Page 1

Contact Temperature Sensor SC-T

Contact Temperature Sensor SC-T

Contact Temperature Sensor SC-T

Item Name

Probe

Definition

Cable length

SC-Tn3-2

NTC 3kΩ at 25°C (77°F)

B

25/50

3935

2m, (6.5ft)

SC-Tn10-2

NTC 10kΩ at 25°C (77°F)

B

25/50

3935

SC-Tn11-2

NTC 10kΩ at 25°C (77°F)

B

25/50

3630

SC-Tn12-2

NTC 10kΩ at 25°C (77°F)

B

25/50

3380

SC-Tn20-2

NTC 20kΩ at 25°C (77°F)

B

25/50

4200

SC-Tn100-2

NTC 100kΩ at 25°C (77°F)

B

25/50

4200

SC-Tp1-2

PT100

EN60751

SC-Tp2-2

PT1000

EN60751

SC-Tk5-2

NI1000

5000 ppm/K

AMS-2

Tightening strap for ½-3in pipes

AMS-3

Tightening strap for 3-6in pipes

Sensing Probe

Thermistor:

Range: (Probe only)

Accuracy:

-40…0°C (-40…32°F):

0…50°C (32…122°F):

50…100°C (122…212°F):

> 100°C (> 212°F):

NTC

-70…150°C (-94…302°F)

0.5 K

0.2 K

0.5 K

1 K

Platinum-Film:

Range: (Probe only)

Accuracy

PT according EN 60751

-70…200°C (-94…392°F)

EN 60751, Class B, ask for other class

Nickel Thin Layer:

Range: (Probe only)

Accuracy

1000 Ω at 0°C, 5000 ppm/K

-60…200°C (-76…392°F)

DIN 43760

Cable

Standard

Size

Insulation material

Operating Temperature

Ratings

2 x 0.20 mm2 (AWG 24)

PVC

-40…80°C (-40…176°F)

UL758, 1581/CSA C22.2 No 210.2

High temperature

Size

Insulation material

Operating temperature

Ratings

-H

2 x 0.35 mm2 (AWG 22)

FEP

-60...200°C (-76…392°F)

ULR/CSA C22.2 No 210.2

Plenum rated

Size

Insulation material

Operating temperature

Ratings

-P

2 x 0.5 mm2 (AWG 20)

Plenum PVC

-20…75°C (-4…167°F)

UL C(UL) PLENUM CMP OR E355847

FPLP UL

Single insulated PVC

Size

Insulation material

Operating Temperature

Ratings

-A

2 x 0.20 mm2 (AWG 24)

PVC

-40…80°C (-40…176°F)

UL758,1581 CSA C22.2 No.210.2

Environment

Operation

Climatic conditions

Temperature depends on cable

type

To IEC 721-3-3

class 3K5

See above

Transport & storage

Climatic conditions

Temperature

Humidity

Mechanical conditions

To IEC 721-3-2 and IEC 721-3-1

class 3K3 and class 1K3

-40…80°C (-40…176°F)

< 95% RH non-condensing

class 2M2

Standards

conform according to

EMC Standard 89/336/EEC

EMEI Standard 73/23/EEC

EN 61 000-6-1/ EN 61 000-6-3

Automatic electrical controls for

household and similar use

Special requirement on

temperature dependent controls

EN 60 730 –1

EN 60 730 – 2 – 9

Pollution Class

Normal acc. to EN 60 730,

RoHS compliant

Degree of Protection

IP65 to EN 60 529

Safety Class

III (IEC 60536)

Housing

Probe

Brass

Dimensions (Diameter x L)

Probe: ø 6 x 35 mm (ø 0.25” x 1.4”)

Contact Plate: 20x30mm (0.8” x 1.2”)

Weight (including package)

80g (2.8oz)

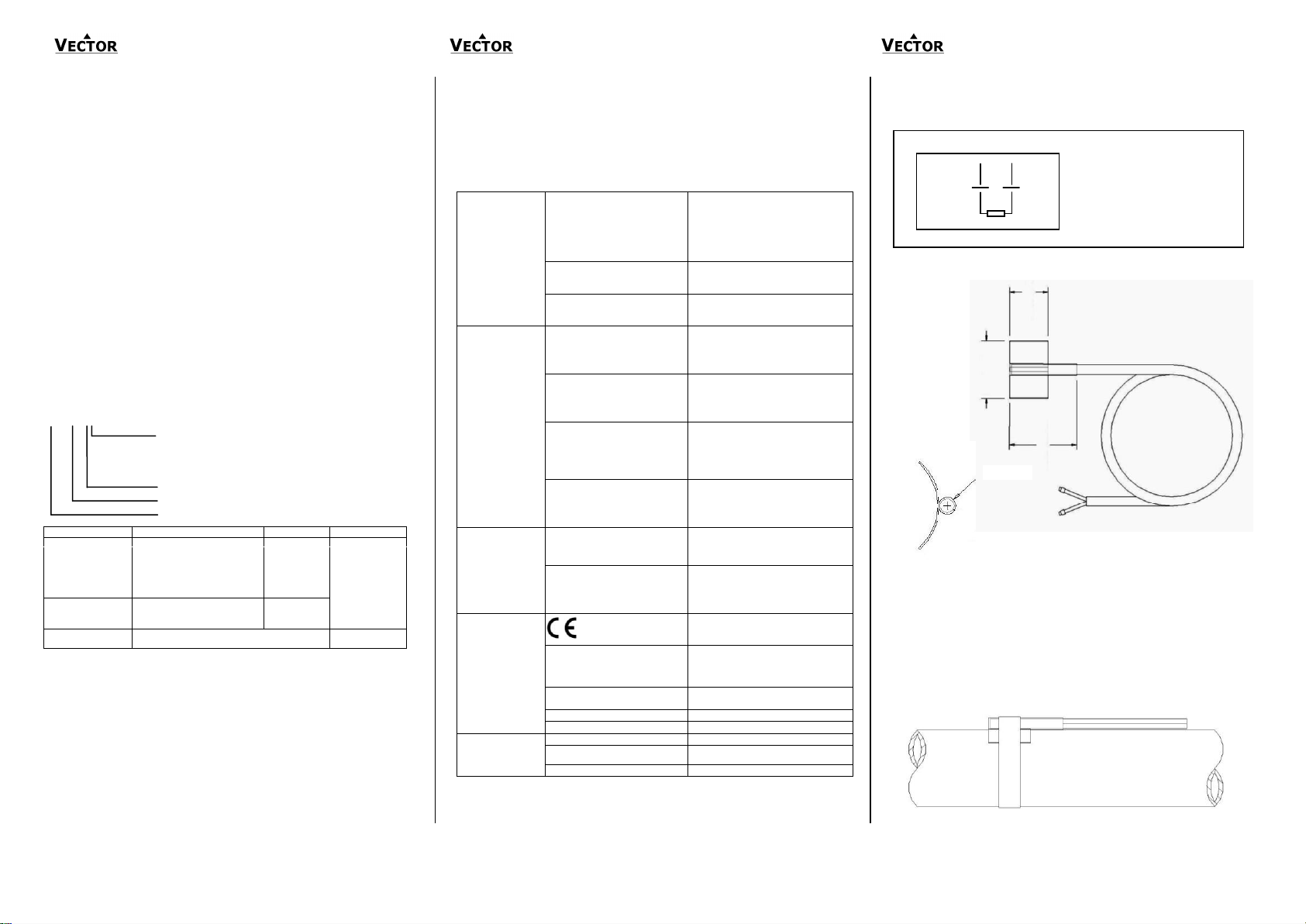

SC-Tn10-2A

Cable type:

default: PVC cable double insulated

-H = High temperature

-P = Plenum rated

-A = PVC cable single insulated

Cable length in Meter

Sensing Element (see below)

Sensor Type: Sensor with flying lead

20

(0.8)

35 (1.4)

30 (1.2)

6 (0.2)

SC-T

SC-T, Flying Lead Contact Temperature Sensor

Features

Thermistors and PT sensing elements to fit your system

Strap-On mounting for pipes or arched surfaces

Simple installation

Wide range of temperature probes

Including 2m (6.5ft) wire

Applications

Measure temperature for heating, ventilation and air conditioning

applications

For heating or cooling mode detection in 2-pipe systems

As frost protection sensor

Temperature sensor

The sensor measures the temperature by use of a glass packed thermistor

with a negative temperature coefficient (NTC), a platinum film (PT) or a nickel

thin layer (NI) based probe. Its resistance changes according to the

temperature. The change follows a specified curve. A summary of such curves

is printed on the back of this document. Contact our sales department for

curves or sensing elements not yet listed below.

Compensating conductor resistance

The length and type of conductors used to connect the sensor to the

measuring electronic influences the accuracy of the measurement. Especially

for elements with low resistance this has to be taken into account.

Compensation needs to be performed by the measurement electronics.

Ordering

Technical Specification

Warning! This device is intended to be used for comfort applications. Where a

device failure endangers human life and/or property, it is the responsibility of the

owner, designer and installer to add additional safety devices to prevent or detect

a system failure caused by such a device failure. The manufacturer of this device

cannot be held liable for any damage caused by such a failure.

Failure to follow specifications and local regulations may endanger life, cause

equipment damage and void warranty.

Wiring & Installation

Wiring Diagram

Dimensions [mm](in)

Installation

Mount the sensor on a supply or return pipe depending on application.

Make sure the maximum allowed temperature limit is not exceeded.

For better temperature transfer between sensor and medium use heat

conducting paste or heat conducting pads.

If possible place the sensor on the upper side of the pipe to prevent

permeation by condensate.

Bend the wings of the contact sensor to fit to the radius of the pipe.

Place the heat conducting pad or liquid between pipe and sensor and use the

tightening strap to fix the sensor to the pipe. Use moderate torque, do not

crush the sensor.

Doc: 70-00-0215A, V1.0, 20140722 © 2012-2014 Vector Controls GmbH, Switzerland Subject to alteration

www.vectorcontrols.com

Page 2

Contact Temperature Sensor SC-T

Contact Temperature Sensor SC-T

Contact Temperature Sensor SC-T

°C

°F

Tn3 [kΩ]

Tn5 [kΩ]

Tn10 [kΩ]

Tn11 [kΩ]

Tn12 [kΩ]

Tn20 [kΩ]

Tn100 [kΩ]

B

25/50

3935

3470

3935

3630

3380

4200

4200

B

25/85

3974

3535

3974

3687

3435

4260

4260

B

25/100

3988

3526

3988

3715

3455

4285

4285

Signal type

NTC 3k

NTC 5k

NTC 10k-2

NTC-10k-3

NTC 20k

NTC 100k

-50

-58

201,1

161,9

670,2

441,3

329,2

1711

8558

-40

-40

100,9

89,49

336,4

239,7

188,4

814,0

4095

-30

-22

53,09

54,07

177,0

135,3

111,3

415,6

2077

-20

-4

29,12

33,21

97,08

78,91

67.74

220,6

1105

-10

14

16,60

21,07

55,33

47,54

42.45

122,4

612,4 0 32

9,795

13,73

32,65

29,49

27.28

70,20

351,0

10

50

5,969

9,041

19,90

18,79

17.96

41,56

207,8

20

68

3,747

6,064

12,49

12,26

12.09

25,34

126,7

25

77

3,000

5,000

10,00

10,00

10,00

20,00

100,00

30

86

2,417

4,139

8,057

8,194

8,313

15,88

79,43

40

104

1,598

2,875

5,327

5,592

5,828

10,21

51,06

50

122

1,081

2,032

3,603

3,893

4,161

6,718

33,60

60

140

0,746

1,463

2,488

2,760

3,021

4,518

22,59

70

158

0,525

1,069

1,751

1,990

2,229

3,100

15,50

80

176

0,376

0,792

1,255

1,458

1,669

2,168

10,84

90

194

0,275

0,601

0,915

1,084

1,266

1,542

7,707

100

212

0,203

0,464

0,678

0,817

0,973

1,114

5,571

110

230

0,536

0,354

0,512

0,624

0,752

0,818

4,092

120

248

0,123

0,272

0,410

0,481

0,605

0,609

3,046

130

266

0,097

0,212

0,322

0,380

0,487

0,460

2,298

140

284

0,077

0,169

0,257

0,300

0,395

0,351

1,755

150

302

0,063

0,137

0,210

0,240

0,325

0,271

1,356

°C

°F

Tp1 [Ω]

Tp2 [Ω]

Tk5 [Ω]

Tk6 [Ω]

PT100

DIN 60751

PT1000

DIN 60751

NI1000,

K=5000

NI1000

K=6180

-50

-58

80,28

803,0

790,88

742,55

-40

-40

84,27

843,0

830,84

791,31

-30

-22

88,22

882,0

871,69

841,46

-20

-4

92,16

922,0

913,48

892,96

-10

14

96,09

961,0

956,24

945,82

0

32

100,00

1000,0

1000

1000

10

50

103,90

1039,0

1044,79

1055,52

20

68

107,79

1078,0

1090,65

1111,36

30

86

111,67

1117,0

1137,62

1170,56

40

104

115,54

1155,0

1185,71

1230,11

50

122

119,40

1194,0

1234,98

1291,05

60

140

123,24

1232,0

1285,45

1353,40

70

158

127,07

1270,5

1337,15

1417,21

80

176

130,89

1309,0

1390,12

1482,50

90

194

134,70

1347,0

1444,39

1549,34

100

212

138,50

1385,0

1500,00

1617,79

110

230

142,29

1423,0

1556,98

1687,89

120

248

146,06

1460,5

1615,37

1759,72

130

266

149,80

1498,0

1675,19

1833,35

140

284

153,60

1536,0

1736,48

1908,87

150

302

157,30

1573,0

1799,27

1986,35

160

320

161,05

1610,5

1863,60

2065,89

170

338

164,75

1647,5

1929,50

2147,58

180

356

168,45

1684,5

1997,00

2231,53

190

374

172,15

1721,5

2066,15

2317,83

200

392

175,85

1758,5

2136,96

2406,60

Resistance Table for Thermistors (NTC)

Resistance Table for Platinum Film and NI1000 Elements

Doc: 70-00-0215A, V1.0, 20140722 © 2012-2014 Vector Controls GmbH, Switzerland Subject to alteration

www.vectorcontrols.com

Loading...

Loading...