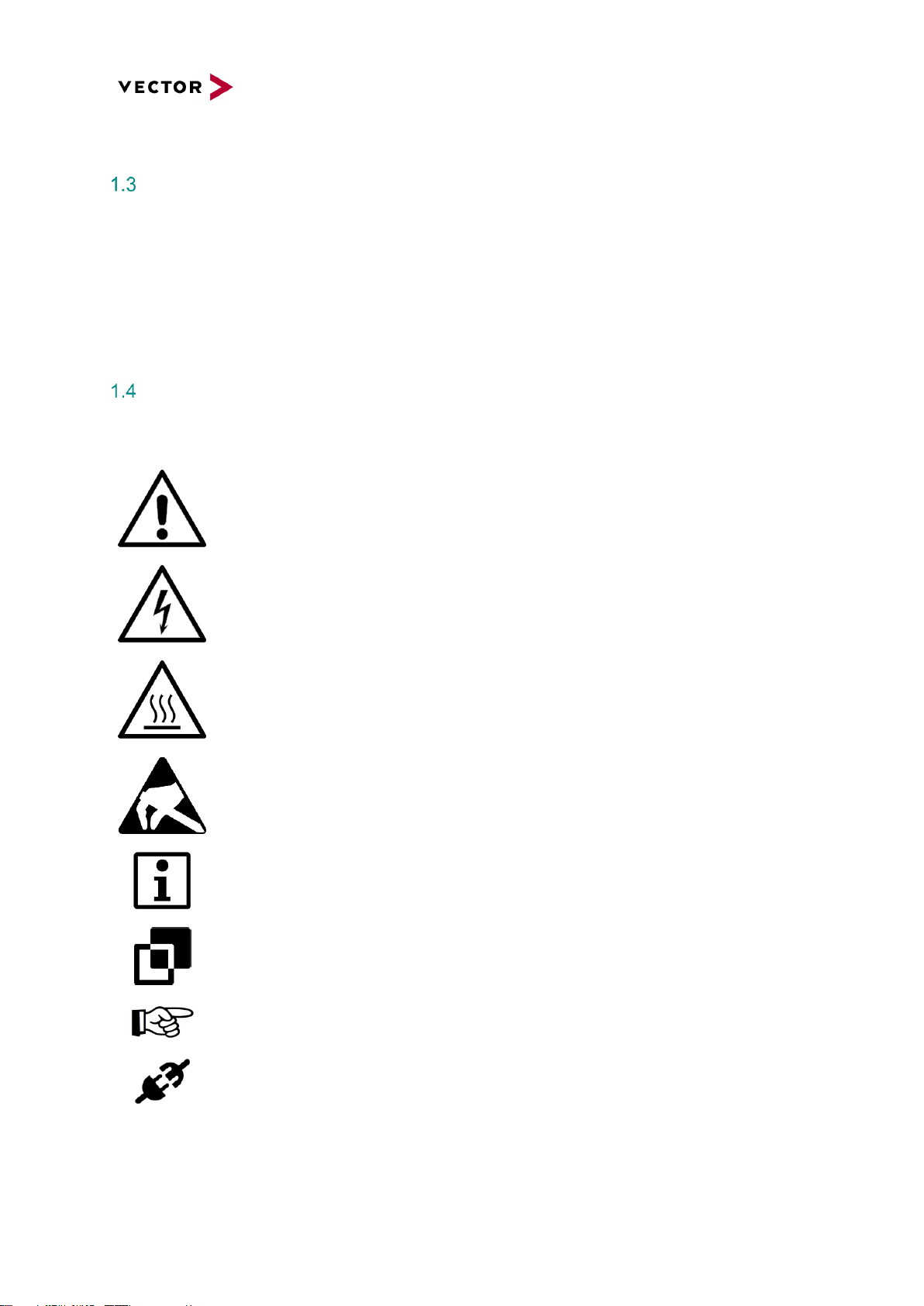

Used symbols and their meanings

Symbol

Meaning

Warning of general hazard. The kind of hazard is specified by the text next to the

symbol.

Warning of hazardous electrical voltage and the effects thereof.

This symbol refers to a hot surface that should not be touched without appropriate

precautions. There is danger of burning!

Warning of damages by electrostatic discharge

ESD (Electrostatically Sensitive Device) warning symbol

This symbol refers to general information about device and user manual.

This symbol introduces diverse details as to product configurations.

This symbol indicates that, in the case of non-observance of the warning, the device

or parts thereof could be damaged.

This symbol refers to instructions and recommendations for the connection of external

peripherals and their wiring.

Page 8

2 Safety

In order to avoid personal injuries and damage to property, you have to read and understand the

following safety instructions and hazard warnings prior to installation and use of this hardware. Keep

this documentation (manual) always near the hardware.

Please observe the notes in chapter 1.1 in addition to this chapter.

Proper Use and Intended Purpose

The hardware may only be operated (i) according to the instructions and descriptions of this manual; (ii)

with the electric power supply designed for the hardware, e.g. USB-powered power supply; and (iii) with

accessories manufactured or approved by Vector.

The hardware is exclusively designed for use by skilled personnel as its operation may result in serious

personal injuries and damage to property. Therefore, only those persons may operate the hardware who

(i) have understood the possible effects of the actions which may be caused by the hardware; (ii) are

specifically trained in the handling with the hardware, bus systems and the system intended to be

influenced; and (iii) have sufficient experience in using the hardware safely.

The knowledge necessary for the operation of the hardware can be acquired in workshops and internal

or external seminars offered by Vector. Additional and hardware specific information, such as „Known

Issues“, are available in the „Vector KnowledgeBase“ on Vector´s website at www.vector.com. Please

consult the „Vector KnowledgeBase“ for updated information prior to the operation of the hardware.

Hazards

The hardware may control and/or otherwise influence the behavior of control systems and electronic

control units. Serious hazards for life, body and property may arise, in particular, without limitation, by

interventions in safety relevant systems (e.g. by deactivating or otherwise manipulating the engine

management, steering, airbag and/or braking system) and/or if the hardware is operated in public areas

(e.g. public traffic, airspace). Therefore, you must always ensure that the hardware is used in a safe

manner. This includes, inter alia, the ability to put the system in which the hardware is used into a safe

state at any time (e.g. by „emergency shutdown“), in particular, without limitation, in the event of errors

or hazards.

Comply with all safety standards and public regulations which are relevant for the operation of the

system. Before you operate the system in public areas, it should be tested on a site which is not

accessible to the public and specifically prepared for performing test drives in order to reduce hazards.

Battery notice

CAUTION!

There is a risk of explosion if the battery is replaced incorrectly. Replace only with the

same or equivalent type recommended by the manufacturer. Discard used batteries

according to the manufacturer’s instructions.

Please also see the battery supplementary sheet!

Valid only for devices containing a battery.

Page 9

Electrostatically Sensitive Components (ESD)

A sudden electrostatic discharge could destroy sensitive components. Therefore, proper packaging and

grounding prescriptions must be observed. Please always observe the following safety advices.

1. Plug-in cards always have to be transported in electrostatically safe containers or bags.

2. Please leave electrostatically sensitive components in their containers until they have reached the

electrostatically safe assembly site.

3. Take care that you are correctly grounded if you touch electrostatically sensitive components.

4. Make sure that electrostatically sensitive components are stored in protective packages or on

antistatic mats.

Grounding practices

By observing the following measures, electrostatic damage to the device can be avoided.

1. Lay out antistatic mats at the work place. Wear a grounding strap which is connected to the work

place and the working tools.

2. Use antistatic foot mats, foot grounding equipment or air ionizers to provide additional safety.

3. Only touch sensitive components, plug-in cards and units on the housing or at the outer edges of

the plug-in cards.

4. Avoid contact with pins, wires and conductor tracks.

5. Make sure that all voltage and signal sources are switched off before establishing or disconnecting

electric connections or connecting testing devices.

6. Avoid non-conductive materials such as usual mounting accessories made of plastics or

polystyrene at the work place.

7. Use conductive tools (e.g. ESD screwdrivers) when working on electrostatically sensitive units and

components.

8. Always put plug-in cards and drives on the antistatic mat with the component side downwards.

Warning of hot surface

The BRICK CORE COM System can become very hot during operation and should

not be touched without appropriate precautions. There is danger of burning!

Disclaimer

Claims based on defects and liability claims against Vector are excluded to the extent damages or errors

are caused by improper use of the hardware or use not according to its intended purpose. The same

applies to damages or errors arising from insufficient training or lack of experience of personnel using

the hardware.

Page 10

3 System Configuration

The BRICK CORE COM is available in various variants. This means that, for each area of application,

an optimum ratio of system scope, performance and price can be obtained. Please observe the following

chapters to obtain detailed information on the different options of configuration of the BRICK CORE

COM and additional accessories.

A BRICK CORE COM system can comprise 3 HW feature sets:

• BRICK CORE COM computer core

• Add-on BRICK CORE COM STORAGE BAY

• Add-on BRICK CORE COM PCIe

The add-on feature sets are optional. They can be assembled on the computer core

exclusively by the manufacturer or authorized partners. A subsequent extension by

the customer is not provided.

Page 11

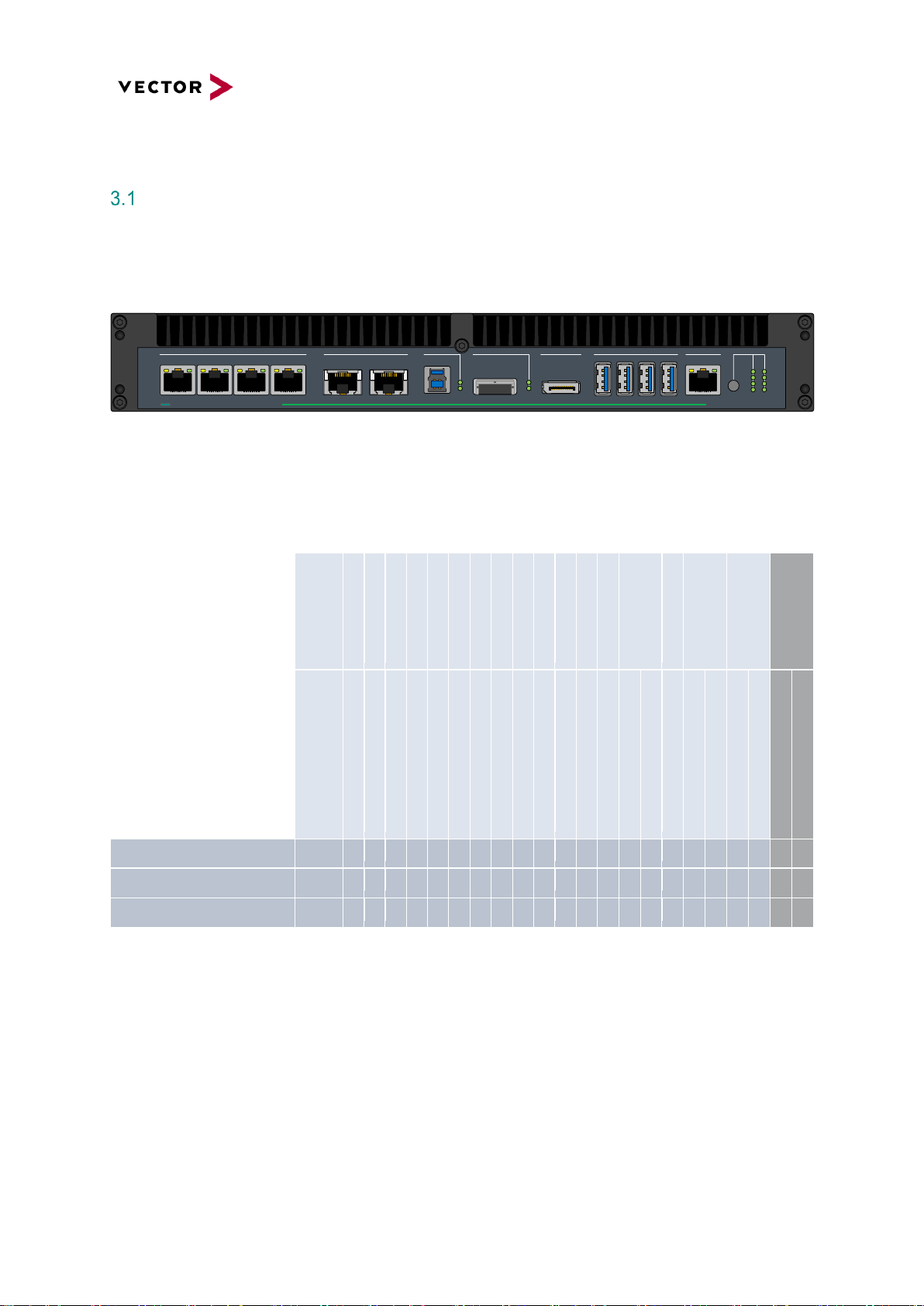

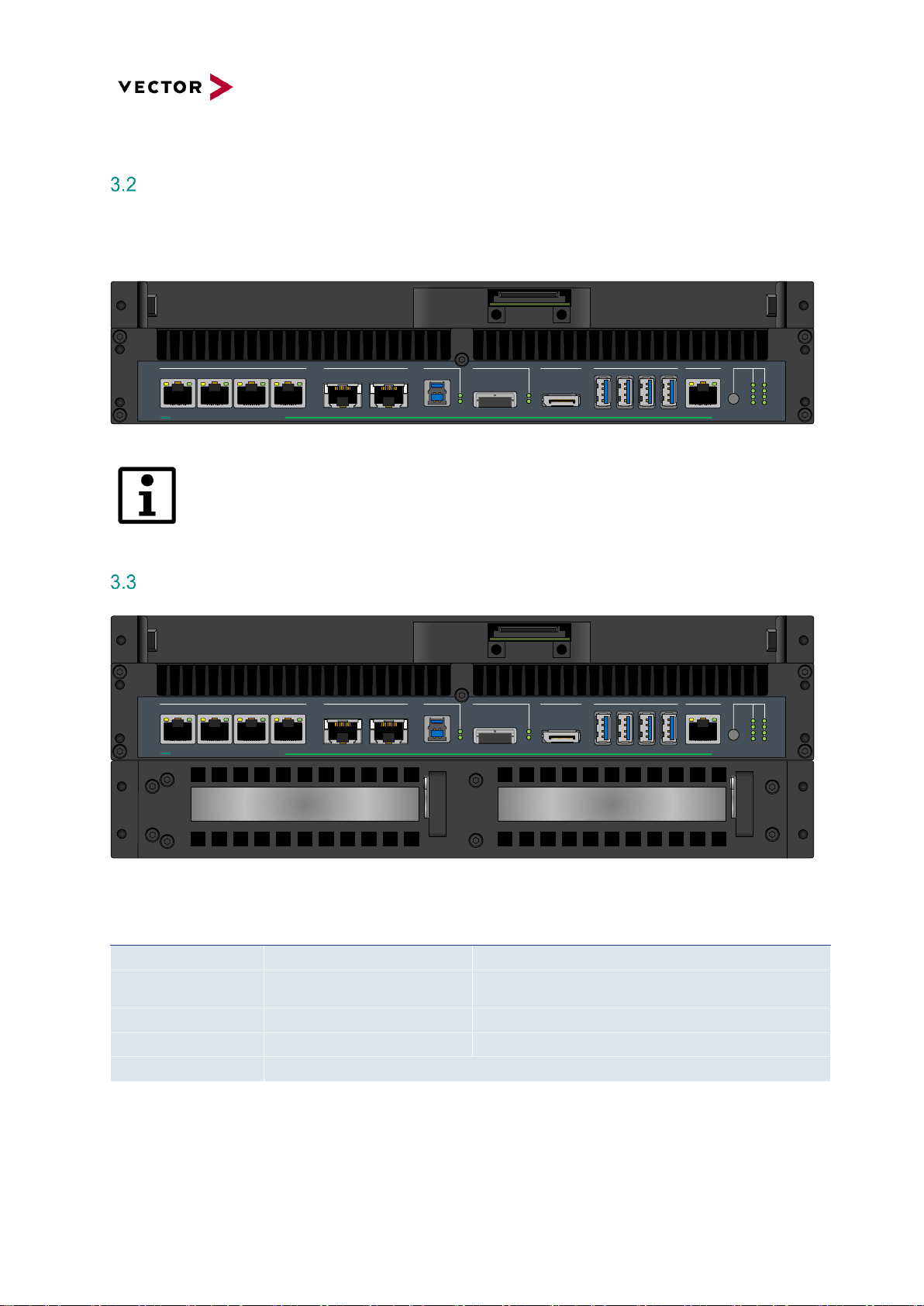

BRICK CORE COM computer core

is an actively vented high-performance Computer Core based on x86 architecture with a special

substructure for hardware time synchronized operation of 1GbE and 10GbE Logging ports based on

integrated GPS time signal or an external IEEE 802.1as time master.

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

Figure 1: BRICK CORE COMplus

For the BRICK CORE COM computer core, the following HW equipment features are available for the

respective device configuration:

CPU/Graphic

Temp. Perfor. Class

RAM

RAM

Mass Storage OS

OS

1Gb Eth. IF

10Gb Eth. IF

USB

eSATA SFF8088

DP

USB Client

GPS

AUDIO

CFast

SYS CTRL

GPIO

Add-ons (not part of

the computer core)

Material

Number

Intel® Core i7® 5700EQ/GT2 P6 Active

-25 ~ 70°C @ 2,8 GHz

32 GByte 16 GByte 128GByte Industrial SSD Win® 7 Pro

6xRJ45 1Gb Ethernet 2x RJ45 10Gb Ethernet 4x USB 3.0 2x eSATA 6G SFF8088 1x Display Port USB 3.0 Client GPS

Headphone out Microphone in CFast Slot (no card) K15/Ignition Function BRICK System Com. Inte

rface

4xGPI

4xGPO

STORAGE BAY Add

-on

PCIe Add-on

BRICK CORE COM 5700EQ-16-128-ST

22510

✓

✓

opt.

✓

✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

✓

-

BRICK CORE COM 5700EQ-16-128-ST-P

22511

✓

✓

opt.

✓

✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

BRICK CORE COM 5700EQ-16-128-0-P

22512

✓

✓

opt.

✓

✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ - ✓

- = not available

✓ = available

opt. = optional

Page 12

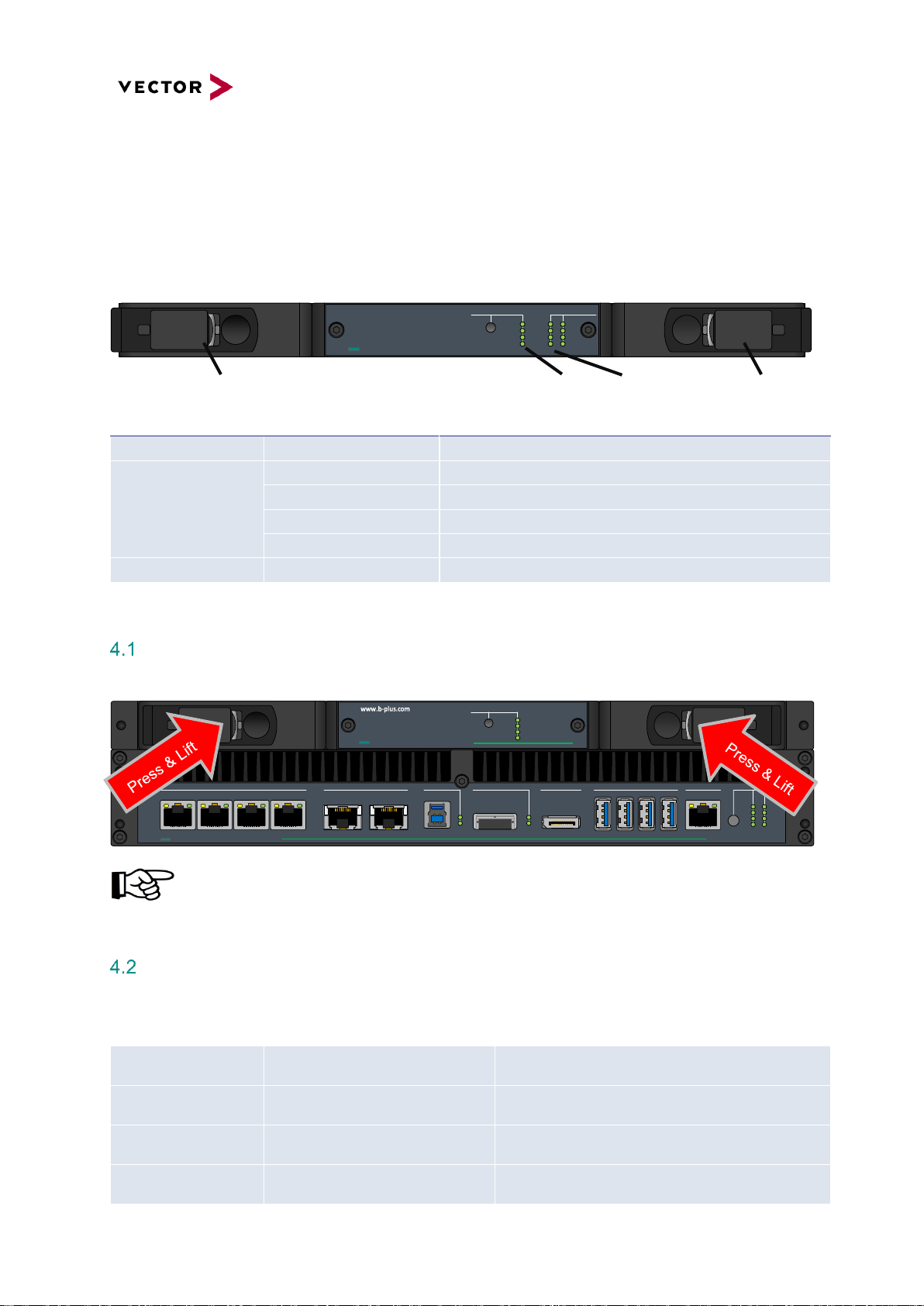

Add-On BRICK CORE COM STORAGE BAY

If large amounts of data with a high continuous band width are to be written or read the computer core

can be extended by a reception fixture for a BRICK STORAGE cartridge.

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

Figure 2: BRICK CORE COMplus including STORAGE BAY attachment frame

Systems with a STORAGE BAY are always actively vented.

Add-On BRICK CORE COM PCIe

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

XX XX PCIe Slot | Mech x8 ; Elec x8PCIe Slot | Mech x16 ; Elec x8

Figure 3: BRICK CORE COMplus including STORAGE BAY and PCIe Add-on

Insertion of non-validated PCIe cards may void certification and warranty.

SPC PCIe Add On

Value

Description

Operating Temperature

-25… +70°C

Add-On PCIe cards may have different specification

PCIe Slot Power

Limited power 1x 60W or 2x 30W

maximum

Power supply only via bus interface, no separate power

connector, max current all slots 5A @12V, 2A @3,3V

PCIe Slot left

Mechanical x16, electrical x8

8 Lanes PCIe 3.0 extension slot

PCIe Slot right

Mechanical x8, electrical x8

8 Lanes PCIe 3.0 extension slot

PCIe Card size

max. half size cards, 106.68 mm (height) X 175.26 mm (long), 1 Slot mounting

Page 13

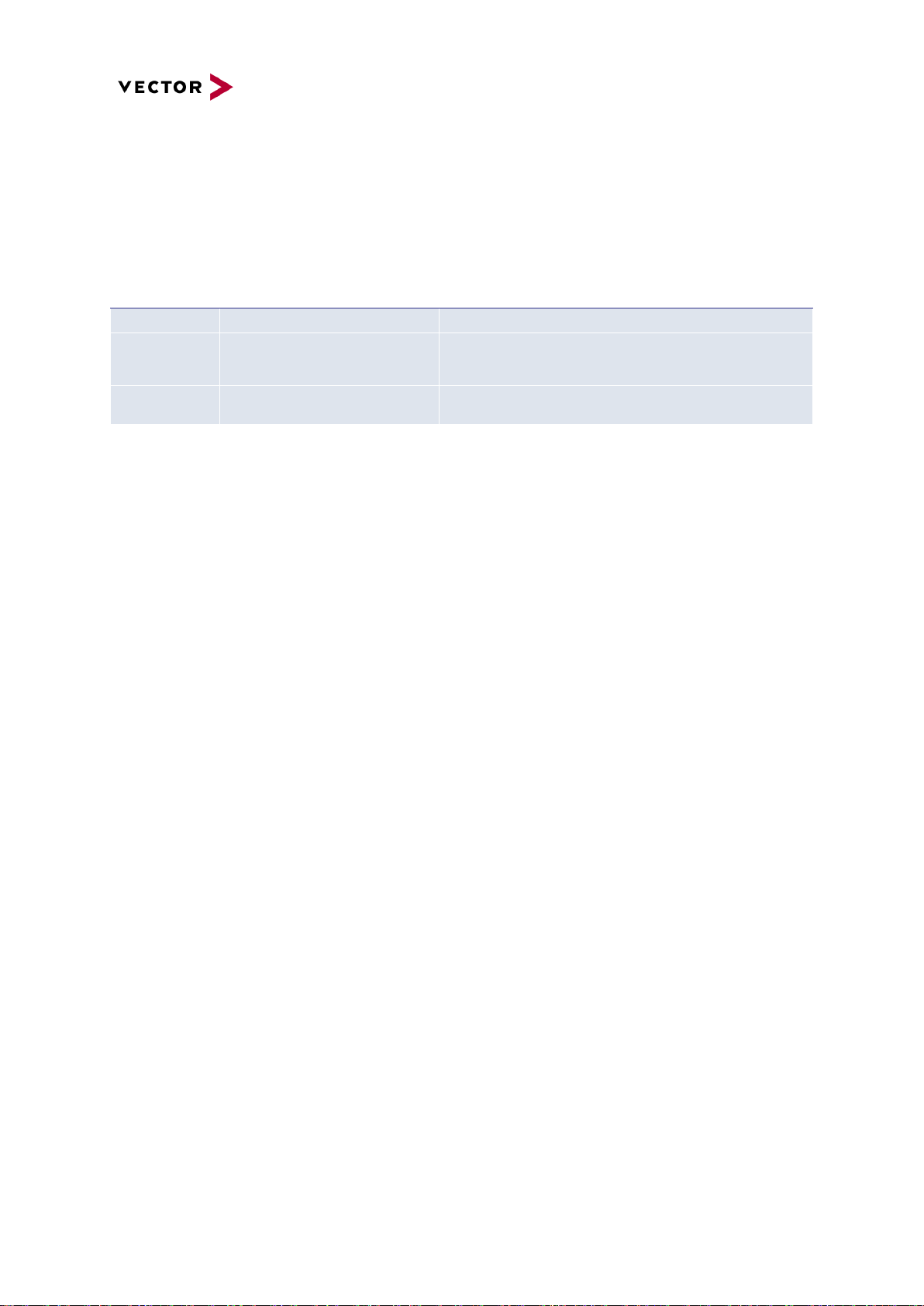

4 BRICK STORAGE

If large amounts of data with a high bandwidth are to be recorded reliably the BRICK CORE COM system

can be extended by a 1/2U (22mm) BRICK CORE COM STORAGE BAY. In this case, the STORAGE

BAY accommodates the mass storage device in the form of a BRICK STORAGE cartridge.

LOCK/UNLOCK DRIVE STATUS

BRICK STOR AGE

4 8

3 7

2 6

1 5

PCIe

LOCK

POWER

STATUS

Figure 5: BRICK STORAGE

Lock / Unlock BRICK STORAGE cartridge

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

LOCK/UNLOCK

BRICK STORAGE

plus

PCIe

LOCK

POWER

STATUS

The BRICK STORAGE cartridge is not hot plug capable. Make sure your system is shut

down before you insert or remove the cartridge. Insertion or withdrawal of the BRICK

STORAGE cartridge during operation can cause data loss.

BRICK STORAGE cartridge order Information

Item number

Designation

Description

1

Fastener / Lock lever

Fastener to lock and unlock to remove cartridge

2

LED PCIe

Indicates PCI Express connection established and active

LED LOCK

Indicates cartridge locked correctly

LED POWER

Indicates Cartridge Power OK

LED STATUS

Green Indicates Status (Temp) OK. red indicates NOK (temp. low or high)

3

LED 1-8 Drive Status

Red indicates drive failure, green Drive activity

Material Number

Designation

Description

180120

BRICK STORAGE Cartridge 4TB

- 4 TB Storage prosumer SSD (0-60°C), up to 1GB/s

- RAID Controller preconfigured as RAID 0/NTFS

180121

BRICK STORAGE Cartridge 8TB

- 8 TB Storage prosumer SSD (0-60°C), up to 1GB/s

- RAID Controller preconfigured as RAID 0/NTFS

180122

BRICK STORAGE Cartridge 12TB

- 12 TB Storage prosumer SSD (0-60°C), up to 1GB/s

- RAID Controller preconfigured as RAID 0/NTFS

180123

BRICK STORAGE Cartridge 16TB

- 16 TB Storage prosumer SSD (0-60°C), up to 1GB/s

- RAID Controller preconfigured as RAID 0/NTFS

❶

❷

❸

❶

Page 14

5 Accessories

For using BRICK CORE COM in the lab or in vehicle the following accessories are available.

Material

Number

Designation

Description

22514

BRICK UPS 200

200Watt managed Li-ion UPS with 160Wh

22513

BRICK THUNDER DOCK

Highspeed Thunderbolt® Adapter to download data from a

BRICK STORAGE cartridge over a Thunderbolt® interface to a

PC-System

22442

BRICK Cable Guard

Cable Guard to secure connected cables to avoid loss cable and

connector damages.

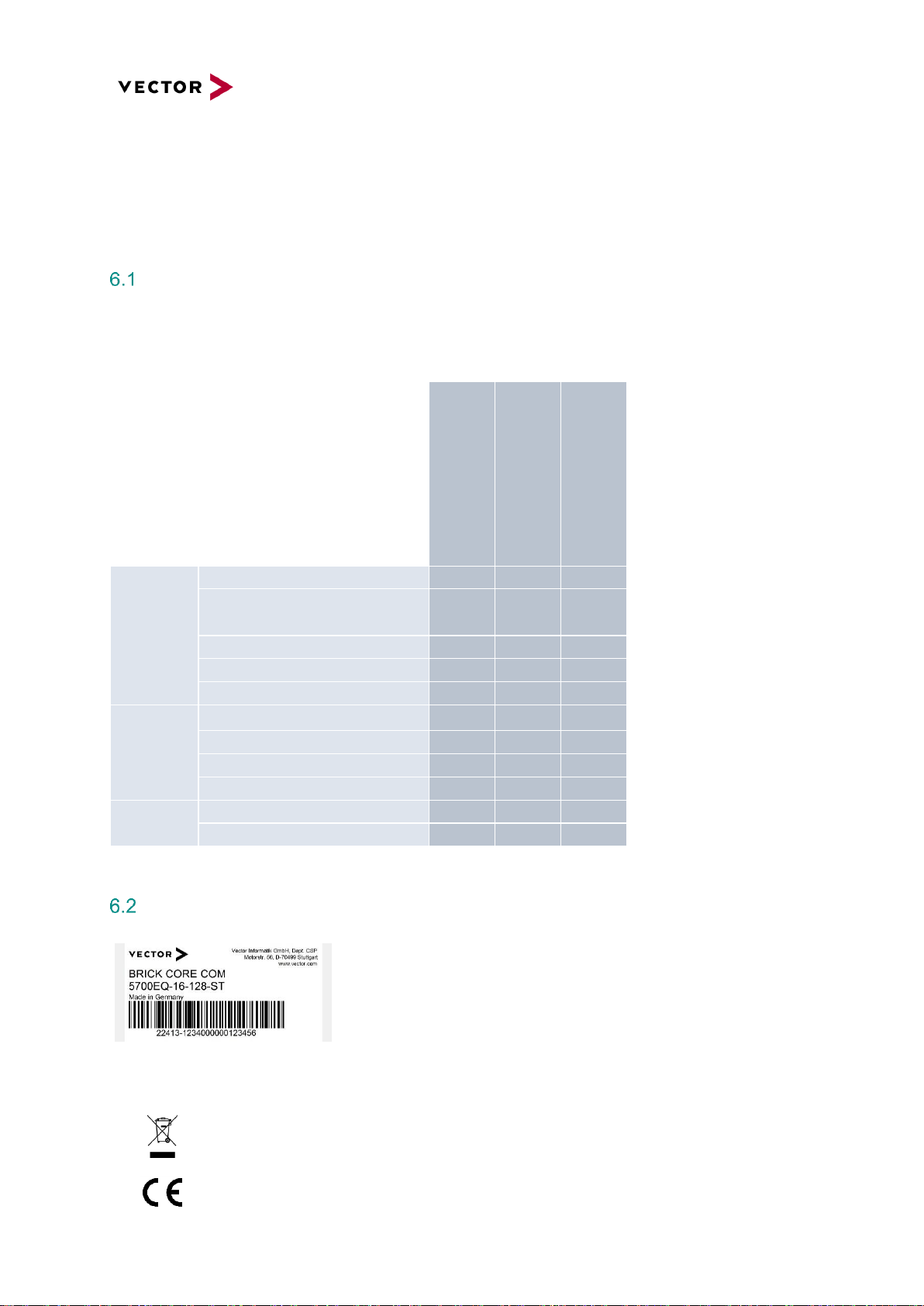

Page 15

6 Product Identification

Scope of delivery

The scope of delivery depends on the ordered system or set configuration. Please check the scope of

delivery according to the survey printed below.

Type Plate

The type plate as shown is located on the bottom of the device.

The example data used here refer to the revision D01.

Figure 4: BRICK CORE COM type plate (example)

Symbol

Meaning

Legal notice regarding the disposal of used appliances (WEEE)

CE label

BRICK CORE COM 5700EQ

-16-128-ST

BRICK CORE COM 5700EQ

-16-128-ST-P

BRICK CORE COM 5700EQ

-16-128-0-P

Power Supply

Power supply line red-black, open end, 4qmm /1.5m

✓ ✓ ✓

Desktop type power supply AC

110-240V 50/60Hz, 220W, 24V, 9.5A

incl. Power cord EURO CEE7/7

opt.

opt.

opt.

Power cord UK (UK Plug)

opt.

opt.

opt.

Power cord USA/JP (NEMA 5-15, 3-pol)

opt.

opt.

opt.

Power cord CN (China Type 1)

opt.

opt.

opt.

Accessories

GPS-Antenna

✓ ✓ ✓

SYSCTRL Cable, KL15 yellow, FLRY 0.5qmm

✓ ✓ ✓

GPIO Cable

✓ ✓ ✓

OS Recovery Stick for Windows® / Linux

✓ ✓ ✓

Documentation

Manual BRICK CORE COM (on Recovery Stick)

✓ ✓ ✓

Safety supplement

✓ ✓ ✓

- = not available

✓ = available

opt. = optional

Page 16

7 Technical Specification

Technical Characteristics of BRICK CORE COM:

Features

Details

BRICK CORE COM 5700EQP6

Processor

Intel® Core 5700EQ 4x 2,6GHz (3,4GHz)

Graphic support

Intel® GT2 HD Graphics 5600, Base clock:

300 MHz; GT Turbo: up to 1000 MHz

Execution Units / Pixel Pipelines: 24EU / 3, Max Graphics Memory 2048MB,

GFX Memory Bandwidth (GB/s) 25.6,

GFX Memory Technology DVMT,

API (DirectX/OpenGL) 11.2 / 4.3 + OCL 2.0,

Shader Model 5.0,

Hardware accelerated Video MPEG2, VC-1, AVC, Blu-ray (+3D)

RAM

16GByte (2x 8GB SODIMM), DDR3L-1666

OS-Storage

128GByte M.2 SSD up to 512GByte M.2 SSD

Network interfaces

6x1Gbe (4x Intel® I210 Hardware Timestamp Support, 1x Intel® I210 TS 802.1AS,

1x Intel® I218LM)

2x 10Gbe (Intel X540)

USB interfaces

4xUSB3.0 Host (1000mA)

1xUSB3.0 Client (USB3380, need special software support)

Audio interfaces

Microphone input, stereo headphone output

Monitor interfaces

1xDP 1.2 (Display Port), maximum resolution: 3840x2160

External storage interfaces

CFast Slot,

2x eSATA 6G via SFF8088 plug connector

WLAN (Option)

802.11 a/b/g/n (Option)

GPS

ublox LEA-M8S

LTE

SIMCom SIM7100E 4G/LTE (project-based Option, limited certification), mini SIM

slot

GPIO

4xGPI: V_ON>1.95V, V_OFF<1.75V (+-5%), Umax 32V

4xGPO: Highside (switching of the input voltage, max. 1A per channel)

On/Off control “Ignition”

1x Digital Input via SYSCTRL plug connector (Ignition),

On: >4,75V / Off: <4,15V (+-5%), Umax 32V

BRICK system control interface

1x CAN, termination resistor switchable, 1x Digital Input (On/Off control)

Operating systems

Windows 7 Professional for embedded system

Housing dimensions

320 x (44 - 110) x 250 (B x H x T) mm (see details below)

Supply voltage

12V DC / 24 DC, safe in case of dropdown pulses (cranking) down to 6.5V

Cooling

Active (passive on request with different power / performance setup)

Power consumption typically

BRICK CORE COM based on Intel Core i7 5700EQ (without STORAGE and PCIe):

approx. 110 Watts depending on the system utilization

Power consumption maximum

BRICK CORE COM maximum rate 200W (in full configuration)

Standby (OFF) current

< 50 µA (RTC, GPS, µC Stby.)

Weight

BRICK CORE COM (without STORAGE BAY Add-on): approx. 5kg

Page 17

Environmental Characteristics and Conformity

Characteristics

Details

Operating temperature

-25°C to +70°C (for active cooled systems, without STORAGE cartridge)

Storage temperature

-40°C to +85°C

Air humidity

90% non-condensing

Vibration and shock

EN 60068-2-64:2008 (10-1000Hz – 33,8 m/s²)

EN 60068-2-27:2009 (half sine, 11ms, 500 m/s²)

IP protection class

IP2X

Electromagnetic compatibility (EMC)

RED Directive 2014/53/EU

Electrical safety

LVD Directive 2014/35/EU

RoHS II directive

2011/65/EU

USA / FCC

Part 15 Subpart B / FCC ID (W-LAN Module)

CANADA

ICES 003

BRICK Temperature Management

Critical Temperature protection for the BRICK CORE COM computing unit including Add On.

BRICK System Critical Temperature warnings (absolute maximum rates)

BRICK System Critical Temperature values

Sensors

Temperature Settings BRICK

max

min

Ambient BRICK Temp. located at backside (reference)

80

-25

Storage internal (reference)

80

-25

The critical Temperature values are continuously polled

at startup and during runtime by the BRICK µC System

HMI Indication

In a critical temp case at startup

the System will not be powered on and an Error Code

(LED) will be shown.

too high

too low

In a critical temp case during operation

the system will be set to LimpHome state (power down

but µC active) and an Error Code (LED) will be shown.

The System can only be re-powered by pressing power

button (Note: 3°C threshold)

Page 18

BRICK STORAGE cartridge temperature warnings

Critical temperature protection for BRICK CORE COM systems with BRICK STORAGE cartridge.

BRICK STORAGE cartridge temperature warnings

BSC Temperature Warning Settings

max

min

Cartridge Temperature HDD (internal)

60

>0

Cartridge Temperature SSD PRO (internal)

70

-20

Cartridge Temperature SSD industrial (internal)

tbd

-25

Storage Temperature warnings (see table), are

continuously polled by an independently µC System

HMI Indication

In a warning case (temp. out of range) at startup

the Cartridge will not be powered and a Warning LED is

set, to activate the Cartridge a restart under good

conditions is necessary

In a warning case (temp. out of range) during runtime

the Warning LED is set but the Storage keep running (to

avoid data lost) up to critical temp

Page 19

Mechanical Details:

BRICK CORE COM

Features

Details

Computer Core Unit

Base computing Unit with DC/DC power

Housing dimensions

320 x 44 x 250 (B x H x T) mm

Weight

approx. 5,0kg

Housing material and Surface

Solid aluminum housing with black anodized surface,

please note, due to this chemical process minimal differences in color are possible

All dimensions are given in millimeters [mm].

Figure 5: BRICK CORE COM mechanical drawing

Page 20

BRICK CORE COM with STORAGE BAY Add-on

Features

Details

Further external storage interfaces

Base computing Unit with DC/DC power and

PCIe 3.0-based STORAGE BAY Add-on.

Housing dimensions

320 x 66 x 250 (B x H x T) mm

Weight

approx. 5,5kg

Housing material and Surface

Solid aluminum housing with black anodized surface,

please note, due to this chemical process minimal differences in color are possible

All dimensions are given in millimeters [mm].

Figure 6: BRICK CORE COM with STORAGE BAY mechanical drawing

Page 21

BRICK CORE COM with STORAGE BAY and PCIe Add-ons

Features

Details

Further external storage interfaces

Base computing Unit with DC/DC power

PCIe 3.0-based STORAGE BAY Add-on and

PCIe Ad- on

Housing dimensions

320 x 110 x 250 (B x H x T) mm

Weight

approx. 7kg

Housing material and Surface

Solid aluminum housing with black anodized surface,

please note, due to this chemical process minimal differences in color are possible

All dimensions are given in millimeters [mm].

Figure 7: BRICK CORE COM with STORAGE BAY and PCIe mechanical drawing

Page 22

8 Product Description

BRICK CORE COM Computer Core

Front side BRICK CORE COM Computer core

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

Figure 8: BRICK CORE COMplus front view connectors

Pos.

Designation

Description

1 Mounting holes with inner thread M4 (depth approx. 11.5mm)

2 Air outlets left and right for actively vented BRICK CORE COM systems

3

1GbE/TS 1,2,3,4

1Gb Ethernet Port (dedicated I210 per Port, TS-capable)

4

10GbE, 1,2

10Gb Ethernet Port (TR-capable need XTSS TR license)

5

USB Client

USB 3.0 Client Port (need project-based software support)

6

DP

Display Port

7

2xSATA

2xSATA 6G via SFF8088 (only Lanes 1 and 2 are supported)

8

USB3.0 1,2,3,4

USB3.0 Port

9

1GbE MGMT

1Gb Ethernet Port (adapted for System Management via Remote Desktop)

10

HMI PWR

On/Off button

11

HMI LED A1-4, B1-3

User LED (controlled via application software SIODI), see details in chapter 9.9

12

HMI LED B4

Operating status indication (Power LED), see details in chapter 9.9

❸

❹

❺

❻

❼

❽

❾

❿

⓬

⓫

❷

❶

❶

Page 23

Rear side BRICK CORE COM Computer core

ON

1 2

GPS

OPT1 OPT2

1 2

WLAN

AUDIO 802.1AS CFast SIM SYSCTRL

CAN

OPT

1 2

3 4

1 2 3 4

5 6 7 8

GPIO POWER 12/24V =

Figure 9: BRICK CORE COMplus rear view connectors

Pos.

Designation

Description

1 - Mounting holes with inner thread M4 (depth approx. 11.5mm)

2 - Air intake opening left and right for actively vented BRICK CORE COM systems

3

GPS

GPS Antenna connection

4

OPT1

HF SMA connector for option (i.e. LTE)

5

OPT2

HF SMA connector project specific option

6

WLAN 1,2

WLAN Antenna connection (Prim, Aux)

7

MIC Symbol

Audio input, stereo microphone

8

SPK Symbol

Audio output, stereo headphones

9

Temp

Opening for temperature sensors for system temperature management

10

802.1AS

1Gb Ethernet Port (optional: with specific time synchronization function)

11

Cover plate for CFast

and miniSIM socket

CFast Slot (CFast not included in the scope of delivery)

miniSIM socket (need option LTE)

12

SYSCTRL

BRICK System control connector

13

SYSCTRL SW

DIP-Switch for CAN termination for the system control connector

14

GPIO

4 GPI and 4 GPO

15

POWER

Power supply connector

❸

❹

❺

❻

❼

❽

❾

❿

⓬

⓫

⓭

⓮

⓯

❷

❶

❶

Page 24

BRICK CORE COM with STORAGE BAY

Depending on the configuration, a BRICK CORE COM system may be equipped with a STORAGE BAY.

Front side BRICK CORE COM with STORAGE BAY

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

Figure 10: BRICK CORE COMplus front view STORAGE BAY connectors

Pos.

Designation

Description

1 Mounting holes with inner thread M4 (depth approx. 11.5mm)

2 Guide rollers

3 Connection terminal for the STORAGE CARTRIDGE

Into the STORAGE BAY, A STORAGE CARTRIDGE can be inserted from the front.

+ =

Figure 11: BRICK CORE COM STORAGE insert

Inserting or withdrawal of the BRICK STORAGE cartridge during operation can cause data

loss.

More information about the BRICK STORAGE cartridge can be found in the chapter referring

to accessories.

❶

❷

❸

❷

❶

Page 25

9 Interfaces, Control Elements and Indicators

1GbE/TS 1/2/3/4

These connectors are designed as RJ45 sockets with integrated LEDs and correspond to a 1000BASE-

T Ethernet interface according to IEEE 802.3 clause 40.

With activated Platform Timesync Service PTSS (part of BRICK XTSS) these ports are hardware time

synchronized with the defined time master and are able do a timestamp capturing of incoming data

frames.

Pin

Signal

RJ45 Network socket 1-4

1

GBEx_MDI0+

Figure 12: Pin assignment 1GbE/TS

2

GBEx_MDI0-

3

GBEx_MDI1+

4

GBEx_MDI2+

5

GBEx_MDI2-

6

GBEx_MDI1-

7

GBEx_MDI3+

8

GBEx_MDI3-

LED on the right

ACT = green

LED on the left

LINK100 = yellow

LINK1000 = green

Pin ❶

Pin ❽

Page 26

10GbE 1/2

These connectors are designed as RJ45 sockets with integrated LEDs and correspond to a 10GBASE-

T Ethernet interface according to IEEE 802.3an.

With activated Platform Timesync Service PTSS (part of BRICK XTSS) these ports are hardware time

synchronized with the defined time master. With activated XTSS-TR (time-relay) this ports can

synchronize connected IEEE 802.1AS devices like MDILink.

Pin

Signal

RJ45 Network socket 1-2

1

GBEx_MDI0+

Figure 13: Pin assignment 10GbE/TS

2

GBEx_MDI0-

3

GBEx_MDI1+

4

GBEx_MDI2+

5

GBEx_MDI2-

6

GBEx_MDI1-

7

GBEx_MDI3+

8

GBEx_MDI3-

USB Client

Pin

Signal

USB 3.0 Type B socket

1

VBUS

Figure 14: Pin assignment USB Client

2

D- 3 D+

4

GND 5 SSTX-

6

SSTX+

7

GND 8 SSRX-

9

SSRX+

Matching counterpart: USB 3.0 Type B plug and USB 1.0/2.0 Type B plug

This Port need project-based software adaption, this is not included in standard OS package

Pin ❸

Pin ❾

Pin ❽

Pin ❼

Pin ❺

Pin ❻

Status

Pin ❷

Pin ❹

Pin ❶

Page 27

DP (DisplayPort)

Pin

Signal

DisplayPort socket 20-pole

1

LANE0+

Figure 15: Pin assignment DisplayPort

2

GND 3 LANE0-

4

LANE1+

5

GND 6 LANE1-

7

LANE2+

8

GND 9 LANE2-

10

LANE3+

11

GND

12

LANE3-

13

CONFIG1

14

CONFIG2

15

AUX+

16

GND

17

AUX-

18

HPD

19

RTN_PWR

20

PWR

Matching counterpart: Customary DisplayPort cables.

It is recommended to use high-quality DisplayPort cables, especially for longer cable

lengths. The use of DisplayPort to HDMI and DisplayPort to DVI adapters is possible but,

also in this case, high-quality components should be used.

Pin ❶

Page 28

2x Serial ATA (SATA) Port

Pin

Signal

Mini SAS x4 socket / SFF-8088 socket

A1

GND

Figure 16: Pin assignment mini SAS x4

A2

SFF_SATA1_RXP

A3

SFF_SATA1_RXN

A4

GND

A5

SFF_SATA0_RXP

A6

SFF_SATA0_RXN

A7

GND

A8

Not connected

A9

Not connected

A10

GND

A11

Not connected

A12

Not connected

A13

GND

B1

GND

B2

SFF_SATA1_TXP

B3

SFF_SATA1_TXN

B4

GND

B5

SFF_SATA0_TXP

B6

SFF_SATA0_TXN

B7

GND

B8

Not connected

B9

Not connected

B10

GND

B11

Not connected

B12

Not connected

B13

GND

Matching counterpart: Mini SAS plug (SFF-8088)

Please note that only the Lanes 1 and 2 are supported by BRICK CORE COM

A1

A13

B13

B1

Page 29

USB3.0 Port 1/2/3/4

In the basic configuration, the system is provided with four USB 3.0 interfaces. To the USB interfaces,

various USB devices can be connected. Both ports are equipped with a current limit at 1000mA.

Pin

Signal

USB3.0 Type A sockets

1

VBUS *1

Figure 17: Pin assignment USB3.0 1/2/3/4

2

D- 3 D+ 4 GND

5

RX- 6 RX+

7

GND 8 TX-

9

TX+

*1 Overcurrent protection by self-resetting fuse (maximally 1000mA)

Matching counterpart: In order to achieve the data transmission rates typical for

USB3.0 connecting cables with USB3.0 type A plugs have to be used. Besides, the

connected peripheral devices have to support USB3.0.

Also a connection of devices with USB1.0/2.0 type A plugs is possible.

1GbE MGMT Port

Pin

Signal

RJ45 Network socket

1

GBEx_MDI0+

Figure 18: Pin assignment 1GbE MGMT

2

GBEx_MDI0-

3

GBEx_MDI1+

4

GBEx_MDI2+

5

GBEx_MDI2-

6

GBEx_MDI1-

7

GBEx_MDI3+

8

GBEx_MDI3-

This Ethernet port is not recommended for data capturing (No TS), it can be used for

connecting the BRICK to a LAN for setup or maintenance.

Pin ❶

Pin ❽

Pin ❾

Pin ❽

Pin ❼

Pin ❻

Pin ❺

Pin ❶

Pin ❷

Pin ❸

Pin ❹

Page 30

HMI Power

Pin

Signal

1 VIN+ typ. 12/24V (6V – 32V)

Figure 19: Pin assignment HMI PWR

2

VIN- 3 VIN+ typ. 12/24V (6V – 32V)

4

VIN-

Matching counterpart:

Molex MiniFit Sr. Receptiple Housing Art.-Nr.: 42816-0212

Molex Female Crimp Terminal 12, 10 & 8 AWG Art.-Nr.: 42815-0012

HMI Power button and LEDs

System Override: the microcontroller-based system management controller may override the

user programmed LED state in case of the described system warning or system shut down to

limp home state.

LED

Signal

PWR

On/Off button

Figure 20: HMI Power button and LEDs

A1

User LED

Programmable by SIODI application software

A2

A3

A4

B1

User LED

Programmable by SIODI application software

B2

User/System

Programmable by SIODI application software

System override: red BRICK UPS config error

B3

User/System

Programmable by SIODI application software

System override: red: System down state low temp

B4

System Status

Green: Indication of operating status (Power LED)

System override: System down state high temp

Pin ❷ / ❹

Pin ❶ / ❸

Page 31

GPS SMA/F

SMA socket, for using GPS antennas with SMA/M plug.

Pin

Signal

SMA socket

1

SMA GPS

Figure 21: Pin assignment GPS

2

Insulation

3

GND

SMA Port OPT1/2

SMA-RP (reverse polarity) socket, e.g. for connecting customary antennas with SMA-RP plug.

If used for LTE antenna 4G/LTE/GPS with SMA/M connector a gender changer is needed.

SMA-RP WLAN 1/2

SMA-RP (reverse polarity) socket, e.g. for connecting customary WLAN antennas with SMA-RP plug.

Pin

Signal

SMA-RP socket

1

SMA WLAN (1 prim, 2 aux)

Figure 23: Pin assignment WLAN 1/2

2

Insulation

3

GND

Matching counterpart: SMA-RP plug

Pin

Signal

SMA-RP socket

1

Option 1 SMA (preferred for LTE)

Option 2 SMA-RP project specific

Figure 22: Pin assignment OPT1/2

2

Insulation

3

GND

Page 32

Microphone Input

This connector can be used for connection of a microphone.

- Pre-amplifier with selectable 0 dB, +10 dB, +20 dB, and +30 dB gain settings

- Programmable, low-noise MIC bias level

Pin

Signal

Description

3.5mm jack socket

1

Sleeve

Ground

Figure 24: Pin assignment microphone

2

Ring

Right channel with stereo plugs, negative phase

with symmetrical connections

3

Tip

Left channel with stereo plugs, positive phase

with symmetrical connections, signal („hot“) with

mono connectors

Matching counterpart: 3.5mm stereo jack plug (TRS plug)

Page 33

Headphones Output

This connector is suitable for connecting wired headphones and earphones to the BRICK CORE COM.

A connection of actively intensified audio devices to this connector is not recommended as this may

cause an overregulation of the audio signal.

- 101 dB Dynamic range (A-wtd)

- -89 dB THD+N

- Minimum impedance 16 Ohm

- Maximum output power 50mW per channel

Pin

Signal

Description

3.5mm jack socket

1

Sleeve

Ground

Figure 25: Pin assignment headphones

2

Ring

Right channel with stereo plugs, negative phase

with symmetrical connections

3

Tip

Left channel with stereo plugs, positive phase

with symmetrical connections, signal („hot“) with

mono connectors

Matching counterpart: 3.5mm stereo jack plug (TRS plug)

Page 34

1GbE/802.1AS

This connector is designed as a RJ45 sockets with integrated LEDs and corresponds to a network

interface according to IEEE 802.1AS that can be used for timing and synchronization of time-critical

applications.

With activated Platform Timesync Service PTSS and Cluster Timesync (BRICK XTSS) this port can be

the time master alternatively to the internal GPS for PTSS and CTSS.

It is also able do a timestamp capturing of incoming data frames.

Pin

Signal

RJ45 Network socket

1

GBEx_MDI0+

Figure 26: Pin assignment 1GbE 802.1AS

2

GBEx_MDI0-

3

GBEx_MDI1+

4

GBEx_MDI2+

5

GBEx_MDI2-

6

GBEx_MDI1-

7

GBEx_MDI3+

8

GBEx_MDI3-

Pin ❶

Pin ❽

Page 35

CFast Slot

Pin

Signal

SATA Segment

S1

GND

Figure 27: Pin assignment CFast

S2

TX+

S3

TX-

S4

GND

S5

RX-

S6

RX+

S7

GND

Key

Power Segment

PC1

CDI (Card Detect In)

PC2

GND

PC3

Not connected

PC4

Not connected

PC5

Not connected

PC6

Not connected

PC7

GND

PC8

Not connected

PC9

Not connected

PC10

Not connected

PC11

Not connected

PC12

Not connected

PC13

3.3V PC14

3.3V PC15

GND PC16

GND

PC17

Not connected

S1

S7

PC1

PC17

Page 36

SYSCTRL (internal System Control)

Pin

Signal

3.50mm Pitch connector and DIP switch

1

CAN_HIGH

Figure 28: Pin assignment SYSCTRL

2

IGN_IN, Thresholds: On: >4,75V / Off: <4,15V (+-5%),

Umax 32V

3

CAN_LOW

4

n.c.

DIP switch 1 defines the CAN bus termination

DIP switch 2 is reserved for future applications

Configuration

1 2 CAN Termination (120R)

ON

OFF

This CAN Interface is for BRICK System internal use to connect

System components like BRICK UPS

Matching counterpart:

Molex UltraFit Receptiple Housing Art.-Nr.: 172258-1004

Molex Female Crimp Terminal 22 & 20 AWG Art.-Nr.: 172253-3123

Page 37

GPIO General Purpose I/Os

Pin

Signal

1 OUT4

Figure 29: Pin assignment GPIOs

2

OUT3

3

OUT2

4

OUT1

5

IN4 6 IN3 7 IN2

8

IN1

IN

Input

Switching thresholds: V_ON >1.95V, V_OFF<1.75V (+-5%),

Umax 32V, internal pull down 10K

OUT

Output Voltage

Highside (switching input voltage), max. 1A per channel

Max programmable switching frequency 1Hz

Matching counterpart:

Molex UltraFit Receptiple Housing Art.-Nr.: 172258-1008

Molex Female Crimp Terminal 22 & 20 AWG Art.-Nr.: 172253-3123

Electrical characteristics Input/Output

Symbol

Description

Value

Unit

Min

Typ

Max

VIN

Input voltage continuous full load

10

12

32 V V

IN min

Input voltage (short-term crank safe)

6,5

V

V

GPI,LOW

GPI Low voltage

1,75

V

V

GPI,HIGH

GPI High voltage

1,95 V V

GPI max

GPI input voltage max

32

V

R

IN,GPI

GPI input resistance

10 kΩ

V

IGN_IN,LOW

IGN_IN Input Low voltage

4,15

V

V

IGN_IN,HIGH

IGN_IN Input High voltage

4,75 V V

IGN_IN max

IGN_IN input voltage max

32

V

R

IN,IGN_IN

IGN_IN input resistance

12 kΩ

V

GPO

GPO output voltage

VIN

32

V

I

GPO max

GPO output current max

1 A f

GPO min

GPO output frequency

1

Hz

Page 38

10 Typical Installation

Vehicle Power Wiring Diagram BRICK CORE COM and UPS (for reference

only)

Figure 30: Power Wiring Diagram BRICK CORE COM and BRICK UPS

Page 39

11 BIOS/UEFI BRICK CORE COM 5700EQP616G

11

Determination of the BIOS version

To determine the current BIOS version please check the system information tab within the BIOS.

Operation

In the BIOS setup, the system behavior can be adapted to individual requirements. The BIOS setup

offers a series of menus to make changes to the system and to switch features on or off.

The Setup Utility changes system behavior by modifying the Firmware configuration. The setup

program uses a number of menus to make changes and turn features on or off.

Function keys during POST:

[F2]

Enter BIOS Setup

[F5]

Boot Menu

[ESC] + [2]

Enter BIOS Setup via Remote Keyboard in Console Redirection Mode

Function keys in the setup:

[F1]

Help

[F9]

Load default settings

[F10]

Save and Exit

.

This chapter describes important settings to be used for operation of the BRICK CORE

COM. All necessary settings are BIOS default (F9). Special Add-On configuration

(SPC) may need different settings.

Please consult your manufacturer before adjusting parameters in BIOS to avoid

functional restrictions of your BRICK CORE COM.

Page 40

Advanced HDD Configuration

Parameters

Options

Description

SATA Device

Enabled

Disabled

General activation of the SATA function

SATA Speed Limit

Auto

Gen 2

Gen 1

Fastest SATA speed

Interface Combination

IDE

AHCI

RAID

Defines the interface type of the mass

storage

Aggressive Link Power

Disabled

Enabled

Aggressive Link Power Management

for HDD Ports

ComExpress SATA0

Port Enable -> Disable, Enable

Hot Plug -> Disable, Enable

SATA Device Type -> Hard Disk

Drive, Solid State Drive

eSATA-Lane 1

ComExpress SATA1

Port Enable -> Disable, Enable

Hot Plug -> Disable, Enable

SATA Device Type -> Hard Disk

Drive, Solid State Drive

eSATA-Lane 2

ComExpress SATA2

Port Enable -> Disable, Enable

Hot Plug -> Disable, Enable

SATA Device Type -> Hard Disk Drive,

Solid State Drive

M.2-based internal SSD

Page 41

ComExpress SATA3

Port Enable -> Disable, Enable

Hot Plug -> Disable, Enable

SATA Device Type -> Hard Disk Drive,

Solid State Drive

CFast-Slot

Please note that, upon misadjustment of these parameters, the system does not boot any

more or data on the corresponding data media are even destroyed. Besides, misadjustment

may cause that data media are no longer recognized.

Advanced South Bridge Configuration

Parameters

Options

Description

SMBUS Device

Disabled

Enabled

Activates/Deactivates SMBUS Device

State After G3

State S5

State S0

Last State

S5 System works in the ATX mode

Page 42

Advanced Onboard UART & CPLD Configuration

Parameters

Options

Description

Serial Port 0

Disabled

Enabled

COM UART SER0 is not available!

Serial Port 1

Disabled

Enabled

COM UART SER1 is not available!

GPIO IRQ

Disabled

14

15

Configuration IRQ for GPIO pins

I2C IRQ

Disabled

14

15

Configuration IRQ of the I2C controller

Page 43

12 Commissioning and Maintenance

In order to avoid injuries and damage caused by direct or indirect contact with hot surfaces the

following instructions must be observed:

BRICK CORE COM must be positioned and installed in a maintenance area or in an operating

facility of limited access.

The users having permission to enter the maintenance area or the operating facility must have

received adequate instructions regarding the risks.

Important instructions!

For positioning and installation or removal of the BRICK CORE COM System, please observe

the relevant instructions given in this user manual.

The device must only be positioned and installed by maintenance personnel responsible in this

area (that is familiar with the associated risks).

The device can be operated in all positions except with the upper side downwards.

In order to avoid overheating of the platform, keep a distance of at least 100 mm to the upper

cooling fins of the chassis (passively cooled variant).

In case of installation in a housing (e.g. a control cabinet): The housing (control cabinet) must

have enough space for the BRICK CORE COM System and the corresponding spaces for air

circulation and cable connections. Moreover, the housing must have sufficient, possibly active,

ventilation to avoid overheating.

The cooling fins and the inlet and discharge openings of the housing must not be blocked

(covered).

Page 44

Initial commissioning

1. Connect the DC supply cable of the power supply unit to the rear side (1) of the BRICK CORE COM

system.

ON

1 2

GPS

OPT1 OPT2

1 2

WLAN

AUDIO 802.1AS CFast SIM SYSCTRL

CAN

OPT

1 2

3 4

1 2 3 4

5 6 7 8

GPIO POWER 12/24V =

2. Connect a suitable monitor which is able to display a resolution of at least X x Y to the display

port (2) at the front side. (Later the resolution can be reduced)

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

3. Connect a compatible mouse to the USB port (e.g. 3).

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

4. Connect a compatible keyboard to the USB port.

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

❶

❷

❸

❹

Page 45

5. Connect the table power pack to the mains supply by using the country-specific network supply

line

6. For BRICK CORE COM with STORAGE BAY Add-on please insert Cartridge

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

LOCK/UNLOCK

BRICK STORAGE

plus

PCIe

LOCK

POWER

STATUS

7. Please start the BRICK CORE COM system via the power button (5). Hold the button down until

the LED B4 (6) turns green.

For vehicle installation you can use IGNITION IN (SYS Controll) for boot and shut

down the system.

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

LOCK/UNLOCK

BRICK STORAGE

plus

PCIe

LOCK

POWER

STATUS

8. The system will now boot the operating system defined in the scope of delivery. The LED B4 (6)

will first shine red before turning green.

1GbE/TS

1 2 3 4

10GbE

1 2

USB Client

DP

2x SATA

USB3.0

1 2 3 4

1GbE MGMT HMI

PWR

A B

1

2

3

4

BRICK CORE COM

plus

LOCK/UNLOCK

BRICK STORAGE

plus

PCIe

LOCK

POWER

STATUS

❺

❻

Page 46

BRICK Core COM 5700EQP6 Operating system

Your system will be delivered, depending on the configuration, with an operating system installed.

If you have ordered your BRICK CORE COM with a preinstalled operating system all drivers are installed

in accordance with the ordered system configuration. When switched on the first time, the system will

be fully operational. Please observe the following instruction.

Important information when using pre-installed "WINDOWS 7 PROFESSIONAL

FOR EMBEDDED SYSTEMS" operating systems:

The terms and conditions for using the pre-installed operating systems are defined in

the document "Microsoft Software License Terms".

Page 47

Handling of internal components

This section contains important information about the safe handling of internal components. Please

follow the instructions when handling all internal components of the BRICK CORE COM systems.

When installing or removing additional plug-in cards, please follow the following instructions:

Please observe the “general safety instructions for IT equipment” and installation

instructions.

The installation and removal of additional plug-in cards may only be made by a

qualified trained employee in accordance with the instructions of this manual.

Before removing the device cover please make sure that your system is switched off

and disconnected from the voltage supply.

Please observe the safety instructions regarding electrostatically sensitive

components (ESC). Failure to observe this warning may cause damage to the device

or components of the device.

The BRICK CORE COM system might get hot during operation and should not be

touched without adequate precautions. There is danger of burning.

Loading...

Loading...