AC35

Installation and maintenance instruction

GB

for air curtains

IMPORTANT: Read these instructions before the product is installed and used.

Save the instructions for future use.....................................................................................................2

Ar t.nr: 172786-01

AC35

Assembly and operating instructions

Safety

• For all installations of electrically heated products

should a residual current circuit breaker 300 mA for

re protection be used.

• Keep the areas around the air intake and exhaust grilles free from possible obstructions!

• CAUTION! During operation the surfaces of the unit

can be hot!

• e unit must not be fully or partially covered with

clothing, or similar materials, as overheating can result

in a re risk! (E)

• e appliance can be used by children, aged from 8

years and above, and by persons (children included)

with reduced physical, sensory, or mental capabilities,

or lack of experience and knowledge, if they have been

given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards

involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made

by children without supervision.

Children, of less than 3 years of age, should be kept

away unless continuously supervised.

Children, aged from 3 years and less than 8 years, shall

only switch on/o the appliance, provided that it has

been placed or installed in its intended normal operating position and they have been giving supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved. Children,

aged from 3 years and less than 8 years, shall not plug

in, regulate and clean the appliance or perform user

maintenance.

General instructions

Read these instructions carefully before installation and

use. Keep this manual for future reference.

e product may only be used as set out in the assembly and

operating instructions. e guarantee is only valid if the product is used in the manner intended and in accordance with

the instructions.

Application area

e AC35 air curtain unit is supplied with electrical

heating or hot water heating. AC35 is intended for entrances and smaller doors up to 3.5 metres in height.

Protection class for units with electrical heating: IP20.

Protection class for units with water heating: IP21.

Operation

Air is drawn in at the top/rear of the unit and blown out

downwards/outwards so that it shields the door opening and minimizes heat loss. To achieve the optimum

curtain eect the unit must extend the full height/width

of the door opening.e grille for directing exhaust air

is adjustable and is normally angled outwards to achieve

the best protection against incoming cold air.

e eciency of the air curtain depends on the air

temperature, pressure dierences across the doorway and

any wind pressure.

NOTE! Negative pressure in the building considerably

reduces the eciency of the air curtain. e ventilation should

therefore be balanced.

Mounting

e air curtain range includes possibilities for horizontal

installation and for vertical installation and the units can

also be installed recessed into suspended ceilings.

Horizontal mounting

e air curtain unit is installed horizontally with the

supply air grille facing downwards as close to the door as

possible. Minimum distance from outlet to oor for electrically heated units is 1800 mm. For other minimum

distances, see g. 3.

For the protection of wider openings, several units can

be mounted next to each other using a joining kit

(g. 9).

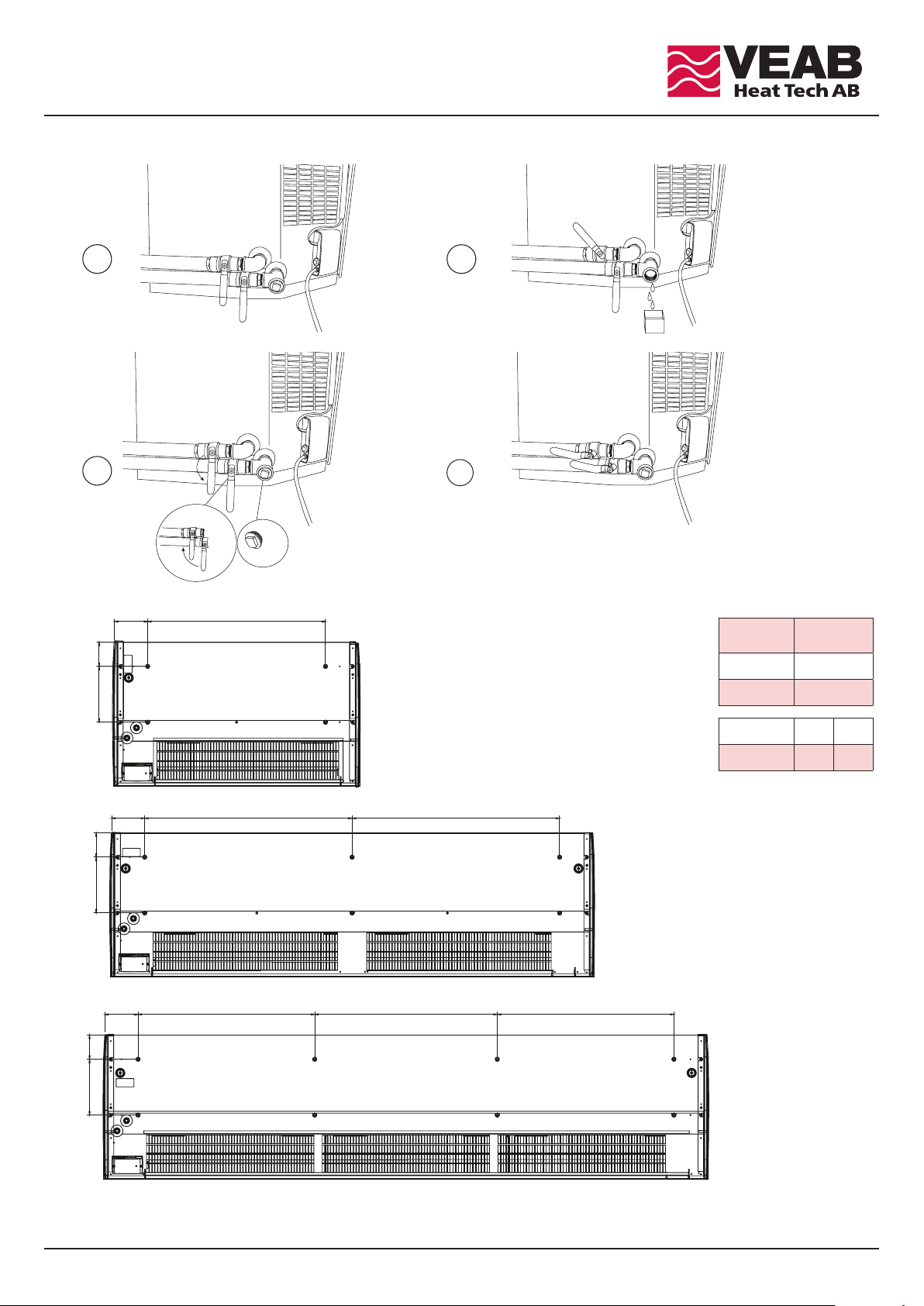

Mounting with wall brackets PA34WB (g. 6)

1. 1. Remove the plastic covers on the

wall brackets.

(Fig. 6A)

2. 2. Mount the brackets on the wall according to

measures in g. 6B.

3. 3. Fasten the hammer head screws on the unit in

the

holes M8. (Fig. 5 and 6C)

4. 4. Lock the nuts so that the hammer head screws

are

at 20 mm height. Note the direction of the screw

heads. (Fig. 6C)

5. 5. Slide the unit on the consoles. (Fig. 6D)

6. 6. Lock the nuts against the bracket and put the

plastic

covers on again. (Fig. 6E)

2

AC35

Horizontal mounting on the ceiling

readed rods, wire suspension kits and ceiling brackets

for ceiling mounting are available as accessories, see g.

7 and 8 and separate manuals.

Vertical mounting PL3JK

Units from 1,5 metres and longer may be used vertically.

For vertical mounting, all units must be supplemented

with a vertical kit containing everything needed for a

practical installation of oor standing units.

e unit can be reversed and placed on either side of the

door. Connections and PC Board PLS are positioned

near oor level when the air curtain is placed to the left

of the door and at the top when it is placed to the right

(seen from the inside).

e accompanying oor edging is attached to the oor

with fasteners appropriate to the surface.

Two units can be mounted directly on top of each other,

the oor edging is then used as a joining bracket.

e air curtain must be secured to wall or ceiling, use

PL3JK (accessory).

A design kit which gives a neater installation that

conceals cables and pipes is available as accessory, see

accessories pages.

See separate manual.

Electrical installation

e installation, which should be preceded by an omnipolar switch with a contact separation of at least 3

mm, should only be wired by a competent electrician

and in accordance with the latest edition of IEE wiring

regulations.

e control system is pre-installed in the air curtain with

an integrated control card, (see g. 2).

PLS is supplied pre-programmed with quick-t connections.

Modular cables are connected to the control board. See

manual for PLS.

Unit with water heating

Connected via the built-in PLS control board with

2 m cord and plug.

Unit with electrical heating

e installation is made on the top of the unit (horizontal) or on the reverse (vertical).

Control supply is 230V~ and cable is routed from the

built-in PLS control board.

Power supply for heating (400V3N~) is connected to

terminal block in the internal connection boxes. 2-metre

and longer units require dual power supplies. e largest

cable diameter for the terminal block is 16 mm². e

cable glands used must meet the protection class requirements. In the distribution board it is to be indicated that

”the air curtains can be supplied from more than one

connection”.

See wiring diagrams.

Type Output

[kW]

AC35-10-E08 8 400V3N~ 2,5

AC35-15-E12 12 400V3N~ 4

AC35 -20- E16

AC35-25-E20

1

2 m and 2.5 m-units are connected with two power supplies, see p. 2. 2.5 meter units have electric batteries with two dierent eects, and the electric battery on the left, on a horizontal unit,

seen from inside the room, has the highest eect.

2

Dimensioning of external wiring shall comply with applicable regulations and local deviations

may occur.

1

8 / 8 400V3N~ 2,5 / 2,5

1

8 / 12 400V3N~ 2,5 / 4

Voltage

[V]

Minimum area 2

[mm2]

Start-up (E)

Note! When using for the rst time or when starting up

after a long period of disuse, a small amount of smoke

and a slight odour may occur temporarily, which is

completely normal.

3

AC35

Connecting the water coil (W)

e installation must be carried out by an authorised

installer.

e water coil has copper tubes with aluminium ns and

is suitable for connection to a closed water heating system. Steel connection pipe. e heating coil must not be

connected to a mains pressure water system or an open

water system.

Note that the unit shall be preceded by a regulating

valve, see valve kits.

e water coil is connected on top of the unit (horizontal

mounting) or on the reverse (vertical mounting) via connections DN20 (3/4’’), external thread. Flexible hoses are

available as an accessory, see accessories pages.

e connections to the heating coil must be equipped

with shut o valves (included in valve kits) to allow problem free removal.

A vent valve should be connected at a high point in the

pipe system. Air valves are not included.

For vertical installation and bottom water connection it

is not possible to bleed the coil in the unit. Ensure that

the water coil is lled with water and that no air remains, prior to commissioning. See g. 4.

Our recommended solution is to use a T-connection and

shut o valves. Small air bubbles may remain, but will

disappear with normal operation.

NOTE: Care must be taken when connecting

the pipes. Use a wrench or similar to hold the

air curtain connections to prevent straining

of the pipes and subsequent water leakage

during connection to water supply pipe-work.

Filter (W)

e water coil is protected against dirt and blockage by

an air lter which covers the coil face. In environments

where the lter needs cleaning often, it is advisable to

use an external intake lter (see accessories pages), which

provides an easier maintenance, since the unit does not

need to be opened.

Service, repairs and maintenance

For all service, repair and maintenance rst carry out the

following:

1. Disconnect the power supply.

2. Loosen the screws and raise the front panel.

e front is blocked in open position with the front

hatch hook, see g 1A or removed completely, see

g. 1B. e service hatch is removed by loosening

the screws.

3. After service, repairs and maintenance fasten the

service hatch and the front. When the front has been

removed it is important to be sure it is rmly seated

in the front locks again, see g. 1B.

Adjustment of the air curtain and air ow

e direction and speed of the air ow should be adjusted considering the load on the opening. Pressure

forces aect the air stream and make it bend inwards

into the premises (when the premises are heated and the

outdoor air is cold).

e air stream should therefore be directed outwards to

withstand the load. Generally speaking, the higher the

load, the greater the angle that is needed.

Basic setting fan speed

e fan speed when the door is open is set using the

control. Note that the air ow direction and fan speed

may need ne adjustment depending on the loading of

the door.

4

AC35

Maintenance

Unit with water heating:

e appliance lter should be cleaned regularly to ensure

the air curtain eect and the heat emission from the

device. How often depends on local circumstances.

A clogged lter is not a risk, but the appliance function

can fail.

1. Disconnect the power.

2. Loosen the screws and raise the front panel.

e front is blocked in open position with the front

hatch hook, see g 1A.

3. Remove the lter and vacuum clean or wash it.

If the lter is clogged or damaged, it may need to

be changed.

All units:

Since fan motors and other components are maintenance

free, no maintenance other than cleaning is necessary.

e level of cleaning can vary depending on local conditions. Undertake cleaning at least twice a year. Inlet and

exhaust grilles, impeller and elements can be vacuum

cleaned or wiped using a damp cloth. Use a brush when

vacuuming to prevent damaging sensitive parts. Avoid

the use of strong alkaline or acidic cleaning agents.

Overheating

e air curtain unit with electric heater is equipped with

an overheat protector. e overheat protection is reset by

turning o the switch and the unit cools. If it is deployed due to overheating, reset as follows:

1. Disconnect the electricity with the fully

isolated switch.

2. Allow the electrical coil to cool.

3. Determine the cause of overheating and rectify

the fault.

4. Connect the air curtain again.

All motors are equipped with an integral thermal safety

cut-out. is will operate, stopping the air curtain

should the motor temperature rise too high. e cut-out

will automatically reset when the motor temperature has

returned to within the motor’s operating limits.

Fan replacement

1. Determine which of the fans is not functioning.

2. Disconnect the cables to the relevant fan.

3. Remove the screws securing the fan and lift

the fan out.

4. Install the new fan as above in reverse order.

Replacing a electric coil (E)

1. Mark and disconnect the cables to the electric

coil package.

2. Remove the mounting screws securing the electric

coil package in the unit and lift it out.

3. Replace faulty electric coil.

4. Install the electric coil package in reverse order

to the above.

Replacing the water coil (W)

1. Shut o the water supply to the unit.

2. Disconnect the connections to the water coil.

3. Remove the mounting screws securing the coil

in the unit and lift the coil out.

4. Install the new coil in reverse order to the above.

Draining the water coil (W)

e drain valves are on the underside of the coil on the

connector side. It can be accessed via the service hatch.

Temperature control

Temperature control of PLS maintains the exhaust temperature to approx. +40 °C. If the temperature should

exceed anyway there is an overheating alarm. For more

information see the manual for PLS.

5

AC35

Trouble shooting

If the fans are not working or do not blow properly, check

the following:

at the intake grille/lter is not dirty.

Check the functions and settings of the control system

PLS, see manual for PLS.

If there is no heat, check the following:

Check the functions and settings of the control system

PLS, see manual for PLS.

For units with electrical heating, check also the following:

Power supply to electric heater coil; check fuses and

circuit-breaker (if any).

at the overheat protection for the motors has not been

deployed.

For units with water coil, check also the following:

at the water coil is air free.

at there is enough water ow.

at incoming water is heated enough.

If the fault cannot be rectied, please contact a qualied

service technician.

Residual current circuit breaker (E)

When the installation is protected by means of a residual

current circuit breaker, which trips when the appliance

is connected, this may be due to moisture in the heating

element. When an appliance containing a heater element

has not been used for a long period or stored in a damp

environment, moisture can enter the element.

is should not be seen as a fault, but is simply rectied

by connecting the appliance to the mains supply via a

socket without a safety cut-out, so that the moisture can

be eliminated from the element. e drying time can

vary from a few hours to a few days. As a preventive

measure, the unit should occasionally be run for a short

time when it is not being used for extended periods of

time.

6

AC35

DN20 (3/4”),

L1

528

275

outside thread

275 33

364

L

528

2 m; 2,5 m

160

A

L

(mm)A (mm)

205 92

43

AC 35-10/ 35-15: 4 M8

PL3510/3515: 4 M8

AC35-20: 6 M8

40

PLS

PL3520: 6 M8

PL3525: 8 M8

AC35-25: 8 M8

AC35-10 1073 72

AC35-15 1583 72

AC35-20 2073 74

AC35-25 2583 71

L1

(mm)

AC35-15 1589

AC35-20 2079

AC35-25 2589

23

40

7

AC35

100

2

Fig. 1A

Open the unit by raising the front panel. The front is

blocked in open position with the front hatch hook.

PLS

Fig. 2

Control card PLS is integrated in the air

curtain at delivery.

Fig. 1B

When the front has been removed it is important to be

sure it is rmly seated in the front locks again.

Fig. 3

Minimum distance.

8

AC35

160

L

AB

57

Filling the water coil

Fig. 4

1

3

2

4

B

B

A

A

L

(mm)

AC35-10 750

AC35-15 1260

AC35 205 92

74

875

770

875

45

160

B

A

160

A B

Fig. 5

M8-holes for mounting.

9

AC35

79

19

120

11

40

AC35 + PA34WB

A

B

D

PA34WB

E

F

C

20 mm

AC35-W-15 2 pcs

Fig. 6

See separate manual for PA34WB.

10

AC35-W-20 3 pcs

AC35-W-30 4 pcs

AC35

PA34CB

PA34TR

PA34WS

(PA34CB)

Fig. 7

PA34TR + PA34CB.

See separate manual for PA34TR.

Fig.8

PA34WS + PA34CB

See separate manual for PA34WS.

PL3JK

11

AC35

Note! The top of the air

curtain must be secured

in the wall or ceiling.

Fig. 9

See separate manual for PL3JK

PL3JK

12

AC35

Accessories Horizontal

Wall bracket for 1 and 1.5

PA34WB15

PA34WB20

PA34WB30

meter unit

Units: 2 pcs

Wall bracket for 2 meter unit

Units: 3 pcs

Wall bracket for 2.5-meter

unit

Units: 4 st

AC35-10/15 Fig. 6

AC35-20 Fig. 6

AC35-25 Fig. 6

Brackets for mounting the unit

horizontally on the wall.

Length: 400 mm

PA34WB

PA34CB15

PA34CB20

PA34CB30

PA34WS15

PA34WS20

PA34WS30

PA34TR15

PA34TR 20

PA34TR30

PL3JK

Ceiling brackets for 1 and 1.5

meter unit Units: 4 pcs

Ceiling brackets for 2 meter

unit

Units: 6 pcs

Ceiling brackets for 2.5 meter

unit

Units: 8 pcs

Wire suspension kit for 1 and

1.5 meter units

Units: 4 pcs

Wire suspension kit for

2 meter units

Units: 6 pcs

Wire suspension kit for

2.5 meter units

Units: 8 pcs

Threaded rods for 1 and 1.5

meter unit

Units: 4 pcs

Threaded rods for 2 meter unit

Units: 6 pcs

Threaded rods for 2.5 meter

unit

Units: 8 pcs

Connecting bracket with

mounting hardware

AC35-10/15 Fig. 7/8

AC35-20 Fig. 7/8

AC35-25 Fig. 7/8

AC35-10/15 Fig. 8

AC35-20 Fig. 8

AC35-25 Fig. 8

AC35-10/15 Fig. 7

AC35-20 Fig. 7

AC35-25 Fig. 7

AC35 Fig. 9

Ceiling brackets for mounting the

unit on the ceiling using wires or

threaded rods (not included).

Wire suspension kit with

bright-galvanized wires with

wire locks for ceiling installation. Used with ceiling mounts

(PA34CB15/20/30).

Length: 3 m

Threaded rods for ceiling mounting.

Used with ceiling mounting

brackets PA34CB.

Length: 1 m

For joining together horizontal

air curtains. Provides a neat and

uniform installation.

Also used for vertical mounting.

PA34CB

PA34WS

PA34TR

PL3JK

Accessories Vertical

PL3JK Vertical kit for AC35 AC35 Fig. 9

AXP300 Collision guard AC35

Used to adapt a unit for vertical mounting. Contains

oor edging and mounting hardware to brace the

top. The vertical kit makes it possible to mount two

units on top of each other. One vertical kit is required per unit. Also used as a connecting bracket for

horizontal mounting.

Floor positioned guard against collisions

with, e.g., a shopping trolley.

13

PL3JK

AXP300

AC35

Accessories PLS

PLSB Control unit Basic Incl. control unit PLSUB1 and 5 meter modular

cable with RJ12 quick connect.

IP30

PLSAC Control unit Competent Incl. PLSUA1 control unit, box cover, PLSC1X hub

unit, PLSDC door switch, and 2 modular cables

with RJ12 quick connects (1 pc 3 m, 1 pc 5 m).

IP30

PLSB

PLSRTX External room

temperature sensor

SIRECJ4 RJ11 coupler (4/4) Used to join together two RJ11 or RJ12 connec-

SIRECJ6 RJ12 coupler (6/6)

SIRECC403

SIRECC405 Length 5 m

RJ11 modular cable (4/4)

SI RECC 410 Length 10 m

SI RECC 415 Length 15 m

SIRECC603

SIRECC605 Length 5 m

RJ12 modular cable (6/6)

SIRECC610 Length 10 m

SIRECC615 Length 15 m

PAMLK Motor alarm board Provides a potential free alarm connection

70x33x23 mm

tors.

Length 3 m

Length 3 m

when thermal contact is triggered in the motor.

Installed in the air curtain.

PLSAC

PLSRTX

SIRECJ4 / SIRECJ6

SIRECC

PAMLK

Control valves for water systems (optional)

Type Connection

VOS15LF DN15

VOS15NF DN15

VOS20 DN20

VOS25 DN25

VOT15 DN15

VOT20 DN20

VOT25 DN25

VAT

VOT

14

VOS

VAT

AC35

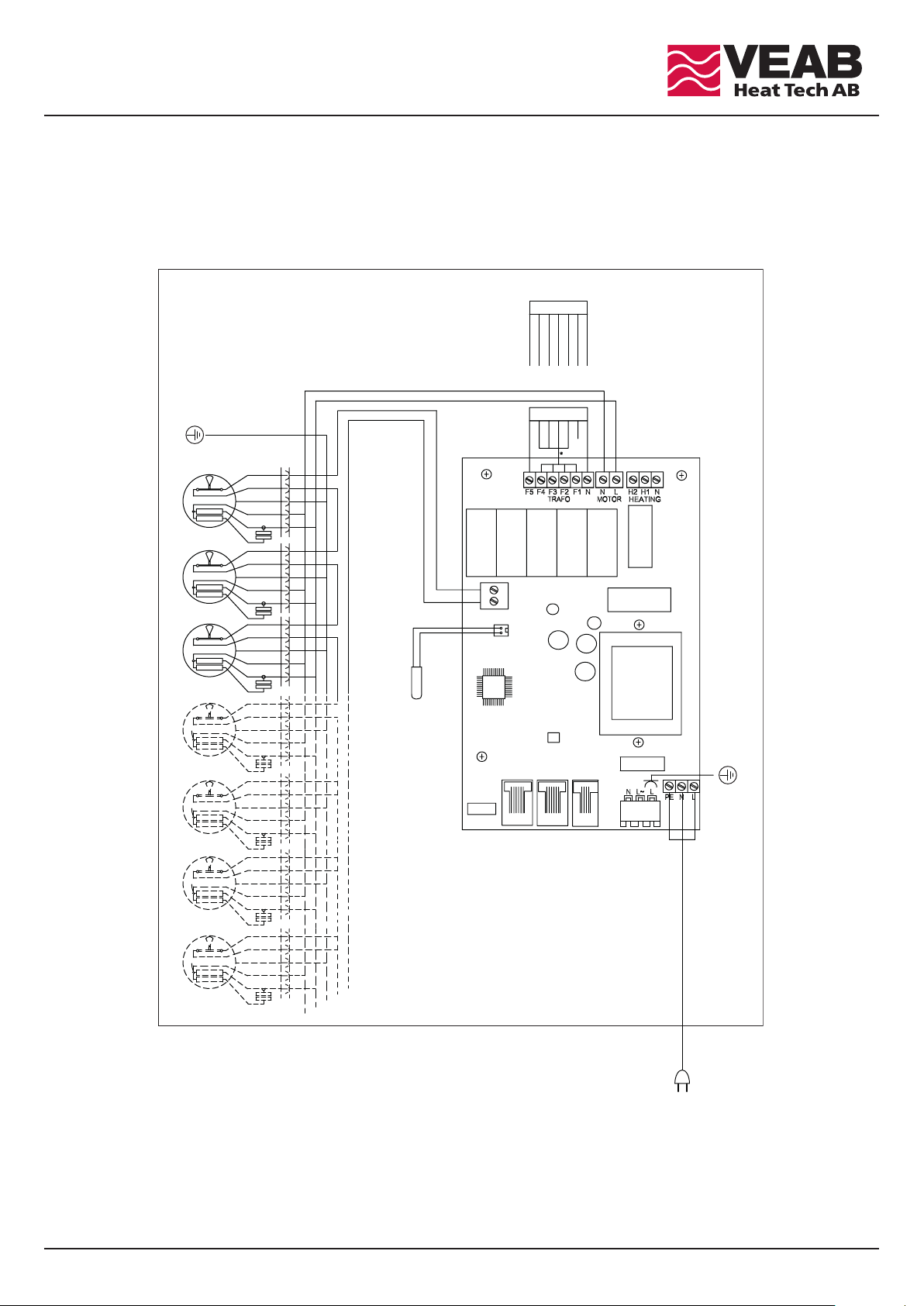

AC35-E

3520E/3525E

3510E/3515E

°C°C°C

PLSB1

Transformer

145V

170V

230V

200V

Yellow

Orange

Red

Brown

Transformer

145V

170V

230V

200V

120V

120V

Black

100V

Green

100V

N

N

Blue

Blue

400V3~

N N

400V3~

Grey

Blue

Black

Black

3510E

3515E

3520E

3525E

White

White

Motor

protection

sensor

Internal

°C°C°C°C

Actuator

C2

C1

ROOM

230V~

230V~

15

AC35

230V~

AC35-W

3510W

3515W

Transformer

230V

200V

Yellow

Orange

Transformer

230V

200V

°C°C°C

°C°C°C°C

White

White

PLSB1

Motor

protection

sensor

Internal

170V

Red

170V

145V

Brown

145V

120V

Black

120V

N

100V

Green

Blue

N

100V

Blue

Black

3520W

3225W

Actuator

Supply

230V~

C2

C1

ROOM

230V~

16

AC35

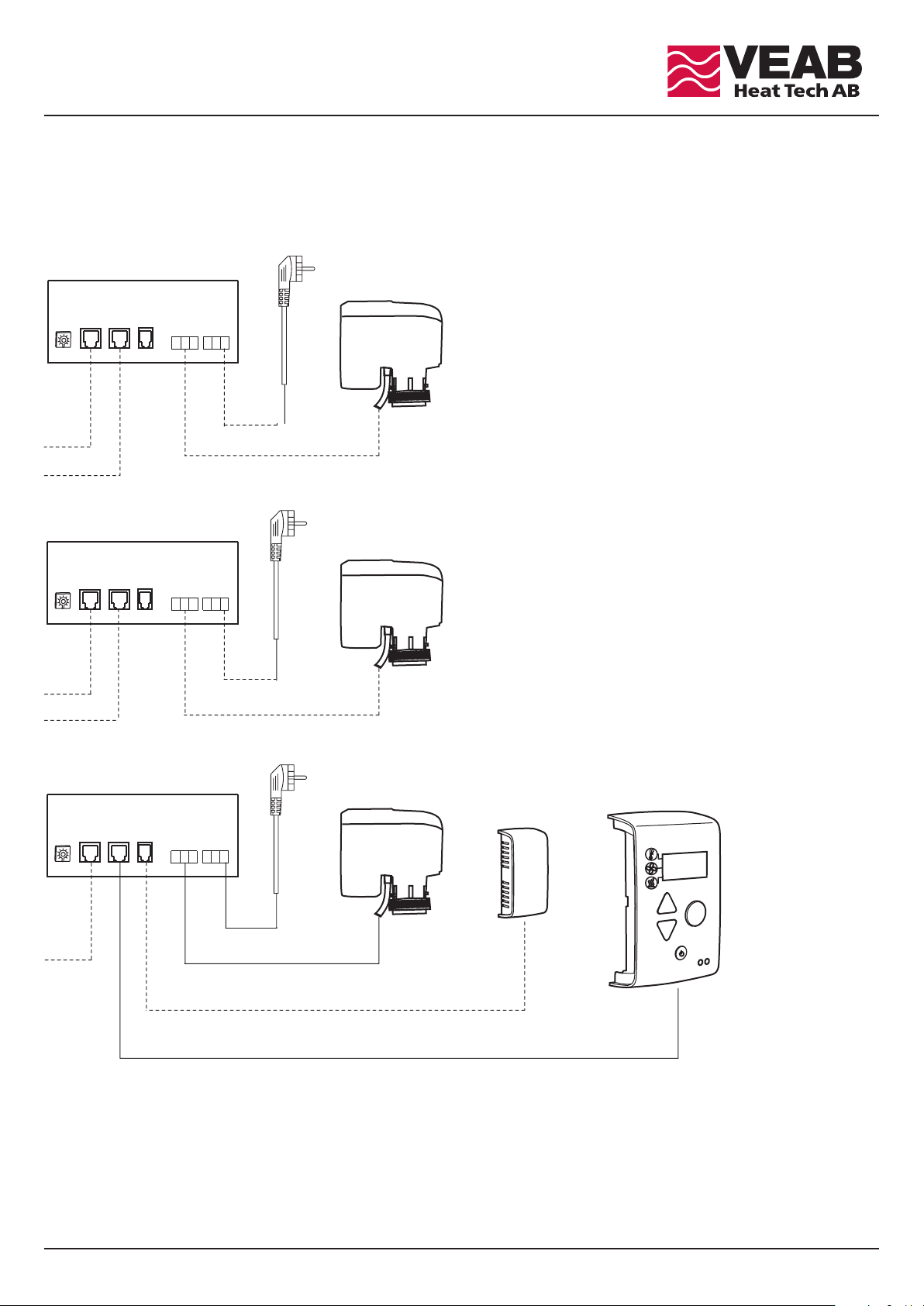

PLS Basic

AC35-E

PLSB1

230V~

Pot.

Unit ID

C2X5C1

ROOM

X3

X4

ACTUATOR

N L

PE

SUPPLY

PE

N

L

PLS Basic - Parallel connection

PLSRTX

(optional)

PLSUB1

PLSB1 PLSB1

Pot.

Unit ID

C2X5C1

ROOM

X3

X4

ACTUATOR

N L

PE

SUPPLY

PE

N

L

230V~

Pot.

Unit ID

C2X5C1

PLSRTX

ROOM

X3

X4

ACTUATOR

N L

PE

SUPPLY

PE

N

L

230V~

(optional)

PLSUB1

Wiring diagrams for PLSAC Competent, see manuals for PLS.

17

AC35

PLS Basic

AC35-W

PLSB1

Pot.

Unit ID

C2X5C1

SD230 PLSRTX

ROOM

X3

X4

ACTUATOR

N L

PE

SUPPLY

PE

N

L

230V~

(optional)

PLSUB1

C

18

AC35

PLS Basic - Parallel connection

AC35-W

PLSB1

SD230

C2X5C1

Pot.

Unit ID

PLSB1

C2X5C1

Pot.

Unit ID

ROOM

X3

X4

ACTUATOR

N L

SUPPLY

PE

PE

N

230V~

L

SD230

ROOM

X3

X4

ACTUATOR

N L

PE

SUPPLY

PE

N

230V~

L

PLSB1

SD230

Pot.

Unit ID

C2X5C1

ROOM

X3

X4

ACTUATOR

N L

PE

SUPPLY

PE

N

230V~

L

Wiring diagrams for PLSAC Competent, see manuals for PLS.

PLSRTX

(optional)

PLSUB1

19

AC35

NB: We reserve us from typographical errors and the right to make changes and improvements to the contents of this manual without prior notice.

VEAB H eat Tech AB

Box 265

S-281 23 H ässleholm

SWEDEN

Visitors adress

Stattenavägen 50

Delivery adress

Ängdalavägen 4

Org.no/F-skatt

556138-3166

VAT.n o

SE5 56138316601

Postal Cheque Ser vice

48 51 08- 5

Bank Transfer

926-0365

Fax

Int +46 451 410 80

E-mail

veab@veab.com

Phone

Int +46 451 485 0 0

Website

www.veab.com

20

Loading...

Loading...