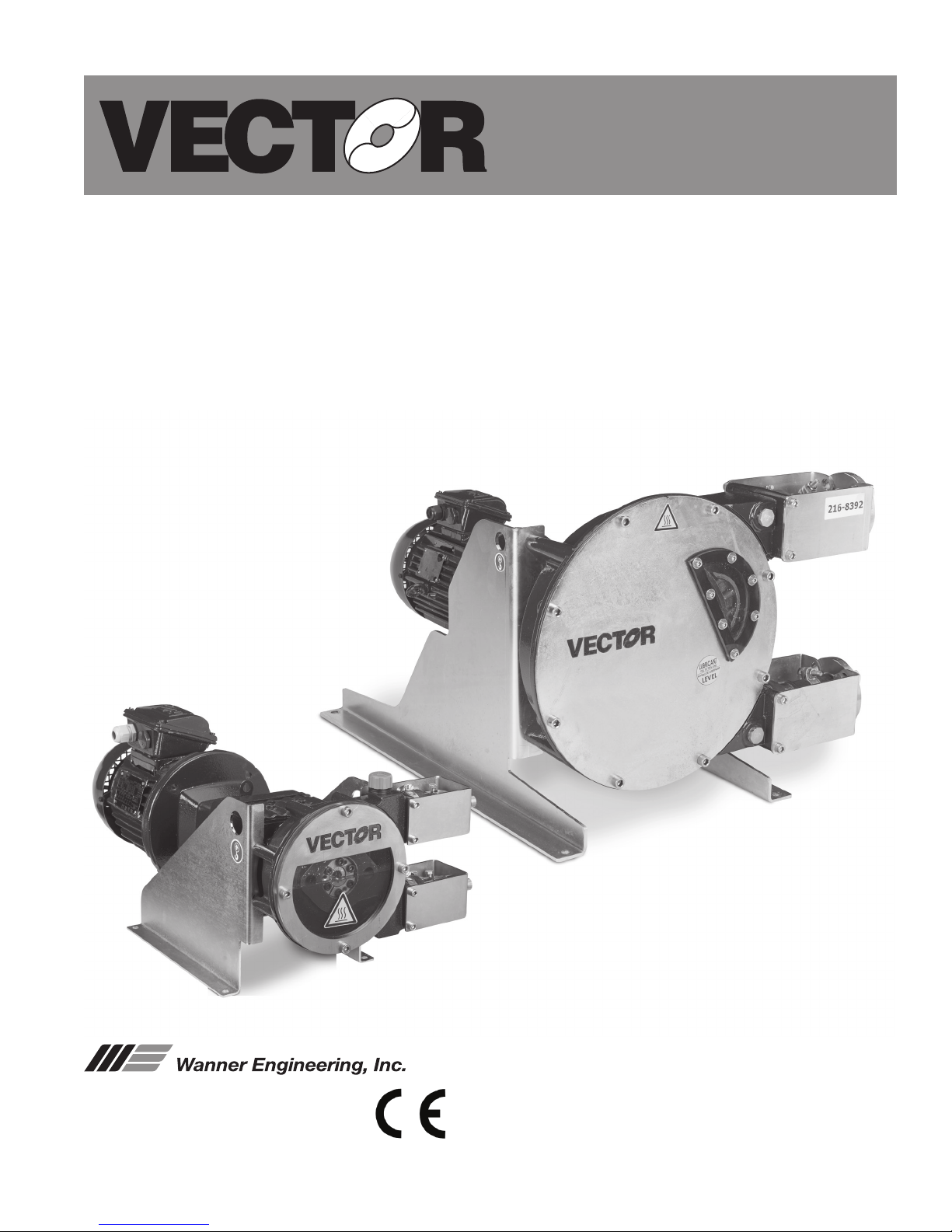

Page 1

W0582

Installation, Operation

and Maintenance Manual

VEC-991-4000B

Peristaltic Pumps

Vector 4000 Series

Models: 4003, 4004, 4006, 4007, 4009, 4010,

& 4014

Model: 4004

1204 Chestnut Avenue, Minneapolis, MN 55403

Tel: (612) 332-5681 Fax: (612) 332-6937

Toll-free fax [US only]: (800) 332-6812

www.vectorpump.com

email: sales@wannereng.com

Model: 4010

Page 2

Vector 4000 Important Precautions

Safety Measures

! CAUTION

Important Precautions

• To avoid personal injury or pump damage, follow all

instructions and safety precautions carefully.

• Don’t exceed the manufacturer’s recommended RPM

or pressure limits.

• Follow all codes and hydraulic recommendations on

installation and operation of the pumping system.

• To prevent vibration, mount thepump andmotor securely

to a rigid, level base.

• For safety and easier servicing, provide adequate work

space around the pump. Allow space to remove the front

co

ver, hose clamps, hose, and drive unit.

W0387

Safety Precautions

General remarks

These safety and installation instructions contain important

information and precautionary notes and must be available to

those operating the pump. Please read them thoroughly prior to

installation, electrical connection and use of the pump. Operating

instructions for components of pumps must be followed.

These safety and installation instructions do not cover local

regulations. Installers and operators must also observe local

regulations during installation and operation.

Each pump must be labeled by the end user to warn of any hazards

that the system process may produce; e.g. corrosive chemicals

or hot process etc.

All personnel involved in the operation, maintenance, inspection

and installation of the pump must be fully qualied to perform

the work. The personnel’s responsibilities, competence, and

supervision must be clearly dened by the operator. To the extent

that if the personnel in question is not already in possession of

the requisite know how, appropriate training and instruction must

be provided. In addition, the operator is responsible for ensuring

that the contents of the operating instructions are fully understood

by all the responsible personnel.

When installing a Vector pump in conjunction with a motor, or motor

and frequency controller, the relevant manuals must be referred

to for electromagnetic compatibility.

All safety instructions in this manual and all relevant local health

and safety regulations must be followed.

Pay attention to the weight of the pump before attempting to lift

either manually or when selecting appropriate lift equipment.

1. Mechanical risk:

Ensure that all protections (cover, sight glass, ventilator hood,

coupling protection) are in place before operating the pump.

Disconnect the electrical supply before any mechanical work,

except during hose replacement.

Hose replacement must be done with the pump cover closed.

While replacing a hose, wear protective gloves and clothes.

Keep hands away from the brackets, suction and discharge

anges.

During pump maintenance, check that lifting points are correctly used.

The frame of the pump must be rmly fastened to the ground.

2. Electrical risk:

Ensure that the electrical installation conforms to the local

standards required; especially regarding ground and thermal

protection.

3. Operational risk:

Check that the materials to be pumped are compatible with the

following:

• Peristaltic pump operation.

• Hose material.

• Lubricant.

• Inserts material.

• Shoe material.

Wanner cannot guaranty the hose lifetime or the material loss

due to a hose burst. It is the operator’s responsibility to prevent

pumped liquid loss with additional hose rupture detectors and

or automatic shut down valves. Check guarantee for further

information.

Ensure that the pump is compatible with the process.

Ensure that the pump suction side pressure is correct.

To avoid hose rupture, make sure that:

• The pump casing is not lled with the pumped material.

• That the suction line is not on load. Otherwise the material

may empty into the pump casing and leak out of the pump.

• That the discharge line is not under pressure. Otherwise the

pumped material may be forced back into the pump casing

and leak out of the pump.

A leakage detector as well as automatic shut down valves are

recommended in order to prevent hose rupture.

When draining the pump following a hose rupture, make sure

the lubricant and pumped material are disposed of properly.

Complete or partial blockage of the positive displacement

pump discharge line can lead to a dangerous high pressure

condition. Before operating the pump, make sure there is no

complete or partial hose blockage.

Before each use, check the direction of rotation of the pump.

While placing the pump under vacuum, mount window screw

using an airtight glue to avoid air leakage.

2

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 3

Vector 4000 Contents

1 IMPORTANT PRECAUTIONS 2

1.1 Safety Measures 2

1.2 Contents 3

2 HOW TO USE THIS MAINTENANCE MANUAL

2.1 Use of the Pump 4

2.2 Responsibility 4

2.3 User Training and Instruction 4

2.4 Limited Warranty 4

3 DESCRIPTION 5

3.1 Identication 5

3.2 Description of Pump Operation 5

3.3 Pump Parts 6

3.4 Pump Hose 9

3.5 Pump Gearbox 9

3.6 Electrical Motors 9

3.7 Available Options 9

4 I N STA LL AT ION

4.1 Inspection 10

4.2 Installation Planning 10

4.3 Piping 10

4.4 Lifting the Pump 11

5 PUMP STARTUP 11

5.1 Preparations 11

5.2 Startup 11

6 MAINTENANCE 11

6.1 Emptying and Filling of Lubricant 11

6.2 Hose Cleaning 13

6.3 Hose Replacement 13

6.3.1 Removing of the Hose 13

6.3.2 Cleaning of the Pump Casing 15

6.3.3 Reassembly of the Hose 15

6.4 Replacement of Spare Parts 17

6.5 Shoe Shimming 21

6.6 Additional Information 22

6.7 Periodic Check 23

7 STORAGE 23

7.1 Pump Storage 23

7.2 Hose Storage 23

8 TROUBLESHOOTING 24

9 CHARACTERISTICS AND TECHNICAL SPECIFICATIONS 26

9.1 Dimensions 26

9.2 Parts List 29

9.3 Lubrication Table 35

9.4 Shoe Shimming Table 35

9.5 Generated Noise and Temperature 36

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

3

Page 4

Vector 4000 Introduction

2. HOW TO USE THIS MAINTENANCE MANUAL

This technical manual covers the Vector 4000 Series pumps.

The manual provides instructions on how to install, start, and

maintain the pumps. All persons, installers, and users must

read the manual in its entirety prior to installation and use.

Your local Wanner distributor is also available for additional

information .

For a reply, please include the following information:

- Type of pump

- Pump

Also visit our website www.vectorpump.com for further information.

2.1 USE OF THE PUMP

The pump was dened for specic application. Any other use

which does not comply with this use invalidates the warranty.

Wanner cannot be held responsible for damage or possible

injury incurred during the use of the pump. The pump was designed in accordance with applicable norms and directives. Use

the pump only for applications represented above. If you want

to change your application, rst contact your Wanner distributor.

2.2 RESPONSIBILITY

Wanner will be under no circumstances responsible for damage

or wounds caused by non respect of security directives and

maintenance instructions contained in this manual, or by negligence during the installation, use, service or repair of Wanner

hose pumps. Moreover, additional directives of security can be

necessary according to working conditions or according process. Contact your Wanner distributor if you notice a potential

danger during the use of the pump.

2.4 Limited Warranty

Wanner Engineering, Inc. (“Wanner”) extends to the original

purchaser of equipment supplied or manufactured by Wanner

and bearing its name, a limited one-year warranty from the

date of purchase against defects in material or workmanship,

under normal use and service, and provided the equipment

is installed, operated and maintained in accordance with

instructions supplied by Wanner. Wanner will repair or replace,

at its option, defective parts without charge if: (a) you provide

written notice of any defect within thirty (30) days from the

discovery of the defect; (b) the claim is received by Wanner

before the expiration of the warranty period; and (c) such parts

are returned with transportation charges prepaid to Wanner

Engineering, Inc., 1204 Chestnut Avenue, Minneapolis,

Minnesota 55403. A return goods authorization must be

received prior to the return of the defective part. No allowance

will be made for repairs undertaken without WEI’s written

consent or approval.

2.3 USER TRAINING AND INSTRUCTION

Every person who installs, uses, or performs any operations or

maintenance on the pump must be qualied. The person must

also read and be familiar with this technical manual.

Any temporary personnel must be supervised by skilled users.

The order of operational steps dened in this manual must be

followed. Store this manual next to the pump so that it can be

consulted at any time.

4

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 5

Vector 4000 Description

3 DESCRIPTION

3.1 Identication

Vector pumps are identied by the nameplate located on

the upper bracket. It includes the type and model number of

the pump. This model number indicates information regarding pump materials, type of the hose, characteristics of the

gearbox, and characteristics of the motor. The gearbox as well

as the motor have their own nameplates on which include the

reduction ratio, power, and electrical voltage.

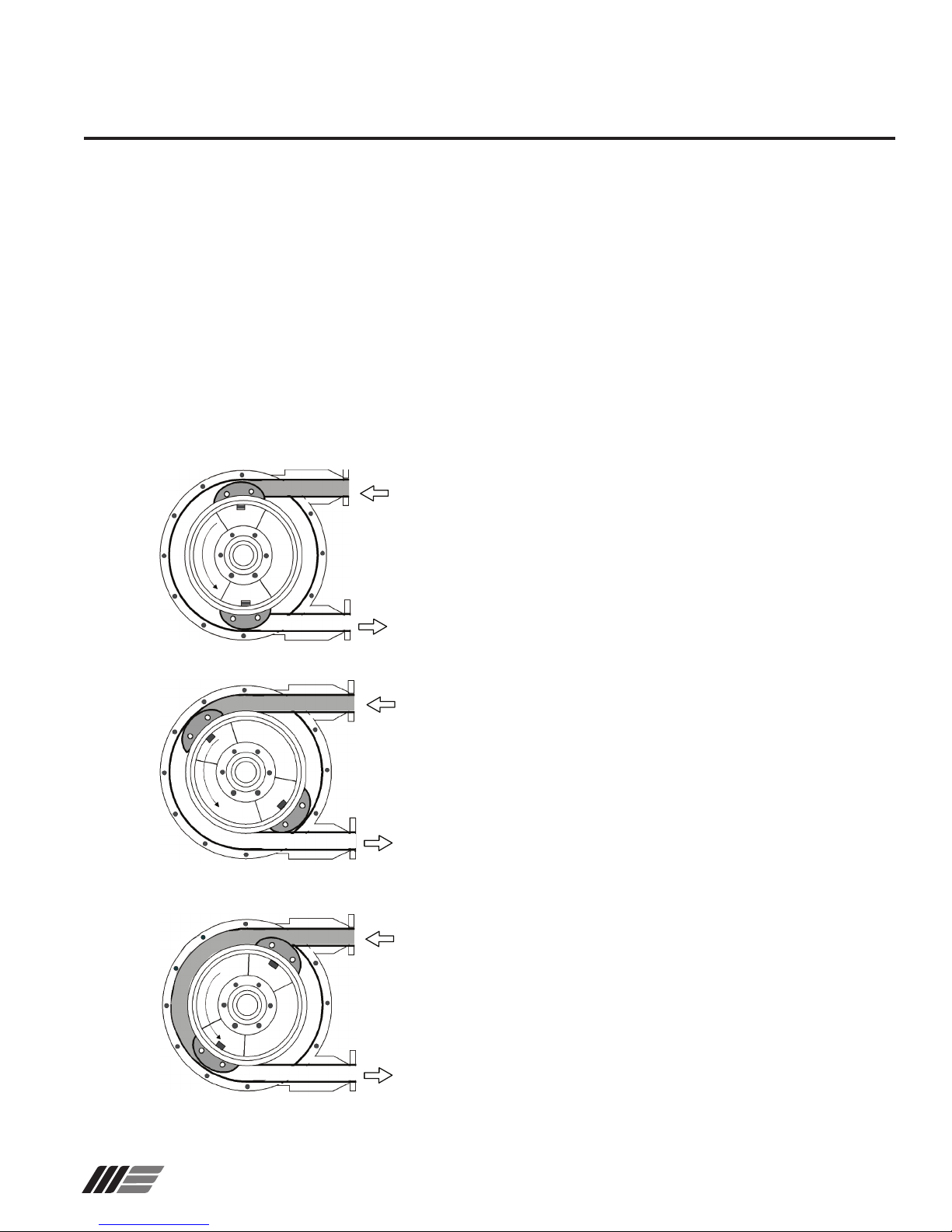

3.2 Description of Pump Operation

PHASE 1

The pump hose is compressed successively by two pressing

shoes assembled on a rotating wheel. The rst shoe, by pressing the walls of the hose, will create a vacuum and suck the

pumped liquid into the hose.

Wanner Engineering, Inc.

PHASE 2

The pumped liquid has now entered the hose. The second

shoe will compress the hose and push the liquid towards the

pump outlet.

PHASE 3

As soon as, at the discharge side, the shoe is detached from

the hose, the other shoe diametrically opposite is already in

compression thus avoiding an internal material leakage. The

material is then successively sucked and pushed due to the

wheel rotation.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

5

Page 6

Vector 4000 Description

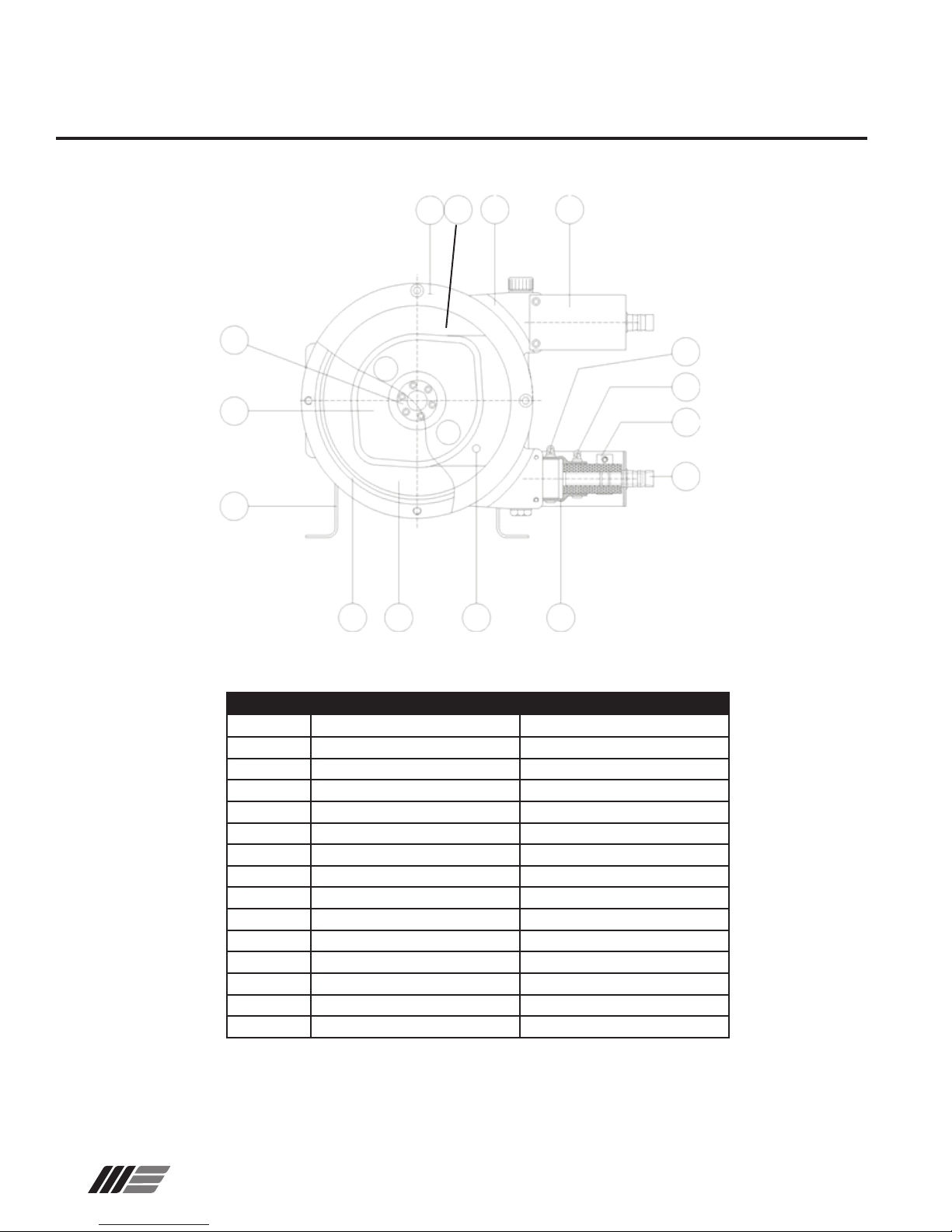

3.3 PUMP PARTS

19

3

21

271 1

18

7

8

9

12

1610

614

VECTOR 4003, 4004

PART NO DESIGNATION 4003, 4004 MATERIAL

1 CASING CAST IRON

2 COVER, TRANSPARENT LEXAN

3 WHEEL CAST IRON

6 SLEEVE EPDM

7 CLAMP ON CASING STAINLESS STEEL

8 CLAMP SLEEVE / HOSE STEEL

9 CLAMP ON HOSE STEEL

10 SEAL COVER NITRILE

12 INSERT STAINLESS STEEL

14 LUBRICANT GLYCERIN BLEND

16 HOSE NR/NBR/EPDM

18 BRACKET ELECTROPLATED STEEL

19 HUB STEEL

21 FRAME ELECTROPLATED STEEL

71 COVER PLATE ELECTROPLATED STEEL

6

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 7

Vector 4000 Description

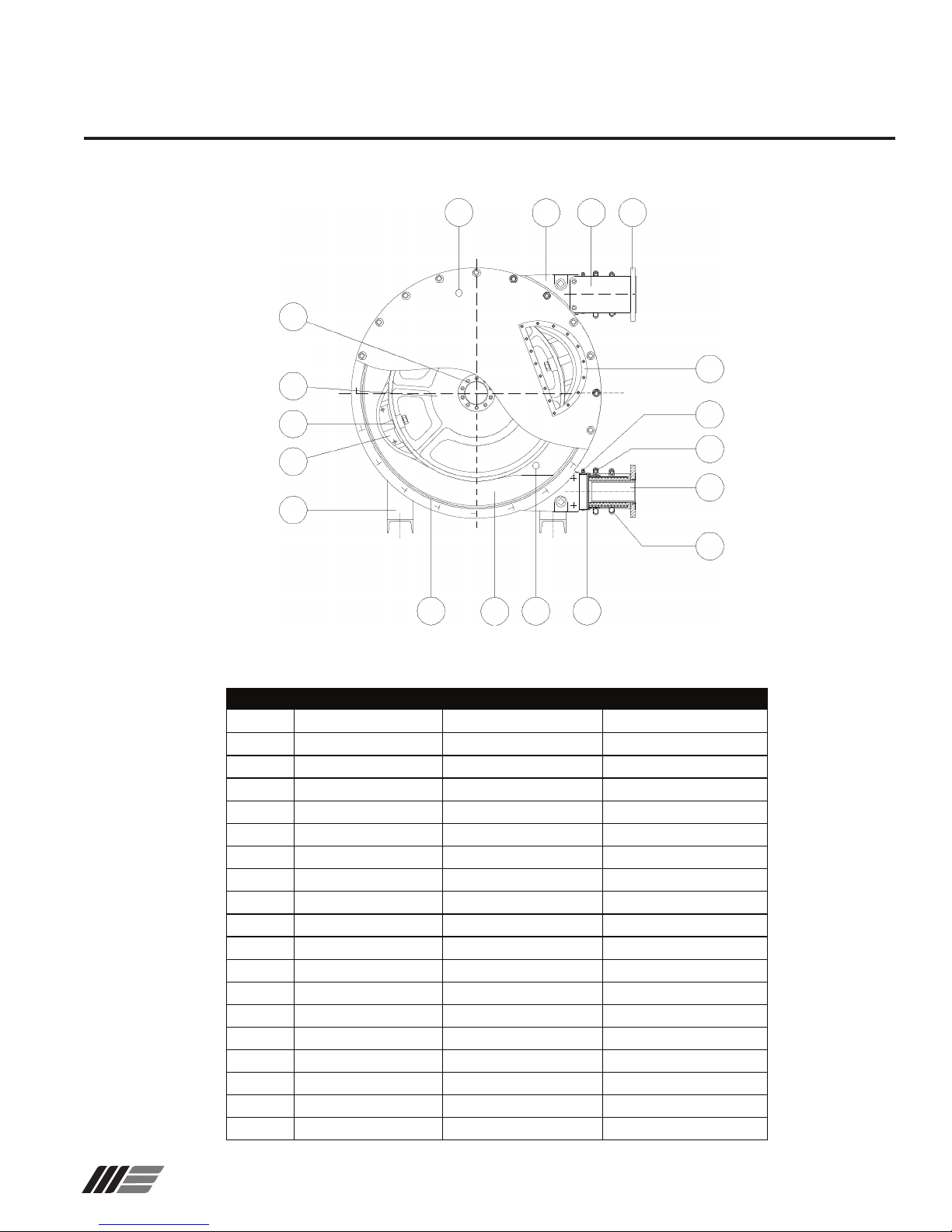

3.3 PUMP PARTS

19

20

3

4

5

21

PART NO DESIGNATION

1

CASING

2

COVER

3

WHEEL

4

SHIM

5

SHOE

6

SLEEVE

7

CLAMP ON CASING

8

CLAMP SLEEVE / HOSE

9

CLAMP ON HOSE

10

SEAL COVER

12

INSERT

14

LUBRICANT

15

SIGHTGLASS

16

HOSE

18

BRACKET

19

HUB

21

FRAME

46

SIGHT GLASS SEAL

47

INLET/OUTLET FLANGE

2

10

VECTOR 4006, 4007, 4009, 4010

16

4006, 4007 MATERIAL

CAST IRON

ELECTROPLATED STEEL

CAST IRON

GALVANIZED STEEL

ALUMINIUM

EPDM

STAINLESS STEEL

STAINLESS STEEL

STAINLESS STEEL

NITRILE

STAINLESS STEEL

GLYCERIN BLEND

LEXAN

NR/NBR/EPDM

ELECTROPLATED STEEL

STEEL

STEEL

NITRILE

STAINLESS STEEL

1

14

47

18

6

4009, 4010 MATERIAL

CAST IRON

STEEL

CAST IRON

GALVANIZED STEEL

ALUMINIUM (4009) / CAST IRON (4010)

EPDM

STEELCK

STAINLESS STEEL

STEEL

NITRILE

STAINLESS STEEL

GLYCERIN BLEND

LEXAN

NR/NBR/EPDM

ELECTROPLATED STEEL

STEEL

STEEL

NITRILE

STAINLESS STEEL

15

7

8

12

9

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

7

Page 8

Vector 4000 Description

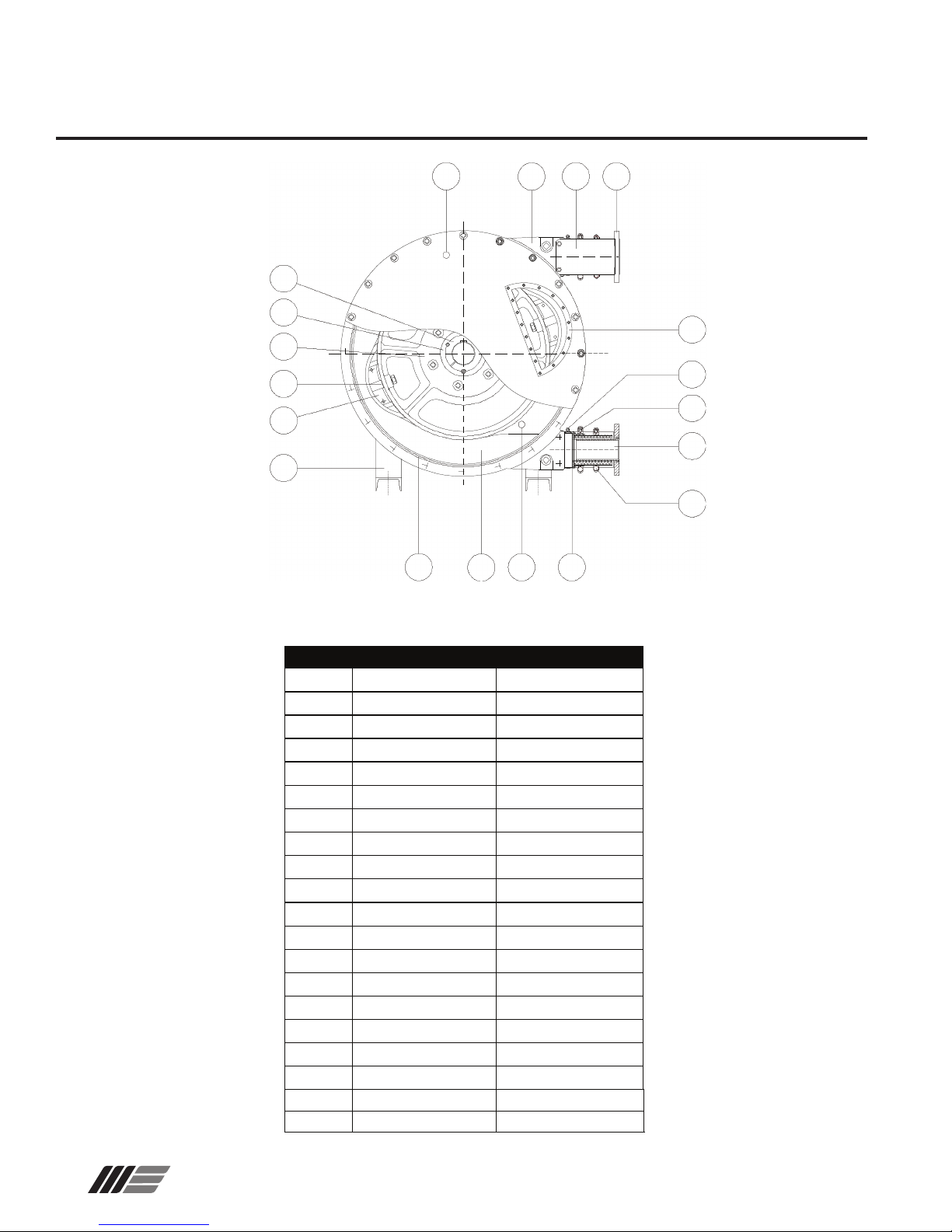

3.3 PUMP PARTS

2

1

18

47

19

20

15

3

4

5

21

7

8

12

9

10 16 14 6

PART NO DESIGNATION

1

CASING

2

COVER

3

WHEEL

4

SHIM

5

SHOE

6

SLEEVE

7

CLAMP ON CASING

8

CLAMP SLEEVE / HOSE

9

CLAMP ON HOSE

10

SEAL COVER

12

INSERT

14

LUBRICANT

15

SIGHT GLASS

16

HOSE

18

BRACKET

19

HUB

20

BOLT ON PLATE

21

FRAME

46

SIGHT GLASS SEAL

47

INLET/OUTLET FLANGE STAINLESS STEEL

VECTOR 4014

4014 MATERIAL

CAST IRON

STEEL

CAST IRON

GALVANIZED STEEL

CAST IRON

EPDM

STAINLESS STEEL

STAINLESS STEEL

STEEL

NITRILE

STAINLESS STEEL

GLYCERIN BLEND

LEXAN

NR/NBR/EPDM

ELECTROPLATED STEEL

STEEL

CAST IRON

STEEL

NITRILE

8

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 9

Vector 4000 Description

3.4 PUMP HOSE

Wanner hoses are manufactured according to strict specications for the best performance of the pump and to assure optimum hose life. Hoses are available in four materials: Natural

Rubber (NR), perbunan (NBR), EPDM, and Hypalon. The hose

material must be compatible with the liquid pumped. Consult

your Wanner distributor to obtain the correct hose for your use.

Vector 4000 pumps operate in temperatures between + 14°F

and +176°F. Pumps are painted with a 150µ Polyurethane

paint to resist corrosive environments. Pumps are designed for

indoor and outdoor use.

HOSE DIMENSIONS (dimensions in mm)

PUMP INNER ø THICKNESS LENGTH

4003 10 11 570

4004 15 11 830

4006 25 14.5 1090

4007 32 15.5 1300

4009 40 13.5 1500

4010 51 15 1820

4014 80 21.5 2910

3.5 GEARBOX

Gearboxes are sized according to the pump’s radial loads.

Consult the gearbox maintenance manual for the type, quan-

tity, and frequency of oil changes.

3.6 ELECTRICAL MOTORS

The standard motors provided on pumps are TEFC motors and

require a 230/460 VAC, 60Hz, 3Ø voltage source. If the pump

is to be used in an explosive environment, please contact the

factor y.

3.7 AVAILABLE OPTIONS

The following Vector Pump options are available:

- Hose rupture detector.

- Pulsation dampener.

Please contact your Wanner distributor for additional information about these options

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

9

Page 10

Vector 4000 Installation

W0383A

6 to 8 feet

6 to 8 feet

4 INSTALLATION

4.1 INSPE C T I O N

The pump must be checked upon receipt for any possible

damage or incomplete shipment. Notify Wanner Engineering

of any discrepancies immediately.

Check all boxes or packages containing spare parts or

accessories packed with the pump.

4.2 INSTALLATION PLANNING

Location

1. Locate the pump near the liquid source, so that the suction line

is short and direct.

2. When practical, locate the pump above the level of the liquid; if

the hose fails, the pumpage drains back into the tank.

3. Allow space to remove the front cover, hose, and drive

unit. See Inlet Hose Length Chart (A).

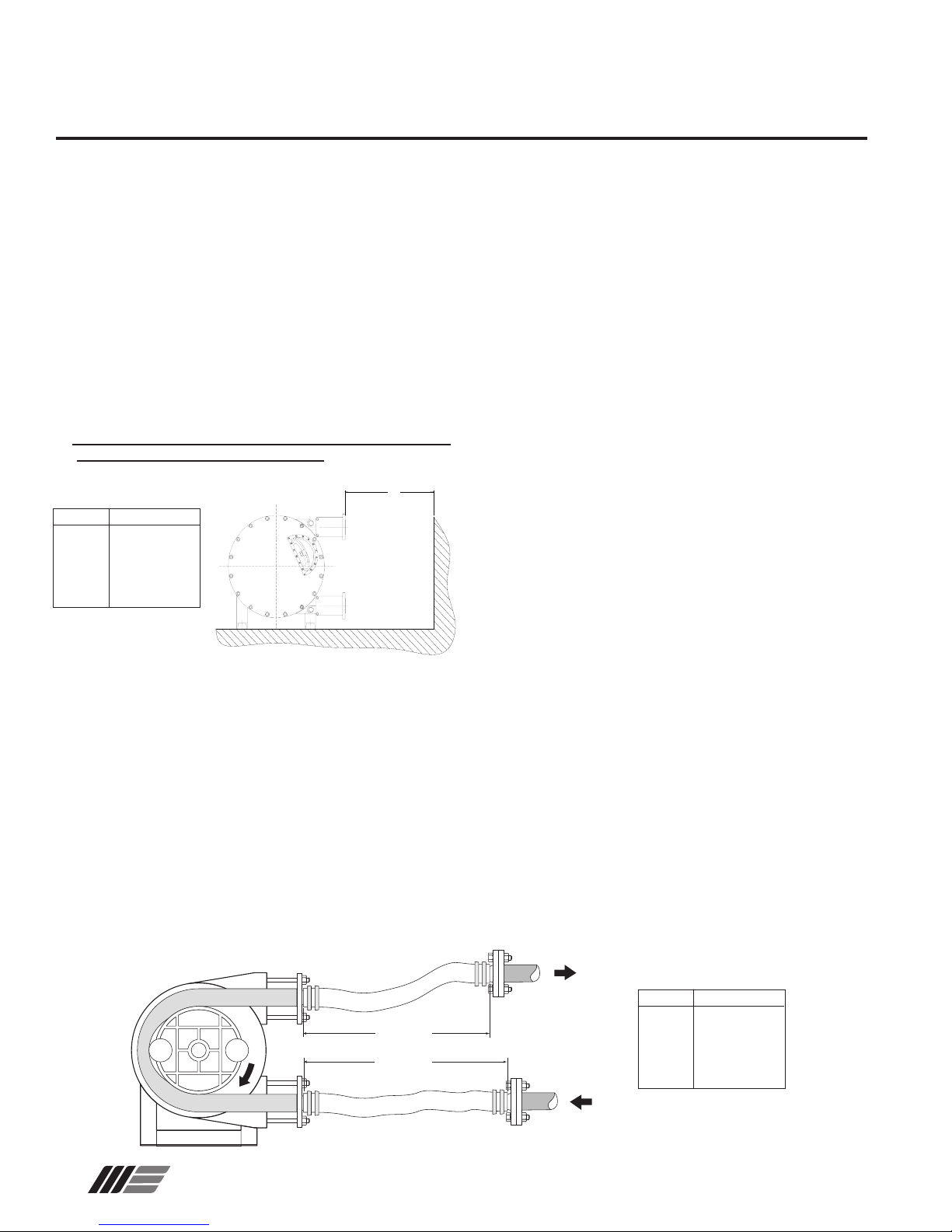

Inlet Hose Length Chart (A)

A

PUMP DISTANCE (A)

4003 1.3 ft

4004 1.6 ft

4006 2.6 ft

4007 3.3 ft

4009 3.9 ft

4010 4.6 ft

4014 6.5 ft

Foundation

The foundation should be suciently rigid and substantial to

absorb any vibration, and to permanently support the base plate

at all points. A concrete foundation, poured on a solid footing of

adequate thickness to support the pumping unit provides the

most satisfactory foundation.

The base plate should be installed in a level position. The size

and location of the base mounting holes are shown on the pump

specication sheets. Use the dimensions provided in the pump

specication data sheets for general piping.

Note: For a detailed description of proper procedures

for grouting base plates, refer to the Hydraulic Institute

Standards.

4.3 PIPING

Inlet piping:

1. Size the inlet line 1.5 or two sizes larger than the pump suction

opening.

2. Suction lines should be as short and direct as possible.

3. See Site Plumbing Figure below. Install 6 to 8 feet of

reinforced exible hose between pump and rigid piping to

absorb vibration, expansion and contraction, and to make

maintenance easier.

Note: The inlet hose must be capable of withstanding a

vacuum. This avoids hose collapse which will restrict

ow.

4. Install an inlet pressure/vacuum gauge on the inlet side of the

pump.

5. To reduce turbulence and resistance, do not use 90° elbows.

If turns are necessary in the suction line use 45° elbows or

long sweeping elbows when required.

6. Install piping supports where necessary to relieve strain on

the inlet line and to minimize vibration.

7. In some cases, a pulsation dampener may be required to

decrease acceleration head and pulsations. Mount dampener

within ten pipe diameters of the pump suction connection. The

closer the better.

Discharge piping:

1. See Site Plumbing Figure below. Install a length, B,

of reinforced flexible hose (one size larger than pump

connection) between pump and rigid piping. This will absorb

vibration, provide for expansion and contraction. It also

creates a reservoir and eases the replacement of the hose.

2. Size the rigid discharge line to be at least the size of the pump

inlet connection.

3. Install piping supports where necessary to relieve strain on

discharge piping and to minimize vibration.

4. Install a pressure gauge in the discharge piping.

5. In some cases, a pulsation dampener may be required

to decrease pulsations. Mount dampener within ten pipe

diameters of the pump discharge connection. The closer the

better.

6. Install a pressure relief valve to protect the pump and piping.

10

Wanner Engineering, Inc.

Site Plumbing Figure

B

B

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

PUMP DISTANCE (B)

4003 2 ft

4004 2 ft

4006 2.5 ft

4007 3 ft

4009 4 ft

4010 5 ft

4014 8 ft

Page 11

Vector 4000 Installation and Maintenance

4.4 LIFTING THE PUMP

Pumps are provided with two lift rings tted on the upper part

of the frame. While lifting the pump, do the following:

1. Lift the complete hose pump using the lifting rings plus

additional support on the gearbox and the motor using

suitably rated straps or slings.

2. Never exceed a lift’s upper weight limit. Refer to the Pump

Weight table below to determine the size of lift required.

3. The motorized pump, given its centre of gravity, will tend

to overbalance on the pump head side. Make sure that

the persons are at a security distance of the pump to avoid

any risk of wound.

4. Never raise the pump otherwise than by the pump’s lifting

rings.

5. Never raise the pump by it’s orices nor by it’s brackets.

Pump Weight

Pump 4003 4004 4006 4007 4009 4010 4014

Lb. 55 77 176 287 463 694 2050

5. PUMP STARTUP

5.1 PREPARATIONS

1. Connect the electrical motor in accordance with the local

rules and regulations. Perform this work by qualied

personnel.

2. Make sure that the lubricant level arrives at the level of the

sight glass. Add lubricant if required by the breather

or by the sight glass. See 6.1.

3. Make sure the shimming of the pump is according to the

pump process. See 6.5.

4. Check the direction of rotation of the pump. It is

recommended to install a rotation inverter on the motor

for the hose change.

5. 2 STARTU P

1. Install piping at the inlet and outlet of the pump.

2. Make sure that valves at the inlet and outlet are opened.

3. Start the pump by checking its direction of rotation by the

sight glass.

6. MAINTENANCE

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

6.1 CHANGING LUBRICANT.

Check lubricant level every 1000 hours. Change as follows:

1. Stop the pump

2. Place a tray underneath the drain plug (23)

3. If necessary, install a tap and a drain circuit instead of the

drain plug

4. Make sure tray will hold the quantity of lubricant during

the drainage process. See 9.3 Lubrication Table for quantity.

5. Unscrew the drain plug and drain lubricant

6. Position and tighten drain plug by applying Teon® band

or waterproof paste of close drain tap.

7. Remove sight glass (15) as well as seal (46) and ll the

casing with Wanner lubricant. See 9.3 Lubrication Table for

quantity. Fill with lubricant to the level of the sight glass or

underneath the shaft line. See illustration below.

Note: You can also ll the casing by removing the

breather cap (52) at the back of the pump casing.

8. Check the condition of the seal (replace if necessary).

Reassemble sight glass (or tighten the breather cap).

Maximum lubricant

level

15,46

52

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

Wanner Engineering, Inc.

23

Note: If the pump is mounted with the inlet/outlet posi-

tioned upwards, lubricant drainage is obtained by unscrewing some cover bolts in the lower part.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

11

Page 12

Vector 4000 Maintenance

W0582

6.1 CHANGING LUBRICANT. (Cont’d)

FOR MODELS 4003, 4004:

Unscrew breather plug (52). Place a funnel inside the

breather plug hole and ll the casing with the Wanner lubricant.

See 9.3 Lubrication Table for quantity. Fill lubricant to just

underneath the shaft.

52

12

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 13

Vector 4000 Maintenance

6.2 HOSE CLEANING

The hose can be cleaned without removing. Use water or

cleaning liquid (check compatibility with hose material). With

Some pumped material requires cleaning after each use to

avoid material hardening in the hose.

CAUTION: Make sure that the cleaning liquid temperature

is the same as the hose material.

6.3 HOSE REPLACEMENT

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

CAUTION: Before any hose change, check the following

points:

1. Skilled personnel are to perform this service and have read

and understand this manual.

2. Close inlet and outlet valves to minimize material loss.

3. Wear clothes that provide protection when using the

pumped material.

4. Observe all safety and environmental rules governing the

use of the pumped material.

6.3.1 HOSE REMOVAL

1. Disconnect and remove suction and discharge piping.

2. Drain lubricant as outlined in Section 6.1.

3. Loosen clamps (8) and (9) at the suction inlet.

Remove insert (12) and ange (47) See Figure 1.

8

9

47

12

Figure 1

FOR MODELS 4003, 4004:

3. Loosen clamps (8) and (9) at suction inlet. Remove

circlips (24) and remove bracket (18) and insert (12). See

Figure 2.

8 9

24

12

18

Figure 2

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

13

Page 14

Vector 4000 Maintenance

6.3.1 HOSE REMOVAL (Cont’d)

4. -At the discharge outlet, loosen clamps (8) and (9).

-Remove the insert (12) and remove the ange (47) as

well as the brackets (18). See Figure 3.

5. Remove clamps.

9 8

47

FOR MODELS 4003, 4004:

At the pump outlet, loosen clamps (8) and (9).Remove circlips (24)

and dismantle bracket (18). Remove insert (12) and clamps.

See Figure 5.

8

9

12

18

WARNING!

The hose can come out of the pump casing very fast and

cause harm. Ensure that no one is in front of the pump´s

outlets when removing the hose.

WARNING!

Use care when you jog/run the motor to avoid injury.

6. Carefully jog/run motor to expel hose from pump casing

outlet side. See Figure 4.

12

Figure 3

Pump casing

24

18

Figure 5

Figure 4

14

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 15

Vector 4000 Maintenance

6.3.2 PUMP CASING CLEANING

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

This operation is necessary when a hose burst has caused

material contamination inside the pump casing.

1. Unscrew cover bolt s (33) by leaving two cover bo lt s partly

fastened to the casing. Partially remove the cover (2) from

the casing and x a shackle in one of the cover’s highest bolt

holes (4014 is equipped with a lifting ring). Unfasten the

remaining cover bolts and remove the cover. See Figure 6.

2. Check the state of the cover seal (10) and replace if

necessary.

3. Check the state of wear of the pressing shoes (5) and

replace them if necessary. See 6.4.

CAUTION: A wear of shoes can cause problems to the

pump and provoke abnormal hose lifetime.

4. In the case of a hose burst, it is possible that the shaft seal (26)

and seal ring (27) have been damaged when pumping an

abrasive liquid. See 6.4 and Parts List to replace.

5. Wash the casing with clear water and remove any residue.

6. Dry the pump casing entirely.

7. Replace the cover seal in its groove.

8. Reassemble the pump cover.

6.3.3 REASSEMBLY OF THE HOSE

2,10

6

33

Figure 6

5

47

WARNING! You should never assemble a new hose without a mounted cover.

1. Pre-assemble the ange (47) at the inlet port with two

bracket bolts See Figure 7.

FOR MODELS 4003, 4004:

Temporarily mount the bracket 18 at the inlet port.

2. Clean the new Wanner hose carefully. Slightly coat it with

Wanner lubricant. Slightly lubricate the inside of the

sleeve (6).

18

Figure 7

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

15

Page 16

Vector 4000 Maintenance

6.3.3 REASSEMBLY OF THE HOSE (Cont’d)

3. Insert hose at the outlet port. See Figure 8.

WARNING!

Use care when you jog/run the motor to avoid injury.

4. Reverse the direction of rotation of the motor.

5. While pushing on the hose, jog/run the motor and check the

direction of rotation.

6. The shoes mounted on the wheel are going to “swallow” the

hose and push it out of the inlet port. Jog the motor to bring

the hose against the ange (47). See Figure 9.

7. Assemble the clamps (8) and (9) on the inlet side. Mount

the insert (12) into the hose. Tighten clamps.

FOR MODELS 4003, 4004

Dismantle the bracket 18. Mount clamps on the hose. Mount

the insert into the hose. Fix bracket (18) and block the insert

with circlips (24). Tighten clamps.

Outlet Port

Figure 8

Note: If you have diculty assembling inserts into the

pump hose, coat them slightly with Wanner lubricant.

Never use another lubricant.

8. Assemble the brackets (18) and pre-assemble ange (47) on

the outlet side with two temporary bolts.

FOR MODELS 4003, 4004

Assemble the brackets at the outlet side.

9. Reverse the direction of rotation of the motor.

WARNING!

Use care when you jog/run the motor to avoid injury.

10. Jog/run the motor to bring the hose against the discharge

ange.

11. Perform step 7 at discharge side.

12. Fill the pump with the necessary quantity of Wanner

lubricant. See 6.1. and 9.3.

13. Take away the temporary ange bolts and x the piping on

both suction and discharge sides.

14. Open the valves at the suction and discharge sides.

15. Check the direction of rotation of the pump. Check for any

possible lubricant leakage by the inserts, sleeves or cover.

18

47

Figure 9

16

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 17

Vector 4000 Maintenance

6.4 REPLACEMENT OF SPARE PARTS

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

6.4.1 REPLACEMENT OF PUMP SHOES (except 4003 and

4004)

WARNING!

Use care when you jog/run the motor to avoid injury.

1. Jog/run the motor and position one of the shoes in front of

the sight glass.

2. Cut the power supply.

3. Drain the lubricant. See 6.1.

4. Remove the pump cover (2) as well as the cover seal (10).

See Figure 10 and Figure 11.

5. Disassemble the shoe which is not in contact with the hose

and put aside the shims if any. Check that the pin (30) is

still on the wheel (4006, 4007, 4009, 4010).

6. Mount a new shoe on the wheel with shoe bolt (28) and shoe bolt

washer (29). Slide the shims (4) between the shoe and the

wheel before tightening.

CAUTION: Be careful of the position of the shoe with centering pin 30 (4006, 4007, 4009, 4010).

7. Tighten the shoe onto the wheel.

8. Temporarily reassemble the cover with three cover bolts (33)

positioned 120° from each other.

WARNING!

Use care when you jog/run the motor to avoid injury.

9. Jog the motor 180° to bring the second shoe in front of the

sight glass.

10. Remove the cover once again and perform steps 5 thru 7.

11. Reposition the cover and tighten all cover bolts.

2,10

Figure 10

28,29

Wanner Engineering, Inc.

Figure 11

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

17

Page 18

Vector 4000 Maintenance

6.4.2 REPLACEMENT OF THE SEAL RING (27) AND THE

SHAFT SEAL (26)

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

Wanner hose pumps are equipped with a leakage channel to

observe wear of the seal ring or the shaft seal. This channel is

at the back of the pump casing underneath the gearbox ange.

It also protects the gearbox seals by leaving the lubricant or

the material to pass freely at the back of the pump casing. See

Figure 12, Figure 13, and Figure 14.

41

72

27

LEAKAGE

CHANNEL

Figure 12

PUMPS 4006, 4007, 4009, 4010

1. Isolate the pump from the power supply.

2. Empty the lubricant and clean out the pump. See 6.1.

3. Remove the pump hose. See 6.3.1.

4. Disassemble the pump cover and remove the cover

seal (10).

5. Disassemble the wheel by unscrewing the hub (19).

6. Remove the wheel of the pump shaft with a suitable lifting

equipment.

7. Support the gear motor with a suitable lifting equipment.

8. Unscrew nuts (41), washers (72) and remove gearbox from

pump casing.

9. Cut out and remove seal sleeve (27) if damaged.

10. Slip on spacer ring (73) if used and glue to the

shaft.

Note: Contact Factory before performing step 11!

11. Position new seal ring (27) against spacer ring or

the gearbox shaft’s shoulder. Fill the key groove with

silicone mastic to ensure correct sealing.

12. Remove the shaft seal (26) with a drift punch.

13. Replace with new shaft seal using a suitable tool

(wooden or plastic cylinder). Check the mounting

position of the seal (opened side turned to the cover).

26

Cylinder Tool

Figure 13

18

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 19

Vector 4000 Maintenance

14. Mount the gear motor on the casing being careful not to

damage the shaft seal. Tighten nuts (41) and washers (72).

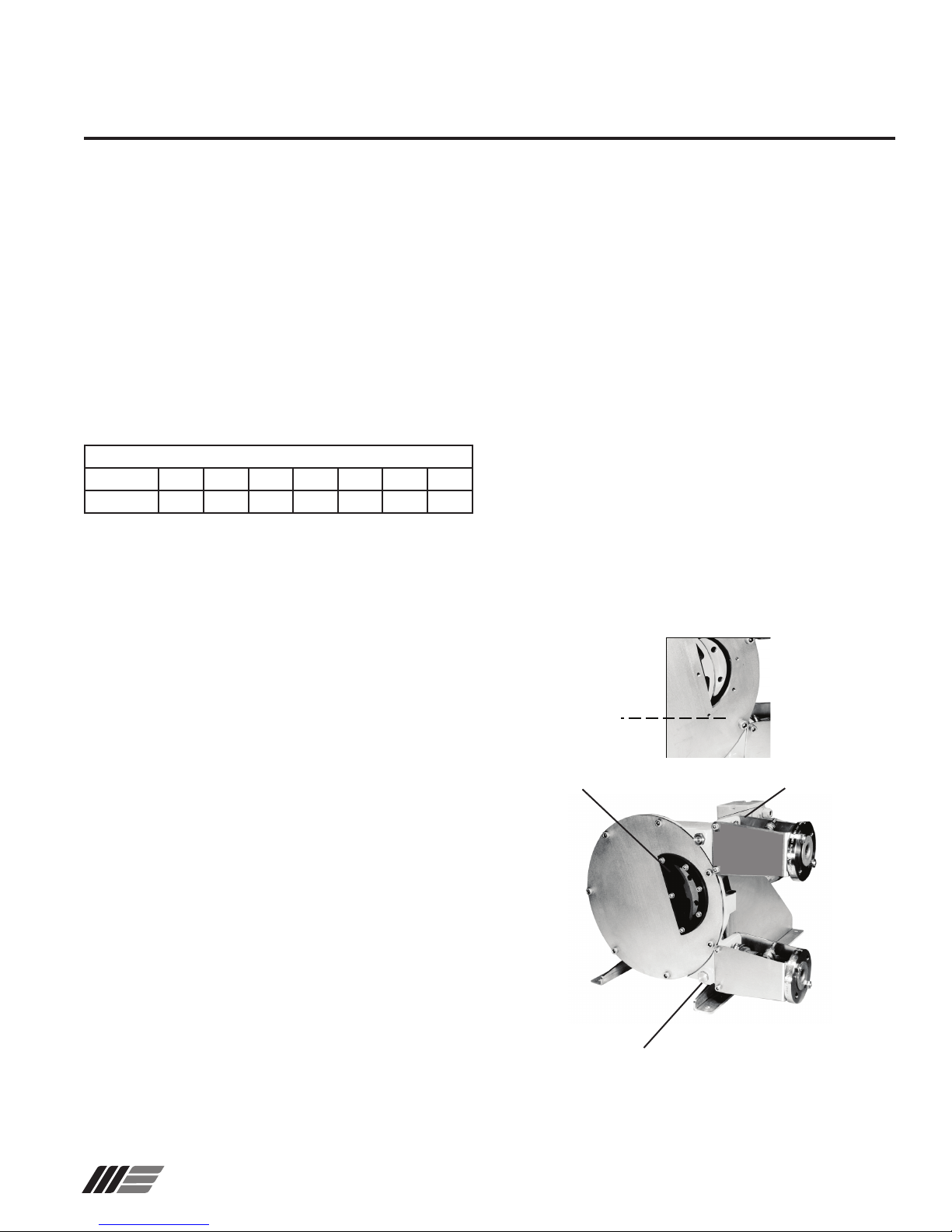

15. Mount the wheel on the pump shaft. Position and space

wheel as indicated by the illustration in Figure 15. Refer

to the Positioning Distances (L) table, depending on the

pump used.

19

LL

Figure 15

Figure 14

Model: 4003 4004 4006 4007 4009 4010 4014

Distance: 4 2.75 5.5 6 5 3 8

Distance (L) in mm (plus or minus 0.5 mm)

Positioning Distances (L)

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

19

Page 20

Vector 4000 Maintenance

16. Cross tighten the expandible hub (19) with a dynamometric

spanner to the torque gure specied in the Hub Torque

table. Check the wheel position once again. See Figure 16.

Hub Torque TABLE

Torq u e

Spanner

Figure 16

17. Mount the cover seal (10) in its groove and mount the

cover.

18. Mount the pump hose as stated in 6.3.3.

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

1. Steps 1 thru 10. for Vector pumps 4003 and 4010.

2. Disassemble the seal ange (25) and remove the shaft

seal with a screwdriver or a similar tool.

3. Take the new shaft seal (26) between the thumb and index

ngers and form a “gure 8”.Insert seal into its groove. See

Figure 17.

25

PUMP TYPE TORQUE Nm

4003, 4004 12

4006, 4007 13

4009 27

4010 35

4014 11 0

67

26

Figure 17

4. Mount gear motor on pump casing. See 6.4.2., step 13.

5. Replace the O-ring (67) if necessary and reassemble the

seal ange.

6. For pump 4014, perform steps 14 thru 17 as above.

20

Wanner Engineering, Inc.

“gure 8”

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 21

Vector 4000 Maintenance

6.5 SHOE SHIMMING (except 4003 and 4004)

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

Note: This paragraph does not apply to pumps 4003, 4004.

CAUTION: The shimming of shoes is an operation which

consists in adding shims under the shoe to stop any internal leakage. An internal leakage considerably reduces

the life time of the hose as well as the ow. As a result,

it is essential to adjust the shoe’s shimming according

to the rotation speed of the pump, the desired discharge

pressure and the liquid viscosity.

WARNING! Never run the pump without the sight glass.

The shoe shimming can be made without disassembling the

hose or the cover. Shims are inserted or removed thru the

sight glass opening as described in the following steps.

See Figure 18 illustrations.

WARNING!

Use care when you jog/run the motor to avoid injury.

37

1. Jog/run the motor and bring a shoe in front of the sight

glass.

2. Cut the power supply of the pump.

3. Unscrew the sight glass bolts (37) and remove taking care in

not damaging the seal.

4. Slightly unscrew the shoe’s fastening bolt(s) and lift the shoe (5)

o the wheel with a screwdriver or a similar tool.

5. You can now either slide in or remove the necessary

number of shims under the shoe.

Note: Consult the shimming table 9.6 to determine the

precise number of shims according to your application.

6. Tighten the shoe bolts (28).

7. Reassemble the sight glass with its seal.

8. Re-connect and jog/run the motor to bring the second shoe

WARNING!

Use care when you jog/run the motor to avoid injury.

in front of the sight glass.

9. Cut the power supply of the pump.

10. Repeat steps 3 thru 7.

Replace the sight glass seal (46) if necessary.

5

Inserting Shims

Wanner Engineering, Inc.

Figure 18

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

21

Page 22

Vector 4000 Maintenance

6.6 ADDITIONAL INFORMATION

Note: The numbers in parentheses are Reference Numbers located in the Parts List exploded views of this manual.

6.6.1 MAINTENANCE AND PERIODIC INSPECTIONS TABLE (4003, 4004, 4006, 4007, 4010, and 4014).

1 Pump hose replacement In prevention, change the pump hose

after 90 % of the life time of the rst

hose.

2 Lubricant replacement. At the end of two hose changes or 5000

hours of use. Otherwise, in every hose

break

3 Gearbox oil replacement. Refer to the gearbox maintenance

manual provided with the pump.

4 Replacement of the seal ring (27). In case of presence of lubricant in the

leak channel.

5 Replacement of the shaft seal (26). In case of presence of lubricant in the

leak channel.

6 Replacement of the shaft seal (105)

and (10 6)

7 Replacement of the shoes. If these are worn on the contact

8 Replacement of the cover seal (10). In the case of a leak around the pump

8 Replacement of the sleeves (6). If damaged. Refer to 6.3. Perform steps

9 Replacement of the bearings (103)

and (104)

In case of presence of oil in the leak

channel or at the lip seals.

surface.

cover.

If there are abnormal noises coming

from the bearing case.

See 6.3.

See 6.1. and 9.3.

See 6.4.2.

See 6.4.2.

See 6.4.2. and 6.6.

See 6.4.1.

See 6.3.2.

1 thru 4 of 6.3.1 and change

sleeves. Use care.

See 6.4. and 6.6.

9 Check the lubricant level. Before starting the pump and

periodically during the pump service.

10 Check for lubricant leakage at the

leakage channel.

11 Check the pump casing to dis-

cern possible leakages around the

cover, the sight glass, the anges and

the sleeves.

12 Check for wear on the shoe’s pressing

surface.

13 Check the presence of a gearbox oil

leakage.

14 Check for strange noises coming

from the pump, gearbox and bearing case or abnormal pump casing

temperature.

22

Wanner Engineering, Inc.

Before starting the pump and periodically during the pump service.

Before starting the pump and periodically during the pump service.

At every hose change. See 6.4.

Before starting the pump and periodically during the pump service.

Periodically during the pump service.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

See 6.1.

See 6.4.

See 3.5.

Page 23

Vector 4000 Maintenance and Storage

6.6.2 SETUP

Note: The numbers in parentheses are Reference Numbers

located in the Parts List exploded views of this manual.

Before the setting up the pump, check the following:

1. The pump with its drive and frame must be xed to a solid

base with a slope which does not exceed 5mm for 1m and

must be rmly fastened to this one.

2. The alignment of pump and drive shafts must be made in

accordance with instructions given by the manufacturer of

the coupling. Refer to the specic notice of such material.

To achieve alignment and coupling, use a perfectly straight

ruler to control the misalignment, and a feeler gauge for

angular misalignment. Control four points (top, bottom, left,

right) at each stage of the installation (after setting on

foundations, after xing pipes and after a rst start).

3. Make sure there is enough room around the pump to carry

out maintenance. If that was not the case, envisage

the moving of the pump in a space provided for this

purpose.

4. Make sure the room is adequately ventilated to relieve the

heat generated by the pump. Leave a space behind

the motor ventilator hood so as not to obstruct the air intake.

6.6.3 PUMP STARTING

Perform the procedures outlined in the PUMP STARTUP section 5, before pump operation.

6.7 PERIODIC CHECK

Regularly check the absence of grease coming from the leakage channel or from lip seal (106).

7 STORAGE

7.1 PUMP STORAGE

Store the pump in a sheltered and dry place and ensure that

the storage room temperature is between 68°F and 113°F.

Protect the pump if necessary and block the inlet and outlet

orices:

1. If the pump stays without working more than 1 month, with

draw the hose from the pump or remove one of the shoes

as well as its centering pin and position the wheel

so that the second shoe can be seen threw the sight glass.

For models 4003,4004, position the wheel so that one of the

cam lobes remains submerged in the lubricant.

2. If you can neither remove the hose or one of the shoes,

run the pump 5 minutes a week.

7.2 HOSE STORAGE

Hoses must be stored sheltered from light in a cool place.

CAUTION: Hose performance is reduced after two years,

due to material aging.

6.6.4 BEARING CASE DISMANTLING AND LIP SEAL REPLACEMENT

Perform steps in 6.4.2. Disassemble the bearing case in the

same way as for the gearbox.

1. Remove lip seals (105) and (106) from the bearing

case.

2. Remove circlips (107).

3. Remove shaft with bearings.

4. Disassemble bearings and replace them together with shaft (102)

as needed.

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

23

Page 24

Vector 4000 Troubleshooting

8 TROUBLESHOOTING

PROBLEM POSSIBLE REASON RESOLUTION

The pump does not work No power supply. Check that the pump power switch is in

the “ON” position.

Check the motor connection.

The pump wheel stalls. Check the hose.

Check that the discharge pressure is not

too high.

Check that the material hasn’t blocked the

hose.

The lubricant level detector has been

activated.

Low capacity or pressure Not enough Shims under shoes. Add the sucient number of shims.

Air leak at the inlet of the pump. Check and tighten pump clamps (if nec-

Valve closed or partly closed at inlet. Open valve.

Wor n hose. Replace hose.

Material too viscous or excessive pump

speed in comparison with the material

viscosity.

Piping blocked or partly blocked at inlet. Unblock piping and ensure good material

Check lubricant level.

Check if the pump hose has burst. Replace.

essary).Check inlet piping seals.

Check with your Wanner distributor.

ow.

24

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 25

Vector 4000 Troubleshooting

8 TROUBLESHOOTING

PROBLEM POSSIBLE REASON CORRECTION

Hose life is too short. Incompatibility of the hose with the

pumped material.

Discharge pressure too high. Check that the discharge pressure of the

Pump speed too high. Reduce pump speed.

Wrong shimming. Check shimming.

Pumped material temperature too high. Contact your Wanner distributor.

Lubricant leakage around the cover Loose cover bolts. Cover seal wear. Tighten cover bolts. Replace cover seal.

Lubricant leakage in the leakage channel

(underneath the gearbox ange)

Lubricant leakage at the sleeves Loose clamps or damaged sleeve(s). Tighten clamps. Replace sleeves.

Pipe pulsations. Piping not connected correctly. Fix piping connections.

Shaft seal or seal ring wear. Replace.

Process creating abnormal pulsations

due to the pumped material, the speed

of pump, discharge pressure, or the pipe

sizing.

Make sure the compatibility of the hose

with your material and contact your Wanner distributor.

pump does not exceed 15 bars (or 8 bars

for 4003, 4004). Check that the outlet

piping is not blocked up and that all

valves are opened.

Make sure that the security valve works

co rrec tly.

Make sure that the piping friction losses

do not exceed the value requested for an

appropriate functioning of the pump.

Contact your Wanner distributor.

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

25

Page 26

Vector 4000 Dimensions

9 CHARACTERISTICS AND TECHNICAL SPECIFICATIONS

9.1 VECTOR 4000 PUMP DIMENSIONS: 4003, 4004, 4006, 4007, 4010, 4014 FLANGED GEAR MOTOR and FPSHS series

PUMPS 4003, 4004

M

O

L

N

4 x K

P

I

J

3 LOBES

2 LOBES

H

H

D

Q

Q

F

G

C

E

B

A

Model A B C D E F G H I J

4003 103.5 115 226 95 256 220 240 33.5 260 280

4004 73 193 296 145 322 250 280 51.75 300 330

Model K L M N O P Q

4003 4xø9 - 46.5 34.5 ø16 * 56 81.25

4004 4xø13 - 49 35.5 ø20 * 68.8 124.75

Note: all units in mm.

ALL DIMENSIONS AND TECHNICAL DATA IS SUBJECT TO CHANGE WITHOUT NOTICE

26

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 27

Vector 4000 Dimensions

B C D E F G H I J

L M N

Q

65 69

83 89

9.1 VECTOR 4000 PUMP DIMENSIONS: 4006, 4007

L D C

M N

O

H

E

H

B

4 x K

P

I F

J

G

Q Q

A

Model

4006

4007

Model

4006

4007

Note: all units in mm.

A

95

122.5

K

4xø13

4xø13

262

330

-

-

355.5

435.5

190

238

416

525.5

O

(ANSI FLANGE)

1in. 150 lb

1.5 in. 150 lb

311

426

61

109

351

476

P

110

157.75

110

157.75

560

770

600

810

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

27

Page 28

Vector 4000 Dimensions

N

Q

86

B C D E F G H I J

9.1 VECTOR 4000 PUMP DIMENSIONS: 4009, 4010, 4014

L

N

O

M

4xK

P

I

J

D C

Q Q

H

E

H

F

G

B

A

MODEL

4009

4010

4014

MODEL

4009

4010

4014

Note: all units in mm.

A

110

164.5

262

K

4xø19

4xø19

4xø27

430

554

876

M

75

94.5

140.5

400

517.5

803

102

142

28

Wanner Engineering, Inc.

291

360

555

O

(ANSI FLANGE)

1.5 in. 150 lb

2.0 in. 150 lb

3.0 in. 150 lb

616

801.5

1320

340

513

690

P

87

152

210

170

256.5

345

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

420

593

830

170

186.5

345

850

950

1300 1400

1050

950

Page 29

Vector 4000 Parts

51 6

41

27

39

7 848 9

16

26 23 52 18 42 21

3

121

42 72

19

10

2

34

33

71 not shown. See 3.3. Vector 4003, 4004 Description.

Vector 4003, 4004

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

29

Page 30

Vector 4000 Parts

768125 151237

8 9 48

27

22

40

3

74

24 27 14 139 26

A

12

23

47

16

10

2

46

15

38

37

35 3633

B

DETAIL B

19

30

28

29

5

DETAIL A

4

Vector 4006, 4007

30

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 31

Vector 4000 Parts

768125 151237

8 9 48

27

22

40

3

74

24 27 14 139 26

A

12

23

47

16

10

2

46

15

38

37

35 3633

B

DETAIL B

19

30

28

29

5

DETAIL A

4

Vector 4009, 4010

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

31

Page 32

Vector 4000 Parts

63 78 64

Lifting ring on

4014 cover.

32

37 72

37

22

31

19

48

42 72

26 25 43

70*

67

6 7 8 9

B

14136 21

A

12 10 2 46 51 83 7316

47

2315 25 18

3435 36 33

C

DETAIL C

20

3

30**

DETAIL A

28

29

4

5

DETAIL B

Vector 4014

32

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 33

Vector 4000 Parts List

X X X

X X X

X X X

X

X

X X X

X X X

X X

X X X

X X X

X X X

X X X

X

X X X

X X X

X X X

X X X

X X X

X

X X X

X X X

X

X

X

X X X

X

X

X X X

X X X

X X X

X X

X

X

9.2 VECTOR 4000 Parts List

F.

Ref # DESCRIPTION 4003 4004 4014

1

CASING

2

COVER, TRANSPARENT

3

WHEEL

4

SHIM

5

SHOE

6

SLEEVE

7

CLAMP SLEEVE

8

CLAMP ON SLEEVE / HOSE

9

CLAMP ON HOSE

10

COVER SEAL

12

INSERT

14

LUBRICANT

15

SIGHT GLASS

16

HOSE

18

BRACKET

19

HUB

20

BOLT ON PLATE

21

FRAME

22

LIFT RING

23

OIL PLUG

24

CIRCLIPS

25

SEAL FLANGE

26

SHAFT SEAL

27

SEAL SLEEVE

28

SHOE BOLT

29

SHOE BOLT WASHER

30

SHOE CENTERING PIN

31

BOLT ON PLATE SCREW

32

NUT FOR 31

33

COVER BOLT

34

COVER BOLT WASHER

35

COVER STUD

36

NUT FOR 35

37

SIGHT GLASS BOLT

38

WASHER FOR 37

39

FRAME BOLT

40

WASHER FOR 39

41

GEARBOX STUD

42

NUT FOR 41

43

SEAL FLANGE BOLT

46

SIGHT GLASS SEAL

47

INLET & OULET FLANGE

DESIGNATION

FPSH 05

FPSH10

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

FPSH15

FPSH20

X

4006 to

FPSH25 TO

4007

FPSH40

X

X

X

X

X

X

X

X

X

X

4009 to

FPSHX40 TO

4010

X

X

X

FPSH80

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

33

Page 34

9

CLAMP ON HOSE

X X X X

10

COVER SEAL

X

X X X

12

INSERT

X

X X X

14

LUBRICANT

X

X X X

15

SIGHT GLASS

X

X

16

HOSE

X

X X X

18

BRACKET

X

X X X

19

HUB

X

X X X

20

BOLT ON PLATE

21

FRAME

X

X X X

22

LIFT RING

23

OIL PLUG

X

X X X

24

CIRCLIPS

X

X

25

SEAL FLANGE

26

SHAFT SEAL

X

X X X

27

SEAL SLEEVE

X

X X X

28

SHOE BOLT

X

X

29

SHOE BOLT WASHER

X

X

30

SHOE CENTERING PIN

X

X

31

BOLT ON PLATE SCREW

32

NUT FOR 31

33

COVER BOLT

X

X X X

34

COVER BOLT WASHER

X

35

COVER STUD

X

36

NUT FOR 35

X

37

SIGHT GLASS BOLT

X X

38

WASHER FOR 37

X

X

39

FRAME BOLT

X

X X X

40

WASHER FOR 39

X

X X X

41

GEARBOX STUD

X

X X X

42

NUT FOR 41

X

X X

43

SEAL FLANGE BOLT

46

SIGHT GLASS SEAL

X

X

47

INLET & OULET FLANGE

X

X

X X X

X X

X X X

X

X X X

X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Vector 4000 Parts List (Cont’d)

9.2 VECTOR 4000 Parts List (Cont’d)

F.

Ref # DESCRIPTION 4003 4004 4014

48 BRACKET BOLT

49 BRACKET BOLT WASHER

51 90° BEND

52 BREATHER PLUG

63

101 BEARING CASE

102 SHAFT

103 ROLLAR BEARING

104 BALL BEARING

105 LIP SEAL

106 LIP SEAL

107 CIRCLIPS

108 GREASER

109 SHAFT KEY

LIFT RING ON COVER

64

BOLT FOR 63

67

O RING FOR SEAL FLANGE

70

GEARBOX CENTRING FLANGE

71

COVER PLATE

72

WASHER for 41

73

SPACER RING

74

PLUG

110 SHAFT KEY

DESIGNATION

FPSH 05

FPSH10

X

X

X

X

X

X

X

X

X

X

X

X

X

FPSH15

FPSH20

X

X

4006 to

FPSH25 TO

FPSH40

4007

X X

4009 to

FPSHX40 TO

4010

FPSH80

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

34

Wanner Engineering, Inc.

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

Page 35

Vector 4000 Lubrication and Shoe Shimming

0

2

3

4

3

0

2

3

0 to 45 4

3

0

2

1

3

2

4

3

9.3 LUBRICATION TABLE

9

The table indicates the quantity of lubricant necessary for every pump size.The table indicates the quantity of lubricant

necessary for every pump size. Employ only Vector lubricant for Vector hose pumps. Refer to 6.2 for

lubricant emptying and filing.

QUANTITY OF LUBRICANT (LITRES)

QUANTITY OF LUBRICANT (LITRES)

.4 SHOE SHIMMING TABLE

Refer to 6.5 to remove or add shims. The table below points out the necessary number of shims under every

shoe according to the speed, pressure and the temperature of the product. Respect these indications scrupulously

to optimize the hose life and to avoid a possible deterioration of the internal parts.

For temperatures over 140°F, withdraw one shim in comparison with the table below.

For viscosities over 3000cP or concentrations exceeding 300g / l, withdraw one shim in comparison with the table below.

For a suction lift higher than 4 metres, add one shim to the following figures.

CAUTION: Every shoe must include the same number of shims (0.5mm).

PUMPS

PUMPS

4003

(QUARTS)

(QUARTS) 42

0.4

4014

.42 .85 1.5 2.4 6.3 9.5

40

4004

0.8

4006

1.4

4007

2.3

4009

6

4010

9

PUMP TYPE 4006

Pressure bar (psi) Speed - Rpm

∆P ≤ 5 (72.5)

5 (72.5) ≤ ∆P ≤ 7.5 (108.75)

7.5 (108.75) ≤ ∆P ≤ 10 (145)

10 (145) ≤ ∆P ≤ 15 (217.5) 10 (145) ≤ ∆P ≤ 15 (217.5)

PUMP TYPE 4009

Pressure bar (psi) Speed - Rpm

∆P ≤ 5 (72.5)

5 (72.5) ≤ ∆P ≤ 7.5 (108.75)

7.5 (108.75) ≤ ∆P ≤ 10 (145)

10 (145) ≤ ∆P ≤ 15 (217.5)

Wanner Engineering, Inc.

0 to 40

40 to 160

0 to 40

40 to 125

0 to 40

40 to 105

0 to 40

40 to 90

0 to 55

55 to 120

0 to 55

55 to 95

0 to 55

55 to 75

0 to 55

55 to 60

Number of

Number of

shims

0

1

2

shims

0

Pressure bar (psi) Speed - Rpm

∆P ≤ 5 (72.5)

5 (72.5) ≤ ∆P ≤ 7.5 (108.75)

7.5 (108.75) ≤ ∆P ≤ 10 (145)

PUMP TYPE 4007

0 to 40

40 to 140

0 to 45

45 to 140

0 to 45

45 to 110

45 to 80

Number of

shims

0

1

2

United States Instant Information: www.vectorpump.com

(612) 332-5681 Fax (612) 332-6937 VEC-991-4000B

35

Page 36

Vector 4000 Shoe Shimming

0

2

3

4

0

2

3

4

TEMPERATURE

The cover and the pump casing can become very hot due to the friction on the hose and liquid temperature. If

you need to limit the pump temperature, please contact your Wanner distributor.

9.4 SHOE SHIMMING TABLE

PUMP TYPE 4010

Pressure bar (psi) Speed - Rpm

0 to 30

30 to 100

0 to 30

30 to 65

0 to 30

30 to 50

0 to 30

30 to 42

∆P ≤ 5 (72.5)

5 (72.5) ≤ ∆P ≤ 7.5 (108.75)

7.5 (108.75) ≤ ∆P ≤ 10 (145)

10 (145) ≤ ∆P ≤ 15 (217.5)

Number of

shims

0

1

2

3

Pressure bar (psi) Speed - Rpm

∆P ≤ 5 (72.5)

5 (72.5) ≤ ∆P ≤ 7.5 (108.75)

7.5 (108.75) ≤ ∆P ≤ 10 (145)

10 (145) ≤ ∆P ≤ 15 (217.5)

PUMP TYPE 4014

0 to 20

20 to 60

0 to 20

20 to 47

0 to 20

20 to 37

0 to 20

20 to 31

Number of

shims

0

1

2

3

9.5 GENERATED NOISE AND TEMPERATURE

NOISE

The Wanner Pumps do not generate more than 60dB during their operation.

1204 Chestnut Avenue, Minneapolis, MN 55403

Tel: (612) 332-5681 Fax: (612) 332-6937

Toll-free fax [US only]: (800) 332-6812

www.vectorpump.com

email: sales@wannereng.com

36

© 2016 Wanner Engineering, Inc. Printed in USA

VEC-991-4000B 12/2016, Revised 5/2017

Loading...

Loading...