VEB BERLIN SR59 Operating Manual

Operating Manual for

STADTROLLER

BERLIN

SR59

VEB INDUSTRIEWERKE LUDWIGSFELDE

Edition 1960

The Stadtroller „SR 59-Berlin“ is a Product of VEB Industriewerke Ludwigsfelde.

Scooterstation offers full parts support for the SR59 Berlin scooter within the US. If you need parts

you can contact us at: (503)-231-2768 or e-mail us at sales@scooterstation.com

This operating manual was was written by a collective of Authors of the VEB Industriewerke

Ludwigsfelde.

All rights reserved – Technical books press Leipzig GDR – Type setting & print: Technical books

print Naumburg (Saale) GDR.

Editorship conclusion: 11/1/1959

KG 12/3/60

A lot of unnecessary frustration

will be avoided if you don´t put this operating manual aside carelessly, but instead briefly familiarize

yourself with the directions and suggestions this manual provides. All sections of this manual have

been compiled by skilled personell and serve the purpose of imparting knowledge about this vehicle

to you without which the operation of a modern motorvehicle would just be impossible. We want to

give you the maintenance and care advice necessary for you to be able to enjoy your vehicle,

instead of having to spend your valuable free time at an authorized dealers shop, that you should

better use for your own recreation.

It´s a simple fact that any new motorvehicle should be treated with a lot of care and attention. This

is why you will save lots of money, frustration and potential anger if you apply the knowledge

gained from this operating manual. Not only should you consider the given advice for a single ride,

but for the entire time in which you drive your motorscooter.

Please consider that the observance of our advice essentially contributes to the preservation of

your property and thus to the peoples property.

If you don´t find the information on the following pages sufficient or if you need additional advice,

you can always trustfully contact one of our authorized dealers. They will always help and advise

you, because our authorized dealers ought to avoid repairs before they happen by making qualified

suggestions and giving helpful advice.

VEB Industriewerke Ludwigsfelde

This manual was translated into english by Stephan Henkel and is property of Scooterstation Inc.,

OR. U.S.A. Copying or reproduction of this manual is prohibited without the written consent of

Scooterstation Inc.,USA. © 2002 Scooterstation. All rights reserved.

LEGAL DISCLAIMER:

This manual is to serve the purpose of reference only. Scooterstation is not responsible for any

malfunction or damage of your scooter resulting in the use of this manual. Scooterstation is not

responsible for any possible personal injuries or death that may result in the use of this manual.

Table of contents

1. Technical data ..................................................................................................... 11

1.01 Engine......................................................................................................... 11

1.02 Transmission and drivetrain........................................................................ 12

1.03 Brakes......................................................................................................... 13

1.04 Wheels........................................................................................................ 14

1.05 Suspension.................................................................................................. 14

1.06 Steering....................................................................................................... 15

1.07 Electrical system......................................................................................... 15

1.08 Frame.......................................................................................................... 15

1.09 Body............................................................................................................ 16

1.10 Equipment

1.11 Dimensions & weight.................................................................................... 16

1.12 amounts of fillings........................................................................................ 17

2. Description.............................................................................................................. 18

2.1 Engine........................................................................................................... 18

2.11 Mode of operation.............................................................................. 18

2.12 Crankshaft......................................................................................... 22

2.13 Crankcase......................................................................................... 25

2.14 Cylinder and Cylinder head................................................................ 27

2.15 Piston and piston rod......................................................................... 29

2.16 Fan.................................................................................................... 30

2.17 Electrical System.............................................................................. 32

............................................................................................ 16

2.161 Verifying the fan-drivebelt..................................................... 30

2.162 Changing the drivebelt.......................................................... 31

2.171 alternator............................................................................. 32

2171.1 Verifying the Electrical system............................... 34

2.171.2 Electrical tuneup (every 6000 miles)...................... 35

2.127 Battery.................................................................................. 37

2.172.1 Maintenance.......................................................... 38

2.172.2 Insufficient charging of Battery............................... 39

2.173 Lights and signals................................................................. 39

2.173.1 Failure of signal horn

2.174 Regulator.............................................................................. 41

2.175 Ignition.................................................................................. 41

2.18 Carburetor and airfilter...................................................................... 43

2.181 Maintenance of carburetor.................................................... 45

2.182 Cleansing the airfilter............................................................ 50

2.2 Power Train................................................................................................. 52

2.21 Primary Transmission and clutch...................................................... 52

2.211 Adjusting the clutch.............................................................. 53

2.22 Gearbox............................................................................................ 55

2.23 Rear powertransmission.................................................................... 56

2.231 Chain maintenance.............................................................. 57

2.3 Chassis....................................................................................................... 60

2.31 Frame............................................................................................... 60

2.32 Front wheel balance beam fork......................................................... 61

2.321 Disassembling the balance beam fork.................................. 62

2.322 Adjusting the steering column bearings................................ 63

2.33 Rear wheel suspension..................................................................... 64

2.331 Disassembling the rear wheel suspension............................ 65

2.34 Brakes.............................................................................................. 66

2.341 Brake maintenance............................................................. 67

2.35 Axles and wheels............................................................................. 69

2.351 Flat tire............................................................................... 70

2.36 Tank................................................................................................ 74

2.361 Cleansing the fuelfilter

.................................................... 75

2.37 Driver- and buddyseat...................................................................... 76

2.38 Instrument panel and theft protection............................................... 77

2.39 Tools................................................................................................ 78

3. Operating instructions............................................................................................ 80

3.1 Location and purpose of control levers and knobs....................................... 80

3.101 Air lever (Choke).............................................................................. 81

3.102 Throttle............................................................................................. 81

3.103 Ignition and lightswitch...................................................................... 82

3.104 Dipswitch.......................................................................................... 84

3.105 Clutch............................................................................................... 85

3.106 Kickstarter........................................................................................ 86

3.107 Foot gear switch............................................................................... 86

3.108 Rear brake foot lever........................................................................ 88

3.109 Front brake lever.............................................................................. 89

3.110 Sidestand......................................................................................... 89

3.111 Tip up hook...................................................................................... 90

3.2 Correct operation........................................................................................ 90

3.21 Before your first ride......................................................................... 90

3.22 Running in........................................................................................ 92

3.23 Starting up........................................................................................ 93

3.24 Start and shifting gears................................................................ 94

3.25 Shifting down gears on a slope......................................................... 94

3.26 Slowing down / using your brakes..................................................... 96

3.27 Stopping........................................................................................... 96

3.28 Mothballing the bike for storage........................................................ 96

4. Checkup- and maintenance work........................................................................... 98

4.1 General Information.................................................................................... 98

4.2 What do do ?.............................................................................................. 98

4.21 Daily................................................................................................. 98

4.211 Before leaving the driveway................................................ 98

4.212 During stays in transit.......................................................... 99

4.213 After returning..................................................................... 99

4.22 Lubricating the engine...................................................................... 99

4.23 Lubricating the chassis..................................................................... 100

4.24 maintenance of sparkplug................................................................ 100

4.241 What does the sparkplug´s face tell us ?............................. 102

4.25 Cleansing the exhaust pipe.............................................................. 103

4.3 Troubleshooting.......................................................................................... 104

4.31 Engine won´t start............................................................................. 104

4.32 Red controllamp doesn´t go out after start or lights up during ride..... 107

4.33 Fan controllamp doesn´t go out after start or lights up during ride..... 107

4.34 Engine doesn´t run smooth................................................................ 107

4.35 Engine stalls abruptly......................................................................... 108

4.36 Excessive fuel consumption............................................................... 108

4.37 Headlight doesn´t work...................................................................... 109

4.38 Adjusting the Headlight..................................................................... 110

5. Repair instructions....................................................................................... 112

5.1 Engine, removal and installation of.............................................................. 112

5.2 Cylinderhead, removal of

....................................................................... 113

5.3 Cylinder, removal of

5.4 Piston, removal of....................................................................................... 113

5.5 Pistonring, inspection of and exchange....................................................... 114

.............................................................................. 113

5.6 Piston and cylinder, installation of............................................................... 115

5.7 Ignition timing, adjustment of...................................................................... 117

5.8 Wheelbearing, exchange of......................................................................... 118

6. Parts support and technical service.............................................................. 120

Illustration 1: Berlin SR59 as viewed from the left

Illustration 2: Berlin SR59 as viewed from the right

1 Technical data

1.01 Engine

Mode of operation Two-stroke

Process Loop scavenging

Piston stroke 58mm

Cylinder bore 56mm

No. Of cylinders and

Orientation 1 cylinder, standing, leaning 15º forward

Piston displacement 143ccm

Compression ratio 7.75:1:8.1

Room for compression 20,4ccm

Continous output at 4000rpm 6.5hp

Maximum output at 5100rpm 7.5hp

Max. torque at 3500rpm 1.15kgm

Coolant Forced air (axial load supercharger)

Lubrication 4%

Carburetor

Design Round slidegate valve carburetor

Type 24 KN 1-1

Passage 24mm

Main jet 90

Needle jet 67

Idle jet 40

Needle setting 3

slidegate valve-cut out4mm

Idle air screw 2,5 to 3 revolutions, open

Weight of float 10,6grams

Airfilter Baffle wet air filter with intake silencer

Ignition Battery Ignition

Spark plug Isolator M 14-240

Length of thread 10mm

Elektrodenabstand 0,6mm

Unterbrecherkontaktabstand 0,4mm

Vorzündung 4mm of OT (28% crankangle), fixed setting

Piston

Material Si 20

Piston rings 2 Compression rings

Oversizes for cylinder-diameter 56.25; 56.50; 56.75; 57.00mm

Crankshaft bearings

Amount 3

Type Ball bearings

Connecting rod bearings Doublerowed roller bearings, cageless, with friction disc

Dimension of rolls 5x5 in compliance to DIN 5402

1.02 Transmission and power transmission

Clutch Multiple disc clutch in oilbath, adjustable at motor

and handlebar

Coating Frictionlambals „Original Cosid“

Number of compression

springs 6

Transmission Docked to engine, hand controlled

Number of gears 4

Idle motion display electronic pilot lamp on lefthandside of controlpanel

Gearshift by footswitch and circuit breaker

Gears

1. gear 3.05 :1

2. gear 1.805 :1

3. gear 1.285 :1

4. gear 1 :1

Ratio

Engine/Transmission 2.75 :1

Transm./Rear wheel 2.19 :1

Gear ratio

1. Gear 18.4 :1

2. Gear 10.8 :1

3. Gear 7.73 :1

4. Gear 6.02 :1

Kickstart ratio 3.76 :1

Power transmission

Engine/Transmission Sleeve chain 3/8“ x 7.7 x 5Dmr.

44 links

Transm./Rear wheel Chain ½“ x ¼ “

x 8.51 Dmr. 94 rollers

1.03 Brakes

Foot brake Drum brake

Effective to Rear wheel

Operates through Bowden cable

Handbrake Drum brake

Effective to Front wheel

Operates through Bowden cable, adjustable at

hub and handle bar

Diameter of brake drums

rear/front 150mm

Brake lining

width 24mm

Material „Original Cosid“, glued on

1.04 Wheels

Type Full disc wheels, light alloy

Axles

Front wheel Normal axle

Rear wheel Knockout spindle

Rims Drop base rims 2.50 C x 12

Tires

Dimensions 3.50-12

Type Block profile

Air Pressure

Front 1.2atü (17.64psi) single driver

Rear 1.5atü (22.05psi) single driver

Front 1.4atü (20.58psi) with buddy

Rear 2.0atü (29.40psi) with buddy

1.05 Suspension

Front wheel suspension Balance beam fork, Pressure spring with friction damping

Effect Proportional

Displacement 110mm

Rear wheel suspension Trapezoid swing, torsion spring (patented), hydraulically

absorbed

Effect Proportional

Displacement 70mm

1.06 Steering

Lenkkopfwinkel 25º

Vorderradnachlauf 75mm

Lenkanschlag At Steering shaft

Lenkwinkel 90º

1.07 Electrical System

alternator Voltage regulating

Type GMR 6/60

Manufacturer FEK (Fahrzeugelektrik Karl-Marx-Stadt)

Performance 60W

Propulsion Anchored directly on crankshaft tap

Controller RSC 60/6 on Blowercasing

Charging control lamp on the lefthandside of the controlpanel

Fuse 15A

Ignition coil TJ 6/1 at crankshaft tap

Battery

Voltage 6V

Capacity 8Ah

Negative pole to ground

Headlight 130mm face

Main light 35/35W Bilux

1.08 Frame

Type Central frame

Seams Electrical and autogenic welding seams

Stand Sidestand on left side of floorboard

1.09 Body

Front Fender, Legshield, headlight with casing,

instrument panel

Floor and Rear Floorboard made from GA1-alloy, Rear hood

with removable toolbox and tippable seats, that

can be locked

Number of seats 2

1.10 Equipment

Speedometer Installed on instrumentpanel with nightlight

Propulsion through the front wheel

Tools Under the seats in the rear hood

1.11 Measurements and weights

Maximum length 2080mm

Maximum width 650mm

Maximum height 950mm

Wheelbase 1430mm

Ground clearance 110mm (loaded)

Wading capability 240mm

Turning circle 4.0 Meters

Weight 140Kg (309lbs.)

Dry curb weight 131Kg (289lbs.)

Maximum weight 300Kg (662lbs.)

Pressure on front axle

unloaded 51Kg (112lbs.)

loaded 100Kg (221lbs)

Pressure on rear axle

unloaded 84Kg (185lbs.)

loaded 200Kg (442lbs.)

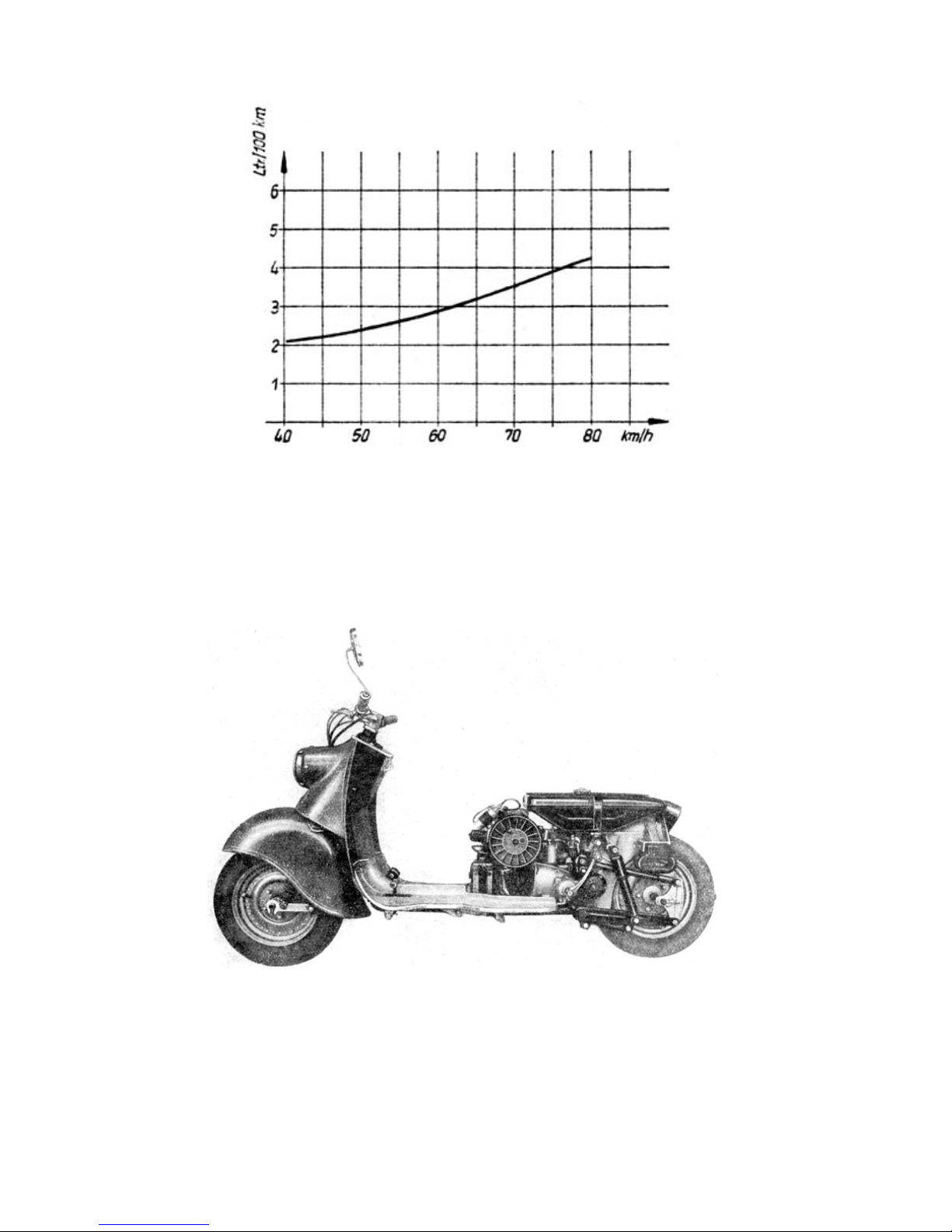

Avg. Fuel consumption 2.8liters/100Km (85mpg)

Fuel consumption at speeds

of 40Km/h (25mph) 2.1l/100Km (112mpg)

of 50Km/h (31mph) 2.4l/100Km (99mpg)

of 60Km/h (37.5mph) 2.9l/100Km (82mpg)

Top speed 82Km/h (51mph)

Continous top speed 75Km/h (47mph)

climbing ability (single driver) 1

st

gear 33% (30º) at 15Km/h (9.5mph)

nd

2

gear 18% (16º) at 30Km/h (19mph)

rd

3

gear 12% (11º) at 50Km/h (31mph)

th

4

gear 5% (4.5º) at 60Km/h (37.5mph)

1.12 Filling amounts

Fuel tank 12 liters ( 3.2 US gallons)

Reserve in fuel tank 1.5 liters (1.6 US liquid quarts

Transmission oil 0.4 – 0.45 liters (0.84-0.95 US liquid pints)

Radius with one tank filling appx. 350Km (219miles)

)

2 Description

2.1 Engine

2.11 Mode of operation

The aircooled supercharged single cylinder two-stroke engine of the SR59 Cityscooter operates as

a loop-scavenging-triple-port-Engine. This engine is an advanced version of the reliable and

successful 125cc two-stroke motor of the MZ-125-2 Motorbike. The following section describes the

mode of operation of the RM150 engine:

As the piston moves upward (from bottom dead center (BDC) to top dead center(TDC)), a vacuum

is created beneath the piston in the enclosed volume of the crankcase. The piston uncovers a little

air inlet just before reaching the top dead center. This little air inlet is the end of the intake port,

through which fresh air enters the crank case due to the vacuum created before. Because this very

same air had to pass through the carburetor prior to entering the crank case, it is mixed with just the

right amount of fuel and oil (the oil being necessary for the lubrication of the engine) When the

piston is on a downward move after passing TDC it relocks the intake port and thus compresses the

air/fuel mix. By now, the oil has dropped out of the mix and attached itself to bearings and other

parts within the engine. Just before reaching BDC two openings called transfer ports are uncovered

in the cylind

The scavenging phase has begun. Meaning that the unburned mixture gasses are flowing out of the

transfers and merging together to form a loop. The gasses travel up the backside of the cylinder

and loops around in the cylinder head to scavenge out the burnt mixture gasses from the previous

power stroke. It is critical that the burnt gasses are scavenged from the combustion chamber, to

make room for as much unburned gasses as possible. Now the loop of unburned mixture gasses

have traveled into the exhaust pipe's header section. Most of the gasses aren't lost because a

compression pressure wave has reflected from the baffle cone of the exhaust pipe, to pack the

unburned gasses back into the cylinder before the piston closes off the exhaust port. Now the

crankshaft has rotated past bottom dead center (BDC 180 degrees) and the piston is on the

upstroke. The compression wave reflected from the exhaust pipe is packing the unburned gasses

er.

back in through the exhaust port as the piston closes off the port to start the compression phase.

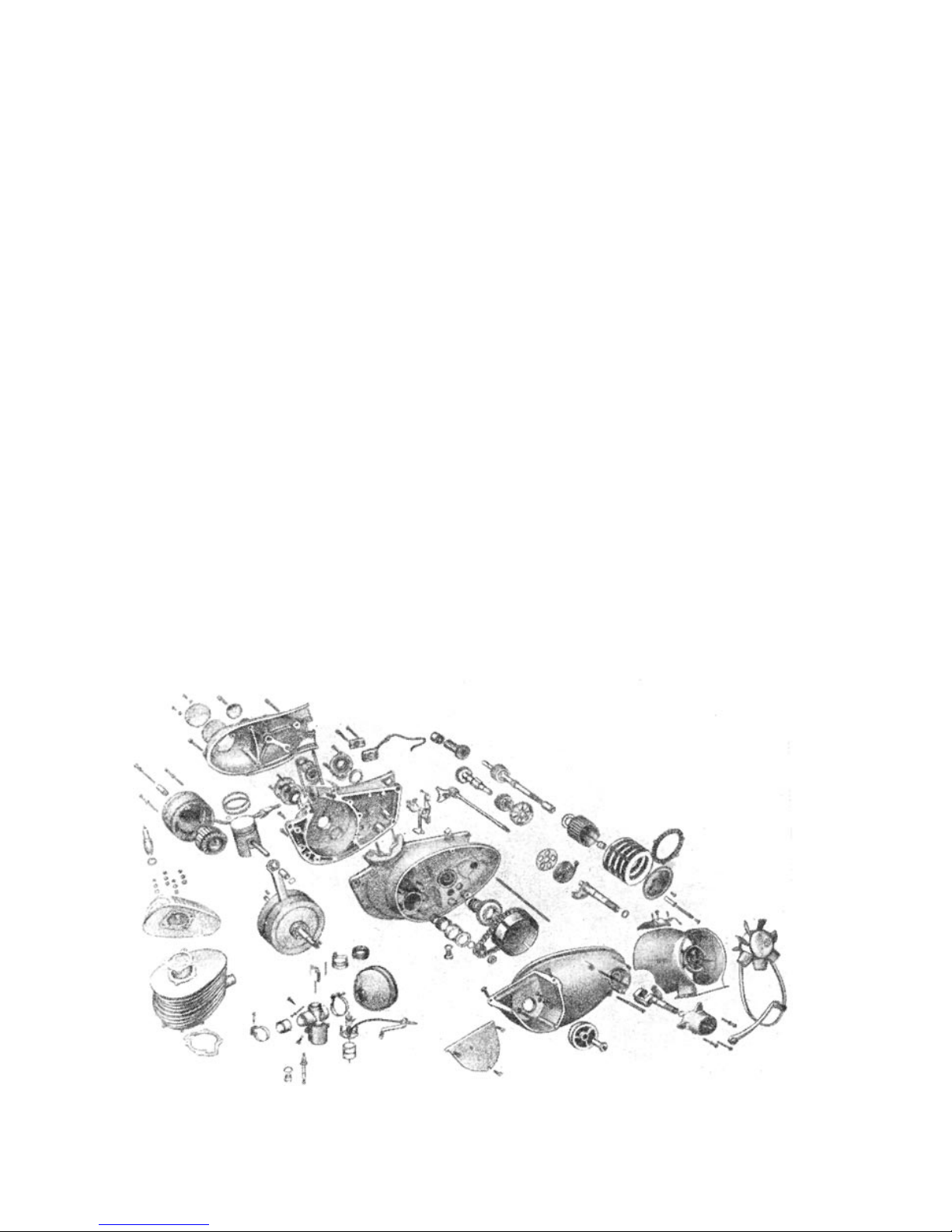

Image 3. Explosion drawing of engine

Image 4. Power curve chart

Image 5. Gas consumption curve

In the crankcase the pressure is below atmospheric producing a vacuum and a fresh charge of

unburned mixture gasses is flowing through the intake into the crankcase. The unburned mixture

gasses are compressed and just before the piston reaches TDC, the ignition system discharges a

spark causing the gasses to ignite and start the process all over again.

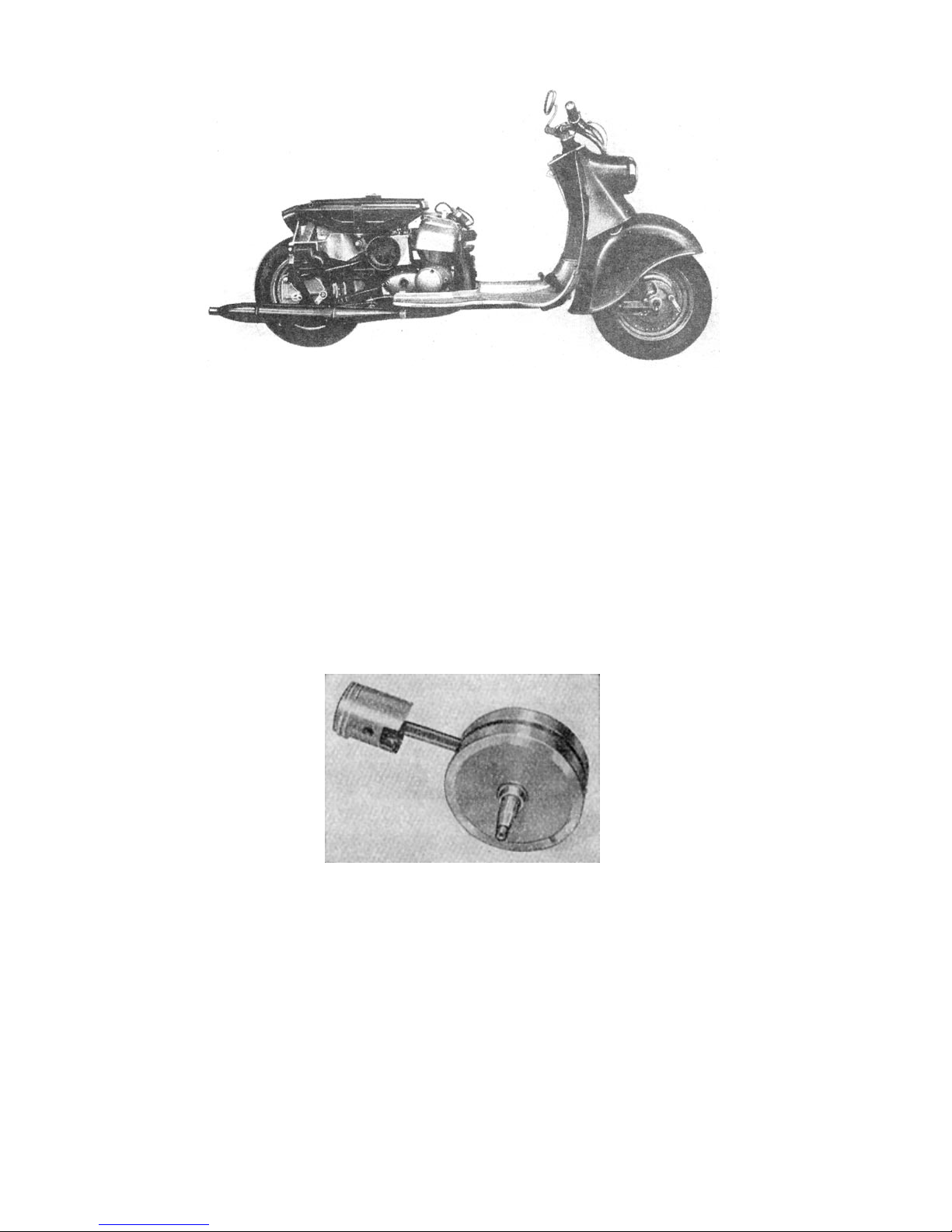

Image 6. Motor viewed from left side

Image 7. Motor viewed from right side

2.12 Crankshaft

The crank is made from several metal parts, that were manufactured hydraullically under several

tons of pressure. These parts consist of the two strokediscs, the two crank pivots and the

strokepivot on which the connecting rod is installed on a doublerowed rollerbearing. A polished

seperator disc seperates the two rows of rollers and thus keeps an ideal tracking and also insures

sufficient lubrication even at high revolutions. At the top end of the connecting rod there is a

bronze bushing into which the piston bolt is installed.

The crank is installed into the crankcase by one ball bearing on the right and two ballbearings on

the left. The necessary pressuretightness of the crankendings at the bearings is achieved by spring

pressured crank seals on each side.

Image 8. Crank with connecting rod and

piston

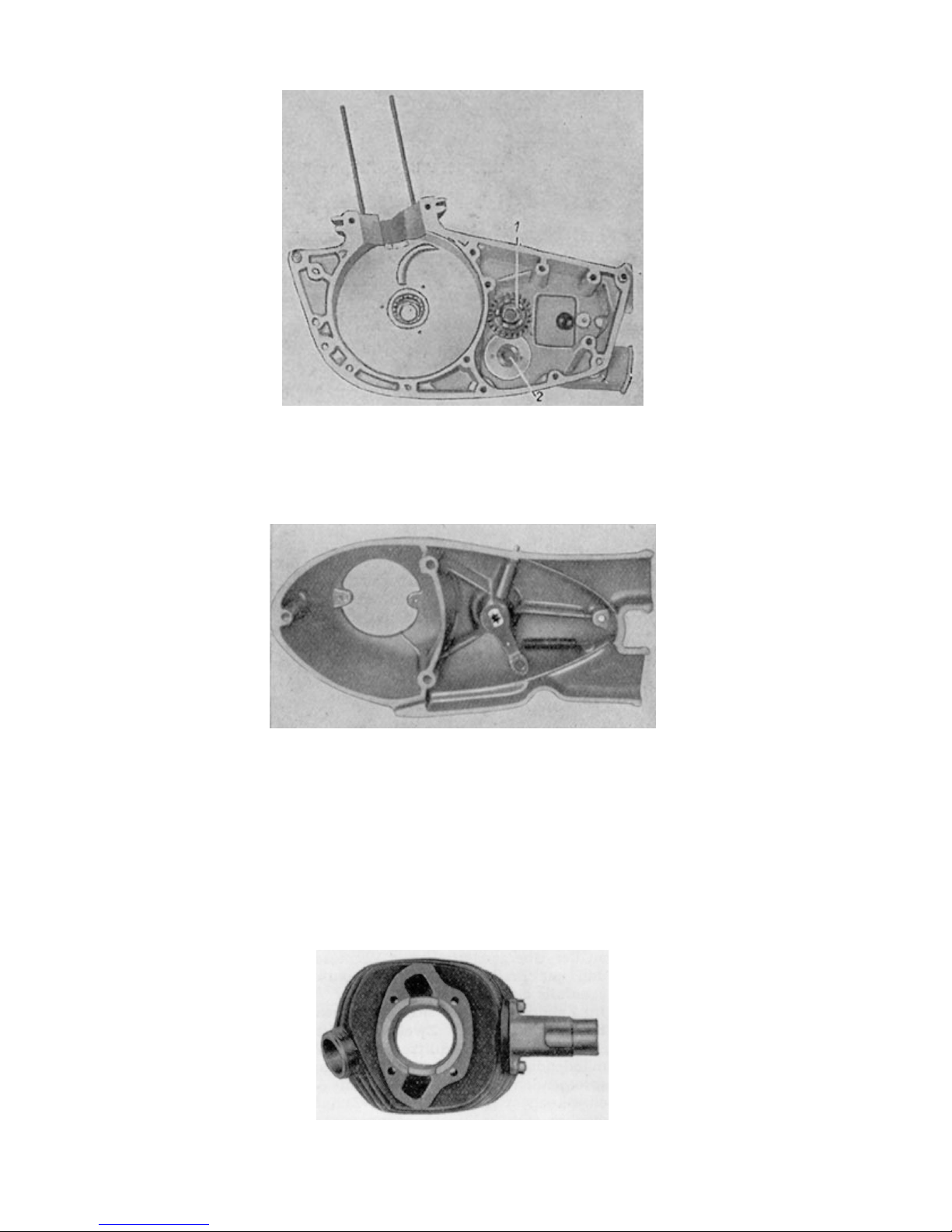

2.13 Crankcase

The enginecase is sliced vertically through the middle. The front section contains the crankcase

and the rear section the transmissioncase.The crankcase picks up the crank and carries the

cylinder. The two halfes of the engine case are held together by screws . The seperation surfaces

of both halfes of the engine case should have minor amounts of a fluid sealer applied to them prior

to closing the enginecase. Two lightmetal cast lids close the exposed areas around the sides of the

enginecase.

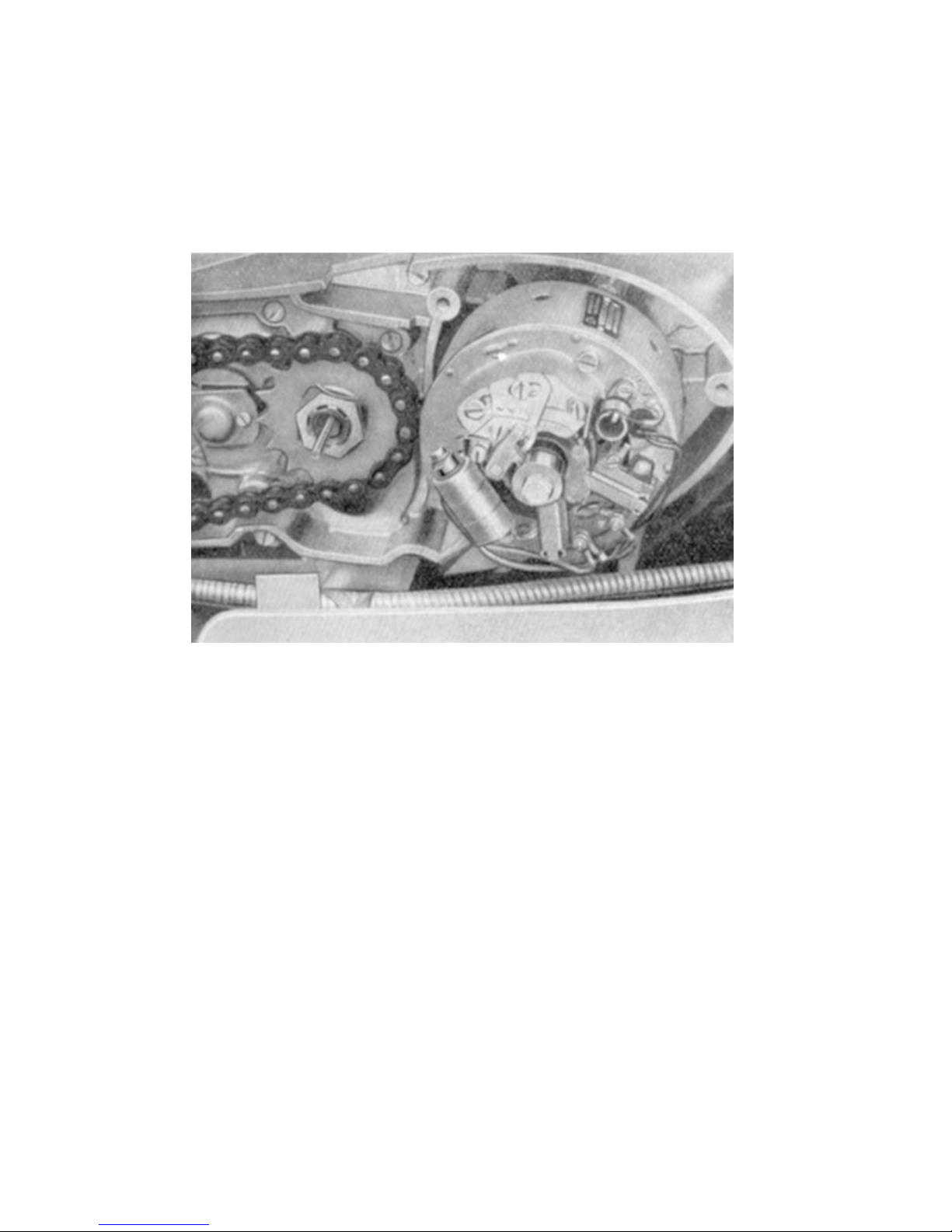

Image 9. Crankcase section

(1)Ratchet

(2)Bushing for countershaft

The main transmission of power including the clutch can be found in the left area while the

alternator and the clutch access are installed in right side, well protected from dirt.

Image 10. Lightmetal lid, right side

2.14

Cylinder and Cylinderhead

The cylinder is made of special grey cast iron and is covered with large scaled cooling fins.

Together with the cylinderhead which is also equipped with cooling fins, it is frimly screwed onto the

crankcase using four long special screws. At the foot of the cylinder a paper seal supplies the

necessary sealing.

Image 11. Cylinder

Where the cylinder and the crankcaes meet, the crankcase is also equipped with some cooling

fins, to harmonize the optical impression of the engine.

Precisely carved, you will find the previously decribed (sect. 2.11, mode of operation) transfer ports

in the cylinder. The two port openings located on the sides at the foot of the cylinder are

corresponding with the adjacent ports in the crankcase. When the cylinder is worn out, it can be

rebored and fitted with the next larger size of piston. The measurements for reboring the cylinder

are as follows: 56,25; 56,50; 56,75 and 57mm.

Image 12. Cylinder and Exhaust connectors Image 13. Cylinder head

A sparkplug that is necessary for the ignition of the gas/air mix, sits in the center of the cylinder

head. The cooling fins are oriented in direction of the supercharger blower.

2.15 Piston and piston bolt

The purpose of the silicon bearing cast lightmetall alloy piston is to pick up the pressure from the

burnig fuel. The oscillation of the piston caused by the work cycles is transformed into the

necessary rotational movement by the crank. The sealing of the piston toward the cylinder walls is

achieved by the presence of two 2,5mm wide piston rings which are secured against rotating by

safety lock pins, to protect them from getting into the transfer ports, which could otherwise do harm

to the engine. The piston is connected to the crank by a specially hardened lapped piston bolt that

is secured against shifting by circlips.

Image 14. Orientation of aggregate, right side

2.16 Fan

An axial load supercharger forces fresh cool air onto the cooling fins of the cylinder to cool the

warm air that is being produced by the cycle process of the running engine. The axial load

supercharger is made from two components: a light metal fan casing and an air guiding cover that

directs the air.

The flywheel is driven by a 8x5x474 drivebelt. The drivebelt is hooked onto the left crank pivot

secured by a beltdisc. A supercharger alarm system consisting of a contact and an orange pilot

lamp on the right hand side of the instrument panel, supplies the appropriate control and security

incase of possible blockage or snapping of the belt.

2.161 Inspection of the blower beltdrive

The belt for the flywheel should be loosly streched. It should also easily put the flywheel into

motion. If fitted too loose, it will lead to the belt „throbbing“, bearing the danger that the belt will

make contact to the housing and thus be subjected to premature wear. Also when the belt is

installed too tight, it will show signs of premature wear, because the tension that occurs during

operation adds to the initial tension of the belt. This leads to excessive friction on the belt´s profile,

which will cause the belt to eventually snap.

It is hard to give an exact value for the tension necessary for the belt but it´s safe to say, that when

you can push the installed drivebelt in by about 1/3 of an inch, that the tension set is just about right

to achieve the longest endurance of your belt. By using distancing strips between the blowercase

and the clutch lid the right tension of the belt can be set.

2.162 Changing the drivebelt

a) Removal of engine housing

b) Removal of alloy lid on the left half of the enginecase underneath the blower by unscrewing

the two upper and loosening the lower cylinderscrew.

c) Remove lower drivebelt disc (right-hand-thread) using a 19mm socket and remove disc.

Image 15. Belt drive

d) Unscrew the three screws of the guide rim and remove the guide rim. On the extenstion of the

guide rim you you have the flywheel and the drivebelt disc. Now you can install the new drive belt.

(A reserve belt is in the toolbox).

e) Repeat steps a) through d) in reverse order.

2.17 Electrical System

The electrical system consists of the following:

a) alternator 6V, 60W

b) Led-battery 6V, 8Ah (K20)

c) Ignition coil

d) Cntroller switch

e) Ignition and lightswitch

f) Circuit breaker and condenser (mounted on the holding cap of the alternator)

g) Sparkplug (in Cylinder head)

h) Headlight (Hi beam, low beam and parking light)

i) Charging control lamp (red, on the lefthandside of the controlpanel)

j) Neutral gear control lamp (green, on the lefthandside of the controlpanel)

k) Control lamp for Supercharger (orange, on the righthandside of the controlpanel)

l) Signal horn

m) Brake-, tail- and licenseplate lamp

n) Wiring harness

o) Control lamp (unused. Can be used for Hi-beam display for instance)

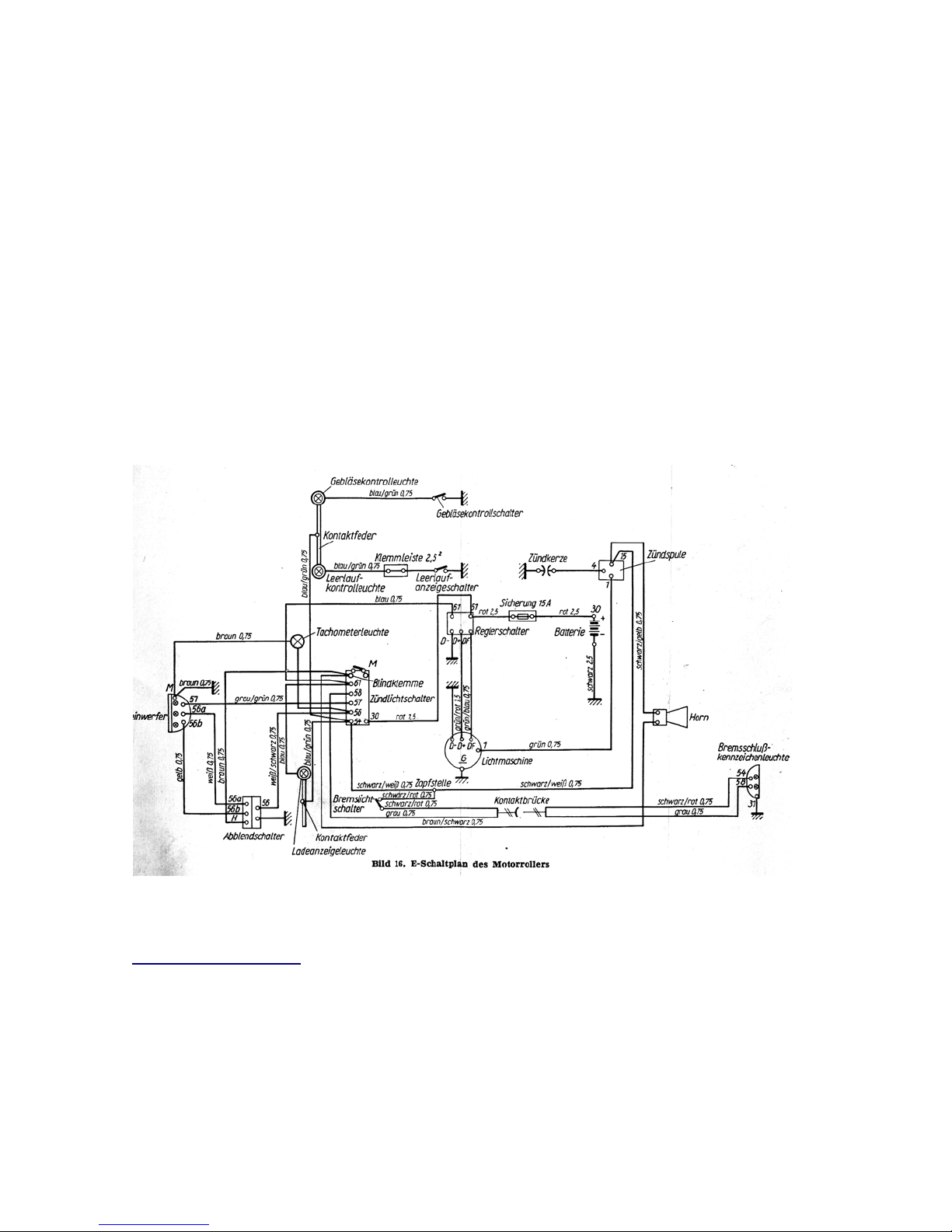

Image 16. Wiring diagram

Suggestion: A more detailed and colored version of the wiring diagram can be downloaded from

our website at

www.scooterstation.com

2.171 alternator

The genereator generates the electricity necessary for ignition, lights and signal horn. Also the

alternator charges the battery through a controller switch.

Image 17. alternator

The battery functions as a direct current shunt link alternator. The alternator is made from two main

parts. The anchor and the holding cap.

The controller switch is installed on the blowerhousing and keeps the alternators voltage steady,

regardless of the number of revolutions the engine is doing or how many of the lights are currently

turned on.

Also the controller switch automatically switches the battery off, when reaching a high enough

number of revolutions as well as switching battery support on when the revolutions fall under a

certain amount. When the red controll lamp on the controlpanel expires, the battery is being

charged by the alternator. When the red control lamp is on, it shows that the battery is currently

feeding the electrical system.

The anchor that carries the commutator, sits directly on the cone of the right crank pivot. It gets

screwed together with the circuit breaker cam using a long hexagonal nut. The holding cap contains

the pole housing with poles and field coils on the inside. The front face carries the circuit breaker

and the condenser as well as the brushes that are forced onto the commutator by springs and

supply the current. A three wired cable connects the alternator with the regulator-aggregate and the

circuit breaker with the ignition coil. The aeration of the of the alternator housing, wich is enclosed

by a housing lid, is achieved by a sufficiently large breakout in the partition wall of the housing. The

housing lid itself carries a little detachable plate, which if taken off the housing lid, enables easy

monitoring of brushes, condenser and commutator.

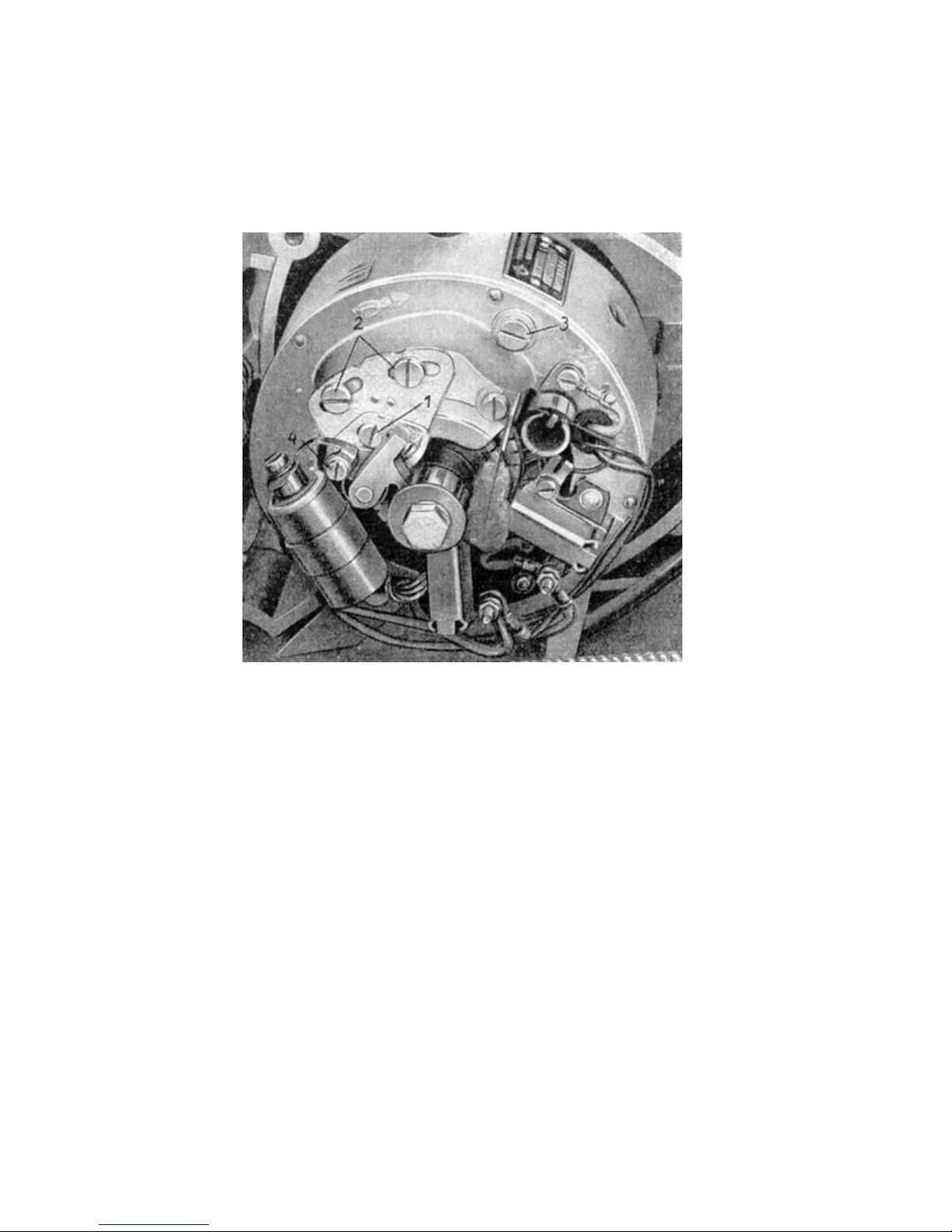

2.171.1 Monitoring the electrical system

During regular operation the electrical system doesn´t need any extra attention. However it is

necessary to have the electrical system inspected and serviced by special personnell (IKA dealers

workshop) every 6.000 miles. Merely the breaker points should be inspected for abrasion every

1.000 miles.

When the cam is in it´s highest position, the contact gap should be 0,4mm. Less or more gap will

result in bad starting behaviour, unsteady running, less performance and higher gas consumption of

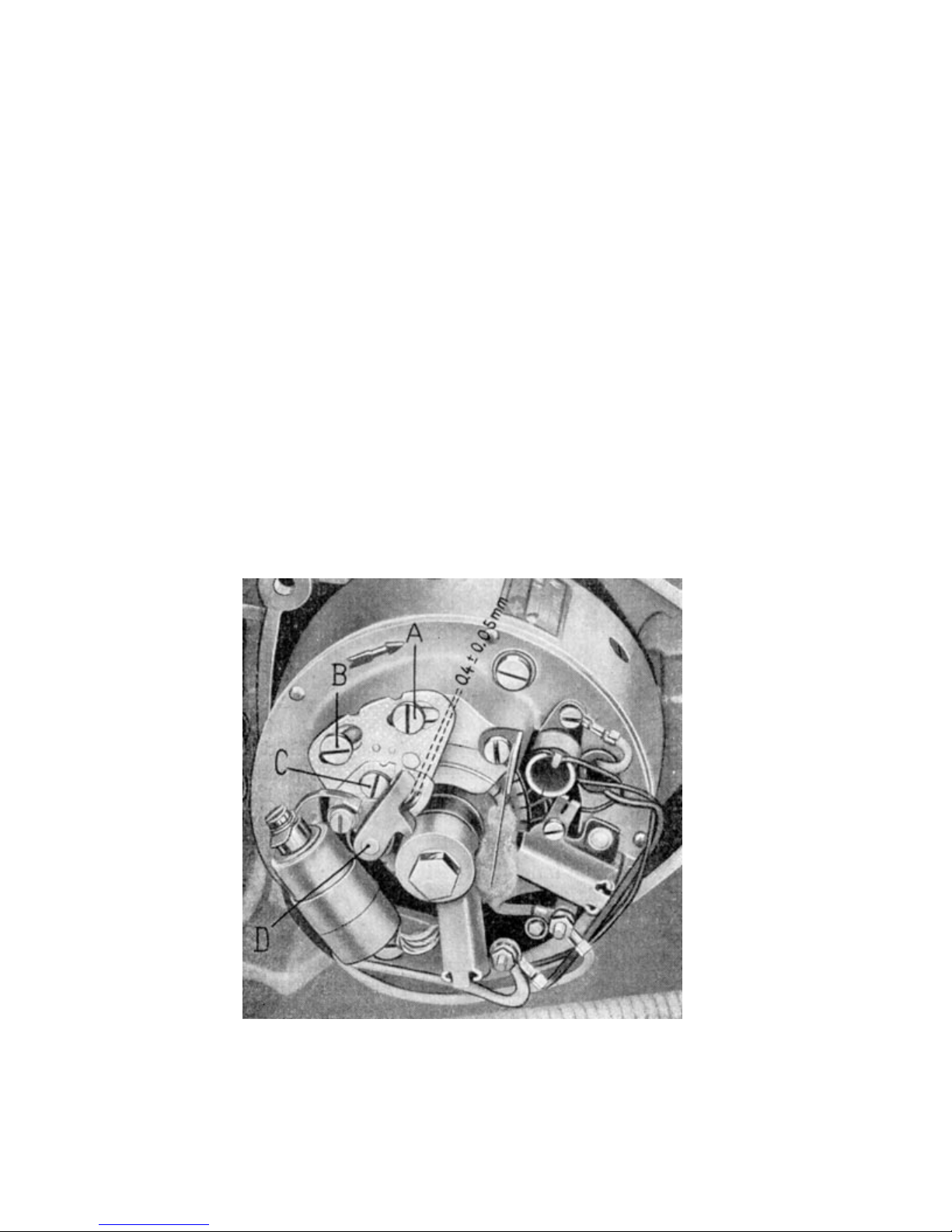

the engine. Adjustment of the points is done with detached circuit breaker cover (see image 18) and

loosened clamping screw ( C ), by pivoting the smaller statorplate around the bolt (D). The pan

head screws (A and B) are not to be loosened during this procedure.

The clamping screws ( C ) and (B) are to be tightened again after adjustment. If the breaker points

have burned spots, they are to be smoothed out using a contact file. More vigorous signs of

conflagration on the points indicate a defecticve condensor. The advice of a professional electric

technician is now essential to have the defective part replaced.

2.171.2

Electrical tuneup (every 6000 miles)

The regular 6000mile inspection of the electrical system consists of a check up on proper

positioning and insulation of the wiring and faultless seating of all clamping screws and

connectors. All contacts are checked for cleanness and are polished if needed. (This covers ignition

coil contacts, ground contact of the battery, regulator contacts, alternator contacts, tail- and

stoplight connecting contacts in the front of the rear housing and on the frame).

Image 18, Statorplate

The condition of the commutator and the carbon as well as the tension of the carbon springs will be

inspected. The positive (+) carbon´s wear is heavier compared to the negative carbon (-). The

lowest height of the carbon may not exceed 11mm. After reaching this height, the carbon should be

Loading...

Loading...