Page 1

VA TECH ELIN EBG Elektronik

Operating and Mounting instructions

The Power Drives Company

>pDRIVE< CX profi

Page 2

The requirements for a successfull commissioning are a correct selection of the unit, projection and

mounting. In case of further questions, please contact the supplier or call the manufacturer of the unit

directly.

Capacitor discharge !

Before any work on or in the unit, disconnect from the mains and wait at least 5 minutes until the

D.C.link capacitors have been fully discharged. Check that the device is no longer alive by measuring

the voltage at the D.C.link capacitor.

Automatic restart !

In case of certain parameter adjustments it may happen that the frequency inverter starts up

automatically after switching on the mains again. You have to guarantee, that no person and no other

equipment is in danger.

Commissioning and service !

Works on or in the unit must only be undertaken by properly qualified staff in full compliance of the

appropriate instructions and pertinent regulations. Note that a fault may cause potential-free contacts

and/or PCBs to carry mains potential. To avoid any risk to humans, obey the regulations concering

”Work on Live Equipment” explicitly.

Delivery conditions:

Our deliveries and services are based on the ”General Terms of Delivery of the Austrian Electrical

Industries” latest edition.

Specifications in this instruction:

We are constantly striving to improve our products and adapt them to the latest state of technical

development. We therefore reserve the right to modify the specifications given in this instruction at any

time, particulary those refering to measures and dimensions. All planning hints and connecting samples

are non-binding suggestions, for which we are unable to assume any liability, particulary since the

regulations to be complied with depend on the type and location of the plant and on the use of the

instruments.

Regulations:

It is the users responsibility to ensure that the instrument and its component parts are used in

compliance with applicable regulations. It is not permitted to use these instruments in residential areas

without special measures to supress radio frequency interferences.

Patent and Trade Marks:

Please note that we do not guarantee any connections, instruments or processes described herein to be

free from patent or trademark right of third parties.

Keep this instruction near the unit to hand !

Safety instructions

General information, note exactly !

Page 3

Operating & Mounting instructions – 8 074 143.03/03 – Page 1

Operating and Mounting the Frequency inverter

>pDRIVE< CX profi

11...37 kW, 3 AC 380...480 V

Topic Page

Operating 3

Parameters 17

Displays 61

Projecting 67

Mounting 73

Connection 77

Options 90

Start-up Log Appendix A

This manual includes the topics operating, description of parameters and displays,

projecting, mounting, connection and options.

Regulations for the observance of the CE-directive and the new Power-Drive-Standard

(EN 61800-3) are described in chapter “CE Marking”.

In case of damage or incomplete delivery, please inform the supplier or the insurance

company.

The manufacturer declines responsibilitiy for faults occuring during transport or

unpacking.

OperatingParameters

DisplaysProjecting

MountingConnection

Options

Page 4

Operating & Mounting instructions – 8 074 143.03/03 – Page 2

Configurable

LED display

STOP/RESET button

to stop the motor or

confirm error

POTENTIOMETER

to adjust the frequency.

The LED lights up as

soon as the frequency

can be set using the

potentiometer

STR button

to save new data and

parameter settings

UP/DOWN buttons

for editing data and for

parametrization

FUNC button

to switch between

display level, 1st and

2nd control level

Operating using the control panel built-in

Description of the control panel

RUN button

starts the inverter when it

is not controlled via the

terminal strip

Quick navigation and adjustment of parameters

The method described above is used for quick selection of parameters. Also the adjustmend of

parameters can be handled in this way.

Page 5

Operating & Mounting instructions – 8 074 143.03/03 – Page 3

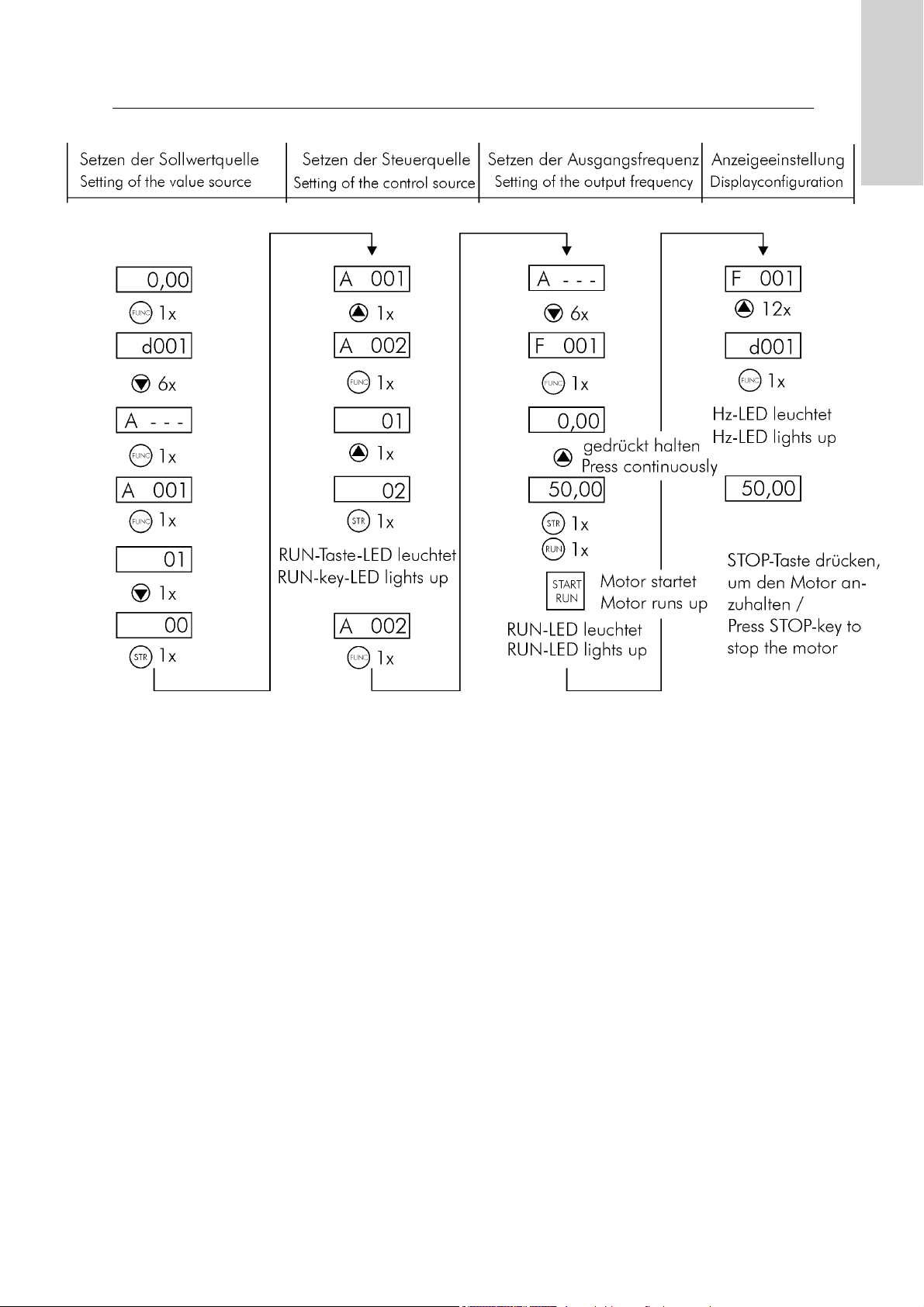

Operating

Example of programming to set the frequency and to start the inverter

Page 6

Operating & Mounting instructions – 8 074 143.03/03 – Page 4

Power-LED:

lights up when the inverter is connected to mains supply, that means there is a voltage.

Alarm-LED:

lights up in case of a trip at the inverter.

Hz-LED:

indicates that the value of the display shows frequency in hertz.

V

-LED:

lights up if the value of the display is the voltage in volts or the power in kW.

A

-LED:

indicates that the value of the display shows motor current in amperes or the power in kW.

%-LED:

lights up if the value of the display shows an parameter in %.

PO

TENTIOMETER-LED:

lights up if parameter A001 is set to 00; that means the frequency reference value is defined on the

control panel by the potentiometer.

RUN-button-LED:

indicates that the motor can be started at any time by pressing the RUN button.

Flashes as soon as parameter A002 is set to 02.

PRG

-LED:

lights up as soon as a parameter of the 2nd control level or one of parameters d001 or F001 to

F004 is called.

Lights up if you try to change a parameter during an alarm message.

RUN-LED:

lights up as soon as the motor exceeds the start-up frequency or runs up.

LEDs on the control panel

RUN-LED

PRG-LED

RUN-button

LED

Power-LED

Alarm-LED

Hz-LED

V-LED

A-LED

POTI-LED

%-LED

Page 7

Operating & Mounting instructions – 8 074 143.03/03 – Page 5

Operating

Overview of control levels

Page 8

Operating & Mounting instructions – 8 074 143.03/03 – Page 6

Changing the indication of the LED display:

1.) Switch to the 1st user level using the FUNC button.

2.) Use the UP/DOWN buttons to select the required display.

3.) Press the STR button to confirm the selection and to return to the display level.

Changing parameter settings on the 1st control level:

1.) Switch to the 1st control level using the FUNC button.

2.) Use the UP/DOWN buttons to select the required parameter.

3.) Press the FUNC button to switch to setting mode.

4.) Use the UP/DOWN buttons to enter the new setting.

5.) Press the STR button to confirm, save and return to 1st control level. Press the FUNC button to

return to the 1st control level without saving.

6.) Select the required display (e.g. d001) and press the FUNC button to confirm.

Changing parameter settings on the 2nd control level:

1.) Switch to the 1st control level using the FUNC button.

2.) Use the UP/DOWN buttons to select the required parameter group A, b, C, H or P.

3.) Press the FUNC button to enter the selected parameter group (2nd control level).

4.) Use the UP/DOWN buttons to select the required parameter.

5.) Press the FUNC button to switch to setting mode.

6.) Use the UP/DOWN buttons to enter the new setting.

7.) Press the STR button to confirm, save and return to 2nd control level. Press the FUNC botton to

return to 2nd control level without saving.

8.) Press the FUNC button to return to the 1st control level.

9.) Select the required display (e.g. d001) and press the STR button to confirm.

Page 9

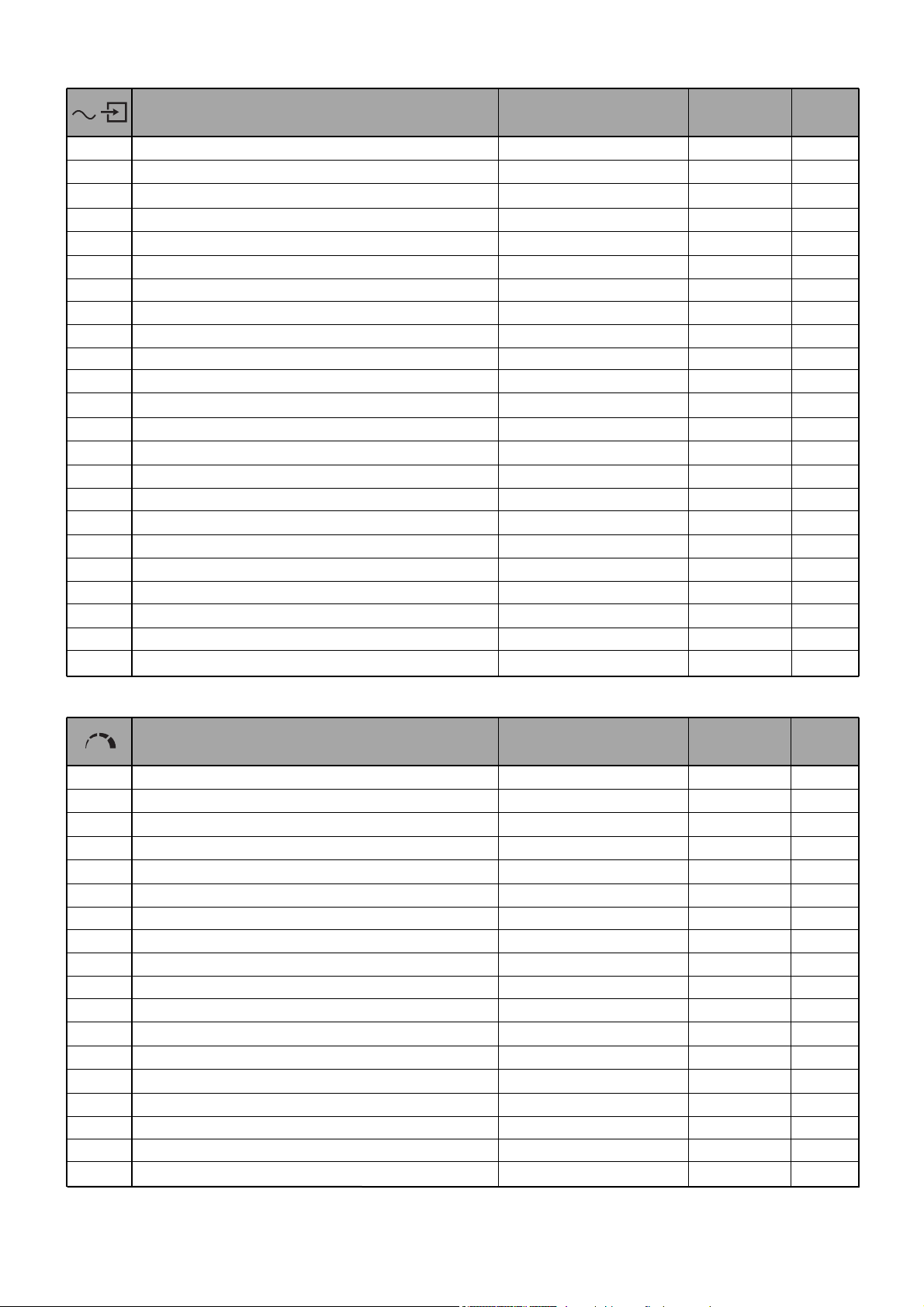

Overview of parameters

The following overviwe shows all parameters arranged according to their functions.

Display actual values Factory See

Parameter name Adjusting range default page

d001 Output frequency read only - 16

d002 Output current read only - 16

d003 Direction of rotation read only - 16

d004 PID controller feedback read only - 16

d005 Condition of digital inputs read only - 17

d006 Condition of digital outputs read only - 17

d007 Output frequency scaled read only - 17

d013 Output voltage read only - 17

d014 Output power read only - 17

d016 Operating hours motor read only - 17

d017 Operating hours inverter read only - 17

Base settings Factory See

Parameter name Adjusting range default page

A003 Base frequency 30...400 Hz 50 Hz 18

A004 Maximum frequency 30...400 Hz 50 Hz 18

F002 1st Acceleration ramp 0,01...3600 s 30 s 18

F003 1st Deceleration ramp 0,01...3600 s 30 s 18

F001 Output frequency 0,00...400,0 Hz - 18

A020 Internal pre-set speed if A001=02 0,00...400,0 Hz 0,00 Hz 18

A001 Method of speed command 00 to 05 01 19

A002 Method of run command 01 to 05 01 19

Operating & Mounting instructions – 8 074 143.03/03 – Page 7

Operating

Page 10

Operating & Mounting instructions – 8 074 143.03/03 – Page 8

Analog inputs Factory See

Parameter name Adjusting range default page

A011 External frequency start O (0...10V) 0,00...400,0 Hz 0,00 Hz 19

A101 External frequency start OI (4...20mA) 0,00...400,0 Hz 0,00 Hz 19

A111 External frequency start O2 (-10...+10V) -400,0...+400,0 Hz 0,00 Hz 19

A012 External frequency end O (0...10V) 0,00...400,0 Hz 0,00 Hz 19

A102 External frequency end OI (4...20mA) 0,00...400,0 Hz 0,00 Hz 19

A112 External frequency end O2 (-10...+10V) -400,0...400,0 Hz 0,00 Hz 19

A013 Analog signal ref. for Start O (0...10V) 0...100 % 0 % 19

A103 Analog signal ref. for Start OI (4...20mA) 0...100 % 0 % 19

A113 Analog signal ref. for Start O2 (-10...+10V) -100...+100 % -100 % 19

A014 Analog signal reference for end O (0...10V) 0...100 % 100 % 20

A104 Analog signal ref. for end OI (4...20mA) 0...100 % 100 % 20

A114 Analog signal ref. for end O2 (-10...+10V) -100...+100 % 100 % 20

A015 External frequency start pattern O (0...10V) 00 or 01 01 20

A105 Ext. frequency start pattern OI (4...20mA) 00 or 01 01 20

A005 AT Terminal selection 00 or 01 01 21

A006 O2 Control selection 00 to 02 00 21

A016 Time constant for analog signals 1...30 30 21

C081

Adjustment 0...10 V input 0...9999 Default 22

C082

Adjustment 4...20 mA input 0...9999 Default 22

C083

Adjustment -10...+10 V input 0...9999 Default 22

C121

Offset-adjustment 0...10 V input 0...9999 Default 22

C122

Offset-adjustment 4...20 mA input 0...9999 Default 22

C123

Offset-adjustment -10...+10 V input 0...9999 Default 22

Multispeeds Factory See

Parameter name Adjusting range default page

A019 Multi speed selection 00 or 01 00 22

A021 Multi speed 1 0,00...400,0 Hz 0,00 Hz 22

A022 Multi speed 2 0,00...400,0 Hz 0,00 Hz 22

A023 Multi speed 3 0,00...400,0 Hz 0,00 Hz 22

A024 Multi speed 4 0,00...400,0 Hz 0,00 Hz 22

A025 Multi speed 5 0,00...400,0 Hz 0,00 Hz 22

A026 Multi speed 6 0,00...400,0 Hz 0,00 Hz 22

A027 Multi speed 7 0,00...400,0 Hz 0,00 Hz 22

A028 Multi speed 8 0,00...400,0 Hz 0,00 Hz 22

A029 Multi speed 9 0,00...400,0 Hz 0,00 Hz 22

A030 Multi speed 10 0,00...400,0 Hz 0,00 Hz 22

A031 Multi speed 11 0,00...400,0 Hz 0,00 Hz 22

A032 Multi speed 12 0,00...400,0 Hz 0,00 Hz 22

A033 Multi speed 13 0,00...400,0 Hz 0,00 Hz 22

A034 Multi speed 14 0,00...400,0 Hz 0,00 Hz 22

A035 Multi speed 15 0,00...400,0 Hz 0,00 Hz 22

A038 Jogging frequency 0,00...9,99 Hz 1,00 Hz 23

A039 Stop mode of jog function 00 to 05 00 23

Page 11

Operating & Mounting instructions – 8 074 143.03/03 – Page 9

Operating

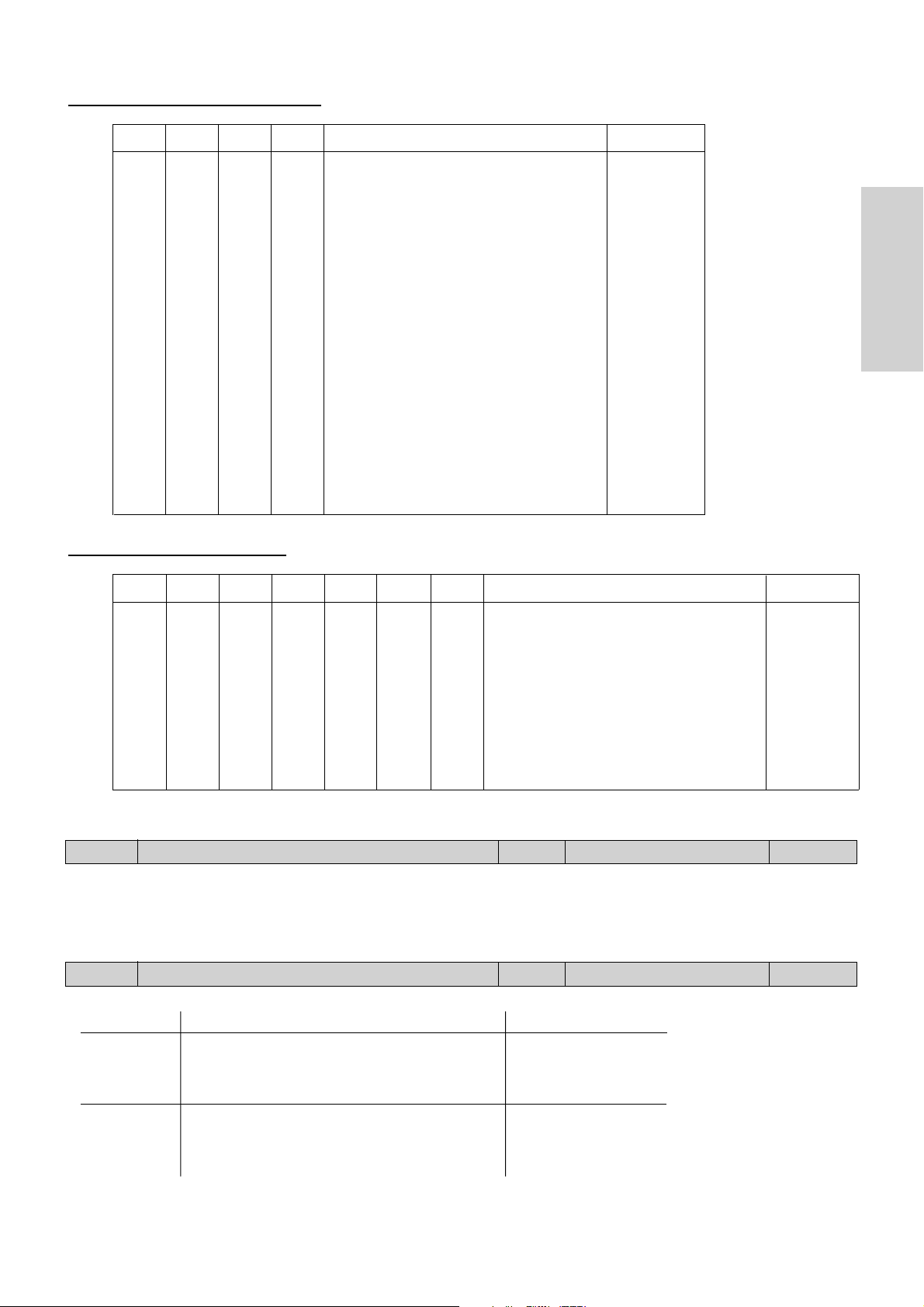

V/f characteristic Factory See

Parameter name Adjusting range default page

A041 Torque boost method selection 00 or 01 00 24

A042 Manual torque boost setting 0,0...20,0 % 1,0 % 24

A043 Manual torque boost frequency point 0,0...50,0 % 5,0 % 24

A044 V/f characteristic setting 00 to 02 00 24

A045

Voltage gain setting 20...100 % 100 % 25

b036

Start reduced voltage selection 00 to 06 00 25

b100

Free adjustable V/f: frequency 1 0...b102 0 Hz 25

b101

Free adjustable V/f: voltage 1 0,0...800,0 V 0,0 V 25

b102

Free adjustable V/f: frequency 2 0...b104 0 Hz 25

b103

Free adjustable V/f: voltage 2 0,0...800,0 V 0,0 V 25

b104

Free adjustable V/f: frequency 3 0...b106 0 Hz 25

b105

Free adjustable V/f: voltage 3 0,0...800,0 V 0,0 V 25

b106

Free adjustable V/f: frequency 4 0...b108 0 Hz 25

b107

Free adjustable V/f: voltage 4 0,0...800,0 V 0,0 V 25

b108

Free adjustable V/f: frequency 5 0...b110 0 Hz 25

b109

Free adjustable V/f: voltage 5 0,0...800,0 V 0,0 V 25

b110

Free adjustable V/f: frequency 6 0...b112 0 Hz 25

b111

Free adjustable V/f: voltage 6 0,0...800,0 V 0,0 V 25

b112

Free adjustable V/f: frequency 7 0...400 Hz 0 Hz 25

b113

Free adjustable V/f: voltage 7 0,0...800,0 V 0,0 V 25

DC brake Factory See

Parameter name Adjusting range default page

A051

Selection of DC braking 00 or 01 00 26

A052

DC braking: frequency 0,00...60,00 Hz 0,50 Hz 26

A053

DC braking: waiting time 0,0...5,0 s 0,0 s 26

A054

DC braking: braking torque 0...70 % 0 % 26

A055

DC braking: braking time 0,0...60,0 s 0,0 s 26

A056

DC braking: edge/level selection 00 or 01 01 26

A057

DC braking: braking torque (start) 0...70,0 % 0 % 26

A058

DC braking: braking time (start) 0,0...60,0 s 0,0 s 26

A059

DC braking: carrier frequency 0,5...12,0 kHz 3,0 kHz 26

b090

Dynamic braking ratio 0,0...100,0 % 0,0 % 29

b095

Dynamic braking selection 00 to 02 00 29

b096

Dynamic braking ON-level 660...760 V 720 V 29

V/f

Page 12

Operating & Mounting instructions – 8 074 143.03/03 – Page 10

2.

Frequency limits Factory See

Parameter name Adjusting range default page

A061

Frequency upper limit 0,00...400,0 Hz 0,00 Hz 29

A062

Frequency lower limit 0,00...400,0 Hz 0,00 Hz 29

A063

1st Jump frequency 0,00...400,0 Hz 0,00 Hz 30

A064

1st Jump frequency width 0,00...10,0 Hz 0,50 Hz 30

A065

2nd Jump frequency 0,00...400,0 Hz 0,00 Hz 30

A066

2nd Jump frequency width 0,00...10,0 Hz 0,50 Hz 30

A067

3rd Jump frequency 0,00...400,0 Hz 0,00 Hz 30

A068

3rd Jump frequency width 0,00...10,0 Hz 0,50 Hz 30

PID Configuration Factory See

Parameter name Adjusting range default page

A071

Selection of PID function: ON/OFF 00 or 01 00 32

A072

PID controller: Proportional gain (kp) 0,2...5,0 1,0 32

A073

PID controller: Integral gain(Tn) 0,0...3600 s 1,0 32

A074

PID controller: Differential gain(Tv) 0,00...100,0 s 0,00 32

A075

PID controller: Scale conversion 0,01...99,99 1,00 33

A076

PID controller: Feedback destination 00 or 01 00 33

C044

PID controller: Level of deviation 0...100 % 3,0 % 33

Automatic voltage regulation Factory See

Parameter name Adjusting range default page

A081

Selection of AVR function 00 to 02 02 34

A082

Selection of voltage for AVR 380...480 V 400 V 34

Ramp adjustment Factory See

Parameter name Adjusting range default page

A092

2nd Acceleration ramp 0,01...3600 s 15,00 s 34

A093

2nd deceleration ramp 0,01...3600 s 15,00 s 34

A094

Select method of 2nd stage 00 or 01 00 34

A095

Switch-over 1./2. acceleration ramp 0,00...400,0 Hz 0,00 Hz 35

A096

Switch-over 1./2. deceleration ramp 0,00...400,0 Hz 0,00 Hz 35

A097

Pattern of acceleration ramp 00 to 03 00 35

A098

Pattern of deceleration ramp 00 to 03 00 35

A131

Acceleration curve constant 01 to 10 02 35

A132

Deceleration curve constant 01 to 10 02 35

b091

Stopping mode selection 00 or 01 00 35

A069

Acceleration stop frequency 0,00...400,0 Hz 0,00 Hz 35

A070

Acceleration stop time 0,0...60,0 s 0,0 s 35

V/f

Page 13

Operating & Mounting instructions – 8 074 143.03/03 – Page 11

Operating

Thermal protection Factory See

Parameter name Adjusting range default page

b012

Electronic overload setting 0,2...1,2 x I

FI FI-INOM

36

b013

Electronic overload characteristic 00 to 02 01 36

b015

Free electronic thermal: frequency 1 0...400 Hz 0 Hz 36

b016

Free electronic thermal: current 1 0,0...1000 A 0,0 A 36

b017

Free electronic thermal: frequency 2 0...400 Hz 0 Hz 36

b018

Free electronic thermal: current 2 0,0...1000 A 0,0 A 36

b019

Free electronic thermal: frequency 3 0...400 Hz 0 Hz 36

b020

Free electronic thermal: current 3 0,0...1000 A 0,0 A 36

Overload protection Factory See

Parameter name Adjusting range default page

b021

Selection of 1st overload restriction 00 to 02 01 37

b022

Level of 1st overload restriction 0,5...1,5 x I

FI 1,20 x IN 37

b023

Rate of 1st decel. at overload restriction 0,10...30,00 s 1,00 s 37

b024

Selection of 2nd overload restriction 00 to 02 01 37

b025

Level of 2nd overload restriction 0,5...1,5 x IFI 1,20 x IN 37

b026

Rate of 2nd decel. at overload restriction 0,10...30,00 s 1,00 s 37

Digital inputs Factory See

Parameter name Adjusting range default page

C001

Function of input 1 01 to 39, NO 18 38

C002

Function of input 2 01 to 39, NO 16 38

C003

Function of input 3 01 to 39, NO 03 38

C004

Function of input 4 01 to 39, NO 02 38

C005

Function of input 5 01 to 39, NO 01 38

C011

Condition of input C01 00 or 01 00 45

C012

Condition of input C02 00 or 01 00 45

C013

Condition of input C03 00 or 01 00 45

C014

Condition of input C04 00 or 01 00 45

C015

Condition of input C05 00 or 01 00 45

C019

Condition of input FW 00 or 01 00 45

b098

Thermistor type seleciton 00 to 02 00 45

b099

Thermistor error level 0...9999 Ω 3000 Ω 45

C085

Standardization of thermistor input 0...100 Default 45

C101

Reference up/down selecteion 00 or 01 00 45

C102

Reset function selection 00 to 02 00 45

C103

Neustart nach Reset 00 or 01 00 45

A

Page 14

Operating & Mounting instructions – 8 074 143.03/03 – Page 12

Digital outputs Factory See

Parameter name Adjusting range default page

C021

Function of relay 11 00 to 13 01 46

C022

Function of relay 12 00 to 13 00 46

C026

Function of relay AL 00 to 13 05 46

C031

Relay output 11: Inversion 00 or 01 00 48

C032

Relay output 12: Inversion 00 or 01 00 48

C036

Relay output AL: Inversion 00 or 01 01 48

Output functions Factory See

Parameter name Adjusting range default page

C040

Overload signal output mode 00 or 01 00 49

C041

Level of overload signal 1 0...2 x I

NOM INOM 49

C042

Arrival signal for Acceleration 1 0,0...360,0 Hz 0,0 Hz 49

C043

Arrival signal for Deceleration 1 0,0...360,0 Hz 0,0 Hz 49

C061

Level of thermal motor protection 0...100 % 80 % 50

b034

Run/Power on time 0...9999 0 50

Undervoltage / Autoreset Factory See

Parameter name Adjusting range default page

b001

Selection of restart mode 00 to 03 00 50

b002

Allowable undervoltage time 0,3...1,0 sec 1,0 sec 50

b003

Retry waiting time 0,3...100,0 sec 1,0 sec 50

b004

Undervoltage trip during stop 00 to 02 00 51

b005

Undervoltage Number of retry 00 or 01 00 51

b006

Input phase loss protection 00 or 01 00 51

b007

Matching frequency setting 0,00...400,0 Hz 0,00Hz 51

General functions Factory See

Parameter name Adjusting range default page

F004

Running direction of RUN key read only 00 51

b035

Direction restriciton (input) 00 to 02 00 52

b082

Start frequency adjustment 0,10...9,99 Hz 0,50 Hz 52

b083

Carrier frequency setting 0,5...12,0 kHz 3,0 kHz 52

b086

Frequency converted value setting 0,1...99,9 1,0 52

b087

Selection of STOP key 00 or 01 00 52

b088

After FRS cancelled 00 or 01 00 52

b092

Cooling fan control 00 or 01 00 53

b037

Display selection 00 to 02 00 53

Motor data Factory See

Parameter name Adjusting range default page

H003

Motor kW rating 0,20...75,0 kW Default 53

H004

Motor poles 2 / 4 / 6 / 8 4 53

H006

Motor stabilisation constant 0...255 100 53

Page 15

Operating & Mounting instructions – 8 074 143.03/03 – Page 13

Operating

2nd Set Factory See

Parameter name Adjusting range default page

A203 2nd Base frequency 30...400 Hz 50 Hz 53

A204 2nd Maximum Frequency 30...400 Hz 50 Hz 53

F202 2nd Acceleration ramp 0,01...3600 s 30 s 53

F203 2nd Deceleration ramp 0,01...3600 s 30 s 54

A220 2nd Internal pre-set speed 0,00...400,0 Hz 0,00 Hz 54

A241 2nd Torque boost method selection 00 or 01 00 54

A242 2nd Manual torque boost setting 0,0...20,0 % 1,0 % 54

A243 2nd Manual torque boost frequency point 0,0...50,0 % 5,0 % 54

A244 2nd V/f characteristic setting 00 to 02 00 54

A261

2nd Frequency upper limit 0,00...400,0 Hz 0,00 Hz 54

A262

2nd Frequency lower limit 0,00...400,0 Hz 0,00 Hz 54

A292

2nd Second acceleration ramp 0,01...3600 s 15,00 s 55

A293

2nd Second deceleration ramp 0,01...3600 s 15,00 s 55

A294

2nd Method of second stage selection 00 or 01 00 55

A295

2nd Stage Acceleration change over point 0,00...400,0 Hz 0,00 Hz 55

A296

2nd Stage Deceleration change over point 0,00...400,0 Hz 0,00 Hz 55

b212

2nd Electronic overload setting 0,2...1,2 x IFIIN FU-INOM 55

b213

2nd Selection of electronic overload charact. 00 to 02 01 55

H203

2nd Motor kW rate 0,20...75,0 kW Default 55

H204

2nd Motor poles 2 / 4 / 6 / 8 4 55

H206

2nd Motor stabilisation constant 0...255 100 55

Analog outputs Factory See

Parameter name Adjusting range default page

C027

Function of FM PWM output 00 to 07 00 56

C028

Function of AM analog output 00 to 07 00 56

C029

Function of AMI analog output 00 to 07 00 56

b080

AM analog adjustment 0...255 180 57

b081

FM PWM meter adjustment 0...255 60 57

C087

AMI analog adjustment 0...255 50 57

C086

AM analog offset 0,0...10,0 V Default 57

C088

AMI analog offset 0,0...20,0 mA Default 57

Energy saving Factory See

Parameter name Adjusting range default page

A085

Operation mode selection 00 or 01 00 57

A086

Energy saving response 0,0...100,0 50,0 57

e

Page 16

Operating & Mounting instructions – 8 074 143.03/03 – Page 14

PCB

2

1

Serial communication Factory See

Parameter name Adjusting range default page

C070

Data command 02 to 05 02 58

C071

Transmission speed 02 to 06 04 58

C072

Identification code 1...32 1 58

C073

Data bits 7 or 8 7 58

C074

Parity 00 to 02 00 58

C075

Number of Stop bits 1 or 2 1 58

C078

Waiting time 0...1000 ms 0 58

Option cards Factory See

Parameter name Adjusting range default page

P001

Option 1 Selection on error 00 or 01 00 58

P002

Option 1 Selection on error 00 or 01 00 58

Software lock, Factory default Factory See

Parameter name Adjusting range default page

b031 Software lock 00 to 10 01 59

b084 Factory default setting 00 to 02 00 59

b085 Kind of factory default 00 to 03 01 59

Fault memory Factory See

Parameter name Adjusting range default page

d080 Number of trips read only - 61

d081

... Trip messages read only - 61

d086

d090 Warning monitor read only - 65

RS485

Page 17

Operating & Mounting instructions – 8 074 143.03/03 – Page 15

Operating

Commissioning

Before working with the equipment check following points:

1.) Check that mains supply and motor cables are connected properly.

2.) Are the control lines properly connected to the right terminals ?

3.) s the frequency inverter properly grounded and assembled ?

4.) Remove installation residues, such as cable residues, in order to avoid short circuits.

5.) Are all screws and terminals tight ?

6.) Is the motor designed for the intended frequency range, in particular for the maximum

frequency ?

Factory defalut (initialisation):

All >pDRIVE< CX frequency inverters are initialised on delivery, i.e. with the default settings (default)

entered. The devices can be reset to these defaults settings at any time.

To reset the default settings, proceed as follows:

1.) Adjust parameter b084 to setting 01.

2.) Select the European configuration with parameter b085=01 (= default setting).

3.) Press the FUNC, UP and DOWN buttons at the same time.

4.) Hold these three buttons and press the STOP/Reset button to confirm.

5.) The inverter automatically starts initialisation. (The relevant country setting appears on the

display). If “d001” appears on the diplay, the procedure has finished.

Note:

If the software lock is active, a reset to factory default is not possible.

Commissioning via the built-in keypad:

The built-in control panel allows to control the frequency inverter without additional wiring of the

control terminals.

1.) Switch on the mains supply; the Power LED on the control panel lights up.

2.) Set parameter A002 to 02.

3.) The LED above the RUN button lights up.

4.) SSet parameter A001 to 00.

5.) The LED above the potentiometer lights up. Press the RUN button and turn the potentiometer.

The motor starts turning and the RUN LED lights up.

6.) Press the STOP button to stop the motor.

Check the following points after commissioning:

1.) Did the motor turn in the right direction ?

2.) Was there an error message during acceleration or deceleration ?

If the error message Overcurrent or Overvoltage appeared, increase the acceleration or

deceleration time.

3.) Were there any abnormal motor noises or vibrations ?

Page 18

1.) see parameter b031

2.) If such parameters are adjusted, no start command is accepted during adjustment.

Impulse contacts and retained commands will be ignored as long as the inverter is still in setting

mode.

Rechtslauf/forward Linkslauf/reverse Stop

Operating & Mounting instructions – 8 074 143.03/03 – Page 16

Description of parameters

The parameters of the >pDRIVE< CX are arranged and described according to their functions.

The following example explains the attributes of parameters:

A038 Jogging frequency VIC 0,0...9,9 Hz 1,0 Hz

Group of parameter

Number of parameter

Name of parameter

Adjusting range

Factory default

Parameter description:

adjustable only

if software lock is open 1.)

adjustable in pulse lock state 2.)

parameter is adjustable

Display actual values

d001 Output frequency - read only -

Displays the output frequency on the LED display.

If this display mode is selected, the Hz-LED right of the display lights up.

d002 Output current - read only -

Displays the motor current on the LED display.

If this display mode is selected, the A-LED right of the display lights up.

d003 Direction of rotation - read only -

Displays the direction of rotation on the display.

d004 PID controller feedback - read only -

Displays the actual PID controller value scaled using parameter A075.

Display = Feedback PID controller x A075

If the PID controller is not active, the display shows:

Page 19

Eingangsnr.:

Input No.:

EIN/ON (24 V) FW

AUS/OFF (0 V)

5 4 3 2 1

Ausgangsnr.:

Output No.:

EIN/ON (24 V)

AUS/OFF (0 V)

AL 12 11

EIN/ON (24 V)

AUS/OFF (0 V)

Operating & Mounting instructions – 8 074 143.03/03 – Page 17

Parameters

d005 Condition of digital inputs - read only -

Status display (ON/OFF) of digital inputs on the LED display.

d006 Condition of digital outputs - read only -

Status display (ON/OFF) of digital outputs on the LED display.

d007 Output frequency scaled - read only -

Displays the scaled output frequency on the LED display. The scaling factor can be set using

parameter b086.

Display = Output frequency * b086

This function is used e.g. for converting the frequency into speed.

d013 Output voltage - read only -

Displays the output voltage on the LED display.

If this display mode is selected, the V-LED right of the display lights up.

d014 Output power - read only -

Displays the output power on the LED display.

If this display mode is selected, the A-LED and V-LED right of the display light up.

d016 Operating hours motor - read only -

Displays the operating hours of the motor with d016, that means the time how long the inverter is in

operating (Run) state.

0. - 9999. Operating hours x1

1000 - 9999 Operating hours x10

d017 Operating hours inverter - read only -

Displays the operating hours of the inverter, that means the time how long the inverter is supplied

with voltage.

0. - 9999. Operating hours x1

1000 - 9999 Operating hours x10

Page 20

Operating & Mounting instructions – 8 074 143.03/03 – Page 18

Base settings

Get Started

A003 Base frequency VIC 30...400 Hz 50 Hz

Adjustment of the base frequency. The base frequency is the frequency at which the output voltage

reaches its maximum value. Normally, the base frequency is equal to the nominal motor frequency.

A004 Maximum frequency VIC 30...400 Hz 50 Hz

Adjustment of maximum frequency. Between base frequency and maximum frequency the output

voltage is constant (field suppression).

F002 1st Acceleration ramp VC 0,01...3600 s 30 s

Setting of required acceleration time. The time is in reference with the range from 0 Hz to maximum

frequency (parameter A004).

F003 1st Deceleration ramp VC 0,01...3600 s 30 s

Setting of required deceleration time. The time is in reference with the range from 0 Hz to maximum

frequency (parameter A004).

F001 Output frequency VC 0,00...400,0 Hz -

Setting the reference value in MANUAL operation via the buttons at the keypad instead of the

potentiometer. Therefore, parameter A001 must be set to position 02.

A020 Internal pre-set speed if A001=02 VC 0,00...400,0 Hz 0,00 Hz

Entry of frequency reference value, if function A001 is set to position 02. Allows the entry of a

minimum frequency to which the inverter runs up without selecting a digital input “CF1...CF4” as

soon as a Start-command is issued.

If the PID controller is active, the adjusting range changes into 0 to 100 %.

Page 21

Operating & Mounting instructions – 8 074 143.03/03 – Page 19

Parameters

A001 Method of speed command VIC 00 to 05 01

Setting Reference via

00 Potentiometer on the keypad

01 Control terminals (analog inputs or multi speeds)

02 Parameter F001, A020/A220 or motorpotentiometer

03 RS 485

04 Option 1

05 Option 2

A002 Method of run command VIC 01 to 05 01

Setting Control command via

01 Control terminals (FW, REV inputs)

02 RUN button at keypad

03 RS 485

04 Option 1

05 Option 2

Analog inputs

Analog Input

A011 External frequency start O (0...10V) VIC 0,00...400,0 Hz 0,00 Hz

A101 External frequency start OI (4...20mA) VIC 0,00...400,0 Hz 0,00 Hz

A111 External frequency start O2 (-10...+10V) VIC -400,0...+400,0 Hz 0,00 Hz

This parameters adjust the output frequency at minimum reference value at the analog input (e.g.

0 V, 4 mA or -10V). Therefore, parameter A015 or A105 must be set to position 00. If the PID

controller is activated, the adjusting range changes into 0 to 800 or to the process sizes depending

on parameter A075.

A012 External frequency end O (0...10V) VIC 0,00...400,0 Hz 0,00 Hz

A102 External frequency end OI (4...20mA) VIC 0,00...400,0 Hz 0,00 Hz

A112 External frequency end O2 (-10...+10V) VIC -400,0...400,0 Hz 0,00 Hz

This parameters adjust the output frequency at maximum reference value at the analog input (e.g.

10 V, 20 mA or +10 V). If the PID controller is activated, the adjusting range changes into 0 to 800

or to the process sizes depending on parameter A075.

A013 Analog signal reference for Start O (0...10V) VIC 0...100 % 0 %

A103 Analog signal ref. for Start OI (4...20mA) VIC 0...100 % 20 %

A113 Analog signal ref. for Start O2 (-10...+10V) VIC -100...+100 % -100 %

This parameters define the minimum reference value if it should be other than 0 V, 4 mA or -10 V.

100 % are equivalent to 10 V or 20 mA.

Page 22

Operating & Mounting instructions – 8 074 143.03/03 – Page 20

A015 External frequency start pattern O (0...10V) VIC 00 or 01 01

A105 Ext. frequency start pattern OI (4...20mA) VIC 00 or 01 01

Setting Function

00 Motor starts-up with external frequency

start setting

01 Motor does not start-up until a

reference > A013

A014 Analog signal reference for end O (0...10V) VIC 0...100 % 100 %

A104 Analog signal ref. for end OI (4...20mA) VIC 0...100 % 100 %

A114 Analog signal ref. for end O2 (-10...+10V) VIC -100...+100 % 100 %

This parameters define the maximum reference value if it should be other than 10 V, 20 mA or

+10 V. 100 % are equivalent to 10 V or 20 mA.

Page 23

Operating & Mounting instructions – 8 074 143.03/03 – Page 21

Parameters

A005 AT Terminal selection VIC 00 or 01 01

Setting Function

00 Switching between 0...10V and 4...20mA (O / OI)

01 Switching between 0...10V and -10...+10V (O / O2)

A006 O2 Control selection VIC 00 to 02 00

Setting Function

00 Single reference value (without f-correction)

01 Addition of f-correction without changing direction

02 Addition of f-correction with change of direction

Parameter Terminal Main f-correction Change of

A006 A005 AT 1.) reference value direction 2.)

00 00 0 0...10V − no

00 00 1 4...20mA − no

00 01 0 0...10V − no

00 01 1 -10...+10V − yes

01 00 0 0...10V -10...+10V no

01 00 1 4...20mA -10...+10V no

01 01 0 0...10V -10...+10V no

01 01 1 -10...+10V − yes

02 00 0 0...10V -10...+10V yes

02 00 1 4...20mA -10...+10V yes

02 01 0 0...10V -10...+10V yes

02 01 1 -10...+10V − yes

1.) Set digital input to function “16 AT switch-over to automatic reference value”

(0...open, 1...closed)

2.) Change of direction allowed (if sum of reference values < 0)

If no digital input is set to “16 AT Switch-over to automatic reference value”, A006 has following

function:

Setting Function

00 Single reference value -10...+10V

01 Addition of 0...10V and 4...20mA without changing direction

02 Addition of 0...10V and 4...20mA with change of direction

A016 Time constant for analog signals VIC 1...30 30

In order to realize shoerter reaction times to changes of the reference values, the set value for this

function can be reduced. However, the smaller this value, the smaller the filter effect for interfering

residual frequency on the reference signal is.

Setting 1 ............................ 30

Filter effect for interfering frequency low ................ high

Reaction time to changes in reference fast .......... slow

Page 24

Operating & Mounting instructions – 8 074 143.03/03 – Page 22

C081

Adjustment 0...10 V input VC 0...9999 Default

C082

Adjustment 4...20 mA input VC 0...9999 Default

C083

Adjustment -10...+10 V input VC 0...9999 Default

C121

Offset-adjustment 0...10 V input VC 0...9999 Default

C122

Offset-adjustment 4...20 mA input VC 0...9999 Default

C123

Offset-adjustment -10...+10 V input VC 0...9999

This adjustments are done in factory and should not be changed!

A019 Multi speed selection VIC 00 or 01 00

Setting Function

00 “binary” function (selection with CF1...CF4)

01 “bit” function (selection with SF1...SF7)

A021 Multi speed 1 VC 0,00...400,0 Hz 0,00 Hz

A022 Multi speed 2 VC 0,00...400,0 Hz 0,00 Hz

A023 Multi speed 3 VC 0,00...400,0 Hz 0,00 Hz

A024 Multi speed 4 VC 0,00...400,0 Hz 0,00 Hz

A025 Multi speed 5 VC 0,00...400,0 Hz 0,00 Hz

A026 Multi speed 6 VC 0,00...400,0 Hz 0,00 Hz

A027 Multi speed 7 VC 0,00...400,0 Hz 0,00 Hz

A028 Multi speed 8 VC 0,00...400,0 Hz 0,00 Hz

A029 Multi speed 9 VC 0,00...400,0 Hz 0,00 Hz

A030 Multi speed 10 VC 0,00...400,0 Hz 0,00 Hz

A031 Multi speed 11 VC 0,00...400,0 Hz 0,00 Hz

A032 Multi speed 12 VC 0,00...400,0 Hz 0,00 Hz

A033 Multi speed 13 VC 0,00...400,0 Hz 0,00 Hz

A034 Multi speed 14 VC 0,00...400,0 Hz 0,00 Hz

A035 Multi speed 15 VC 0,00...400,0 Hz 0,00 Hz

The multispeeds are selected using the digital commands CF1...CF4 or SF1...SF7, which must be

programmed on the terminals first. See Digital inputs.

Multispeeds are pure reference values. The ON and OFF commands are not influenced by the

selection of multispeeds, that means that an additional Start command is necessary for operation

Multispeeds

Multi Speeds

Note:

Multispeeds always override the actual reference value, independent from the setting of

parameter A001.

If no digital input is selected at parameter A001 = 01, the reference value is set using the

analog inputs.

Page 25

Operating & Mounting instructions – 8 074 143.03/03 – Page 23

Parameters

Multi speeds − “binary” function

CF1 CF2 CF3 CF4 Adjusted value Parameter

0 0 0 0 Internal preset speed if A001=02 A020

1 0 0 0 Multispeed 1 A021

0 1 0 0 Multispeed 2 A022

1 1 0 0 Multispeed 3 A023

0 0 1 0 Multispeed 4 A024

1 0 1 0 Multispeed 5 A025

0 1 1 0 Multispeed 6 A026

1 1 1 0 Multispeed 7 A027

0 0 0 1 Multispeed 8 A028

1 0 0 1 Multispeed 9 A029

0 1 0 1 Multispeed 10 A030

1 1 0 1 Multispeed 11 A031

0 0 1 1 Multispeed 12 A032

1 0 1 1 Multispeed 13 A033

0 1 1 1 Multispeed 14 A034

1 1 1 1 Multispeed 15 A035

Multispeeds

− “bit” function

SF1 SF2 SF3 SF4 SF5 SF6 SF7 Adjusted value Parameter

0000000Internal preset speed if A001=02 A020

1xxxxxx Multispeed 1 A021

01xxxxx Multispeed 2 A022

001xxxx Multispeed 3 A023

0 0 0 1 x x x Multispeed 4 A024

0 0 0 0 1 x x Multispeed 5 A025

000001x Multispeed 6 A026

0000001 Multispeed 7 A027

A038 Jogging frequency VC 0,00...9,99 Hz 1,00 Hz

The jog function is used for checking, setting or adjusting the application. For this purpose, the

digital command “Jog mode” (see Digital inputs) is available.

A039 Stop mode of jog function VIC 00 to 05 00

Setting Stop-function

00 Idle stop after jog mode Jog mode only

01 Normal deceleration after jog mode possible during

02 DC braking after jog mode Stop status

03 Idle run after jog mode Jode mode also

04 Normal deceleration after jog mode during operation

05 DC braking after jog mode possible

Page 26

Operating & Mounting instructions – 8 074 143.03/03 – Page 24

V/f characteristic

V/f

V/f

A041 Torque boost method selection VIC 00 or 01 00

Setting Function

00 manual boost

01 automatic boost

A042 Manual torque boost setting VC 0,0...20,0 % 1,0 %

A043 Manual torque boost frequency point VC 0,0...50,0 % 5,0 %

For applications which require higher starting torque, the standard starting torque can be increased.

Use parameter A041 to select between automatic and manual boost. Parameter A042 defines the

value by which the torque has to be boosted. The range in which this boost takes effect is defined by

parameter A043.

A044 V/f characteristic setting VIC 00 to 02 00

Parameter to set one of the possible V/f characteristics.

Setting Function

00 constant torque

01 reduced torque (Economy mode)

02 free adjustable V/f characteristic (b100...b113)

At manual boost, the torque is increased

between 0 Hz and 50 % of the base

frequency.

At automatic boost, this process depends on

the load.

Note:

Beware of overloading the

motor

Page 27

Operating & Mounting instructions – 8 074 143.03/03 – Page 25

Parameters

A045

Voltage gain setting VC 20...100 % 100 %

The output voltage can be set within the range of 20...100 % of the motor voltage set with

parameter A082.

b036

Start reduced voltage selection VIC 00 to 06 00

With this parameter the control time of the start voltage is set.

Setting 00 ............................... 06

Control time fast ................. slow

b100

Free adjustable V/f: frequency 1 VIC 0...b102 0 Hz

b101

Free adjustable V/f: voltage 1 VIC 0,0...800,0 V 0,0 V

b102

Free adjustable V/f: frequency 2 VIC 0...b104 0 Hz

b103

Free adjustable V/f: voltage 2 VIC 0,0...800,0 V 0,0 V

b104

Free adjustable V/f: frequency 3 VIC 0...b106 0 Hz

b105

Free adjustable V/f: voltage 3 VIC 0,0...800,0 V 0,0 V

b106

Free adjustable V/f: frequency 4 VIC 0...b108 0 Hz

b107

Free adjustable V/f: voltage 4 VIC 0,0...800,0 V 0,0 V

b108

Free adjustable V/f: frequency 5 VIC 0...b110 0 Hz

b109

Free adjustable V/f: voltage 5 VIC 0,0...800,0 V 0,0 V

b110

Free adjustable V/f: frequency 6 VIC 0...b112 0 Hz

b111

Free adjustable V/f: voltage 6 VIC 0,0...800,0 V 0,0 V

b112

Free adjustable V/f: frequency 7 VIC 0...400 Hz 0 Hz

b113

Free adjustable V/f: voltage 7 VIC 0,0...800,0 V 0,0 V

With parameters b100 to b113 a free adjustable V/f characteristic can be programmed.

The parameters for torque boost (A041 / A241) and for the base frequency (A003 / A203) are not

active.

Page 28

Operating & Mounting instructions – 8 074 143.03/03 – Page 26

F

ree adjustable V/f characteristic:

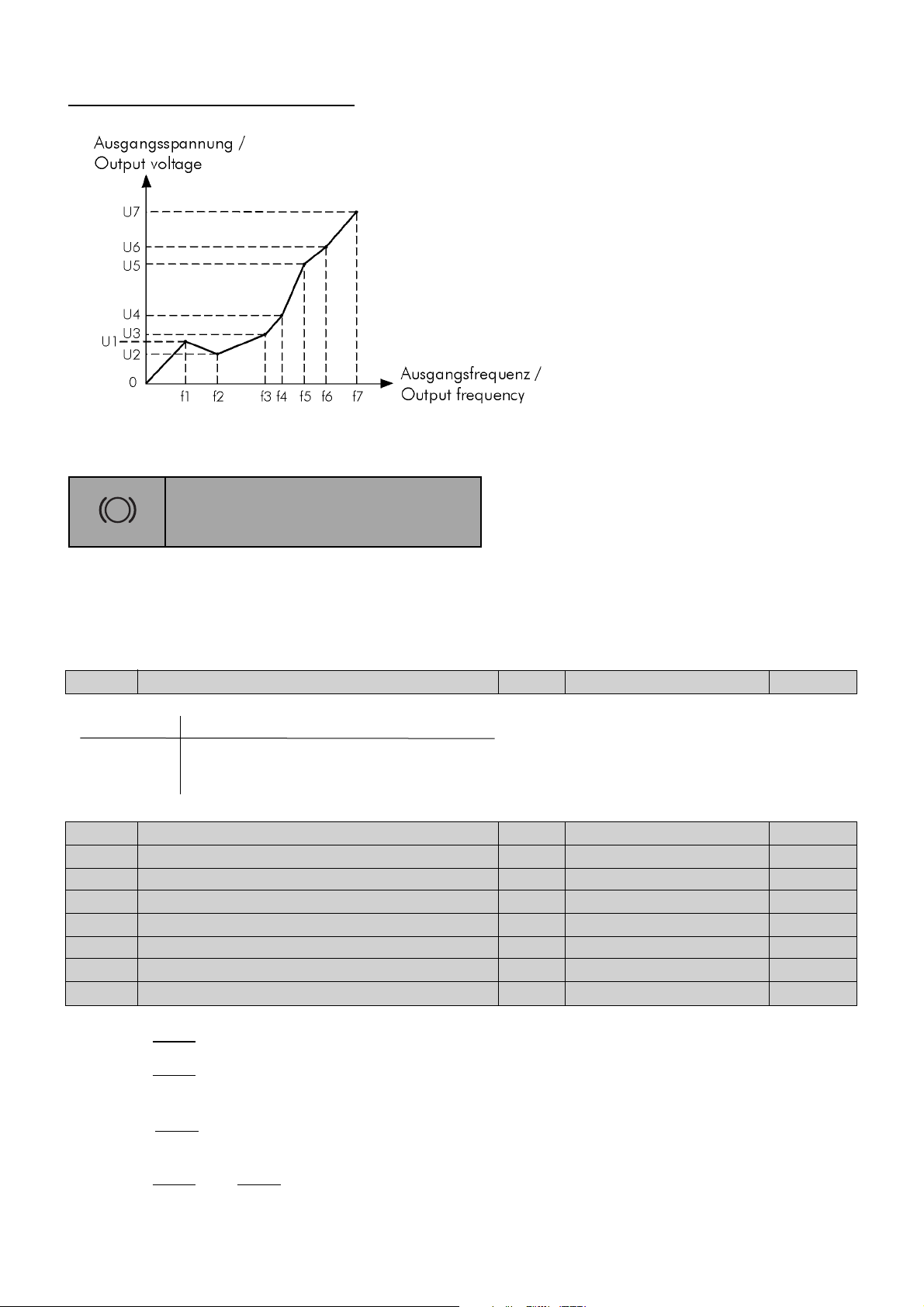

The frequency inverters >pDRIVE< CX profi have an adjustable DC brake. By locking a clocked DC

rotor voltage onto the base of the motor, the rotor produces a braking torque that

counteracts the rotation. With the help of the DC brake, braking a drive to minimum speed is

possible, before the mechanical brake is activated.

A051

Selection of DC braking VIC 00 or 01 00

Setting Function

00 can be controlled with digital input DB

01 alwaysactive

A052

DC braking: frequency VIC 0,00...60,00 Hz 0,50 Hz

A053

DC braking: waiting time VIC 0,0...5,0 s 0,0 s

A054

DC braking: braking torque VIC 0...70 % 0 %

A055

DC braking: braking time VIC 0,0...60,0 s 0,0 s

A056

DC braking: edge/level selection VIC 00 or 01 01

A057

DC braking: braking torque (start) VIC 0...70,0 % 0 %

A058

DC braking: braking time (start) VIC 0,0...60,0 s 0,0 s

A059

DC braking: carrier frequency VIC 0,5...12,0 kHz 3,0 kHz

Parameter A051

defines whether the internal DC brake is active or not.

Parameter A052

defines the frequency at which the DC brake starts. The setting is possible in the

range of 0,0 to 60,0 Hz.

Parameter A053

defines when the DC injetion braking is activated after the frequency set at A052 is

exceeded. During this time the motor is running idle.

Parameter A054

and A057 define the power value with which DC injection braking is carried out.

0% mean “very low“ and 70% “very high“.

DC brake

Braking

Page 29

Operating & Mounting instructions – 8 074 143.03/03 – Page 27

Parameters

Parameter A055 and A058 define the duration of DC injection braking. The value is set within the

range from 0,1 to 60 seconds.

Parameter A056

defines wheter the DC brake is active depending on time or depending on a

contact.

Parameter A059 defines the carrier frequency during DC braking. With high carrier frequency the

maximum possible braking torque is reduced.

DC brake always active (A051=01):

If the DC brake is active (A051 = 01) this function is active at each Start and/or Stop.

After the Start-command the DC brake is active during the time set with parameter A058.

After the Stop-command the inverter runs down along the set deceleration ramp and starts with DC

braking at the frequency set with parameter A052.

Page 30

Operating & Mounting instructions – 8 074 143.03/03 – Page 28

Note:

The DC brake causes a heating of the connected motor.

Be sure that the motor does not get to warm.

DC brake controlled via digital input (A051=00)

The DC brake is activated via a digital input (D8: C001...C005=7).

Page 31

Operating & Mounting instructions – 8 074 143.03/03 – Page 29

Parameters

b090

Dynamic braking ratio VIC 0,0...100,0 % 0,0 %

Adjusting the allowed duration time of the braking resistor (only at CX profi 11 and 15).

Setting 0,0 % means that the internal braking unit is not active.

Frequency limits

Limits

A061

Frequency upper limit VIC 0,00...400,0 Hz 0,00 Hz

A062

Frequency lower limit VIC 0,00...400,0 Hz 0,00 Hz

Defining the frequency range within a range from 0 to parameter A004 (max. 400 Hz). If the values

are set to 0,00 Hz, their function is cancelled.

Without parameter A061 and A062 With parameter A061 and A062

b095

Dynamic braking selection VIC 00 to 02 00

Setting Function

00 not active

01 only active during operation

02 always active

b096

Dynamic braking ON-level VIC 660...760 V 720 V

Defines the ON-level of the braking unit depending on the DC link voltage.

Page 32

Operating & Mounting instructions – 8 074 143.03/03 – Page 30

A063

1st Jump frequency VIC 0,00...400,0 Hz 0,00 Hz

A064

1st Jump frequency width VIC 0,00...10,0 Hz 0,50 Hz

A065

2nd Jump frequency VIC 0,00...400,0 Hz 0,00 Hz

A066

2nd Jump frequency width VIC 0,00...10,0 Hz 0,50 Hz

A067

3rd Jump frequency VIC 0,00...400,0 Hz 0,00 Hz

A068

3rd Jump frequency width VIC 0,00...10,0 Hz 0,50 Hz

To avoid possible resonance in the drive system, it is possible to program three jump frequency

ranges using functions A063...A068.

The jump frequency defines the frequency at which the drive should not be operated in steady-state.

The adjustable jump frequency range determines the frequency range faded out and actions

symmetrical to the jump frequency.

General

The PID controller is designed as a process controller with the variable “Frequency [Hz]”, whereby

P (kp), I (T

N) and D (Tv) can be adjusted individually. The reverence and actual value are standardi-

sed in % (range 0...100 %). For better presentation, they can be converted to the individual plant

value using A075 (e.g. flow 0...30 l/h).

The PID controller output is limited with 0 Hz (or A062) at the bottom and with the maximum

frequency A004 (or A061) at the top end. As a result, there is no reversal of the motor in the event

of negative deviation.

In order to optimize the disturbance behaviour of the controller, it is advisable to set the acceleration

and deceleration ramps as small as possible.

PID Configuration

PID

Page 33

Operating & Mounting instructions – 8 074 143.03/03 – Page 31

Parameters

PID reference value

The reference value is selected using parameter A001. The following values can be used as

reference source:

Reference value Settings Standardization

Potentiometer built-in A001 = 00 0...100 %

Parameter value F001 A001 = 02 0...100 % x Parameter A075

Multispeeds A020...A035 0...100 % x Parameter A075

Analog input O (0...10 V) A001 = 01 0...100 % (independent from A011...A014

Analog input OI (4...20 mA) 0...100 % or A101...A104)

Actual value

One of the two analog inputs (O or OI) can be used as actual value input (selectio with A076).

The actual value registration is adjusted using the analog input function.

See parameters A011...A014 or A101...A104.

The settings of parameters A011 and A012 are changed by activating the PID controller (A071)

from Hz to % and by setting parameter A075 to process values.

Note:

By using the PID controller, the digital function “Automatic reference value (4..20 mA)” is not available!

Note:

Because of the influence of parameter A071 to the scaling of the reference and actual value, it is

important to change this parameter before changing any other!

Displays

Parameter d004 allows the display of the actual value, parameter F001 displays the reference value

on the LED. This values can be converted to process values using the display factor A075.

If parameter F001 is selected, the current PID reference value is displayed. It is not updated continuously.

The actual value display (parameter d004) is updated continuously.

Page 34

Operating & Mounting instructions – 8 074 143.03/03 – Page 32

A071

Selection of PID function: ON/OFF VIC 00 or 01 00

The PID controller is activated and deactivated using parameter A071.

Setting Function

00 PID controller not active

01 PID controller active; with digital input to setting 23 (PID enable) switch-over to

manual control

Generally is:

T

N is right at kp = 1

kp ≠ 1 ⇒ T

N = TN x kp

TN = selected reset time (A073) at kp = 1

T

N* = effective reset time at kp = 0,5

T

N* = TN x 0,5

*) After setting the scale conversion (parameter A075) this parameters are adjusted and displayed in process

sizes.

**) If the PID controller is active, the reference value is set and displayed in percent or in process size

dependent on A075. By switch-over to manual controll (DIx ... 23 PID enable) the values are scaled and

also displayed in Hz.

This values are scaled with parameters A011...A014 (terminal O [V]) and A101...A104 (terminal OI [mA]).

The display parameters F001 and d004 are updated continuously !

A072

PID controller: Proportional gain (kp) VIC 0,2...5,0 1,0

A073

PID controller: Integral gain(Tn) VIC 0,0...3600 s 1,0

A074

PID controller: Differential gain(Tv) VIC 0,00...100,0 s 0,00

Parameters A072, A073 and A074 are used to

set the PID controller factors.

Please not that the individual factors can be set

separately, but that they have an influence on

each other. If P (kp) is changed, T

N also

changes

..

Page 35

Operating & Mounting instructions – 8 074 143.03/03 – Page 33

Parameters

A075

PID controller: Scale conversion VIC 0,01...99,99 1,00

Parameter A075 allows the setting of a conversion factor for the proper process presentation of the

PID reference and actual value on the LED display.

Parameters A011 (A101), A012 (A102), d004, F001 and A020...A035 are converted in accordance

with the setting of A075.

A076

PID controller: Feedback destination VIC 00 or 01 00

Parameter A076 defines the type of feedback signal.

Setting Function

00 Current signal at terminals OI - L

01 Voltage signal at terminals O - L

C044

PID controller: Level of deviation VIC 0...100 % 3,0 %

Adjusting the difference between reference and actual value in percent, at which a signal is to be

issued. The setting can be done in a range from 0,0 to 100,0 % with a resolution of 0,1 % (bipolar).

The AVR function (Automatic Voltage Regulation) stabilises the motor voltage in case of fluctuating

intermediate circuit voltage (e.g. due to unstable mains supply or because of intermediate circuit

voltage drops or surges due to short acceleration or deceleration times) in order to maintain such a

high torque - especially during acceleration.

Automatic voltage regulation

AVR

V/f

During the delay phase (generatoric operation) the DC link voltage increases (as shown above). This

leads to an increase of the motor voltage. This higher motor voltage causes a higher braking torque.

Therefore, the AVR function for deceleration can be deactivated with function A081.

Page 36

Operating & Mounting instructions – 8 074 143.03/03 – Page 34

A081

Selection of AVR function VIC 00 to 02 00

Parameter A081 switches the “Automatic Voltage Regulation” for the motor on and off.

Setting Function

00 AVR function active

01 AVR function not active

02 AVR function not active during deceleration

A082

Selection of voltage for AVR VIC 380...480 V 400 V

The nominal motor voltage (380 / 400 / 415 / 440 / 460 / 480 V) is set with parameter A082.

(output voltages higher than the mains voltage are not possible)

Allows to switch the time ramps adjusted with F002 and F003 to the ramps adjusted with A092 and

A093 during operation. This can be done either at any time using an external signal or when exact,

set frequencies are reached.

Ramp adjustment

Speed ramps

2.

A092

2nd Acceleration ramp VIC 0,01...3600 s 15,00 s

A093

2nd deceleration ramp VIC 0,01...3600 s 15,00 s

A094

Select method of 2nd stage VIC 00 or 01 00

Setting Function

00 Switch-over via an external signal on a digital input (setting: 09)

01 Switch-over when the frequencies set at parameter A095 and A096 are reached

Page 37

Operating & Mounting instructions – 8 074 143.03/03 – Page 35

Parameters

A095

Switch-over 1./2. acceleration ramp VIC 0,00...400,0 Hz 0,00 Hz

A096

Switch-over 1./2. deceleration ramp VIC 0,00...400,0 Hz 0,00 Hz

Particularly, this switch-over is used for EMERGENCY STOP functions and speed-related acceleration

and deceleration times. The adjusted acceleration/deceleration time is related to the maximum

frequency A004.

A097

Pattern of acceleration ramp VIC 00 to 03 00

A098

Pattern of deceleration ramp VIC 00 to 03 00

These two parameters determine whether the acceleration (A097) and/or deceleration (A098) are

linear or follow an S ramp.

Setting Function

00 linear

01 S ramp

02 U ramp

03 U ramp inverted

A131

Acceleration curve constant VIC 01 to 10 02

A132

Deceleration curve constant VIC 01 to 10 02

This two parameters determine how intensive the acceleration ramp (A131) and/or the deceleration

ramp (A132) have an S-curve. Setting: 01...slight S-ramp; 10...strong S-ramp

b091

Stopping mode selection VIC 00 or 01 00

This parameter defines the behaviour of the inverter after a Stop-command.

Setting Function

00 Deceleration ramp

01 Idle-run

A069

Acceleration stop frequency VIC 0,00...400,0 Hz 0,00 Hz

A070

Acceleration stop time VIC 0,0...60,0 s 0,0 s

With this function the acceleration process can be stopped. Parameter A070 defines how long the

acceleration process is stopped after reaching the frequency set with A069.

Page 38

Operating & Mounting instructions – 8 074 143.03/03 – Page 36

b012

Electronic overload setting VIC 0,2...1,2 x I

FI FI-INOM

A thermal motor contactor (“maximum continuous current”) can be set by entering the nominal

motor current in A.

b013

Electronic overload characteristic VIC 00 to 02 01

Defines the characteristic curve of the thermal motor contactor.

Setting Function

00 reduced load torque (self-ventilated)

01 constant load torque (force-ventilated)

02 free adjustable load torque

Thermal protection

Electronic Overload

Note:

If the value is higher than the nominal motor current, the motor cannot be protected by an

electronic motor contactor. In this case, thermistors or similar mechanism are required.

After a power cut, the thermal motor model always starts up again with a “cold” machine !!

b015

Free electronic thermal: frequency 1 VIC 0...400 Hz 0 Hz

b016

Free electronic thermal: current 1 VIC 0,0...1000 A 0,0 A

b017

Free electronic thermal: frequency 2 VIC 0...400 Hz 0 Hz

b018

Free electronic thermal: current 2 VIC 0,0...1000 A 0,0 A

b019

Free electronic thermal: frequency 3 VIC 0...400 Hz 0 Hz

b020

Free electronic thermal: current 3 VIC 0,0...1000 A 0,0 A

With this parameters the free adjustable electronic overload characteristic is defined (see above).

Page 39

Operating & Mounting instructions – 8 074 143.03/03 – Page 37

Parameters

b021

Selection of 1st overload restriction VIC 00 to 02 01

This parameter defines when the current limitation is active.

Setting Function

00 not active

01 during acceleration and constant speed

02 only at constant speed

b022

Level of 1st overload restriction VIC 0,5...1,5 x I

FI 1,20 x IN

Defines the value in amperes at which the inverter tries to reduce the load by decreasing the output

frequency.

b023

Rate of 1st decel. at overload restriction VIC 0,10...30,00 s 1,00 s

When reaching the adjusted current limit, the frequency is reduced according to the set ramp.

b024

Selection of 2nd overload restriction VIC 00 to 02 01

b025

Level of 2nd overload restriction VIC 0,5...1,5 x I

FI 1,20 x IN

b026

Rate of 2nd decel. at overload restriction VIC 0,10...30,00 s 1,00 s

With the parameters B021...b023 and b024...b026 two different overload restrictions can be set.

The switch-over is done via a digital input (OLR: C001...C005 = 39).

Overload protection

Overload restriction

A

Note:

The overload restriction is not active during deceleration.

Page 40

Operating & Mounting instructions – 8 074 143.03/03 – Page 38

C001

Function of input 1 VIC 01 to 39, NO 18

C002

Function of input 2 VIC 01 to 39, NO 16

C003

Function of input 3 VIC 01 to 39, NO 03

C004

Function of input 4 VIC 01 to 39, NO 02

C005

Function of input 5 VIC 01 to 39, NO 01

Parameter Control terminal Default

C001 1 18 External reset

C002 2 16 Switch-over O/OI

C003 3 03 CF2

C004 4 02 CF1

C005 5 01 Start reverse

The programmable inputs (control terminals 1 to 5)can be allocated to the parameters in

accordance with the following table:

Setting Short-cut Function Setting Short-cut Function

01 REV Start reverse 21 STP Stop impulse

02 CF1 Fix A 22 F/R Forward/reverse

03 CF2 Fix B 23 PID PID enable

04 CF3 Fix C 24 PIDC PID reset

05 CF4 Fix D 27 UP Motorpot increase

06 JG Jog mode 28 DOWN Motorpot decrease

07 DB DC braking 29 UDC Motorpot reset

08 SET 2nd set 31 OPE Local control

09 2CH 2nd accel./decel. ramp 32 SF1 FIX 1

11 FRS Impulse lock-free run 33 SF2 FIX 2

12 EXT External fault 34 SF3 FIX 3

13 USP Restart lock at 35 SF4 FIX 4

undervoltage (USP) 36 SF5 FIX 5

14 CS Bypass signal 37 SF6 FIX 6

15 SFT Software lock 38 SF7 FIX 7

16 AT Switch-over to automatic 39 OLR Switch-over of

ref. value 4...20 mA overload restriction

18 RS External reset NO NO no function

20 STA Start impulse

Digital inputs

Input terminals

Page 41

Operating & Mounting instructions – 8 074 143.03/03 – Page 39

Parameters

Explanations of the functions for the digital inputs

Start/Stop via switch contacts:

When the contacts are closed, a Start command is

issued in the right direction (acceleration on

gradient), when open, a stop command is issued

(deceleration on gradient). The simultaneous

closing of Start forward and Start reverse also

issues a Stop command to the inverter.

Multispeeds (“binary” function):

The multispeeds (maximum 15) are selected via

the signals CF1...4 according to the table:

CF1 CF2 CF3 CF4 Reference value

0 0 0 0 analog value

1 0 0 0 1 (A021)

0 1 0 0 2 (A022)

1 1 0 0 3 (A023)

0 0 1 0 4 (A024)

1 0 1 0 5 (A025)

0 1 1 0 6 (A026)

1 1 1 0 7 (A027)

0 0 0 1 8 (A028)

1 0 0 1 9 (A029)

0 1 0 1 10 (A030)

1 1 0 1 11 (A031)

0 0 1 1 12 (A032)

1 0 1 1 13 (A033)

0 1 1 1 14 (A034)

1 1 1 1 15 (A035)

The number of digital inputs to be programmed

depends on the number of multispeeds actually

needed. The multispeeds are programmed in

parameter group A. The multispeeds are pure

reference values without any Start/Stop

commands.

Therefore, Parameter A001 “Method of speed

command” must be set to 01 “control terminals” !

Jog mode:

If the Jog command is activated, the inverter

accelerates the motor with the fastest possible

acceleration time to the set jog frequency A038.

00 Start FWD

01 Start REV

02 Fix A

03 Fix B

04 Fix C

05 Fix D

06 Jog mode

Page 42

Operating & Mounting instructions – 8 074 143.03/03 – Page 40

DC brake:

If this command is activated, the DC brake is

active.

Switch-over of parameters:

If this command is activated, the inverter switches

over to the 2nd set of parameters. Motor data,

minimum and maximum limits and the acceleration and deceleration times are switched over.

The concerned parameters are named A2xx.

Switch-over of ramps:

Two sets of acceleration and deceleration ramps

are avaliable. The signal “2nd ramp” is used to

switch between these two ramp sets. The values of

acceleration and deceleration time must be set in

parameter group A.

Contact closed: 2nd set of ramps active

Impulse lock:

If this command is activated, the inverter is locked

immediately, allowing the motor to come to standstill freely. The function can be inverted

(parameters C011 to C015). By setting parameter

b088 to position 00, the inverter starts from 0 Hz

once the FRS signal is cancelled.

However, if parameter b88 is set to position 01,

the inverter starts with the acutal frequency fo the

motor (“interception of the motor“).

In both cases, the inverter starts after the waiting

time set with parameter b003. If the speed of the

motor is declined during this time beneath the

matching (restart) frequency set with parameter

b007, a restart happens at 0 Hz.

07 DC brake

08 2nd Set

09 2nd ramp

11 Impulse lock

Netzspannung/

Mains supply

FRS-Signal/

FRS command

Ausgangsfrequenz

Output frequency

b088=00

Ausgangsfrequenz

Output frequency

b088=01

1

0

1

0

1

0

1

0

Page 43

Operating & Mounting instructions – 8 074 143.03/03 – Page 41

Parameters

External fault:

The activated command leads to immediate fault

shut-down with the error message „E12 - Ext.

fault“. Using this input, plant errors can be

integrated in the control of the frequency inverter.

The error message cn be realised using the break

or make contact (parameter C011 to C015).

Restart lock for undervoltage (USP)

This function prevents an automatic motor start

when the voltage returns after a power cut or

undervoltage. A restart is only possible after

resetting the error or by switching the Start

command on/off.

12 Ext. fault

13 USP

Notes:

If the USP function is activated and the

power supply comes back or is

switched-on during a Start-command,

the inverter trips with E13.

The USP function is also executed after

an undervoltage trip E09.

Netzspannung/

Mains supply

Startbefehl/

Start command

USP-Klemme/

USP-terminal

USP-Meldung/

USP-message

1

0

1

0

1

0

1

0

Ausgangsfreq./

Output freq.

1

0

Page 44

Operating & Mounting instructions – 8 074 143.03/03 – Page 42

Bypass signal:

An activation of the command leads an holding of

the running motor after mains operaiton.

After the switch-over from bypass to inverter operation, the inverter takes over the running motor

after the waiting time set with parameter b003.

If the speed of the motor has declined during this

time the matching (restart) frequency set with

parameter b007, a restart is done at 0 Hz.

Software lock:

This function allows an additional lock for

parameter changes via the terminals. Thus, it is

possible e.g. to lock the parameter editing

function via an externa key switch.

Contact open: parametrization enabled,

Contact closed: parametrization locked.

Switch-over to automatic reference value

(4..20 mA)

By closing the contact, it is possible to define the

frequency ref. value usnig a current input signal

(4...20mA). When the contact is open, the

frequency is defined via a voltage input signal

(0...10V). If the contact is closed, the frequency is

defined via the 4...20 mA analog input (terminals

OI - L). If the contact is open, the analog signal

0...10 V (terminals O - L) is conductive. If no

digital input is parametrized for this function, the

two reference values are added (f-correction).

15 Software lock

14 Bypass signal

16 Automatic ref.

value (4 .. 20 mA)

Bypaßschütz/

bypass contactor

Motorschütz/

Motor contactor

Netzschütz/

Mains contactor

CS

Ausgangsfreq./

Output freq.

1

0

1

0

1

0

1

0

1

0

Verriegelungszeit/

Cut-off time

0,5...1s

b003

Page 45

Operating & Mounting instructions – 8 074 143.03/03 – Page 43

Parameters

External reset:

Allows you to confirm an error via the terminals.

During operation, an external Reset-command

stops the inverter!! The signal must not be inverted

and must not be issued for more than 4 seconds.

A permanent reset is not possible. If the inverter is

running without problems, it runs to 0 Hz when an

RS signal is issued! In plants, where a common

reset signal is used for all devices, parameter

C102 must be set to position 02 !

Start/Stop via impulses:

An impulse contact (N.O.) leads a Start-command.

An impulse contact (N.C.) leads a Stop-command.

Closing the contact leads to a change of direction.

Contact open = Forward

PID controller:

If the PID controller is activated (A071=1), the

command “PID enable” disables the PID

controller and the PID ref. value acts directly on

the output frequency.

Motorpotentiometer:

Reference values via the motorpotentiometer are

defined via the signals “Motorpot increase” and

“Motorpot decrease”.

Thereby, the reference value is increased and

decreased with the adjusted acceleration/

deceleration time (F002/F003 and F202/F203) as

long as the command is active.

The motorpotentiometer is activated via parameter

A001 = 02.

The command “Motorpot reset” deletes the

reference value, if he is stored with parameter

C101 = 01.

Local control:

By closing this contact, the control via the keypad

is activated. After pressing the RUN key, the

inverter accellerates up to the reference value set

with F001 - independent from A002 “Method of

run command”.

If the contact is closed during operation, the drive

stops first.

18 External reset

20 Start impulse

21 Stop impulse

22 Forward/

reverse

27 Motorpot increase

28 Motorpot decrease

29 Motorpot reset

23 PID enable

24 PID reset

31 Local control

Page 46

Operating & Mounting instructions – 8 074 143.03/03 – Page 44

Multispeeds (“bit”-function):

The multispeeds (maximum 7) are selected using

the signals SF1...SF7 according to the table:

SF1 SF2 SF3 SF4 SF5 SF6 SF7 Ref. value

0000000analog value

1xxxxxx 1 (A021)

01xxxxx 2 (A022)

001xxxx 3 (A023)

0001x x x 4 (A024)

00001x x 5 (A025)

000001x 6 (A026)

0000001 7 (A027)

If several multispeeds are selected at one time, the

lower value has priority.

The number of multispeeds depends on the actual

number of digital inputs. Maximum 5 free

adjustable digital inputs are available at a

standard control terminal.

The multispeeds are programmed in parameter

group A. The multispeeds are pure reference

values without any Start/Stop commands.

Switch-over of overload restriction:

With this command a switch-over between the two

different overload restrictions (b021...b023 and

b024...b026) is possible .

This command has no effect !

Notes:

You can not use the same value for parameters C001 to C005.

If a parameter is to be shifted to another terminal, the “from” terminal must be set first,

then the old value set for the “to” terminal.

32 Fix 1

33 Fix 2

34 Fix 3

35 Fix 4

36 Fix 5

37 Fix 6

38 Fix 7

39 Switch-over of

overload restriction

NO no function

Page 47

Operating & Mounting instructions – 8 074 143.03/03 – Page 45

Parameters

C011

Condition of input C001 VIC 00 or 01 00

C012

Condition of input C002 VIC 00 or 01 00

C013

Condition of input C003 VIC 00 or 01 00

C014

Condition of input C004 VIC 00 or 01 00

C015

Condition of input C005 VIC 00 or 01 00

C019

Condition of input FW VIC 00 or 01 00

This parameters define the status of the programmable digital inputs C001 to C005 and FW.

Setting State

00 N.O.

01 N.C.

b098

Thermistor type seleciton VIC 00 to 02 00

Setting Function

00 Thermistor not active

01 Thermistor active (PTC-behaviour)

02 NTC active

b099

Thermistor error level VIC 0...9999 Ω 3000 Ω

This parameter defines the trigger value of the thermistor monitoring.

C085

Standardization of thermistor input VC 0...100 Default

This balance is set in factory and should not be changed.

C101

Reference up/down selecteion VIC 00 or 01 00

Setting Function

00 Does not store value of motorpotentiometer

01 Stores value of motorpotentiometer

C102

Reset function selection VC 00 to 02 00

Setting Function

00 Reset at positive ramp

01 Reset at negative ramp

02 Reset at positive ramp, no effect during operation

If position 00 or 01 is adjusted, a Reset-signal during operation locks the output.

C103

Reset restart function selection VIC 00 or 01 00

Setting Function

00 Restart with 0 Hz

01 Holds the motor during restart

Page 48

Operating & Mounting instructions – 8 074 143.03/03 – Page 46

C021

Function of relay 11 VIC 00 to 13 01

C022

Function of relay 12 VIC 00 to 13 00

C026

Function of relay AL VIC 00 to 13 05

The programmable relay outputs (terminals 11 and 12 and also AL) can be programmed using

parameters C021, C022 and C026. The following functions can be programmed:

Setting Short-cut Function

00 RUN Operation

01 FA1 „Reference value arrival“ - signal

02 FA2 „Frequency exceeded“ - signal (C042, C043)

03 OL Overload message

04 OD PID deviation too high

05 AL Error message

06 FA3 „Frequency arrival“ - signal (C042, C043)

08 IP Mains failure

09 UV Undervoltage

11 RNT Operating hours motor exceeded (b034)

12 ONT Operating hours inverter exceeded (b034)

13 THM Temperature alarm (C061)

Function: RRUN C021, CC022 oor CC026 == 00 RRUN ““Operation”

Digital outputs

Output terminals

Note:

If the frequency value of the inverter is smaller than the start frequency (which is set with

parameter b082), there is no “Operation”-signal (RUN).

Function: FFA1 C021, CC022 oor CC026 == 001 FA1 “Ref. vvalue aarrival”

Function: FFA2 C021, CC022 oor CC026 == 002 FA2 “Frequency eexceeded”

Function: FFA3 C021, CC022 oor CC026 == 006 FA3 “Frequency aarrival”

The frequency at which the signal is to be issued during acceleration is set using parameter C042

(hysteresis -0,5 Hz bis +1,5 Hz).

The frequency at which th signal is to be issued during deceleration is set using parameter C043

(hysteresis +0,5 Hz bis -1,5 Hz).

Start-Befehl/

Start command

Ausgangsfrequenz/

Output frquency

Betrieb - Signal/

RUN - Signal

1

0

1

0

1

0

ON

Page 49

Operating & Mounting instructions – 8 074 143.03/03 – Page 47

Parameters

Function: OOL C021, CC022 oor CC026 == 003 OL “Overload mmessage”

This message is issued as soon as the motor current exceeds the value set for parameter C041, both

during motor and generator operation.

Funktion FA1: C021, C022 oder/or C026 = 1

Function: OOD C021, CC022 oor CC026 == 004 OD “PID ddeviation ttoo hhigh”

This message is issued as soon as the difference between reference value and actual value exceeds

the value set for parameter C044 (bipolar).

“Sollwert erreicht” / “Reference value arrival”

f

0.5 Hz

1.5 Hz

Funktion FA2: C021, C022 oder/or C026 = 2

“Frequenz überschritten” / “Frequency exceeded”

f

Ausgangssignal

60 ms

0.5 Hz

60 ms

f

C042

Ausgangssignal

1.5 Hz

Funktion FA3: C021, C022 oder/or C026 = 6

“Frequenz erreicht” / “Frequency arrival”

0.5 Hz

0.5 Hz

1.5 Hz

C042

Output

signal

60 ms

1.5 Hz

0.5 Hz

C043

1.5 Hz

C043

60 ms 60 ms

I [A]

b022

Motorstrom

Motor current

min. 1 sec

Überlastsignal /

overload signal

t

t

Page 50

Operating & Mounting instructions – 8 074 143.03/03 – Page 48

Function: AAL C021, CC022 oor CC026 == 005 AL “Error mmessage”

If one of the outputs C021 or C022 is set to position 05, an error signal is issued if an error occurs.

During mains failure the error signal will continue only as long as there is still power in the inverter.

Function: IIP C021, CC022 oor CC026 == 008 IP “Mains ffailure”

This message occurs as soon as the Input phase loss protection (b006) triggers.

Function: UUV C021, CC022 oor CC026 == 009 UV “Undervoltage”

This message occurs as soon as the undervoltage monitoring of the DC link triggers.

Function: RRNT C021, CC022 oor CC026 == 111 RNT “Operating hhours mmotor”

If the operating time of the motor (d016) exceeds the value set with b034, a message is indicated.

Function: OONT C021, CC022 oor CC026 == 112 OONT ““Operating hhours iinverter”

If the operating time of the inverter (d017) exceeds the value set with b034, a message is indicated.

Function: TTHM C021, CC022 oor CC026 == 113 THM “Temperature aalarm”

As soon as the thermal motor model exceeds the value set with C061, a message is displayed.

C031

Relay output 11: Inversion VIC 00 or 01 00

C032

Relay output 12: Inversion VIC 00 or 01 00

C036