Page 1

Quick Startup Guide for

SIMOVERT MASTERDRIVES

6SE70 VC

Vector Control

Section 1: Parameterization of Base Dri ve

Section 2: Parameterization of Rectifier

Section 3: Simovis Trace Setup Method

Section 4: When Should a Drive be re-Tuned

DROM-02069

Page 2

We reserve the right to modify functions, technical data, standards, drawings and parameters.

We have checked the contents of this document to ensure that they coincide

with the described hardware and software. However, deviations cannot be

completely ruled-out, so we cannot guarantee complete conformance.

However, the information in this document is regularly checked and the

necessary corrections will be included in subsequent editions. We are thankful

for any recommendations or suggestions.

e-mail:

Page 2 Version 1.0 March 1, 2000

mailto:drives.support@sea.siemens.com

Page 3

NOTE:

These instructions do not purport to cover all details or variations in equipment, nor to

provide for every possible contingency to be met in connection with installation,

operation or maintenance. Should further information be desired or should particular

problems arise which are not covered sufficiently for the purchaser’s purposes, please

contact your local Siemens office.

Further, the contents of these instructions shall neither become a part of nor modify

any prior or existing agreement, commitment or relationship. The sales contract

contains the entire obligation of Siemens Energy & Automation. The warranty

contained in the contract between the parties is the sole warranty of Siemens Energy &

Automation. Any statements contained herein do not create new warranties nor

modify the existing warranty.

Note:

This Quick Startup Guide is not an autonomous document, but is intended to direct users to

the section in the Operating Instructions which are important for start-up. Thus, these brief

instructions can only be completely valid when used in conjunction with the Operating

Instructions. It is especially important to observe the warning and information regarding

potential hazards in the Operating Instructions.

Warning:

• Electrical equipment has parts an components which are at hazardous voltage levels.

• If the warning information in the detailed Operating Instructions is not observed, this

can result in severe bodily injury or material damage.

• Only appropriately qualified personnel may work with this equipment.

• These personnel must be knowledgeable with all of the warning information and

service/maintenance measures of the Operating Instruction.

Perfect and safe operation of this equipment assumes professional transport, storage, erection

and installation as well as careful operating control and service.

Version 1.0 March 1, 2000 Page 3

Page 4

Page 4 Version 1.0 March 1, 2000

Page 5

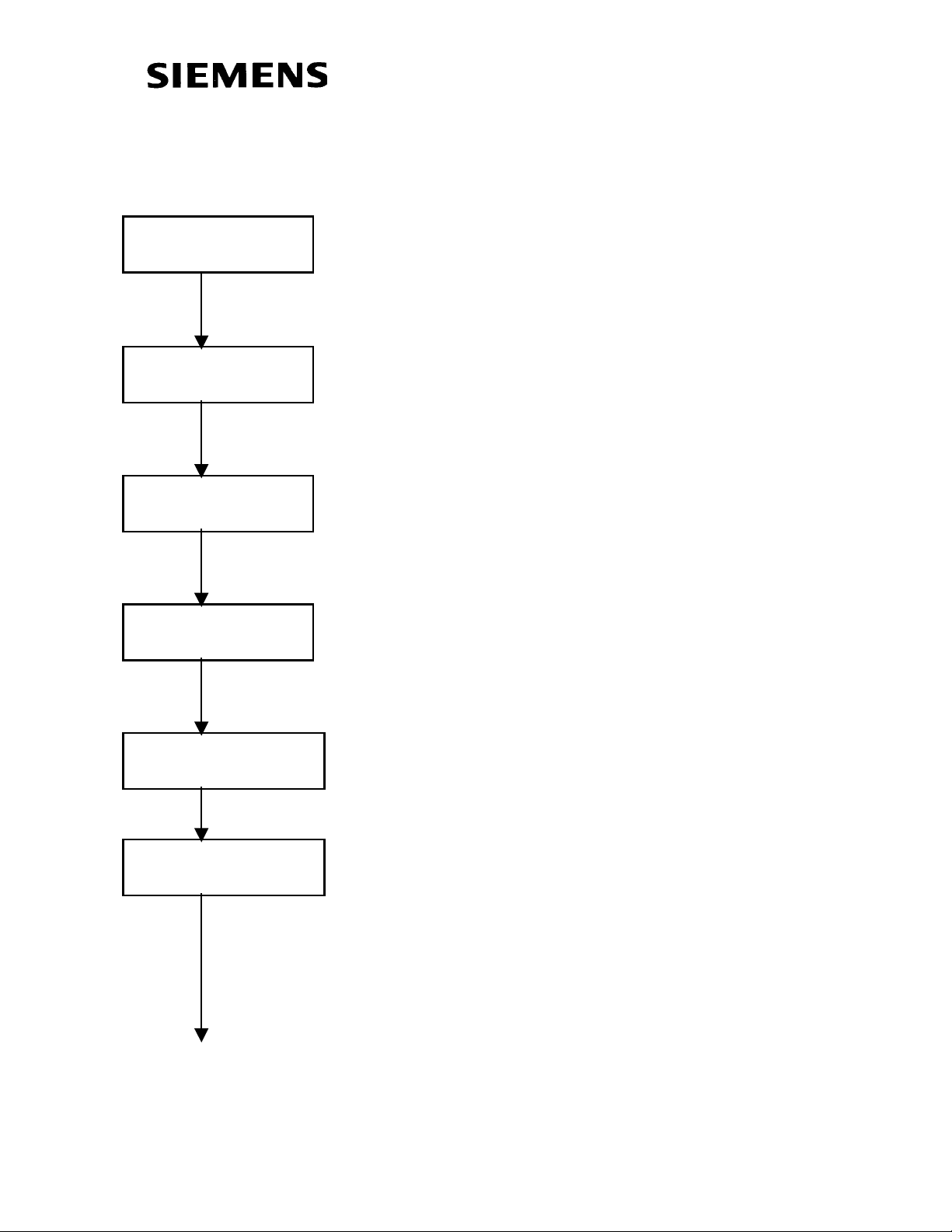

Section 1:

Parameterization of Base Unit

SIMOVERT MASTERDRIVES

6SE70 VC

Vector Control

1.1 Power Section Defintion

1.2 Factory Reset

1.3 Basic Start-up

1.3.1 Volts/Hz without encoder feedback

1.3.2 Volts/Hz with encoder feedback

1.3.3 Vector Control without encoder feedback

1.3.4 Vector Control with encoder feedback

1.4 Drive Control Word

1.5 Communication Board Configuration

Note: Refer to Operating Instruction Manual for power and control connections.

Version 1.0 March 1, 2000 Page 5

Page 6

Page 6 Version 1.0 March 1, 2000

Page 7

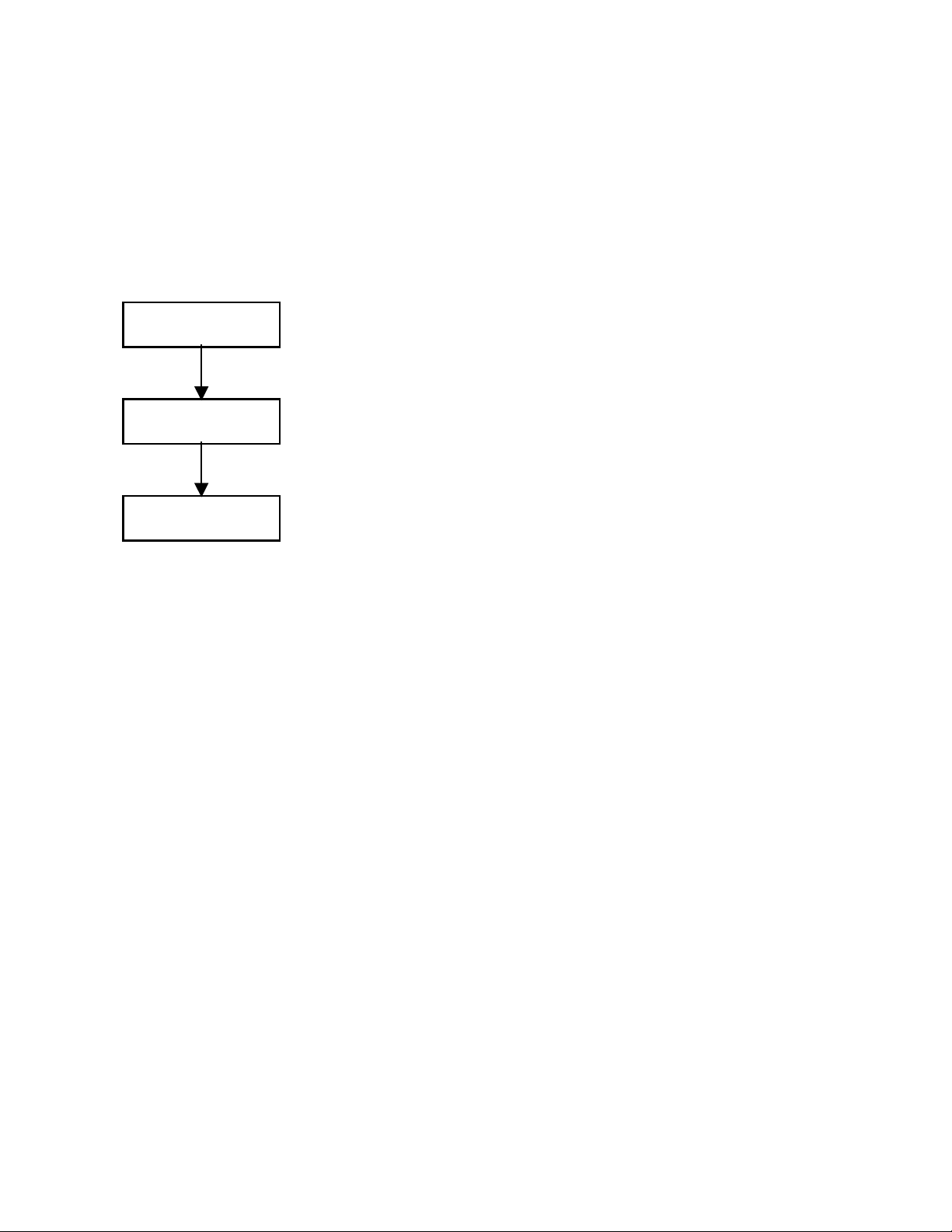

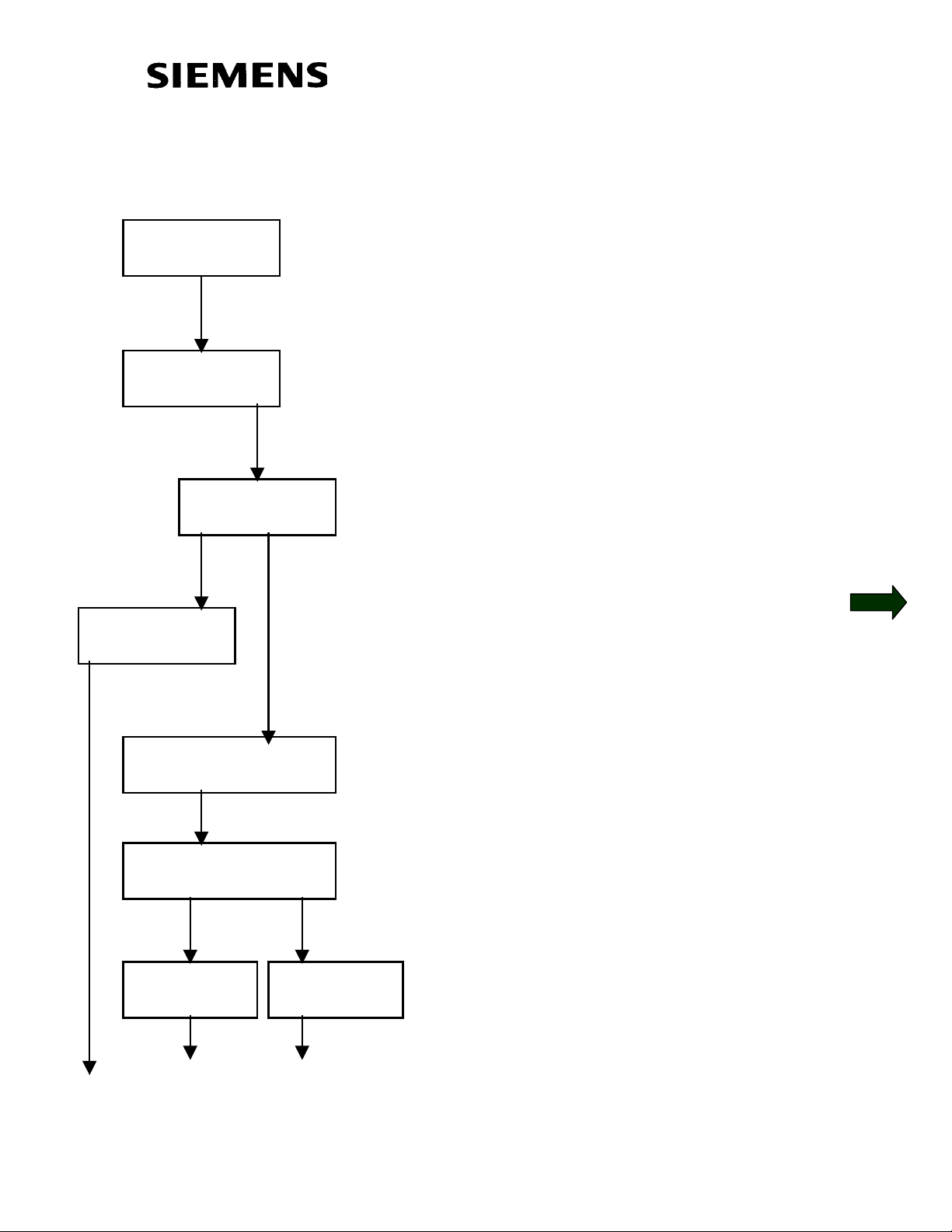

1.1 Power Section Definition

Note: Power Section is pre-defined at the factory. Power Section

Definition is required if a new board CUVC board is put into the drive or

boards are switched between units with different ratings. Drive should

be defaulted and re-parameterized after Power Section Definition.

P060 = 8

P070 = ?

P060 = 1

Select “Power Section Definition”

Menu

Input Code for unit (PWE)

(Refer to Compendium section

6.3 or use the bookmark “PWE

Listing” or check the following

table)

Return to Parameter Menu

Version 1.0 March 1, 2000 Page 7

Page 8

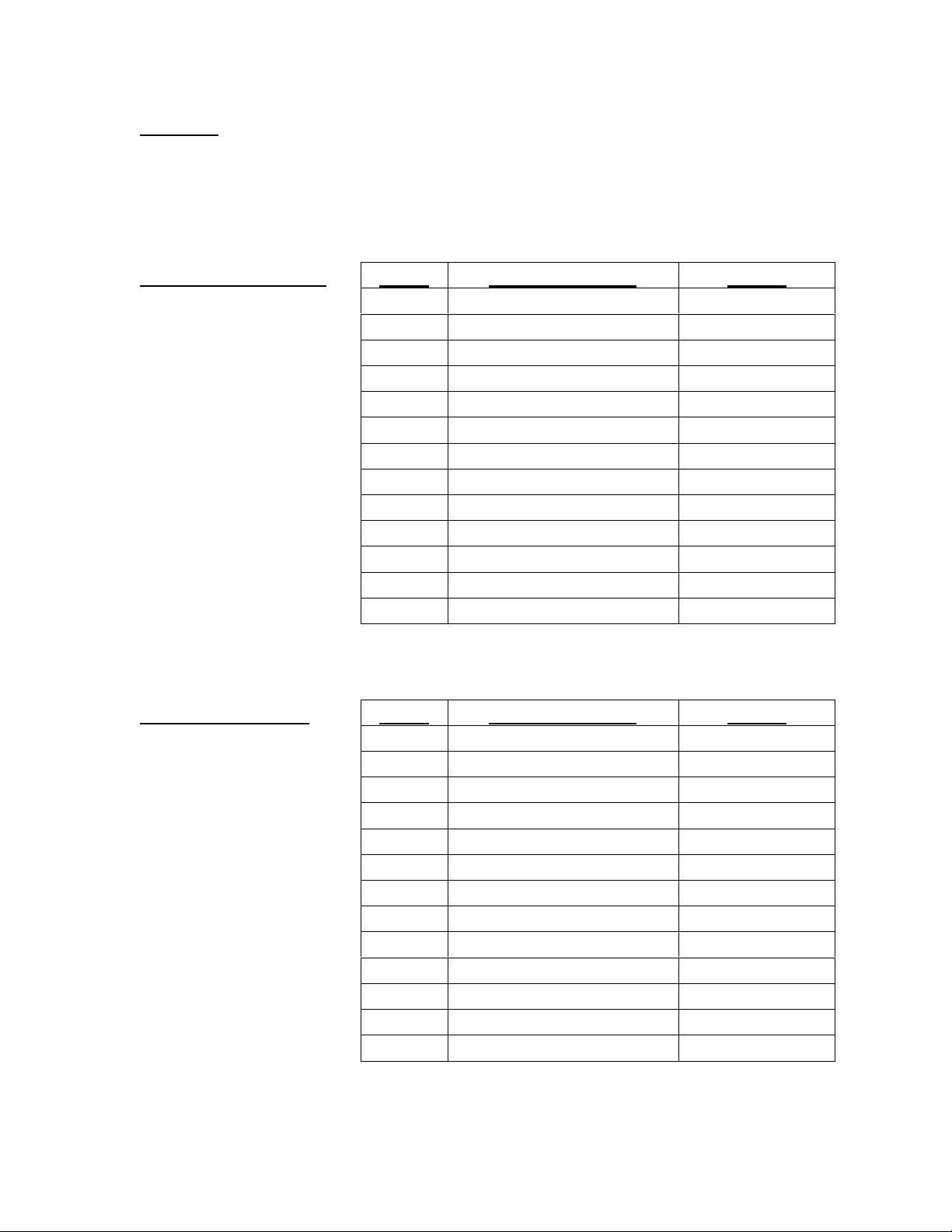

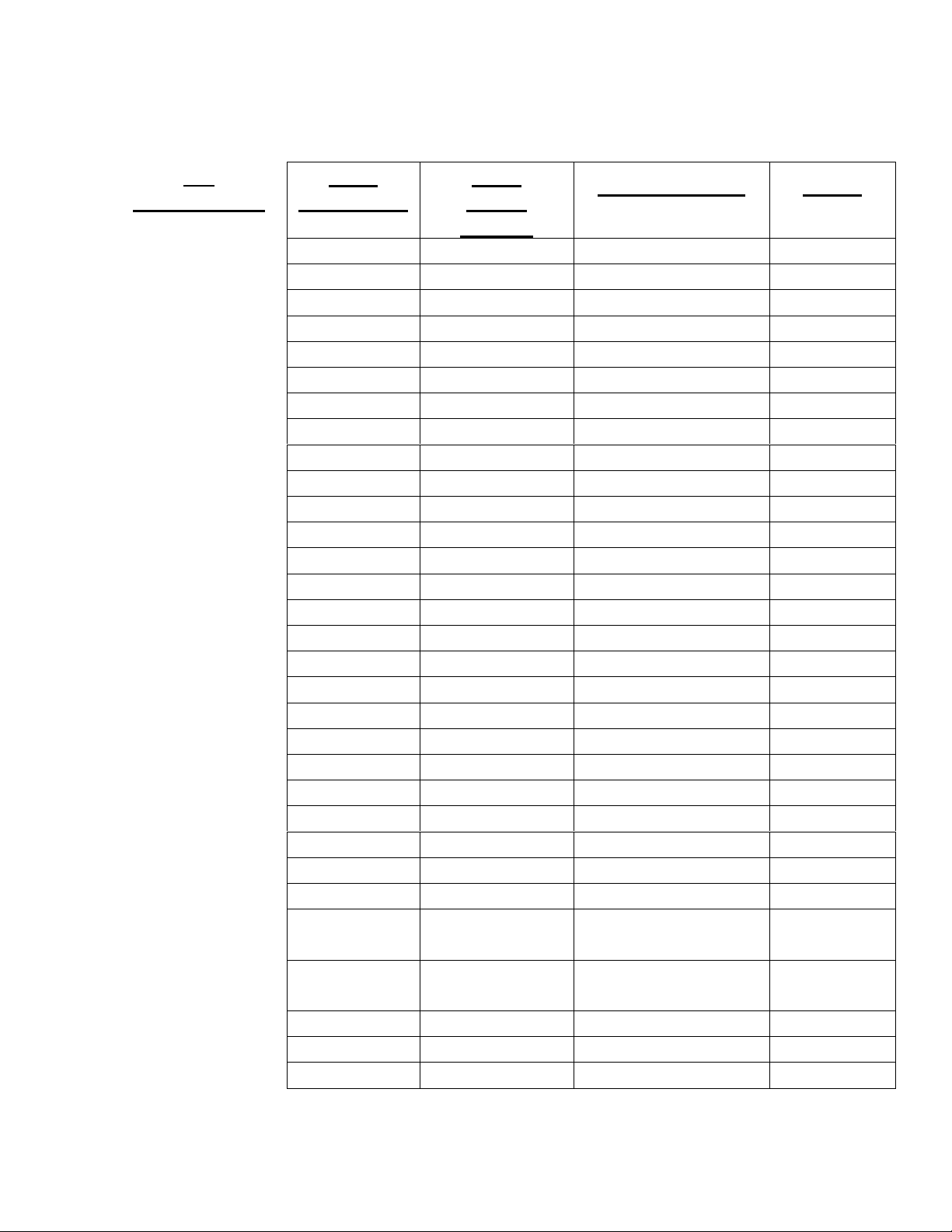

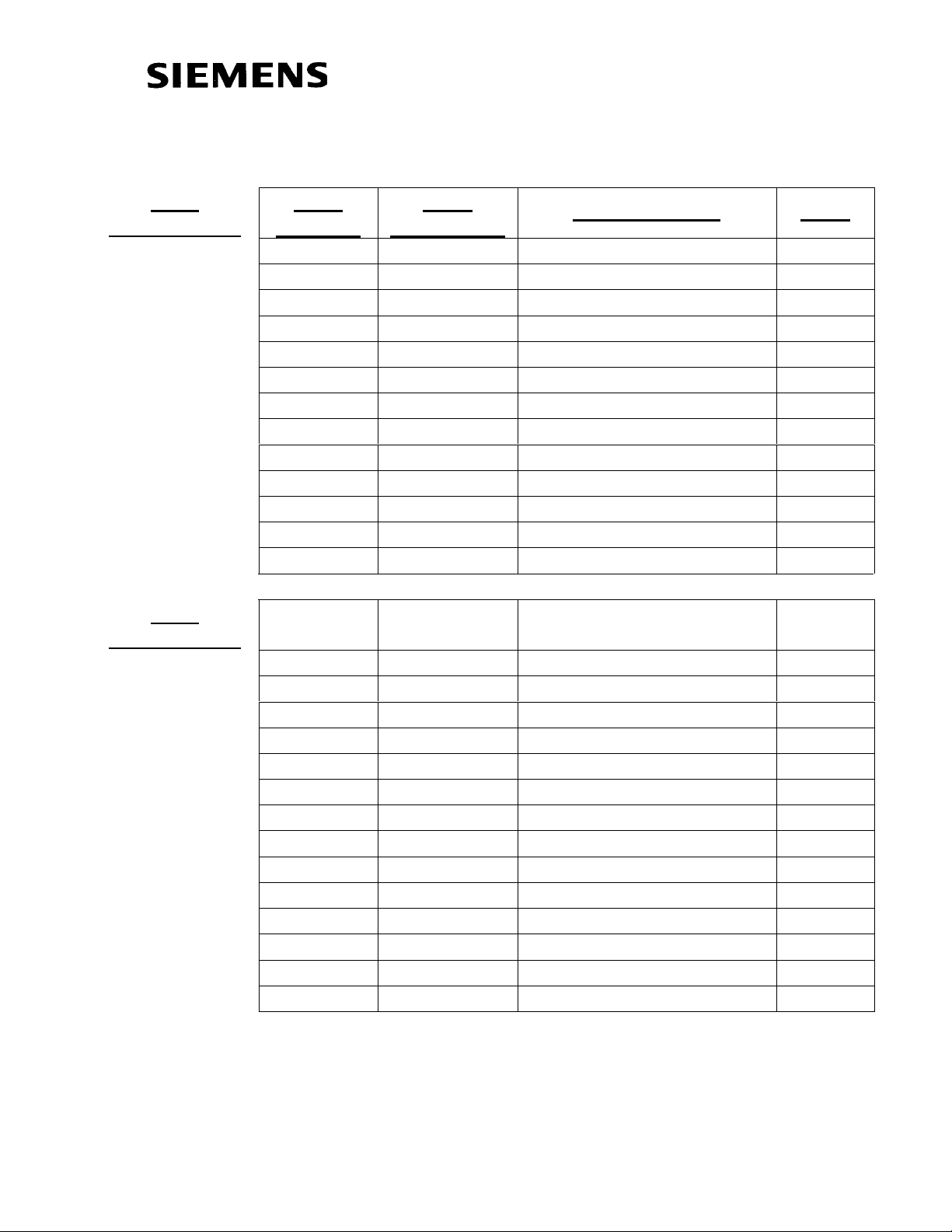

Unit List

P070: Parameter Value (PWE)

P072: Rated Output Current in Amps In[A]

Frequency Converter

AC-AC type

3 AC 200V to 230V

PWE Order Number In[A]

14 6SE7021-1CA60 10.6 21 6SE7021-3CA60 13.3 27 6SE7021-8CB60 17.7 32 6SE7022-3CB60 22.9 39 6SE7023-2CB60 32.2 48 6SE7024-4CC60 44.2 54 6SE7025-4CD60 54.0 64 6SE7027-0CD60 69.0 70 6SE7028-1CD60 81.0 13 6SE7031-0CE60 100.0 29 6SE7031-3CE60 131.0 41 6SE7031-6CE60 162.0 87 6SE7032-0CE60 202.0

*1

Frequency Inverter

DC-AC type

DC 270V to 310V

PWE Order Number In[A]

15 6SE7021-1R60 10.6

22 6SE7021-3RA60 13.3

28 6SE7021-8RB60 17.7

33 6SE7022-3RB60 22.9

40 6SE7023-2RB60 32.2

49 6SE7024-4RC60 44.2

55 6SE7025-4RD60 54.0

65 6SE7027-0RD60 69.0

71 6SE7028-1RD60 81.0

20 6SE7031-0RE60 100.0

34 6SE7031-3RE60 131.0

86 6SE7031-6RE60 162.0

92 6SE7032-0RE60 202.0

*1

Page 8 Version 1.0 March 1, 2000

Page 9

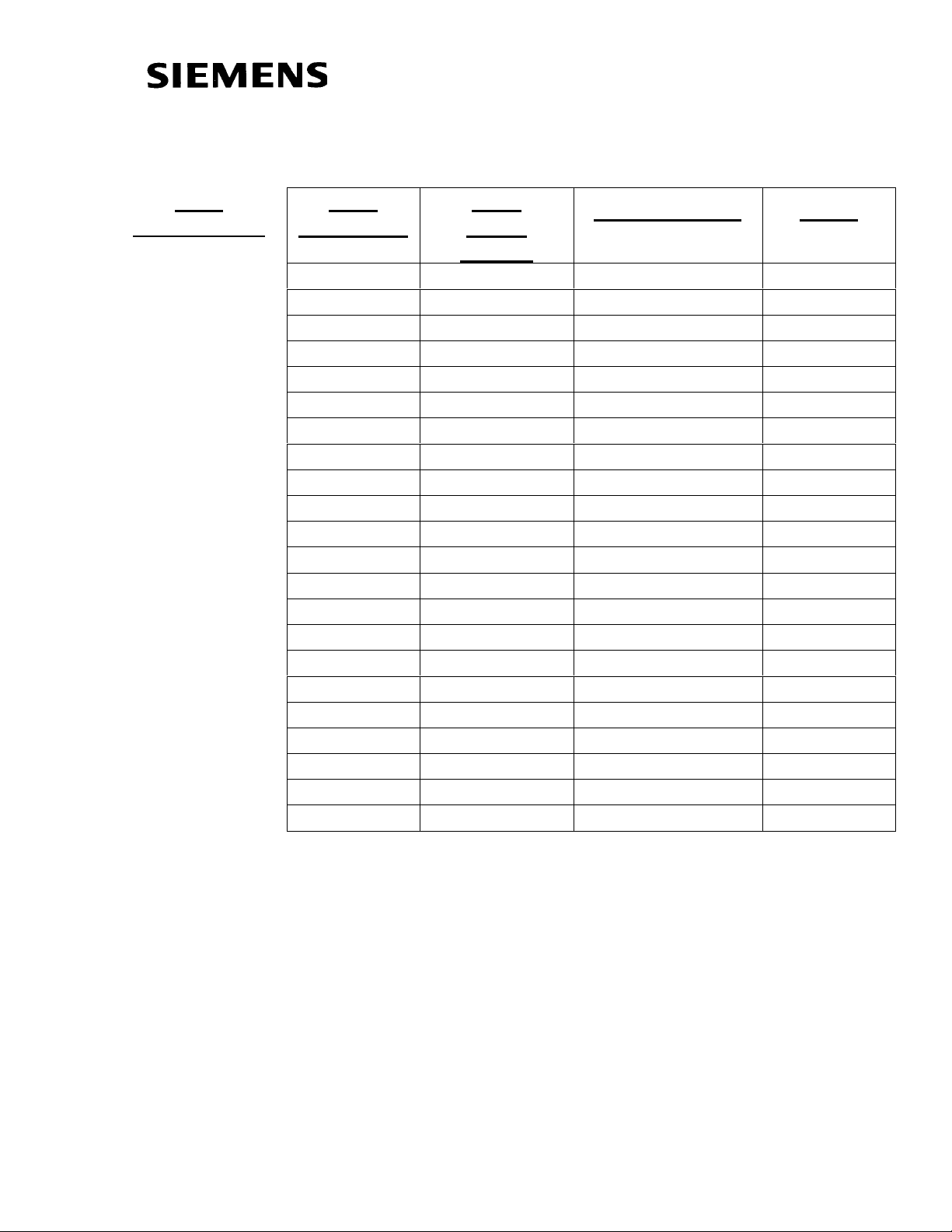

Frequency Converter

AC-AC type

3 AC

380V to 460V

Air Cooled

PWE

PWE

Order Number In[A]

Water

Cooled

3 6SE7016-1EA61 6.1

9 6SE7018-0EA61 8.0

11 6SE7021-0EA61 10.2

18 6SE7021-3EB61 13.2

25 6SE7021-8EB61 17.5

35 6SE7022-6EC61 25.5

42 6SE7023-4EC61 34.0

46 6SE7023-8ED61 37.5

52 6SE7024-7ED61 47.0

56 6SE7026-0ED61 59.0

66 6SE7027-2ED61 72.0

74 6SE7031-0EE60 92.0

82 6SE7031-2EF60 124.0

90 6SE7031-5EF60 146.0

98 6SE7031-8EF60 186.0

102 6SE7032-1EG60 210.0

108 6SE7032-6EG60 260.0

112 6SE7033-2EG60 315.0

116 6SE7033-7EG60 370.0

147 233 6SE7035-1EK60 510.0

151 237 6SE7036-0EK60 590.0

164 168 6SE7037-0EK60 690.0

*1

1

*

Version 1.0 March 1, 2000 Page 9

Based on 3kHz carrier frequency setting, larger frames have maximum carrier

frequency restrictions

Page 10

Frequency Inverter

DC-AC type

DC

510V to 650V

PWE

Air Cooled

PWE

Water

Order Number In[A]

Cooled

4 6SE7016-1TA61 6.1

10 6SE7018-0TA61 8.0

12 6SE7021-0TA61 10.2

19 6SE7021-3TB61 13.2

26 6SE7021-8TB61 17.5

36 6SE7022-6TC61 25.5

43 6SE7023-4TC61 34.0

47 6SE7023-8TD61 37.5

53 6SE7024-7TD61 47.0

57 6SE7026-0TD61 59.0

67 6SE7027-2TD61 72.0

75 6SE7031-0TE60 92.0

83 6SE7031-2TF60 124.0

91 6SE7031-5TF60 146.0

99 6SE7031-8TF60 186.0

103 6SE7032-1TG60 210.0

109 6SE7032-6TG60 260.0

113 6SE7033-2TG60 315.0

117 6SE7033-7TG60 370.0

120 206 6SE7035-1TJ60 510.0

123 209 6SE7036-0TJ60 590.0

126 212 6SE7037-0TK60 690.0

127 213 6SE7038-6TJ60 860.0

134 6SE7041-1TM60 1100.0

135 221 6SE7041-1TK60 1100.0

140 226 6SE7041-3TM60 1300.0

150 236 6SE7041-6TM60 1630.0

153 239 6SE7042-1TQ60 2090.0

154 199 6SE7041-3TL60 1300.0

163 167 6SE7037-0TJ60 690.0

181 247 6SE7038-6TS60 6450.0

185 250 6SE7041-1TS60 6270.0

194 244 6SE7042-5TN60 2470.0

*1

Page 10 Version 1.0 March 1, 2000

Page 11

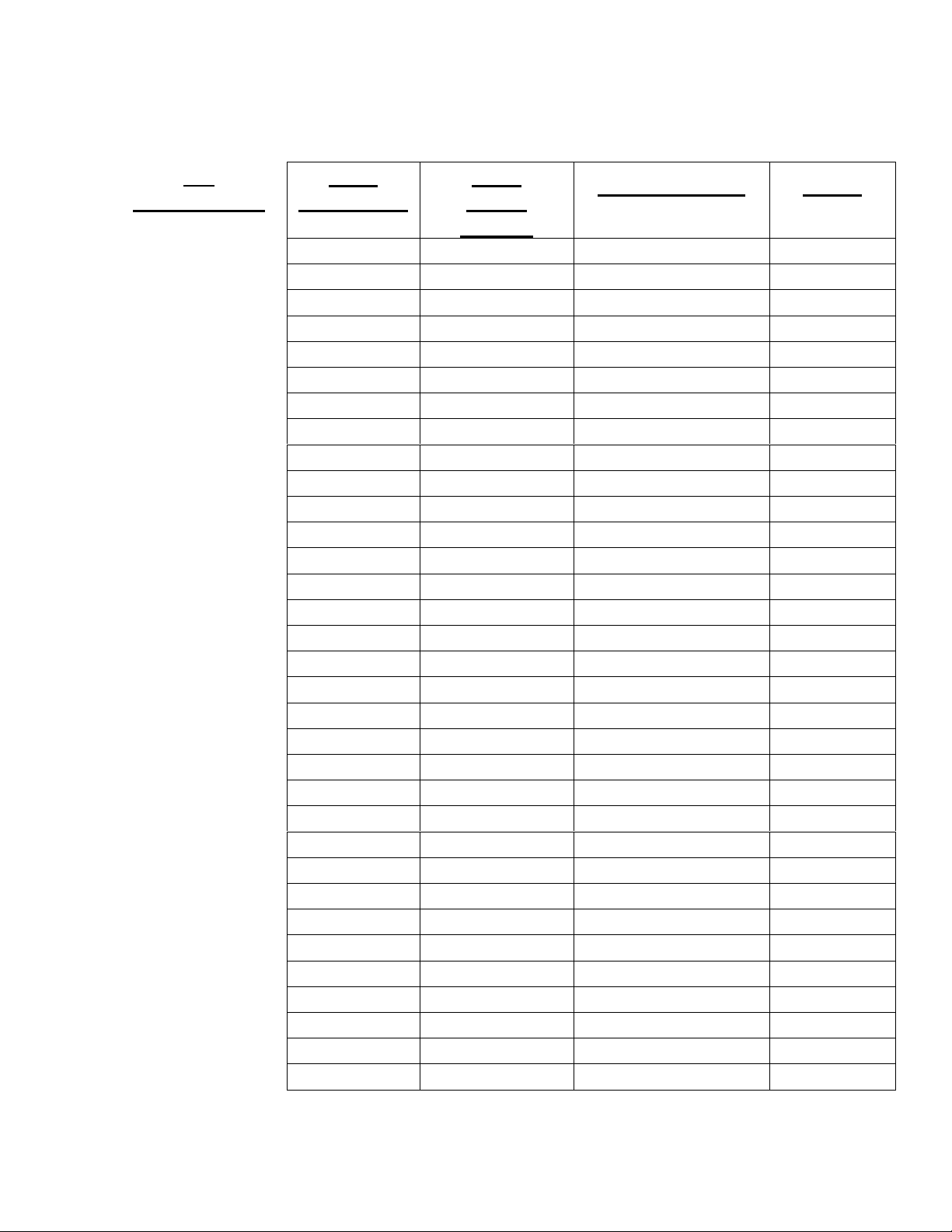

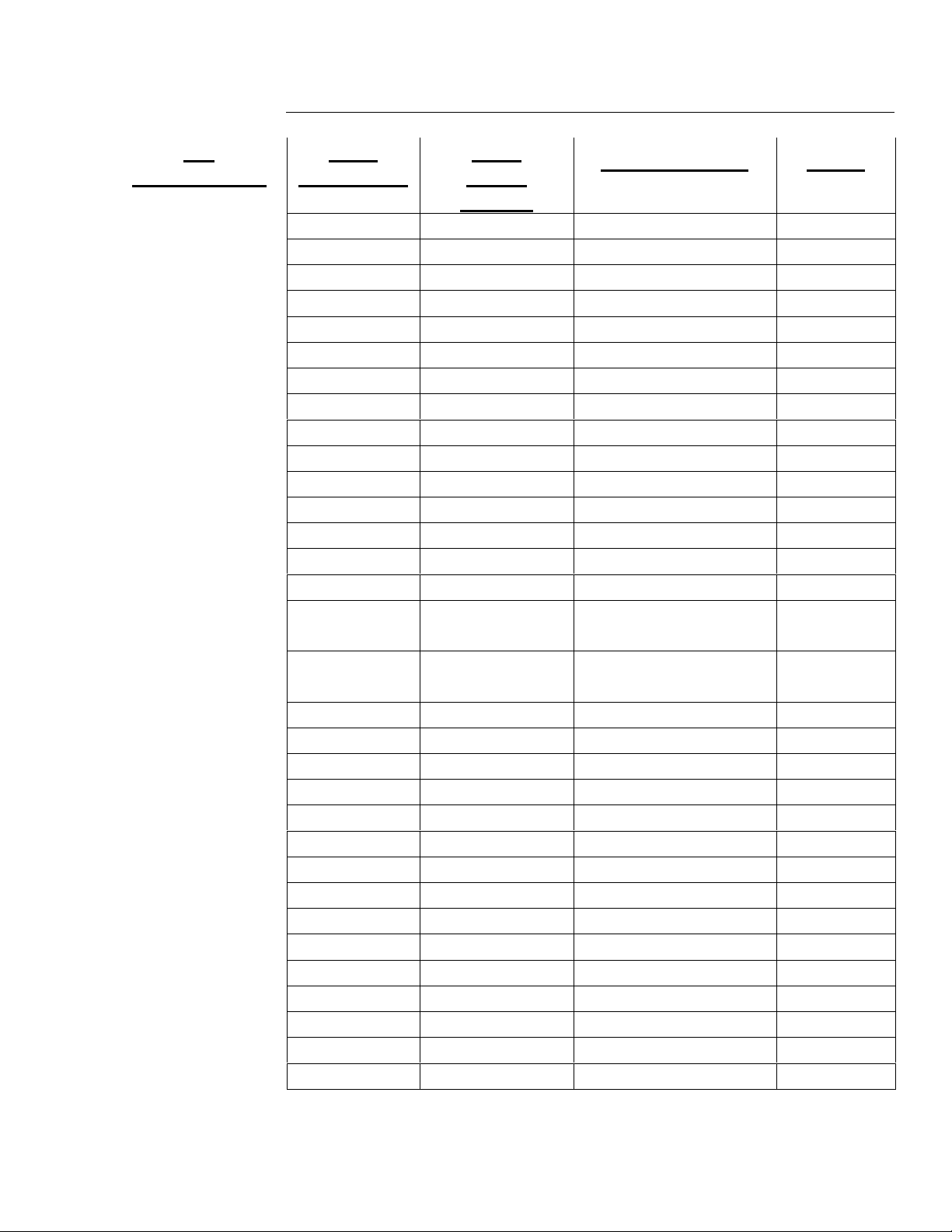

Frequency Converter

AC-AC type

3 AC

500V to 575V

Air Cooled

PWE

PWE

Order Number In[A]

Water

Cooled

1 6SE7014-5FB61 4.5

5 6SE7016-2FB61 6.2

7 6SE7017-8FB61 7.8

16 6SE7021-1FB61 11.0

23 6SE7021-5FB61 15.1

30 6SE7022-2FC61 22.0

37 6SE7023-0FD61 29.0

44 6SE7023-4FD61 34.0

50 6SE7024-7FD61 46.5

60 6SE7026-1FE60 61.0

62 6SE7026-6FE60 66.0

68 6SE7028-0FF60 79.0

78 6SE7031-1FF60 108.0

84 6SE7031-3FG60 128.0

94 6SE7031-6FG60 156.0

100 6SE7032-0FG60 192.0

104 6SE7032-3FG60 225.0

136 222 6SE7033-0FK60 297.0

141 227 6SE7033-5FK60 354.0

143 229 6SE7034-5FK60 452.0

*1

1

*

Version 1.0 March 1, 2000 Page 11

Based on 3kHz carrier frequency setting, larger frames have maximum carrier

frequency restrictions

Page 12

Frequency Inverter

DC-AC type

DC

675V to 810V

PWE

Air Cooled

PWE

Water

Order Number In[A]

Cooled

2 6SE7014-5UB61 4.5

6 6SE7016-2UB61 6.2

8 6SE7017-8UB61 7.8

17 6SE7021-1UB61 11.0

24 6SE7021-5UB61 15.1

31 6SE7022-2UC61 22.0

38 6SE7023-0UD61 29.0

45 6SE7023-4UD61 34.0

51 6SE7024-7UD61 46.5

61 6SE7026-1UE60 61.0

63 6SE7026-6UE60 66.0

69 6SE7028-0UF60 79.0

79 6SE7031-1UF60 108.0

85 6SE7031-3UG60 128.0

95 6SE7031-6UG60 156.0

101 6SE7032-0UG60 192.0

105 6SE7032-3UG60 225.0

110 200 6SE7033-0UJ60 297.0

114 202 6SE7033-5UJ60 354.0

118 204 6SE7034-5UJ60 452.0

121 207 6SE7035-7UK60 570.0

124 210 6SE7036-5UK60 650.0

128 214 6SE7038-6UK60 860.0

130 216 6SE7041-0UM60 990.0

132 218 6SE7041-1UM60 1080.0

138 224 6SE7041-2UM60 1230.0

144 230 6SE7041-4UM60

6SE7041-4UQ60

148 234 6SE7042-1TQ60

6SE7041-6UQ60

155 195 6SE7041-1UL60 1080.0

157 6SE7042-4ULJ60 2450.0

159 197 6SE7041-1UL60 1230.0

*1

1400.0

1580.0

Page 12 Version 1.0 March 1, 2000

Page 13

Frequency Inverter

DC-AC type

DC

675V to 810V

Air Cooled

Frequency Converter

AC-AC type

3 AC

660V to 690V

Air Cooled

PWE

PWE

Order Number In[A]

Water

Cooled

161 6SE7043-3UR60 3270.0

165 6SE7044-1UR60 4090.0

169 6SE7044-8UR60 4900.0

173 6SE7045-7UR60 5720.0

177 6SE7046-5UR60 6540.0

179 245 6SE7036-5UR60 4940.0

182 248 6SE7038-6US60 6540.0

186 251 6SE7041-1US60 6160.0

188 253 6SE7041-2US60 5840.0

190 240 6SE7042-1UN60 2050.0

192 242 6SE7042-3UN60 2340.0

PWE

PWE

Order Number In[A]

Water

Cooled

58 6SE7026-0HF60 55.0

72 6SE7028-2HF60 82.0

76 6SE7031-0HG60 97.0

80 6SE7031-2HF60 118.0

88 6SE7031-5HF60 145.0

96 6SE7031-7HG60 171.0

106 6SE7032-1HG60 208.0

137 223 6SE7033-0HK60 297.0

142 228 6SE7033-5HK60 354.0

146 232 6SE7034-5HK60 452.0

*1

*1

Frequency Inverter

DC-AC type

DC

890V to 930V

PWE

Air Cooled

PWE

Water

Order Number In[A]

Cooled

59 6SE7026-0WF60 60.0

73 6SE7028-2WF60 82.0

Version 1.0 March 1, 2000 Page 13

*1

Page 14

DC

890V to 930V

PWE

Air Cooled

PWE

Water

Order Number In[A]

Cooled

77 6SE7031-0WG60 97.0

81 6SE7031-2WF60 118.0

89 6SE7031-5WF60 145.0

97 6SE7031-7WG60 171.0

107 6SE7032-1WG60 208.0

111 201 6SE7033-0WJ60 297.0

115 203 6SE7033-5WJ60 354.0

119 205 6SE7034-5WJ60 452.0

122 208 6SE7035-7WK60 570.0

125 211 6SE7036-5WK60 650.0

129 215 6SE7038-6WK60 860.0

131 217 6SE7041-0WM60 990.0

133 219 6SE7041-1WM60 1080.0

139 225 6SE7041-2WM60 1230.0

145 231 6SE7041-4WM60

6SE70414WQ60

149 235 6SE7041-6WM60

6SE7041-6WM60

152 238 6SE7034-5WK60 452.0

156 196 6SE7041-1WL60 1080.0

158 6SE7042-4WR60 2450.0

160 198 6SE7041-2WL60 1230.0

162 6SE7043-3WR60 3270.0

166 6SE7044-1WR60 4090.0

170 6SE7044-8WR60 4900.0

174 6SE7045-7WR60 5720.0

178 6SE7046-5WR60 6540.0

180 246 6SE7036-5WS60 4940.0

183 249 6SE7038-6WS60 6540.0

187 252 6SE7041-1WS60 6160.0

189 254 6SE7041-2WS60 5840.0

191 241 6SE7042-1WN60 2050.0

193 243 6SE7042-3WN60 2340.0

*1

1400.0

1580.0

Page 14 Version 1.0 March 1, 2000

Page 15

1.2 Factory Reset

P053 = 6

P060 = 2

P366 = 0

P970 = 0

6: Parameter Changes permitted

via PMU and Serial Interface

(OP1 and PC)

2: Menu Select = Fixed Settings

Select Factory Setting

0: Standard

Start Parameter Reset

0: Parameter Reset

1: No Parameter Change

Version 1.0 March 1, 2000 Page 15

Page 16

Page 16 Version 1.0 March 1, 2000

Page 17

1.3 Basic Start-up without Motor Connected to Load

1.3.1 Volts/Hz without Encoder

P060 = 5

P071 = ?

P095 = ?

P095 = 2 10 or 11

P097 = ?

P060=5

Select “Drive Settings”

P071 = Input Line Voltage

AC-AC Converter=460Volt

DC-AC Inverter = 620Volt

P095 = Select Motor Type

2: Asynchronous 1PH7 Motor

10: IEC Induction Motor

11: NEMA Induction Motor

P097 = Motor Code number for

1PH7 motor (See Appendix)

P101 = 460

P102 = xxx

P095 = 10 11

P104 = ?

P105 = ?

Motor Nameplate Information

P101= Motor Voltage (V)

P102 = Motor Rated Current (A)

P104 = Cos (phi) per nameplate

P105 = Rated Horsepower

Version 1.0 March 1, 2000 Page 17

Page 18

P106 = ?

P107 = 60

P108 = xxxx

P115 = 1

P340 = 3

P106 = NEMA Motor Nameplated

efficiency (if unknown set =0.8)

P107 = Rated Motor Frequency

P108 = Nameplated Rotor RPM

P115 = 1

“Automatic Parameterization”

P340 = Carrier Frequency

Low # = Cooler Motor and Drive

High # = Lower Motor Noise

P383 = xxxx

P452 = 100

P383 = Motor Thermal Time

Constant. If constant unknown use

general guidelines;

2 Pole Motor = 480 seconds

4 Pole Motor = 600 seconds

6 Pole Motor = 720 seconds

P452 = Maximum Forward Speed in

Percentage (usually 100%)

Page 18 Version 1.0 March 1, 2000

Page 19

P453 = -100

P060 = 1

P128 = xxxx

P462 = xxxx

P453 = Maximum Reverse Speed in

Percentage (usually -100%)

P060 = Return to Parameter Menu

P128 = Maximum Motor Current

Options: P128 = P102

P128=1.1*P102

P128=1.5*P102

P462 = Acceleration Time in seconds

P464 = Deceleration Time in seconds

P464 = xxxx

P443i2= 11

P443i2(Index2) = 11

Configures drive for analog input

(0-10Vdc) to be active at

terminals X101 pin#15 and

pin#16

If 4-20mA is required closed

CUVC board mounted jumper

S3, position 1 and 2.

Start/Stop Control is located on

the PMU (operator control panel

mounted directly on the drive)

Speed Setpoint is controlled with

the Up / Down arrows.

Version 1.0 March 1, 2000 Page 19

Page 20

Connect External Wiring as connection diagram.

r

Custome

Connection Points

Internal Connections

Step 1: Dry set of contacts between terminals X101, pin#1 and pin#5 for Local/Remote Mode Selection. Jumper if not required.

Step 2: Dry set of contacts between terminals X101, pin#1 and pin#8 for

Coast to Stop Selection. Jumper if not required.

Step 3: Dry set of contacts between terminals X101, pin#1 and pin#9 for Source of Main Start/Stop Selection.

Step 4: Dry set of contacts between terminals X101, pin#1 and pin#7 for

Source of Fault Reset. Leave open if not required. “P” button on PMU

will be fault reset location if pin#7 is not used.

Step 5: Dry set of contacts between terminals X101, pin#1 and pin#6 for

Fixed Speed or Preset Speed Selection. Leave open if not required.

Page 20 Version 1.0 March 1, 2000

Page 21

Speed value is determined by P402. A selection of P402=100% will be

a full speed reference setpoint.

Step 6: Fault Status is provided by a 24 Vdc signal at terminals X101

pin#3 with respect to pin#2. Leave open if not required.

Step 7: Drive Operating Status is provided by a 24 Vdc signal at

terminals X101 pin#4 with respect to pin#2.

Step 8: Connect external speed reference 0-10Volt or 4-20 mA (CUVC

board mounted jumper S3 pin 2 and 2 must be closed for mA input).

Adjust over the full range and monitor P447. With a zero input r447

should read near 0.00, and with full value r447 should read near 100%.

Step 9: Connect the motor to the load, unless the plan is to install an

encoder feedback or change to Vector Control.

Standard Commissioning for a Volts/Hz

controlled motor without feedback is

complete, after adjusting only 19

parameters.

Version 1.0 March 1, 2000 Page 21

Page 22

1.3.2 Volts/Hz with Encoder

Note: Complete section 1.3.1 before operating the motor with encoder feedback.

P060 = 5

P100 = 0

P130 = ?

P151 = ?

P060=5

Select “Drive Settings”

P100=0

Selects Volts/Hz

with Encoder Feedback

P130 = Select Type of Encoder

11: Pulse Encoder

15: Pulse Encoder with Zero Pulse

P151 = Pulse Per Revolution (PPR)

P060 = 1

Page 22 Version 1.0 March 1, 2000

P060 = Return to Parameter Menu

Page 23

Additional Connection for +15 Vdc Encoder.

Step 10: Set Speed Reference to 20%.

Step 11: Provide Start command. Note that if Signal A and Signal B are

reversed, the motor will accelerate rapidly.

Step 12: Connect the motor to the load, unless the plan is to change to

Vector Control.

Standard Commissioning for a Volts/Hz

controlled motor with feedback is

complete, after adjusting only 24

parameters.

Version 1.0 March 1, 2000 Page 23

Page 24

1.3.3 Vector Control without Encoder Feedback

Note: Complete section 1.3.1 (Volts/Hz control without encoder feedback).

P060 = 5

P100 = 3

P060 = 1

P115 = 4

P060=5

Select “Drive Settings”

P100=3

Selects Vector Control

without Encoder Feedback

P060 = Return to Parameter Menu

If you plan to use an encoder, go to

section1.3.4, otherwise continue.

P115 = 4 No-Load Measurement

Uncoupled motor will ROTATE.

Alarm message “A080” will appear,

and a start command must be issued

within 20 seconds to perform the test,

otherwise P115 will unset.

Wait

Page 24 Version 1.0 March 1, 2000

This test will adjust the following

parameters

P103, P120

Wait for display to change back

o

to

009.

Page 25

P115=5

Wait

P115=5 Controller Optimization

Alarm message “A080” will appear,

and a start command must be issued

within 20 seconds to perform the test,

otherwise P115 will unset.

This test is best performed on a

coupled motor under actual conditions;

however, if the load is cyclic (0-100%

load variation), manual tuning may be

preferred.

This test will adjust the following

parameters

P116, P223, P235, P236,

P240, P471

Step 10: Set Speed Reference to 20%, and monitor speed feedback r000, current feedback r004, and actual DC BUS r006. If stable increase speed in increments and continue to monitor feedbacks.

Standard Commissioning for a Vector

Controlled motor without feedback is

complete, after adjusting only 24

parameters, and utilizing two of the selftuning options.

Version 1.0 March 1, 2000 Page 25

Page 26

1.3.4 Vector Control with Encoder Feedback

Note: Complete section 1.3.1 (Volts/Hz control without encoder feedback), and

section 1.3.3 (Vector control without encoder feedback)

Step 10: Operate the uncoupled motor if sections 1.3.1 and 1.3.3 are complete and

verify operation of the motor without faults.

P060=5

P060 = 5

P100 = 4

Select “Drive Settings”

P100=4

Selects Vector Control

with Encoder Feedback

Connect encoder as per

diagram

P130 = ?

P151 = ?

P060 = 1

P115 = 4

P130 = Select Type of Encoder

11: Pulse Encoder

15: Pulse Encoder with Zero Pulse

P151 = Pulse Per Revolution (PPR)

P060 = Return to Parameter Menu

P115 = 4 No-Load Measurement

Uncoupled motor will ROTATE.

Alarm message “A080” will appear,

and a start command must be issued

within 20 seconds to perform the test,

otherwise P115 will unset.

Page 26 Version 1.0 March 1, 2000

Page 27

Wait

P115=5

Wait

This test will adjust the following

parameters

P103, P120

Wait for display to change back

o

to

009.

P115=5 Controller Optimization

Alarm message “A080” will appear,

and a start command must be issued

within 20 seconds to perform the test,

otherwise P115 will unset.

This test is best performed on a

coupled motor under actual conditions;

however, if the load is cyclic (0-100%

load variation), manual tuning may be

preferred.

This test will adjust the following

parameters

P116, P223, P235, P236,

P240, P471

Step 11: Set Speed Reference to 20%, and monitor speed feedback r000, current feedback r004, and actual DC BUS r006. If stable increase speed in increments and continue to monitor feedbacks.

Standard Commissioning for a Vector

Controlled motor with feedback is

complete, after adjusting only 31

parameters, and utilizing two of the selftuning options.

Version 1.0 March 1, 2000 Page 27

Page 28

Page 28 Version 1.0 March 1, 2000

Page 29

1.4 Drive Control Word

Function Diagrams will be referred to in bra ckets with the ir number. Please refer to

function diagrams in the compendium. Example [Diagram Number]

Assign Digital Inputs

Assign Off2(Coast Stop)

Assign Off3(Quick Stop)

Assign ON/OFF1

Digital Inputs/Outputs:

Binector Assignments for Control

may be made from Digital Inputs

P555, P556 & P557 can be used

to assign Coast to Stop

P558, P559 & P560 can be used

to assign Quick Stop

P554 MUST be assigned to

activate drive. Note:

Acceleration and Deceleration

will be based on ramp generator

[320]

[180] Assign Other

Functionality as

Required

See [190]

Assign Other Control

Functionality as

Required

Version 1.0 March 1, 2000 Page 29

Page 30

Page 30 Version 1.0 March 1, 2000

Page 31

1.5 Communication Board Configuration

P060 = 4

CBx Inserted?

NO

P711 = ?

to

P721.1…5 = ?

SLB Inserted?

NO

P740 = ?

P741 = ?

P742 = ?

P740

= 1

P743 = 0

P745 = ?

YES

YES

P740 = 0

Select “Board Configuration”

Menu

Parameterize CBx Boards

See Function Diagrams

Simolink Address

0: Dispatcher (Master)

>0: Transceiver (Slave)

SLB Telegram Failure Time

SLB Transmit Power

1: Up to 15 m

2: Up to 25 m

3: Up to 40 m

P743=0,

node evaluation.

Enter Number of Channels

Automatic number of

P746 = ?

P749.1…8 = ?

YES

Enter Simolink Cycle Time

correspond to pulse frequency, i.e. =3.2)

Simolink Receive Address =

Node. Channel

(must

CBP Inserted?

NO

P918.1…2 = ?

Input CBP Bus Addresses

Return to Parameter Menu

P060 = 1

Version 1.0 March 1, 2000 Page 31

Page 32

Page 32 Version 1.0 March 1, 2000

Page 33

Section 2:

Parameterization of a Rectifer

Unit

SIMOVERT MASTERDRIVES

6SE70 VC

Vector Control

2.0 Power Section Defintion

2.1 Factory Reset

Basic Start-up

2.2 Rectifier or Regen without auto-transformer

2.3 Regen with auto-transformer

Version 1.0 March 1, 2000 Page 33

Page 34

Page 34 Version 1.0 March 1, 2000

Page 35

2.0 Power Section Definition

Note: Power Section is pre-defined at the factory. Power Section

Definition is required if a new board CUR board is put into the drive or

boards are switched between units with different ratings. CUR cards will

exist Regen Rectifiers and Large Common Rectifiers. The smaller

Common Rectifier will not have parameters. Drive should be defaulted

and re-parameterized after Power Section Definition.

P051 = 3

P052 = 2

P070 = xxx

P052 = 0

P51=3 : Export Mode

P52=2: Function select “Initialization”

Input Code for unit (PWE)

(Refer to the following table)

Return to Parameter Menu

Version 1.0 March 1, 2000 Page 35

Page 36

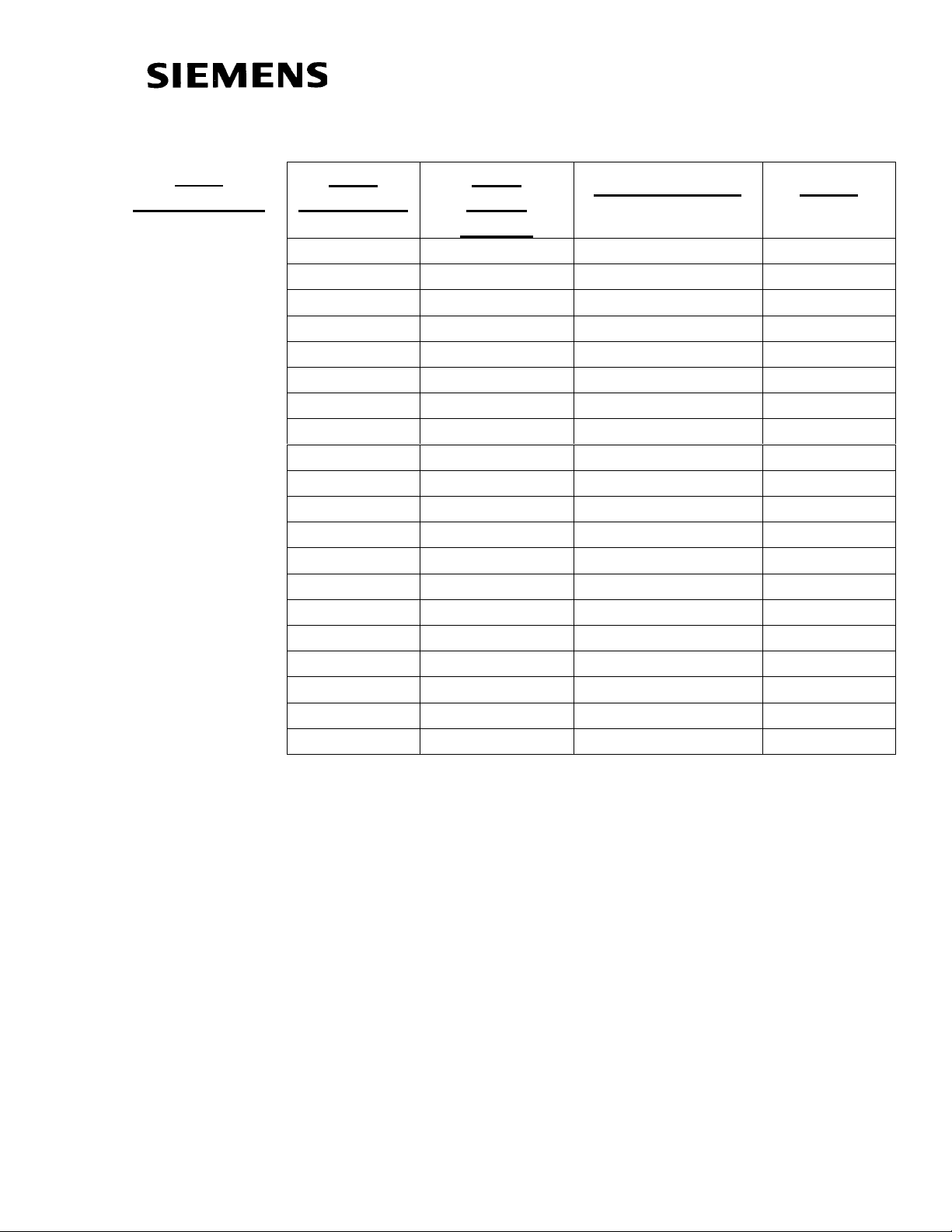

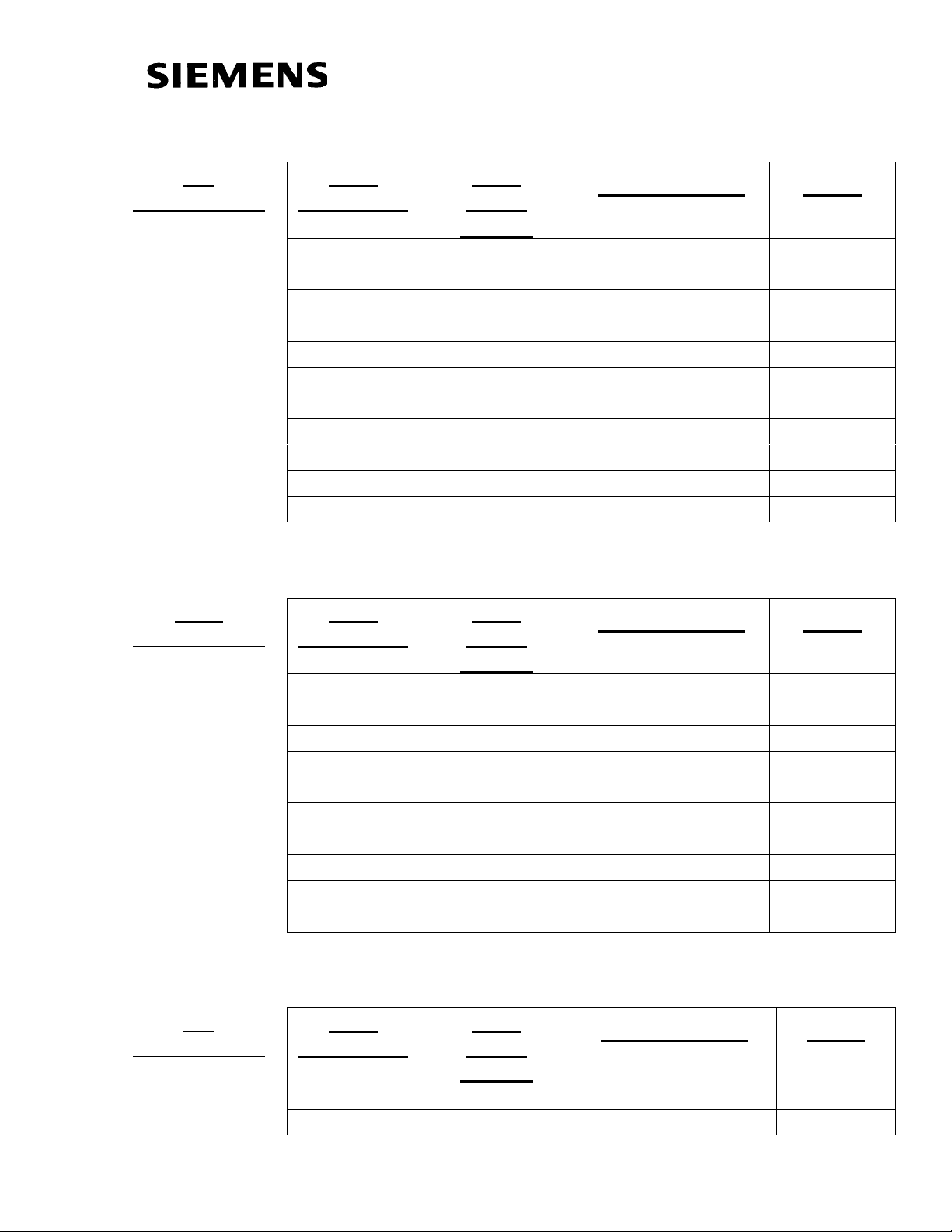

Unit List

P070: Parameter Value (PWE)

P075: Rated DC Output Current in Amps In[A]

Large Common Rectifier

AC-DC type

3 AC 380V to 460V

PWE Order Number In[A

103 6SE7038-2EH85-0AA0 821.0 105 6SE7041-0EH85-0AA0 1023.0 109 6SE7041-3EK85-0AA0 1333.0 118 6SE7041-8EK85-0AA0 1780.0

3 AC 500V to 575V 101 6SE7037-7FH85-0AA0 774.0

104 6SE7041-0FH85-0AA0 1023.0 107 6SE7041-3FK85-0AA0 1285.0 111 6SE7041-5FK85-0AA0 1464.0 120 6SE7041-8FK85-0AA0 1880.0

3 AC 660V to 690V 102 6SE7037-7HH85-0AA0 774.0

106 6SE7041-0HH85-0AA0 1023.0 108 6SE7041-3HK85-0AA0 1285.0 110 6SE7041-5HK85-0AA0 1464.0 119 6SE7041-8HK85-0AA0 1880.0

Page 36 Version 1.0 March 1, 2000

Page 37

Regenerative Rectifier

AC-DC type

3 AC

380V to 460V

Air Cool

PWE

PWE

Order Number In[A]

Water Cool

14 6SE7022-1EC85-1AA0 21.0

20 6SE7024-1EC85-1AA0 41.0

31 6SE7028-6EC85-1AA0 86.0

39 6SE7031-7EE85-1AA0 173.0

42 6SE7032-2EE85-1AA0 222.0

48 6SE7033-1EE85-1AA0 310.0

51 6SE7033-8EE85-1AA0 375.0

54 6SE7034-6EE85-1AA0 463.0

57 6SE7036-1EE85-1AA0 605.0

63 6SE7038-2EH85-1AA0 821.0

66 6SE7041-0EH85-1AA0 1023.0

73 6SE7041-3EK85-1AA0 1333.0

79 6SE7041-8EK85-1AA0 1780.0

3 AC

500V to 575V

15 6SE7022-7FC85-1AA0 27.0

21 6SE7024-1FC85-1AA0 41.0

28 6SE7027-2FC85-1AA0 72.0

32 6SE7028-8FC85-1AA0 94.0

38 6SE7031-5FE85-1AA0 151.0

44 6SE7032-4FE85-1AA0 235.0

46 6SE7032-7FE85-1AA0 270.0

49 6SE7033-5FE85-1AA0 354.0

52 6SE7034-2FE85-1AA0 420.0

55 6SE7035-4FE85-1AA0 536.0

61 6SE7037-7FH85-1AA0 774.0

67 6SE7041-0FH85-1AA0 1023.0

71 6SE7041-3FK85-1AA0 1285.0

74 6SE7041-5FK85-1AA0 1464.0

80 6SE7041-8FK85-1AA0 1880.0

Version 1.0 March 1, 2000 Page 37

Page 38

Regenerative Rectifier

AC-DC type

3 AC

660V to 690V

Air Cool

PWE

PWE

Order Number In[A]

Water Cool

36 6SE7031-4HE85-1AA0 140.0

43 6SE7032-2HE85-1AA0 222.0

47 6SE7032-7HE85-1AA0 270.0

53 6SE7034-2HE85-1AA0 420.0

56 6SE7035-3HE85-1AA0 536.0

62 6SE7037-7HH85-1AA0 774.0

68 6SE7041-0HH85-1AA0 1023.0

72 6SE7041-3HK85-1AA0 1285.0

75 6SE7041-5HK85-1AA0 1464.0

81 6SE7041-8HK85-1AA0 1880.0

Page 38 Version 1.0 March 1, 2000

Page 39

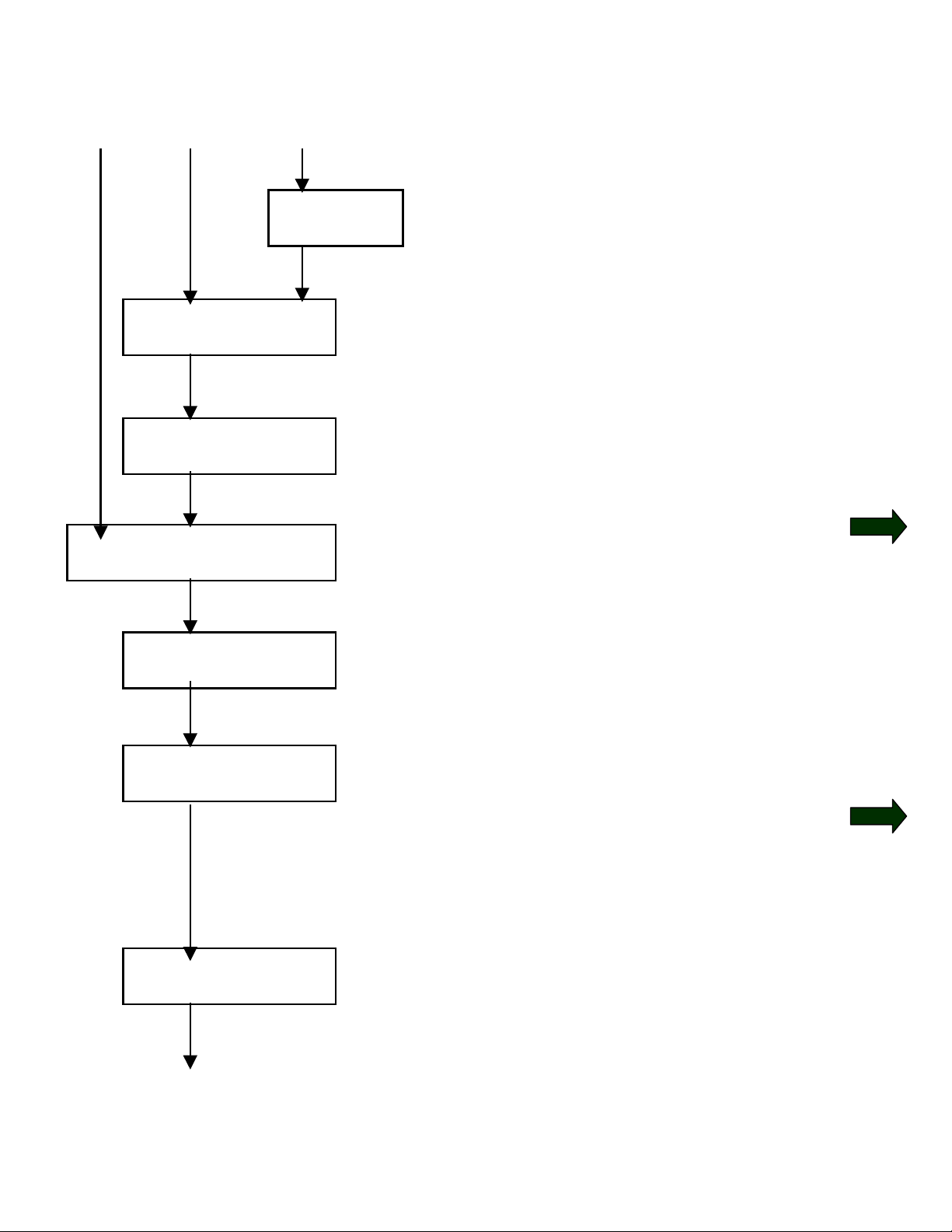

2.1 Factory Reset

P051 = 3

P052 = 2

P077 = 0

P052 = 0

P51=3 : Export Mode

P52=2: Function select “Initialization”

P077=0 for standard default

P052=0 Return to Parameter Menu

P052 = 1

Version 1.0 March 1, 2000 Page 39

P052=1 Perform Factory Reset

Page 40

Page 40 Version 1.0 March 1, 2000

Page 41

2.2 Basic Start-up (Regenerative Rectifier without

Autotransformer)

P051 = 2

P053 = 6

P052 = 5

P071 = 460

P051=2

Select “Basic Mode Settings”

P053 =6 Access Parameter

P052 = 5

Drive Settings

P071 = Input Rectifier Voltage

Generally = 460 Volt

P320 = 20

P773 = 1.00

Version 1.0 March 1, 2000 Page 41

P320 = 20

Smooth Load Amps, to

prevent input line sags

from effecting the DC BUS

regulator

P773= 1.00

Deadband Converter, to

prevent “toggling” between

Regen and Rectifier

bridges.

Page 42

P052 = 21

P052 = 0

With DC BUS connected to the

COMMON DC BUS of the system, set

P52=21 and provide a start command

at terminal X101, pin #9

The circuit identification test will take

about 10 seconds.

P052=0 Drive back to ready mode.

Standard Commissioning for a Common

Rectifier or a Regenerative Rectifier

without Autotransformer is complete, after

adjusting only 8 parameters.

Page 42 Version 1.0 March 1, 2000

Page 43

Connect External Wiring as connection diagram.

r

Custome

Connection Points

Internal Connections

Step 1: Dry set of contacts between terminals X101, pin#6 and pin#13 for Local/Remote Mode Selection. Jumper if not required.

Step 2: Dry set of contacts between terminals X101, pin#6 and pin#10

for Coast to Stop Selection. Jumper if not required.

Step 3: Dry set of contacts between terminals X101, pin#6 and pin#9 for Source of Main Start/Stop Selection.

Step 4: Dry set of contacts between terminals X101, pin#6 and pin#11

for Source of Fault Reset. Leave open if not required. “P” button on

PMU will be fault reset location if pin#11 is not used.

Step 5: Drive Operating Status is provided by a 24 Vdc signal at

terminals X104 pin#19 with respect to pin#20.

Version 1.0 March 1, 2000 Page 43

Page 44

Page 44 Version 1.0 March 1, 2000

Page 45

2.3 Basic Start-up (Regenerative Rectifier with

Autotransformer)

P051 = 2

P053 = 6

P052 = 5

P071 = 460

P051=2

Select “Basic Mode Settings”

P053 =6 Access Parameter

P052 = 5

Drive Settings

P071 = Input Rectifier Voltage

Generally = 460 Volt

P320 = 20

P773 = 1.00

Version 1.0 March 1, 2000 Page 45

P320 = 20

Smooth Load Amps, to

prevent input line sags

from effecting the DC BUS

regulator

P773= 1.00

Deadband Converter, to

prevent “toggling” between

Regen and Rectifier

bridges.

Page 46

P571 = 0

P318 = 95

P052 = 21

P571=0 Selects Autotransformer

P318 = 95%

Selects percentage of nominal

DC BUS voltage. In cases where

the input line voltage is

dependable a setting of 100% is

permissible.

With DC BUS connected to the

COMMON DC BUS of the system, set

P52=21 and provide a start command

at terminal X101, pin #9

P052 = 0

The circuit identification test will take

about 10 seconds.

P052=0 Drive back to ready mode.

Standard Commissioning for a

Regenerative Rectifier with

Autotransformer is complete, after

adjusting only 10 parameters.

Page 46 Version 1.0 March 1, 2000

Page 47

Section 3:

Simovis Trace Setup Method

SIMOVERT MASTERDRIVES

6SE70 VC

Vector Control

Version 1.0 March 1, 2000 Page 47

Page 48

Page 48 Version 1.0 March 1, 2000

Page 49

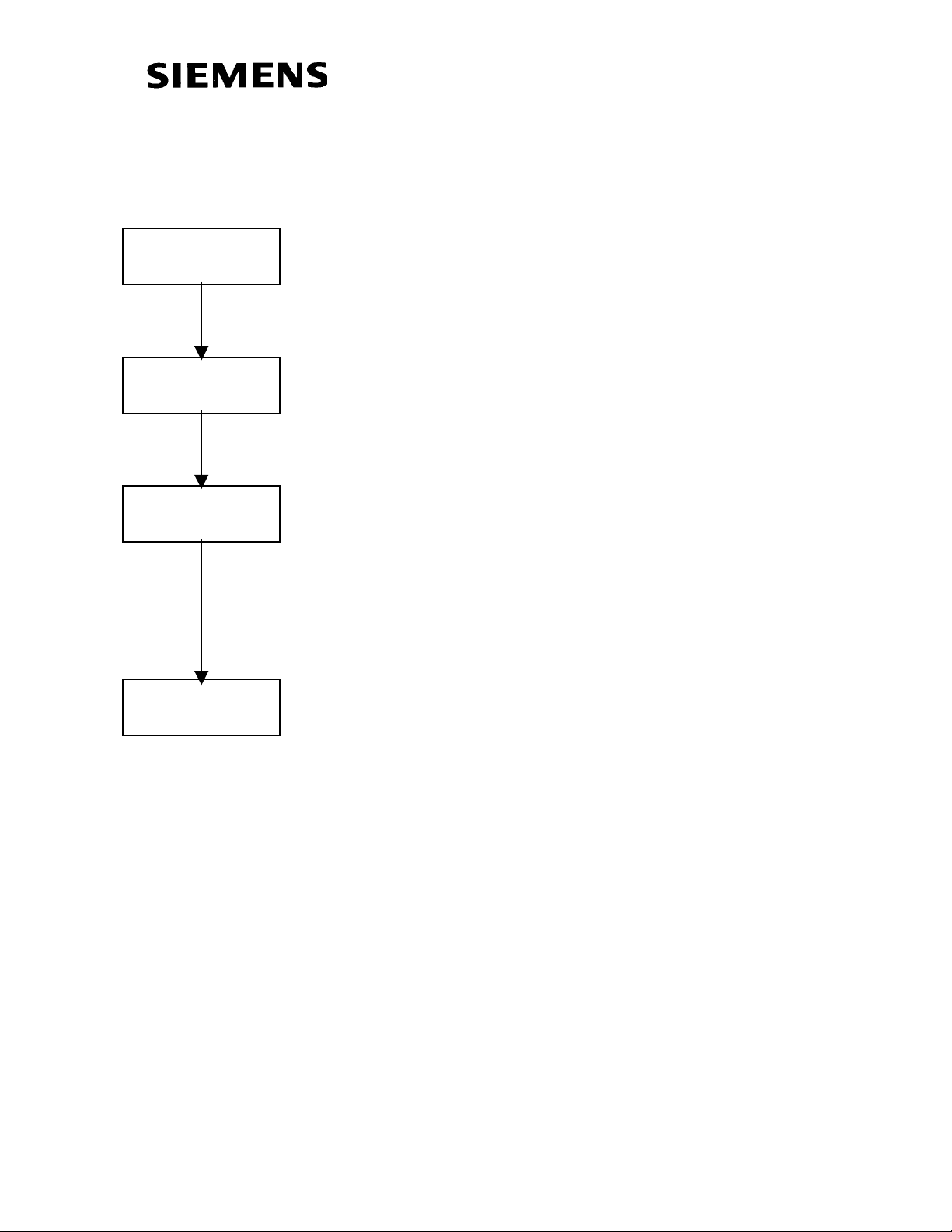

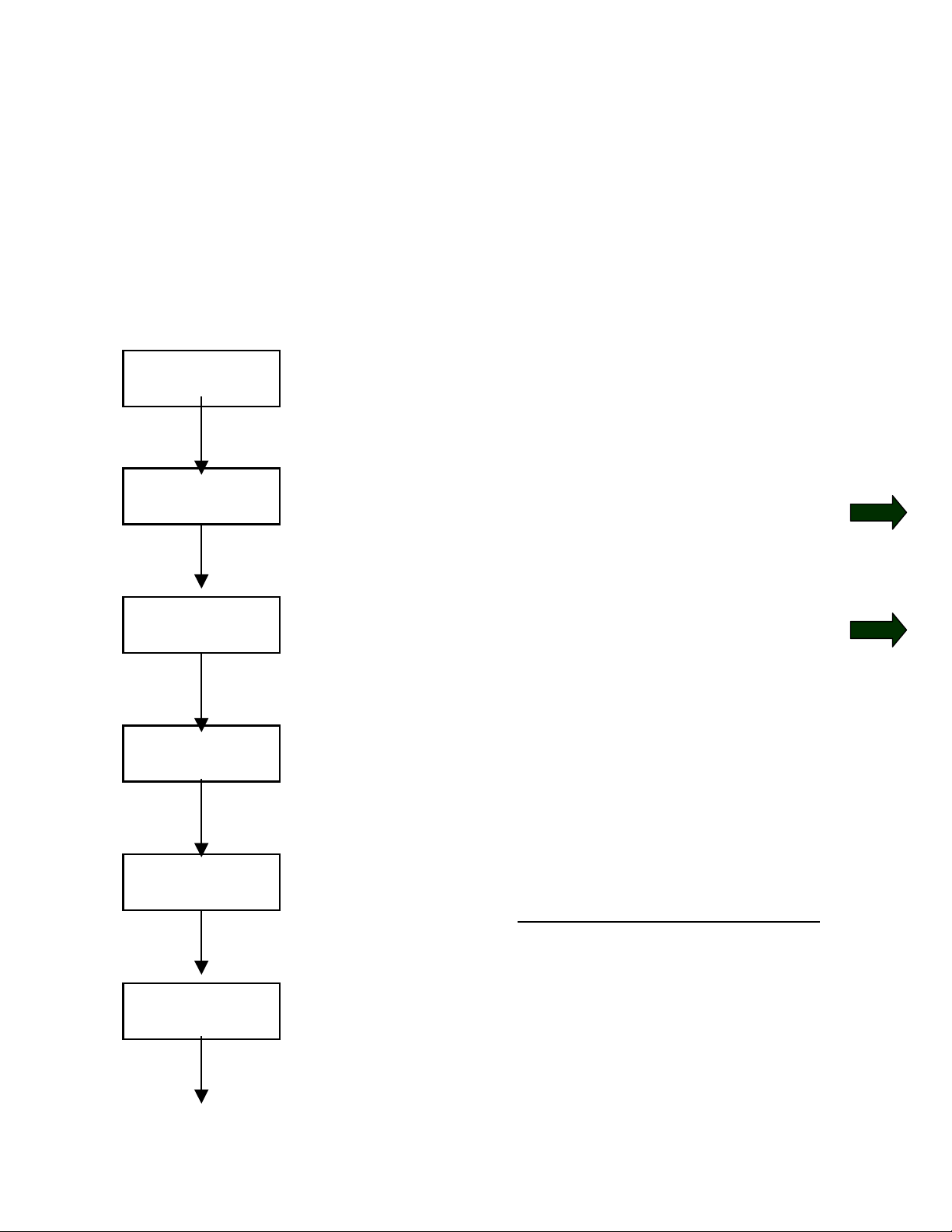

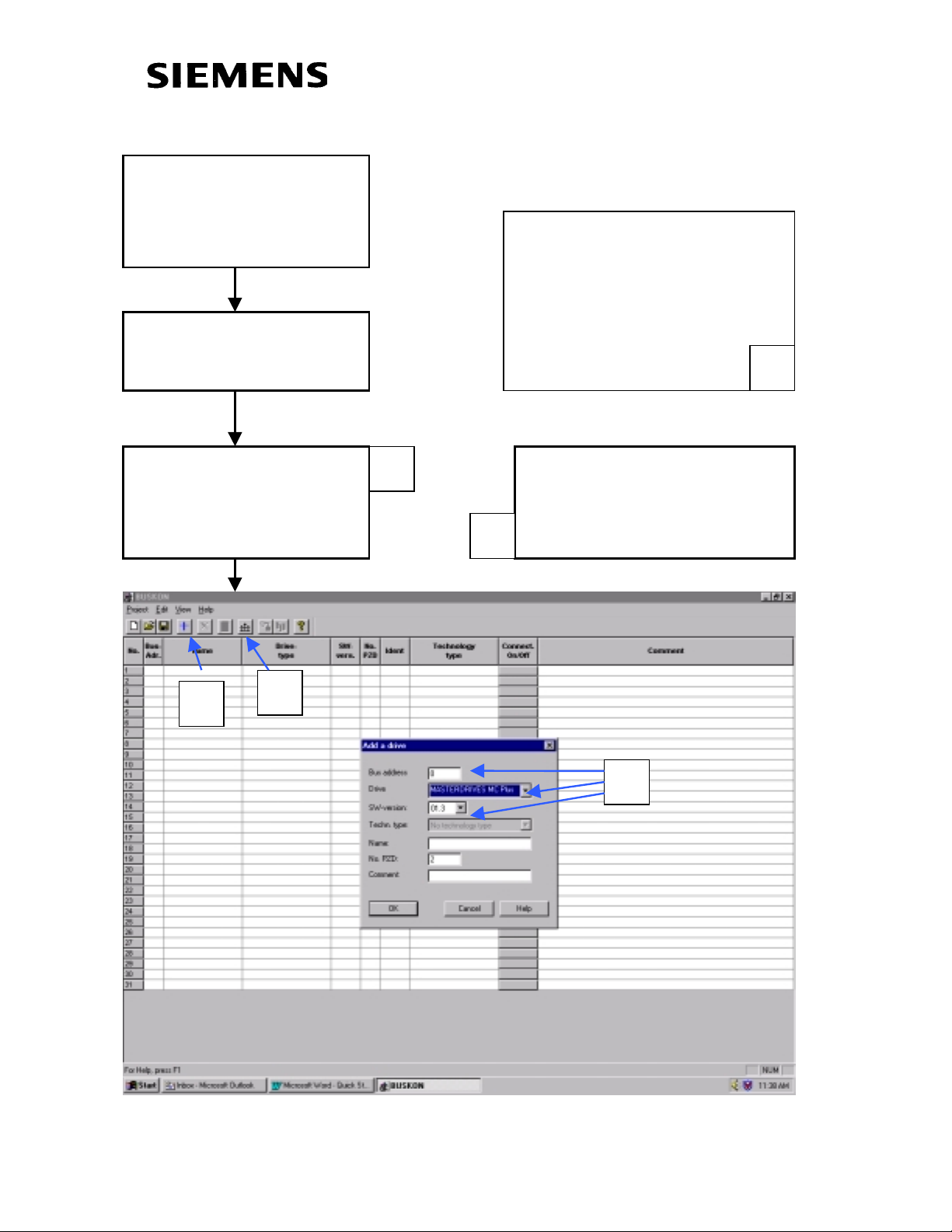

3.0 Simovis Trace

N

(

)

Load Simovis from

Vector Control

Documentation CD

Launch Simovis

Option: To speed up your

communication link set the

drive P701 = 38,400 with the

PMU and configure Simovis

for 38,400 communication.

from Desktop Icon

Add a Drive in

Simovis Bus

Configuration

A

C

A

Select USS Bus Address,

Drive and SW Version.

ote: Proper Simovis Cable

B

must be used.

B

C

RS 232

Version 1.0 March 1, 2000 Page 49

Page 50

Double Click Selected

Drive to start Simovis

Window

Verify Drive

Connection

A

Select Trace from

Diagnostics Menu Bar

B

Green Box should be lit up

in the lower left corner

B

A

Page 50 Version 1.0 March 1, 2000

Page 51

Select Record Settings in

the Lower Left Corner

Select Desired Channels

to Record

Set the Record Interval

and Pre-trigger

Select Trigger Channel

A

B

C

D

Each Interval = (4.0 / P340) seconds.

Pre-trigger is in Percentage (%).

To Trigger With a Binector, Select:

Trigger Channel = K431

Trigger Condition “=” “1 Hex”

K431 is the output of a Binector to

Connector Converter that will be

configured on the following page.

Function

Diagram

[720]

B

C

D

A

Version 1.0 March 1, 2000 Page 51

Page 52

Select “Function Block

N

g

pag

Grafics” from the

Parameter Menu Bar

A

To Configure the Trace to

Trigger with a Binector

follow instructions on this

e.

C

Select Function

umber 289

Zoom X 2

(with right Mouse click)

B

Set Trigger Binector in

U076.01

(i.e. U076.01 = 18 Din5)

Activate Block

U952.89 = 4

D

A

C

The block activated by Parameter

U952.89 is selected with 289.

K431 can now be used to

trigger the Trace function

when Binector

asserted hi

(i.e. DIN 5) is

h.

D

Function

Diagram

[720]

B

Page 52 Version 1.0 March 1, 2000

Page 53

Go to the Trace Window

(Diagnostics Menu – Trace)

Verify Record Settings

Start Trace

C

Trigger Trace

Observe Status Message

A

B

D

A

C DB

Version 1.0 March 1, 2000 Page 53

Page 54

Select Data Trace A

N

d

Click Data Set to

make it Active

Scale

Vertical Axis

B

Scale

Horizontal Axis

ote: Background can be change

with right mouse click.

Traces can be saved for reference.

C

Click and Drag

scale to shift it up

and down.

Y▲& Y ▼ to

change Scale

Click and drag “T”

marker to shift

Horizontal Scale.

Move “[ ]” to

change scale

A

B

C

Page 54 Version 1.0 March 1, 2000

Page 55

Section 4:

When to Re-Tune the Drive

SIMOVERT MASTERDRIVES

6SE70 VC

Vector Control

Version 1.0 March 1, 2000 Page 55

Page 56

Page 56 Version 1.0 March 1, 2000

Page 57

4.0 Conditions that would merit re-tuning the drive

Hardware additions made to the drive, such as an output reactor or a

dv/dt filter.

Physical changes to the process, such as the motor being changed

(even if the it is an identical motor, bearing changes and coupling

changes can have an influence on performance), gearbox changes,

length of motor cables changed.

Process changes, such as motor loading, and speed range changes to

name a few. Note that since the type of change described is wideranging manual tuning may be a better alternative. Review the

parameters effected for P115=5.

Software changes, P068, P095, P097, P100(this includes any changes

in P101 through P109), P339, P340, P357.

Exceptions:

• If the carrier frequency of P340 is adjusted in multiples that retuning is not required (ie: 2.5 kHz to 5.0 kHz)

• If P100 is changed from a value of 4 to 5.

Repair or Maintenance, such as replacing either the motor or the CUVC

logic card.

Exceptions:

• If tuning parameters P103, P116, P120, P223, P235, P236, P240 and P471 had been recorded prior to the CUVC card being replaced.

Version 1.0 March 1, 2000 Page 57

Loading...

Loading...