Page 1

www.marine.vdo.com

www.marine.vdo.com

AcquaLink

®

Nav Box and

System AcquaLink

Installation

Instruction

06/2016 - EN (3.0)

®

Page 2

AcquaLink

®

Page 3

Content

1. Preliminary Remarks 4

2. Safety Instructions 5

2.1 Installation 5

2.2 Preliminary Remarks 7

2.3 Safety Instructions for 7

Maintenance 7

3. The Nav Box System 8

3.1 Installation of the Nav Box 8

3.2 Data Management 9

3.3 Power Connection 10

4. Connections 11

4.1 NMEA 2000® 12

4.2 SAE J1939 14

4.3 VDO Bus 17

4.4 VDO Sensor 19

4.5 NMEA 0183 20

4.6 Analogue Inputs 22

4.6.1 Resistive Inputs 24

4.6.2 Resistive Data Conversion 32

4.6.3 Frequency Input 34

4.6.4 Ampere Input 35

4.7 Buzzer Output 36

4.8 USB 36

4.9 Log Port 37

4.10 WMA Port 38

Content

5. Hardware Specications 39

3

Page 4

Preliminary Remarks

1. Preliminary Remarks

In purchasing the VDO AcquaLink Nav

Box system you have decided on a high

value product, which has been manufactured according to acknowledged technical standards. Modern production processes and compliance with currently

applicable quality assurance standards

guarantee that our products leave the factory in perfect condition.

4

We thank you for making a good choice,

and we are convinced that this instrument

will be reliable and a great help to you and

keep you safe at sea.

In order to ensure easy and safe handling

of your VDO system, you should familiarize yourself with all the features and functions.

Please take the time to read these instructions carefully and completely.

Page 5

2. Safety Instructions

2.1 Installation

This product has been developed, manufactured

and tested in accordance with the requirements

of EC and UL directives and the acknowledged

state of the art.

Please follow all the instructions given in this

handbook exactly.

ATTENTION

Please pay attention to all text

passages labeled with this symbol. These are very important

hints for operating and security

of the instruments.

Safety Instructions

5

Page 6

Safety Instructions

DANGER!

Before beginning work, the

negative Terminal of the battery

should be disconnected!

• Use of information provided by

the VDO system does not release

you from the responsibility over

your ship and demands well

seamanship. Always use your

nautical experience in interpreting

the displayed values.

• If you carry out this work yourself,

wear suitable working clothes. Do

not wear wide fitting clothes. If you

have long hair, wear a hair-net.

Clothes and hair can get caught in

moving and rotating parts.

• Wearing of metallic or conductive

jewellery, such as necklaces,

bracelets, rings etc. is not allowed

when working on the electrical

installation on board.

• Please note that with

disconnection of the battery, all

volatile electronic memories lose

their input values and must be

reprogrammed.

DANGER!

Explosion hazard!

Before beginning work on the engine compartment of petrol engines, switch on the ventilator of the

engine compartment.

• Ensure that necessary clearance

is provided behind the cable

opening, at the position where

the gauge is to be installed.

• When selecting the installation

position for gauges or displays,

take care that no stringers

are drilled. Be careful also

of furniture, floorboards,

superstructure boxes, cables

etc.

• When carrying out installation

work with a sealing compound,

solvent vapours can be

formed. Make sure of adequate

ventilation and follow the

instructions for use of the sealing

compound manufacturer.

• Please note, that the Nav Box is

not a ISO8846 certified product

and should not be installed

inside the engine compartment.

6

Page 7

2.2 Preliminary Remarks

• For the installation only use VDO

and NMEA 2000 approved cables.

• If you don’t use standard cables, the

wires used should be adequately

insulated or should have sufficient

electrical strength, and the contact

point should be protected against

electrical shock hazard. The

electrical conducting components

of the connected consuming

devices should also be protected

against direct contact through

suitable measures. Installation of

bare metallic wires and contacts is

not allowed.

• Take account of the wire cross

section. A reduction of the wire

cross section results in a higher

current density. This can cause

the wire to heat up and potentially

cause fire.

• Connect the wires only in

accordance with the wiring diagram.

Safety Instructions

2.3 Safety Instructions for

Maintenance

The VDO Nav Box system is maintenance-free. Do not use cleaning

agents.

Repairs on the system should be carried out only by VDO authorized specialists !

7

Page 8

The Nav Box System

3. The Nav Box System

The Nav Box is the heart of the VDO

AcquaLink system. To operate the

AcquaLink system you need the Nav

Box, at least one AcquaLink 4.3’’TFT

and one Nav Control. The sytem can

be accomplished with 110mm and

52mm gauges and a wide array of

sensors and transducers.

Additionally the Nav Box converts

SAE J1939 and analogue signals to

NMEA 2000.

In order to program and adjust the

system you need to refer to the

NavBox operation manual. This instruction focuses on the installation

and the connection of the NavBox to

optional sensors and transducers.

3.1 Installation of the Nav Box

In the Box:

• Nav Box

• 3 pin power cable

• 26 pin cable for analogue input

• Mounting screws

• Installation instruction

• Mouting template

• Operation manual

• 3x VDO Bus terminators

8

Please use the mounting template to

determine a proper installation location. The Nav Box can be mounted

horizontally but it is recommended

to mount the unit vertically on a bulkhead or other structure with the

cable connections pointing to the

bottom. This helps water to run off

and protect the cables from bending

and chafng.

You also have a better access to the

status LEDs on top of the unit.

Page 9

Installation of the Nav Box

1

1

2

3

Position

1 Mounting screw holes (Use all four screws to secu-

rely install the unit)

2 Status LEDs

3 Protection shield (protects connectors, offers addi-

tionally water spray protection)

Description

1

1

3.2 Data Management

The Nav Box system supports various data inputs. The received data is

prioritized in following order:

• Priority #1: Analogue Input

• Priority #2: NMEA 2000

• Priority #3: SAEJ 1939

• Priority #4: NMEA0183

9

Page 10

Power Connection

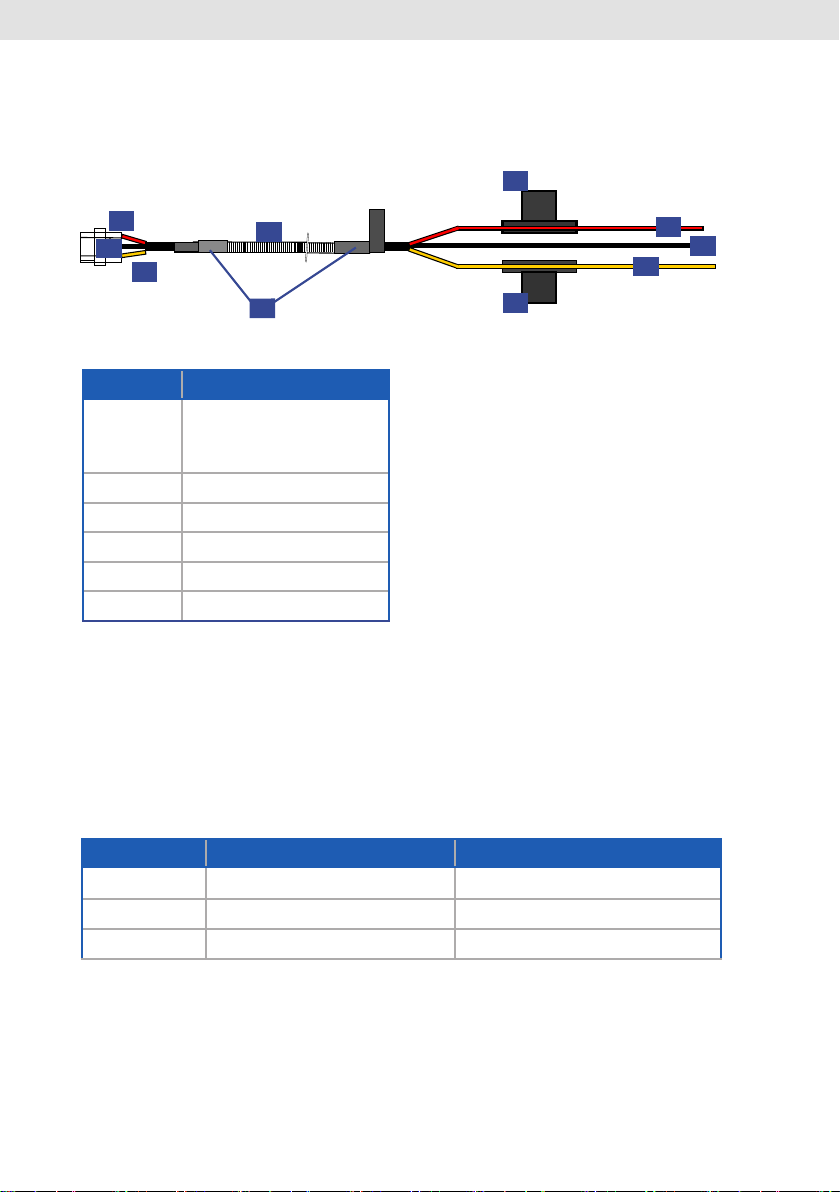

3.3 Power Connection

6

1

2

3

4

5

Position Description

1 Red

(see table "Power

Connection" for details)

2 Black

3 Yellow

4 Ribbed hose

5 Heat sink (2x)

6 Fuse 10 Amp

1

2

3

6

10

Power Connection

PIN No. Color Signal

1 Red Terminal 30 (Battery)

2 Black Terminal 31 (GND)

3 Yellow Terminal 15 (Ignition)

Page 11

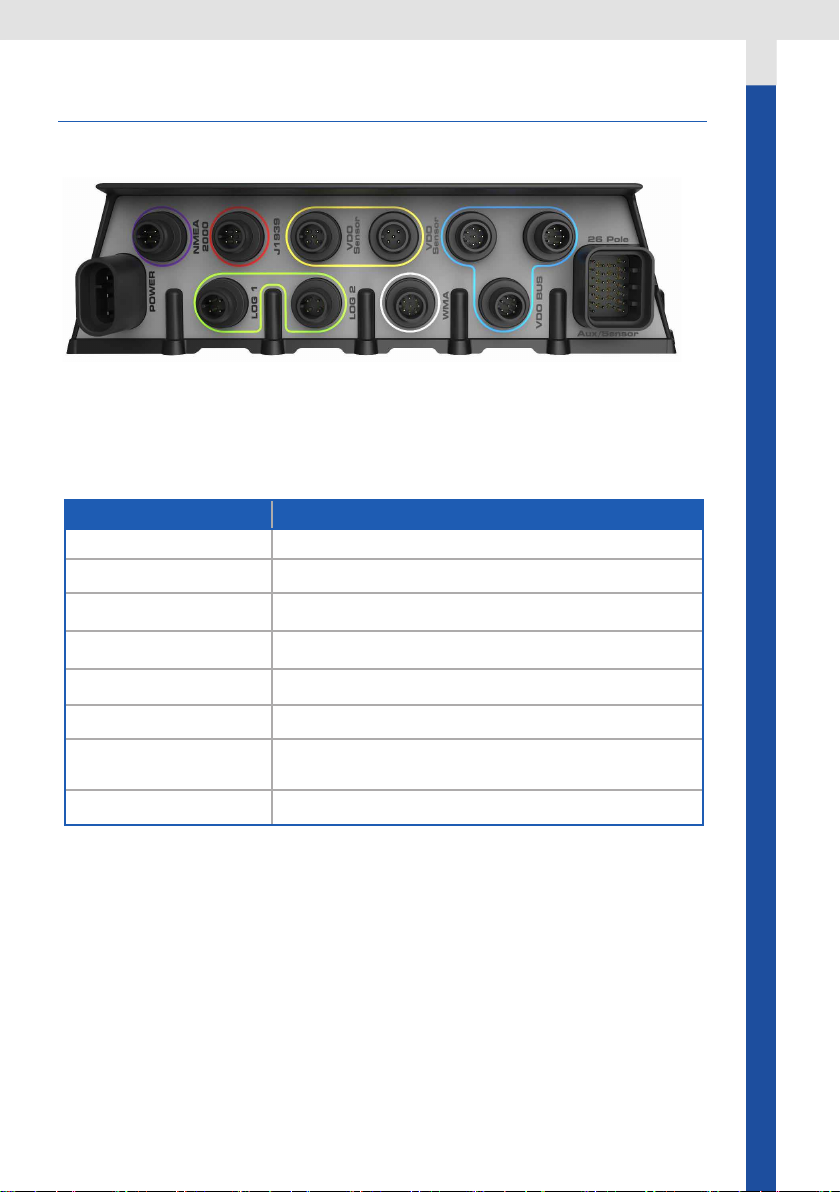

4. Connections

Nav Box: Connections

The NavBox features following

connection types:

Connections

Position

Description

POWER for 3 pin power cable

NMEA 2000

®

5 pin M12 Micro C

SAE J1939 1x SAE J1939 Input (5pin M12)

VDO Bus 3x VDO Bus (8 pin M12)

LOG 1 & LOG 2 2x Log Input (4 pin M12)

WMA 1x Wind Input (8 pin M12)

26 POLE AUX /

26 pin Analogue/NMEA0183 Input

SENSOR

VDO Sensor 2x CAN BusVDO Sensor Input (5 pin M12)

11

Page 12

NMEA 2000

4.1 NMEA 2000®

The Nav Box can be connected to an

existing NMEA 2000 system. Please

visit www.NMEA.org to nd information about NMEA 2000.

NMEA 2000 Pinout

PIN No. Signal

1 Shield

2 NET-S (V+)

3 NET-C (V−)

4 NET-H (CAN H)

5 NET-L (CAN L)

12

For NMEA 2000 voltage drop calculations

please refer to this LEN list:

Instrument LEN

Nav Box 3

Nav Control 4

110 mm Gauge 4

52 mm Gauge 2

4.3‘‘ TFT 12

Page 13

The Nav Box can receive and transmit

NMEA 2000 data. It can also convert

analogue, NMEA 0183 and SAE J1939.

It supports the reception of following

NMEA 2000 PGNs:

PGN HEX Message Name

59904 00EA00 ISO Request

60928 00EE00 ISO Address Claim

65281 00FF01 VDO Bus Proprietary Single-Frame Message

(End Of Line)

60416 00EC00 ISO Transport Protocol, Connection Manage-

ment - RTS group function

60160 00EB00 ISO Transport Protocol, Data Transfer

59392 00E800 ISO Acknowledgment

126208 01ED00 NMEA - Request group function

130306 01FD02 Wind Data

129026 01F802 COG & SOG, Rapid Update

128259 01F503 Speed, Water Referenced

128267 01F50B Water Depth

129025 01F801 Position, Rapid Update

129033 01F809 Local Time Offset

127250 01F112 Vessel Heading

127489 01F201 Engine Parameters, Dynamic

127488 01F200 Engine Parameters, Rapid Update

130312 01FD08 Temperature - DEPRECATED

130314 01FD0A Actual Pressure

127251 01F113 Rate of Turn

127257 01F119 Attitude

130310 01FD06 Environmental Parameters - DEPRECATED

130311 01FD07 Environmental Parameters- DEPRECATED

127245 01F10D Rudder

NMEA 2000

13

Page 14

SA E J19 39

PGN HEX Message Name

127505 01F211 Fluid Level

127493 01F205 Transmission Parameters, Dynamic

126992 01F010 System Time

130316 01FD0C Temperature, Extended Range

129283 01F903 Cross Track Error

129284 01F904 Navigation Data

127508 01F214 Battery Status

129291 01F90B Set & Drift, Rapid Update

For transmitting PGNs please refer to Chapter “SAE J1939” and Analogue Inputs.

In case multiple instances of the same

value are received from the NMEA

2000 network, the Nav Box has

following priorities:

• For Time Data:

1 - " System Time "

2 - "Local Time Offset"

• For Barometric Date:

1 - "ActualPressure"

2 - "EnvironmentalParameters2"

3 - "EnvironmentalParameters"

• For Temperature Data:

1 - "Temperature_Ext"

2 - "Temperature"

3 - "EnvironmentalParameters2"

4 - "EnvironmentalParameters"

4.2 SAE J1939

In general, if one message contains an

error value, the next one is considered.

NMEA 2000 Engine Support

The Nav Box system supports up to

four NMEA 2000 engines. The engines

have to be properly programmed with

individual instance numbers (0-3) by

an engine technician.

Please refer to the Operation manual

to set up the Tachometers with the

right instance numbers.

14

SAE J1939 Pinout

Page 15

PIN No. Signal

1 Shield (internally not connected)

2 Ignition (internally connected to battery when

system is ON)

3 GND

4 CAN H

5 CAN L

The Nav Box has three SAE J1939 connections:

SAE J1939 Installation

The Nav Box supports one SAE J1939

engine connection. .

SAEJ1939 Installation

Important:

If you use any of the three SAEJ1939

ports you need to terminate all three

SAE J1939 ports with three 180 ohm

resistors!

VDO offers an optional 180 ohm inline

terminator (A2C99794200).

Data Handling

The Nav Box has an interface that is

SAEJ1939 Multi Engine support

Four Engines in one CAN Bus system

SAE J1939 compatible. It is used to receive en gine data and distributes them

over VDO Bus and NMEA 2000 to make

them available for both the NMEA2000

network and the AcquaLink system.

The NavBox supports up to four SAE

J1939 engines if they are in the same

CAN Bus network system and have

different source addresses (0-3).

Supported SAE J1939 Messages:

SAE J1939 supported SPNs Description

PGN 61444 - SPN 190 Engine Speed

PGN 65270 - SPN 102 Engine Turbocharger Boost Pressure

PGN 65263 - SPN 100 Engine Oil Pressure

PGN 65262 - SPN 175 Engine Oil Temperature 1

PGN 65262 - SPN 110 Engine Coolant Temperature

PGN 65266 - SPN 183 Engine Fuel Rate

PGN 65253 - SPN 247 Engine Total Hours of Operation

PGN 65263 - SPN 109 Engine Coolant Pressure

15

Page 16

Data Handling

SAE J1939 supported SPNs Description

PGN 65276 - SPN 96 Fuel Level

PGN 65270 - SPN 173 Exhaust Gas Temperature

PGN 65269 - SPN 108 Barometric Pressure

PGN 65269 - SPN 171 Ambient Air Temperature

PGN 65272 - SPN 127 Transmission Oil Pressure

PGN 65272 - SPN 177 Transmission Oil Temperature

PGN 65279 - SPN 97 Water in Fuel Indicator

The Nav Box distributes the received

SAEJ1939 data to the NMEA 2000 network.

Following data is converted and

transmitted:

SAEJ1939 Input Data NMEA 2000 output

Engine Speed (RPM) 127488 Eng. Parameters, Rapid Update

Boost Pressure 127488 Eng. Parameters, Rapid Update

Engine Oil Pressure 127489 Eng. Parameters, Dynamic

Engine Oil Temperature 1 127489 Eng. Parameters, Dynamic

Engine Coolant Temperature 127489 Eng. Parameters, Dynamic

Engine Fuel Rate 127489 Eng. Parameters, Dynamic

Engine Total Hours of Operation 127489 Eng. Parameters, Dynamic

Engine Coolant Pressure 127489 Eng. Parameters, Dynamic

Fuel Level 127505 Fluid Level

Exhaust Gas Temperature 130316 Temperature Ext

Barometric Pressure 130314 Actual Pressure

Ambient Air Temperature 130316 Temperature Ext

Transmission Oil Pressure 127493 Trans. Parameter Dynamic

Transmission Oil Temperature 127493 Trans. Parameter Dynamic

16

The Nav Box also receives all

DM1 DTC messages of the SPN List

above.

Page 17

4.3 VDO Bus

VDO Bus Pinout

PIN No. Signal

1 Ignition / Terminal 15

2 GND / Terminal 31

3 Battery + / Terminal 30

4 CAN H

5 CAN L

6 Shield

7 Ignition / Terminal 15

8 GND / Terminal 31

VDO Bus

The VDO Bus is an NMEA2000-based

communication used within the Acqualink system to share the information

gathered from the system interfaces as

well as to distribute proprietary messages containing status information of the

system itself. The VDO Bus uses M12 8

Pin cables and all devices are powered

through the network.

The NavBox has three VDO Bus ports,

so three separate VDO Bus segments

can be installed. This helps to reduce

the power drop in the system and allows an easy installation in all areas of

the vessel.

Every 110mm gauge, 4.3’’ TFT

and Nav Control features two

equal VDO Bus connectors in the

rear.

The units are daisy chained together.

17

Page 18

VDO Bus

Important:

• All three VDO Bus segments have to

be terminated with a VDO Terminator

(included in box).

• If you haven’t connected an

instrument or Nav Control to

a Nav Box port, connect the

terminator directly to the not used

NavBox VDO port.

• If you have connected displays or

gauges, use the terminator on last

empty VDO port on the last unit in

the chain.

• There mustn't be any empty

connector

VDO Bus Limitations

Note:

VDO Bus cables have two female connectors. In order to extent the cable

length an optional gender changer

connector is needed (A2C38805500).

18

The NavBox provides power to all the

110mm gauges and 4.3’’ TFTs connected to the system. Due to the power

consumption and the resistance of the

cables, there are limitations of the maximum cable length and number of

possible instruments in the system.

In order to have a properly working

system the voltage drop of every of the

three VDO Bus segments have to be

calculated.

1 LEN = 0.05 Ampere

LEN List for VDO Products:

Instrument LEN

NavBox 3

NavControl 4

110 mm Gauge 4

52 mm Gauge 2

4.3‘‘ TFT 12

Page 19

Calculation

Calculation

12V power supply:

The voltage drop for every segment of

the VDO Bus is calculated as follow:

Ohm‘s Law: E (voltage drop) = I (circuit

current) x R (wire resistance)

R = 2/2x Cable Length (m) x Power

Pair Resistance / 100

I = LEN (Load Equivalency Number) x

0.050 amps

L = Total length of VDO Bus cables in

one segment

-> E = 0.05 x LEN x L x 0.057

The voltage drop for each VDO Bus

Segment shouldn’t be higher than 3V

4.4 VDO Sensor

You can connect the VDO Navsensor

and VDO NMEA 2000 Windsensor directly to the NavBox without using the

NMEA 2000 Network

Note:

VDO Bus has 2x AWG 22 Power/

Ground cables -> so there is different

voltage drop calculation than NMEA

2000.

24V power supply:

If using a 24V system the voltage drop

may not be higher than 9V.

Note:

The maximum Number of LEN in the

NavBox system is 120 equals 6 Ampere.

Note:

One 120ohm resistor has to be installed as close as possible to the sensor.

19

Page 20

NMEA 0183

4.5 NMEA 0183

The NavBox can receive NMEA 0183

data and distributes it over VDO Bus

and NMEA2000 to make them available for both the AcquaLink system and

the NMEA 2000 network.

The NavBox supports following NMEA

0183 sentences:

NMEA 0183 supported sentences Description

RMC Recommended Minimum Navigation

Information

MTW Sea-Water temperature

DBT Depth Below Transducer

VHW Water Speed and Heading

VTG Track Made Good and Ground Speed

XTE Cross-Track Error, Measured

MWV Wind Speed and Angle

HDM Heading - Magnetic

HDG Heading - Deviation & Variation

BWC Bearing and Distance to Waypoint, Latitu-

de, N/S, Longitude, E/W, UTC, Status

20

Page 21

The received data is converted to following NMEA 2000 data:

NMEA 0183

NMEA 0183

Input Data NMEA 2000 / VDO Bus output

sentence

UTC Time 126992 SystemTime

Latitude 129025 PosRapidUpdate

Longitude 129025 PosRapidUpdate

RMC

Speed Over Ground Not forwarded with this sentence

Only over VTG so far

MTW Water Temperature 130316 Temperature_Ext

DBT Depth, meters 128267 WaterDepth

True Heading –

VHW

Magnetic Heading 127250 VesselHeading

Speed Through Water 128259 Speed, Water Referenced

VTG Speed Over Ground 129026 COGSOGRapidUpdate

XTE Cross Track Error 129283Cross Track Error

MWV Wind Angle 130306 Wind

Wind Speed 130306 Wind

HDM Magnetic Heading 127250 VesselHeading

Magnetic Heading 127250 VesselHeading

HDG

Deviation 127250 VesselHeading

BWC Bearing (True) To Waypoint 129284 Navigation Data

21

Page 22

Analog Inputs

NMEA 0183 Connection

To connect a NMEA 0183 device to the

NavBox use the analogue harness included in the box.

Sensor NavBox Pin Color Description

NMEA 0183 Rx 20 White/Red NMEA 0183 Rx A

14 Brown/Red NMEA 0183 Rx B

4.6 Analogue Inputs

The NavBox allows supports several

analogue inputs. The received data is

displayed in the AcquaLink system

and converted to NMEA 2000 messages

26 Pole Aux/Sensor

22

26 Pole Pinout

26 Pole

1

20

14

8

2

21

15

9

3

22

16

10

4

23

17

11

5

24

18

12

6

25

19

13

7

26

Aux/Sensor

Page 23

Analogue Inputs

Position Description

1 Connector type: Tyco Super Seal 1.0 mm (Tyco PN: 1473416-1)

2 Shrink tube (2x)

3 Ribbed hose

6 Label imprint

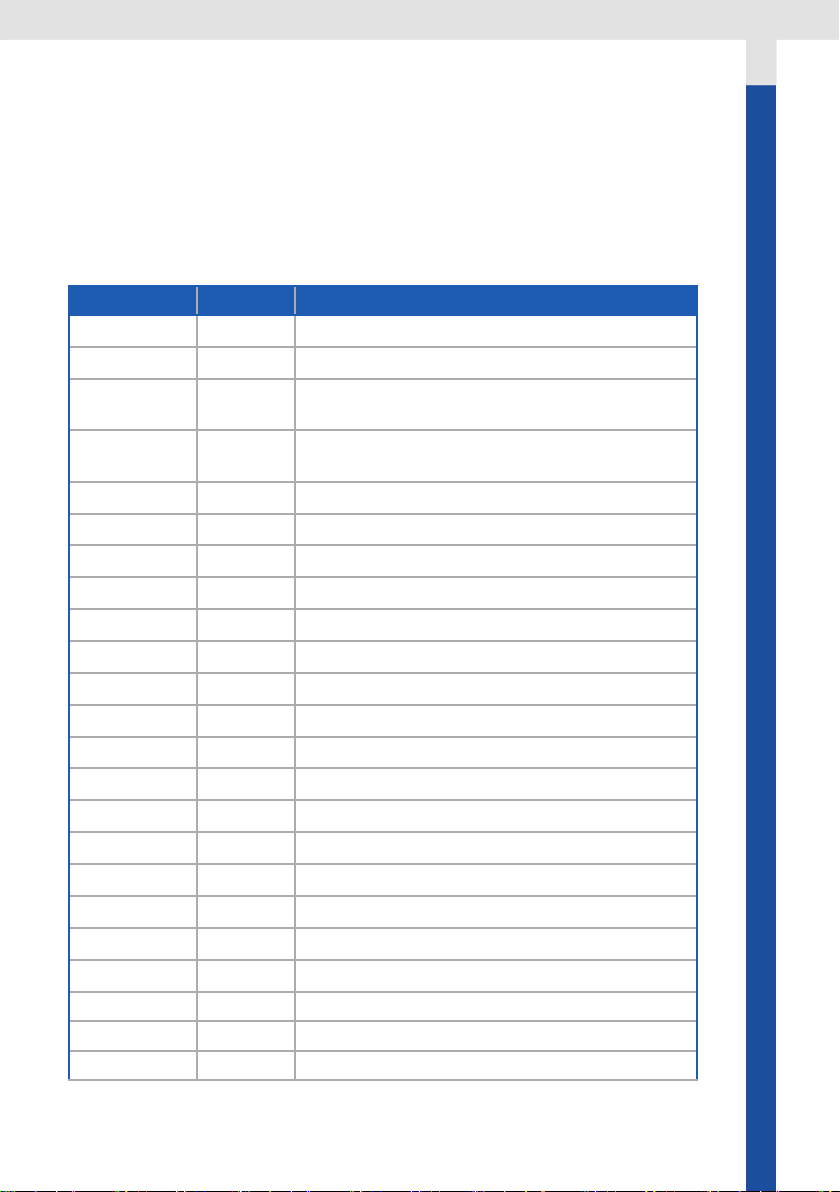

Pin Signal In-/output range Coding TBD

1 Low Side Switch (Buzzer) 0.5A max brown

6 0-5V GND black

7 High Side (Aux) 0.7A max red

8 Engine Freq. GND - brown-blue

9 Engine Freq. (universal WWG) 0–4 kHz; W, 1, Ind,

white-blue

Generator, Lightning Coil

10 Engine Cool Water Temp 0–500 Ohm blue

11 NMEA0183 B (Talker) RS422 white

12 NMEA0183 A (Talker) RS422 white-grey

13 Engine Oil Temp 0–500 Ohm violet

14 NMEA0183 B (Listener) RS422 brown-red

15 Engine Oil Pressure 0–500 Ohm green

16 Rudder Angle 0–500 Ohm yellow

17 Fuel 1 0–500 Ohm white-green

18 Fuel 1 GND - brown-green

19 Transmission oil pressure 0–500 Ohm; 0–30 Bar pink

20 NMEA0183 A (Listener) - white-red

21 Fresh Water 4–20 mA white-yellow

22 Black Water 4–20 mA grey

23 Amperemeter (−) +/−60 mV yellow-brown

24 Amperemeter (+) +/−60 mV red-blue

25 Signal GND - pink-brown

26 0-5V (Signal 1) 0–5V grey-brown

23

Page 24

Fuel Level

4.6.1 Resistive Inputs

The NavBox implements six resistive

inputs to allow the connection of the

following sensors:

• Fuel Level sensor

• Rudder Angle sensor

• Engine Oil Temperature sensor

• Engine Oil Pressure sensor

• Transmission Oil Pressure sensor

• Engine Coolant Water Temperature

sensor

Fuel Level

There are three different Ohm ranges

for the fuel sensor input available:

• 2-90 ohm

• 3-18 0 o h m

• 240-33.5 ohm

24

Available VDO products:

A2C Number Description

226-801-015-001G Adjustable Lever Arm Sensor 10–180 ins grnd

A2C59510162 Adjustable Fuel Lever Arm Sensor 10–180 Ω w/c

A2C59510163 Adjustable Fuel Lever Arm Sensor 240–33 Ω w/c

A2C59510164 Adjustable Fuel Lever Arm Sensor 90–0 Ω w/c

A2C59510165 Adjustable Lever Arm Sensor ALAS I

A2C59510166 Adjustable Lever Arm Sensor ALAS I

A2C59510167 Adjustable Lever Arm Sensor ALAS I

A2C59510168 Adjustable Fuel Lever Arm Sensor 10–180 Ω wo/c

A2C59510169 Adjustable Fuel Lever Arm Sensor 240–33 Ω wo/c

A2C59510170 Adjustable Fuel Lever Arm Sensor 90–0 Ω wo/c

A2C59510171 Adjustable Lever Arm Sensor ALAS I

A2C59510172 Adjustable Lever Arm Sensor ALAS I

A2C59510173 Adjustable Lever Arm Sensor ALAS I

Page 25

Connection

Sensor NavBox Pin Color Description

Fuel 17 White/Green Fuel Input

GND 18 Brown/Green Fuel GND

For calibration please refer to the

Operation manual.

Rudder Angle

The NavBox system supports one resistive rudder sensor input.

Ohm range: 5–190 Ohm

A2C Number Description

A2C110295001 Rudder angle sensor single station 10–180 Ω

Rudder Angle

Connection

Sensor NavBox Pin Color Description

Rudder 16 Yellow Rudder Angle

GND 25 Pink/Brown Signal GND

For calibration please refer to the

Operation manual.

25

Page 26

Temperature Sensors

Temperature Sensors

The Nav Box supports one input for

engine oil and one for coolant oil temperature.

Available VDO sensors:

A2C Number Description

323-801-001-006N Temp Sender 120°C (Earth Ret) M14 x 1.5

323-801-001-007N Temp Sender 120°C (Earth Ret)

323-801-001-008N Temp Sender 120°C(Earth Ret)5/8-18UNF-3A

323-801-001-009N Temp Sender 120°C (Earth Ret)

323-801-001-010N Temp Sender 120°C (Earth Ret) 1/2-14NPTF

323-801-001-022N Temp Sender 120°C (Earth Ret)

323-801-001-029N Temp Sender 250F M16X1.5 801/1/29

323-801-001-040N Temp Sender 120°C (Earth Ret) M16 x 1.5

323-801-001-058C Temp Sender, Elec.

323-801-004-002N Temp Sender 150°C (Earth Ret) M14 x 1.5

323-801-004-003D Temp Sender 150°C (Earth Ret) R1/2

323-801-004-007D Temp Sender 150°C (Earth Ret) 1/2-14NPTF

323-801-004-012C Temp Sender 150°C (Earth Ret) M16 x 1.5

323-801-004-017D Temp Sender 150°C (Earth Ret)

323-801-004-039D Temp Sender 150°C (Earth Ret) M14 x 1.5

323-801-005-001D Temp Sender 250F 1/8-27NPT

323-801-008-002D Temp Sender Outside Air −25°+1

323-801-010-001D Temp Sender 150°C (Earth Ret) M10 X 1.5

323-801-012-001D Temp Sender 150°C (Earth Ret)

323-801-012-002D Temp Sender 150°C (Earth Ret)

323-801-012-003D Temp Sender 150°C (Earth Ret)

323-801-017-001N Temp Sender 120°C (Earth Ret) M10 X 1

26

Page 27

Temperature Sensors

A2C Number Description

323-805-001-001N TRAS.VDO 14*1,5 120° PI

323-805-001-002C Temp Sender 120°C(Insul/Ret)5/8

323-805-001-004N Temp Sender 120°C (Insul/Ret)

323-805-001-005N Temp Sender 120°C(Insul) 3/8-18 NPTF

323-805-001-015N Temp Sender 120°C (Insul/Ret) M18 x 1.5

323-805-003-001N Temp Sender 150°C (Insul/Ret) M14 x 1.5

323-805-003-002N Temp Sender 150°C (Insul) 1/4-18NPFT

323-805-003-003N Temp Sender 150°C (Insul/Ret) 5/8-18UNF

323-805-039-001C TRASM.130°C 14x1.5

323-805-042-001C Temp Sender 140°C (Insul) M14x1.5 Spec Con

A2C59515306 Temp Sender (Neutral Version A2C59900814)

A2C59515307 Temp Sender (Neutral Version A2C59900815)

A2C59900813 Temp Sender (PDMA2C53025662:323-805-55-1)

A2C59900816 Temp Sender (PDMA2C53308318:40250127)

323-803-001-001D Temp Sender 120°C( Earth) WC100° M14 x 1.5

323-803-001-004D Temp Sender 120°C (Earth) WC90° M14 x 1.5

323-803-001-006D Temp Sender 120°C (Earth) WC96°

323-803-001-007D Temp Sender 120°C (Earth) WC110°

323-803-001-008D Temp Sender 120°C (Earth) WC110° M14x 1.5

323-803-001-009D Temp Sender 120°C (Earth) WC102° M14x 1.5

323-803-001-011D Temp Sender 120°C (Earth) WC98° 5/8-18NF-3

323-803-001-012D Temp Sender 120°C (Earth) WC100° 5/8-18NF

323-803-001-013D Temp Sender 120°C (Earth) WC106° M14x 1.5

323-803-001-016D Temp Sender 120°C (Earth) WC94° M14x 1.5

323-803-001-019D Temp Sender 120°C (Earth) WC95° 1/2-14NPT

323-803-001-022D Temp Sender 120°C (Earth) WC118° M14x 1.5

323-803-001-025D Temp Sender 250F WC217F 1/2-14NPT

323-803-001-028D Temp Sender 120°C (Earth) WC98° M14x 1.5

27

Page 28

Pressure Sensors

A2C Number Description

323-803-001-030D Temp Sender 120°C (Earth) WC100° 1/2-14NPT

323-803-001-032D Temp Sender 250F WC230F 1/2-14NPT

323-803-001-059D Temp Sender 120°C (Earth) WC105° 5/8-18NF

323-803-001-060D Temp Sender 120°C (Earth) WC105° 1/2-14NPT

323-803-002-002D Temp Sender 150°C (Earth) WC120° M14X 1.5

323-803-002-007D Temp Sender 150°C (Earth) WC130° M14X 1.5

323-803-002-010C Temp Sender 150°C (Earth) WC135° M14x 1.5

323-803-002-016D Temp Sender 150°C (Earth) WC130° M14x 1.5

323-803-002-017D Temp Sender 150°C (Earth) WC120° M14x 1.5

323-803-002-019D Temp Sender 150°C (Earth) WC135° M14x 1.5

323-803-002-020D Temp Sender 150°C (Earth) WC110° M14x 1.5

325-805-003-001C Temp Sender 120°C (Insul) 1/4-18 D/Stat.

325-805-003-003C Temp Sender 120°C (Insul) 3/8-18

323-809-019-003A Temp Sender 120°C (Insul) M18x1.5 Spec Con

Connection

Sensor NavBox Pin Color Description

Temp 10 Blue Coolant Water Temp

GND 25 Pink/Brown Signal GND

For calibration please refer to the

Operation manual.

Pressure Sensors

The Nav Box supports one input for

engine oil and one for transmission oil

pressure.

Available VDO products:

28

13 Violet Engine Oil Temp

Page 29

TFT-Display einbauen

A2C Number Description

360-081-029-001C Press Sender 5 Bar (E/Ret) M10 x 1(Short)

360-081-029-001C Press Sender 5 Bar (E/Ret) M10 x 1(Short)

360-081-029-004C Press Sender 80 PSI 1/8-27NPT 29/4

360-081-029-008C Press Sender 5 Bar (E/Ret) 1/4-

360-081-029-012C Press Sender 150 PSI 1/8-27NPT 29/12

360-081-029-013C Press Sender 10 Bar (E/Ret) M12x1.5

360-081-029-020C Press Sender 10 Bar (E/Ret) 1/4-18NPTF

360-081-029-026C Press Sender 5 Bar (E/Ret) M14

360-081-029-026K Press Sender 5 Bar (E/Ret) M14 x 1.5

360-081-029-033C Press Sender 10 Bar (E/Ret) M14 x 1.5

360-081-029-041C Press Sender 5 Bar (E/Ret) 1/8-27NPTF

360-081-029-042C Press Sender 10 Bar (E/Ret) 1/8-27NPTF

360-081-029-059C Press Sender 5 Bar (E/Ret) M18 x 1.5

360-081-029-062C Press Sender 10 Bar 1/8-28BSP 2

360-081-029-085C Press Sender 5 Bar (E/Ret) M12

360-081-037-003C Press Sender 25 Bar (E/Ret) M18 x 1.5

360-081-037-006C Press Sender 16 Bar (E/Ret) M14 x 1.5

360-081-037-007C Press Sender 16 Bar (E/Ret) 1/8-27NPTF

360-081-037-008C Press Sender 25 Bar (E/Ret) M10 x 1

360-081-037-010C Press Sender 25 Bar (E/Ret) 1/8-27NPFT

360-081-037-017C Press Sender 25 Bar (E/Ret) M14 x 1.5

360-081-037-018C Press Sender 25 Bar (E/Ret) M18 x 1.5

360-081-037-019C Press Sender 16 Bar (E/Ret) M12 x 1.5

360-081-032-001C Press Sender 5 Bar (Insul/Ret) 1/8-27NPFT

360-081-032-002C Press Sender 5Bar (Insul/Ret) M10x1

360-081-032-003C Press Sender 10 Bar (Insul/Ret) M10x1

360-081-032-004C Press Sender 10 Bar (E/Ret) M12 x 1.5

360-081-032-006C Press Sender 10 Bar (Insul/Ret) M14 x 1.5

360-081-032-007C Press Sender 5 Bar (Insul/Ret) 1/8-27NPTF

360-081-032-011C Press Sender 2 Bar (Insul/Ret) M12 x 1.5

360-081-032-013C Press Sender 5 Bar (Insul/Ret) M18 x 1.5

Pressure Sensors

29

Page 30

Pressure Sensors

A2C Number Description

360-081-032-014C Press Sender 150 PSI FG 1/8-27NPT 32/14

360-081-032-025C Press Sender 2 Bar (Insul/Ret)1

360-081-032-053C Press Sender 10 Bar (Insul/Ret) M12 x 1.5

360-081-032-057C Press Sender, Elec.

360-081-032-058C Press Sender, Elec.

360-081-032-060C Press Sender 5 Bar (Insul/Ret) M14 x 1.5

360-081-038-001C Press Sender 25 Bar (Insul/Ret)

360-081-038-002C Press Sender 25 Bar (Insul/Ret)

360-081-038-003C Press Sender 25 Bar (Insul/Ret)1/8-27nptf

360-081-038-005C Press Sender 25 Bar (Insul/Ret) M18 x 1.5

360-081-051-012C Press Sender 10 Bar (Insul/Ret) M16 x 1.5

360-081-051-013C Press Sender 7 Bar (Insul/Ret)1/8-27NPTF

360-081-030-004C Press Sender 5 Bar (E/Ret) W/C

360-081-030-008C Press Sender 5 Bar (E/Ret) W/C 0.5 M12

360-081-030-009C Press Sender 150 PSI WC7 M10X1K 30/9

360-081-030-010C Press Sender 5 Bar (E/Ret) W/C1.4 1/8-27

360-081-030-015C Press Sender 10 BAR WC0.8 1/8-27NPT

360-081-030-017C Press Sender 10 Bar (E/Ret) W/C0.9 M10x1

360-081-030-018C Press Sender 5 Bar (E/Ret) W/C1.2 M10x1

360-081-030-019C Press Sender 10 Bar (E/Ret) W/C1.5 M12

360-081-030-020C Press Sender 80 PSI(E/Ret) W/C8

360-081-030-022C Press Sender 10 Bar (E/Ret) W/C

360-081-030-023C Press Sender 80 PSI WC7 1/8-27NPT 30/23

360-081-030-028C Press Sender 5 Bar(E/Ret)W/C0.5

360-081-030-030C Press Sender 10 Bar(E/Ret)W/C0.7 M14x1.5

360-081-030-032C Press Sender 10 Bar(E/Ret)W/C0.5 M14x1.5

360-081-030-036C Press Sender 5 Bar(E/Ret)W/C0.5 M18x1.5

360-081-030-037C Press Sender 10 Bar(E/Ret)W/C0.75 M18x1.5

360-081-030-039C Press Sender 10 Bar(E/Ret)W/C0.75 M10x1

360-081-030-041C Press Sender 10 Bar(E/Ret)W/C2.

360-081-030-049K Press Sender 5 Bar(E/Ret)W/C0.4 1/8-27NPT

360-081-030-052C Press Sender 10 Bar(E/Ret)W/C0.4 1/8-27NP

30

Page 31

Pressure Sensors

A2C Number Description

360-081-030-063C Press Sender 10 Bar (E/Ret) W/C1.0 M14x1.5

360-081-030-070C Press Sender 10 Bar (E/Ret) W/C0.5 M18x1.5

360-081-030-071C Press Sender 5 Bar (E/Ret) W/C0.4 M14x1.5

360-081-030-074C Press Sender 10 Bar (E/Ret) W/C0.5 M18x1.5

360-081-030-086C Press Sender 5 Bar (E/Ret) W/C0.5 1/8-27NPT

360-081-030-097C Press Sender 5 Bar (E/Ret) W/C0.5 M14x1.5

360-081-030-100C Press Sender 10 Bar (E/Ret) WC4.0 1/8-27NPT

360-081-030-107C Press Sender 10 Bar (E/Ret) W/C5.

360-081-030-112C Press Sender 10 Bar(E/Ret)W/C1.35 M10x1

360-081-030-119C Press Sender 5 Bar(E/Ret)WC1.4 1/8-27NPTF

360-081-030-122C Press Sender 10 Bar (E/Ret) W/C0.75 M18x1.5

360-081-030-138C Press Sender 10 Bar (E/RET) W/C1.25 1/8-27

360-081-030-152C Press Sender 10 Bar (E/Ret) W/C5.2 M10x1

360-081-030-157C Press Sender 5 Bar (E/Ret) W/C0.5 M18x1.5

360-081-034-002C Press Sender 5 Bar (E/Ret) W/C0.25 M14x1.5

360-081-053-003C Press Sender 25 Bar (E/Ret) W/C5.5 M18x1.5

360-081-061-002C Press Sender 10 Bar (E/Ret) W/C0.7 M14x1.5

360-081-061-006C Press Sender 10 Bar (E/Ret) W/C5.0 M12x1.5

360-081-062-002A Press Sender 5 Bar (E/Ret) W/C0.4 M14x1.5

360-081-062-003C Press Sender 10 Bar (E/Ret) W/C5.5 M14x1.5

360-081-062-004A Press Sender 5 Bar (E/Ret) W/C1.0 M14x1.5

360-081-062-005A Press Sender 10 Bar (E/Ret) W/C3.0 M14x1.5

360-081-039-002C Press Sender 5 Bar (Insul) WC0.8 1/8-27NPTF

360-081-039-003C Press Sender 10 Bar (Insul) WC0.8 1/8-27NPT

360-081-039-004C Press Sender 80 PSI (Insul) WC10 1/8-27NPTF

360-081-039-007C Press Sender 10 Bar (Insul) WC1.0 M14 x 1.5

360-081-039-015C Press Sender 5 Bar (Insul) WC0.25 1/8-27

360-081-063-001C Press Sender 10 Bar (Insul) WC5.2 M12 x 1.5

360-081-064-001C Press Sender 5Bar (Insul) WC0.25 M18 x 1.5

360-081-064-003C Press Sender 5 Bar (E/Ret) W/C0.25 M18x1.6

360-081-064-004C Press Sender 10 Bar (Insul) WC0.6 M18 x 1.5

362-081-001-002C Press Sender 150 PSI 1/8-27NPT

31

Page 32

Resistive Data Conversion

A2C Number Description

360-081-030-085C Press Sender, Elec.

362-081-001-002K Press Sender, Elec., DUAL-STATIO

362-081-002-001K Press Sender 350 PSI 1/8-27NPT

362-081-002-003C Press Sender 400 PSI (E/Ret) 1/

362-081-002-004C Press Sender 400 PSI (E/Ret) 1/

362-081-003-002K Press Sender 150 PSI 1/8-27NPT DUAL

362-081-004-001C Press Sender 350 PSI DUAL 4:1

365-100-010-121C Electronic Press Sensor 10 bar (40692031)

365-100-016-121C Electronic Press Sensor 16 bar (40692032)

365-100-030-121C Electronic Press Sensor 30 bar (40692033)

Connection

Sensor NavBox Pin Color Description

Pressure 15 Green Engine Oil Pressure

19 Pink Transmission Oil Pressure

GND 25 Pink/Brown Signal GND

32

For calibration please refer to the

Operation manual.

4.6.2 Resistive Data Conversion

The received data is converted to

NMEA 2000 data and transmitted to a

NMEA 2000 network

Resistive Input Data NMEA 2000 / VDO Bus output

Fuel Level 127505 Fluid Level

Rudder Angle 127245 Rudder

Engine Oil Temperature 127489 Eng. Parameters,

Engine Oil Pressure 127489 Eng. Parameters,

Transmission Oil Pressure 127493 Trans. Parameter Dynamic

Coolant Water Temperature 127489 Eng Parameters

Page 33

Resistive Data Conversion

Current Inputs (4 ... 20 mA)

The NavBox implements two 4 ... 20 mA

current inputs to allow the connection

of the following sensors:

• Fresh Water sensor

• Waste Water sensor

Available VDO products:

A2C Number Description

N02-240-802 OL Watertanksensor 600 mm

N02-240-902 Sender Black Water 600 mm 4–20 mA 12/24 V

N02-240-904 Sender Black Water 1200 mm 4–20 mA 12/24 V

N02-240-906 Sender Black Water 1500 mm 4–20 mA 12/24 V

N02-240-402 Sensor Fresh water 600 mm 4–20 mA 12/24 V

N02-240-404 Sensor Fresh water 1200 mm4–20 mA12/24 V

N02-240-406 Sender Fresh Water 1500 mm 4–20 mA 12/24 V

Connection

Sensor NavBox Pin Color Description

4..20mA 21 White/Yellow Fresh Water

22 Grey Waste Water

GND 25 Pink/Brown Signal GND

For calibration please refer to the

Operation manual.

Data Conversion

The received data is converted to

NMEA 2000 data and transmitted to a

NMEA 2000 network

Current Input Data NMEA 2000 / VDO Bus output

Fresh Water Level 127505 Fluid Level

Waste Water Level 127505 Fluid Level

33

Page 34

Frequency Input

4.6.3 Frequency Input

The NavBox supports one frequency

input to allow the connection of the

following sensors:

• Engine Speed signal (pulses)

The frequency range for this input

is 0 to 4kHz.

Supported VDO products:

A2C Number Description

340-216-005-001C Generator Sender 90 mm Alt. 2159-50004201

340-216-005-002C Generator Sender 63 mm Alt. 2159-50004401

340-216-010-003C Generator Sender 25 mm Alt. 2159-50004601

A2C59513983 Blocking Oscilator

340-216-010-004C Generator Sender 90.2 mm M18x1.5 21.5-30V

340-804-005-001C Inductive Sender 35 mm (Kostal)

340-804-005-007C Inductive Sender 35 mm (Kostal)

340-804-005-013A Inductive Sender 71.4 mm (Kostal) M18x1.5

340-804-005-028C Inductive Sender 63.4 mm (Kostal) M18x1.5

340-804-005-033C Transm. Inductive 18x1.5 L.T.63

340-804-006-002C Inductive Sender Unit, Elec.

340-804-006-007C Inductive Sender 34 mm (Blade) M18x1.5

340-804-007-002A Inductive Sender 28.5 mm (Blade) M18x1.5

340-804-007-003C Inductive Sender 34 mm (Blade) M18x1.5

340-804-007-004C Inductive Sender 28.5 mm (Blade)3/4-16UNF

340-804-007-011C Inductive Sender 34 mm (Blade) M18x1.5

340-804-007-011G Inductive Sender 34 mm (Blade) M18x1.5

340-804-007-019C Inductive Sender 70.7 mm (Blade) M18x1.5

340-804-030-005B Inductive Sender 25 mm M18x1.5

340-804-077-007C Sensor Turbo Speed DDC

340-807-001-001C Generator Type Sender 3000 RPM

340-807-001-003C Generator Type Sender 3000 RPM

34

Page 35

A2C Number Description

340-808-001-001C Generator Type Sender 3000 RPM

340-808-001-002C Generator Type Sender 3000 RPM

Connection

Sensor NavBox Pin Color Description

Freq. 9 White/Blue Engine Freq.

GND 8 Brown/Blue Engine Freq. GND

For calibration please refer to the

Operation manual.

Data Conversion

The received data is converted to

NMEA 2000 data and transmitted to a

NMEA 2000 network.

Ampere Input

Current Input Data NMEA 2000 / VDO BUS output

Engine Speed (RPM) 127488 Eng. Parameters, Rapid Update

4.6.4 Ampere Input

The NavBox supports one ampere

input.

The voltage range for this input shall

be 0 to +/−60mV.

Supported VDO products:

A2C Number Description

A2C59514043 SHUNT AMMETER 60A

A2C59514047 SHUNT AMMETER 150A

35

Page 36

Buzzer Output

Connection

Sensor NavBox Pin Color Description

Ampere 23 Yellow/Brown Amperemeter (−)

24 Red/Blue Amperemeter (+)

For calibration please refer to the

Operation manual.

Data Conversion

The received data is converted to

NMEA 2000 data and transmitted to a

NMEA 2000 network.

Current Input Data NMEA 2000 / VDO BUS output

Battery Current 127508 - Battery Status

36

4.7 Buzzer Output

The NavBox buzzer output can be ac-

tivated in alarm situations and congu-

red through the alarm menu.

Connection

Sensor NavBox Pin Color Description

Buzzer (LSS) 1 Brown Buzzer Out (Low Side Switch)

GND 25 Pink/Brown Signal GND

4.8 USB

In the current software version the

USB connection can only be used for

service functions.

Page 37

4.9 Log Port

Log Port Pinout

PIN No. Signal In-/output range

1 Sensor Power 8V

2 LOG IN 0.2–800Hz

3 GND 0.2–800Hz

Log Port

The NavBox supports two VDO Sumlog sensors. The system automatically

detects the sensor with the faster

speed through water data and distributes it to the system.

All VDO Sumlog sensors are compatible.

Please refer to the Sumlog installation

instruction for details.

Data Conversion

PGN Description

128259 Speed, Water Referenced

37

Page 38

WMA Port

4.10 WMA Port

WMA Port Pinout

PIN No. Signal In-/output range

1 Power 8V

2 Not Used

3 COS 2-6V

4 GND 0V

5 SIN 2–6V

6 Wind Speed 0.8–100Hz

7 Not Used

8 Not Used

The NavBox supports one analogue VDO Windsensor

38

Following sensors are supported:

• “Standard” Series Sensors

• Logic Series Sensors

• AcquaLink analogue Sensors

Please refer to the Windsensor installation instruction for details.

Data Conversion

PGN Description

130306 Wind Data

Page 39

5. Hardware Specifications

Hardware Specifications

39

Page 40

Hardware Specifications

40

Position

Description

Housing Material Al Mg9 F/ e-coated (epoxy based) black RAL9005

Top Cover PBT GB20 black

Connectors VDO Bus: 3x M12 8 Pin; Power: 3 Pin AMP Superseal;

NMEA 2000: 1x M12 5 Pin; SAEJ1939: 1x M12 5 Pin;

WMA: 1x M12 8 Pin, Log: 2x M12 4 Pin; 26 Pin Analogue Harness

Operating temperature −20° / +70°

Storage temperature −40 / +85°

Operating voltage range 8 – 28 VDC

Protection Class IP 67

According to IEC 60529:2001; in nominal position

EMC DIN-EN 61000-6-2:2006 IEC 60945:2002

Approval CE

Page 41

41

Page 42

Continental Automotive Switzerland AG

Industriestrasse 18

9464 Rüthi

Switzerland

Phone: +41 7176 79-111

www.marine.vdo.com/

VDO – A Trademark of the Continental Corporation

The info rmati on provi ded in this broc hure co ntains o nly gene ral des cript ions or p erfo rmanc e characteristic s,

which do not always apply as descri bed in ca se of actual use or w hich may c hange as a result of f urther devel opment of the produc ts. Thi s infor mation i s merel y a techni cal des cript ion of th e product. It is not meant or i ntende d

to be a special guarantee for a particular quality or particular durability. An obligation to provide the respective

charac teristics sh all only ex ist if exp ressly agreed i n the ter ms of contract. We reser ve the right to make c hanges

in availab ility a s well as te chnic al chan ges wit hout pr ior noti ce.

A2C12119500 | C ontine ntal Automotive Switzerlan d AG I Englis h © 2016

42

Loading...

Loading...