Page 1

CANcockpit

Flexible instrumentation with CAN bus technology

www.vdo.com

Page 2

2

CANcockpit

Handle complex requirements with ease

The VDO brand is synonymous with customised solu-

tions that handle sophisticated technical tasks while

offering maximum ease of operation. VDO products are

deployed in a wide range of applications from construction vehicles, agricultural and forestry equipment

to stationary machines, sports cars and boats.

CANcockpit is the flexible system solution for process-

ing data from various analogue and digital sensors

via a central instrument connected to a CAN bus. It can

Engine

CAN bus 1 (e. g., SAE J1939)

CAN bus 2 (e. g., CAN Open)

be precision con figured to meet specific needs and is

simple to expand whenever required. In add i tion, this

modular instrumentation solution may be integrated

into existing VDO panel solu tions. Thanks to the

powerful WINgauge software it is exceptionally easy to

program. CANcockpit is also capable of processing

two CAN protocols (e. g., SAE J1939 and CAN open)

simultaneously.

Central instrument

Sample panel solution

Analogue

Frequency

Programming

Page 3

3

CANcockpit

Profit from these benefits

• Flexibility – Data from up to two CAN

buses running different protocols

(e. g., SAE J1939 and CAN open) can be

processed simultaneously.

• Safety – Easy DTC (diagnostic trouble

code) handling of the protocol defined

by J1939 through comprehensive functionality and setting options.

• Diagnostic support – Configuration

checking, plus online recording of

selected measurement values via recor der

function for download onto PC and

evaluation using standard tools.

• Compatibility – Analogue, frequency and

CAN inputs are available.

• Integration – CANcockpit can easily be

incorporated into existing VDO panel

solutions, with different bezels helping to

simplify fitting.

• Programmability – Specific limits can

be set and programmed so that an alarm

triggers when they are excee ded.

• Modularity – Simple cabling requirements

and straightforward subsequent expansion.

• Convenience – Automatic plausibility check

for the parameters entered and various

functional checks carried out by special

WINgauge software during input phase.

• Personalisation – Flexible LC-display

options allow icons to be defined

and corporate logos to be displayed.

• Readability – Display instruments

designed for maximum clarity.

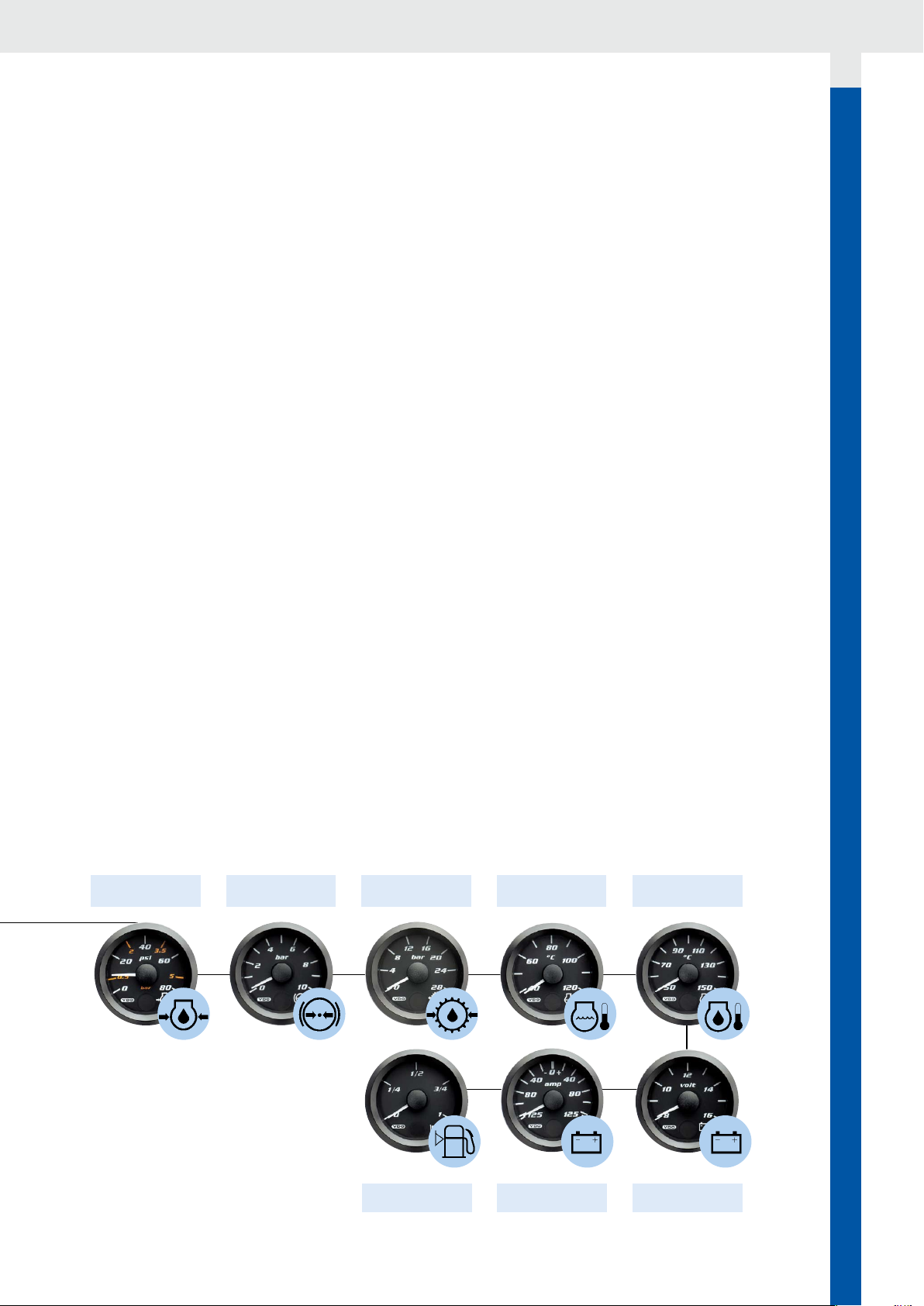

Engine oil

pressure

Up to 16 instruments can be controlled

by a central instrument. Integration

into VDO panel solutions can be carried

out easily.

Brake

pressure

Transmission

oil pressure

Coolant

temperature

Oil

temperature

Battery voltageBattery currentFuel

Page 4

4

Variable configuration

options

CANcockpit, the flexible solution for a wide range of

applications, offers numerous configuration and ex-

pansion options. It is based around a central instrument

which can be either a tachometer or a speedometer.

The central instrument features two CAN inputs sup-

porting different CAN protocols, two frequency in-

Basic configuration

Sample requirement:

A generator is to be fitted with a tachometer measuring up to 3,000 rpm. There is only one CAN bus;

the limit values and settings are clearly defined.

CANcockpit provides the solution:

Once the tachometer has been set up as the central

instrument you will have access to the desired tachometer display and the op tion of viewing other data,

e. g., as part of an inspection routine, as and when

required. All data can be displayed on the central

instru ment, allowing you to monitor current engine

data at any time without the need for other satellite

instruments.

puts, three resistive inputs, one 4–20 mA input, plus

one 0–5 volt input. In addition, it is equipped with two

switched outputs, a configurable digital display field

and more. Three sample standard applications are

shown below:

Standard configuration

Sample requirement:

Instrumentation for a digger is one example of a

standard configuration using CANcockpit. A tachometer and four more instruments need to be added

to a CAN bus.

CANcockpit provides the solution:

Once the instrumentation solution has been programmed (a simple procedure), key engine data such as

coolant/engine oil/ transmission oil temperatures will be

displayed alongside rpm and operating hours, plus

fuel level – giving you a clear overview of crucial information at all times.

CAN bus 1 CAN bus 1

(e. g., SAE J1939)

Basic configuration

CAN bus 1

Analogue

Complex configuration

Standard configuration

Page 5

5

Complex configuration

Sample requirement:

Rigorous safety requirements and different vehicle deployment scenarios (construction sites and public

roads) often require complex configurations. One example is a mobile crane, the central instrument of

which is to be hooked up to manage nine more instruments. All data comes from analogue sensors and

frequency sensors via a CAN bus.

CANcockpit provides the solution:

CANcockpit can cover even this complex configuration

with ease. The instruments are connected and set,

allowing a wide range of physical engine data to be displayed at all times, as well as e. g., hydraulic data

(CAN open). For you, this means maximum choice

when it comes to putting together the required

display instruments.

Technical data

Movement Stepper motor

Installation diameter [mm] Central instrument 80, 85, 100, satellite instruments 52, 80, 100

Lighting Backlight, LED, standard white

Protection IP65 IEC 60.529 from front

Lens Glass, coated

Bezel Plastic, black, triangular profile as standard

Future options: triangular profile in chrome and round profile in black

Plug Central instrument: 4 PIN Mate-N-Lok and 26 PIN MODU II

Satellite instruments: 6 PIN Mate-N-Lok

Display angle Approx. 210 ° for the central instrument, 240 ° for other display instruments

Warning light In each satellite instrument

CAN inputs 2 × (e. g., SAE J1939, CAN open)

Frequency inputs 1 × Hall, 1 × universal

Analogue inputs 3 × resistive, 1 × 4 – 20 mA, 1 × 0 – 5 volt

Outputs 2 × switched outputs 0.5 A

Operating voltage 12 – 24 volt (min. 10,5 volt, max. 32 volt)

Installation angle Any for central instrument, 0–85 ° for satellite instruments

Operating temperature – 40 to + 85 °C, limitated LCD readability beyond – 20 °C and + 70 °C

Storage temperature – 40 to + 85 °C

For further information about VDO visit the website at www.vdo.com.

Page 6

6

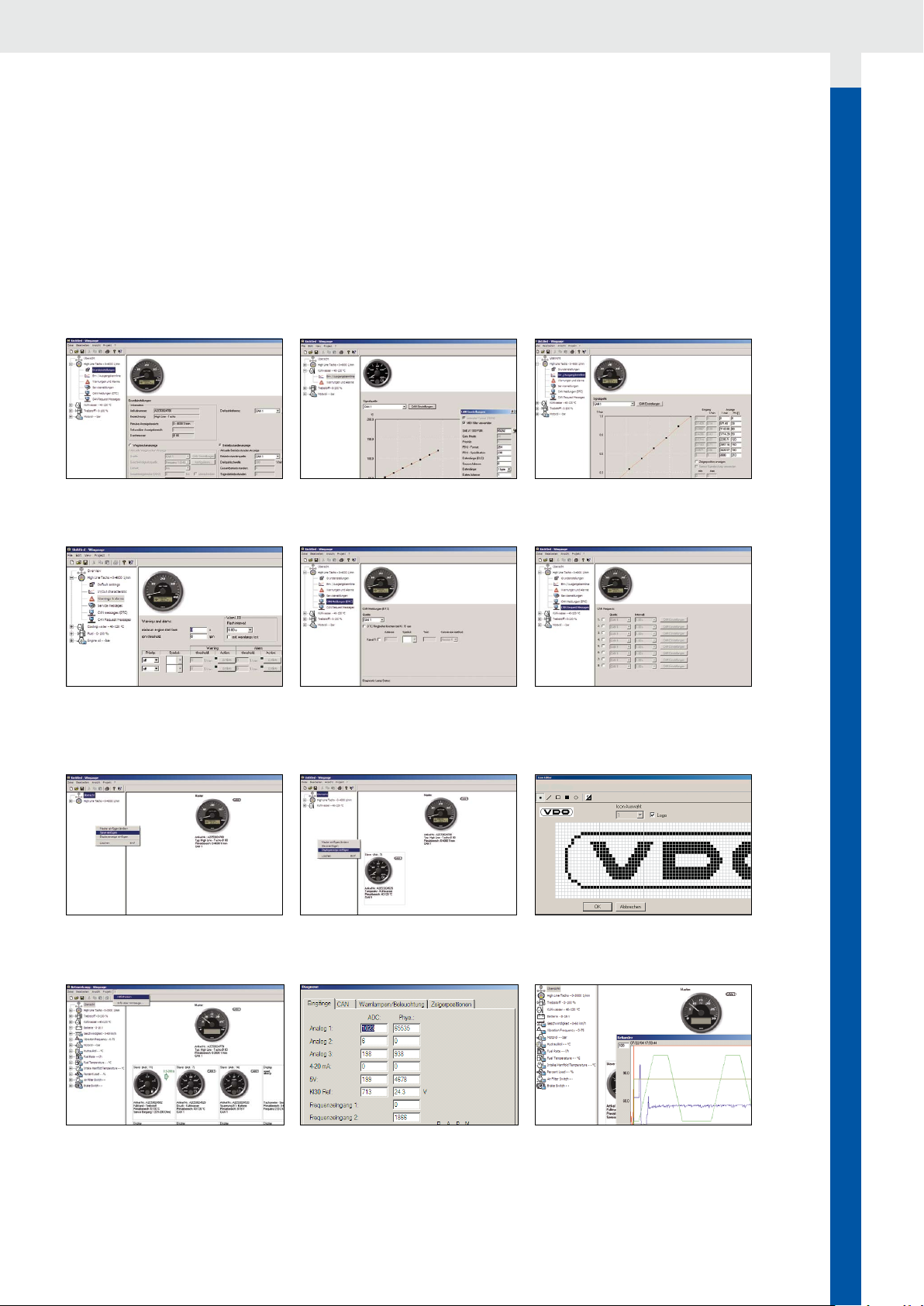

WINgauge

Flexible configuration software

WINgauge has been specially developed for CANcock-

pit. This software enables the convenient and flexible

configuration of individual instruments or a complete

series of instruments. In addition to maximum func-

tionality and customisable programming, WINgauge of-

fers maximum ease of operation. We also offers

training to help you program a CANcockpit solution.

This training tells users everything they need to know

about the innovative features, such as how to personalise the system and integrate corporate logos and

symbols into the central instrument’s display.

Page 7

7

Selecting the central instrument and

basic settings

Setting the basic CAN settings (if applicable)

Sensor database and mapping adjustemnts for optimum performance

Setting warnings and alarms including

choice of response and priorities

Adding satellite instruments Adding display gauges Programming the central instrument,

The individual project is now programmed Numerous diagnostic options are available Capturing, storing and processing select-

DTC handling and personal configuration

with individual messages and symbols

Programming of requests, e. g., query

operating hours

e. g., with a proprietary logo or symbol

ed data by connecting to a PC

Page 8

Continental Trading GmbH

Kruppstrasse 105

60388 Frankfurt

Germany

Phone: +49 69 40805-0

Fax: +49 69 40805-210

industrial@vdo.com

www.vdo.com

VDO – A Trademark of the Continental Corporation

The inf ormatio n provided in this brochure cont ains on ly gene ral des criptio ns or p erforma nce cha racteri stics, which d o not a lways apply as described in case of actual

use or which ma y change as a re sult of further develop ment of the prod ucts. This info rmation is merel y a technical d escription of t he product. This information is not

meant or intended to be a special guarantee for a particular quality or particular durability. An obligation to provide the respective characteristics shall only exist if expressly

agreed in the terms of contract. We reserve the right to make changes in availability as well as technical changes without prior notice.

A2C59512719 I Continent al Trading GmbH I Engl ish © 2008

Printed in Germany

Loading...

Loading...