Page 1

Vision

Components

®

The Smart Camera People

VC20XX Operating Manual

Hardware Specifications and special Software Functions of

VC20XX Smart Cameras

Revision 2.2 October 2007

Document name: VC20XX_HW.pdf

© Vision Components GmbH Ettlingen,

Germany

Page 2

VC20XX Operating Manual

II

Foreword and Disclaimer

This documentation has been prepared with most possible care. However Vision Components GmbH

does not take any liability for possible errors. In the interest of progress, Vision Components GmbH

reserves the right to perform technical changes without further notice.

Please notify

support@vision-components.com if you become aware of any errors in this manual or

if a certain topic requires more detailed documentation.

This manual is intended for information of Vision Component’s customers only. Any publication of this

document or parts thereof requires written permission by Vision Components GmbH.

Trademarks

Code Composer Studio and TMS320C6000, Windows XP, Total Commander, Tera Term, Motorola

are registered Trademarks. All trademarks are the property of their respective owners.

References

Since the VC4XXX smart camera family employs a TI processor, the programming environment and

functions for the VC20XX cameras can be used for this camera.

Further References under “Support + Download” on

www.vision-components.com:

„Support News“ – for up to date information on VC Software and Documentation.

„

Knowledge Base / FAQ“ - searchable Database with latest software developments, frequently asked

questions and demo programs.

“

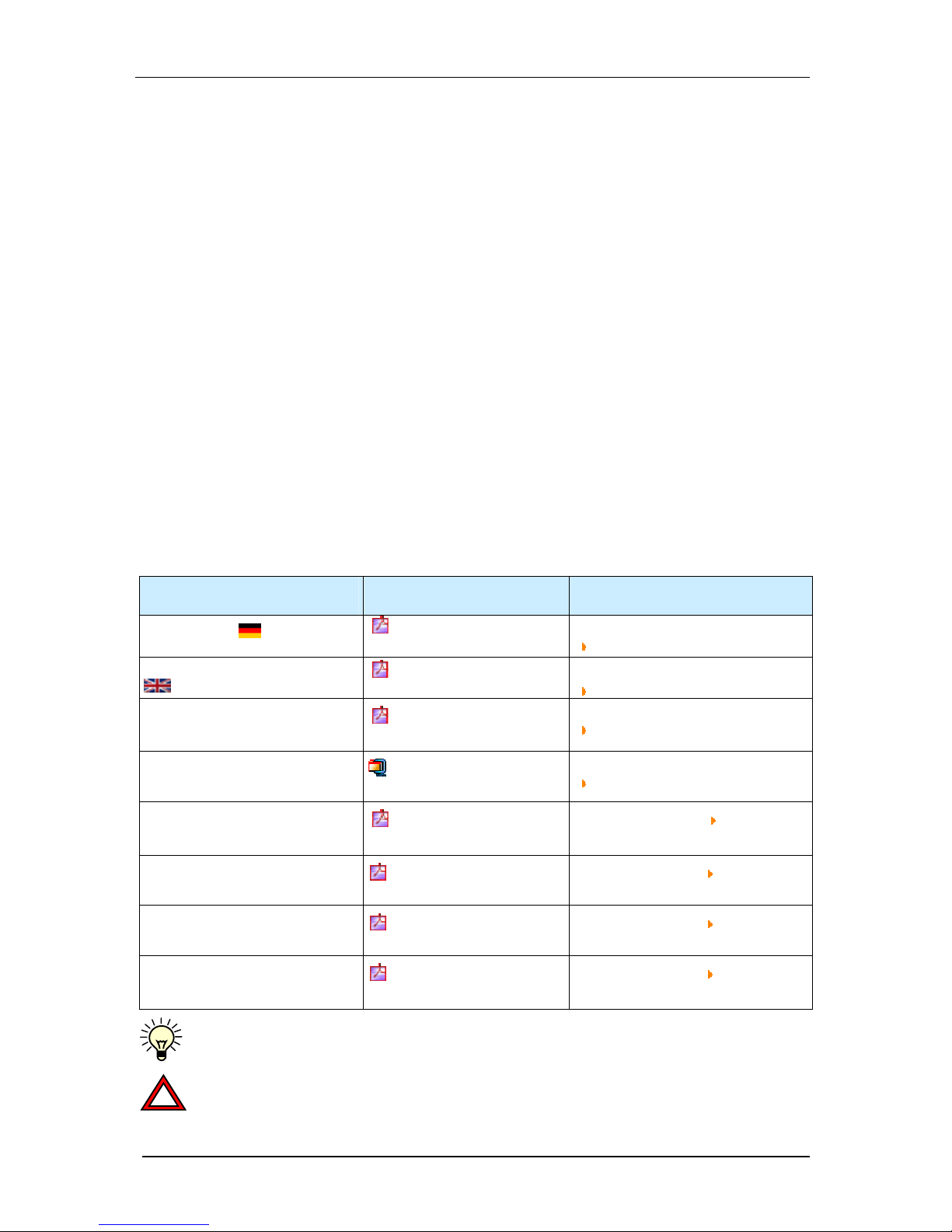

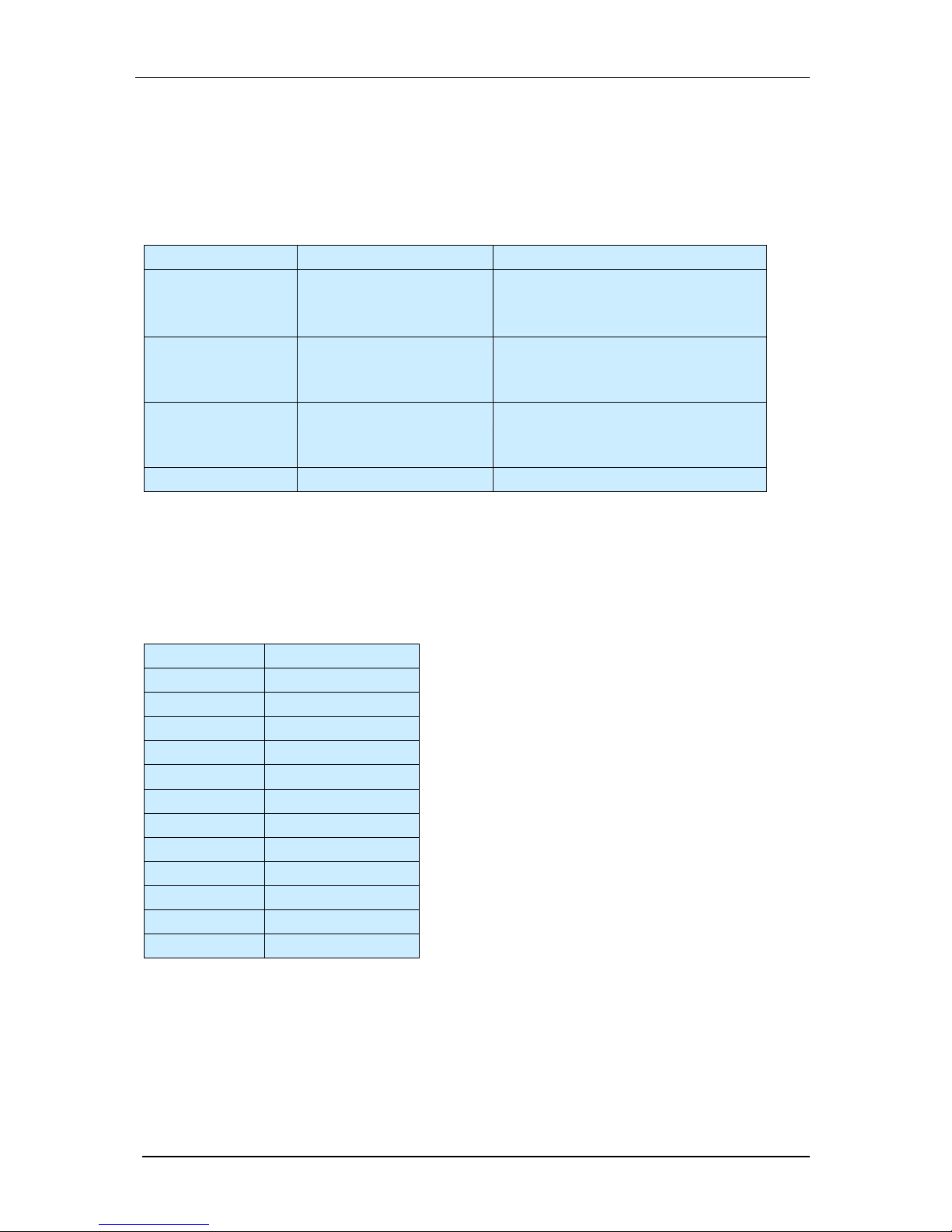

Download Areas” for all documentation and Software downloads – refer to the following table:

Description Title on Website Download Area

Schnellstart VC .

Schnellstart VC Smart

Kameras

Registered User Area

Getting Started VC SDK TI

Getting Started VC Smart Cameras

.

Getting Started VC Smart

Cameras

Registered User Area

Getting Started VC SDK TI

Introduction to VC Smart Camera

programming

Programming Tutorial for

VC20XX and VC40XX Cameras

Registered User Area

Getting Started VC SDK TI

Demo programs and sample code

used in the Programming Tutorial

Tutorial_Code

Registered User Area

Getting Started VC SDK TI

VC4XXX Hardware Manual

VC4XXX Smart Cameras

Hardware Documentation

Public Download Area Hardware

Documentation VC Smart Cameras

VCRT Operation System Functions

Manual

VCRT 5.0 Software Manual

Registered User Area Software

documentation VC Smart Cameras

VCRT Operation System TCP/IP

Functions Manual

VCRT 5.0 TCP/IP Manual

Registered User Area Software

documentation VC Smart Cameras

VCLIB 2.0 /3.0 Image Processing

Library Manual

VCLIB 2.0/ 3.0 Software

Manual

Registered User Area Software

documentation VC Smart Cameras

The Light bulb highlights hints and ideas that may be helpful for a development.

This warning sign alerts of possible pitfalls to avoid. Please pay careful attention to sections

marked with this sign.

!

Author: Peter Neuhaus, VC Support,

mailto:support@vision-comp.com

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 3

VC20XX Operating Manual

III

Table of Contents

1 General Information 1

1.1 Overview Camera Types 2

2 Basic Structure 4

3 Boards 5

3.1 Sensor Boards 5

3.1.1 C6SEN084 6

3.1.2 C6SEN204 6

3.1.3 C6SEN205 7

3.1.4 C6SEN311 7

3.1.5 C6SEN415 8

3.2 CPU Board 8

3.3 DAC Board 9

3.4 Power Board 10

4 PLC I/O Signals 11

4.1 Input Signals 11

4.2 Output Signals 12

4.3 Trigger input and trigger output 12

5 Pin Assignments Camera Interfaces 14

5.1 Pin Assignment Trigger / Keypad Plug Signal 14

5.2 Pin Assignment for the I/O Plug 14

5.3 Pin Assignment for the RS232 (V24) 15

5.4 Pin Assignment LAN/Ethernet 15

5.5 Pin Assignment for the XGA/SVGA Video Output 15

6 Technical Specifications VC20XX Smart Cameras 16

6.1 Technical Specifications VC2028 16

6.2 Technical Specifications VC2038 17

6.3 Technical Specifications VC2038/E 18

6.4 Technical Specifications VC2048/E 19

6.5 Technical Specifications VC2065 20

6.6 Technical Specifications VC2065/C 21

6.7 Technical Specifications VC2065/E 22

6.8 Technical Specifications VC2065/EC 23

6.9 Technical Specifications VC2066 24

6.10 Technical Specifications VC2066/E 25

6.11 Technical Specifications VC2068 26

6.12 Technical Specifications VC2068/E 27

7 Accessories 28

7.1 Trigger Cable 28

7.2 RS232(V24) Cable 28

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 4

VC20XX Operating Manual

IV

7.3

Ethernet patch cable 29

7.4 Power / PLC Cable 29

7.5 SVGA Monitor Cable 29

7.6 Power adapter 30

7.7 Power adapter for rail mounting 30

7.8 VC Keypad C6 30

7.9 Y-cable 30

8 Connecting the Camera 31

8.1 Connecting the camera power 31

8.1.1 Single voltage, with or without PLC signals, no shutdown: 31

8.1.2 Shutdown Function for VC20XX Smart Cameras 32

8.2 Connecting the RS232 Interface 33

8.2.1 Connecting a compatible PC with a 9-pin D sub plug 33

8.3 Connecting the Ethernet Cable 33

8.4 Connecting the VC keypad 33

8.5 Connecting the external trigger 34

8.6 Connecting the external trigger and the VC keypad 34

9 Programming 35

Appendix A: Blockdiagram VC20XX Smart Cameras A

Appendix B: Housing Dimensions VC20XX Smart Cameras B

Appendix E: Drawing Camera Head VC40XX C

Appendix C: Spectral Transmission of IR Filter D

Appendix D: CE Compliance of VC20XX Smart Cameras E

INDEX G

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 5

VC20XX Operating Manual

1

1 General Information

The VC20xx Series smart cameras are compact, light-weight black-and-white or color video cameras

with video memory and an image processor.

They integrate a high-resolution CCD sensor with one of the fastest 32 bit image-processing signal

processors (TMS320C6211). SDRAM memory is used to store program code, data and video images.

Interfaces allow communication with the outside world. The cameras set standards for performance

and integration density.

These cameras are built for industrial deployment. High goals were set as regards the image

resolution, the computational speed, the sturdiness of the casing, and the electromagnetic

compatibility, as mere examples. The cameras are insensitive to vibrations and shocks, while

permitting precise measurements and tests. They are ideally suited as OEM cameras for mechanical

engineering applications.

Only one supply voltage is required to operate the cameras (24 volts). An image processing system or

a PC with a frame grabber board is not necessary. Simple control problems can even be implemented

with the integrated process interfaces. For more complex control tasks, the cameras can be connected

to a PLC.

This documentation describes the camera hardware. However, in many cases the software

documentation is decisive. For this, please consult the software manuals.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 6

VC20XX Operating Manual

2

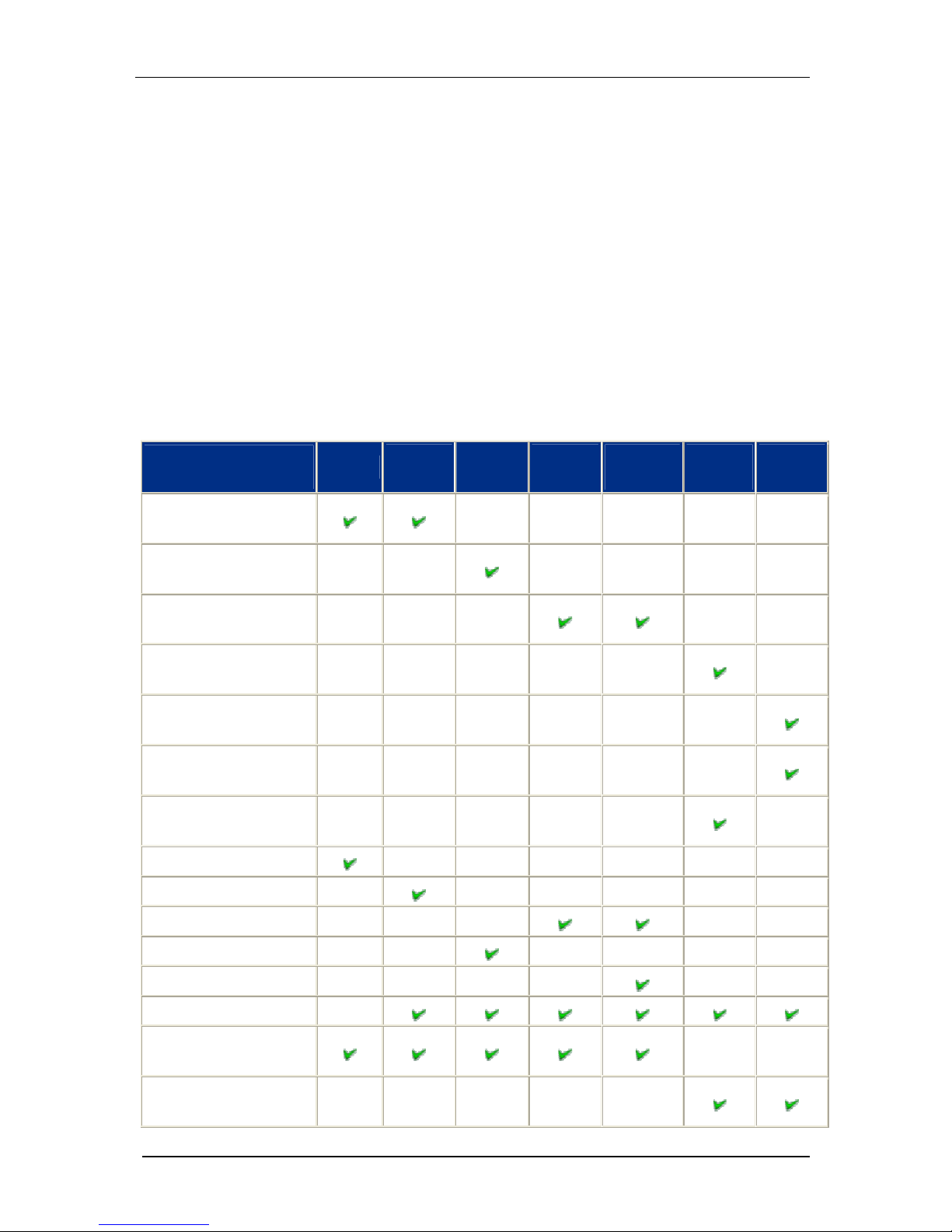

1.1 Overview Camera Types

All VC20XX Cameras contain the following features:

- 16 MB SDRAM

- 2 MB Flash Eprom

- 8 bit overlay (translucent overlay possible)

- integrated 4 Digital Inputs, 4 Digital Outputs, 24V

- Texas Instruments CPU TMS 320C62XX; 1200MIPS

- Low speed shutter up to 10 seconds

- Programmable gain and offset

- 24V Power Supply

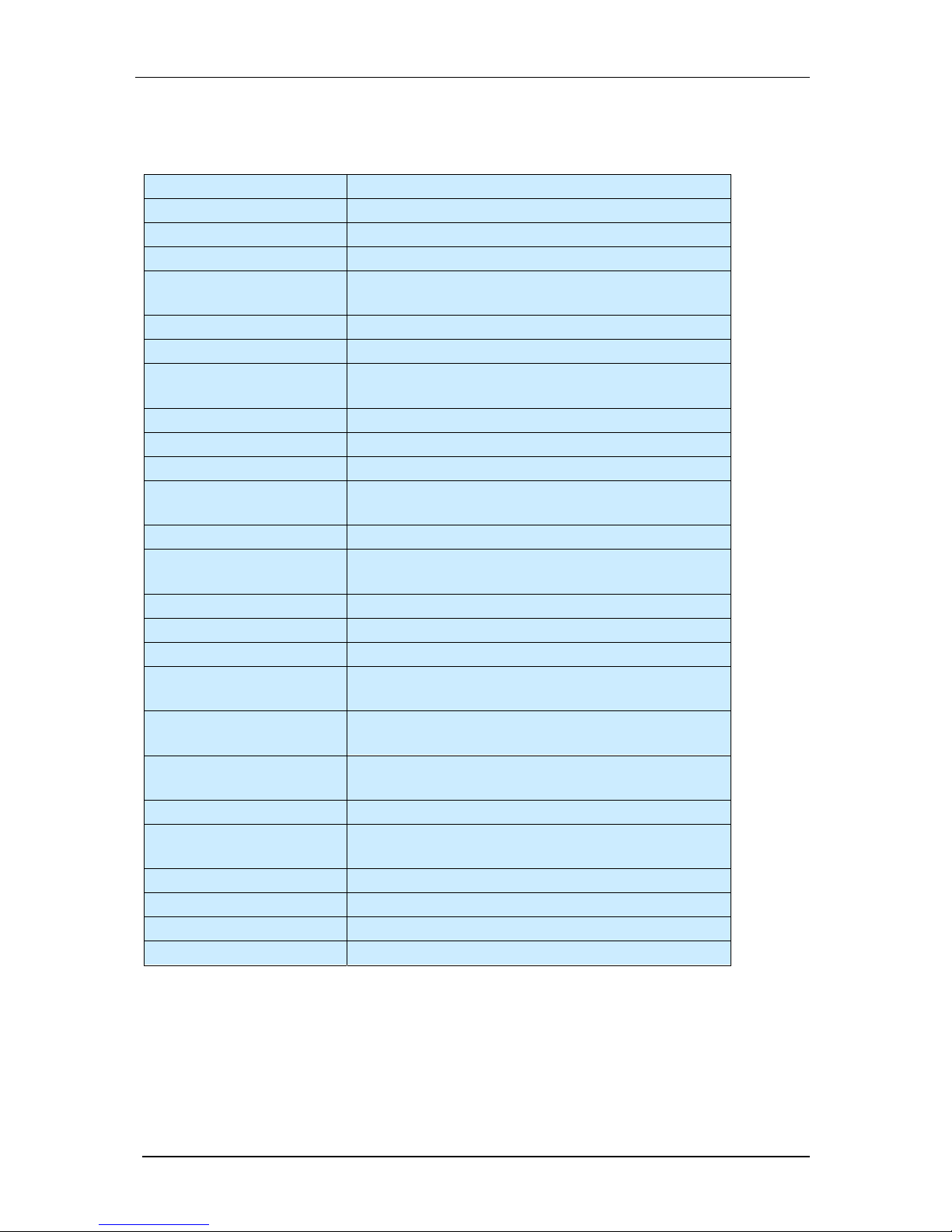

The following table shows the different features of each camera model:

VC20XX SELECTION

TABLE

VC2028

VC2038

VC2038E

VC2048E

VC2065

VC2065E

V2065C

VC2065CE

VC2066

VC2066E

VC2068

VC2068E

Sony 1/3" Progressive Scan

CCD640x480 pixel

Kodak 1/3" Progressive

Scan CCD 640x480 pixel

Sony 1/2" Progressive Scan

CCD 782x582 pixel

Sony 1/3" Progressive Scan

CCD 1024x768 pixel

Sony 1/2" Progressive Scan

CCD 1280x1024 pixel

14 Hz full Frame, 28 Hz 2x

Binning

17 Hz full Frame, 34 Hz 2x

Binning

25 Hz full Frame

40 Hz full Frame

45 Hz full Frame

110 Hz full Frame

Color

16 MB Multimedia Card

SVGA (800x600 Pixel)

output, noninterlaced

SXVGA (1280x1024 Pixel)

output, noninterlaced

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 7

VC20XX Operating Manual

3

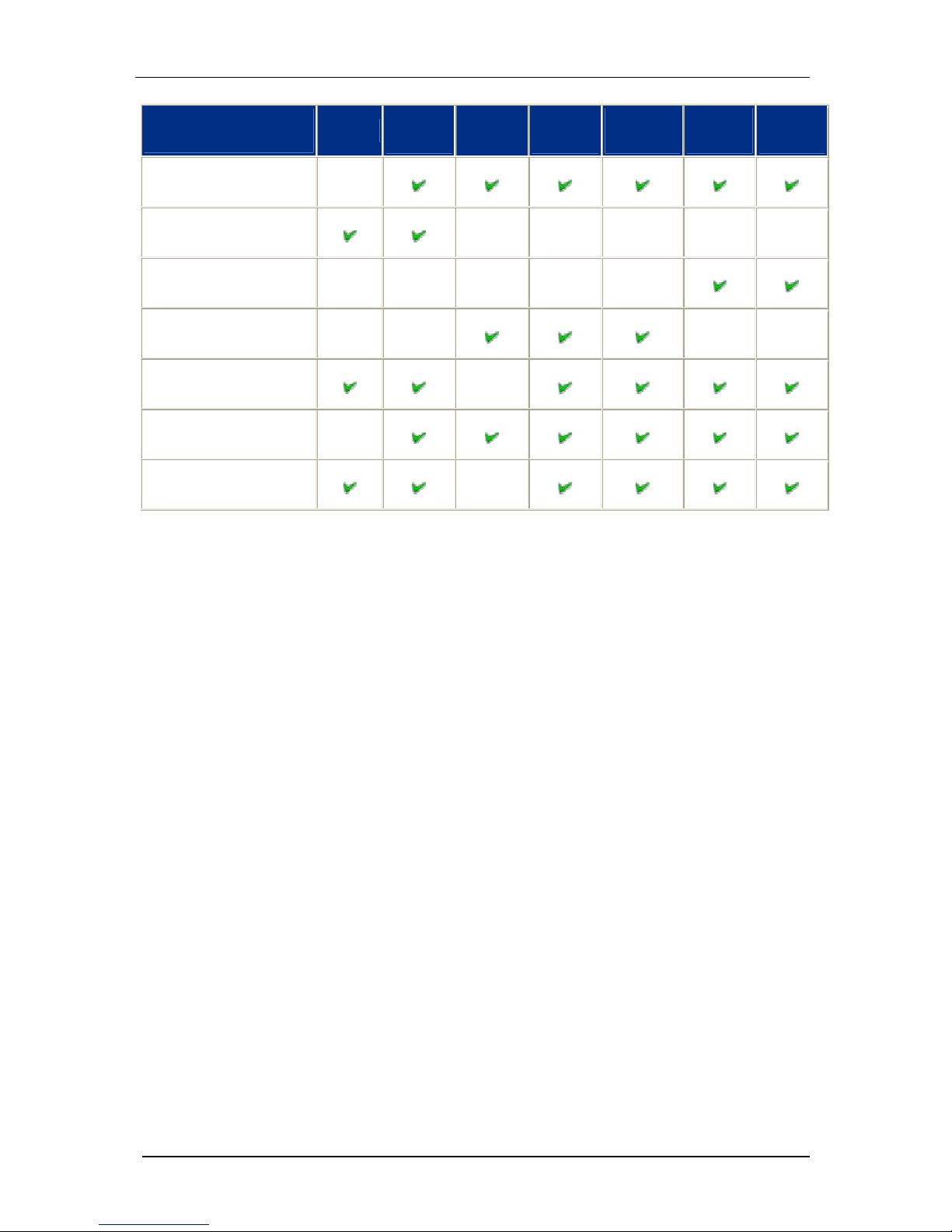

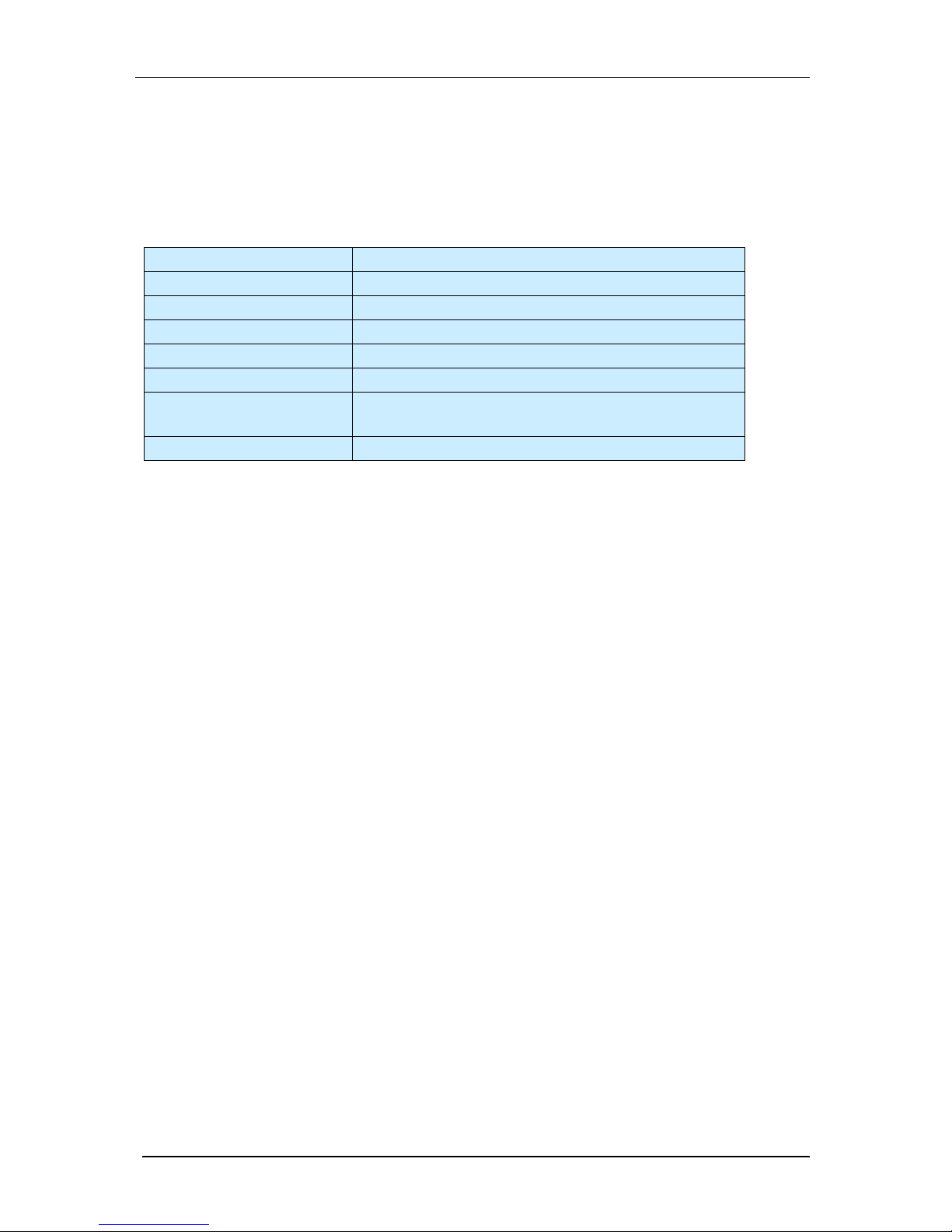

VC20XX SELECTION

TABLE

VC2028

VC2038

VC2038E

VC2048E

VC2065

VC2065E

V2065C

VC2065CE

VC2066

VC2066E

VC2068

VC2068E

integrated Fast Trigger

contact (external contact)

1)

High speed shutter down to

33 microseconds

High speed shutter down to

9 or 10 microseconds

High speed shutter down to

5 microseconds

RS232 up to 115.200 Baud

(optional)

Fast Ethernet 100MBit

(optional) 2)

Size: 110x50x36mm+foot/

Weight: 488g

3)

1) The use of the VC2028 is recommended for imaging static (non moving) objects only.

2) If ordering a camera with Ethernet interface please add the suffix "/E" to the camera name (i.e.

VC38/E, VC2065/EC).

3) Dimension of housing VC2048: 111x80x36 + mounting plate, weight: 516g

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 8

VC20XX Operating Manual

4

2 Basic Structure

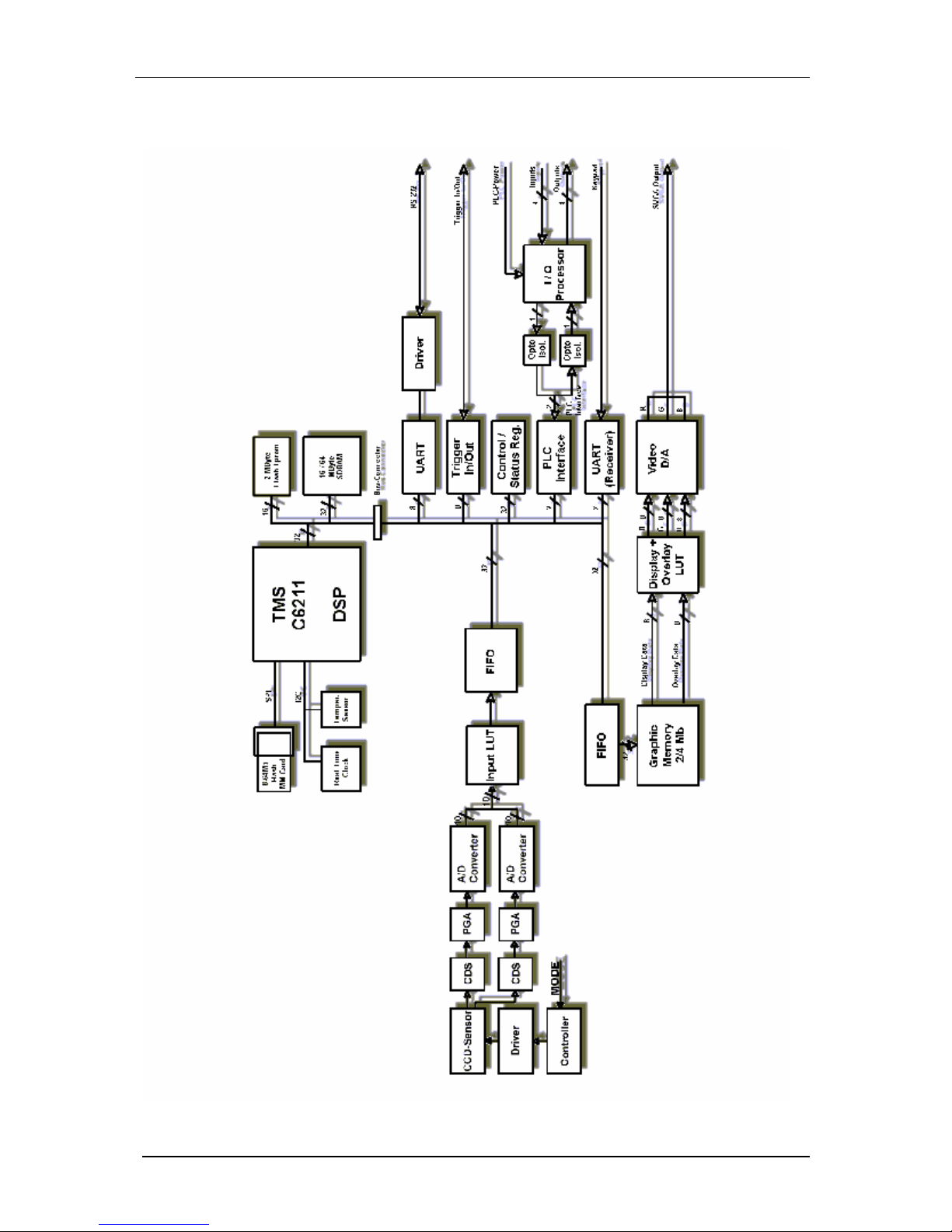

The image is formed by a high-resolution progressive scan CCD sensor. One or two channels of video

output are digitized. An input lookup-table is available for basic pixel-preprocessing. The image is

stored in SDRAM memory using one of the 16 DMA channels (EDMA).

The video and graphics display on the monitor is performed in a very similar way: Data is stored in the

main SDRAM memory, either due to a previous video capture or to computing by the DSP. Graphics

data is then transferred to the graphics refresh buffer (SGRAM). This may happen periodically or on

demand. The SGRAM is read out at a fast refresh rate to provide a high-quality, flickerfree display.

A dual 3x256x8 output lookup-table gives you abundant choices for the appearance of images and

graphics.

The video capture and graphics output channels are completely independent. The storage area for

each may be chosen to be identical (necessary for live image display) or completely different. If the

latter is chosen, you may capture an image "in the background" while displaying a completely different

one.

The TMS320C6211 DSP is one of the fastest 32 DSPs. It features a RISC-like instruction set, up to 8

instructions can be executed in parallel, two L1 cache memories (4KBytes each) and a 64 KByte L2

cache on chip. Its high speed 16-channel DMA controller gives additional performance. The DSP uses

fast external SDRAM as main memory. A flash EPROM and a built-in multi-media card provide nonvolatile memory.

See

Appendix A: Blockdiagram VC20XX Smart Cameras.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 9

VC20XX Operating Manual

5

3 Boards

The electronic circuitry of the camera contains four printed curcuit boards (PCB).

The following presents an overview of the boards:

Description Designation Function

Sensor boards

C6SEN084, C6SEN204

C6SEN205, C6SEN311

C6SEN415

CCD sensor, driver & controller,

digitization of the video signal, blackand-white and color versions

CPU board

C6CPU

TMSC6211 signal processor with

SDRAM, FLASH memory, multi-media

card adaptor

DAC board

C6DAC

SVGA quality video output with graphics

memory, video capture, interfaces

(RS232, etc.)

Power board

C6PWR Power supply, PLC interfaces

3.1 Sensor Boards

Camera Type Sensor Board

VC2028 C6SEN084

VC2038 C6SEN084

VC2038/E C6SEN084

VC2048/E C6SEN311

VC2065 C6SEN415

VC2065/E C6SEN415

VC2065/C C6SEN415

VC2065/EC C6SEN415

VC2066 C6SEN204

VC2066/E C6SEN204

VC2068 C6SEN205

VC2068/E C6SEN205

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 10

VC20XX Operating Manual

6

3.1.1 C6SEN084

This board takes the picture. It is used in the VC2028, VC2038 and VC2038/E

The CCD sensor 1/3" SONY ICX424AL (B/W) is used. The board controls the CCD sensor and

processes the analog signal.

The progressive scan type CCD sensor used is ideally suited for industrial machine vision tasks. In

contrast to the conventional technique it provides the following features:

• 1/3" sensor

• resolution: 640x480 pixels

• square pixel format, 7.4(H) x 7.4(V) µm

• full-frame shutter

• can be triggered externally (except VC2028)

• sensor read out in full-frame mode (non-interlaced)

• shutter speed down to 30,80,... µsec in steps of 50 microseconds up to 20 sec

• 40fps @ 640x480 (VC2028 : 25fps@640x480)

• CCD processors providin g CDS, programmable gain and offset, auto black level

compensation and 10 bit AD-conversion

The diverse features of this board (high-speed and low-speed shutter, external trigger, etc.) are

configured via software.

For the exact setting of the configuration, refer to the description of the configuration program in the

software documentation.

3.1.2 C6SEN204

This board takes the picture. It is used in the VC2066 and VC2066/E

The CCD sensor ICX204AL (B/W) is used. The board controls the CCD sensor and processes the

analog signal.

The progressive scan type CCD sensor used is ideally suited for industrial machine vision tasks. In

contrast to the conventional technique it provides the following features:

• 1/3" sensor

• higher resolution: 1024x768 pixels

• square pixel format, 4.64 µ m

• full-frame shutter

• can be triggered externally

• sensor read out in full-frame mode (non-interlaced)

• shutter speed down to 10 µsec and up to 20 sec

• 16fps @ 640x480 or 2 x binning @ 32fps

• CCD processors providin g CDS, programmable gain and offset, auto black level

compensation and 10 bit AD-conversion

The diverse features of this board (high-speed and low-speed shutter, external trigger, etc.) are

configured via software.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 11

VC20XX Operating Manual

7

For the exact setting of the configuration, refer to the description of the configuration program in the

software documentation.

3.1.3 C6SEN205

This board takes the picture. It is used in the VC2068 and VC2068/E

The CCD sensor ICX205AL (B/W) is used. The board controls the CCD sensor and processes the

analog signal.

The progressive scan type CCD sensor used is ideally suited for industrial machine vision tasks. In

contrast to the conventional technique it provides the following features:

• 1/2" sensor

• higher resolution: 1280x1024 pixels

• square pixel format, 4.65 µ m

• full-frame shutter

• can be triggered externally

• sensor read out in full-frame mode (non-interlaced)

• shutter speed down to 9 µsec and up to 20 sec

• 13,75fps @ 1280x1024 or 2 x binning @ 27,5fps

• CCD processors providin g CDS, programmable gain and offset, auto black level

compensation and 10 bit AD-conversion

The diverse features of this board (high-speed and low-speed shutter, external trigger, etc.) are

configured via software.

For the exact setting of the configuration, refer to the description of the configuration program in the

software documentation.

3.1.4 C6SEN311

This board takes the picture. It is used in the VC2048/E

The CCD sensor KAI0330D (B/W) is used. The board controls the CCD sensor and processes the

analog signal.

The progressive scan type CCD sensor used is ideally suited for industrial machine vision tasks. In

contrast to the conventional technique it provides the following features:

• 1/2" sensor

• resolution: 640x480 pixels

• square pixel format, 9(H) x 9(V) µm

• full-frame shutter

• can be triggered externally

• sensor read out in full-frame mode (non-interlaced)

• shutter speed down to 18,36,72, µsec then steps of 36 microseconds up to 20 sec

• 112fps @ 640x480 !!!

• CCD processors providin g CDS, programmable gain and offset, auto black level

compensation and 10 bit AD-conversion

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 12

VC20XX Operating Manual

8

The diverse features of this board (high-speed and low-speed shutter, external trigger, etc.) are

configured via software.

For the exact setting of the configuration, refer to the description of the configuration program in the

software documentation.

3.1.5 C6SEN415

This board takes the picture. It is used in the VC2065, VC2065/E, VC2065/C and VC2065/EC.

The CCD sensor ICX415AL (black-and-white) or ICX415AK (color) is used. The board controls the

CCD sensor and processes the analog signal.

The progressive scan type CCD sensor used is ideally suited for industrial machine vision tasks. In

contrast to the conventional technique it provides the following features:

• 1/2" sensor

• higher resolution: 782x582 pixels

• square pixel format

• full-frame shutter

• can be triggered externally

• sensor read out in full-frame mode (non-interlaced)

• shutter speed down to 5 µsec and up to 20 sec

• double speed video capture @ 45fps

• CCD processors providin g CDS, programmable gain and offset, auto black level

compensation and 10 bit AD-conversion

The diverse features of this board (high-speed and low-speed shutter, external trigger, etc.) are

configured via software.

For the exact setting of the configuration, refer to the description of the configuration program in the

software documentation.

3.2 CPU Board

The "C6CPU" Board

The TMS320C6211 DSP is one of the fastest 32 bit DSPs. It features a RISC-like instruction set, up to

8 instructions can be executed in parallel. Turthermore it features two L1 cache memories (4KBytes

each) and a 64 KByte L2 cache on chip.

The DSP uses fast external SDRAM as main memory. Up to 4 memory banks can be permanently

open providing fast access without unnecessary RAS commands.

A flash EPROM and a built-in multi-media card provide for non-volatile memory.

Most of the I/O functions (graphics display, video capture, etc.) are performed by Vision Components'

proprietary DMA Hardware without overhead for the CPU.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 13

VC20XX Operating Manual

9

The location of the SDRAM buffers for graphics display, overlay display and video capture can be

selected independently.

Identical SDRAM buffers for graphics display and video capture may be chosen to produce live video

display.

Board C6CPU

processor TMS320C6211 150MHz

SDRAM 16 Mbytes (400 MB/sec)

Flash-EPROM 2 Mbytes (16bit wide)

Multi-Media Card Adaptor 8-256 MBytes

Clock Real time clock, battery backed-up

DMA

16 independent DMA channels (EDMA) 1 very high speed

DMA (QDMA)

special features on-board temperature sensor

3.3 DAC Board

The "C6DAC" Board

The "C6DAC" board is practically the periphery for the CPU board. Here, the digital video signal from

the sensor board is the input using an input lookup-table and buffered with FIFO memory.

The board is also responsible for the SVGA graphics output. Graphics (8 bits per pixel) and overlay

data (8 bits per pixel) are stored in the on-board SGRAM. 2 independent lookup-tables for graphics

and overlay data together with a 3x8 bits D/A converter produce the RGB analog video for the SVGA

output.

The 8 bit pixel-mask register allows for individual selection of overlay planes.

Overlay data have priority over graphics data. Graphics pixels are displayed only if all unmasked

overlay bits for that pixel are zero.

Functions of the board:

• video capture with input LUT, FIFO buffer

• graphics and overlay display with 16 Mbytes refresh memory,

• 2 independent LUTs for graphics and overlay, 8bit overlay mask register

• 3x8bit video D/A (SVGA output)

• UART and driver for RS232 (Ethernet versions : Ethernet PHY)

• UART receiver for VC Keypad (9600 baud)

• Trigger In/Out signals

• PLC communication inte rface

• Status & Control Register

• Interrupt controller for CPU

• DMA Controller

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 14

VC20XX Operating Manual

10

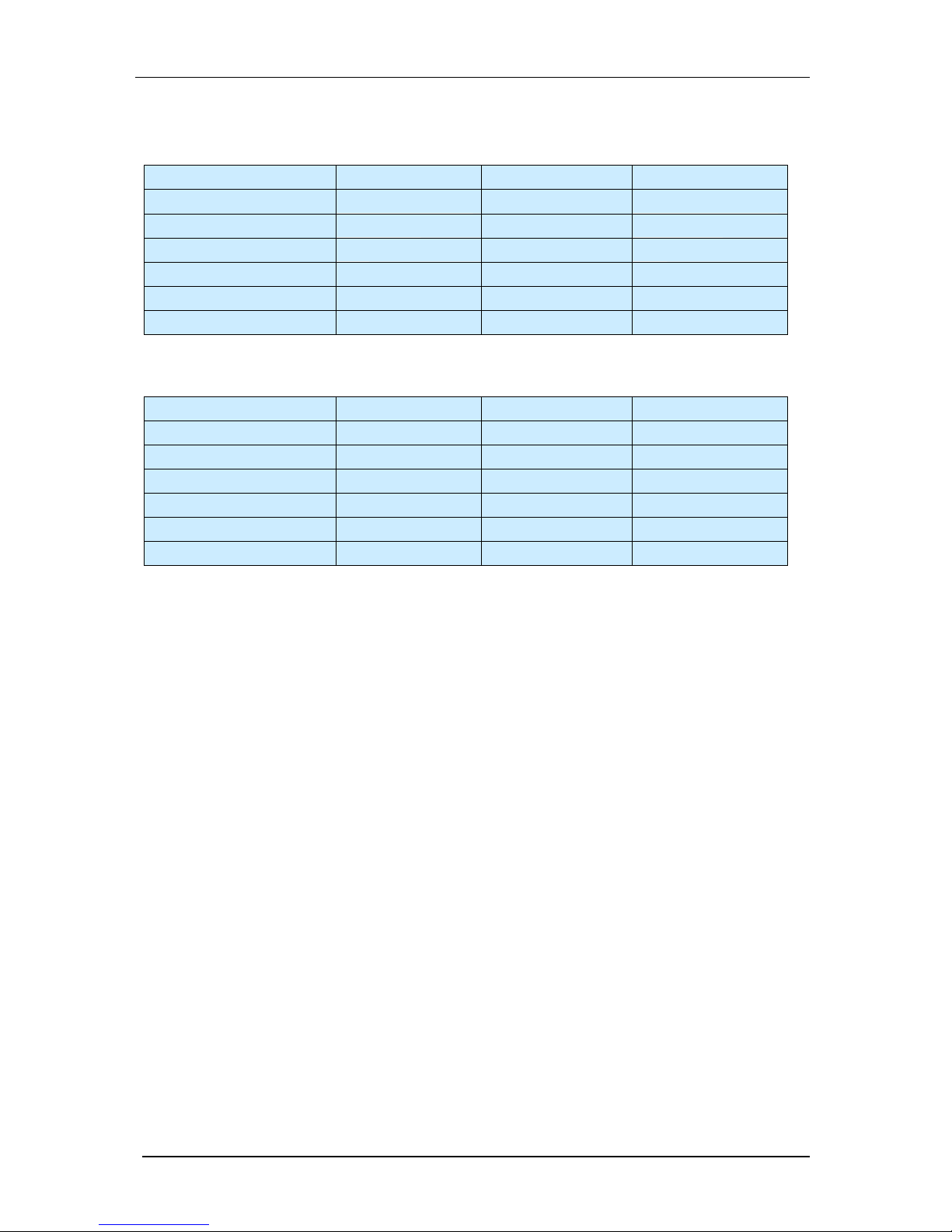

The technical specifications for the SVGA output signals :

Horizontal frequency: 45.072 kHz VBP: 32 lines

Vertical frequency: 67.68 Hz VFP: 46 lines

Resolution SVGA: 600x800 HSYNC width: 120 pixels

Resolution eff. hor.: 752 HBP: 94 pixels

Resolution eff. ver.: 582 HFP: 74 pixels

VSYNC width: 6 lines Pixel frequency: 46.875 MHz

Polarity HSYNC: positive Polarity VSYNC: positive

The technical specifications for the SXGA output signals :

Horizontal frequency: 64 kHz VBP: 37 lines

Vertical frequency: 60 Hz VFP: 2 lines

Resolution SXGA: 1280x1024 HSYNC width: 130 pixels

Resolution eff. hor.: 1280 HBP: 487 pixels

Resolution eff. ver.: 1024 HFP: 55 pixels

VSYNC width: 3 lines Pixel frequency: 125 MHz

Polarity HSYNC: positive Polarity VSYNC: positive

3.4 Power Board

The "C6PWR" Board

This board contains the power supply for the entire camera. It is also responsible for the galvanic

separation of the signals, and tailors the levels of the PLC-signals (4 inputs, 4 outputs).

The camera is supplied with a nominal voltage of 24 V (+/- 20%). An electronic stabilization of the

supply voltage is not necessary. The camera is internally galvanically separated from the supply

voltage by means of a DC/DC converter, to avoid common ground loops and electromagnetic

interference. A reverse-voltage protection diode protects the camera in case the supply voltage poles

are swapped.

An I/O processor performs PLC I/O , and also monitors PLC voltage failures and overcurrent.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 15

VC20XX Operating Manual

11

4 PLC I/O Signals

The camera has four optically decoupled inputs and four decoupled outputs for controlling machines

and processes.

An I/O processor is responsible for the handling of the PLC I/O signals.

The PLC-compatible inputs (24-V level, the positive signal is connected) include input protection

circuits. A minimum voltage of 14V is required to reliably sense a logic high signal.

The PLC outputs feature a highly integrated MOSFET, high-side switch with built-in protection . It is

possible to switch inductive or capacitive loads. The protective feature of the outputs will produce

pulses on the outputs, if the limiting values are exceeded.

A protective diode ensures, the poles of the supply voltage from the power supply of the PLC can not

be swapped. It is important to connect both the external supply voltage of the outputs (+24V) as well

as GND (GNDIn) of the power supply of the PLC.

The complete circuitry, including the I/O processor, is galvanically separated from the rest of the

camera electronics.

If DC failure of the PLC power is detected, this information is forwarded to the DSP (PLC power failure

interrupt)

Output drivers feature short circuit end thermal overload protection

For additional protection of the output drivers, the I/O processor monitors the total PLC current, and

switches off all outputs if the maximum threshold value is exceeded.

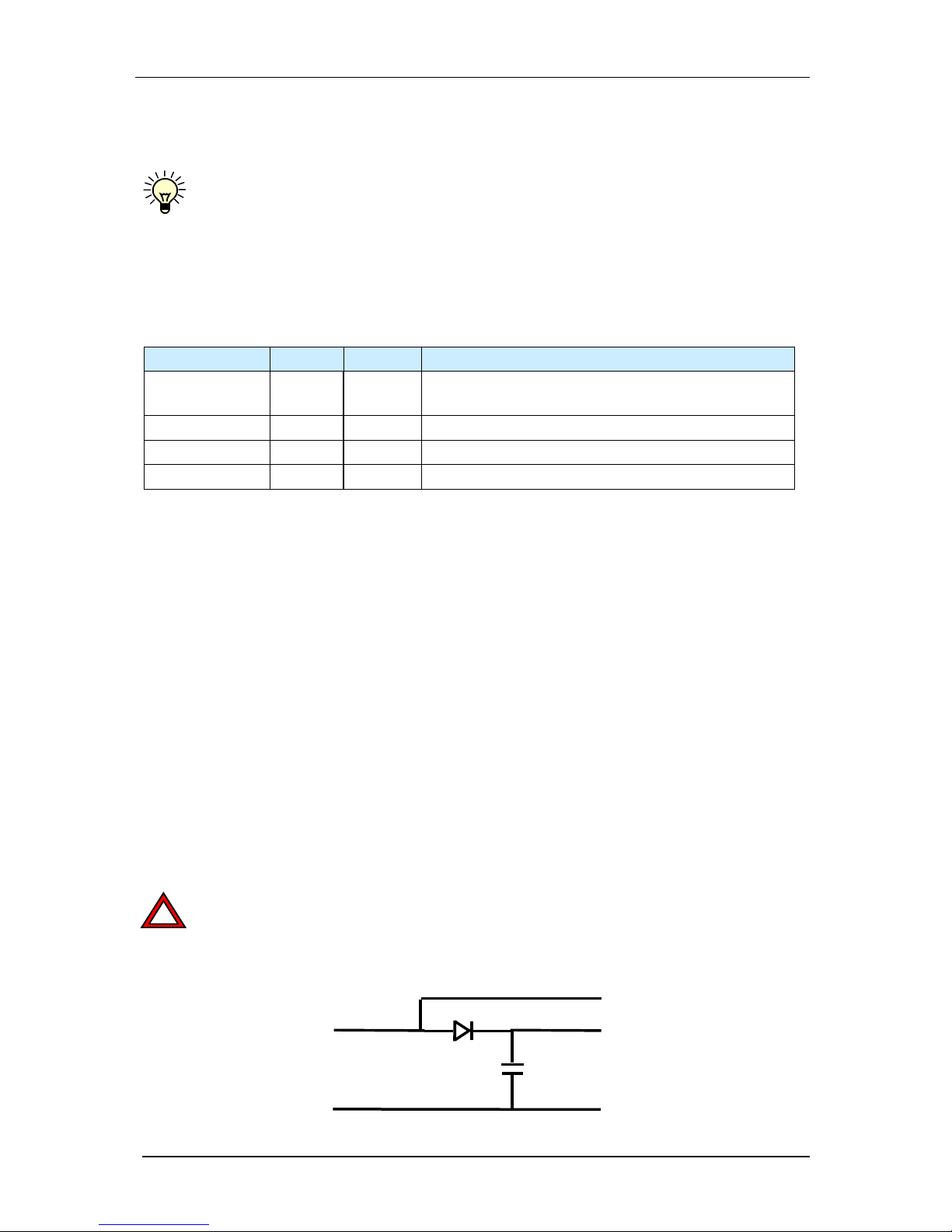

Technical data of the I/O signals:

Inputs

Outputs

Trigger input and trigger output

4.1 Input Signals

Nominal voltage: 24 V +/- 20%

Absolute maximum voltage: voltages greater than 40 V can destroy the inputs

Type:

galvanically separated by optocoupler (PLC

communication interface)

Input current: 1 mA @ 24V

Threshold value: 14 V

Internal signal delay:

100 µsec (signal) + 0..200 µsec (polling) + DSP interrupt

latency

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 16

VC20XX Operating Manual

12

4.2 Output Signals

Operating voltage: 24 V +/- 20%, external source

Absolute maximum voltage: voltages greater than 40 V can destroy the outputs

Type: galvanically separated by MOSFET optocouplers

Switching voltage: positive switching

Current: max. 400 mA per output

Absolute maximum current:

total currents greater than 1000 mA can destroy plugs and

cables

Always consider the total sum of all output currents

Switching power: max. 9.6 W (24 V * 400 mA) per output

Reverse voltage protection yes, for external voltage

Protection against inductive

loads:

yes

Resistance when switched on: 0.2 - 0.8 Ohm

Short circuit protection: full protection

4.3 Trigger input and trigger output

The board features a dedicated fast TTL trigger input (for use as image capture trigger) and a fast TTL

trigger output (as strobe-light trigger). Since both signals are fast at a very low noise margin, it is

recommended to keep the cable as short as possible. Use twisted pair or even coaxial cable for this

purpose. The trigger input has a built-in photocoupler to eliminate ground loops with the external

circuitry. The trigger output, however, is not galvanically separated. The receiving circuit should,

therefore, have a photocoupler of its own.

Please note that input and output are not protected against overcurrent. The output is neither

protected against short circuit nor reverse voltage spikes from inductive loads.

Trigger input assures constant delay without jitter.

Technical data of trigger input:

input voltage: 3-5 V (TTL, CMOS)

input current: 5mA @ 3V / 11mA @ 5V

limiting resistor: built in, 330 Ohm

knee voltage: 1.5 V

reverse voltage protection: shunt diode

switching delay: max. 2µsec + interrupt latency

Trig. In+

yellow cable

Trig. Ingreen cable

330 R

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 17

VC20XX Operating Manual

13

Technical data of trigger output:

output voltage: max. 7V

output current: max. 50mA

pull-up resistor: none, external resistor required

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 18

VC20XX Operating Manual

14

5 Pin Assignments Camera Interfaces

The cameras have four connectors on the rear side:

RS232(V24) or

100MBd Ethernet

HR10A-7R-6PB 6-pin Hirose plug pin contact

Trigger / Keypad HR10A-7R-6SB 6-pin Hirose plug jack contact

SXGA/SVGA/Video HR10A-10R-10SB 10-pin Hirose plug jack contact

DC IN/PLC-I/O HR10A-10R-12PB 12-pin Hirose plug pin contact

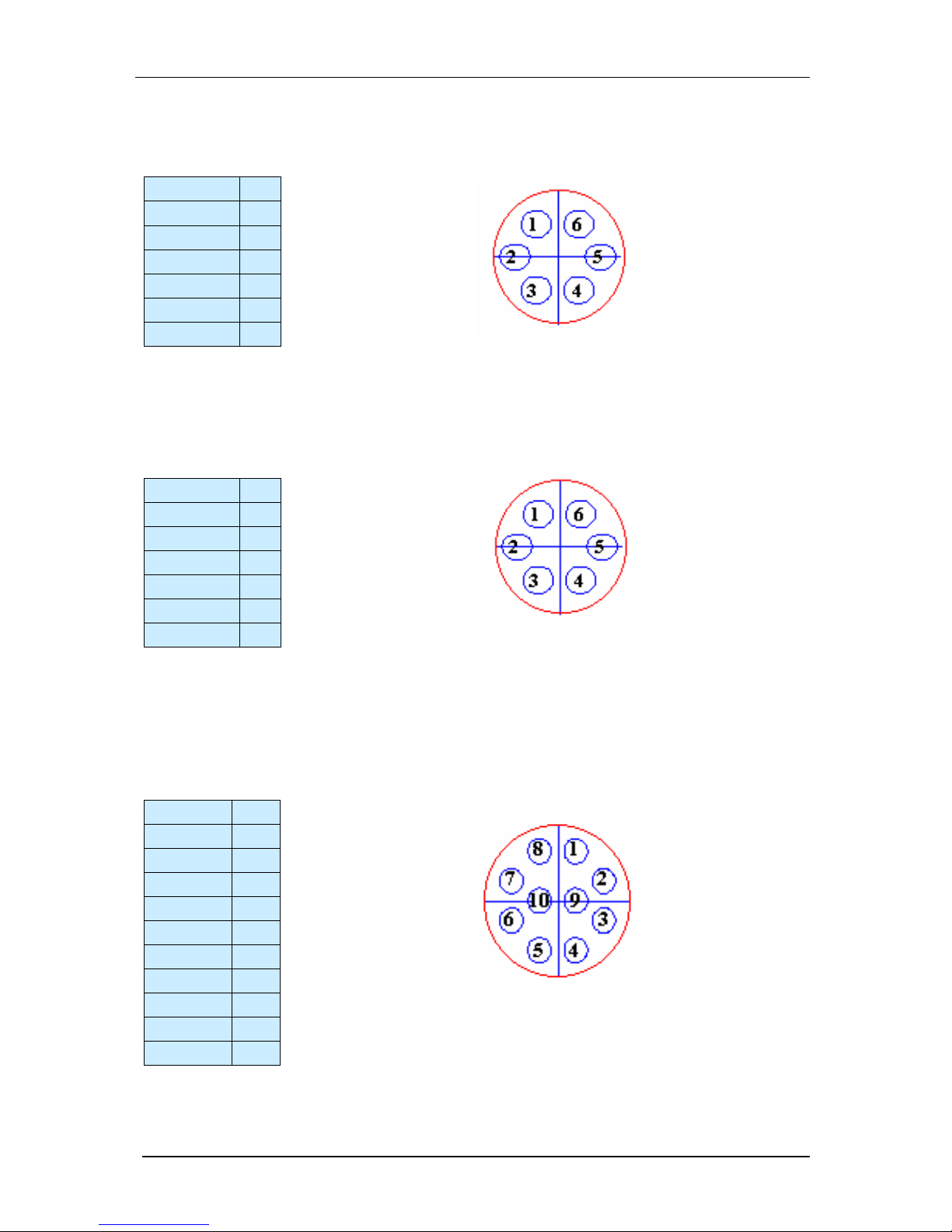

5.1 Pin Assignment Trigger / Keypad Plug Signal

rear view (jack):

Signal Pin

GND 3

5V Out 2

Trigger IN - 1

Trigger IN + 6

Trigger Out 5

Keypad IN 4

They Keypad IN operates with 3.3V TTL @9600 baud / 8 / N / 1

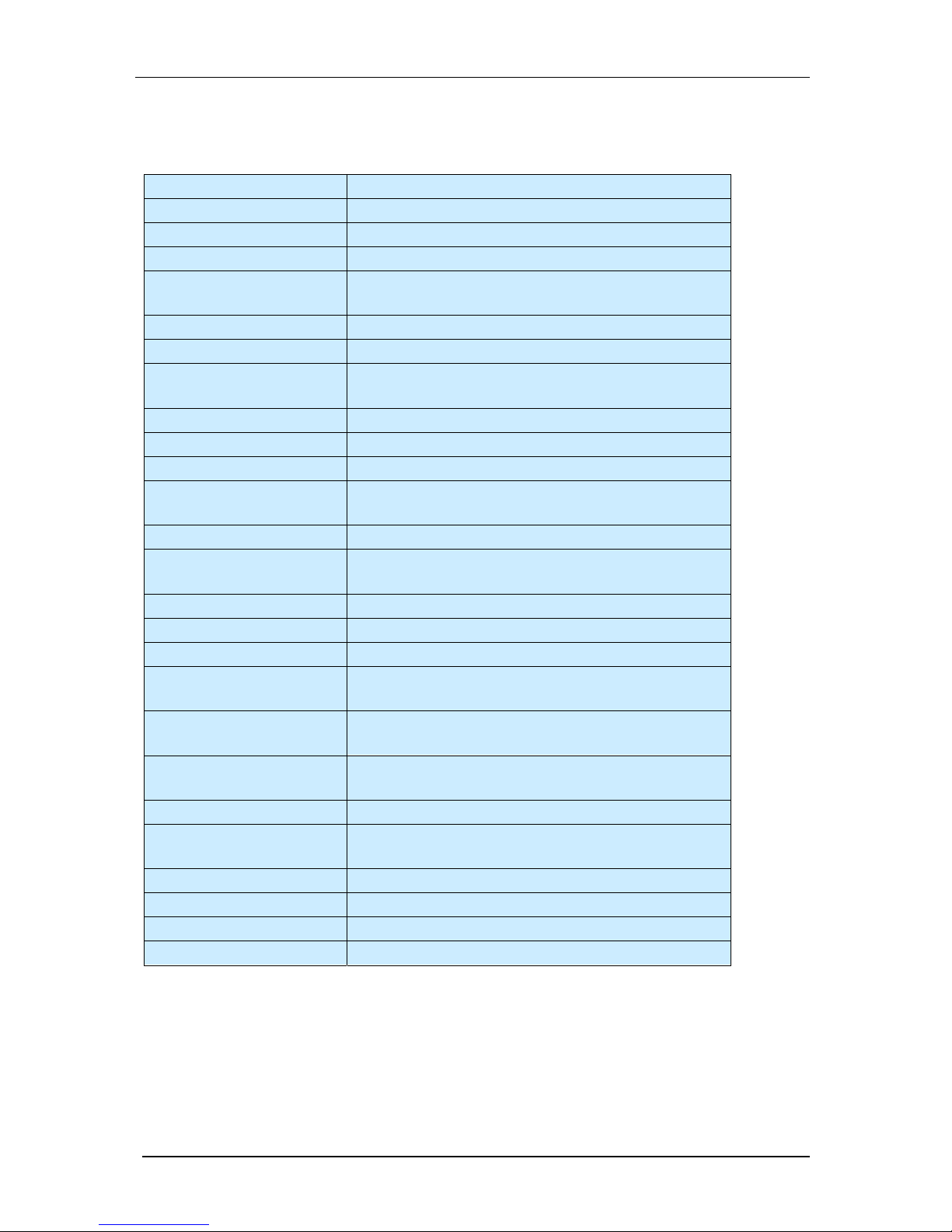

5.2 Pin Assignment for the I/O Plug

Rear view: (pin)

Signal Pin

IN0 12

IN1 4

IN2 11

IN3 10

24V IN / Cam 2

GND IN (common) 3

24V IN/ PLC 1

24V IN/ PLC 9

OUT0 8

OUT1 7

OUT2 6

OUT3 5

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 19

VC20XX Operating Manual

15

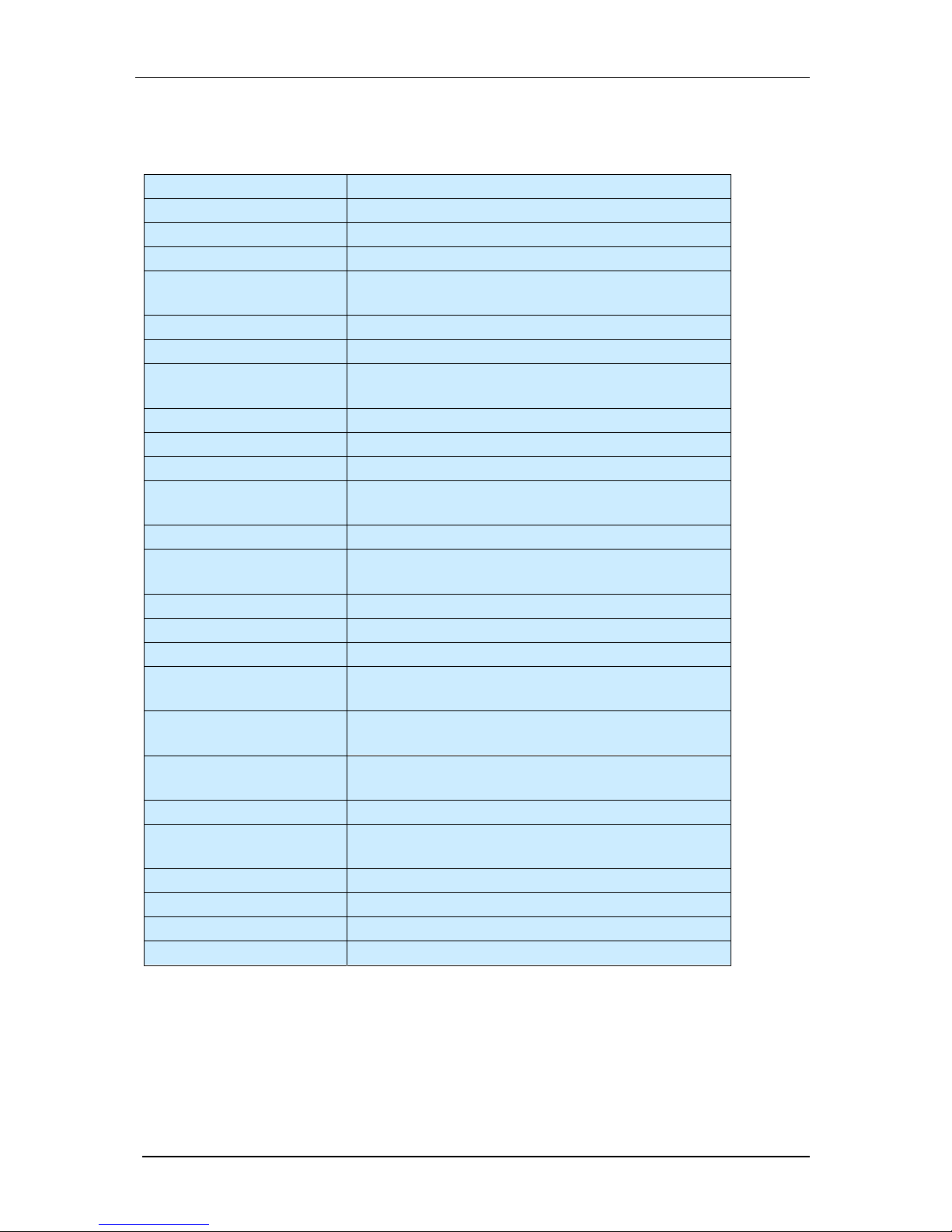

5.3 Pin Assignment for the RS232 (V24)

Rear view: (pin)

Signal Pin

V24 RTS 1

V24 TxD 2

V24 GND 3

NC V24 4

V24 CTS 5

RxD 6

5.4 Pin Assignment LAN/Ethernet

Rear view: (pin)

Signal Pin

T- 1

T+ 2

- 3

- 4

R- 5

R+ 6

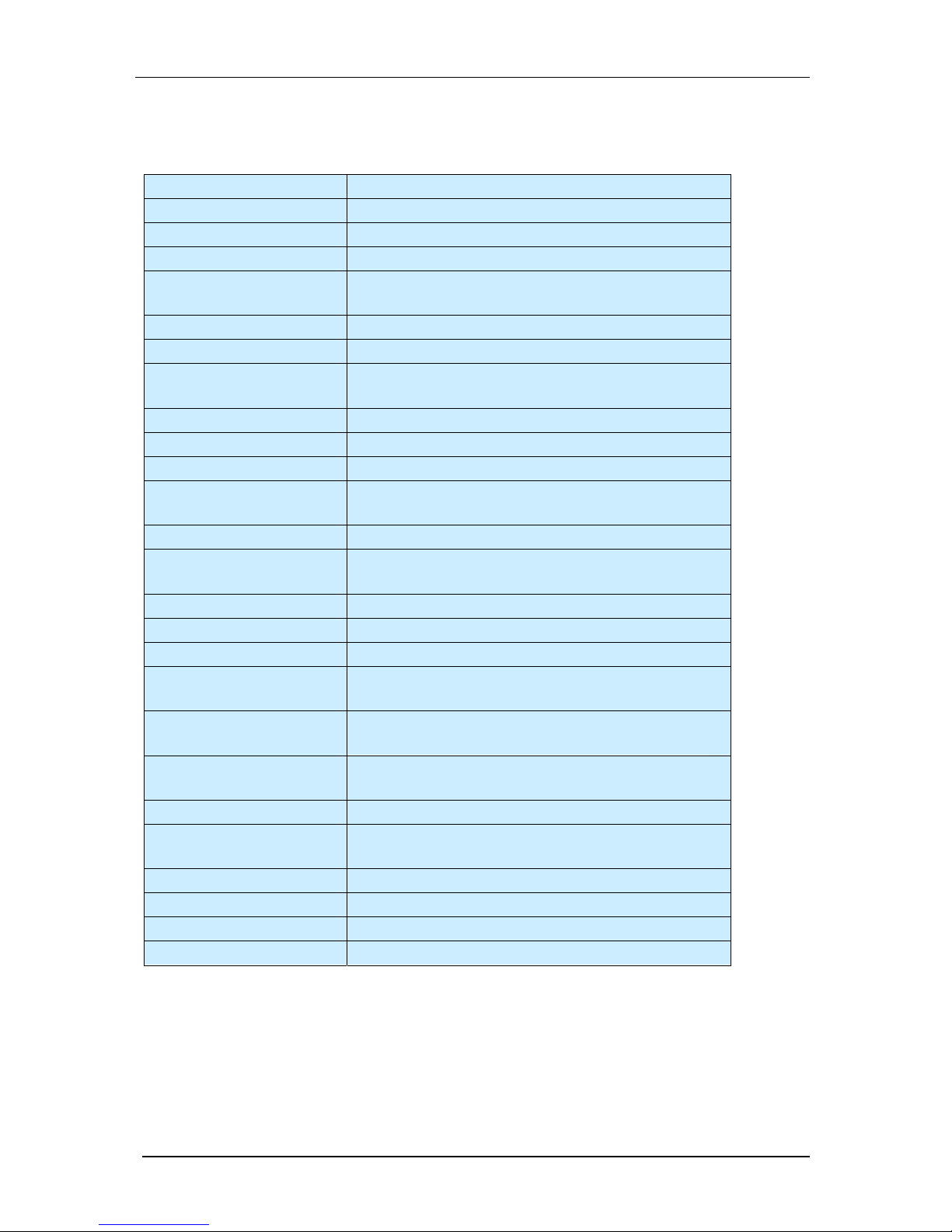

5.5 Pin Assignment for the XGA/SVGA Video Output

rear view (jack):

Signal Pin

G GND 1

G Out 2

R GND 3

R Out 4

VS GND 5

VS Out 6

HS GND 7

B GND 8

B Out 9

HS Out 10

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 20

VC20XX Operating Manual

16

6 Technical Specifications VC20XX Smart Cameras

Technical Specifications VC2028

Technical Specifications VC2038 Technical Specifications VC2038/E

Technical Specifications VC2048/E

Technical Specifications VC2065 TechnicalSpecifications VC2065/E

Technical Specifications VC2065/C Technical Specifications VC2065/EC

Technical Specifications VC2066 Technical Specifications VC2066/E

Technical Specifications VC2068 Technical Specifications VC2068/E

6.1 Technical Specifications VC2028

Sensor: 1/3" SONY ICX424AL

eff. no. of pixels: 640(H) x 480(V)

Pixel size: 7.4(H) x 7.4(V) µm

Chip size: 5.79(H) x 4.89(V) mm

High-speed shutter: 30,80,... microseconds in steps of 50 microseconds (full-

frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking: with 15msec delay, program-controlled ; full-frame / 25

frames per second, no external highspeed trigger

1

Clamping: zero offset digital clamping

A/D conversion: 15.625 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display: black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor: Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 40 full-size images in format 640x480

Flash EPROM: 2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Not available

Process interface: 4 inputs / 4 o utputs, optically decoupled 24 V, outputs

4x400 mA

Serial interface: V24 (RS232) max. 115200 baud

Video output: RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

!

1

Use VC2038 instead of VC2028 for imaging moving objects.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 21

VC20XX Operating Manual

17

6.2 Technical Specifications VC2038

Sensor: 1/3" SONY ICX424AL

eff. no. of pixels: 640(H) x 480(V)

Pixel size: 7.4(H) x 7.4(V) µm

Chip size: 5.79(H) x 4.89(V) mm

High-speed shutter:

30,80,... microseconds in steps of 50 microseconds (full-

frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 40 frames per second

Clamping: zero offset digital clamping

A/D conversion: 15.625 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 40 full-size images in format 640x480

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Serial interface: V24 (RS232) max. 115200 baud

Video output:

RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 22

VC20XX Operating Manual

18

6.3 Technical Specifications VC2038/E

Sensor: 1/3" SONY ICX424AL

eff. no. of pixels: 640(H) x 480(V)

Pixel size: 7.4(H) x 7.4(V) µm

Chip size: 5.79(H) x 4.89(V) mm

High-speed shutter:

30,80,... microseconds in steps of 50 microseconds (full-

frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 40 frames per second

Clamping: zero offset digital clamping

A/D conversion: 15.625 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 40 full-size images in format 640x480

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Ethernet interface: 100 MBit

Video output:

RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 23

VC20XX Operating Manual

19

6.4 Technical Specifications VC2048/E

Sensor: 1/2" KODAK KAI-0330D

eff. no. of pixels: 640(H) x 480(V)

Pixel size: 9(H) x 9(V) µm

Chip size: 7.3(H) x 5.52(V) mm

High-speed shutter:

18,36,72, microseconds in steps of 36 microseconds (full-

frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 112 frames per second

Clamping: zero offset digital clamping

A/D conversion: 2 x 24 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 40 full-size images in format 640 x 480

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Ethernet interface: 100Mbit Ethernet

Video output:

RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 24

VC20XX Operating Manual

20

6.5 Technical Specifications VC2065

Sensor: 1/2" SONY ICX415AL

eff. no. of pixels: 782(H) x 582(V)

Pixel size: 8.3(H) x 8.3(V) µm

Chip size: 7.48(H) x 6.15(V) mm

High-speed shutter:

5,10,15,20, microseconds in steps of 40 microseconds

(full-frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 45 frames per second

Clamping: zero offset digital clamping

A/D conversion: 24 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 35 full-size images in format 782 x 582

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Serial interface: V24 (RS232) max. 115200 baud

Video output:

RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 25

VC20XX Operating Manual

21

6.6 Technical Specifications VC2065/C

Sensor: 1/2" SONY ICX415AK color sensor

eff. no. of pixels: 782(H) x 582(V)

Pixel size: 8.3(H) x 8.3(V) µm

Chip size: 7.48(H) x 6.15(V) mm

High-speed shutter:

5,10,15,20, microseconds in steps of 40 microseconds

(full-frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 45 frames per second

Clamping: zero offset digital clamping

A/D conversion: 24 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 35 full-size images in format 782 x 582

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Serial interface: V24 (RS232) max. 115200 baud

Video output:

RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 26

VC20XX Operating Manual

22

6.7 Technical Specifications VC2065/E

Sensor: 1/2" SONY ICX415AL

eff. no. of pixels: 782(H) x 582(V)

Pixel size: 8.3(H) x 8.3(V) µm

Chip size: 7.48(H) x 6.15(V) mm

High-speed shutter:

5,10,15,20, microseconds in steps of 40 microseconds

(full-frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 45 frames per second

Clamping: zero offset digital clamping

A/D conversion: 24 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 35 full-size images in format 782 x 582

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Ethernet Interface 100Mbit Ethernet

Video output:

RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 27

VC20XX Operating Manual

23

6.8 Technical Specifications VC2065/EC

Sensor: 1/2" SONY ICX415AK color sensor

eff. no. of pixels: 782(H) x 582(V)

Pixel size: 8.3(H) x 8.3(V) µm

Chip size: 7.48(H) x 6.15(V) mm

High-speed shutter:

5,10,15,20, microseconds in steps of 40 microseconds

(full-frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 45 frames per second

Clamping: zero offset digital clamping

A/D conversion: 24 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 35 full-size images in format 782 x 582

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Ethernet interface: 100Mbit Ethernet

Video output:

RGB, 3x75 Ohm, 1 Vpp, SVGA 800x600 output, HSYNC,

VSYNC separate

Horizontal frequency: 45.072 kHz

Vertical frequency: 67.68 Hz

Resolution SVGA: 600x800

Pixel frequency: 46.875 MHz

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 28

VC20XX Operating Manual

24

6.9 Technical Specifications VC2066

Sensor: 1/3" SONY ICX204AL

eff. no. of pixels: 1024(H) x 768(V)

Pixel size: 4.65(H) x 4.65(V) µm

Chip size: 5.8(H) x 4.92(V) mm

High-speed shutter:

10,20,30,45 µsec, then steps of 78 µsec (full-frame

shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 16.5 frames per second (2x binning @ 33fps)

Clamping: zero offset digital clamping

A/D conversion: 15.625 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 20 full-size images in format 1024x768

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Serial interface: V24 (RS232) max. 115200 baud

Video output:

RGB, 3x75 Ohm, 1 Vpp, SXVGA 1280x1024 output,

HSYNC, VSYNC separate

Horizontal frequency: 64kHz

Vertical frequency: 60Hz

Resolution SXGA: 1280x1024

Pixel frequency:

125MHz – when using a TFT, ensure the monitor is

cablable of 125Mhz pixel frequency (i.e. TFT’s with 80Hz

image frequency).

!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 29

VC20XX Operating Manual

25

6.10 Technical Specifications VC2066/E

Sensor: 1/3" SONY ICX204AL

eff. no. of pixels: 1024(H) x 768(V)

Pixel size: 4.65(H) x 4.65(V) µm

Chip size: 5.8(H) x 4.92(V) mm

High-speed shutter:

10,20,30,45 microseconds, longer in steps of 78

microseconds (full-frame shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 16.5 frames per second (2x binning @ 33fps)

Clamping: zero offset digital clamping

A/D conversion: 15.625 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 20 full-size images in format 1024x768

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Ethernet Interface: 100 Mbit

Video output:

RGB, 3x75 Ohm, 1 Vpp, SXVGA 1280x1024 output,

HSYNC, VSYNC separate

Horizontal frequency: 64Khz

Vertical frequency: 60Hz

Resolution SXGA: 1280x1024

Pixel frequency:

125MHz – when using a TFT, ensure the monitor is

cablable of 125Mhz pixel frequency (i.e. TFT’s with 80Hz

image frequency).

!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 30

VC20XX Operating Manual

26

6.11 Technical Specifications VC2068

Sensor: 1/2" SONY ICX205AL

eff. no. of pixels: 1280(H) x 1024(V)

Pixel size: 4.65(H) x 4.65(V) µm

Chip size: 7.60mm (H) 6.20mm (V)

High-speed shutter:

9,17,26,33, .. µsec, then steps of 69 µsec (full-frame

shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 13.75 frames per second (2x binning @

27.5fps)

Clamping: zero offset digital clamping

A/D conversion: 15.625 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 14 full-size images in format 1280x1024

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Serial interface: V24 (RS232) max. 115200 baud

Video output:

RGB, 3x75 Ohm, 1 Vpp, SXVGA 1280x1024 output,

HSYNC, VSYNC separate

Horizontal frequency: 64kHz

Vertical frequency: 60Hz

Resolution SXGA: 1280x1024

Pixel frequency:

125MHz – when using a TFT, ensure the monitor is

cablable of 125Mhz pixel frequency (i.e. TFT’s with 80Hz

image frequency).

!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 31

VC20XX Operating Manual

27

6.12 Technical Specifications VC2068/E

Sensor: 1/2" SONY ICX205AL

eff. no. of pixels: 1280(H) x 1024(V)

Pixel size: 4.65(H) x 4.65(V) µm

Chip size: 7.60mm (H) 6.20mm (V)

High-speed shutter:

9,17,26,33, .. µsec, then steps of 69 µsec (full-frame

shutter)

Low-speed shutter: up to 20 sec. adjustable integration time

Integration: full-frame

Picture taking:

without delay, program-controlled or triggered externally;

full-frame / 13.75 frames per second (2x binning @

27.5fps)

Clamping: zero offset digital clamping

A/D conversion: 15.625 MHz / 10 bit,

Input LUT 1024x8 bit (10bit → 8 bit)

Image display:

black-and-white, Pseudo Color from color lookup table

3x8Bit RGB:live image, still image, graphics

Overlay: 8-bit overlay with LUT, maskable

Processor:

Texas Instruments TMS320C6211 signal processor 150

MHz

RAM: 16 MBytes SDRAM (synchronous dynamic RAM)

Display memory: 16 MBytes SGRAM (synchronous graphics RAM)

Memory capacity: 14 full-size images in format 1280x1024

Flash EPROM:

2 MBytes flash EPROM (nonvolatile memory) for

programs and data,in-system programmable, 16 bit wide

MMC:

Multi-Media Card Adaptor with 16 Mbyte of Card Flash

Memory

Process interface:

4 inputs / 4 outputs, optically decoupled 24 V, outputs

4x400 mA

Ethernet interface: 100 Mbit

Video output:

RGB, 3x75 Ohm, 1 Vpp, SXVGA 1280x1024 output,

HSYNC, VSYNC separate

Horizontal frequency: 64kHz

Vertical frequency: 60Hz

Resolution SXGA: 1280x1024

Pixel frequency:

125MHz – when using a TFT, ensure the monitor is

cablable of 125Mhz pixel frequency (i.e. TFT’s with 80Hz

image frequency).

!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 32

VC20XX Operating Manual

28

7 Accessories

• Trigger Cable

• V24 (RS232) Cabl e

• Ethernet patch cable

• Power / PLC Cable

• SVGA Monitor Cable

• Power adapter

• Power adapter for rail mounting

• VC Keypad C6

• Y-cable

Please refer to the VC website for the correct order numbers under:

“Products -> Hardware -> VC20XX Smart Cameras -> Accessories VC20XX Smart Cameras”

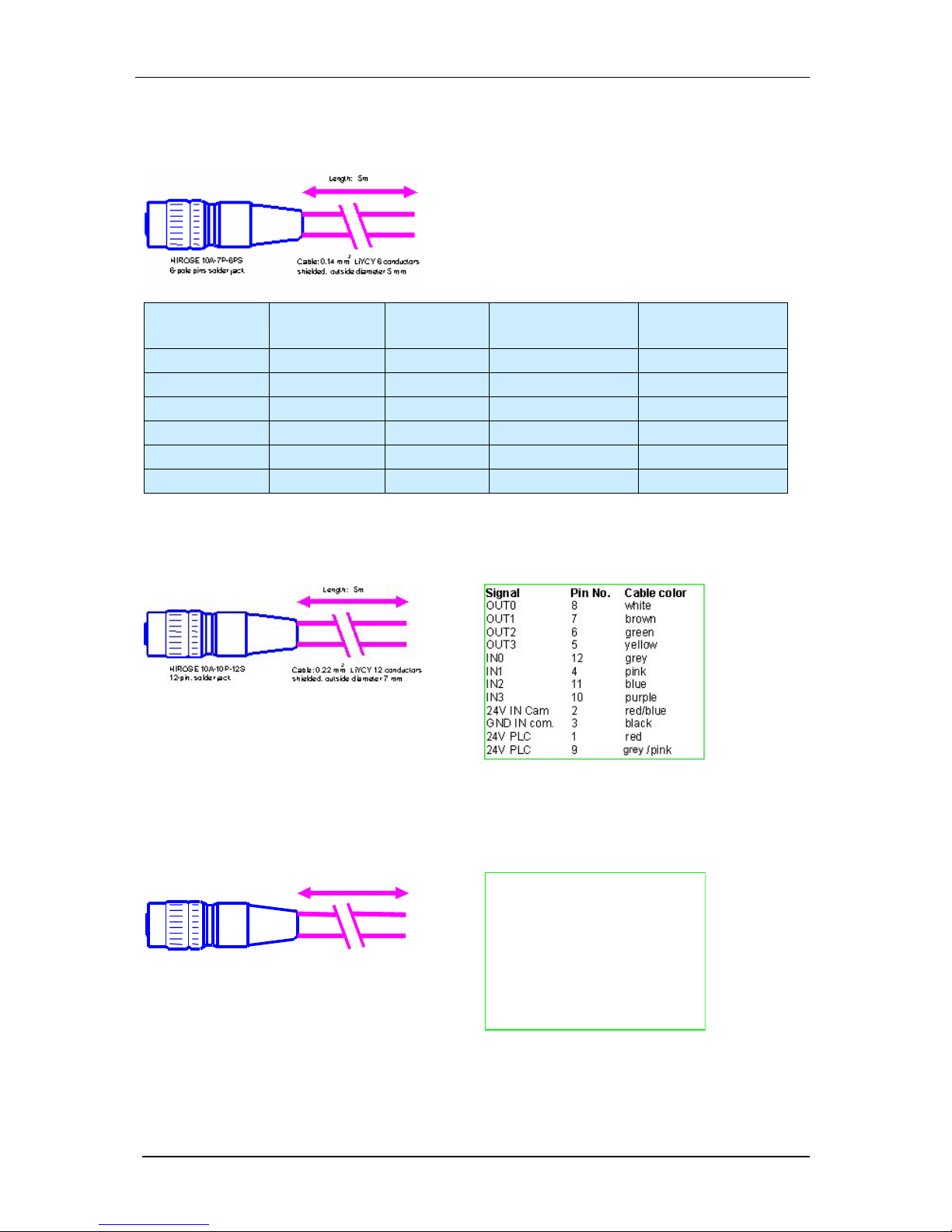

7.1 Trigger Cable

HIROSE 10A-7P- 6SC

6-pin. sol der plug

Length: 5m

Cable: 0.14mm LiYCY 6 conductors

shielded,

outside diam eter 5 mm

2

Signal

Pin Nr. Cable color

GND 3 white

+5V Out 2 brown

Trig. I n - 1 green

Trig. In+ 6 yellow

Trig. Out 5 grey

Keypad I n 4 pink

Equipped on one end with a Hirose plug, length 5m, 10m or 25m

7.2 RS232(V24) Cable

Equipped on one end with a Hirose plug, length 5m, 10m or 25m

Please order "with 2nd connector", if you need a DSUB9 connector at the other end

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 33

VC20XX Operating Manual

29

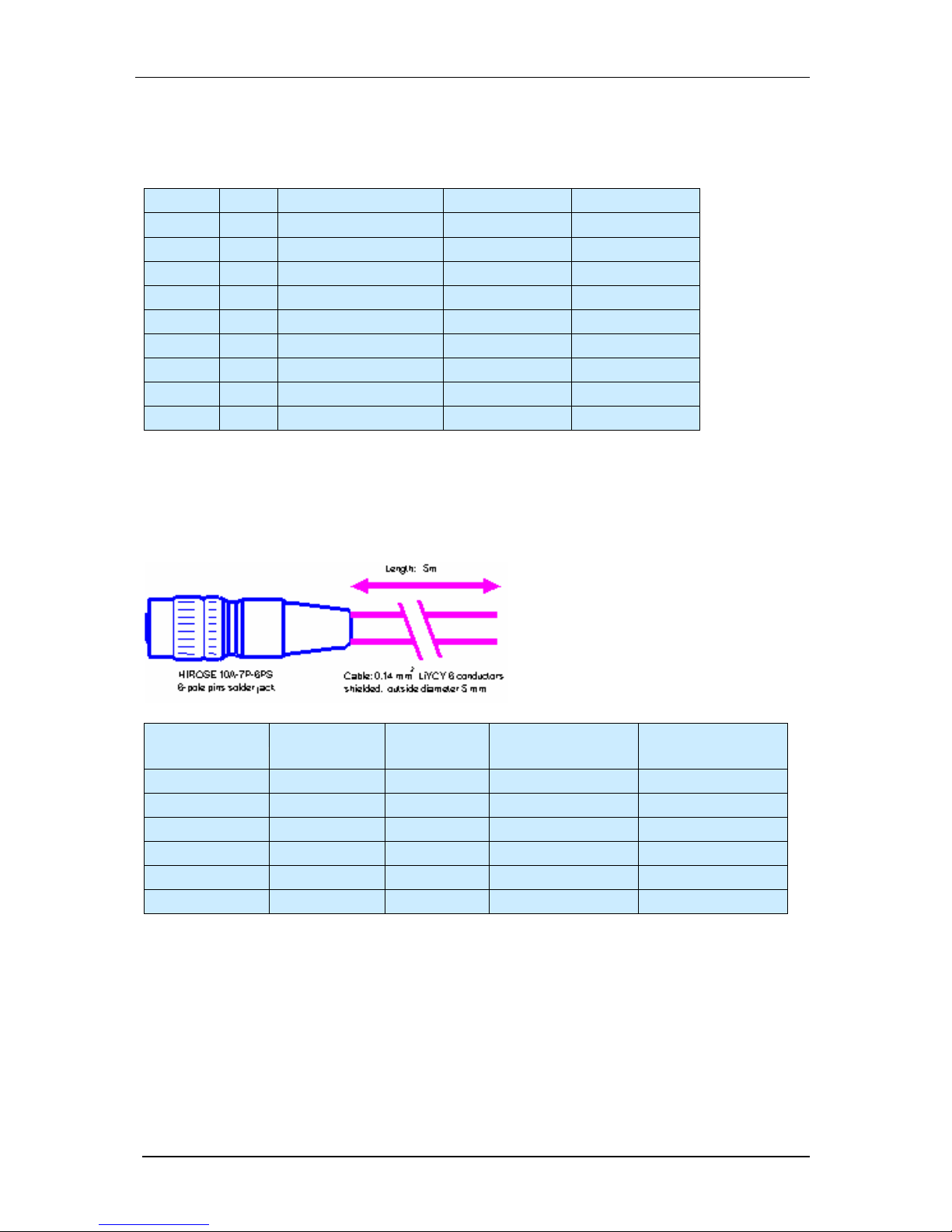

7.3 Ethernet patch cable

Signal Pin (to cam.) Pin (to PC) Cable Color

20m patch cable

Cable Color

10m patch cable

T+ 2 1 yellow white/pink

T- 1 2 orange pink

R+ 6 3 white/green white/green

R- 5 6 green green

- 3 NC - -

- 4 NC - -

7.4 Power / PLC Cable

Equipped on one end with a Hirose plug jack, length 5m, 10m or 25m

7.5 SVGA Monitor Cable

HIROSE 10A- 10P-10P

10-pin. pins solder plug

Length: 5m

Cable: 5 x mini coaxial cable 75 Ohm

outside diam eter 7 mm

Signal

Pin No. Connection

R Out 4 red signal

R GND 3 red shield

G O ut 2 gr een signal

G G ND 1 green shield

B Out 9 blue signal

B GND 8 blue shield

HS Out 10 white signal

HS GND 7 whit e shield

V S Out 6 gray signal

VS GND 5

gray

shi eld

Equipped on one end with a Hirose plug, length 5m, 10m and 25m.

Please order "with 2nd connector", if you need an DSUB15 connector at the other end.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 34

VC20XX Operating Manual

30

7.6 Power adapter

input voltage 100 - 240VAC 50/60 Hz

output voltage DC 24 V +/-5%, max. 630 mA (15 W)

Equipped with 3 m connecting cable with a 12-pin Hirose plug, CE sticker

7.7 Power adapter for rail mounting

Input Voltage 100 - 240VAC 50/60 Hz

Output Voltage DC 24V +/-5%, max. 300 mA (7.5 W)

Equipped with connecting clamps for AC input and 24V output, CE certified

7.8 VC Keypad C6

VC Keypad includes the following keys:

- 4 cursor keys,

- Esc, Return,

- F1, F2 keys

TTL version, 3m cable equipped with 6 pin Hirose connector.

No additional power source required.

Note: The RS232 version of the keypad, used for VCXX cameras is NOT compatible!

7.9 Y-cable

Connectors:

1x HR10A-7P-6P 2x HR10A-7J-6S

Signal HR...6P / Pin Nr. cable color

1. HR10A-7J-6S

Pin Nr.

2. HR10-A7-J6S

Pin Nr.

GND 3 white 3 3

P5V 2 brown 2 2

Trig In 1 green 1 1

Trig InP 6 yellow 6 6

Trig Out 5 gray 5 5

RS IN 4 pink 4 4

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 35

VC20XX Operating Manual

31

8 Connecting the Camera

• Connecting the camera power

• Single voltage, with or without PLC signals, no shutdown

• Dual voltage, with or without PLC signals, shutdown

• Connecting the RS232 Interface (n on Ethernet Versions)

• Connecting a compatible PC with a 9-pin D sub plug

• Connecting a compatible PC with a 25-pin D sub plug

• Connecting the Ethernet Cable (Ethernet Versions)

• Connecting the VC keypad

• Connecting the external trigger

Also consult the “VC20XX Installation Manual” available on the VC Website under:

“Support -> Customer Download Area -> Getting Started VC20XX Smart Cameras …”

8.1 Connecting the camera power

Power must be connected to the 12pin I/O connector. Note, that the voltage is 24V.

Camera power is regulated and galvanically separated inside the camera, so only an unregulated

power source of 24 V +/- 20% is required. The camera is, however, very sensitive to power supply

interruption. Please make sure, that the voltage never exceeds the limits of +/- 20% even for a short

period of time. In case of trouble it is recommended to backup the power supply by a capacitor or a

battery large enough to prevent power interruptions.

The camera has several internal circuits to detect and protocol power failures. Used correctly the

camera is even able to perform a correct shutdown and close all open buffers (see below). This

feature is for emergency only and is not designed to handle very frequent interruptions.

There are different options for the connection of the power supply:

• Single voltage, with or without PLC signals, no shutdown

• Dual voltage, with or without PLC signals, shutdown

For details refer to the following sections.

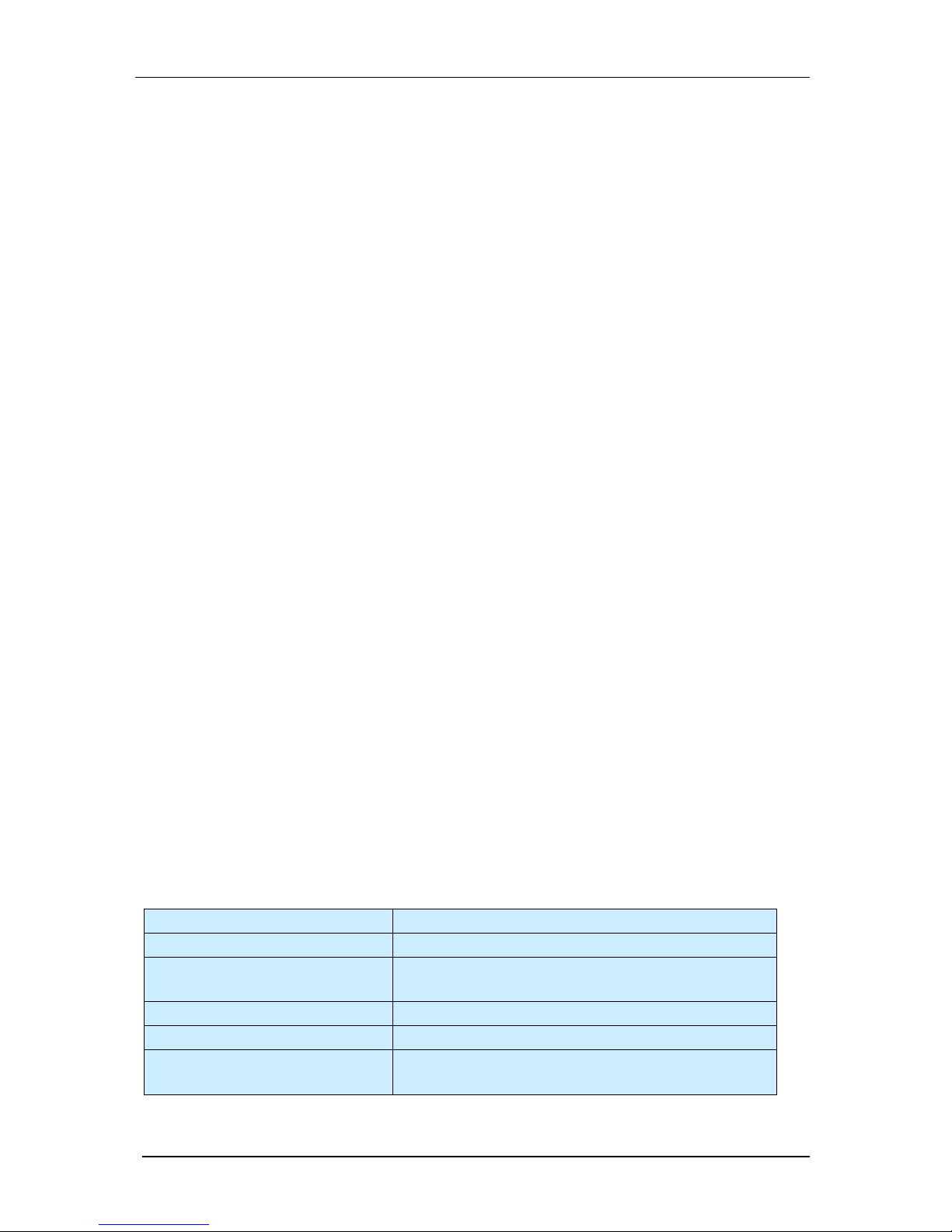

8.1.1 Single voltage, with or without PLC signals, no shutdown:

Signal Pin No. color connect to

24V IN Cam 2 red/blue 24V power supply

24V PLC 1 red 24V power supply

24V PLC 9 blue/pink 24V power supply

GND IN com. 3 black GND power supply

Pins 1 and 9 are are internally connected. Since one connector pin shows a maximum current

rating of 500mA, connect both pins if drawing higher currents from the PLC outputs!

This cabling option does not provide shutdown. Programmer must implement their own

procedures for fail-safe operation.

!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 36

VC20XX Operating Manual

32

8.1.2 Shutdown Function for VC20XX Smart Cameras

VC20XX Smart Cameras incorporate a circuit to detect and protocol power failures. If the PLC

output power supply (12-24V PLC, Pin 1 and 9) of the cameras is interrupted, the system

variable “POWFAIL” is set to “1”. In case the PLC outputs are supplied, the status of

“POWFAIL” is “0” (refer to the sysvar.h).

This behaviour, that can also be checked using the shell command “ht”, can be used to perform a

controlled camera shutdown in case of a power failure.

Connecting the PLC/ Power interface for using this feature:

Signal Pin No. color connect to

24V IN Cam 2 red/blue

24V backup supply (supplying power at least 100ms

longer than grid supply in case of a power failure)

24V PLC 1 red 24V standard power (grid) supply

24V PLC 9 grey/pink 24V standard power (grid) supply

GND IN com. 3 black GND power supply

Here, the PLC voltage (24V PLC) is connected directly to the power (grid-) supply. The main camera

power supply at Pin 2 should remain high for at least 100ms longer than the power supplied to the

PLC supply. This can be done for instance with help of a suitable capacitor.

If a power failure occurs or if the main power supply is turned off, the camera detects this signal not

being present and the POWPLC status is changed from 0 to 1.

The system variable can be polled from time to time using the getvar(POWFAIL) function. This can be

best done using a background task.

The following procedures can be performed:

1. Stopping the operation of all programs and interrupts (no pictures will be taken any longer).

2. Saving all buffers (to multi-media card or flash EPROM).

3. Protocol time and date of the shutdown.

4. The procedure then waits for the backup voltage to disappear or main power to re-establish. If the

latter happens the program might be able to continue where it has stopped. (In this case there

may be some lost images = some parts not checked correctly)

Note that this feature is for emergency use only and is not designed to handle frequent

interruptions. The backup voltage must be able to supply the specified voltage for a period of

at least 100 msec (in addition to the polling delay).

!

24V PLC

GND

to ca mer a

24V PLC

GND

24V backup

from power supply

capacitor

10000µF

Sample Circuit for using the “power fail detect shutdown function”

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 37

VC20XX Operating Manual

33

8.2 Connecting the RS232 Interface

8.2.1 Connecting a compatible PC with a 9-pin D sub plug

Pin (PC) Name cable color Pin (camera)

1 DCD Data Carrier Detect - / - - / 2 RxD Receive Data brown 2

3 TxD Transmit Data white 6

4 DTR Data Terminal Ready - / - - / 5 GND Ground gray 3

6 DSR Data Set Ready -/- - / 7 RTS Request to Send green 5

8 CTS Clear to Send yellow 1

9 RI Ring Indicator - / - - / -

Pink cable should alsways be left open

8.3 Connecting the Ethernet Cable

Signal Pin (to cam.) Pin (to PC)

Cable Color10/ 20m

patch cable

Cable Color

5m patch cable

T+ 2 1 yellow white/pink

T- 1 2 orange pink

R+ 6 3 white/green white/green

R- 5 6 green green

- 3 NC - -

- 4 NC - -

8.4 Connecting the VC keypad

The VC keypad C6 can be connected directly to the Trigger/Keypad ("Trig.") Plug.

Please order the 5V version (VC keypad C6) of the keypad.

For details see : VC Keypad C6

The RS232 version of the keypad is NOT compatible

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 38

VC20XX Operating Manual

34

see Connecting the external trigger and the VC keypad

8.5 Connecting the external trigger

Connect the external trigger input/output directly to the Trigger/Keypad ("Trig.") Plug.

Please order "Trigger cable C6". Lengths available are 5m, 10m and 25m

For details see Trigger / Keypad Cable

see Connecting the external trigger and the VC keypad

8.6 Connecting the external trigger and the VC keypad

You may wish to connect both the keypad and the external trigger at the same time.

In this case you should use a special, short Y-cable with 1:1 connections of all the pins.

You may then proceed as mentioned in

Connecting the VC keypad

Connecting the external trigger

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 39

VC20XX Operating Manual

35

9 Programming

The cameras are programmed in C with the aid of a cross development system. Any commercially

available PC can be used. The minimum required configuration is a Pentium, 4 MB of extended RAM

(8 MB recommended), Win98 or or higher, hard disk, VGA graphics, HD and mouse

The original cross development system supplied by Texas Instruments includes the following IDE

Code Composer Studio:

- ANSI C / C++ compiler

- C runtime library

- C source debugger

- TMS assembler

- TMS simulator

- Linker

- Librarian

- Project Manager

- numerous example programs

The following libraries and aids are also available:

- Real-time operating system for VC cameras with control of video I/O signals, control of

serial interface and of PLC I/O signals, file management system for flash EPROM and Multi

Media Card. (Ethernet Versions : Ethernet control by SW)

- In-circuit emulator

The emulator is connected to the parallel serial interface of a PC. The camera housing must

be opened and the emulator cable must be connected to the diagnosis plug of the camera.

The emulator supports debugging in C and assembly language.

- Standard image processing library

Filters (e.g. Sobel, Median, Laplace, 3x3, ...), imaging operations (addition, subtraction, etc.),

transformations (FFT, etc.) image averaging and noise filters, fast binary image processing

with run-length code (AND, OR, XOR, segmentation, morphological operations), feature

extraction (area, center of gravity, momentum, etc.), graphic functions and much more.

- JPEG image compression

compression and decompression of images according to JPEG standards

- Measurement library *)

Subpixel sampling, compensation of optical properties and diffraction effects, auto-focus, best

straight line, best circle

*) in preparation

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 40

VC20XX Operating Manual

A

Appendix A: Blockdiagram VC20XX Smart Cameras

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 41

VC20XX Operating Manual

B

Appendix B: Housing Dimensions VC20XX Smart Cameras

The housing of the VC2048 has 15mm deep cooling fins left and right of the camera body, making it

80mm wide.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 42

VC20XX Operating Manual

C

Appendix E: Drawing Camera Head VC40XX

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 43

VC20XX Operating Manual

D

Appendix C: Spectral Transmission of IR Filter

Note:

This IR cut filter is incorporated in every VC20XX camera. The IR filter can be removed if

required without loosing Vision Component’s manufacturers warranty. In this case, special

care must be taken not to damage the CCD sensor.

If the camera is used without IR filter it is important to replace it by a clear glass filter of the

same size. The C-mount flangue distance from the CCD is accurately adjusted for the use of

the IR filter – removing the filter decreases the length of the optical path and it may become

impossible to focus some lenses to a larger working distance.

If the IR filter is not to be used, please order your camera with a clear glass filter or contact

Vision Components for obtaining a glass filter.

The order numbers for the clear glass filter is: EK000624

The order number for the IR cut filter (standard) is: EK000625

!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 44

VC20XX Operating Manual

E

Appendix D: CE Compliance of VC20XX Smart Cameras

The cameras are CE compliant. It certifies that numerous measurements were made provin g the

device complies with the appropriate EC regulations. Only electromagnetic compatibility was decisive

for this product.

This means that the cameras are not permitted to radiate electromagnetic waves in excess of a

boundary value layed down in the standard. They must also be insensitive to external radiation (e.g.

from cellular telephones). They must not be sensitive to static discharges, etc.

Unfortunately, it is not possible to limit the question of electromagnetic compatibility to just one device

or component. The entire system must always be considered.

Thus, the accessories such as cables, power supplies, etc., play a significant role for the VC series

cameras.

The manufacturer guarantees the boundary values for CE compliance only if the original accessories

are used.

CE Declaration of Compliance

The CE declaration of compliance for the VC20xx has the following wording. Corresponding

declarations also exist for the other camera models.

CE Declaration of Compliance

This certifies that the product designated as follows:

Machine Vision Camera Types

VC2028 / VC2038 / VC2038/E / VC2048/E,

VC2065/C, VC2065/EC, VC2065 / VC2065/E /

VC2066, VC2066/E, VC2068, VC2068/E

complies with the essential protection demands stipulated in the guideline on electromagnetic

compatibility of the Council for Harmonizing Legal Regulations of the Member States (89/336/EWG).

This declaration is valid for all examples manufactured according to the attached manufacturing

drawings, which are part of this declaration.

The following standards were utilized in judging the electromagnetic compatibility of this product:

EN 50081-2 : 1993

EN 50082-2 : 1993

This declaration is submitted by

Mr. Michael Engel, owner of the company named below

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 45

VC20XX Operating Manual

F

for the manufacturer

Vision Components

Ottostr. 2

76275 Ettlingen

Karlsruhe, 01.11.2003 ..........................................

(legal signature)

Enclosures:

schematic diagrams

mechanical drawings (outside dimensions)

Records of tests conducted by the certified test laboratory

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 46

VC20XX Operating Manual

G

INDEX

Accessories

Ethernet Cable 29

Keypad 30

Overview 28

Power Adapter 30

Power Cable 29

Rail Mount Power Adapter 30

RS232 Cable 28

Serial Cable 28

SVGA Monitor Cable 29

Y-cable 30

backup voltage 32

board

CPU Board 8

DAC Board 9

overview 5

Power Board 10

Sensor Board 5

cable

Ethernet 29

Powercable 29

RS232 28

Cable

Monitor Cable 29

Y-Cable 34

cable SVGA Cable 29

CE Decleration D

Connecting the Camera

Overview 31

Connection

Camera Power 31

Ethernet Cable 33

External trigger 34

External trigger AND keypad 34

VC Keypad 33

CPU Board 8

DAC Board 9

I/O-Plug

Plug Assignment 14

Input Signals 11

Keypad

Plug Assignment 14

Keypad C6 30

Output Signals 12

Overview

Accessories 28

8/E

Connecting the Camera 31

Patch Cable 29

PLC

Input Signals 11

Output Signals 12

Overview 11

Trigger Input 12

Trigger Output 12

Plug Assigment

Keypad 14

Overview 14

Trigger 14

Plug Assignment

I/O-Plug 14

RS232 15

Serial Interface 15

SVGA 15

Video Output 15

Power Adapter 30

Rail Mount 30

Power Board 10

Programming 35

Rail Mount Power Adapter 30

References II

RS232

Plug Assignment 15

RS232 cable 28

Sensor Board 5

Serial Interface

Plug Assignment 15

strcuture

basic 4

SVGA

Plug Assignment 15

technical specifications

overview 15

Technical Specifications

VC2028 16

VC2038 17

VC2038/E 18

VC2048/E 19

VC2065/EC 23

VC2066 24

VC2066/E 25

VC2068 26

VC206 27

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 47

VC20XX Operating Manual

H

Trigger 12

Input 12

Output 12

Plug Assignment 14

VC2028

Technical Specifications 16

VC2038

Technical Specifications 17

VC2038/E

Technical Specifications 18

VC2048/E

Technical Specifications 19

VC2065/EC

Technical Specifications 23

VC2066

Technical Specifications 24

VC2066/E

Technical Specifications 25

VC2068

Technical Specifications 26

VC2068/E

Technical Specifications 27

Video Output

Plug Assignment 15

Y-cable 30

Y-Cable 34

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Page 48

VC20XX Operating Manual

I

Visit the Vision Components site

www.vision-components.com for further information and

documentation and software downloads:

Web Site Menu Links Content

Contact

Distributor list / Enquiry forms

Home

Latest News from VC

Our Company

VC Company Information

News and Events

Trade Show dates

VC Publications

Sign in for free VC Seminars

VC Network

Description of Partner Companies

Application Overview

3

rd

Party Hard- and SW Products for VC Smart

Cameras

Products

VC Smart Camera Overview

Product Overview:

VC44XX High End Camera Series

VC40XX Standard Camera Series

VC4016 / 18 Entry Level Cameras

VC4002L Line Scan Camera

VCSBC Single Board Cameras

VC20XX Smart Cameras

VCSBC Board Cameras

VCM + Viscube Camera Sensors

VC Smart Camera Software

VC Software Development Kit Ti: VCRT Operating System

VCLIB Image Processing Library

VC Special Libraries: M200 D ata Matrix Code Reader

VCOCR Text Recognition Library

Color Lib

Support:

Support News (User Registration required) Tech News – new SW and Documentation

Knowledge Base / FAQ (User Registration

required)

Searchable FAQ Database with programming

Examples and Demo Code

Download Area Download of:

Public Download Area

(free Access)

- Product Brochures

- Camera Manuals

Registered User Area

(User Registration required)

-

Getting Started

- Programming Manuals

- Training Manuals and Demo Code

Customer Download Area

(User- and SW License

Registration required)

- Software Updates

- Demo Code

RMA Number Form Form for Allocation of Repair Numbers.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VC20XX_HW.pdf

Loading...

Loading...