Installation & User Manual

(IOS-U20VB, IOS-U15VB, IOS-U10VB,

IOS-U20IB, IOS-U15IB, IOS-U10IB)

Contents

CHAPTER 1 INTRODUCTION ................................................................... 1

1.1 Notice .................................................................................................................. 1

1.2 Conventions and Symbols ................................................................................ 1

1.3 Safety Instructions ............................................................................................ 3

1.4 Disposing of the Product .................................................................................. 5

CHAPTER 2 SYSTEM OVERVIEW ............................................................ 6

2.1 System Description ........................................................................................... 6

2.2 Product Components ........................................................................................ 8

CHAPTER 3 INSTALLATION ..................................................................... 9

3.1 PC Specifications .............................................................................................. 9

3.2 Installation of Software Driver ........................................................................ 10

3.2.1 EzSensor Classic(IOS-U20VB, IOS-U15VB, IOS-U10VB)Driver Setup .............................. 10

3.2.2 Cable connection & Driver Installation ................................................................................. 12

3.3 Installation of the EzSensor Classic Holder .................................................. 14

CHAPTER 4 IMAGE ACQUISITION BY USING EASYDENT ................... 15

4.1 Installation of EasyDent .................................................................................. 15

4.2 Image Acquisition Overview ........................................................................... 20

4.3 Running the EasyDent ..................................................................................... 21

4.3.1 Patient Registration and Device Selection ........................................................................... 21

4.3.2 Single Shot .............................................................................................................................. 23

4.3.3 Multi Shot ................................................................................................................................. 27

4.3.4 Sequence Shot ........................................................................................................................ 31

CHAPTER 5 IMAGE ACQUISITION BY USING EZDENT-I ...................... 34

5.1 Installation EzDent-i ........................................................................................ 34

5.2 License Activation. .......................................................................................... 40

5.3 Consult DB License Activation ....................................................................... 43

5.4 Preparing for Image Acquisition .................................................................... 46

5.5 Running the EzDent- i...................................................................................... 47

5.5.1 Patient Registration ................................................................................................................ 47

5.5.2 Acquiring Image ...................................................................................................................... 48

5.5.3 Image View............................................................................................................................... 51

CHAPTER 6 MAINTENANCE .................................................................. 52

6.1 Visual Inspection ............................................................................................. 52

6.2 Periodic Maintenance ...................................................................................... 52

6.2.1 Test List ................................................................................................................................... 53

6.2.2 Connection .............................................................................................................................. 53

6.2.3 Cable ........................................................................................................................................ 54

6.2.4 Resolution................................................................................................................................ 54

6.3 Care and Cleaning ........................................................................................... 55

6.4 Precautions ...................................................................................................... 55

6.5 Product complaint ........................................................................................... 56

APPENDIX .............................................................................................. 57

A.1 X-ray Exposure Guide ..................................................................................... 57

A.2 Error Message .................................................................................................. 59

A.3 Troubleshooting .............................................................................................. 61

A.4 Electromagnetic Compatibility Information ................................................... 62

1

Chapter 1 Introduction

1.1 Notice

For the improvement of Product performance, supplementation, and the follow-up of information,

the contents of this manual are subject to change without prior notice.

Please note that our company bears no responsibility for accidental damage nor will we be

obligated to provide warranty service for any damage to equipment due to user error. Please

follow the instructions in this manual closely. Become familiar with the safety precautions and

usage procedures for this Product. Note that the Product may differ slightly from the contents of

this manual, depending on individual Product specifications.

1.2 Conventions and Symbols

1. Convention

The following symbols are used throughout this manual to provide instructions on the

effective use of this Product.

Indicates useful information and tips on how to use our software and

Products.

Indicates important instructions. If not observed, malfunction or damage to

the Product or other property may occur.

Indicates warnings and safety instructions. If not adhered to, there is a

serious risk of injury to the patient and/or the operator.

For U.S.A. users: United State federal law restricts this device to use by or on the order

of physician.

For other countries users: This device to use by or on the order of a licensed person

under the related laws in each country.

2

2. Symbols Descriptions

Item

Symbol Description

1

Type B applied part

2

Refer to instruction manual/ booklet

3

Conforms to CE MDD 93/42/EEC (European Communities)

concerning medical devices

4

Waste Electrical and Electronic Equipment

5

Manufacturer

6

Date of manufacture

7

Serial number

8

Authorized representative in the European Community

9

Handling procedures for Electro-Static Discharge (ESD).

9

Handle with care

10

Fragile, handle with care

11

This way up

3

1.3 Safety Instructions

Indications for Use

EzSensor Classic, an Intra-oral Imaging device, is intended to collect dental x-ray

photons and convert them into electronic impulses that may be stored, viewed, and

manipulated for diagnostic use by dentists.

Before each usage, check the outer surface of the EzSensor Classic for any signs of physical

damage or defect. The surface of the EzSensor Classic should have a smooth finish, with no

evidence of chipping or damage. Otherwise, contact your local Product distributor for further

instructions on how to proceed.

To ensure the correct usage of the EzSensor Classic device in a clinical environment, for which

the intended purposes correspond to its design and application, only dentists or their designated

operators are authorized to operate this Product

Modifications and/or additions to the device must be conducted exclusively by

MANUFACTURER or by parties expressly authorized to do so by MANUFACTURER. Any

modifications or additions must always comply with the standards and generally recognized

rules of good workmanship.

It is the user’s responsibility to ensure compliance with all local safety regulations in effect in the

jurisdiction of installation.

4

Electrical safety

The covers of the Product may be removed only by qualified and authorized technical

personnel.

This Product can only be used in rooms or areas that comply with all laws and regulations

applicable to electrical safety on medical premises, such as IEC standards for the use of an

additional ground terminal for equipotential connections. This Product must always be

disconnected from the power supply before cleaning or disinfecting.

This Product should be connected with a device which is complied with IEC 60601-1.

Water and other liquids must be kept at a distance to avoid penetration of the Product. Liquids

may cause corrosion or the Product to short circuit. No protection is offered against liquid

penetration.

Explosion safety

This Product is not recommended for use in the presence of flammable gases or vapours.

Some disinfectants evaporate and form explosive or flammable mixtures. If disinfectants of this

kind are used, it is important to let the vapours disperse before using the Product again.

For the improvement of Product performance, supplementation, and follow-up of information,

the contents of this manual are subject to change without prior notice.

X-ray protection

The rules of dental radiography apply to digital X-ray systems. Please continue to use

protection for your patients. As a clinician, clear the immediate area when exposing the sensor.

5

1.4 Disposing of the Product

1. WEEE information according to directive 2002/96/EC

(Waste Electrical and Electronic Equipment)

The crossed-out wheeled bin symbol, that is present on the Product, means that

within the European Union the product must be taken to separate collection at the

product end-of life. Therefore, at the end of the life-cycle of the Product, the user

should deliver the device to the proper collection facilities of the Electric and

Electronic Equipments. Alternatively, the user can return the Product to the seller, on a oneto-one basis, as long as he or she is buying a new one of equivalent type and that fulfils the

same functions as the old one.

Disposing of the Product separately avoids possible negative consequences for the

environment and health deriving from inappropriate disposal and enables the constituent

materials to be recovered to obtain significant savings in energy and resources.

Who disposes any Electric and Electronic Equipment, reporting the above symbol, as

unsorted municipal waste, instead of collecting it separately, incurs the administrative

sanctions in accordance with law.

2. Label Location

The label can be found on the EzSensor Classic device.

6

Chapter 2 SYSTEM OVERVIEW

2.1 System Description

This manual covers the installation and operating procedures of the EzSensor Classic(

IOS-

U20VB, IOS-U15VB, IOS-U10VB, IOS-U20IB, IOS-U15IB, IOS-U10IB)

“collectively or individually

referred to as EzSensor or Product”.

Unless otherwise specified, all the information contained in this manual is applicable equally to

all EzSensor Classic types.

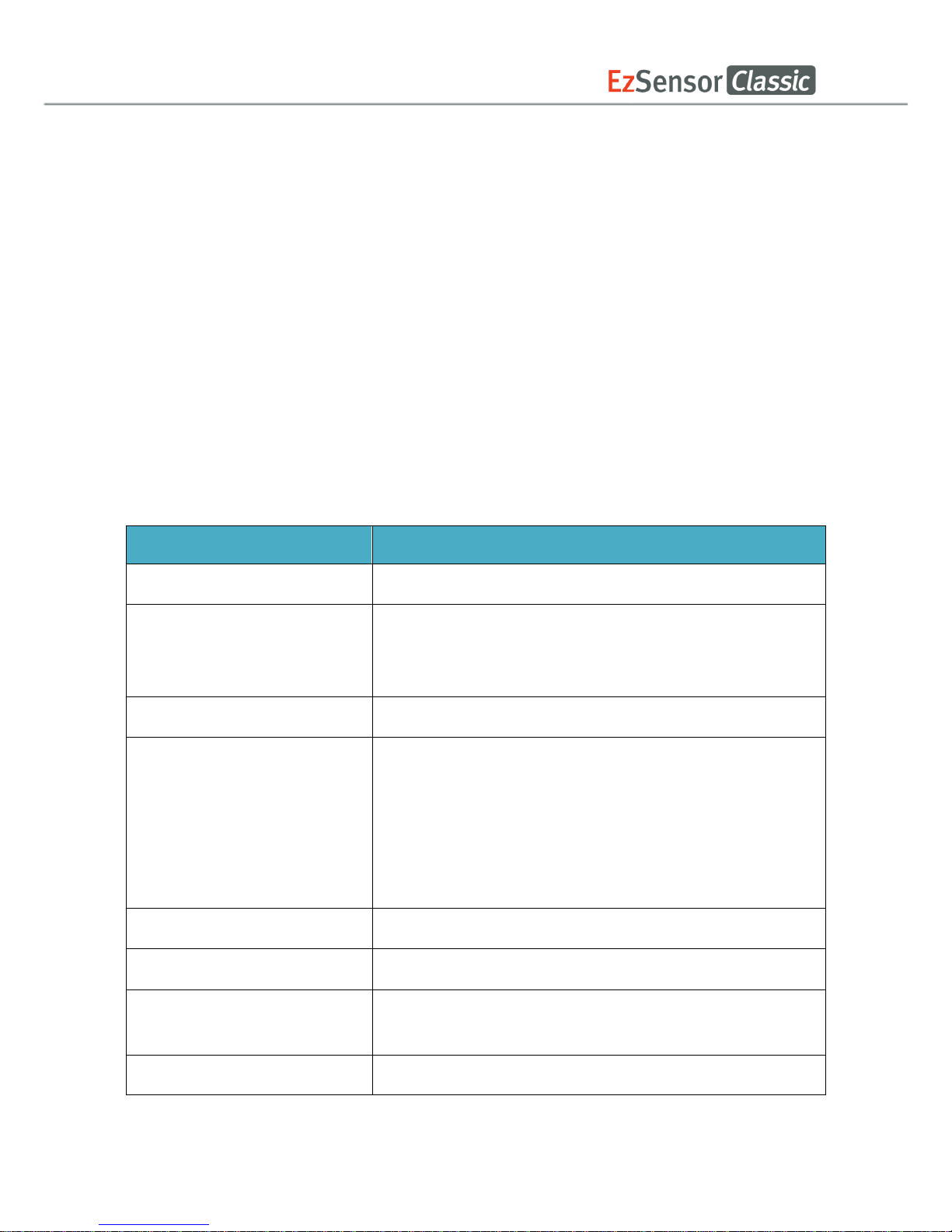

<Table 1. Specifications >

Parameter Description

Detector Structure CMOS Photodiode Array

Dimensions (W x L x T)

Size 1.0: 1.44 x 1.00 x 0.19 inch(36.8 x 25.4 x 4.8 mm)

Size 1.5: 1.55 x 1.15 x 0.19 inch (39.5 x 29.2 x 4.8mm)

Size 2.0: 1.69 x 1.28 x 0.19 inch(42.9 x 31.3 x 4.8 mm)

Pixel Pitch 0.0296 mm

Active Pixel Array

Size 1.0: 1014 x 676 pixels (30.01 x 20.01 mm)

Size 1.5: 1115 x 810 pixels (33.00 x 23.98 mm)

Size 2.0: 1216 x 878 pixels (35.99 x 25.99 mm)

Grayscale 4096 gray levels

Resolution Normal Resolution Mode : 16.89 lp/mm (theoretical)

USB Cable length

between Controller and PC

2.7 m

Electrical rating DC 5V, 500mA

7

Operation mode Global shutter

Ambient Temperature

10℃ to 30℃ (Usage)

-20℃ to 60℃ (Transportation and Storage)

Relative Humidity

30% to 95% (Usage)

10% to 95% (Transportation and Storage)

Air Pressure 700 to 1060 hPa

EU classification Medical Devices 93/42/EEC as a class IIa

Protection against shock Type B applied part

Protection against matter/water

IP 68

The Product has to be installed, transported and stored in the permissible

environmental conditions. Use the provided protective package for transporting or

storage. Also, the Product should not operate in oxygen rich or explosive

environments.

8

2.2 Product Components

The EzSensor Classic device installer should check the following items listed in the table

below before Productinstallation. If the serial numbers of the individual parts do not match, do

not install the Product. Contact your local distributor or agent for support.

This Product should be connected with a device or product which is complied with IEC 60601-1.

<Table 2. EzSensor Classic Product components>

No Components Remarks

1 Sensor Module* 2.7m USB cable is all in one

2 Wrap* (Hygienic Sleeves)

3 Holder for Sensor

4 Silicon cover*

5 S/W Installation CD(or USB)

EasyDent (or EzDent-i)

6 Driver Installation CD USB Device Driver

7

EzSensor Classic Manual

Document

* Patient applied part (Inside Patient environment)

Sensor Module:

Consists of a special CMOS sensor specifically designed for use in radiography and

enclosed in a hermetically sealed ergonomic capsule. The sensitive surface of the

sensor is covered with a thin layer of scintillating phosphorous, through which X-ray

radiation is converted into light and then into an electric charge.

9

Chapter 3 INSTALLATION

3.1 PC Specifications

1. Recommended Server PC Specifications

●Workstation

●Operating System: Window 2000 server or higher

●RAM: 4GB or Higher

●HDD: 1TB or higher

2. Recommended Client PC Specifications

● CPU: Core DUO CPU 1.8GHz or Higher

● Main Memory: 2GB of Higher

● Graphic Card : 512MB or Higher

● HDD: 2GB free space

● Display: 1280x1024x32bpp

3. Operating System

● Window 34&64bit: XP(SP1), Vista, 7, 8, 8.1

We cannot guarantee that EasyDent (EzDent-i) will work properly with an

unregistered copy of Microsoft Windows. Therefore, you should use a

registered, genuine version of Microsoft Windows

....

Turn off the Windows Firewall service for proper communication across the

network for the installed database and file servers.

If you need to install additional software on your computer, please install

only those that are internationally authorized. Take extra precaution when

installing any Active-X controls.

3.2

Installation of Software Driver

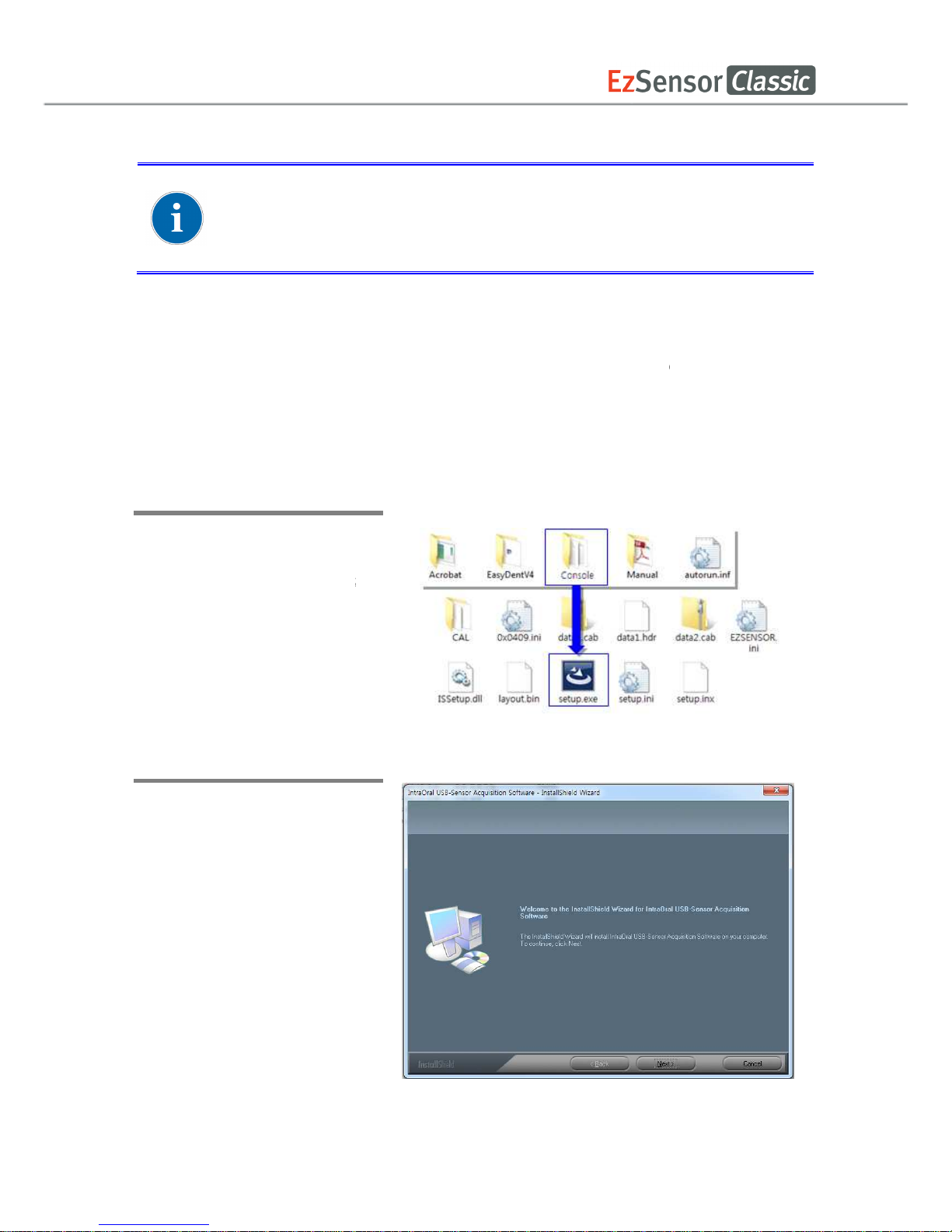

3.2.1

EzSensor Classic

This step is necessary

for the

Calibration data for the

EzSensor Classic

Windows device driver

. A Twain driver is also installed

Step 1

Insert the S/W

Installation CD in

the CD-ROM.

Setup should start

automatically.

If it does not, click Start>Run

and type

Homedirctory:\Console\

setup.exe

Step 2

The install program for ‘

IntraOral

USB-Sensor Acquisition

Software’

will appear. Click the

‘Next’ button.

To operate the intraoral sensor, you need to install the

Driver.

This Product

should be connected with the product

complied with IEC60601

10

(

IOS-U20VB, IOS-U15VB, IOS-U10VB)

Driver Setup

installation of EzSensor Classic.

Capturing software and

will be installed

and downloaded

during this step.

EzSensor Classic

or the device

-1

along with the

EzSensor Classic

which is

Step 3

Check the EzSensor Classic

installation directory and

then

click the ‘Next’ button.

Step 4

The Install shield Wizard will

start configuring the

installation parameters.

The Install-shield wizard will

Copy the calibration files

To your work-station (PC).

Step 5

The Install-shield wizard will

be done.

11

12

3.2.2 Cable connection & Driver Installation

Step 1

Connect the EzSensor

Classic USB Connector to the

USB port on the PC directly.

Be sure to connect the USB

port on backside for

accurate operation.

Do not connect the EzSensor Classic and USB PC Interface cable to your

computer until you have successfully installed the setup program.

Only connect the item that has been specified as part of the Medical

Equipment System.

13

Step 2

Confirmation of Driver installation at the Device Manager.

Method of Confirmation:

Windows 7 : Control Panel System and Security System Device Manager

Windows XP : Settings Control Panel System Hardware Device manager

Select ‘VH EzSensor-N x.x’, located under Imaging Devices. You should see the

message, “This device is working properly”.

EzSensor Classic is supplied to the power and transports data via the USB

port of the PC. Do not disconnect during usage.

14

3.3 Installation of the EzSensor Classic Holder

The EzSensor Classic holder is used for mounting the EzSensor Classic to the wall when not

in use.

When choosing where to install the EzSensor Classic, locate an area that offers easy access

and visibility during patient examinations.

Position the holder on a stable, flat surface. Using the holes at the back of the holder as guides,

fasten the holder securely to the wall using two dry wall screws (included).

15

Chapter 4 Image Acquisition by using EasyDent

4.1 Installation of EasyDent

In this step, EasyDent will be installed. Alternatively, software which supports the Twain

interface can be used instead of EasyDent.

Step 1

Insert the S/W installation CD in

the CD-ROM drive.

Homedirectory:\EasyDent\setup.exe

. Press ‘Enter’.

Step 2

Select the language you want to

install and then click ‘Next’.

16

Step 3

The ‘EasyDentV4 Install Shield

Wizard’ will appear. Click the

‘Next’ button.

Step 4

Select the setup type that best

suits your needs.

Click the ‘Next’ button.

Basic : Installs the basic

version of EasyDent V4

CD-Publishing : Installs the

basic version of EasyDent V4

along with CD-Publishing

capabilities (optional)

For the EasyDent server, select all items.

For PC being used for viewer: Select only the items except for DB & File

servers.

For the detailed installation, refer to the EasyDent installation manual.

17

Step 5

Select the features that you

want to install. Click the ‘Next’

button.

EasyDent Viewer is the

minimum requirement for

EzSensor Classic use.

Step 6

Now you are ready to install.

If you would like to review any

of your installation settings,

click ‘Back’. To proceed with

the installation, click ‘Install’.

Click ‘Cancel’ to exit the

wizard.

18

Step 7

Installing EasyDentV4

Step 8

The program compatibility and

Windows Firewall alarm

messages are shown.

Click 'Run program' button on

the program compatibility

message.

And click 'Allow access' button

on the windows security

message.

19

Step 9

MSDE(Microsoft SQL server

Desktop Engine) is installed

automatically.

Close the SQL Server Service

Manager.

Step 10

Select ‘No, I will restart my

computer later’, and then click

‘Finish’.

20

4.2 Image Acquisition Overview

① Turn on the computer.

② Run the EasyDent.

③ Configure the required X-ray parameters (exposure time, etc.) for the X-ray generator.

④ Before use the sensor, shooting the X-ray with putting the coin on flat receptor of the

sensor is recommend as an operation test.

⑤ Position the EzSensor Classic (IOS-U20IB, IOS-U15IB, IOS-U10IB) at the appropriate

area in the mouth. The flat receptor side of the sensor must face the X-ray source. Note

that the receptor side is marked with a label for ease of recognition

The use of the sensor positioning aid is recommended to guarantee that the sensor is

parallel to the tooth and is at the appropriate angle for exposure.

⑥ The use of the parallel technique with a positioning system or device, if possible, is

highly recommended.

⑦ After preparing the sensor for exposure, acquire an image by pressing the exposure

button of your X-ray source.

Using the EzSensor Classic

with intraoral X-ray

Using the EzSensor Classic

with a Sensor positioning system(optional)

21

4.3 Running the EasyDent

Shot functions are available after patient registration and device selection. Single shot, multi

shot, sequence shot are used frequently. You must be fully aware of the explanations before

capturing image.

4.3.1 Patient Registration and Device Selection

Step 1

Turn on the PC.

Run EasyDent4 Viewer. Click the ‘Patient ( )’ button to register a new patient.

22

Step 2

The new patient registration window will appear. You are asked to register the new patient

and click “Add”.

Step 3

Click ‘Help > Intra-Oral Sensor Setting > Select Device’ on the menu bar.

Select your capture device. At this time, you are asked to select the device and image

quality.

The Productand image processing setting information is stored internally. Change these

settings when using another sensor or changing the image processing option.

Level 4 is basic image processing option. As the level no. is higher, the effect of contrast

and enhancement get increased.

①

Level 1

②

Level 2

③

Level 3

④

Level 4

⑤

Level 5

⑥

Level 6

⑦

Level 7

23

4.3.2 Single Shot

Capture a single image.

Step 1

Start EasyDent by clicking the EasyDent V4Viewer on the desktop.

Search and enter the appropriate patient information.

24

Step 2

Click the ‘Layouts’ tab. Select your favorite layout from the Layout template list.

The Layout Template can be customized. Please refer to the EasyDent manual.

Step 3

Select the ‘Single’ from the Shoot Type list.

25

Step 4

Select the tooth position to capture. The tooth box is selected in blue.

Step 5

Click the ‘SENSOR ( )’ button or ‘Capture ( )’ button.

Step 6

Position the sensor correctly.

26

Step7

After checking the sensor is in the correct position, expose the X-ray after the “Please

expose X-ray” message appears.

The message, “Optimizing Image… Please wait” appears while the image is being

optimized. The image will appear after optimization is complete.

27

4.3.3 Multi Shot

You can capture multiple images continuously until you click stop. Click and drag the image to

its appropriate position after stopping capture.

Step 1

Select the ‘Multiple’ from the Shoot Type list.

28

Step 2

Select the tooth position to capture. A blue rectangle will be drawn on the tooth box.

Step 3

Click the ‘SENSOR ( )’ button or ‘Capture ( )’ button.

Step 4

Position the sensor correctly.

29

Step5

Expose the X-ray after the “Please expose X-ray” message appears.

The message, “Optimizing Image… Please wait” appears while the image is being

optimized.

30

Step 6

If you want to acquire more images, continue to expose the x-ray when the ‘Press the X-ray

(shot) button’ message appears.

To finish, double click on the ‘Press the X-ray (shot) button’ message box. And then the

image will appear after optimization is complete.

Step 7

Click and drag the image to its appropriate position.

31

4.3.4 Sequence Shot

You can capture multiple images according to a pre-saved order. Capturing according to the

order will ensure the images appear automatically in the correct positions.

Step 1

Select your favorite sequence from the Shoot Type list. Red numbers represent the capture

order.

The Sequence shot can be customized. Please refer to the EasyDent manual.

Step 2

Click the ‘SENSOR ( )’ button or ‘Capture ( )’ button.

Step 3

Position the sensor correctly.

32

Step 4

Capturing according to the order, the images appear automatically in the correct positions.

Expose the X-ray after the “Please expose X-ray” message appears.

The message, “Optimizing Image… Please wait” appears while the image is being

optimized.

33

Step5

If you want to finish, double click the ‘Press the X-ray (shot) button’ message box. And then

according to the capturing order, the images appear automatically in the correct positions.

All images are saved in the Database server automatically.

By double clicking on the image, the image is shown as large size at any

function’s table.

34

Chapter 5 Image Acquisition by using EzDent-i

5.1 Installation EzDent-i

In this step, EzDent-i will be installed. Alternatively, software which supports the Twain interface

can be used instead of EzDent-i.

Step 1

Open [Setup.exe] from [Setup]

folder to install EzDent-i Sever

or Client for Windows.

Step 2

The window for selecting

installation mode will be

shown. To setup the Server

environment, start the

installation by clicking the

[Server] button.

35

Step 3

The window for component

setting will be displayed

After selecting programs to

install among EzServer,

Consult Data, and Implant DB,

click the [EzServer] button.

Step 4

To continue click the [Next]

button, followed by the [install]

button to proceed.

When the installation of EzServer is complete, the other components

(Consult Data and Implant DB) will automatically start installing.

If users did not select any other components, the installation is finished

.

36

Step 5

Users can select the

installation type of Implant DB,

If users prefer to install

multiple fixture models, select

[complete], click the [Next]

button to proceed.

Step 6

In case that [Custom] in

implant DB is selected, Select

the name of manufacturers

you want to install and click

the [Next] button to go

forward.

If users prefer to install the implant models separately, select [Custom] and

click the [Next]button

37

Step 7

Compile [setup.exe] and click

the button, [EzDent-i],

‘The License Agreement’

window will be shown. If the

conditions are acceptable,

select

[I accept the terms of the

license agreement] and click

[Next] button.

38

Step 8

Type in the company and user

name and click the [Next]

button

Step 9

After specifying the location to

install the program, click the

[Next] button to go forward.

39

Step 10

After installation of EzDent-i

Console is complete, select

[Yes, I want to restart my

computer now] and click the

[Finish] button. Then, the PC

will be restarted.

It is strongly recommended to restart the PC to apply the changes

occurring in the system during the EzDent-i installation.

5.2

License Activation

Step 1

Connect the USB Dongle Key

to the PC, and open VTNL.

exe

Opening VTNL

To open VTNL program, install ADB.exe file first. If the executable file is

not installed, the installation process of ADB program will automatically

start when opening VTNL program.

40

.

Step 2

The following License

Activation Wizard appears if

you have not activated a

license previously

Select the dongle key (first)

item, and then click the

[Next] button.

Step 3

When the following VT

License Plug in Option

Window appears, select the

license key from the list and

install by clicking the [OK]

button.

41

Step 4

After clicking the [OK] button,

the following VT License

Activation Wizard window

appears. Once the license has

been activated, click on the

[Finish] button to complete

your activation. EzDent-i will

then run automatically.

Once the license has been activated, the user

of [Certifications] in the VTNL window.

The

dongle license key number appears on the list of [Volume] in the

VTNL window.

42

’

s PC will appear on the list

43

5.3 Consult DB License Activation

Step 1

Open[Setup.exe] from [Setup]

folder to install EzDent-i

Server or Client for Windows

Step 2

After selecting the install

modes, Click the [Consult

License Activator] button

Consult DB is for the users who have a Consult Premium License. After

activating Consult DB License, the user can utilize video contents for

consultation use.

44

Step 3

After checking the license

information shown at the

Consult Data License Activator

window, Click the [Activate]

button.

Step 4

Select the second option

from the VTLicense

Activation Wizard window.

For activating license using the license key, an internet connection must

be available with the PC.

45

Step 5

Enter the EzDent-i user

information and license key

provided. And then click the

[Next] button. You must enter

more than 3 characters to

activate the [Next] button.

Step 6

Upon successful activation,

the VTLicense Activation

Wizard window will appear,

including the remaining days.

Click the [Finish] button to

end the activation.

.

46

5.4 Preparing for Image Acquisition

① Turn on the computer.

② Run the EzDent-i.

③ Configure the required X-ray parameters (exposure time, etc.) for the X-ray generator.

④ For the operation test before X-ray exposure to patients, X-ray exposure as putting the

coin on flat receptor of the sensor is recommend.

⑤ Position the EzSensor Classic at the appropriate area in the mouth. The flat receptor

side of the sensor must face the X-ray source. Note that the receptor side is marked

with a label for ease of recognition

The use of the sensor positioning aid is recommended to guarantee that the sensor is

parallel to the tooth and is at the appropriate angle for exposure

⑥ The use of the parallel technique with a positioning system or device, if possible, is

highly recommended.

⑦ After preparing the sensor for exposure, acquire an image by pressing the exposure

button of your X-ray source.

Using the EzSensor Classic

with intraoral X-ray

Using the EzSensor Classic

with a Sensor positioning system(optional)

47

5.5 Running the EzDent- i

5.5.1 Patient Registration

Step 1

Turn on the PC. Run EzDent-i. Click the ‘Patient ( )’ button to register a new patient.

Step 2

The “Add Patient” registration window will appear. Register the new patient and click “Add

.”

48

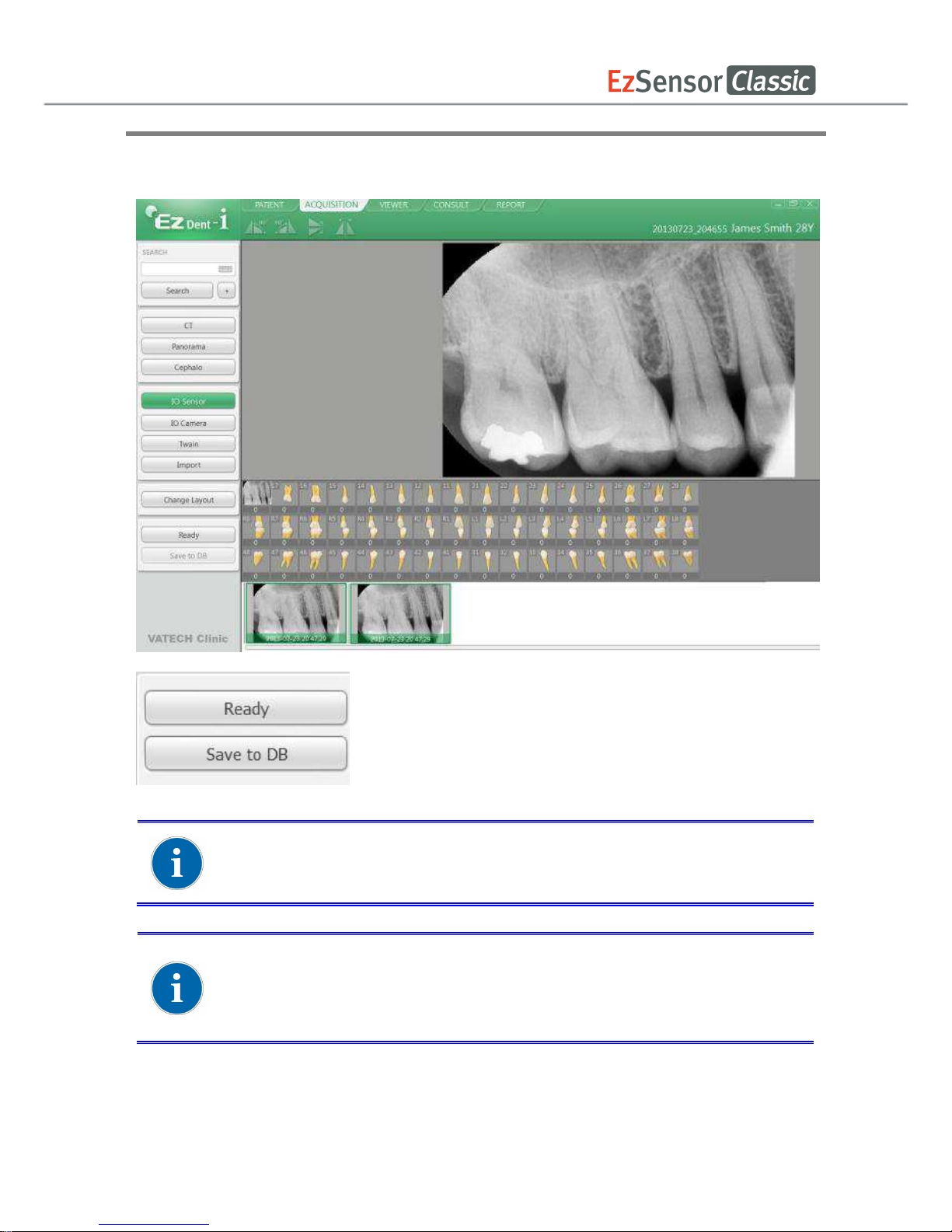

5.5.2 Acquiring Image

Step 1

The Acquisition Tab allows the user to capture/store images with the IO Sensor.

Step 2

Click the [IO Sensor] button in the Acquisition tab. Once the IO sensor is connected, the layout

will change depending on the selected device.

49

Step 3

Click the [Ready] button after positioning the patient. If the IO Sensor equipment is

properly connected, the image acquisition mode will be initiated.

Step 4

Using the exposure switch, shoot the x-ray and the image will be acquired.

The process of acquiring the image is complete.

By double clicking the workspace from the ACQUISITION tab, EzDent-i

will be ready for image acquisition. The [Ready] button provides the same

function.

Double Click

50

Step 5

Select the images from the thumbnails, and then click the [Save to DB] button. The captured

images will be stored in the DB.

If the user wants to select more than 2 images, hold the Ctrl key on the

keyboard and click the desired images from the thumbnails.

To change the way of storing the acquired images, change the

options in settings. With the option “Auto DB Save,” all acquired

images are automatically stored in DB. Another option, Manual, only

stores selected images in DB.

51

5.5.3 Image View

Step 1

Enter the name or chart number of the patient in the Patient Search window and click the

[Search] button or press the Enter key. The search result will appear.

Step 2

Double Click the selected “Patient List”.

The images will be displayed in the VIEWER tab.

52

Chapter 6 Maintenance

For optimal performance, MANUFACTURER recommends the working area be kept clean.

There are no specific cleaning requirements for the EzSensor Classic beyond normal care

and attention for aesthetic appearances.

6.1 Visual Inspection

Like all electrical systems or device, EzSensor Classic requires not only correct usage, but

also visual inspection prior to operation, as well as routine checks at regular intervals. These

precautions will help ensure that the Product operates accurately, safely, and efficiently.

Before use, the operator should check the Productfor any signs of physical damage or defects.

If something out of order is suspected, contact your local Product distributor for further

instructions on how to proceed.

6.2 Periodic Maintenance

Periodic maintenance should be performed as necessary and in accordance with monitored

frequency in the table below. Maintenance should consist of various checks performed by the

operator or by a qualified service technician.

●Check that all cables connected to the EzSensor Classic are undamaged.

●Check for any external damage to the EzSensor Classic that may compromise its ability

to be safely operated. If the EzSensor Classic is defective, the sensor should be returned

to the manufacturer for repair.

●Arrange the sensor and the control box USB cable to prevent damage of the cable’s

rubber tube. They should not be stepped on nor bent and pressed under table legs.

A qualified service technician is a person authorized by Manufacturer or its

distributors.

53

6.2.1 Test List

Test Item Frequency Equipment

Connection

Daily Sensor & PC

Cable

Monthly Cable

Resolution

Annually

Resolution Patterns, Gammex Rmi

6.2.2 Connection

●Object

Check the normal operation of PC when the sensor is connected to the PC

●Procedure

1. Connect the EzSensor Classic USB Connector to the USB Port

2. Confirmation of Driver installation at the Device Manager

Method of Confirmation:

Windows 7: Control Panel System and Security System Device Manager

Windows XP: Settings Control Panel System Hardware Device manager

54

3. Select ‘VH EzSensor-N x.x’, located under Imaging Devices. You should see the

message, “This device is working properly”.

6.2.3 Cable

●Object

Prevent the sensor malfunction caused by the occurrence of external cable stress.

●Procedure

1. Arrange the sensor and the control box USB cable to prevent damage of the cable’s

rubber tube. They should not be stepped on nor bent and pressed under table legs.

2. Check that all cables connected to the EzSensor Classic are undamaged.

6.2.4 Resolution

●Object

Verify the resolution of EzSensor Classic

●Procedure

1. Run EasyDent (EzDent-i) with connecting EzSensor Classic.

2. Attach resolution phantom on the center of the detector with diagonal direction.

3. Set X-ray Condition to 60~70kVp 50mAs and SID to 28cm

4. Confirm that the resolution is over 8lp/mm.

55

6.3 Care and Cleaning

In order to prevent infection, wipe the front plate of the sensor unit with ethanol or

glutaraldehyde solution to disinfect it each time a different patient uses the instrument. If you

plan to use a disinfectant other than those specified above, or you are mixing another

disinfectant with ethanol, please consult a specialist because it may damage the plate.

To clean the EzSensor Classic, the following solutions are listed below. Please observe the

precautions noted.

●Mild soap and water

●Isopropyl alcohol (70%)

●Most alcohol and ammonia based cleaners

●Mild, non-abrasive cleaners

Do not soak or immerse any part of the Product, and be sure to dry it completely after cleaning.

Clean the surface of the Product by moistening it with a soft cotton swab dipped in one of the

cleaning solutions listed above. Gently wipe the surface end-to-end in straight lines, without

applying any pressure. Make sure the liquid does not penetrate the Product through the USB

cable or the sensor cable connectors.

After cleaning the surface of the EzSensor Classic, use a clean lint-free cloth to dry the

Product, as required, until the surface is clean.

※Clean the silicone cover using the same method.

※Do not use the following cleaning materials.

●Hard brushes or scrapers of any kind

●Strong acids or alkaloids

6.4 Precautions

●Do not soak the sensor in water or alcohol.

●Authorized service personnel can repair calibration issues.

●Service personnel cannot handle problems that are not mentioned in this manual.

Please request repairs to the manufacturer through a VATECH dealer.

●Equipment and accessories are to be disposed safely at the end of the Product life

cycle. National regulation must be observed.

56

6.5 Product complaint

Any health care professional (e.g., a customer or user of Product or system) who has any

complaints should notify his or her distributor first, who will handle such issues.

If the Product may have caused or contributed to a serious injury of a patient, your distributor

should immediately notify the manufacturer by telephone, fax, or written correspondence. The

manufacturer will report it to the government according to their reporting process.

Do not modify this equipment without authorization of the manufacturer.

57

Appendix

A.1 X-ray Exposure Guide

The required X-ray dose for the best image is dependent on the following:

- X-ray source (tube assembly, manufacturer, AC/DC, etc.)

- Distance between beam focus and sensor

- Tooth (object) to be X-rayed

- Bone density and age of patient

- Miscellaneous circumstances, etc.

The X-ray dose influences image quality. Based on fundamental laws of physics, an insufficient

dose generally means higher image noise, which leads to poor detail discrimination. On the

other hand, an excessively high dose can cause the sensor to be overexposed. This is also

perceptible by a decrease in detail discrimination, specifically in darker areas.

The effect of image processing reduces the difference between image qualities of different

doses. Users can adjust brightness and contrast in the option menu.

The recommended exposure dose is from 300µGy to 600µGy when measuring without an

object. Exposure time corresponding to the dose may vary depending on the X-ray equipment

used. Recommended exposure times according to positions are as shown on the Exposure

Time Table.

The X-ray dose is maintained through tube voltage (kVp) and current (mA), as well as exposure

time according to the signal level.

Since the exposure time depends on the diagnostic problem as well as the

clinical situation, the selection of an adjustment is the responsibility of the

treating physician.

Image degradations caused by overexposure of the sensor cannot be

compensated, but an insufficient dose can be partially compensated

through image processing.

58

<Table 4. Recommendation on Exposure Time >

Exposure

condition

Dose

(μGy)

60kvp

6mA

60kVp

2mA

65kVp

5mA

Patient

Adult Adult Adult

SID 28cm 18cm 28cm

Intra Oral X-ray Unit

(Model name)

No

Filter

VX 70 AnyRay ESX

Approximate Exposure Time (sec)

Incisor

&

Canine

300 ~ 500

0.12 ~ 0.2 0.1 ~ 0.2 0.18 ~ 0.28

Molar 400 ~ 600

0.16 ~ 0.25 0.15 ~ 0.25 0.24 ~ 0.34

* SID : Source to imaging receptor Distance

*Recommendation on Exposure Time is limited to Intra Oral X-ray Unit in the above table

For larger body types : increase the source current by 25%

For children(5~21age) : reduce the source current (or Exposure time)

by 20%

For edentulous patients : reduce the source current by 20%.

Since the X-ray exposure condition can be changed depending on the age,

gender and bone density of the patient, in case of Pediatric, X-ray exposure

condition can be changed by expert’s judge.

For further information, please refer to FDA Pediatric X-ray Imaging

webpage,

http://www.fda.gov/radiationemittingproducts/radiationemittingproductsandprocedures/medicalimaging/ucm298899.htm)

The X-ray dose required for image acquisition can vary depending on the Xray source and environmental circumstances. You must maintain the

exposure time and change the kVp and mA values according to the signal

level. In addition, if the X-ray source and the distance to the sensor were

changed during the initial installation, the distance (from cone to detector)

must be changed to the 80mm setting.

The exposure time may vary depending on the age, gender, and bone

density of the patient.

59

A.2 Error Message

1. USB device driver is not installed.

● Solution: Please install the device driver again.

2. Control box cannot be initialized.

● Solution: Check and re-connect the USB PC cable.

3. USB device driver is not working properly.

● Solution: Re-install the driver.

4. Capture program is already running.

● Solution: Please close any other programs.

5. Detector response time-out.

● Check and re-connect the USB PC cable. Please try again.

If the same message is displayed again, contact Customer Service.

6. Data communication error.

● Solution: Re-connect the USB PC cable.

7. Canceled image capturing.

●This means that the user canceled image capture. Please try again.

8. Cannot find dark frame.

●Solution: Restore the EzSensor Classic’s calibration data from the S/W installation CD

or re-calibrate the sensor. If the same message is displayed again, contact Customer

Service.

9. Cannot find bright frames for calibration.

● Solution: Reinstall the EzSensor Classic driver.

10. Bad Pixel Map correction error.

●Solution: Restore the EzSensor Classic’s calibration data from the S/W installation CD

or re-calibrate the sensor. If the same message is displayed again, contact Customer

Service.

60

11. Wrong image processing parameters.

● Solution: Check the X-ray source. If the problem persists, call for technical assistance.

12. Cannot load 'EzSensor.dll'.

●Solution: Please re-install the acquisition software.

13. Require 'EzSensor.dll' was damaged.

●Solution: Please re-install the acquisition software.

61

A.3 Troubleshooting

If you experience any problems regarding the EzSensor Classic during operation, please refer

to the troubleshooting table below for corrective measures. If the problem persists, please

contact your local Product distributor.

<Table 5. Troubleshooting Table>

Item

Description Corrective Measure

1

A ‘PID 2XXX NO; #0 (Check

Connection)’ error message is

displayed.

Unplug the USB PC cable from the PC

connector.

Open the Windows Device Manager and

check that the device is installed correctly.

Alternatively, try another USB port on your

computer.

62

A.4 Electromagnetic Compatibility Information

Guidance and manufacturer’s declaration – electromagnetic emissions

The Product is intended for use in an electromagnetic environment as specified below. The customer or

the user of the Product should ensure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR 11

Group 1 The Product uses RF energy only for its internal functions.

Therefore, its RF emissions are very low and are not likely to

cause any interference to nearby electronic equipment.

RF emissions

CISPR 11

Class A The Product is suitable for use in all establishments, including

domestic establishments, and those directly connected to a

personal computer USB port used for domestic purposes.

Harmonics

emission

IEC 61000-3-2

A

Voltage

fluctuation

IEC 61000-3-3

Complies

Guidance and manufacturer’s declaration – electromagnetic emissions

The Product is intended for use in an electromagnetic environment as specified below. The customer or

the user of the Product should ensure that it is used in such an environment.

Immunity test IEC 60601

test level

Compliance

level

Electromagnetic environment –

guidance

Electrostatic

discharge (ESD)

IEC 61000-4-2

± 6 kV contact

± 8 kV air

± 6 kV contact

± 8 kV air

Floors should be wood, concrete or

ceramic tiles. If floors are covered with

synthetic material, relative humidity

should be at least 30%.

Electrical fast

transient/burst

IEC 61000-4-4

± 2 kV for power

supply lines

± 1 kV for

input/output lines

± 2 kV for power

supply lines

± 1 kV for

input/output lines

Mains power quality should be that of a

typical commercial or hospital

environment.

Surge

IEC 61000-4-5

± 1 kV differential

mode

± 2 kV common

mode

± 1 kV differential

mode

± 2 kV common

mode

Mains power quality should be that of a

typical commercial or hospital

environment.

Voltage dips,

short interruption,

and voltage

variations on

power supply

input lines

IEC 60601-4-11

< 5 % U

T

(> 95 % dip in UT)

for 0.5 cycles

40 % U

T

(60 % dip in UT)

for 6 cycles

70 % U

T

(30 % dip in UT)

for 30 cycles

< 5 % U

T

(> 95 % dip in UT)

for 5 s

< 5 % U

T

(> 95 % dip in UT)

for 0.5 cycles

40 % U

T

(60 % dip in UT)

for 6 cycles

70 % U

T

(30 % dip in UT)

for 30 cycles

< 5 % U

T

(> 95 % dip in UT)

for 5 s

Mains power quality should be that of a

typical commercial or hospital

environment. If the user of the Product

requires continued operation during

power mains interruptions, it is

recommended that the Product be

powered from an uninterruptible power

source or battery.

Power frequency

3.0 A/m 3.0

A/m

Power frequency magnetic fields should

63

(50/60 Hz)

IEC 61000-4-8

be at levels characteristic of a typical

location in a typical commercial or

hospital environment.

Conducted RF

IEC61000-4-6

3 Vrms

150 kHz to 80MHz

3 Vrms

150 kHz to

80MHz

Portable and mobile RF communications

equipment should be used no closer to

any part of the Product, including cables,

than the recommended separation

distance calculated from the equation

applicable to the frequency of the

transmitter.

Recommended separation distance

Radiated RF

IEC61000-4-3

3 V/m

80 MHz to 2.5GHz

3 V/m

80 MHz to

2.5GHz

Recommended separation distance

Where P is the maximum output power

rating of the transmitter in watts (W)

according to the transmitter manufacturer

and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF

transmitters, as deter-mined by an

electromagnetic site survey,

(a) Should be less than the compliance

level in each frequency range (b).

Interference may occur in the vicinity of

equipment marked with the following

symbol:

Note 1)Uт is the A.C. mains voltage prior to application of the test level.

Note2) At 80 MHz and 800 MHz, the higher frequency range applies.

Note3) These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with

accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey

should be considered. If the measured field strength the location in which the Product is used exceeds the

applicable RF compliance level above, the EUT should be observed to verify normal operation. If abnormal

performance is observed, additional measures may be necessary, such as re-orienting or relocating the Product.

b Over the frequency range 150 kHz to 80 MHz, field strengths should be less than [V1] V / m.

64

Recommended Separation Distances Between Portable and Mobile RF

Communications Equipment and the Product.

The Product is

intended for use in an electromagnetic environment in which radiated RF disturbances

are controlled. The user The Product

can help prevent electromagnetic interference by maintaining a

minimum distance between portable and mobile RF communications equipment (transmitters) and

The

Product

as recommended below, according to the maximum output power of the communications

equipment.

Rated maximum output

power (W) of transmitter

Separation distance (m) according to frequency of transmitter

150 kHz to 80 MHz 80 MHz to 800 MHz 800 MHz to 2.5 GHz

0.01 0.12 0.12 0.23

0.1 0.37 0.37 0.74

1 1.17 1.17 2.33

10 3.70 3.70 7.37

100 11.70 11.70 23.30

For transmitters rated at a maximum output power not listed above, the recommended separation di

stance (d) in meters (m) can be estimated using the equation applicable to the frequency of the

transmitter, where P is the maximum output power rating of the transmitter in watts (W) according

to the transmitter manufacturer.

N

ote 1:

At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies

Note 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects, and people.

65

Copyright by © 2013 Rayence

The information in this document is subject to change without notice and

does not represent a commitment on the part of the vendor.

This document contains materials protected under International Copyright

Laws. All rights reserved. No part of this manual may be reproduced,

transmitted, or transcribed without the expressed written permission of the

manufacturer and authors of this manual.

If you do not properly set the Product, which in turn causes the Product to

malfunction or fail, we cannot guarantee any responsibility.

Rayence Co., Ltd.

Web Sitewww.rayence.com

14, Samsung 1-ro 1-gil, Hwaseong-si, Gyeonggi-do, Korea

CE symbol grants the product compliance to the European

Directive for Medical Devices 93/42/EEC as a class IIa device.

Authorized by SGS United Kingdom Ltd

VATECH Dental Manufacturing Ltd.

Chancery House, St. Nicholas Way, Sutton, SM1 1JB UK

Tel: +44 020 8652 1900, Fax: +44 020 8652 1909

VATECH America Inc.

2200 Fletcher Ave. Suite 705A, Fort Lee, NJ07024

Tel: +1 888 396 6872

Document No. R-USM-711

Release Version 1.3

Dated Apr. 5, 2016

Distributed by

Vatech Global

13

, Samsung 1

0

-ro 2-gil, Hwaseong-si,Gyeonggi-do,

Korea

Loading...

Loading...