Page 1

MC 885-SDHL

Spray/Dry High/Low Thermostat

VDH doc: 180146 Version: v1.0 Date: 05-02-2018

Software: 110365_MC 885 SDHL File: Do180146.wpd Range: -50/+300C per 1C

* Working principle

The MC 885 SDHL is a thermostat for controlling >on/off= burners with >high/low= burner control by means of

relay contacts. In addition to this, modulating control is also possible. The thermostat supports 2 mode=s

(mode S and mode D), each having their own setpoint. It is possible to alternate between the mode=s using

a digital input. When applied to a spray booth regulation function, mode S can be used for spraying and

mode D for drying. These modes can be optionally be used in other applications; for example, mode S for

night and mode D for day.

The working principle of the controller is determined by the parameter settings. The controller can control

using 1 or 2 mode=s(/setpoints), with 1 or 2 sensors, where appropriate depending on the current mode (S

or D).

The basic regulation function supports the control functions >burner on=, >burner low= and >burner high= as

shown in the functional flow figure. One of these control functions can be set for each relay. If a burner has

to be controlled with a change-over relay contact >burner high/low=, control function >burner high= can be

used for this on RY2 or RY3.

The measurement and control range are both -50 to 300 C, with a readout per 1 C. The control range can

be reduced using the parameter setting. The top display normally gives the measured room temperature

and the bottom display gives the active setpoint.

In addition to the basic regulation function, the controller also has a minimum and maximum alarm detection

and a maximum limit. The temperature and mode=s at which the alarms and limit should work can be set via

the parameters. The desired action when an alarm or limit is triggered can also be set.

If the controller detects a sensor failure, the regulation function stops, an error message appears in the

display and the alarm relay function becomes active.

The controller also has a configurable analogue output, power-up control delay, buzzer, operate/parameter

passwords and an optional RS485 network connection (for ALFANET or Modbus).

The working principle of these functions is described later in this manual.

Page 2

* Operation

The thermostat is operated using seven buttons on the front:

ON/OFF - switches the controller on and off with LED indicator

SETP. - select, view/change the setpoint value

SENS. - view the values from the individual temperature sensors

PRG - access to the internal parameters

RESET ALARM - reset button for resetting alarms with LED indicator

UP - increase the set value (setpoint/parameters)

DOWN - reduce the set value (setpoint/parameters)

* Switching the controller on and off

The LED above the ON/OFF button shows whether the controller is on or off.

Pressing the ON/OFF button (for at least 1 second) switches the controller on or off. If the thermostat is

switched off, then all the displays are blank and its regulating function is disabled. If the thermostat is

switched on, the room temperature is usually displayed in the top display and the active setpoint in the

bottom display. If a controller delay has been defined after a power interruption then the time remaining is

shown in the lower display (blinking).

* View the individual setpoints

In normal operating mode, the room temperature is shown in the top display (default). If necessary, this can

be changed using parameter P80.

The LED=s next to the SENS. Button indicates which temperature is displayed on the top display: >I= =

Sensor-1 (room temperature), >II= = Sensor-2 (channel temperature), >I= and >II= both on = average of Sensor

1 and Sensor 2. The other temperatures (if present and used) can be displayed by now pressing the SENS

button one or more times. A blinking LED indicates that another temperature is being displayed as normal.

A few seconds after releasing the SENS. button or by pressing the ON/OFF button, the normal room

temperature (P80) will reappear in the display.

* View the individual setpoints

The LED=s next to the SETP. button indicate which setpoint is active. This is shown on the bottom display.

The other setpoint will be displayed (if set using P01) by pressing the SETP. button. A blinking LED

indicates that the inactive setpoint is being displayed.

A few seconds after releasing the SETP. button or by pressing the ON/OFF button, the active setpoint will

reappear in the display and the corresponding LED will be illuminated continuously.

* Changing setpoints

Press (if necessary) the SETP. button until the desired setpoint appears in the display and release the

SETP. button. The setpoint can now be changed by pressing the SETP. button at the same time as the UP

or DOWN buttons. A few seconds after releasing the buttons or by pressing the ON/OFF button, the normal

room temperature (P80) will reappear in the display.

* Mode display

The LED=s mode S and mode D next to the top display indicate the active mode of the controller.

The LED (Max. Limit) indicates whether a maximum limit is active.

The LED=s Out-1, Out-2 and Out-3 show the relays that are active.

* Setting internal parameters

The functioning of the controller can be configured using the internal parameters. By pressing the PRG and

DOWN buttons simultaneously, you can access the internal programming menu. A letter >P= followed by a

number (= parameter number) will appear in the top display. The UP and/or DOWN buttons can be used to

look up the desired parameter.

The value of this parameter is shown in the lower display. This value can be adjusted by pressing the SETP.

button at the same time as the UP or DOWN buttons.

A few seconds after releasing the buttons or by pressing the ON/OFF button, the controller returns to the

normal operating mode.

Page 3

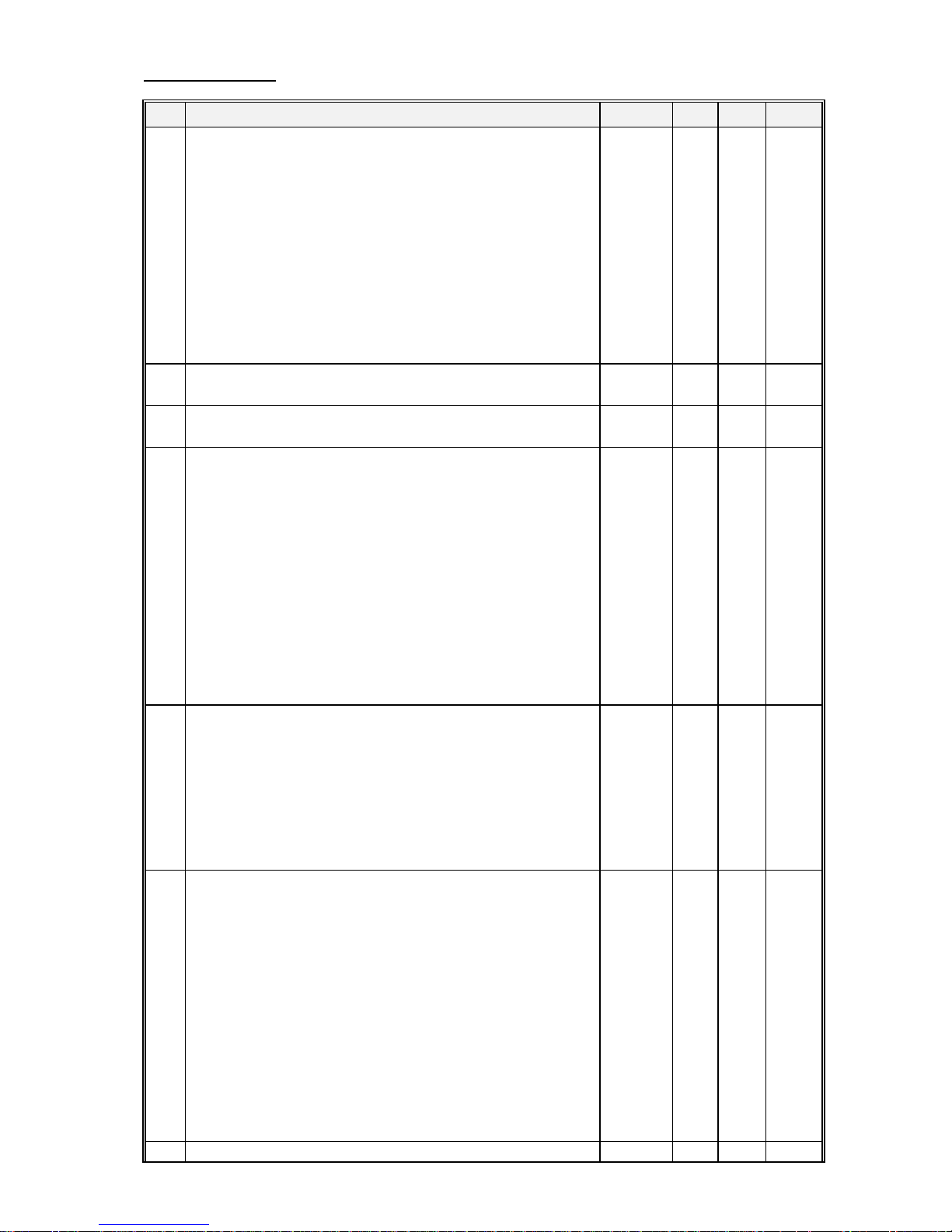

* Parameter table

No. Description

Range

Per Unit Default

01

02

03

04

Dual mode (mode S and mode D) (0 = no, 1 = yes)

(for P01 = no, only mode S)

Channel sensor present (0 = no, 1 = yes)

In mode S, control on

1 = Room temperature

2 = Channel temperature (room temperature if P02 = 0)

3 = Lowest sensor temperature

4 = Highest sensor temperature

5 = Average sensor temperature

In mode D, control on

1 = Room temperature

2 = Duct temperature (room temperature if P02 = 0)

3 = Lowest sensor temperature

4 = Highest sensor temperature

5 = Average sensor temperature

0 1

0 1

1 5

1 5

-

-

-

-

-

-

-

-

0

0

1

1

10

11

Room sensor offset

Channel sensor offset

-15 +15

-15 +15

0.1

0.1

C

C

0.0

0.0

15

16

Minimum adjustable setpoint

Maximum adjustable setpoint

-50 300

-50 300

1

1

C

C

0

+100

20

21

24

25

26

27

28

29

32

33

34

35

36

37

Burner on differential

Burner on offset

Burner low differential

Burner low offset

Burner low only together with >burner on= (0 = no, 1 = yes)

Burner low modulating control (0 = no, 1 = yes)

Burner low duty cycle (for modulating control)

Burner low cycle time (for modulating control)

Burner high differential

Burner high offset

Burner high only together with >burner on= (0 = no, 1 = yes)

Burner high modulating control (0 = no, 1 = yes)

Burner low duty cycle (for modulating control)

Burner low cycle time (for modulating control)

0.1 15

-50 +50

0.1 15

-50 +50

0 1

0 to 1

0 100

5 240

0.1 15

-50 +50

0 1

0 1

0 100

5 240

0.1

0.1

0.1

0.1

-

1

1

0.1

0.1

-

1

1

C

C

C

C

-

%

s

C

C

-

%

s

0.5

+0.5

0.1

-8

1

0

50

60

0.1

-10

1

0

50

60

40

41

42

Relay 1 function

0 = None

1 = Burner on

2 = Burner low

3 = Burner high

4 = Monitor alarm

5 = Control alarm

Relay 2 function

Relay 3 function

0 5

0 5

0 5

1

3

4

45

46

47

48

Analogue output function

0 = None

1 = Room temperature

2 = Channel temperature (room temperature if P02 = 0)

3 = Lowest sensor temperature

4 = Highest sensor temperature

5 = Average sensor temperature

6 = Control temperature

7 = Spraying setpoint

8 = Drying setpoint

9 = Control (= active) setpoint

Analogue output voltage range

0 = 0..5Vdc

1 = 0..10Vdc

Minimum voltage (0V) at temperature

Maximum voltage (P736) at temperature

0 9

0 1

-50 300

-50 300

-

-

1

1

-

-

C

C

0

0

0

100

50 Minimum alarm detection on

0 7 - - 0

Page 4

No. Description

Range

Per Unit Default

51

52

53

54

55

56

0 = None

1 = Room temperature (absolute)

2 = Channel temperature (absolute) (room temperature if P02 = 0)

3 = Lowest sensor temperature

4 = Highest sensor temperature

5 = Average sensor temperature

6 = Control temperature

7 = Control temperature relative to control setpoint

Minimum alarm detection during

0 = Spraying

1 = Drying

2 = Both modes

(always detection for single setpoint)

Minimum alarm temperature

Switch differential for minimum alarm

Time delay for minimum alarm

Action at minimum alarm

(message with code and alarm relay function always appear in display)

0 = None

1 = Disable all burner control

Reset minimum alarm automatically (0 = no, 1 = yes)

0 2

-350 +350

0.1 15

0 99

0 1

0 1

-

1

0.1

1

-

-

-

C

C

min

-

-

2

-50

0.1

0

0

0

60

61

62

63

64

65

66

Maximum alarm detection on

0 = None

1 = Room temperature (absolute)

2 = Channel temperature (absolute) (room temperature if P02 = 0)

3 = Lowest sensor temperature

4 = Highest sensor temperature

5 = Average sensor temperature

6 = Control temperature

7 = Control temperature relative to control setpoint

Maximum alarm detection during

0 = Spraying

1 = Drying

2 = Both modes

(always detection for single setpoint)

Maximum alarm temperature

Switch differential for maximum alarm

Time delay for maximum alarm

Action at minimum alarm

(message with code and alarm relay function always appear in display)

0 = None

1 = Inhibit all burner control

2 = Inhibit burner high

3 = Inhibit burner high, replace with >burner low=

Reset maximum alarm automatically (0 = no, 1 = yes)

0 7

0 2

-350 +350

0.1 15

0 99

0 3

0 1

-

-

1

0.1

1

-

-

-

-

C

C

min

-

-

0

2

+300

0.1

0

1

0

70

71

72

73

74

75

Maximum limit on

0 = None

1 = Room temperature (absolute)

2 = Channel temperature (absolute) (room temperature if P02 = 0)

3 = Lowest sensor temperature

4 = Highest sensor temperature

5 = Average sensor temperature

6 = Control temperature

7 = Control temperature relative to control setpoint

Maximum limit during

0 = Spraying

1 = Drying

2 = Both modes

(always limit for single setpoint)

Maximum temperature limit

Switch differential for maximum limit

Time delay for maximum limit

Action at maximum limit

0 = No limit (same as P70 = 0)

1 = Inhibit all burner control

2 = Inhibit burner high

3 = Inhibit burner high, replace with >burner low=

0 7

0 2

-350 +350

0.1 15

0 99

0 3

-

-

1

0.1

1

-

-

-

C

C

min

-

0

2

+300

0.1

0

1

Page 5

No. Description

Range

Per Unit Default

80

81

82

83

Temperature in top display

1 = Room temperature

2 = Channel temperature (room temperature if P02 = 0)

3 = Lowest sensor temperature

4 = Highest sensor temperature

5 = Average sensor temperature

6 = Control temperature

Controller delay after power interruption

Reset alarm relay after alarm reset (0 = no, 1 = yes)

(without the cause of the alarm being removed)

Buzzer on at alarm (0 = no, 1 = yes

1 6

0 to 99

0 1

0 1

-

1

-

-

-

min

-

-

1

0

0

0

85

86

Operate password (0 = no password)

Parameter password (0 = same as operate password)

0 9999

0 9999

1

1

-

-

0

0

90

91

Network number

Login interval

1 250

1 120

1

1

min

1

5

95

98

99

Software version

Serial number

Production date (year/week)

1.00 ..

99.99

0 9999

00.01 ..

99.52

-

-

-

-

-

-

-

-

-

* Adjusting sensors

The sensors are adjusted using the sensor offset parameters (P111 and P121). If, for example, the

thermostat indicates 2.5C too high for a sensor, then the sensor offset parameter will have to be reduced

by 2.5C.

* Basic regulation function

The basic control is set using parameters P01..04, P20..37 and P40..42:

- A single mode (/setpoint) or 2 modes (/setpoints) (P01)

- Only a room temperature or a channel temperature sensor (P02)

- Control temperature for mode S (and for single mode) (P03)

- Control temperature for mode D (P04)

The basic control supports 3 adjustment functions: >Burner on=, >burner low= and >burner high=. This is shown

in the functional flow figure. The >active setpoint= is determined by the active mode (mode S or D). The

>active control temperature= is the control temperature for the active mode as set using parameters P03 and

P04.

The control settings for these control functions are set using parameters P20..37.

If modulating control is set for a control function, the control function modulating with an adjustable (fixed)

duty cycle and an adjustable (fixed) cycle time will be indicated in the situations shown in the figure >on=.

This modulating control can, for example, be used for a capacity/power setting.

A control function can be selected for each individual relay using parameters P40..42.

Page 6

* Functional flow

Page 7

* Alarms

In addition to the basic control, the controller also has a minimum and maximum alarm detection.

At what temperature (P50/P60), in which mode (P51/P61), at which temperature (P52/P62), with which

differential (P53/P63) and time delay (P54/P64) the alarms should be triggered can be set using

parameters.

If an alarm occurs, the LED above the RESET ALARM button lights up. The alarm report is shown in the

upper display.

Pressing the RESET ALARM button allows the alarms to be reset one by one. Once all the alarms are

reset, the LED above the RESET ALARM button goes out.

What actions that should occur for the various alarms can be set using parameters (P55/P65).

The following alarm notifications can appear in the upper display:

Lo - Minimum alarm

Hi - Maximum alarm

E1 - Sensor-1 defect

E2 - Sensor-2 defect

Solution E1, E2:

- Check that the sensor is connected properly.

- Check sensor (100Ω at 0C).

- Replace sensor

An alarm condition is removed when the cause is eliminated and the alarm has been reset using the RESET

ALARM button.

Automatic reset can be set for the minimum and maximum alarm with parameters (P56/P66). The relevant

alarm condition will be automatically removed when the cause of the error has been removed. An alarm

reset using the RESET ALARM button will then be unnecessary.

After all of the alarms have been rest, the temperature will be displayed again in the upper display,

alternated with any alarm notifications for which the cause has not yet been removed. If the temperature

cannot be measured (out of range), then the display will instead show L for a short-circuited sensor or H for

an open sensor circuit.

* Maximum limit

The basic control can be overruled by the maximum limit, if set using parameters P70..P75.

At which temperature (P70), in which mode (P71), with which differential (P73) and time delay (P74) the

maximum limit should come into effect can be set using parameters. The desired overruling action can be

set using parameter P75.

When the maximum limit is active, this will be indicated by the LED (Max. Limit).

* Controller delay after power failure

The controller supports a delayed regulation function after a power failure. If set (P08), no controller

functions will be performed within the delayed regulation period after the controller is powered up again.

The sensor values, setpoints and parameters can be viewed and modified, though. During the delayed

regulation period, the remaining time is shown blinking in the lower display.

If necessary, the control delay can be cleared by switching the controller off and on again with the ON/OFF

button.

* Passwords

If an operator password has been set (P85), a four-digit password will first need to be given for operations

that affect the regulation function. The text ACode@ appears in the upper display, and A- - - -A in the lower

display.

The UP and DOWN buttons can be used to enter the first digit. The ON/OFF button can then be used to

move on to the next digit. After all 4 digits have been entered correctly in this fashion, the operator action

can be performed. The password remains in force until no buttons have been pressed 2 minutes. After that,

the password has to be entered once more before the controller can be operated again.

There is a parameter password for viewing and changing the parameters. If this has been set (P86), this

password must be entered in the same way as the operator password. The parameter password also

enables the operator actions.

Page 8

* Technical data

Type : MC885 SDHL Sprayer/Dryer High/Low Thermostat

Range : -50/+300C, readout per 1C

Operation : Via push buttons on the front

Front : Polycarbonate IP65

Dimensions : 96 x 96 x 140 mm (H x W x D)

Panel cutaway : 90 x 90 mm (H x W)

Accuracy : 0,5% of the range

Power supply: 100 B 260Vac 47-440Hz of 120 B 370 Vdc, power 5 watts or otherwise: see product

sticker

Relay: RY1 : Function adjustable (P40), default Burner on SPST C-NO contact

RY2 : Function adjustable (P40), default Burner high SPDT C-NO-NC contact

RY3 : Function adjustable (P40), default Burner on SPDT C-NO-NC contact

For all relays: maximum 8A at 250 Vac with Cos phi=1.0

6A at 250 Vac with Cos phi=0.4

or 5A at 30 Vdc

Temp. sensor : Pt100-1 Room temperature sensor a,b,c; 3-wire system

Pt100-2 Room temperature sensor (option) a,b,c; 3-wire system

Digital input : Contact input function spray (open)/dry (closed) Potential free connection

Analogue output : 0-10 Vdc or 0-5 Vdc (P46) measurement or setpoint value output max. 1mA

Choice via parameter P45:

- Room temperature

- Channel temperature (if present)

- Lowest sensor temperature

- Highest sensor temperature

- Average sensor temperature

- Control temperature (active sensor)

- Spray setpoint

- Dry setpoint

- Control (active) setpoint

Communication : Optional RS485 for ALFANET or Modbus (Line-A, Line-B and GND) 2 x twisted pair

shielded connections – see wiring diagram

Buzzer : On the processor PCB, used for alarms (dependent on parameter P82)

Displays : Upper: 4-digit 7-segment display, 13 mm (red) for temperature readout

Lower: 4-digit 7-segment display, 10 mm (red) for setpoint readout

LEDs status : LED mode S mode S active

LED mode D mode S active

LED Max Limit Maximum limit active

LED Out-1 RY1 energised

LED Out-2 RY2 energised

LED Out-3 RY3 energised

Page 9

* Wiring diagram

Page 10

* Dimensions

* Address

VDH Products BV Tel.: +31 (0)50 - 30 28 900

Produktieweg 1 Fax: +31 (0)50 - 30 28 980

9301 ZS Roden Email: info@vdhproducts.nl

The Netherlands Internet: www.vdhproducts.nl

Loading...

Loading...