Page 1

New Generation 2009

Flexible instrumentation with CAN bus technology

www.vdo.com

CANcockpit

Product Manual

VDO - eine Marke des Continental-Konzerns / VDO - Atrademark of the Continental Corporation

Page 2

Topic Chapter

Safety Instructions 1

Description of Functions 2

Installation Instructions 3

Testing Instructions ▼ 4

Software-Description 5

System Components, Spare Parts and Accessories 6

Data Sheets 7

General Information 8

Sales and Service Informations 9

▼ = will follow

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without

express authorization is prohibited. Offenders will be held liable for the payment of damages. All right reserved in the event of

the grant of a patent, utility model or design.

Overview of Chapter

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

TU00-0726-0000002

0609

Page 3

Technische Änderungen vorbehalten Technical details subject to change

1 - 1

TU00-0736-0000002

0609

1. Safety Instructions

Product Manual

Contents

Contents

1.1 Installation 2

Before installation 2

During installation 3

After installation 3

1.2 Electrical Connection 4

1.3 Sensors 5

1.3.1 Pressure Sensor for Oil 5

1.3.2 Temperature Sensor for Oil 6

1.3.3 Temperature Sensor for Engine Coolant 7

1.3.4 Fuel Level Sensor (Lever Type Sensor/Tubular Type Sensor) 8

Page 4

1.1 Installation

• The product is only designed for use in land-bound vehicles (except motorcycles).

• Make sure that the engine cannot be unintentionally started during installation.

Before installation

• Withdraw ignition key from ignition lock.

• Note down all data in temporary electronic memories.

• Before installation refer to the vehicle documents for details of vehicle type and any special features.

• Refer to the construction diagrams to find out the positions of the fuel/hydraulic/pneumatic and electrical lines.

• Take account of any modifications to the vehicle which have to be considered during installation.

• Failure to use the product correctly may cause harm to people, property and the environment. Therefore make sure you

use our product correctly.

• Basic knowledge of vehicle electrics and mechanics is necessary for installation to prevent harm to people, property and

the environment.

• The product has been developed, manufactured and tested in accordance with the basic safety requirements of EC directives and the acknowledged state of the art.

• Short circuits

Short circuits in the vehicle's wiring can cause cable fires, battery explosions and damage to other electronic systems.

Therefore disconnect the minus pole of the vehicle battery before starting work.

If the vehicle has supplementary batteries, the minus poles of these batteries should also be disconnected.

• Modifying or tampering with the product may affect safety. Therefore it must not be modified or tampered with.

• When removing/installing seats, covers and the like, make sure that you do not damage lines or release plug connections.

• Possible data loss

When the batteries' minus poles are disconnected, all the temporary electronic memories lose their entered data.

Therefore, note down all the relevant data for re-programming before disconnection.

1. Safety Instructions

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

1 - 2

TU00-0736-0000002

0609

No smoking!

No naked flames or lights!

Page 5

1.1 Installation

During installation

• During installation make sure that the product's components do not affect or restrict vehicle functions and are themselves not damaged.

• Only install undamaged parts in vehicles.

• During installation make sure that the product does not impair the field of vision and that the product is not positioned

within the impact range of the driver's or passenger's heads.

• When selecting the installation location, make sure there is sufficient space behind the drilled holes and the installation

opening.

• Take account of the routing of lines and cable leads.

• Do not select an installation location within the mechanical and electrical range of the airbag.

• Do not drill holes or cut openings in load-bearing or stabilizing struts or members.

• Err on the small side when predrilling installation apertures with cone-type cutters, compass or jig saws, or files, enlarge if necessary and complete. Deburr edges. Always follow the tool manufacturer's safety instructions.

• When working beneath the vehicle, secure the vehicle in accordance with the vehicle manufacturer's instructions.

• If any work is necessary while the engine is running, take special care. Only wear suitable working clothes because of

the risk of injury due to pinching and burning. Long hair should be worn in a hair net.

• Only use the envisaged multimeters or diode-test lamps to measure wattages and currents in motor vehicles. The use

of conventional test lamps can cause damage to control units and other electronic systems.

After installation

• Firmly connect the earth cable to the minus pole of the vehicle battery.

• (Re-)program the data in the temporary electronic memories.

• Test all(!) vehicle functions.

• CANcockpit components to be cleaned with clear water only.

Observe the IP-degrees of protection (DIN 40050).

1. Safety Instructions

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

1 - 3

TU00-0736-0000002

0609

Page 6

1.2 Electrical Connection

• Take account of the cable cross section

A reduction in the cable cross section results in a higher current density. This can cause the cable to heat up.

• When laying electric cables, use existing cable ducts and routes but without laying cables parallel to ignition cables or

cables leading to high current consumers. Fix the cables with cable tape or adhesive tape.

• Do not route cables over mobile components. Do not fasten cables to the steering column.

• Make sure that the cables are not exposed to tensile, compressive or shear forces.

• If the cables are routed through drilled holes, protect them with rubber sleeves or the like.

• Strip cables only with a cable stripper. Adjust the stripper so that no strands are damaged or severed.

Solder new cable connections only with the soft soldering process or use standard crimp connectors.

• Crimp connections should only be made with a crimping tool. Follow the tool manufacturer's safety instructions.

• Insulate exposed strands so that no short circuiting can occur.

• Faulty wiring can cause short circuiting. Wire the cables only in accordance with the electrical connection diagram.

1. Safety Instructions

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

1 - 4

TU00-0736-0000002

0609

Connect the cables in accordance with the electrical connection diagram.

Page 7

Technische Änderungen vorbehalten Technical details subject to change

1 - 5

TU00-0736-0000002

0609

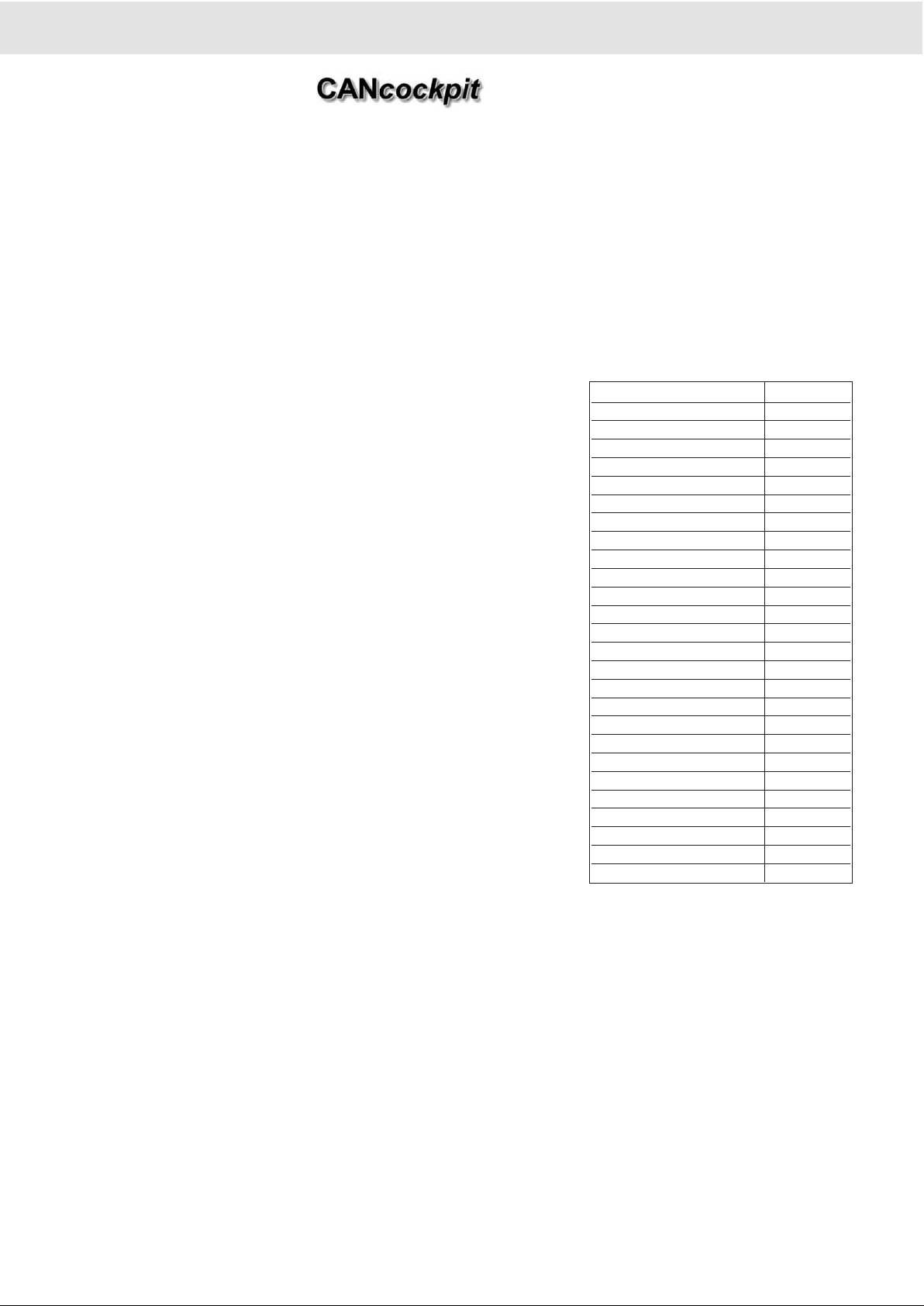

1.3 Sensors

1.3.1 Pressure Sensor for Oil

❒ Sensor installation location: At the place provided by the engine manufacturer, equipment manufacturer or car manu-

facturer in the oil circulation system (most often in place of the oil pressure switch).

❒ Sensor installation only when engine is cold.

❒ When removing the oil pressure switch or the screw from the drilled hole for the oil pressure measuring system, collect

the oil running out of the system in a proper container and dispose of it in accordance with legal regulations.

max.

❒ The values mentioned in the following table for the maximum tightening

torque (Nm max.) refer exclusively to the load-bearing capacity of products.

Prior to using the product, it is important to ask the manufacturer of the vehicle, equipment system or engine in each instance for the maximum torque (? Nm max.) value for the threaded hole into which the product is to be

screwed. Non-observance of the maximum tightening torque specified for

the threaded hole in each instance can result in damage to the vehicle, engine or equipment system.

❒ If the connection thread is cylindrical, a sealing washer or a sealing ring made of copper must be fitted.

❒ Following sensor installation, fill up the system with the required quantity of specified oil.

1. Safety Instructions

Product Manual

M10 x 1 30 Nm

1/8 in. BSPF 30 Nm

1/8 - 27 NPTF 30 Nm

R 1/8 DIN 2999 30 Nm

M12 x 1,5 40 Nm

M12 x 1 50 Nm

M14 x 1,5 50 Nm

1/4 in. BSPF 60 Nm

1/4 - 18 NPTF 60 Nm

3/8 - 18 NPTF 60 Nm

M16 x 1,5 80 Nm

3/8 - 18 Dryseal NPTF 80 Nm

M18 x 1,5 100 Nm

Page 8

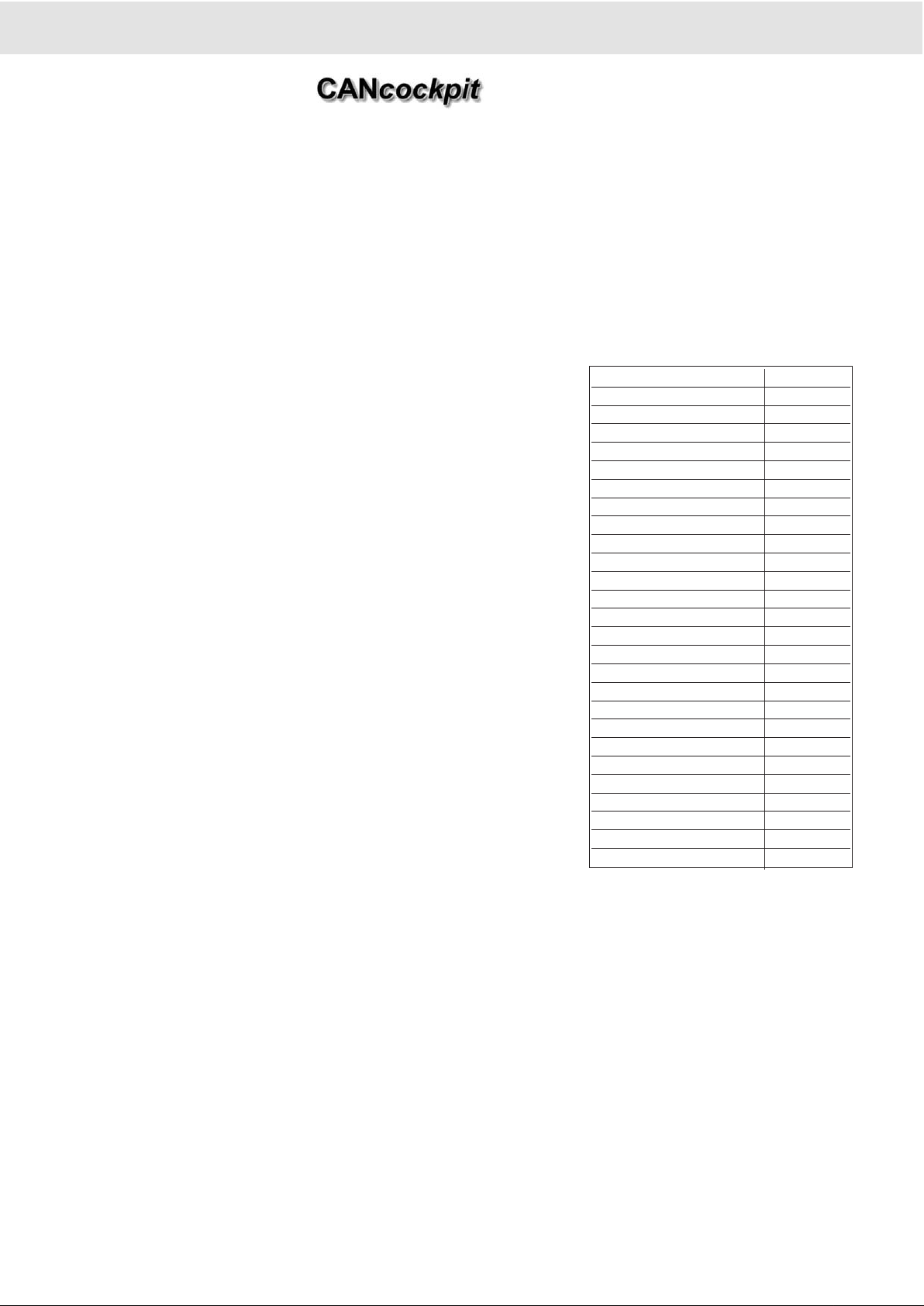

1.3 Sensors

1.3.2 Temperature Sensor for Oil

❒ Sensor installation location: At the place provided by the engine manufacturer, equipment manufacturer or car manu-

facturer in the oil circulation system (e. g. oil drain plug).

❒ Sensor installation only when engine is cold.

❒ When removing the oil drain plug, collect the oil running out of the system in a proper container and dispose of it in ac-

cordance with legal regulations.

max.

❒ The values mentioned in the following table for the maximum tightening tor-

que (Nm max.) refer exclusively to the load-bearing capacity of products.

Prior to using the product, it is important to ask the manufacturer of the vehicle, equipment system or engine in each instance for the maximum torque (? Nm max.) value for the threaded hole into which the product is to be

screwed. Non-observance of the maximum tightening torque specified for

the threaded hole in each instance can result in damage to the vehicle, engine or equipment system.

❒ If the connection thread is cylindrical, a sealing washer or a sealing ring made of copper must be fitted.

❒ Following sensor installation, fill up the system with the required quantity of specified oil.

1. Safety Instructions

M10 x 1 10 Nm

M10 x 1.5 10 Nm

1/8 - 27 NPTF 10 Nm

M12 x 1.5 15 Nm

1/2 - 20 Gang 15 Nm

M14 x 1.25 20 Nm

M14 x 1.5 20 Nm

5/8 - 18 UNF - 3A 20 Nm

1/2 In. 20 Whit. S 20 Nm

1/4 - 18 NPTF 20 Nm

M16 x 1.5 30 Nm

M18 x 1.5 30 Nm

M20 x 1.5 30 Nm

M22 x 1.5 30 Nm

M24 x 1.5 30 Nm

M26 x 1.5 30 Nm

1/2 - 14 NPTF 30 Nm

3/8 - 18 NPTF 30 Nm

R 1/2 30 Nm

R 3/8 30 Nm

3/8 - 18 Dryseal NPTF 30 Nm

3/4 - 16 UNF-3A 30 Nm

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

1 - 6

TU00-0736-0000002

0609

Page 9

1.3 Sensors

1.3.3 Temperature Sensor for Engine Coolant

❒ Sensor installation location: At the place provided by the engine manufacturer, equipment manufacturer or car manu-

facturer in the coolant circulation system (e.g. in place of the temperature warning switch) or in the coolant hose.

❒ Sensor installation only when engine is cold.

❒ Collect the coolant running out of the system in a proper container and dispose of it in accordance with legal regulations.

max.

❒ The values mentioned in the following table for the maximum tightening tor-

que (Nm max.) refer exclusively to the load-bearing capacity of products.

Prior to using the product, it is important to ask the manufacturer of the vehicle, equipment system or engine in each instance for the maximum torque (? Nm max.) value for the threaded hole into which the product is to be

screwed. Non-observance of the maximum tightening torque specified for

the threaded hole in each instance can result in damage to the vehicle, engine or equipment system.

❒ If the connection thread is cylindrical, a sealing washer or a sealing ring made of copper must be fitted.

❒ Following sensor installation, fill up the system with the required quantity of the compositon specified coolant.

1. Safety Instructions

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

1 - 7

TU00-0736-0000002

0609

M10 x 1 10 Nm

M10 x 1.5 10 Nm

1/8 - 27 NPTF 10 Nm

M12 x 1.5 15 Nm

1/2 - 20 Gang 15 Nm

M14 x 1.25 20 Nm

M14 x 1.5 20 Nm

5/8 - 18 UNF - 3A 20 Nm

1/2 In. 20 Whit. S 20 Nm

1/4 - 18 NPTF 20 Nm

M16 x 1.5 30 Nm

M18 x 1.5 30 Nm

M20 x 1.5 30 Nm

M22 x 1.5 30 Nm

M24 x 1.5 30 Nm

M26 x 1.5 30 Nm

1/2 - 14 NPTF 30 Nm

3/8 - 18 NPTF 30 Nm

R 1/2 30 Nm

R 3/8 30 Nm

3/8 - 18 Dryseal NPTF 30 Nm

3/4 - 16 UNF-3A 30 Nm

Page 10

1.3 Sensors

1.3.4 Fuel Level Sensor (Lever Type Sensor/Tubular Type Sensor)

❒ An installation opening remaining to be made in the tank at a suitable point for supply level measurement or at an in-

stallation flange or installation opening already provided by the tank manufacturer.

❒ If an installation opening must be made, the tank must be completely drained first. Fill the fuel into an approved contai-

ner.

❒ Risk of explosion exists due to presence of residual gases in the tank! Make sure that the tank is aired

sufficiently (approx. 10 minutes).

❒ Make a preliminary hole in the installation opening using a drill and then finish the hole using a compass saw or piercing

saw. Comply with the safety instructions of the tool manufacturer. Clean the tank of residue from the drilling or sawing

work.

❒ The safety instructions given by the welding equipment manufacturer and the working regulations applying to welding

work must be respected when welding the tank flange.

1. Safety Instructions

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

1 - 8

TU00-0736-0000002

0609

Page 11

Technische Änderungen vorbehalten Technical details subject to change

2 - 1

TU00-0736-0000002

0609

Contents

Contents

1. System 3

1.1 Main Features 3

1.1.1 Block Diagram CANcockpit 3

1.2 Mechanical Concept 3

1.3 Safety Concept 4

1.3.1 Sensors 4

1.3.2 System Check 4

1.3.3 Satbus 4

1.3.4 WINgauge 4

2. Master Gauges 5

2.1 General Features 5

2.1.1 Main Functions 5

2.2 Mechanical Concept 6

2.2.1 Master dia. 80 mm 6

2.2.2 Master dia. 85 mm 6

2.2.3 Master dia. 100 mm 6

2.3 Input Signal Processing 7

2.3.1 Analog Inputs 7

2.3.1.1 Grounding Concept 7

2.3.1.2 Sensors 7

2.3.2 Input Signal Processing applied to the two frequency inputs 7

2.3.3 Input Signal Processing for CANbus messages 8

2.4 PIN Assignment Description 9

2.4.1 Technical Description 9

2.5 Display Functions 12

2.5.1 Navigation through Display 12

2.5.2 Display Layout 12

2.5.3 Display Functions 14

2.5.3.1 Main Display (Odometer, Hourmeter) 14

2.5.3.2 Alarm Display 14

2.5.3.3 CAN DTC Display 15

2.5.3.4 Warning Display 15

2.5.3.5 Service Message 16

2.5.3.6 Physical Value Display 16

2.5.4 Alarm- and Warning Functions 17

2.5.4.1 Description of the Outputs 17

2.5.4.2 Switch Output Acknowledgement Function 17

2.5.4.3 Alarm and Warning Trigger Conditions 18

2.5.4.4 Alarm and Warning Trigger enabling with Engine running 18

2.5.4.5 Alarm and Warning State Diagram (Maximum Value Algorithm) 19

2. Functional Specification

Product Manual

Page 12

2.5.5 Service 21

2.5.5.1 Reset of Service messages 21

2.5.6 CAN (SAE J1939) DTC (Diagnostic Trouble Codes) messages 22

2.5.6.1 CAN SAE J1939 Elements 22

2.5.6.2 CAN DTC Information Display Requirements 23

2.5.6.3 CAN DTC Display Functions 23

2.5.6.4 Speedometer Master Gauge 25

2.5.6.5 Tachometer Master Gauge 27

3. Satellite Gauges 28

3.1 Mechanical concept 28

3.2 Fault modes 28

3.3 Satellite gauge address 29

3.4 Warning Lamp inside the Satellite Gauge 29

3.5 Tolerance 29

A. Technical Data 30

B. Applied Standards 31

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 2

TU00-0736-0000002

0609

Page 13

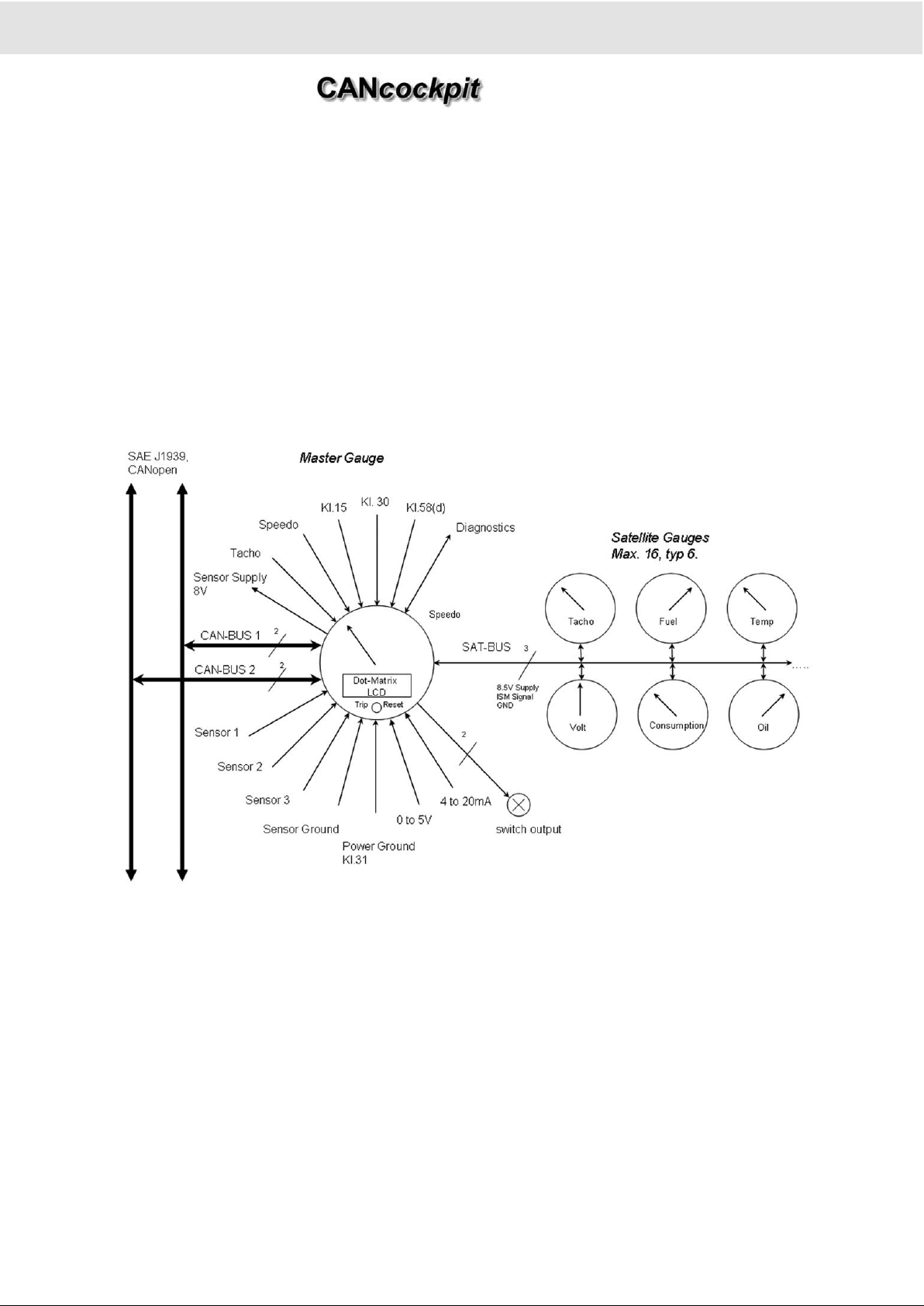

1. System

1.1 Main Features

• Master-Slave relationship between Master gauge and other instruments

• Up to 16 Slave functions on one Master instrument or 32 with the use of two Master instruments

• CAN protocol flexibility ( processing two protocols simultaneously)

• Modular "plug & play" as needed

• Analogue sensor compatible

• Frequency inputs

• Dot-matrix information display

• Switch outputs available

• Flexible to customer needs

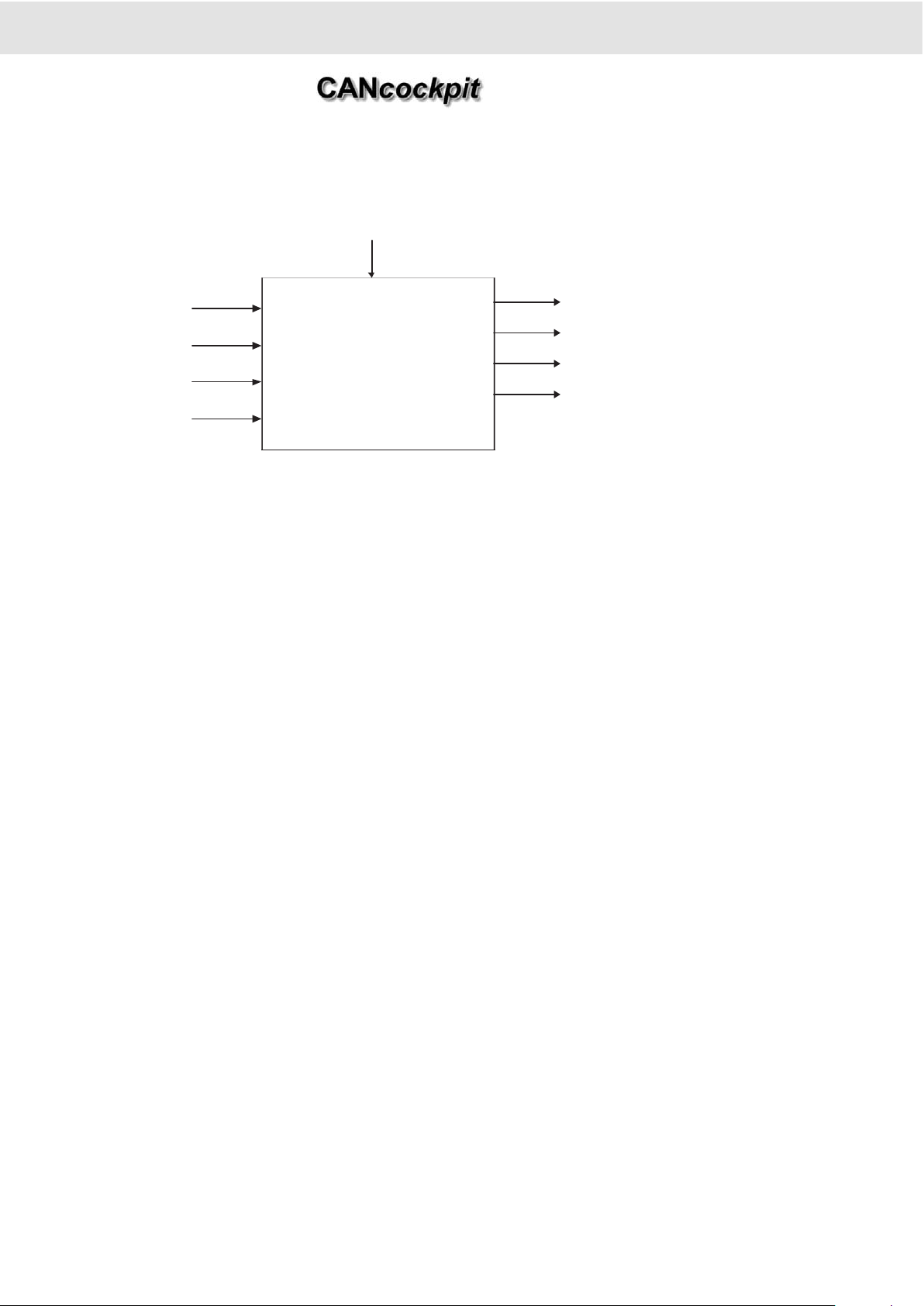

1.1.1 Block Diagram CANcockpit

1.2 Mechanical Concept

The Masters are 80, 85 and 100 mm in diameter, the Satellite gauges dia. 52, 80 and 100 mm.

The dials are translucent backlighted. The illumination of the gauges is realised with white LED's.

The backlighting of the LCD has a yellow LED. The warning lamp in the slave can have a red or yellow LED.

The housing and bezel are made of non-flammable plastic, the design is like a triangle with the black color RAL 9005. The be-

zel is clipable. The lens is flat and frosted. The pointer has a PC hub in black and the pointer arm is OL5105 (white -coated on

the underside). The pointer type is translucent illuminated.

The housings have an indent in the thread at 6 o'clock position, so that an optional key can be

used according to SAE J1226 and SAE J 1399.

The movements are front-mounted stepper motors MW2000, only clockwise indication.

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 3

TU00-0736-0000002

0609

Page 14

1.3 Safety Concept

1.3.1 Sensors

Analog sensors can be checked for short and open circuit.

1.3.2 System Check

When the trip-reset button is pressed while ignition is being turned on, the system-check function is activated and clears the

contents of the DTC List.

If there are any active service messages, they will be displayed on the Dot-Matrix Display starting with the first active service

message. If the reset button is then pressed and held for 5 seconds or longer, this service message will be reset. The next

active service message is displayed thereafter.

To proceed to the next active service message without resetting the displayed code, the button needs to be pressed shortly

(<5 sec). If all active service codes have been displayed, the system check function is started as described below:

1. All warning lamps and illumination of all gauges are activated for 3 seconds.

2. The Master gauge initializes all configured satellite gauges and waits until they are ready or a Satbus timeout occurs.

3. During time.this, all LCD-Dots are turned on for about 1.5 sec, all pointers are moved to their end value

4. Then all LCD-Dots are turned off and the pointers move back to zero, for about 1.5 sec too, and all warning lamps and

illumination will be turned off

5. Firmware version and Check sum of the EEPROM in hexadecimal format are displayed for about 10 sec.

The display format is as follows:

XX represents a hex-coded value

1.3.3 Satbus

After ignition for synchronisation the Master gets feedback from the satellites.

A timeout function can be programmed too. If more satellites are configured, the Master will not get feedback from all gauges.

After a timeout of about 14 seconds, the Master will act as described before, when the Master gets feedback from all satellites.

During normal operation there is no feedback from the satellites.

1.3.4 WINgauge

A system diagnosis function for testing all in- and outputs is implemented in the WINgauge Software.

2. Functional Specification

Product Manual

Small

display

line

Format Description

2 hXX sXX.XX dd_mm_yyyy hXX specifies the Hardware version relevant to the Firmware

sXX.XX refers to the Firmware version, for example s12.A8 stands for V06

dd_mm-yyyy is the Firmware date in day, month and full-year format.

4 nXXXXwXXyXX cXXXXXX nXXXX is the WINgauge serial number of the device as programmed into the

EEPROM.

wXXyXX displays the production week and year in short format.

cXXXXXX shows the actual 3-byte Checksum of the EEPROM as calculated during

the system check.

Technische Änderungen vorbehalten Technical details subject to change

2 - 4

TU00-0736-0000002

0609

Page 15

Technische Änderungen vorbehalten Technical details subject to change

2 - 5

TU00-0726-0000002

0609

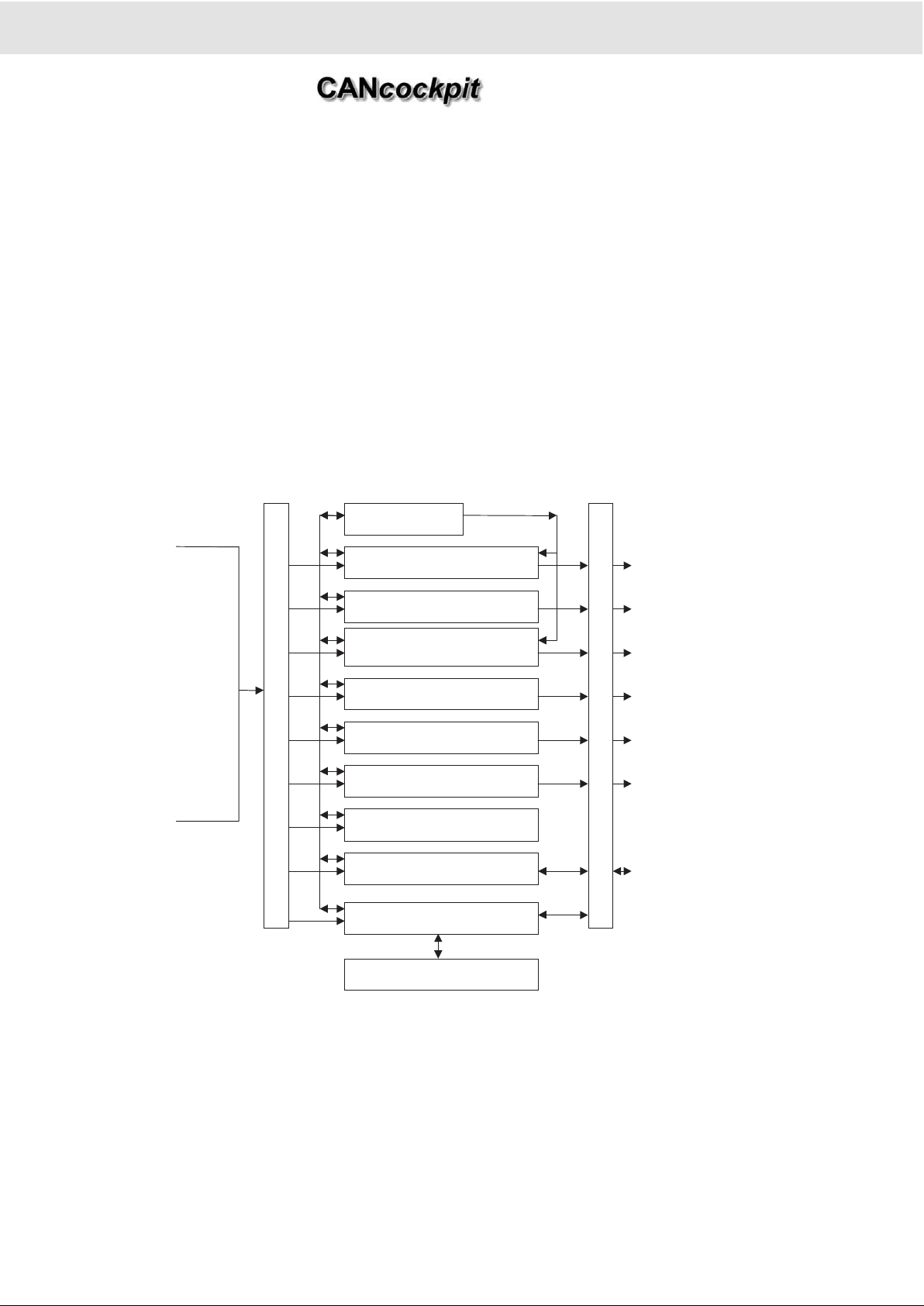

2. Master Gauges

2.1 General Features

The design concept for this design includes:

• 2x High-speed Full-CANbus interface V2.0B compatible.

• Half-duplex serial link to satellite gauges.

• VMC SCAL CDVV Microcontroller with identical firmware.

• Stepper motor MW2000 directly controlled by Microcontroller.

• Satellite gauges use SM2 stepper motor driven by ISM IC.

• LED illumination concept.

• 132 x 33 dots matrix LCD.

• Wide input voltage range switch mode power supply.

• Diagnostic Interface for configuration.

2.1.1 Main Functions

2. Functional Specification

Product Manual

Inputs

Outputs

CAN_1

CAN_2

Frequency_1

Frequency_2

Sensor Input_1

Sensor Input_2

Sensor Input_3

4 to 20 mA

Voltage Input

Illumination

term.15

term.30

Inp

ut

Sig

nal

Pr

oc

es

sin

g

Analogue Gauge Functions

W arning Fu nc ti ons

Odomete r,

Tripmeter

Hourmeter

,

Triphourmeter

Service Intervals

Illumination Control

Power Supply Control

Parameter Memory (EEPROM)

Diagnostics

Frequency-Divider

Ou

tpu

t

Sig

nal

Pr

oc

es

sin

g

Flash-Boot-Loader

Intern al MW2000

SatBus

-Gauges

LCD

Sat-Gauge Warning Lamps

Switch Output_1

Switch Output_2

LCD

LCD

Master Gauge Illumination

SatBus

-Gauge Illumination

Master Gauge Supply

SatBus

Supply

Sensor Supply

K-Line Diagnostic s

Diagnostic Trouble Codes

Page 16

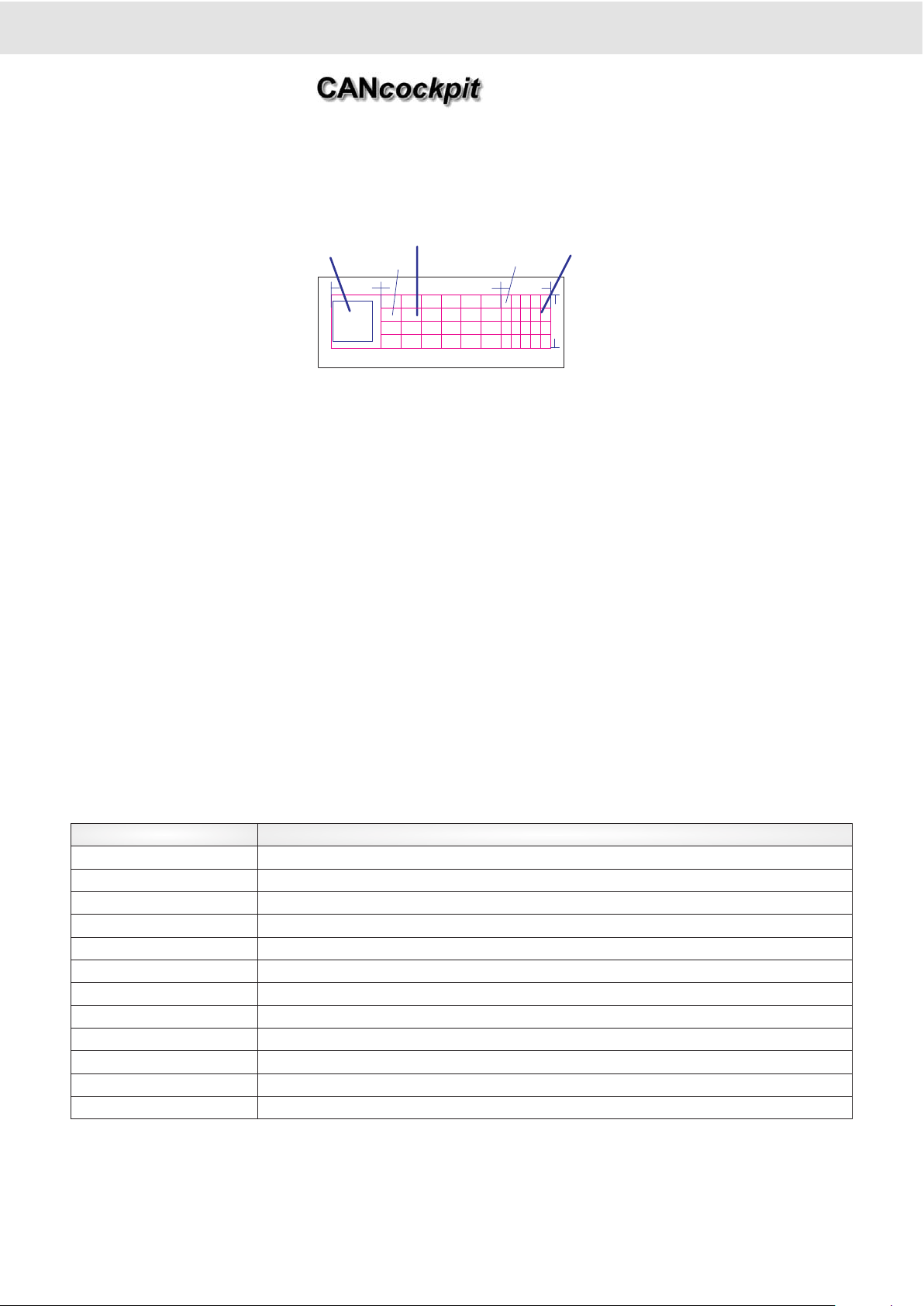

2.2 Mechanical Concept

As the same LCD is used for different Master gauge diameters the pointer position has different eccentricities and indication

angles.

The connectors are 26-Pin MODU II-Connector and 4-Pin MATE-N-LOK from AMP.

2.2.1 Master dia. 80 mm

Two PCB's are necessary for this diameter. They are connected with a standard pin connector

and two distance towers.

2.2.2 Master dia. 85 mm

The PCB assemblies and their corresponding parts of the Ø 80 mm and Ø 85 mm gauges are identical. The difference between the two gauges is the position of the stepper motor on the PCB so that the eccentricity of 7 mm in the Ø 80 mm gauge

can be reduced to 4.5 mm in the Ø 85 mm gauge.

2.2.3 Master dia. 100 mm

For this size, only one PCB assembly is necessary. Input Signal Processing.

Gauge diameter [mm] Eccentricity [mm] Indication angle

80 7 210°

85 4.5 216°

100 0 206°

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 6

TU00-0726-0000002

0609

Page 17

2.3 Input Signal Processing

2.3.1 Analog Inputs

All sensor characteristics can be defined with the WINgauge Software.

2.3.1.1 Grounding Concept

The Master gauge has two main ground lines. Ground term.31 is connected to the vehicle's body (negative battery terminal)

and Sensor Ground is supplied from the instrument; insulated return sender are necessary. The Sensor Ground should not be

connected to vehicle ground, which would result in a higher current flowing through this line and thus produce a signal noise

and measurement error. Sensor Ground and Ground term.31 are joined together inside the Master Gauge. This grounding

principle is necessary to accurately measure analog values. Ground shift on Sensor Ground is minimized by this concept.

2.3.1.2Sensors

The static and dynamic voltage drop of the sensors should not exceed 0.5 V.

Pressure: 10 - 184 Ohms

Temperature: 10 - 700 Ohms

Fuel lever type: 3 - 180 Ohms

Fuel dip-pipe: 0.5 - 90 Ohms

Other sensors: 4 - 20 mA

Other sensors: 0 - 5 V

2.3.2 Input Signal Processing applied to the two frequency inputs

Frequency 1:

The standard modules can be changed to 500 < k < 400 000 pulses/km or miles for the Speedometer

and 0.5 - 400 pulses/rev for the Tachometer.

Maximum frequency is 40 kHz (2 kHz via internal divider).

Frequency 2 as Hall Sensor / Terminal W:

500 < k < 65000 pulses/km or miles for Speedometer and 0.5 - 65 pulses/rev for Tachometer.

Maximum frequency is 2 kHz.

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 7

TU00-0726-0000002

0609

,

Fuel

Sender

Oil Pressure

Sensor

Engine-

Temperature

Vehicle

Sensor-Ground

Chassis GND

Gauge2000 System

Ground Term.31

CANcockpit System

Page 18

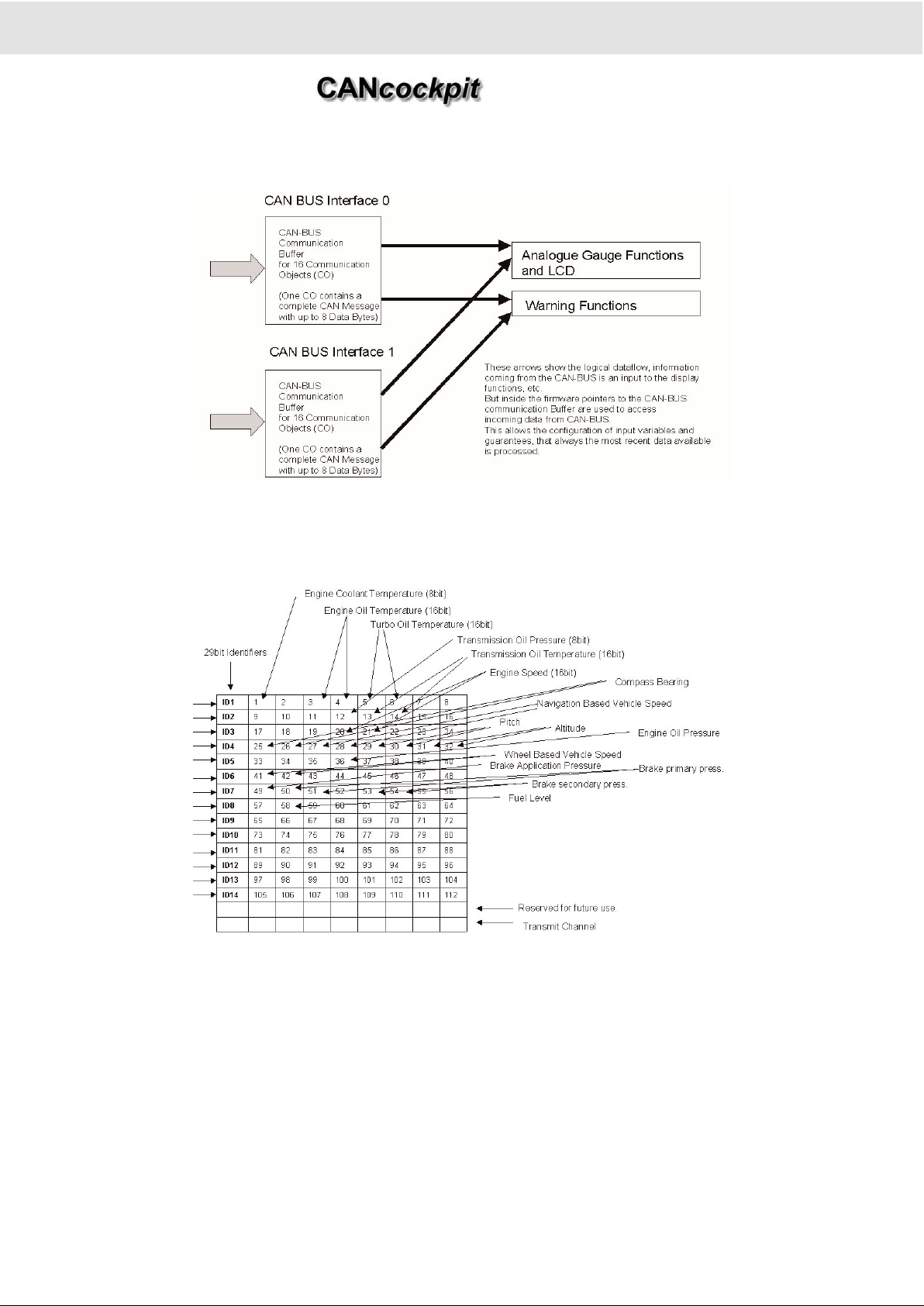

2.3.3 Input Signal Processing for CANbus messages

Example of SAE J1939 Messages received on one of the two CANbus Interfaces.

The Master Gauge CANbus interface conforms to CAN 2.0B specification and supports extended (29Bit) identifiers. The

Gauge acts as a "Standard ECU, which is non-configurable as defined in SAE J1939. The application layer is based on SAE

J1939/71 Rev 2008-01.

Additional communication protocol is CAN Open

For this the different CANbus data bases will be provided by the WINgauge configuration.

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 8

TU00-0726-0000002

0609

Page 19

Technische Änderungen vorbehalten Technical details subject to change

2 - 9

TU00-0726-0000002

0609

2.4 PIN Assignment Description

Master:

2.4.1 Technical Description

PIN 1: Power Supply (terminal 30)

V

Batt

= + 10,5 V to + 32 V

The instrument is supplied with permanent power through this terminal. Current consumption varies depending on the instruments operating mode (standby or active) and number of Slaves.

PIN 2: Ground (terminal 31)

Power ground of the instrument.

PIN 3, 4: CANbus Interface 1

High-Speed Full CANbus V2.0B compatible (10, 20, 50, 125, 250, 500 kbit/s, 1 Mbit/sec.).

12 V and 24 V system compatible.

Cable: shielded, twisted pair with a drain.

Cable Impedance: nom. 120 Ω.

Topology: linear Bus

Trunk Length: max. 40 meters

Drop Length: max. 1 meter

Termination: 2 resistors 120 Ω at each end of the bus.

Related documents: ISO 11898, SAE J1939/11

U

A combination of 29 bit ID and 11 bit ID can`t be processed!

PIN 5, 6: CANbus Interface 2

See on CANbus Interface 1.

PIN 7: Not connected

PIN 8: K-Line Diagnostic Interface

Programming of the EEPROM and the diagnostics carried out via serial diagnostic interface K-Line.

PIN 9, 25: Analog Input 1

Range: 0.5 - 200

Ω

Standard sensors: Tube-type Sensor: 0,5 Ω to 90 Ω

Lever-type Sensor: 3 Ω to 180 Ω.

Sensor has to be connected between theese pins.

PIN 10, 25: Analog Input 2

2. Functional Specification

Product Manual

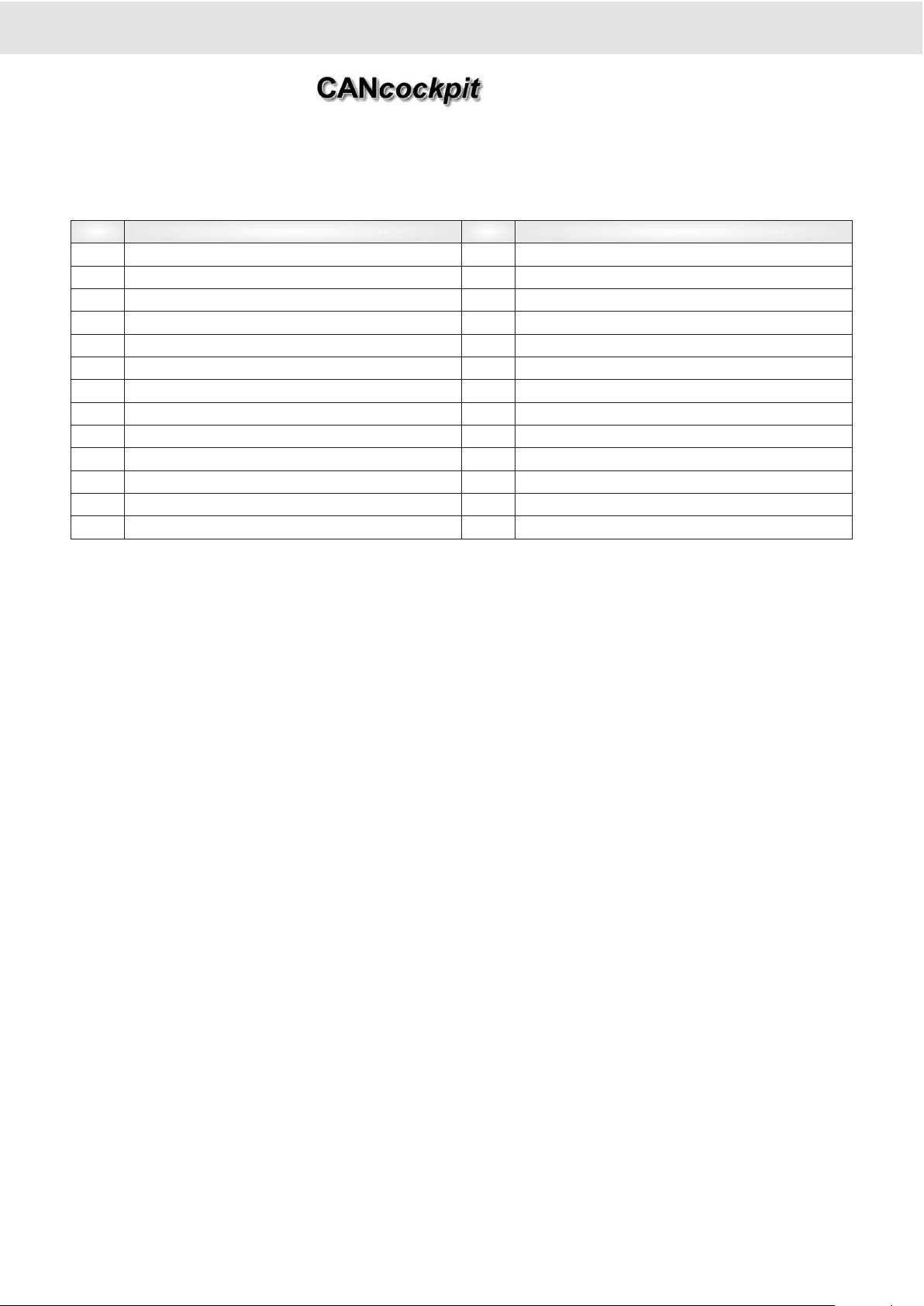

Pin Description Pin Description

1 Power Supply (terminal 30) 14 + 8 V DC for sensor supply

2 Ground (terminal 31) 15 0 - 5 V DC Input

3 CAN1 _High 16 Illumination (terminal 58 (d))

4 CAN1 _Low 17 Ignition (terminal 15)

5 CAN2 _High 18 Frequency Input 2 (0-2 kHz)

6 CAN2 _Low 19 Frequency Input 1 (0-40 kHz)

7 NC 20 Switch-Output_1

8 k-Line 21 Switch-Output_2

9

Analog Input 1 (0,5 - 200 Ω)

22 NC

10

Analog Input 2 (0,5 - 300 Ω)

23 NC

11

Analog Input 3 (10 - 700 Ω)

24 External Switch

12 4 - 20 mAInput 25 Analog GND

13 4 - 20 mAGND 26 Frequency GND

Page 20

Range: 0.5 - 300 Ω

Standard sensors: Pressure sensor(10 - 184 Ω)

Sensor has to be connected between theese pins.

PIN 11, 25: Analog Input 3

Range: 10 - 700

Ω

Standard sensors: Temperature sensor (38 - 700 Ω)

Sensor has to be connected between theese pins.

PIN 12, 13: 4 to 20 mA Input

Range: 4 to 20 mA

A resistor converts the 4 - 20 mA current into proportional voltage. Results are sampled every 31.25 msec by the

Microprocessor.

PIN 14: +8 V sensor power supply:

Voltage: +8 V - 0 %, +10 %

Max. current: 50 mA

U

This output can be used only at 24 V power supply.

PIN 15: 0 - 5 V Input :

Range: 0 - 5 V

Results are sampled every 31.25 msec by the Microprocessor.

PIN 16: Illumination Input (terminal 58 (d):

Range: 0 to U

Bat.

(battery voltage)

Dimming of Master gauge illumination and attached Satellite gauges is controlled by the voltage amplitude at the Illumination

input.

PIN 17: Ignition (terminal 15)

Vign.= + 10,5 V to + 32 V

The Microprocessor senses the voltage at the input and turns it into active mode, if the ignition is turned on.

PIN 18, 26: Frequency Input 2

Hall Sensor and terminal W:

Max. Frequency: 2 kHz

U high min.: 5 - 7 V according to the configurated pulses

Signal type: square, sinus

Max. offset: 0.5 V

Off current max.: 100 µA

Duty cycle: 50 ± 15 %

Pulse ratio: 500 - 65 000 pulses/km or miles

Pulse/rev: 0.5 - 65 pulses/revolution

The Instrument has a pull-up resistor at the ignition in the input circuit. Input can be either road speed or engine speed.

Selection by configuration.

U

Only one frequency input (either Input 1 or 2) can be defined as road speed input.

PIN 19, 26: Frequency Input 1

Universal Frequency Input

Max. Frequency: 40 kHz (2 kHz via internal divider, 1:1; 1:2; ... 1:20)

U

high

min: 1.5 - 10 V according to the configurated pulses

Signal type: square, sinus

Max. offset: 0.5 V

Off current max.: 100 µA

Duty cycle: 50 ± 15%

Pulse ratio: 0.5 - 400 pulses/revolution

The instrument has a pull-up resistor at ignition in the input circuit. Input can be either road speed or engine speed. Selection

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 10

TU00-0726-0000002

0609

Page 21

by configuration. An adjustable frequency divider reduces input frequency, so that it can be processed by the Microprocessor.

U

Only one frequency input (either Input 1 or 2) can be defined as road speed input.

PIN 20: Switch Output 1

Maximum voltage: 32 V

Maximum current: 0.5 A

Warning lamp to be connected between output and supply voltage (terminal 15 or terminal 30).

Switch output controlled by the Microprocessor. The pin turns the output either on or off (static). The output is an open drain

and acts like a low switch to ground.

U

Save against high current with a Fuse 0.5 A!

PIN 21: Switch Output 2

Identical with Switch output 1

PIN 22: Not connected

PIN 23: Not connected

PIN 24: External Switch

Switch has to be connected between this pin and GND

Satellite

PIN 1-3: Satellite Bus Interface (Satbus):

Bus signal levels: 5 V ± 10%

Ground reference: ± 100 mV

Max. Bus length: 10 m

Cable impedance: Standard cable

Connector: 4-Pin MATE-N-LOK AMP

Satbus is used in a Master-/ Slave-configuration and is bi-directional with half-duplex communication. When the system is active, a constant clock signal is produced on the bus by the Master gauge.

Bit-rate on Satbus = 31.25 kHz.

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 11

TU00-0726-0000002

0609

Pin Description Pin Description

1 - 3 GND

2 Satellite - Bus 4 Power Supply

Page 22

2.5 Display Functions

Five main display functions have been specified for the Master gauge. (s. picture below) As the number of displays in each

main function is configurable (except for odometer and hourmeter), the actual number of displays can be up to a maximum of

146.

A maximum of 30 Warnings and 30 Alarms can be set. The Physical Values of the defined Satellite gauges can be shown on

the display (if configured). Atotal of 25 physical value Displays (PVD) are possible, including the physical values inidcated by

the Satellite gauges. Thus with increasing numbers of Slaves defined by WINgauge, the number of freely selectable physical

values to be displayed on the dot-matrix decreases.

2.5.1 Navigation through Display

The order of the display groups is: Odometer / Hourmeter, Alarms, CAN DTCs, Service Messages, Physical Values, Warnings

and then back to Odometer / Hourmeter. The Alarms, CAN-DTCs, Service Messages and Warnings are being monitored and

appear only if they are activated. If the button is pressed more than 2 sec., the LCD shows the main display which is

Odometer / Hourmeter.

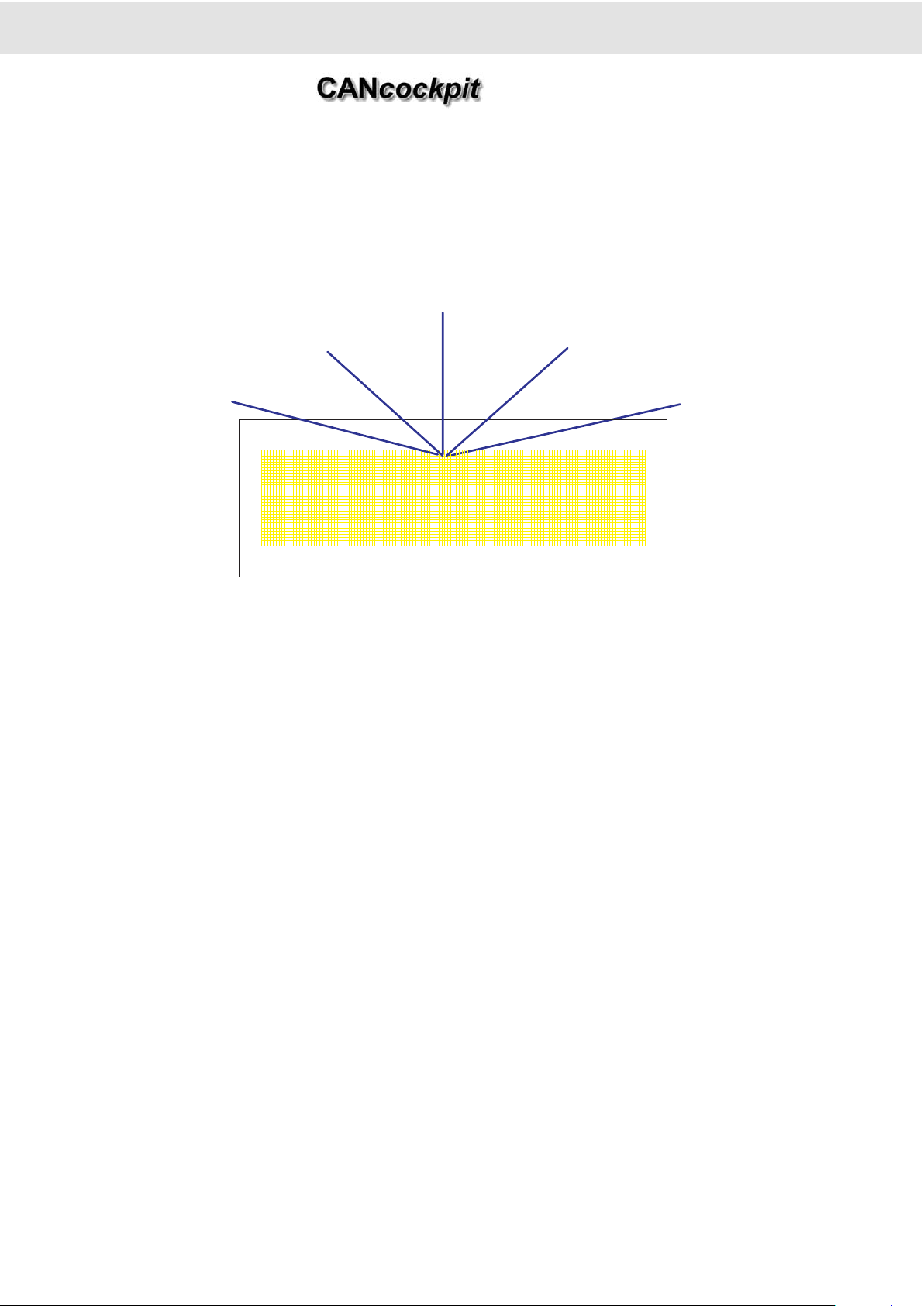

2.5.2 Display Layout

The Dot-matrix Display has 132 x 33 dots.

The following picture shows the proposed display layout. The outer line represents the LCD glass and the inside marks the

active display area. The structure inside has only been drawn for illustration; it is not visible on the display itself

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 12

TU00-0726-0000002

0609

1. Odometer

Hourmeter

2. Physical V alues

Display (max. 25)

3. Se rv ic e In te rv a l

Message (max. 15)

4. CAN Diagnostic

Trouble Codes (max. 5)

5. Warning and Alarm

Messages (max. 30)

45)

60)

Page 23

Technische Änderungen vorbehalten Technical details subject to change

2 - 13

TU00-0726-0000002

0609

The display is structured into three main areas:

1. Symbol Area

This 30 x 32 pixel area is reserved for graphic symbols. The symbols are left aligned to optically enlarge the appearance of

the symbol.

2. Central Area

The centre of the display is organised as one or two lines with 6 digits each. Here it is possible to show alphanumeric ASCII

characters using the large font (12 x 16 pixel). If only one line is displayed, then this line will be centred in vertical direction.

Short text (up to 6 letters) can be used to provide identification for the value displayed. This area is best suited to communicate important numeric values to the user. Values will be shown in the second line on the right, where units appear on the left.

One or two centre lines are configured via WINgauge as well as the description of the short text.

3. Physical Unit Area

The physical unit area is located right of the alphanumeric Centre Lines. In general the unit belonging to the value displayed

on the centre lines is shown here as text. This area is organised as four lines of 5 characters of the small font. If the Unit can

be displayed with less than three ASCII characters, then the large font is applied, else the small font is used. Units will not be

wrapped into the next line.

If there are two Centre Lines, then there will also be two-unit Lines (small Line 2 and Line 4). In case only one Centre Line is

displayed, then only one corresponding Unit Line will be visible (small Line 3).

It is therefore possible to show the following parameters and units to give a clear indication of the valid physical unit which

can be chosen via WINgauge:

2. Functional Specification

Product Manual

24 * 24

12 * 16

6 * 8

30 dots

72 dots

30 dots

32 dots

Dot Matrix Layout

One centre Line or

optional two Alphanumeric Lines

with 6digits (12*16dots) each

Four Alphanumeric

Lines with 5 digits each

Graphic

Symbol Area

Parameter Units

Revolution / rotation 1/min, rpm

Speed km/h, mph, knots

Distances km, m (Meter), mm, miles, mi, M, m (landmile = 1.609 km), nm (nautical mile = 1.852 km)

Power supply Volt, V, A, mA

Time h, hours, min, sec

Temperatures °C, °F

Pressures bar, psi, kPa, Mpa,

Level of liquids %, l, gal (US-gallons)

Fuel consumption l/h, gal/h, km/l, l/100, kg/h, km/kg

Weight kg

Power N, kN, Nm

Diverse Ohm, Grad, deg, appl, Count, qm/h, Gear, Code, SPN, FMI

Page 24

2.5.3 Display Functions

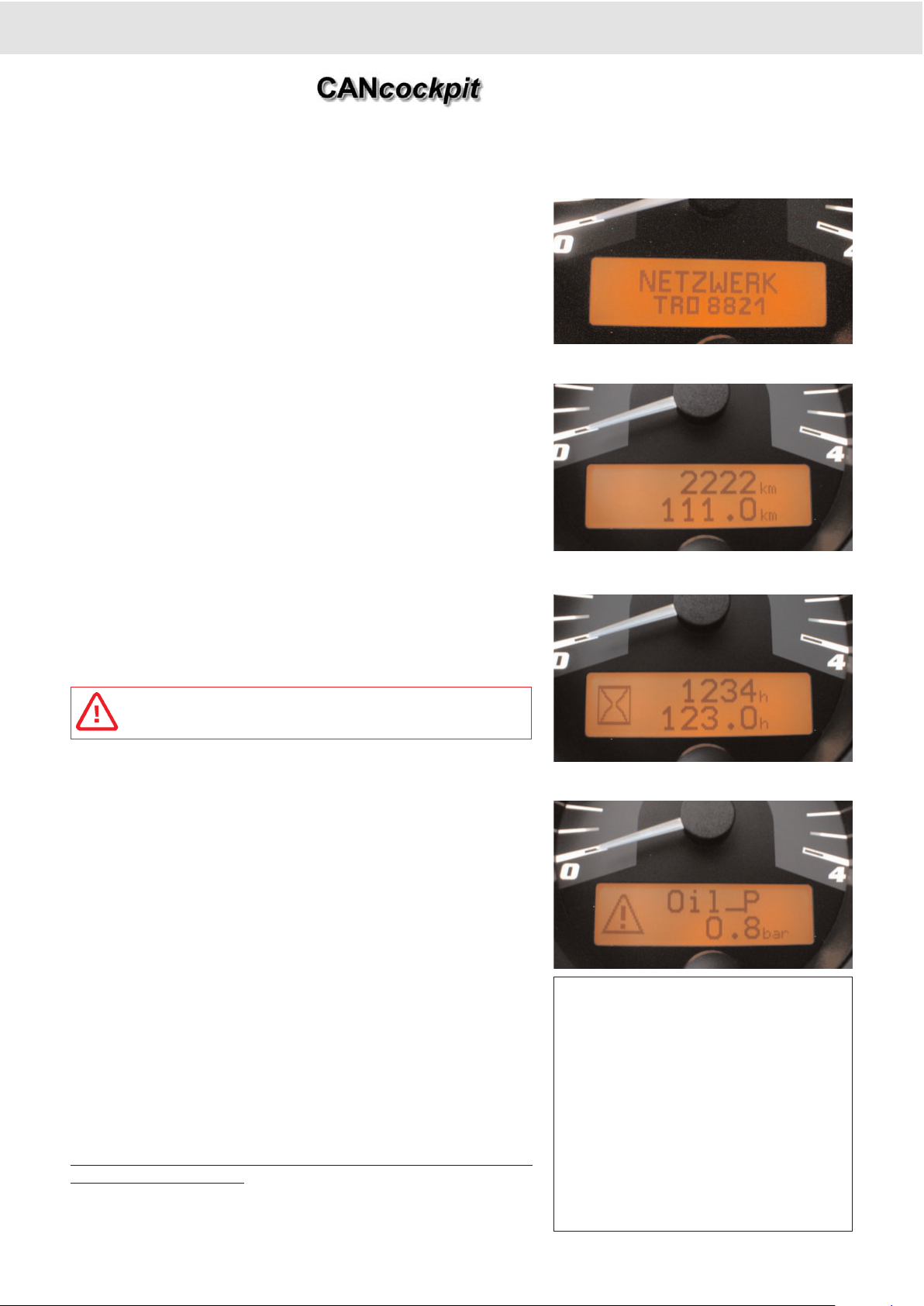

2.5.3.1 Main Display (Odometer, Hourmeter)

The display shows total and trip in two lines. Total has 6 digits and trip has

4 plus 1 digit. The figures roll over to 0.0 after a distance of 999.999 /

9.999 or 100.000 / 1.000 hours. Pressing the button longer than 2 seconds

will reset trip odometer or hourmeter.

A part of the Display can be used to show the company logo as a start-up

display configured by WINgauge

The centre of the display shows the value of the odometer in the first line

and the tripmeter underneath. The physical unit is displayed right to it and

can be either miles or km.

The main display of the tachometer is similar to the speedometer, except

that it shows operating hours instead of odometer and trip meter.

The physical unit is "h" for hours. The digit after the decimal point of the

trip hourmeter shows 1/10h.

if no CAN signal is received, only dashes will be indicated.

2.5.3.2 Alarm Display

If an alarm is triggered the Alarm Display is shown. To alert the user, the

General- Alarm-Symbol is flashing, alternating with the symbol that indicates the type of alarm.

The Central area of the display shows the actual physical value (6digits).

The physical unit appears to the right.

When the customer quits the alarm longer two seconds the Display will

change to the last displayed value (if no other Alarm and Warning is existing which weren't quitted). The General Alarm Symbol will remain in the

graphic Symbol Area with a vertical line on the right side of the symbol to

indicate that the Alarm doesn't correspond to the main display but to another Physical Value.

When different Alarms are present the highest priority will be shown. The

priority of the alarms is defined with the WINgauge Software. If the Alarm

is confirmed and the Alarm condition does not exist anymore then the

Alarm is cleared in the list of active Alarms. If the Alarm is not confirmed

but the Alarm conditon does not exist anymore then the Alarm is still in the

list of active Alarms.

T

o see the different Alarms in the Alarm display group the button has to be

pressed shortly (>50 msec).

2. Functional Specification

Product Manual

Main Display for Tachometer

Physikal

Unit

6 Digit Hourmeter

+ Triphourmeter

Main Display for Speedometer

Physikal

Unit

6 Digit Odometer

+ Tripmeter

Alarm Display

Alternating

ISO Symbol

6 Digit

Label

6 Digit Value

Configuration Option:

• To provide additional information two

Centre Lines can be programmed. The

top line displays a label for identification.

• If no physical value should appear on the

display, then a configuration allows a display, which only shows the alternating

graphic symbol in the centre of the display.

This option is useful, if a digital input triggers

an alarm.

Technische Änderungen vorbehalten Technical details subject to change

2 - 14

TU00-0726-0000002

0609

Physikal

Unit

Page 25

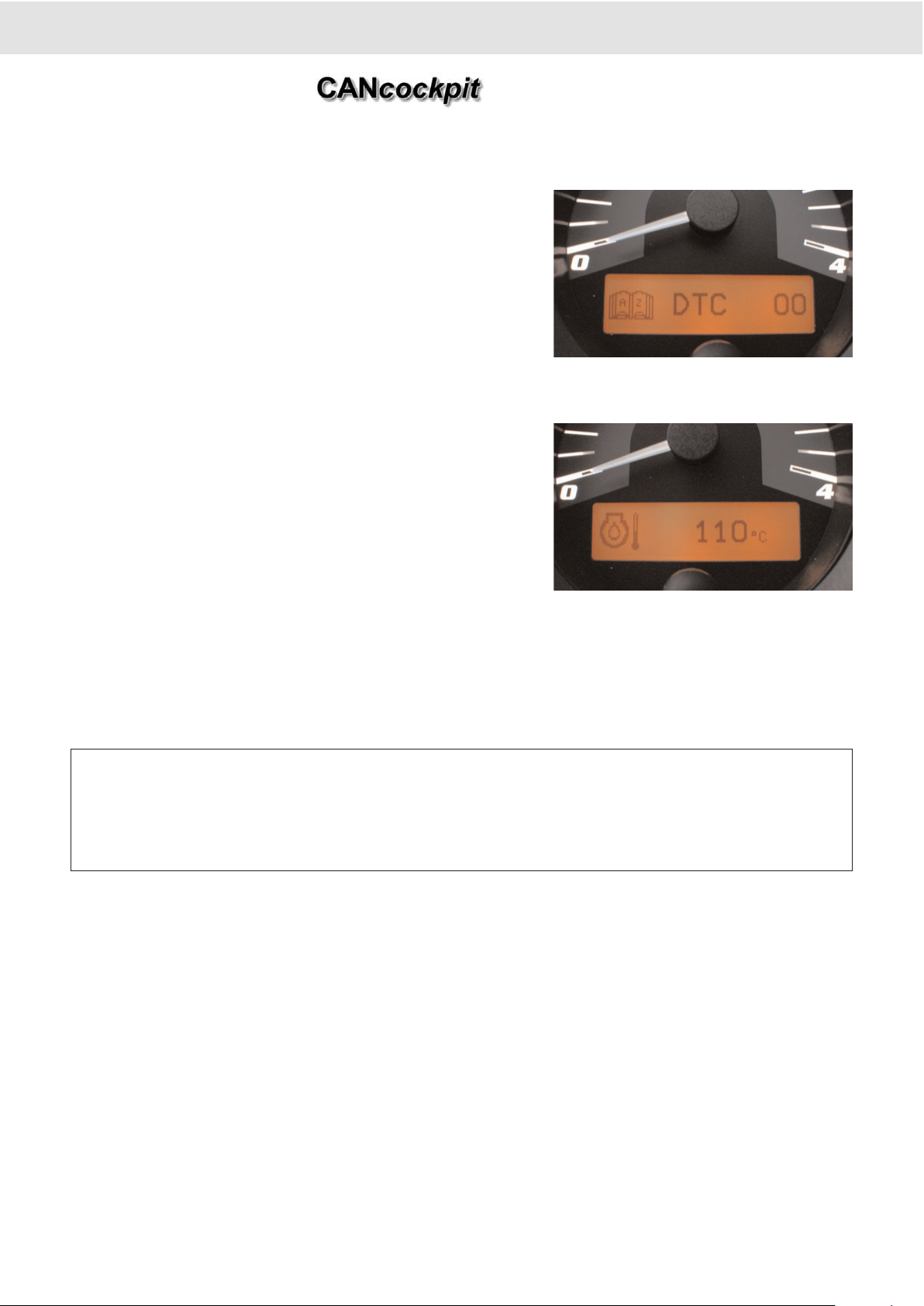

2.5.3.3 CAN DTC Display

1 to 5 independent DTC channels can be configured. Every channel is

able to receive the DTCs from one CAN device (Source Address).

If DTCs are received from any of the configured CAN devices, they will be

stored into a DTC receive buffer. The buffer will be able to hold a total of

40 DTCs and will be implemented as a ring buffer, so that old DTCs can

be overwritten by newly received DTCs

2.5.3.4 Warning Display

In the Warning display the Specific Graphic Symbol (ISO) is flashing at 1

Hz. There is no alternating.

The operator can acknowledge the Warning by pressing the button longer

than two seconds. The Display will change to the Display, which was active before, if no other Alarms and Warnings are existing, which have not

been acknowledged yet.

When different Warnings are present the highest priority will be shown.

The priority of the Warnings is defined with the WINgauge Software.

Alarms have higher priorities than the Warnings. If the Warning condition

vanishes also the Warning will vanish, if it has been acknowledged.

To see the different Warnings in the Warning display group the button has

to be pressed longer than 50 msec.

2. Functional Specification

Product Manual

CAN DTC Display

Symbol for

CAN DTC

Position in

Ring Buffer

6 Digit

Message Label

Warning Display

ISO Symbol

Physical

Unit

6 Digit Label

Configuration Option:

• To provide additional information two Centre-Lines can be programmed. The top line displaying a label for identification.

• If no phsyical value should appear on the display, then a configuration allows a display, which only shows the flashing

graphic symbol in the centre of the display.

• This option is usefull, if a digital input triggers a warning.

Technische Änderungen vorbehalten Technical details subject to change

2 - 15

TU00-0726-0000002

0609

Page 26

2.5.3.5 Service Message

The Service Message indication is based on operating hours and odometer.

The Graphic Symbol Area displays the "Service Symbol" in case a Service

Message becomes due.

The corresponding service code is shown on the centre line of the display

centre. As a "unit" the word "CODE" appears to indicate, that the value is a

code number.

To see the different active Service Messages in the Service Message display group the button has to be pressed longer than 50 msec.

2.5.3.6 Physical Value Display

The graphic display area shows a symbol relating to the physical value displayed. The symbol can be selected via configuration from the defined

symbols in ROM or EEPROM.

In the standard form the physical value is shown on a single Centre-Line,

followed by the physical unit. This unit text can be selected from ROM during configuration.

If the value is outside of the configurated range, then "------" is

shown.

To see the different Physical Values in the Physical Value display group

the button has to be pressed longer than 50 msec

2. Functional Specification

Product Manual

Service Message

Service

Symbol

Service Code

Configuration Option:

The Service Message indication can be configured as stand- alone or interval message.

Physical Value Display

ISO

Symbol

Physical value

6 Digit Value

Physical Value Display

ISO

Symbol

6 Digit

Label

6 Digit Value

Configuration Option:

As an option a text label can provide identification for the value displayed. For example

Battery one of two batteries, or Motor-2 of

two motors. The text label can be configured

via WINgauge with maximum 6 letters.

The physical value is displayed in the lower

centre line.

Physical

Unit

Technische Änderungen vorbehalten Technical details subject to change

2 - 16

TU00-0726-0000002

0609

Page 27

Technische Änderungen vorbehalten Technical details subject to change

2 - 17

TU00-0726-0000002

0609

2.5.4 Alarm- and Warning Functions

The Alarms and Warnings are triggered by the input values. Configuration parameters in EEPROM select the input values.

These variables can have a size of 1, 8 and 16 bit. Possible inputs are engine speed, road speed, data in CAN messages

and analogue sensor values. Input values are then monitored and if the configured thresholds are exceeded, then an Alarm

or Warning action is triggered, resulting in switch outputs being activated.

2.5.4.1 Description of the Outputs

Definitions:

Warning: Is a message to make the operator aware of a condition, which requires his attention.

Alarm: Is a message to alert the operator about a condition, which requires his attention and immediate action. The Alarm is

more severe than a Warning.

The switch outputs are only controlled by the Alarm- and Warning Functions.

The following switch outputs are provided:

a. Output 1 and Output 2

These are two outputs, which act like two switches to ground. The switch output can control i.e. a warning lamp, a buzzer or

a relay. It turns off, when the Alarm condition is not existing anymore, or if the Alarm has been acknowledged and it was configured. It stays on, if another Alarm condition also configured to turn on this output is still active.

b. Display

Every Alarm or Warning activates a display on the dot matrix. When the Alarm is triggered, then the associated display appears on the dot matrix, overwriting the previous display. The display combines a graphic symbol with a physical value (numerical value plus physical unit), describing the input value, which has caused the Alarm or Warning.

c. Warning Lamps in the Satellite Gauges

The Satellite Gauges include a warning lamp. This warning lamp can be turned on and off via the Sat-Bus. An Alarm or

Warning could be configured to activate a warning lamp in each of the Satellite Gauges. The selected warning lamp in the

Satellite Gauge remains on as long as the trigger condition remains, and turns off as soon as the trigger condition is not existing anymore. Flashing of the warning lamp can be configurated.

2.5.4.2 Switch Output Acknowledgement Function

The Acknowledgement Function provides a means to turn off some of the switch output action. This may be desired, if the

Alarm activates a buzzer and the operator wants to turn the buzzer off.

To acknowledge a switch output, the operator must press the button for more than 2 sec, while the Alarm or Warning is active.

When a Warning or Alarm has been acknowledged, then the Switch Outputs (1, 2) will be deactivated, if they have been configured to turn off these outputs.

2. Functional Specification

Product Manual

Input Values

CAN Cockpit Plus

Switch Output Functions

Output 1

Output 2

Display

Lamp in SAT-Gauge 0.. 15

Configuration Data

From EEPROM

Page 28

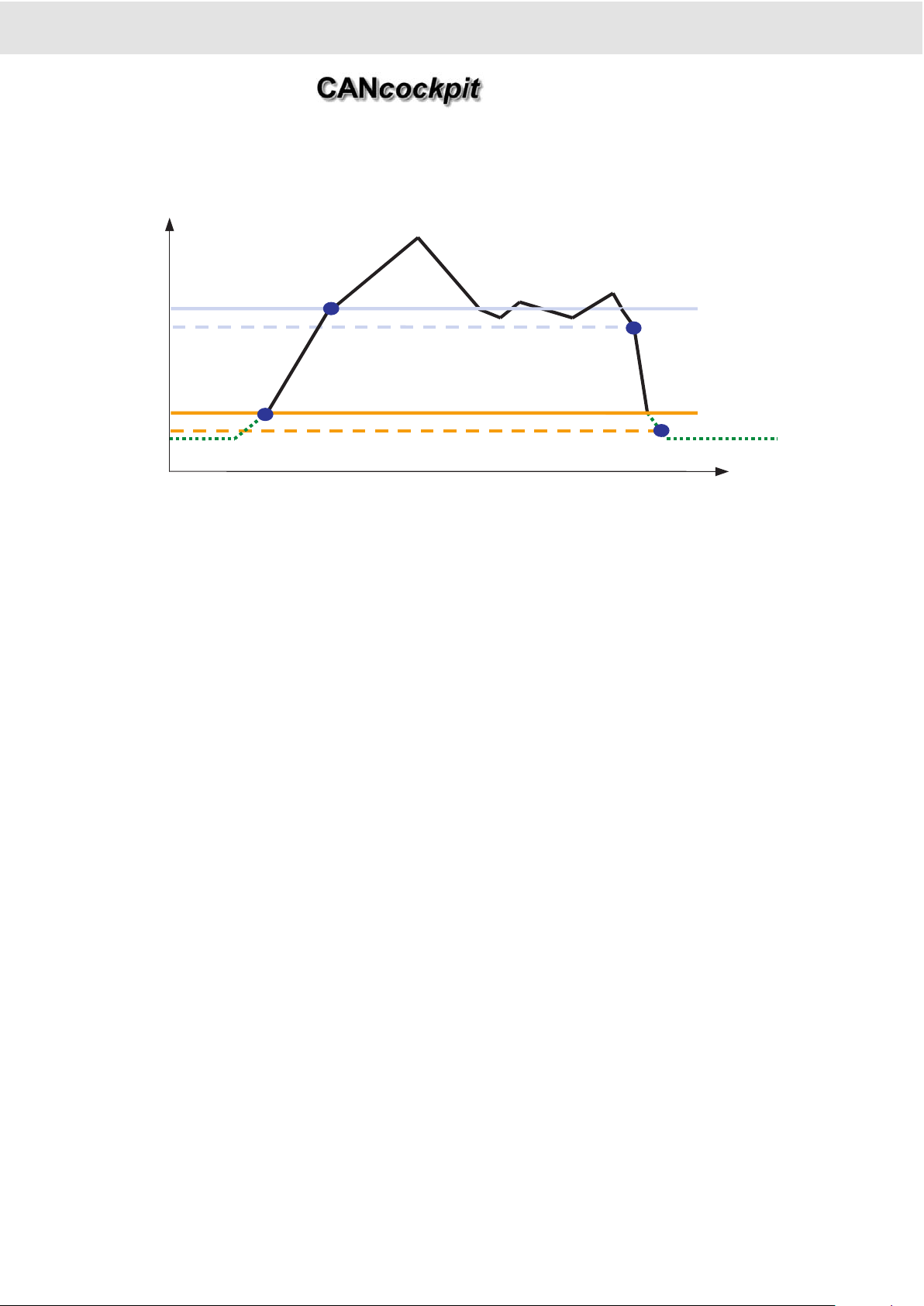

2.5.4.3 Alarm and Warning Trigger Conditions

The diagram above illustrates the Alarm and Warning trigger conditions for the engine coolant temperature as an example.

The Warning threshold is set at 105° C, where the Alarm threshold is reached at 110° C. To prevent repeated on/off cycles of

the Warning or the Alarm an activation hysteresis is applied. Therefore in above example an Alarm is turned off, if the temperature falls below 108° C and the warning is cancelled at 103° C. The hysteresis is 2° C in this case and is the same for both

Alarm- and Warning condition. In addition a turn-on delay from 1 sec to 4 minutes can be configured. The delay time starts,

when the threshold is reached. If the input value falls below the threshold value, then the delay time restarts from this point in

time.

It can be configured, that the Warning is triggered, if a value rises above a threshold (as in the case of the engine coolant

temp.), or if the input value falls below a threshold (e.g. fuel level).

2.5.4.4 Alarm and Warning Trigger enabling with Engine running

Triggering of some Alarms and Warnings only makes sense, when the engine is actually running. Examples are engine oil

pressure or hydraulic pressure. For these situations triggering an Alarm and Warning can be disabled until the engine is running. This conditional trigger enable is selectable for every Alarm and Warning (together) during configuration.

Engine running is detected, by exceeding a separately configurable threshold value: the Alarm and Warning enable engine

speed threshold. The minimum threshold is 0 rpm and the maximum is 32.000 rpm.

An additional trigger-enable time delay starting from engine running condition can be configured. This is helpfull in cases,

where it takes a while until a pressure is built up.

This delay time is settable from 0 to 250 sec with a resolution of 1sec.

2. Functional Specification

Product Manual

T/°C

time/sec

105

103

110

108

Warning

on

Alarm on

Alarm off

Warning off

Technische Änderungen vorbehalten Technical details subject to change

2 - 18

TU00-0726-0000002

0609

Page 29

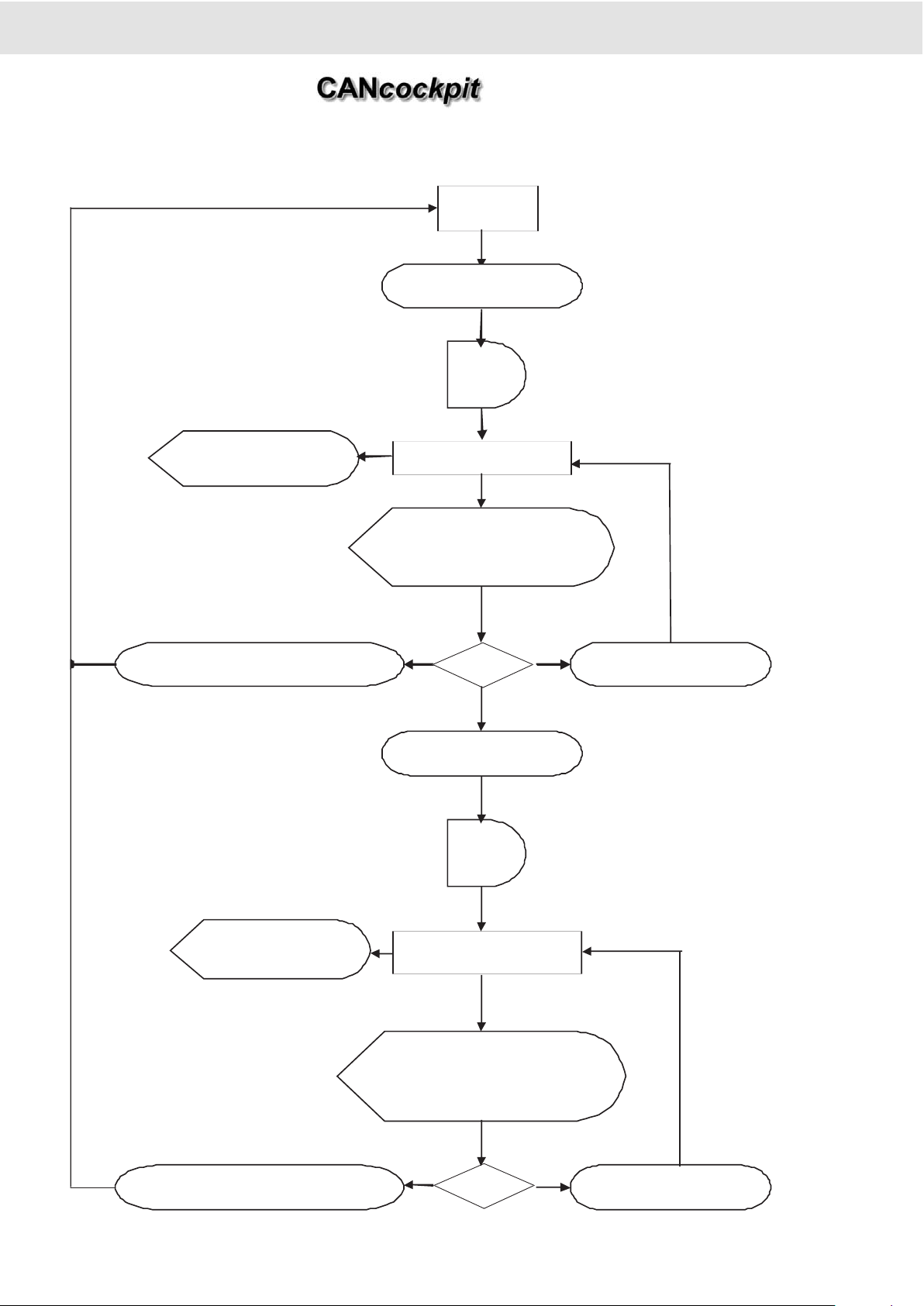

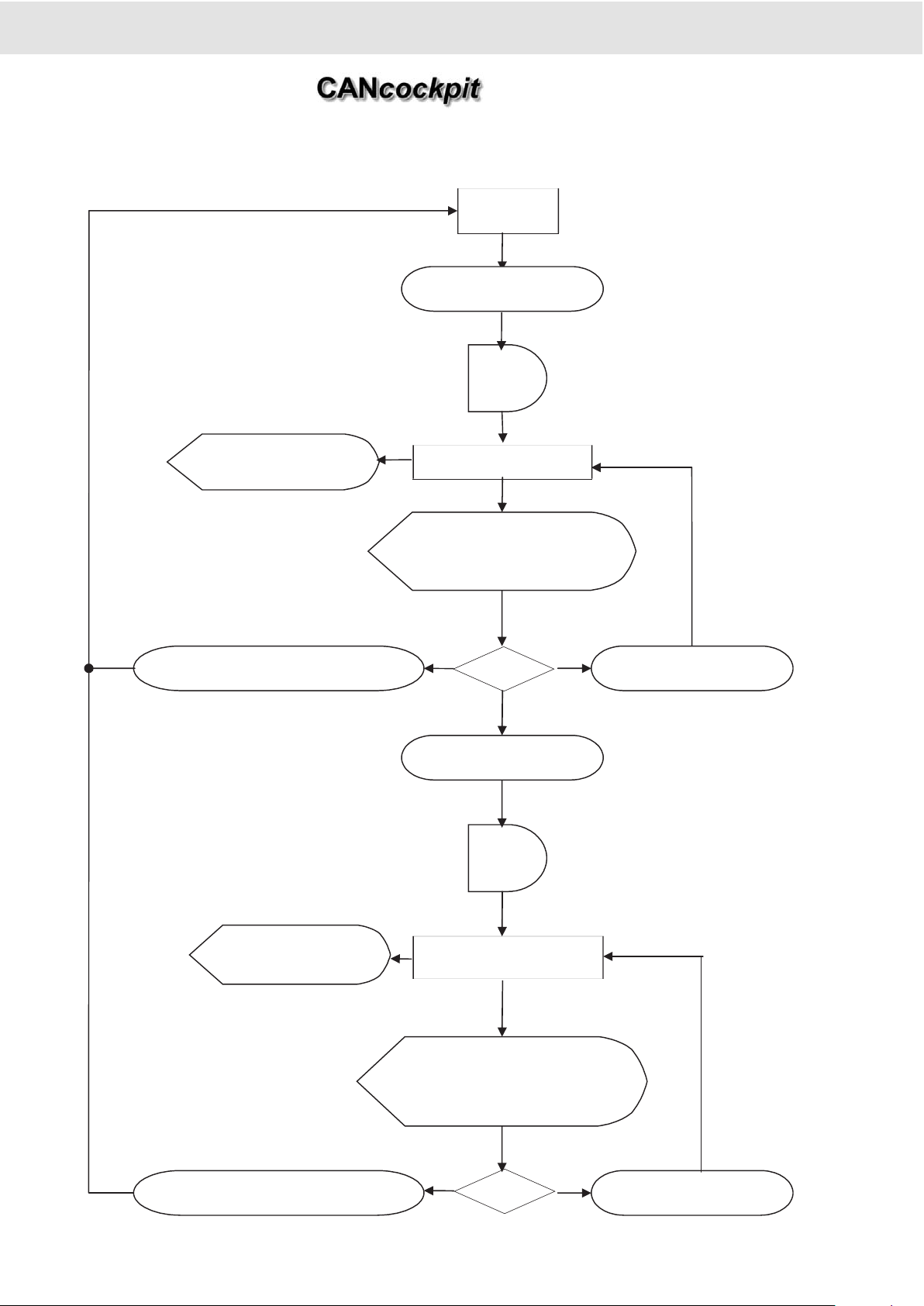

2.5.4.5 Alarm and Warning State Diagram (Maximum Value Algorithm)

2. Functional Specification

Product Manual

VALUE

Warning

Time

delay

Time

delay

Display Warning

Indication *

Alarm

Value > WarnLev el

Value > Alar m Level

Display Alarm

Indication *

Reminder: Alarm li s t and

flas hing Ala r m symbol

and WIN gauge "Alarm

Action"

Re mi nder: Warning list

an d WI Ngauge "Alarm

Action"

?

Value > WarnLev el

Value < WarnLevel - Hysteresi s

Value < Alar m Lev el

?

Value > AlarmLevel + Hysteresis

Technische Änderungen vorbehalten Technical details subject to change

2 - 19

TU00-0726-0000002

0609

Page 30

Alarm and Warning State Diagram (Minimum Value Algorithm)

2. Functional Specification

Product Manual

VALUE

Warning

Time

delay

Time

delay

Display Warning

Indication *

Alarm

Value <= WarnLevel

Value <= AlarmLevel

Display Alarm

Indication *

Reminder: Alarm list and

flashing Alarm symbol

and WINgauge "Alarm

Action"

Reminder: Warning list

and WINgauge "Alarm

Action"

Value <= WarnLevel

Value < WarnLevel - Hysteresis

Value <= AlarmLevel

Value > AlarmLevel + H yster es is

Technische Änderungen vorbehalten Technical details subject to change

2 - 20

TU00-0726-0000002

0609

Page 31

Technische Änderungen vorbehalten Technical details subject to change

2 - 21

TU00-0726-0000002

0609

2.5.5 Service

The Service message is based on the Hourmeter or Odometer.The service message indication can be configured via

WINgauge. There are 15 independent service messages with customer specific settings, which can be configured via

WINgauge. The service messages are implemented as periodic intervals. Amessage which should be indicated only once,

the quantity of intervals would then be 0. Configuration data is stored in EEPROM.

For each of the 15 Service messages following can be specified in a table:

1. Service code number: Range: 1 to 255. 0 needs to be entered to disable this service function.

2. First message after x hours: ( 1h <= x <= 65.000 h )

3. Periodic service time: Range: 1h to 4.095h. If 0h is selected, it means only once (not periodic).

If a Service message has expired, this service code is displayed as a decimal number together with the common service

symbol on the dot-matrix display. The Service message display remains active until this service code is reseted.

2.5.5.1 Reset of Service messages

The reset of the service message function is possible first if it occured and not before.

When a one-time service message will be reseted, then this Service message will be disabled by writing 0 into the service

code field of the Service message table in EEPROM.

When a periodic interval will be reseted then the periodic service time will be added to the hours of the current hourmeter value. This will ensure, that even if a Service message is reseted later than required, the time to the next service indication will

be the periodic interval time as specified.

Example: Service message No.: 12

Service code: 153

First service after: 300 h

Periodic service:100 h

The reset of the Service message is part of the system check function (part of safety check).

Procedure for resetting a Service message:

1. With ignition switched off, push the button and hold down while ignition is being turned on, then the system check function

is activated and clears the contents of the DTC List.

2. If there are any service messages active, then they will be displayed on the Dot-Matrix Display starting with the first active

service message. If the button is then pressed and held for 5 seconds or longer, then this Service message will be reseted. The next active Service message is displayed afterwards. To proceed to the next active service message without resetting the displayed code the button needs to be pressed shortly (<5 sec). If all active service codes have been displayed, then the system check function is started.

2. Functional Specification

Product Manual

Event Time (hourmeter) Display

First service code displayed after 300 h 153

Reset of this service at 340 h

Next service display at 440 h 153

Page 32

2.5.6 CAN (SAE J1939) DTC (Diagnostic Trouble Codes) messages

It will be required to know the CAN source address (SA) of the controller (ECU), which has sent a DTC message, so that the

problem can be located.

The SAE J1939 specifies 13 different diagnostic modes (DM1 to DM13). But for CANcockpit only DM1 is relevant.

In DM1 active DTCs are broadcast on the CAN-Bus. Active means, that these faults are existing at the moment, compared to

faults, which existed sometime in the past.

2.5.6.1 CAN SAE J1939 Elements

DTCs consist of 4 elements defined in SAE J1939:

1. Suspect Parameter Number (SPN) 19 bits

In the DTC, the SPN identifies the faulty element, component, sensor or parameter of a device (ECU).

2. Failure Mode Indicator (FMI) 5bits

The FMI defines the type of failure detected. It provides additional information about the nature of the fault. There are 32 predefined FMIs.

Examples are:

"Out of calibration", "Data Valid but above normal operational range", "Mechanical System not responding or out of adjustment"….

3. Occurrence Count (OC) 7bits

Shows the number of times a fault was active

4. SPN Conversion Method (CM) 1bit

The February 1996 version of SAE J1939-73 contained inadequate definitions to assure consistent implementations.

Consequently the specification of the DTC format was changed. To indicate the new consistent format this bit must be set to 0.

Also the old versions will be supported by CANcockpit.

The number of possible DTCs is very large, therefore efficient filtering is important for this function.

There are two main applications for DTCs (Diagnostic Trouble Codes):

• To inform the operator, that something is not as expected.

Depending on the DTC it can have the nature of an Alarm (most severe), Warning or only Information

• To provide diagnostic information for the workshop, so that system faults can be analyzed and repaired.

2. Functional Specification

Product Manual

DTC

Data Byte 3

8 least significant bits of SPN

Data Byte 4

8 medium significant bits of

SPN

Data Byte 5

3 most significant bits of SPN

plus 5 bit FMI

Data Byte 6

Conversion Method bit plus 7

bit Occurrence Count.

Technische Änderungen vorbehalten Technical details subject to change

2 - 22

TU00-0726-0000002

0609

Page 33

2.5.6.2 CAN DTC Information Display Requirements

1. Information for the operator needs to be brief and clear, so that action can be taken quickly, if required.

• Activate Warning Lamp

• Activate Switch-Output

• Display Short Text

2. For the workshop it is more important to get detailed information, so the cause can be found and fixed.

• DTC List with SPN, FMI and Occurrence Count

The DTC List can also be viewed by the operator, but requires detailed knowledge of the CAN devices reporting the DTCs.

Also it can be expected, that the workshop will have other diagnostic tools, which can access even more Information than

J1939 DM1.

2.5.6.3 CAN DTC Display Functions

2.5.6.3.1 DTC Reception

0ne to five independent DTC channels can be configured. Every channel is able to receive the DTCs from one CAN device

(Source Address).

If DTCs are received from any of the configured CAN devices, they will be stored into a DTC receive buffer. The buffer will be

able to hold a total of 40 DTCs and will be implemented as a ring buffer, so that old DTCs can be overwritten by newly received DTCs.

Every newly received DTC will be compared with latest DTC`s in the ring buffer. If they are different it will be stored in the ring

buffer. Thus avoid overflowing of the ring buffer by toggling transmitted DTC`s.

2.5.6.3.2 DTC List

If the service personnel or the operator wants to check for received DTCs, he can step through the display list until coming to

the DTC-Displays. There will be no automatic display, which comes up and must then be acknowledged. Therefore it is possible to prevent annoying displays coming up, if DTCs are received, which have no actual relevance.

The DTC List function will provide access to the DTCs inside the DTC receive buffer. One DTC Display will exist in the display list for every configured DTC channel (channel 1 to 5).

To see the received DTCs of one channel the operator presses and holds the button for longer than 2sec. At this time the processor will transfer the received DTCs from the DTC Receive Ring Buffer to the DTC List. Only the DTCs of the selected

channel will appear in the DTC List. The most recent DTC will be shown first. Every short press will lead to earlier received

DTCs, until all DTCs have been shown or the button is pressed and held for more than 2sec.

The DTC List will be cleared at ignition off/ on (configurable).

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 23

TU00-0726-0000002

0609

Page 34

2.5.6.3.3 DTC List Display Format

One Graphic Symbol per DTC Channel (Source Address) can be configured and will be shown together with the DTC in the

upper and lower level. It indicates, where the DTC message comes from.

Also the number of received DTC`s on this channel (0-40) which are currently inside the DTC Ring Buffer will be displayed.

Examples:

Electronic Engine Controller (EEC) reports Pre-Filter Oil Pressure

(SPN=1208) was 102 times (occurrence count) above normal operating

range - most severe level (FMI=0).

Index 10 provides information about the position inside the Ring Buffer.

Electronic Engine Controller (EEC) reports System Diagnostic Code #1

(SPN=611), occurrence count information not available (OC=127) and

Special Instructions (FMI=14).

Index 15 provides information about the position inside the Ring Buffer.

Electronic Transmission Controller (ETC) reports Clutch Actuator

(SPN=788) was 2 times Out of Adjustment ((FMI=7)

Index 18 provides information about the position inside the Ring Buffer.

Hydraulic Controller reports Hydraulic Reservoir Temperature (SPN=1508)

one time Above Normal (FMI=3)

Index 40 provides information about the position inside the Ring Buffer.

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 24

TU00-0726-0000002

0609

Page 35

Technische Änderungen vorbehalten Technical details subject to change

2 - 25

TU00-0726-0000002

0609

2.5.6.3.4 Diagnostic Lamp Status

The following diagnostic lamps are defined in SAE J1939:

1. Red Stop Lamp —> Stop Engine

2. Amber Warning Lamp

3. Protect Lamp

4. Malfunction Indicator Lamp

The status information of all configured DTC received channels are collected and the result will be stored in a 16bit status variable (Byte1 and Byte2). It is then possible to configure alarm or warning functions to react on the diagnostic lamp status.

This also has the advantage that normal Alarm- or Warning-Functions are integrated with Alarms or Warnings (DTC Lamp

Status) from the CAN Bus.

2.5.6.3.5 DTC Scan

When DTC`s are received via interrupt, they are immediately stored into the DTC-receive ring buffer. This ring buffer will then

be scanned for 8 specific DTC`s. These DTC`s can be configured via WINgauge with unique icons and labels. Alarm and/ or

Warning Functions can then be configured to trigger on the status of certain bits inside the DTC scan result register.

2.5.6.4 Speedometer Master Gauge

2.5.6.4.1 Tolerance

The overall speedometer accuracy is within 0% to +4% of full scale reading for each indicated value over the operating range

of the instrument.

This fulfills SAE J1226 for the American market and for the European market DIN 75521-2.

2. Functional Specification

Product Manual

SAE J1226 DIN 75 521 - 2

-4% 4% 0 <= v1-v2 <= v2/25 + 5km/h

Actual speed u. Tol. o. Tol. u. Tol. o. Tol.

0 0 0

10 9 ,6 10,4

20 19,2 20,8

30 28,8 31,2

40 38,4 41,6 40 46,6

50 48 52 50 57

60 57,6 62,4 60 67,4

70 67,2 72,8 70 77,8

80 76,8 83,2 80 88,2

90 86,4 93,6 90 98,6

100 96 104 100 109

110 105,6 114,4 110 119,4

120 115.2 124.8 120 129,8

Page 36

2.5.6.4.2 Speedometer Gauge Operation

The Master gauge receives speed information either via CAN or via one of the frequency inputs. During configuration the

source of the speed information has to be defined. The input signal is first converted into a physical speed value. The microcontroller calculates the deflection angle of the speedometer based on this physical speed value and gauge output characteristic.

Specification of odometer storage

The standard Speedometer version of the Master gauge contains an Odometer. It can be configured that also the Tachometer

can have an Odometer instead of an Hourmeter. The Odometer consists of a total Odometer and a Tripodometer. Both can

be displayed on the dot matrix LCD as two lines. Format is 6 digits for total km, landmiles, nautical miles or meter and 4 digits, decimal point and 1 digit for 1/10 kilometer, land mile or nautical mile. The resolution of meter is 1m.

a. Information comes from CAN-Bus Interfaces (one of two):

For the Odometer indication it must be ensured that a ECU is broadcasting this information on the CAN-Bus. If no signal is

received only dashes will be indicated.

b. Total odometer information generated by master gauge:

The Odometer information will be written to EEPROM every 1km. Aring counter algorithm is applied to save and recover the

information from EEPROM. The rest-distance is written to EEPROM 10 sec after ignition has been turned off.

A special 16-word-ring-counter algorithm is applied to recover the odometer in case the battery was disconnected.

With nominal input frequency applied, the odometer shall indicate calculated mileage within ± 0.3% [SAE J1226].

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 26

TU00-0726-0000002

0609

Page 37

2.5.6.5 Tachometer Master Gauge

2.5.6.5.1 Tolerance

The Tachometer indication must be within ± 2% of full scale with nominal voltage applied at temperature of 24 ± 3° C. [SAE

J1399].

2.5.6.5.2 Tachometer Gauge Operation

The Master gauge receives the engine speed information either via CAN-Bus or via one of two frequency inputs. During configuration the source of the engine speed information has to be defined. The input signal is first converted into a physical engine speed value. The micro-controller calculates the deflection angle of the Tachometer.

2.5.6.5.3 Specification of the hourmeter

The standard Tachometer version of the Master gauge contains an Hourmeter. It can be also configured with the WINgauge

that also the Speedometer can contain an Hourmeter.

U

Legal demands are to fulfil!

a. Information comes from CAN-Bus Interfaces (one of two):

For the Hourmeter indication it must be ensured that a ECU is broadcasting this information on the CAN-Bus. If no signal is

received only dashes will be indicated.

b. Total hours information generated by master gauge:

The Hourmeter counts the number of engine hours, when the engine speed exceeds a threshold value configurable via

WINgauge (default value 300 rpm). If the engine speed is below the threshold value the hour counting stops (total and trip).

The last value willI be stored within 10 sec in EEPROM after the ignition is turned off, then counting stops, no matter if the engine is running or not.

The time indication is within + 5 sec with nominal voltage supplied at 25 degrees C and within + 10 sec with nominal voltage

supplied over the full operating temperature range.

The total hour information is backed-up in EEPROM every 7.5 minutes. Aspecial 16-word-ring-counter algorithm is applied to

recover total hours in case battery had been disconnected.

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 27

TU00-0726-0000002

0609

Page 38

3. Satellite Gauges

3.1 Mechanical concept

The movements are front mounted stepper motors SM2, only clockwise indication.

Connectors: AMP 6 Pin MATE-N-LOK

The dials have a 240° scale and a black panel effect for the warning lamps, so without activating of the warning lamp no sign

is visible.

3.2 Fault modes

When ignition is off, the pointers are positioned 6° below the left side of the scales. With ignition on the pointers are moving to

the scale start value. When the gauges receive wrong informations or the analog signals are out of range (configured by

WINgauge), the pointers are moving 6° below the scale start value

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 28

TU00-0726-0000002

0609

Page 39

Technische Änderungen vorbehalten Technical details subject to change

2 - 29

TU00-0726-0000002

0609

3.3 Satellite gauge address

Each Satellite has his fixed address. The address is defined with the Assy PCB.

The matrix of the combination of the gauge type and address:

U

Maximum 16 Satellite gauges can be connected per Master. To avoid grave system conflicts, on each address

is only one gauge allowed.

3.4 Warning Lamp inside the Satellite Gauge

All warning lamps are red except the amber level warning lamps. The WINgauge allows configuration of these warning lamps.

3.5 Tolerance

The Satellites have the pointer accuracy of ± 2.5%.

2. Functional Specification

Product Manual

Address Numbers of the Satellite gauges

00 Speedo / Tacho 1

01 Pressure Engine Oil

02 Pressure Brake 1 / Rudder / Primary air

03 Pressure Transmission Oil

04 Pressure Turbocharger / Tacho 2

05 Temperature Engine Oil

06 Temperature Transmission Oil

07 Coolant Water Temperature

08 Temperature Hydraulics Oil

09 Temperature without Symbol / Gear Oil

10 Pyrometer / Pressure Brake 2 / Turbo / Exhaust

11 Level, Fuel level 1

12 Level, Fresh Water / Cylinder Head / Position Rear Wheel

13 Level, Waste Water / Fuel Level 2 / Pressure Brake 2 (250 bar) / AddBlue / Winch

14 Voltmeter

15 Hydraulic Pressure / Ammeter / Pressure Brake 1(250 bar)

Page 40

A. Technical Data

Operating Temperature

Operating Temperature: -40°C to + 85°C (at nominal voltage)

Visible restrictions: for LCD outside -20°C and +70°C

Storage Temperature

Storage temperature: -40°C to +85°C

LCD Humidity resistance: +65°C ± 2°C

+2

90% r.F. -3%

Supply Voltage

Nominal Voltage: + 12 V and + 24 V

Operating Voltage: + 10,5 V to + 32 V as standard

Test voltage: + 14 V and + 28 V

Total Supply Current: 200 mA ± 20% for Master and 110 mAper Satellite

Satellite supply: + 10,5V to + 32V, current consumption max. 2 A

Sensor supply: + 8 V ± 10% (8 V - 0%, +10% at 24 V), Imax: 50 mA

Ground is connected to the negative battery terminal.

Idle Current

The Ignition off current (stand by mode) is 4 mA for the System (Master and Satellites).

Ground shift

Ground shift on non-analogue inputs are assumed to be < ± 0.5 V.

i.e. all digital input have to work with an additional signal offset of ± 0.5 V

EMC Requirements

See enclosures

Overvoltage Protection

The Master can withstand a voltage of 56 V for 5 minutes without damage (SAE J1810).

I/O circuit protection

The gauges are protected against reversed battery polarity.

Cable requirement

To the Master:

Type cross section: 0,5 mm²

From Master To Satellite

Type cross section: 0,75 mm²

Max quantity of gauges: 16 Satellites

U

Max. cable length: 10 m from Master to the last daisy chained Satellite

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 30

TU00-0726-0000002

0609

Page 41

B. Applied Standards

2. Functional Specification

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

2 - 31

TU00-0726-0000002

0609

Accompanying Documents. For reference only

Document Description Version

SAE J1226 Electric speedometer specification 1983-02

SAE J1399 Electric tachometer specification 1984-06

SAE J1810 Electrical indicating system specification 1993-01

SAE J1939 Recommended practice for truck and bus control 2000-04

SAE J1939 / 11 Physical layer 1999-10

SAE J1939 / 21 Data link layer 2001-04

SAE J1939 / 31 Network layer 1997-12

SAE J1939 / 71 Vehicle application layer 2008-01

SAE J1939 / 81 Network management 2003-05

89/336/EWG

Applied Standards, Breakdown sending to the DIN/EN standards 50 081-1, 50 082-1, 50

082-2 (applied standards, disturbance acc to DIN/EN standards 50 081-1, 50 082-1, 50

082-2)

95/54 EWG Motor vehicle guideline EMV (vehicle guidance emc) 1995-10

DIN 40 839

Electromagnetic compatibility (emc) in road vehicles; disturbances conducted along supply

lines in 12V and 24V onboard systems

1992-10

DIN 70 005 Teil 2 Graphische symbole, Grundlagen und Übersicht (graphic symbols, basis and overview) 1993-12

DIN 75 521 Teil 2 Speedometer instrument panel mounting for motor vehicles 1992-02

DIN-EN 50081-1 Electromagnetic compatibility - generic emission 1993-03

DIN-EN 50 081-2 Electromagnetic compatibility - industrial environment 1994-03

DIN-EN 50082-1 Electromagnetic compatibility - generic immunity emission 1997-11

DIN-EN 50082-2 Electromagnetic compatibility - generic immunity industrial environment 1996-02

IEC 60068-2-11 Corrosion resistance 1995-10

EN IEC 60 529 Schutzarten durch Gehäuse 1991-10

ISO 2575 Road vehicles - symbols for controls, indicators and telltales 2000-03

ISO 3767-1

Tractors, machinery for agricultural and forestry powered lawn and garden equipment symbols for operator controls and other displays.

1998-12

ISO 6405-1 Earth-moving machinery - symbols for operator controls and other displays 1991-12

ISO 7000 Graphic symbols for use on equipment - index and synopsis 1989-11

ISO 7637-1-2 Road vehicles - electrical disturbance by conduction and coupling: 1990-06

UL 94

Part 1: passenger cars and light commercial vehicles with nominal 12V supply voltage electrical transient conduction along supply lines only

1998-10

TPV

Part 2: commercial cars with nominal 24V supply voltage - electrical transient conduction

along supply lines only

1998-10

ISM-Z Test for flammability of plastic materials for parts in devices and appliances 2000-07

VDON 2.1954.001

Technical test specification for mechanical and electronic information systems in motor vehicles

1997-12

VDON 2.1955.070

Specification: customer specific integrated circuit in cmos technology for control of vdostepper motors (SM2/ MW2000)

1997-12

VDON 2.1958.001 Company sign VDO 2000-12

Page 42

Enclosures

Installation instructions TU00-0736-5107120 0609 (Page 1-8)

3. Installation Instructions

Product Manual

Technische Änderungen vorbehalten Technical details subject to change

3 - 1

TU00-0736-0000002

0609

Page 43

www.vdo.com

CANcockpit

Neue Generation I New Generation 2009

Montageanleitung I Installation Instructions

VDO - eine Marke des Continental-Konzerns / VDO - Atrademark of the Continental Corporation

Page 44

Systemkomponenten

System components

Gerät

Gauge

Master-Gerät

(Gehäuse Ø 80mm)

Master gauge

(housing dia. 80mm)

Slave-Gerät (Gehäuse Ø 52mm)

Satelitte gauge (housing dia. 52mm)

Kabelbaum Master (26polig),

Wiring harness master (26-pole)

Bestell-Nr. / Order No.: A2C53041729

3000 mm

200 mm

200 mm

Kabelbaum Master - Slave

Wiring harness master - satelitte

Bestell-Nr. / Order No.: A2C53344035

Kabelbaum Slave - Slave

Wiring harness satelitte - satelitte

Bestell-Nr. / Order No.: A2C53344036

Dichtring

Seal ring

Schraubring

Clamp ring

Technische Änderungen vorbehalten Technical details subject to change

(1-8) - 1

TU00-0736-5107120 0609

Montageanleitung

Installation Instructions

Page 45

Montageanleitung

Installation Instructions

Oder eigener Zusammenbau der Kabelbäume. Nur mit folgenden Teilen:

Or own installation of the wiring harnesses. With following parts only:

8

1

4

5

6

9

7

10

11

12

13

15

14

16

17

3

2

Anwendung / Application:

A: für Kabelbaum Master (26polig) / for wiring harness master (26-pole)

B: für Kabelbaum Master - Slave / for wiring harness master - satelitte

C: für Kabelbaum Slave - Slave / for wiring harness satelitte - satelitte

Technische Änderungen vorbehalten Technical details subject to change

(1-8) - 2TU00-0736-5107120 0609

Pos.

Pos.

Bezeichnung

Designation

Anwendung

Application

Verp.-Einheit

Items / Package

Bestell-Nr.

Order No.

1 Handzange / Hand tool AMPMODU A (AMP-Nr./ No. 0-0169481-1)

2 Gehäuse /Housing AMPMODU A 700

3 Abzugsbügel / Draw-off bracket AMPMODU A 600

4 Kontaktsicherung / Contact seal AMPMODU A 2000

5 Kontaktgehäuse / Contact housing AMPMODU A 500

6 Kontakt (Master) / Contact (master) AMPMODU A 10000

7 Ausstoßwerkzeug / Push out tool AMPMODU A 2

8

Kabel 0,5mm2 / Wire 0.5mm

2

A —

9 Kabelbinder / Cable strap A, B, C —

10 Handzange / Hand tool MATE-N-LOK B, C (AMP-Nr./ No. 0-0734202-1)