1

2

3

4

5

6

7

8

5

10

9a

9b

12

11

13

14

VBG 795V

2005-04-19 38-134800k

General

VBG 795 V, part no.: 09-052000

The VBG 795V coupling is designed for centre axle

trailers, full trailers with boggiefront axles and dollys

that use a Ø 57.5 mm drawbar eye as per the VBG

standard.

The coupling should be mounted to a drawbeam which

fulfi ls the requirements of ISO 3584 cat. 3. The web

thick-ness in the middle of the drawbeam must be 1330 mm with an inner clearance of at least 160 mm.

easiest to mount it to a VBG drawbeam, all of which

meet these requirements.

The coupling has a high-quality corrosion resistance

through electrolytic pre-treatment and a top-coat with

very high wear resistance. To maintain the high quality

of the surface treatment, VBG recommend that no

futher paint is added to the coupling. If the coupling is

over-painted, you run the risk of operational problems,

a sticking signal/indicator pin or that important information is overpainted. Moving parts, plates and

decals must all be thoroughly covered if the coupling

is repainted.

It is

1. Nut cover

2. Castellated nut

3. Split pin

4. Bearing plate, inner

5. Bolt kit

6. Rubber bearing

7. Drawbeam sleeve

8. Bushing

Identify all parts before installation. Installation shall be

done in a proper and competent manner. Always follow

the instructions.

All directives and instructions should be kept in the

vehicle for future service and maintenance.

Contents

Mounting instructions ........................2

Safety check ......................................6

Service – maintenance ......................9

Driver instructions ...........................12

Spare parts list Power actuator .......16

Spare parts list VBG 795V ...............17

9a. Bar spacer washers 4 mm

9b. Bar spacer washer 10 mm

10. Bearing plate, outer

11. Rubber bearing

12. Coupling jaw

13. Mechanism

14. Guiding funnel

a

Drawbeam

sleeve

Drawbeam

5–8,5 mm

Spacers

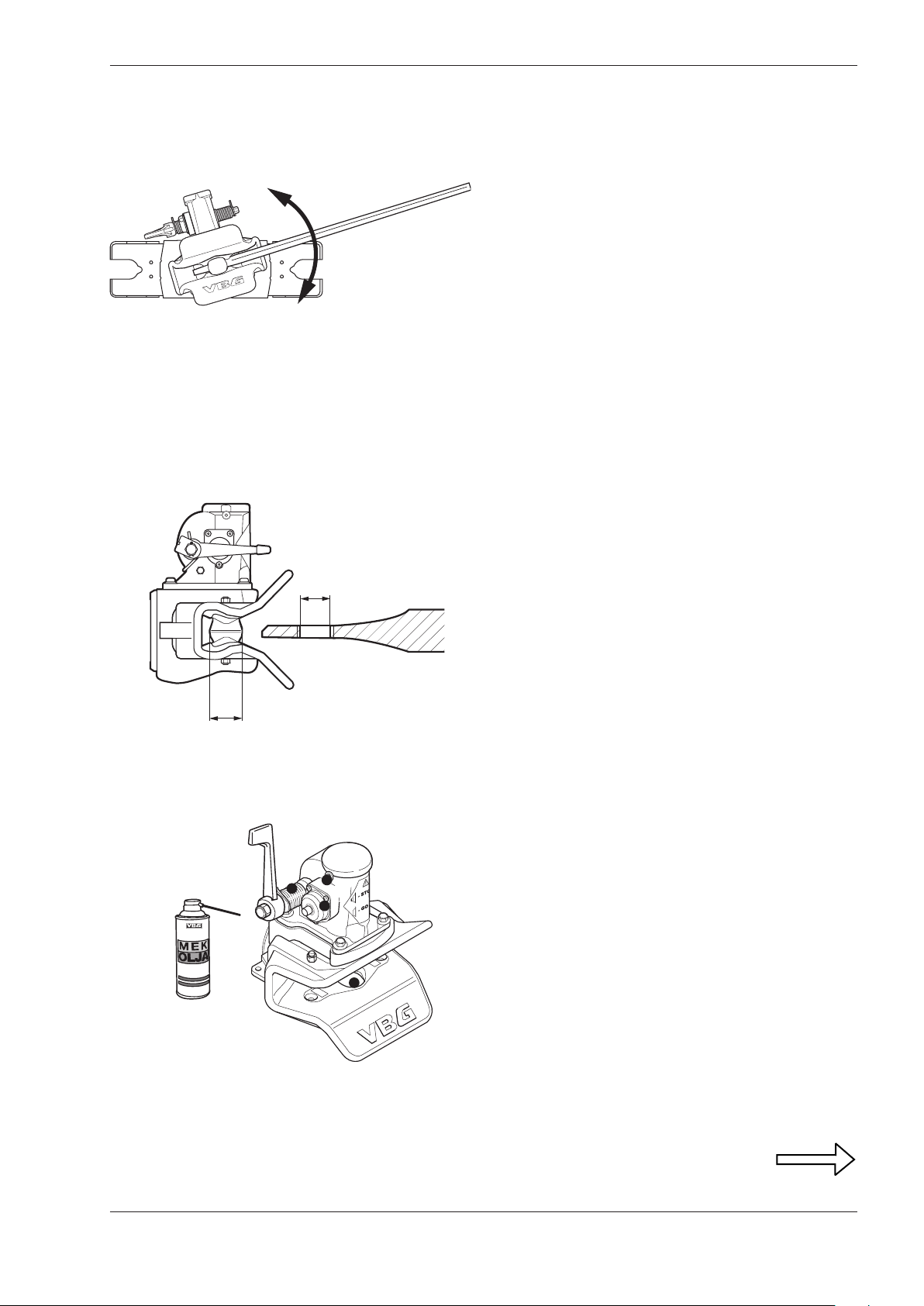

Mounting instructions

Mounting of drawbeam sleeve

• Mount the drawbeam sleeve (a) with four screws as

per the drawing. Flat washers with a minimum hardness

of 200 HB must be under both bolt head and nut.

Tightening torque M20 quality 8.8 (dry): 370 Nm.

Mounting of coupling

• Lubricate the coupling jaw (b) and all its threads with

grease. This prevents rust and makes future service

work easier.

• Fit the attachment parts as shown in the fi gure. Fit the

bar spacer washers on the drawbeam sleeve collar so

that the dimension 5–8,5 mm is achieved. The number

of washers depends on the thickness of the drawbeam,

and the 10 mm washer should be outermost. See fi gure.

Mount accessories such as the coupling mouth extension (c) according to the drawing.

Tightening torque castellated nut 1500 – 2000 Nm.

b

c

d

• Lock the castellated nut with split pin. It is very important that the split pin is completely within the gates

of the castellated nut and is secured as per the picture.

• Lubricate the the castellated nut and the nut cover

with grease.

• Mount the nut cover.

• When the coupling is reassembled after service, a new

split pin must always be used.

Lubrication

Lubricate the coupling weekly with VBG mechanism oil

or similar thin oil. For the maximum effect, the coupling

should be open when it is being lubricated.

VBG do not recommend the use of central greasing

systems.

Lubrication points (see adjacent drawing).

•

Function check

Carry out the function check on page 5.

2

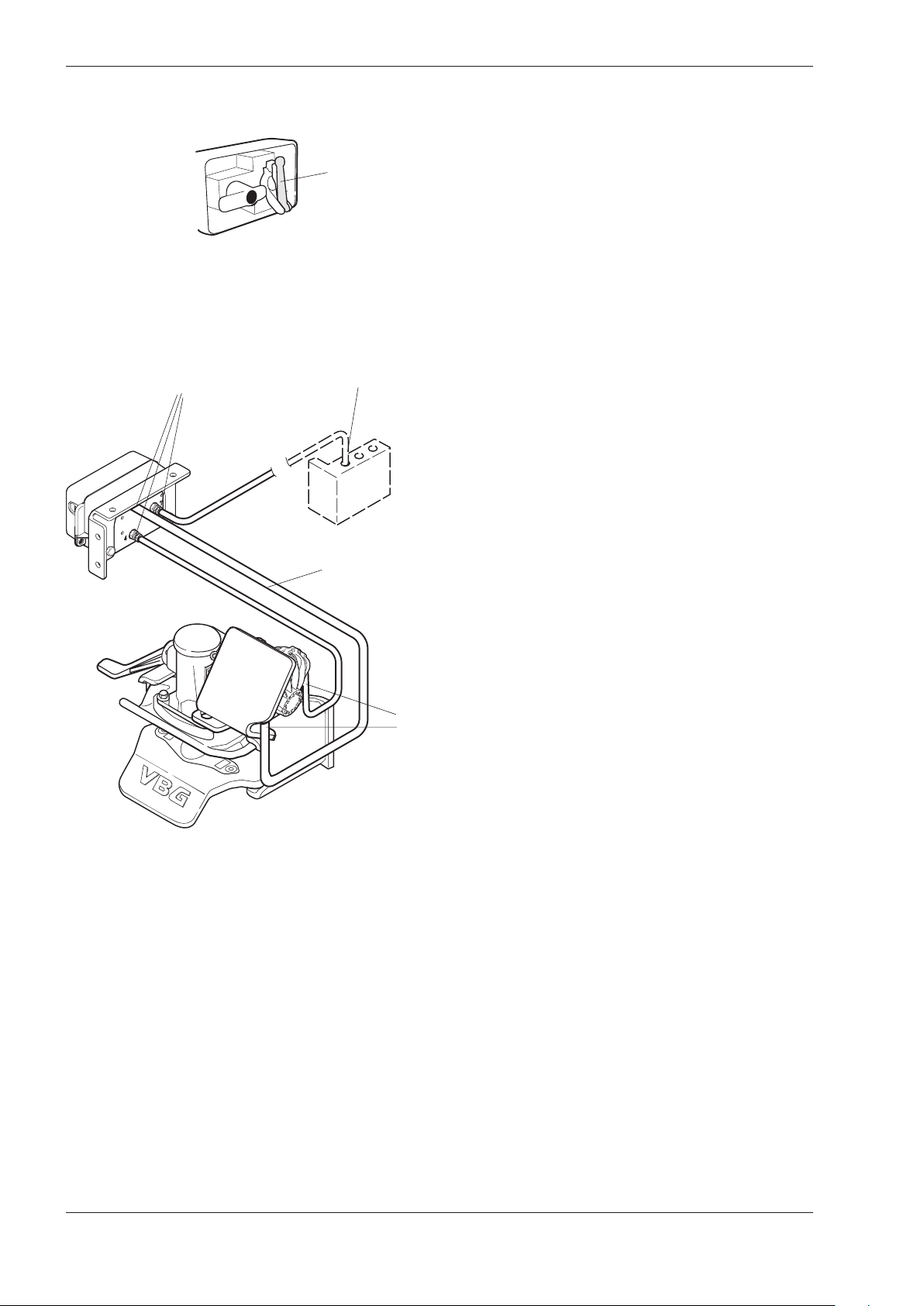

Mounting of a power actuator

If the coupling is to be equipped with a power actuator,

follow the directions below.

ca 5°

Mounting of the actuator on the bracket

• Turn the shaft on the actuator clockwise until it can go

no further and then turn it back approx. 5º.

• Bolt the actuator tightly onto the bracket with the four

screws. Tightening torque M8 quality 8.8 (dry): 25 Nm.

e

i

f

e

h

f

g

Mounting the power actuator on the

coupling

• Remove the two split pins (e) and the right hand

bushing (f).

• Mount the adapter (g) on the hexagonal shaft and fi t

with the roll pin (h) through the hole in the adapter.

• Tap the hexagonal shaft to the left and lock the hook

on the adapter into the hook on the spring.

• Assemble the bushing (f) on the left side and refi t the

split pin.

• Remove the two screws on the right side of the

mechanism (i).

• Place the bracket and actuator on the coupling. Lock

the bracket securely with the two long M12 screws

which accompanied the power actuator unit.

Tightening torque M12 quality 8.8 (dry): 90 Nm.

3

Alt. A

Alt. B

Mounting of the control box

• Mount the control box close to the coupling so that the

operation of the coupling can be watched. The control

box must be positioned so that it is well protected from

vibration, impact, dirt and ice formation.

Mount the control box as shown in Alt. A or B.

NOTE! Electrically controlled control boxes are not

permitted.

Warning!

Never put your fi ngers in the coupling mouth because of the danger

of them being crushed.

2

4

The vehicle´s auxiliary

air system

1

Ø 6

Ø 6

Ø 8

• Turn the handle on the control box to service position

according to “Service position control box” on page

6.

• Connect the supply line to the control box output

(marked 1).

• Connect the other 2 pipes to the control box outputs

(2 and 4). Fit the protective cover.

• Connect the pipe from output 4 on the control box to

the front output of the actuator. The pipe from output 2

is connected to the rear output of the actuator.

• Connect the supply line to the vehicle´s auxiliary air

system. Working pressure 8 bar.

Maximum pressure 10 bar.

Always follow the truck manufacturer’s body building

instructions.

NOTE! Do not connect to the braking system.

Fitting the Pipes

4

+

Brown

Inductive

sensor

Black

Blue

Signal

–

Signal: red and green lamp, (24 V max. 2 W)

60

80

40

100

20

120

approx 1 mm

g

Mounting of inductive sensor

• Change the cover of the original lock indicator for

the cover modifi ed for the inductive sensor. Open the

coupling so that the indicator pin is out. Wind the inductive sensor in until it touches the indicator pin. Wind the

inductive sensor back one turn (the distance between

the indicator pin and the inductive sensor should now

be approximately 1 mm).

Tighten the nuts (g), tightening torque max. 2 Nm.

• If VBG’s Indicator kit (part no. 09-099200) is used –

connect the inductive sensor according to the mounting

instructions. Otherwise connect the inductive sensor to

the vehicle’s electrical system (24 V). See wiring diagram

above. Follow the truck manufacturer’s instructions.

• When the coupling is closed and secured a green

lamp in the cab should light up.

• When the coupling is open, a red lamp in the cab

should light up. If the green lamp comes on when the

coupling is open, adjust the gap between the sensor

and lock pin so that the red lamp comes on.

5

a

Air supply on

Safety check

Carry out the safety check once a week. If the check

shows that any of the wear limits have been exceeded

or that the coupling´s function is reduced, rectifi cation

must be carried out immediately.

Before any work or service is carried out on the coupling

all air supply to the coupling must be cut off. Cut off

the air supply by turning the control box’ red handle a

quarter turn anti-clockwise to OFF.

If the coupling has been damaged

Service position

air supply off

Function check

• Check that the coupling bolt can be raised easily

and that the handle and coupling bolt remain in the up

position.

• Open and close the coupling and check that it corresponds as per the pictures below. If an inductive

sensor is used, item (d) must be complied with.

ALWAYS check that the coupling is closed and secure

before driving. All criteria for closed coupling must be

fulfi lled before you start driving.

a

b

Open coupling

(a) The handle is raised approx. 90º

(b) The indicator pin is out

(c) The coupling bolt is up

(d) Red lamp on in the cab

ab

as a result of jack-knifi ng, driving

into a ditch, or being hit from behind, you must stop and replace

the coupling.

Warning!

Never put your fi ngers in the coupling mouth because of the danger

of them being crushed.

Closed, secure coupling

(a) The handle is down

(b) The indicator pin is completely in

(c) The coupling bolt is down

(d) Green lamp on in the cab

c

• When the coupling is closed, there must be approx.

10 mm

10 mm clearance in the handle before the indicator/

locking pin moves outwards.

c

6

Attachment

• Check that the coupling can be rotated in its mounting. The coupling must be closed when the rotation is

carried out.

Wear limits

A Coupling pin max Ø 55.0 mm

B Drawbar eye max Ø 59.5 mm

Vertical play

B

in the coupling bolt max 5.0 mm

A

Lubrication

Lubricate the coupling weekly with VBG mechanism oil

or similar thin oil. For maximum effect, the coupling

should be open when it is lubricated.

Lubrication points (see drawing on the left)

•

7

Safety check contd.

d

e

f

• Fold out the yellow handle (d). Simultaneously

press on the mark “Press” on the handle and turn the

handle anti-clockwise to “OPEN”. Then turn it back to

“CLOSE”.

The coupling pin should remain in the up/open position.

• Connect to the trailer according to the driver instructions on page 14-15.

Air leaks

• Check that there is no audible air leakage from the

valve (e), the connection to the auxiliary air system (f),

pipes (g) or actuator (h).

Operation check - power actuator

g

• In extreme cold, minor air leaks can occur. These can

be eliminated by cutting off the air supply by turning

the control box’s red handle (d) a quarter of a turn anticlockwise to OFF.

Contact the nearest workshop for corrective measures.

h

8

Service - maintenance

• It is important to remember that a coupling is a safety

critical item and should be treated as such. Proper

preventive maintenance, inspection and lubrication are

essential for a long, safe and trouble-free service life.

B

• The length of service intervals depends on the type of

trailer, load, road- and weather conditions etc. Servicing

A

F

C

F

can best be carried out when other work or inspection

of the vehicle is done, for example every 60 000 or 90

000 km.

• At least once a year the coupling must be dismounted

and inspected for wear, corrosion, cracks or de-formation. Worn out or damaged parts must be replaced.

• If the daily overhaul or safety check shows that any

D

of the wear limits have been exceeded or that the

coupling´s function is reduced, repairs must be carried

E

out immediately.

• The fact that one of the coupling´s wear limits have

been exceeded indicates that other parts need service

as well. Therefore, always remove the coupling from the

drawbeam when changing the mechanism and bushings. Check the mounting parts and the drawbeam and

replace worn out rubber bearings and bushings.

a

d

Wear limits

b

e

c

A inner diameter max 59.5 mm

B outer diameter min 57.0 mm

C inner diameter max 45.7 mm

D outer diameter min 42.5 mm

E outer diameter min 55.0 mm

F Wear plate mark on wear plate

Vertical play

in the coupling bolt max 5.0 mm

Wear parts

(a) Mechanism

(b) Upper and lower jaw bushings

(c) Drawbar eye wear ring

(d) Rubber bearings and drawbeam sleeve bushings

(e) Wear plate

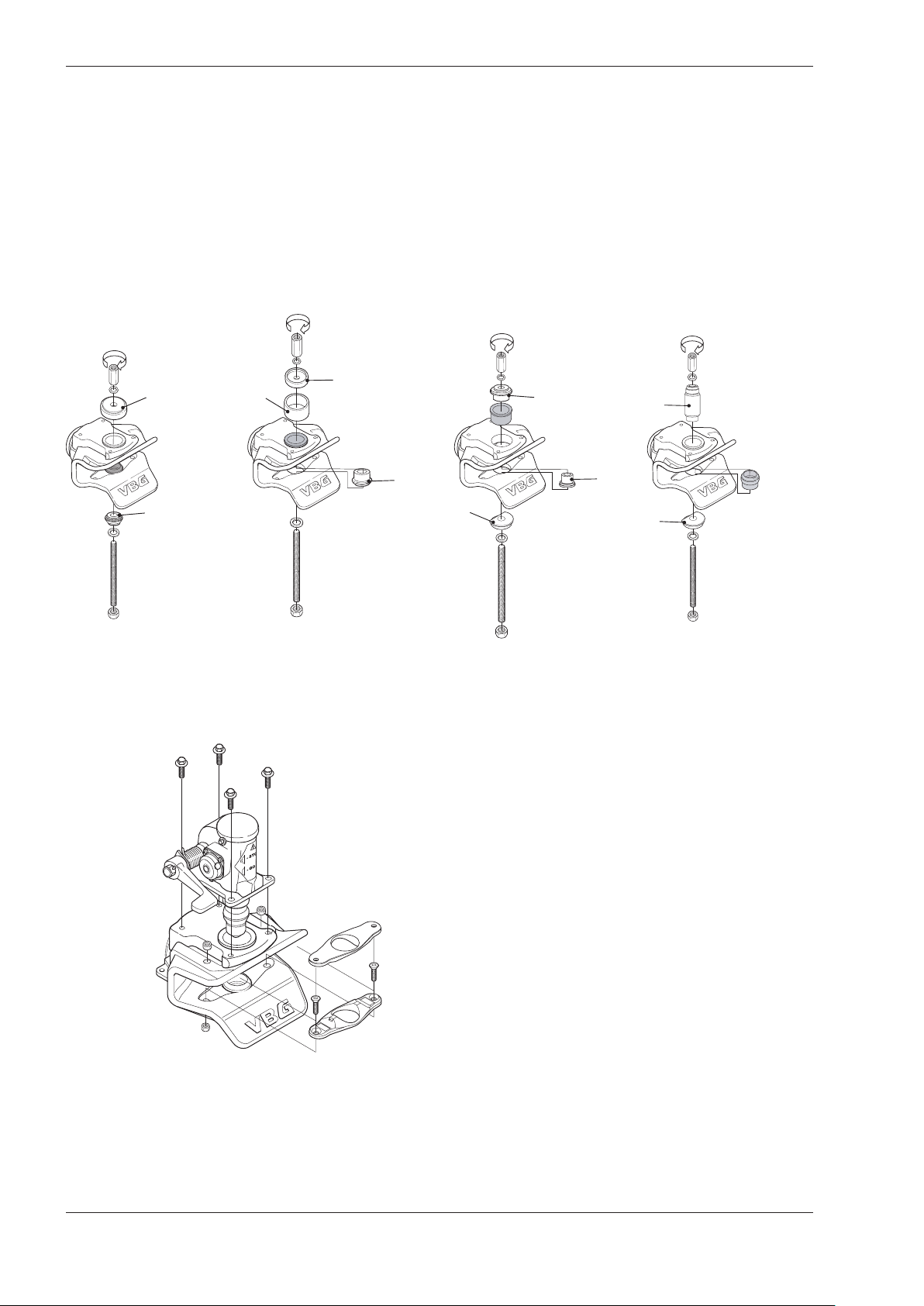

Change of mechanism and bushings

If the coupling is equipped with a power actuator, the air

supply to the control box must be cut off before work

with the coupling is started.

• Remove the mechanism by loosening the four screws

and lift the mechanism from the coupling jaw.

• Remove the wear plate.

9

Service – maintenance contd.

• Change the guide funnel if damaged. Minor damage

and deformations on the funnel are accepted, the guide

funnel is a seperate part from the coupling jaw and as

long as the function is not reduced there is no need to

replace the funnel.

• Change the bushings using VBG service tools. Press

out the old bushings from below and press in the new

bushings from above as per the fi gure.

The bushings must not be welded in.

Use tool no 12 as a

guide in the upper jaw

3

1

2

12a

3

bushing.

Place the tool on the

bushing before assembly.

5a

Removing

Lower jaw bushing

Removing

Upper jaw bushing

2

10

Fitting

Upper jaw bushing

Use tool no 9 as a

guide in the lower

jaw bushing.

9

10

Fitting

Lower jaw bushing

• Mount the wear plate. Tightening torque 47 Nm.

• Put the new mechanism on the coupling jaw and fi t

the screws, but do not tighten completely.

• Carry out the function check on page 6.

• Tighten the screws.

Tightening torque M12 quality 8.8 (dry): 90 Nm.

10

Lubricate the coupling with VBG mechanism oil. For

maximum effect, the coupling must be open when it is

being lubricated.

Lubrication points (see drawing on the left)

•

Attachment check

• Remove the coupling jaw and clean the shaft of rust

h

F

G

and rubber residue.

• Check that the coupling jaw is neither bent, nor has

cracks or any damage due to electrolysis.

• Check the wear limits as per below:

F max. Ø 67.2 mm (without bushings)

G min. Ø 61.6 mm

• Check that there is no cracks forming or deformation

on the drawbeam (i) and that the drawbeam sleeve (j) is

properly attached.

Tightening torque M20 quality 8.8 (dry): 370 Nm.

j

i

l

k

Change of Indicator/locking pin

• Loosen the three bolts holding the lid.

• Remove remaining parts.

• Clean the bearing surfaces for the locking pin (k) and

lubricate with thin grease. Check that the centring pin

(l) is correctly fi tted.

• Mount the parts according to the fi gure.

11

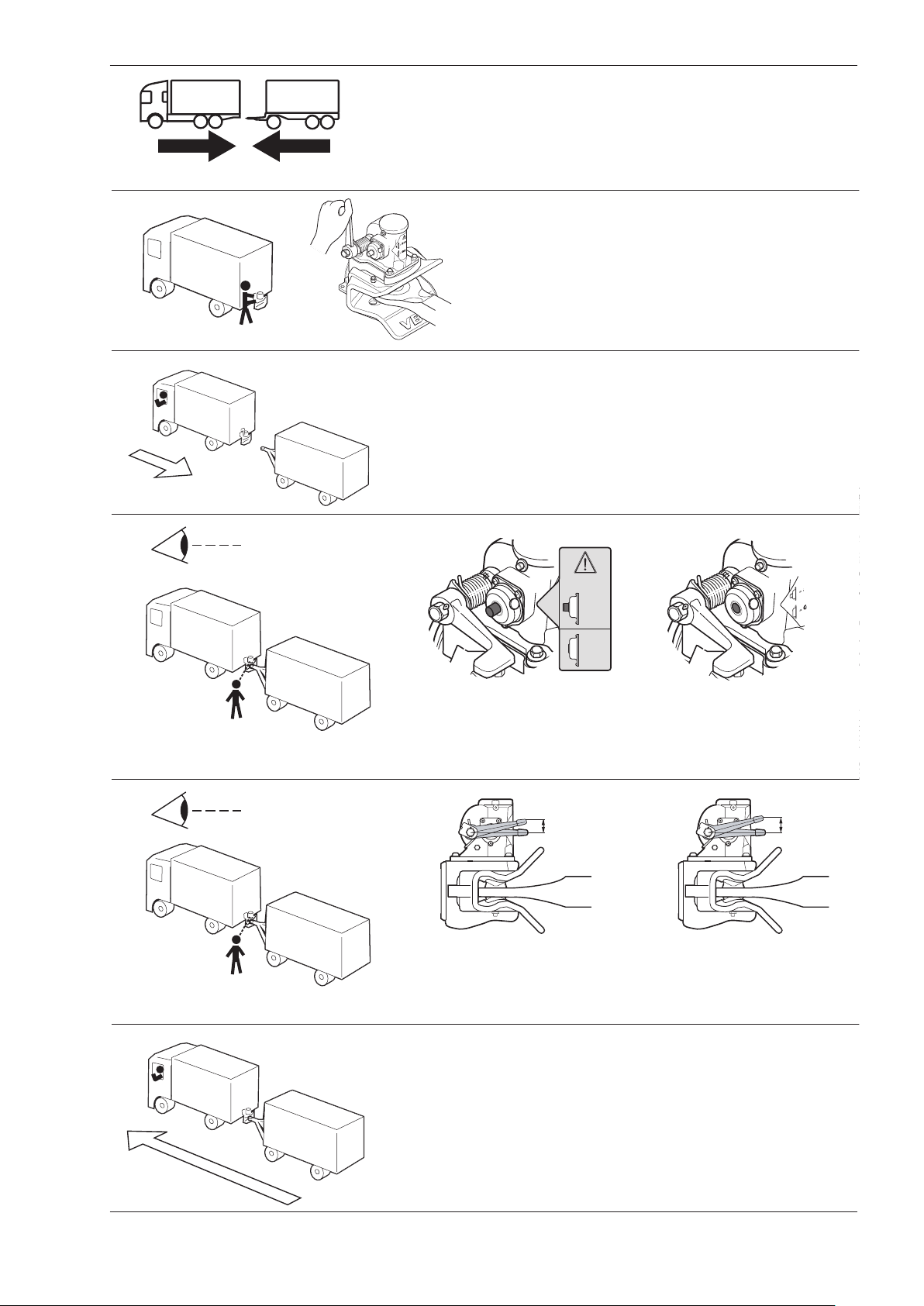

Driver instructions

Uncoupling without power actuator

1

Warning!

Never put your fi ngers into the coupling mouth because of the danger of

them being crushed.

Stand by the coupling handle.

Lift the handle 90º, the handle

locks. The coupling is now open.

2

For functional and road safety reasons, only

those steps described in the Driver instructions

may be carried out using the control box,

power actuator, or air lines during coupling

and uncoupling.

If the coupling does not go to locked position

after repeated attempts at coupling, the power

actuator must be uncoupled immediately. Contact the nearest workshop for fault de-tection

and remedial measures.

Uncouple the trailer. The coupling

is closed when the trailer is disconnected.

12

Coupling without power actuator

1

2

4

Stand by the coupling handle.

Lift the handle 90º, the handle

locks. The coupling is now open.

Connect to the trailer.

STOP

GO

38-08100

Check that the Indicator pin is completely in.

If the Indicator pin is not completely in, the coupling is open and

driving is not, under any circumstances, permitted!

Contact nearest workshop for remedial measures.

5

0 mm ~10 mm

Check that there is approx. 10 mm movement of the handle before

the indicator pin moves outwards. If there is no free movement

of the handle the coupling is open and driving is not, under any

circum-stances, permitted! Contact nearest workshop for remedial

measures.

6

The trailer is secured and driving

can begin.

13

Uncoupling

1

Warning!

Never put your fi ngers into the coupling

mouth because of the danger of them being

crushed.

1+2

1

3

Simultaneously press on the handle where it says “Press” and turn the

handle anti-clockwise to “OPEN”. Then turn it back to “CLOSE”.

2

2

1

2

Uncouple the trailer. The coupling

is closed when the trailer is disconnected.

Before any work or service is carried out on the coupling

all air supply to the coupling must be cut off. Cut off the

air supply by turning the control box’ red handle a quarter

turn anti-clockwise to OFF.

14

Coupling

1

1+2

1

3

Simultaneously press on the handle where it says “Press” and turn the

handle anti-clockwise to “OPEN”. Then turn it back to “CLOSE”.

2

2

1

2

Couple to the trailer.

3

GO

Check that the signal pin goes fully in, and that the green warning

lamp in the cab is on. The coupling is closed and secured, and the

truck can now be driven.

4

The trailer is secured and driving

may begin.

5

STOP

If the red lamp comes on and the signal pin is not completely in, the

coupling is open and the truck must under no circumstances be driven!

Contact nearest workshop for remedial measures.

15

AUSTRALIA

TRANSPEC LIMITED

P O Box 217 1 Cherry Lane

AU - 3028 P.O LAVERTON, VIC 3028

Tel +61 3 92 67 24 44

Fax +61 3 93 69 48 26

BELGIUM/LUXEMBOURG

WABCO Belgium S.A. - N.V.

Petrus Bayensstraat 70

BE – 1702 GROOT-BIJGAARDEN

Tel +32 24810900

Fax +32 24633659

DENMARK

VBG PRODUKTER A/S

Industribuen 20-22

DK – 5592 EJBY

Tel +45 6446 1919

Fax +45 6446 1088

ESTONIA

GOKART AS

Ümera 26

EE-13816 TALLINN

Tel +372 6230622

Faks +372 6230621

FINLAND

H KRAATZ OY

Ruukinmestarintie 9

FI - 02330 ESPOO

Tel +358 9 8093100

Fax +358 9 80931099

FRANCE

ONSPOT Sàrl

14 Route de Sarrebruck

FR - 57645 MONTOY-FLANVILLE

Tel +33 3 8776 3080

Fax +33 3 8776 1944

GERMANY

RINGFEDER VBG GMBH

Oberschlesienstrasse 15

DE - 47807 KREFELD

Tel +49 2151 835 0

Fax +49 2151 835 200

GREAT BRITAIN

FONTAINE INTERNATIONAL

EUROPE LTD.

Enterprise Way

GB - LOWTON WA3 2AG

Tel +44 1942 686000

Fax +44 1942 686006

ICELAND

OSAL OSKAR ANDERSSON

Tangarhofdi 4

IS - 110 REYKJAVIK

Tel +354 587 6619

Fax +354 187 7719

IRELAND

NEWBRIDGE METAL PRODUCTS LTD

Industrial Estate

IE - NEWBRIDGE, Co Kildare

Tel +353 45 431 502

Fax +353 45 433 747

ISRAEL

H KLEIN & SONS LTD

P O Box 1093

Industrial Area-North

IL - ASHDOD 77109

Tel +972 8856 4330

Fax +972 8856 4324

ITALY

NORDAUTO Torino S.R.L.

Via Lanzo 52

IT - 10040 VAL DELLA TORRE (TO)

Tel +39 011 96 89 005

Fax +39 011 96 89 753

JAPAN

SHINKO BOEKI CO LTD

Shibuya Central Bldg

3-14 Udagawa-cho, Shibuya-ku,

JP - TOKYO 150

Tel +81 3 33463 0941

Fax +81 3 33463 1707

NETHERLANDS

WABCO AUTOMOTIVE B.V.

Postbus 8704

NL - 3009 AS ROTTERDAM

Tel +31 10 2888 600

Fax +31 10 2888 601

NEW ZEALAND

TRANSPORT SPECIALTIES LTD

P O BOX 98-971

NZ - S.A.M.C., Wiri, AUCKLAND

Tel +64 9 980 7300

Fax +64 9 980 7306

NORWAY

VBG PRODUKTER A/S

Postboks 94 Leirdal

NO - 1009 OSLO

Tel +47 23 14 16 60

Fax +47 23 14 16 61

POLAND

HYVA POLSKA Sp. z o.o.

ul. Mysliwska 68

PL - 30718 KRAKÓW

Tel +48 12 658 65 05

Fax +48 12 658 44 39

SWEDEN

VBG PRODUKTER AB

Box 1216

SE - 462 28 VÄNERSBORG

Tel +46 521 277700

Fax +46 521 277795

Branch offi ce:

VBG PRODUKTER AB

Kronoskogsvägen 8

SE - 903 61 UMEÅ

Tel +46 90 271 10

Fax +46 90 326 11

SWITZERLAND

AGL für LASTWAGENZUBEHÖRE

Postfach

CH – 6048 HORW

Tel +41 41 340 25 25

Fax +41 41 340 31 79

SWITZERLAND

AMBOFIX METALLBAU

U. Ambühl

Am Schachenrain 36

CH – 4562 BIBERIST

Tel +41 32 6 72 36 83

Fax +41 32 67 22 267

TANZANIA

SUPERDOLL TRAILERS MANUFACTURE CO. LTD

P:O Box 16541

TZ - DAR ES SALAAM

Tel +255 22 2860930

Fax +255 22 2865412

VBG PRODUKTER AB

Herman Kreftings gata 4

Box 1216

SE-462 28 VÄNERSBORG

Tel +46 521 27 77 00

E-mail info@vbg.se

www.vbg.se

Loading...

Loading...