EzSensor

User Manual

Attention

For improvement of product performance, supplementation, or follow-up of information, the contents of this

manual are subject to change without prior notice.

Please note that our company will have no responsibility for accidental damage nor be obligated to perform

warranty service for any damage to equipment due to user error, which is a result to properly follow the

contents of this manual.. Become familiar with the safety precautions and usage procedures for this product.

Note that the product may slightly differ from the contents of this manual depending on individual product

specifications.

The following symbols are used throughout this manual to provide effective use of this product

Indicates useful information and tips on how to use our software and

product.

Indicates important instructions. If not observed, malfunction or damage to

the system or other property may occur.

Indicates warnings and instructions for safety. If not adhered, serious risks

and injury may be caused to the patient and the operator.

1

Safety Procedures

The device must be installed and used in accordance with the safety regulations and instructions supplied

in this user manual for the purposes and applications which it is intended for.

Before each usage, check the outer surface of the EzSensor for any signs of physical damage or defect.

The surface of the EzSensor should have a smooth finish, with no evidence of chipping or damage.Otherwise,

contact your local distributor of VATECH & E-WOO products for further instructions on what to do.

To ensure correct usage of the EzSensor device in a clinical environment, for which intended purposes

correspond to its design and application, only dentists or their designated operators are authorized to

operate this system.

Modifications and/or additions to the device must be done exclusively by VATECH & E-WOO personnel or

by parties expressly authorized for the purpose by VATECH & E-WOO. Any modifications or additions must

always comply with the standards and generally recognized rules of good workmanship.

It is the user’s responsibility to ensure compliance with all local safety regulations in effect in the

state/country of installation.

Electrical safety

The covers of the device may be removed only by qualified and authorized technical personnel.

This device can only be used in rooms or areas which comply with all laws and regulations applicable to

electrical safety in the medical premises, such as CEI standards for the use of an additional ground terminal

for equipotential connections. This device must always be disconnected from the power supply before

cleaning or disinfecting.

Water and other liquids must not be permitted to penetrate inside the device, where they could cause short

circuit or corrosion. No protection is supplied against liquid penetration.

Explosion safety

This device is not recommended to be used in the presence of flammable gases or vapours. Some

disinfectants evaporate and form explosive or flammable mixtures. If disinfectants of this kind are used, it is

important to let the vapours disperse before using the device again.

For improvement of product performance, supplementation, or follow-up of information; the contents of this

manual are subject to change without separate prior notice.

2

Symbols

Symbols Descriptions

Item Symbol

1

2

3

4

Label Location

Description

Authorized representative in the European Community.

Type B applied

Indicates to the user to check the accompanying documents (this User

Guide) for more information about EzSensor.

Handle with care

The E-WOO TECHNOLOGY logo and the following label can be found on the EzSensor device.

• Medical Image Processing Unit

• Model : EzSensor

• SN : EZS-00000000 Date :

Contents

Contents

1. INTRODUCTION ......................................................................................................5

1.1. System Description ....................................................................................................... ............................... ..................................................5

1.2. System Components ................................................................................................................... ............................................7

1.3. Cone indicator (Optional) ............................................................................................................. .......................................10

2. HARDWARE INSTALLATION .............................................................................11

2.1. General Information ............................................................................................................. .................................................11

2.2. Specifications

.................................................................................................................... .......................................................11

2.3. Cable Connection & Driver Installation

...................................................................................... ....................................14

2.4. Installation of the EzSensor Holder ...........................................................................................................................................................19

3. SOFTWARE SETUP AND USAGE .......................................................... .........................20

3.1. Installation of EasyDent V4

................................................................................................................... .............................20

3.2. Image Acquisition with EzSensor ..................................................................................................................... .................25

3.3. Running the EasyDent V4 ............................................................................................................. .......................................26

4. MAINTENANCE .......................................................................................................35

4.1. Visual Inspection ..................................................................................................................................... ...............................35

4.2. Periodic Maintenance .............................................................................................................................................................35

4.3. Cleaning .................................................................................................................................................... .................................35

5. WARRANTY ........................................................................................................................36

APPENDIX ....................................................................................................................37

1. LED Indicators .....................................................................................................................................................................................................37

2. X-ray Exposure Guid

................................................................................................................................. ...............................38

3. Error Code

.....................................................................................................................................................................................42

4. Troubleshooting

...........................................................................................................................................................................45

4

1. Introduction

1. Introduction

1.1. System Description

EzSensor is a modern digital imaging solution for intraoral dental radiography. Its advanced CMOS

technology provides excellent image quality. For patient comfort, the EzSensor’s ergonomic design is

based on human intraoral anatomy.

EzSensor is a digital X-ray imaging system designed specifically for dental radiography within the oral cavity.

The system captures X-ray images and makes them available for display and storage across your network

of computers.

EzSensor is connected by a ‘USB A-A’ cable (supplied separately) to a compatible Console PC. The

Console PC runs Windows XP or Windows Vista and also provides power for the device.

Support for the EzSensor is provided by compatible software programs such as EasyDent V4. For other

custom applications, a programmer’s guide is available.

The EzSensor includes a detachable holder that can be mounted to a wall or other stable surface.

EzSensor is available in two sizes(1.5 and 1.0). Size 1.0 is suitable for children, while size 1.5 is appropriate

for adult patients.

● Excellent image quality based on advanced CMOS technology

● Optimized sensor shape for human oral structure

● Low-dose performance

● Easy-to-use USB 2.0 interface

5

1. Introduction

< Table 1. Specifications >

Parameter

Detector Structure

Dimension(W x L x T)

Pixel Pitch

Active Pixel Array

Dynamic Range

Signal to Noise Ratio

USB Cable length between Controller and

PC

6

Description

Low Noise Hybrid CMOS

1.14 x 1.52 x 0.19 inch

(29.2 x 38.7 x 4.9 mm)

0.035 mm

686 x 944 pixels

(24.01 x 33.04 mm)

4096

>37dB

3 m

1. Introduction

1.2. System Components

The EzSensor device installer should check the following items listed in the table below before system

installation. If the serial numbers of the individual parts do not match, do not install the system and contact

your local distributor or agent for support.

< Table 2. EzSensor Cable Connections >

No

1.

2.

Sensor Module

Control Box

Components

Remark

3.

4.

5.

6.

7.

8.

USB Cable (3M)

Holder for Control box

Holder for Sensor

EasyDent V4 Installation CD

Driver Installation CD

EzSensor Manual

USB 2.0 (Mandatory)

Document

1. Sensor Module

Consists of a special CMOS sensor specifically designed for use in radiography and enclosed in a

hermetically sealed ergonomic capsule. The sensitive surface of the sensor is covered with a thin

layer of scintillating phosphorous through which X-ray radiation is converted into light and then into

an electric charge.

7

1. Introduction

2. Control Box

Provides power for the sensor, timing and synchronization of sensor signals, signal pre-amplification,

analogue/digital signal conversion, USB port interface and optical insulation of all connections.

3. USB Cable(3M)

Used to transmit output signal from the control box to the computer.

4. Control Box Mount

Used to mount the control box at the preferred location.

5. Sensor Holder

Used to stow the sensor when not in use.

8

1. Introduction

6. EasyDent V4 Installation CD

7.DriverInstallationCD

9

1. Introduction

1.3. Cone indicator (Optional)

The cone indicator is an intraoral positioning device specifically designed to support and align the sensor

with the X-ray source when positioning along the upper or lower jaw.

Please refer to the appendix for more information. (Pages 46 ~ 48)

10

2. Hardware Installation

2. Hardware Installation

2.1. General Information

To operate the intraoral sensor, you need to install EasyDent V4 and the EzSensor driver.

2.2. Specifications

We cannot guarantee that EasyDent V4 will work properly with an

unregistered copy of Microsoft Windows. Therefore, you should use

registered, genuine version of Microsoft Windows.

2.2.1. PC Specifications

① Operating System

● Microsoft Windows XP Home Edition Version 2002 Service Pack 2 or above.

● Microsoft Windows Vista Home Edition or above.

② Hardware Requirements

● Main CPU: Intel Pentium IV 3.0 GHz

● Main Memory: 512 MB of RAM (DDR2)

● Video Memory: 64 MB

● HDD: 80 GB (larger size of HDD and SATA/7200 rpm are preferred)

● CD-ROM (prefer CD-RW)

● USB 2.0 (Mandatory)

● Network Card: 1 EA

● Monitor: Min. resolution: 1024*768

● Keyboard/Mouse

Turn off the Windows Firewall service for proper communication across the

network for the installed database and file servers.

If you need to install additional software on your computer, please install

only those that are internationally authorized. Take extra precaution when

installing any Active-X controls.

11

2. Hardware Installation

2.2.2. EzSensor Driver Setup

This step is necessary for the installation of EzSensor. Calibration data for the EzSensor will be installed

along with the Windows device driver.

Step 1

Insert the EzSensor Driver

Installation CD in the CD-ROM.

Setup should start automatically.

If it does not, click Start > Run

and type D:\EzSensor\setup.exe

Step 2

The install program for ‘E-Woo

Intraoral Detector Software’ will

appear. Click the ‘Next’ button.

12

2. Hardware Installation

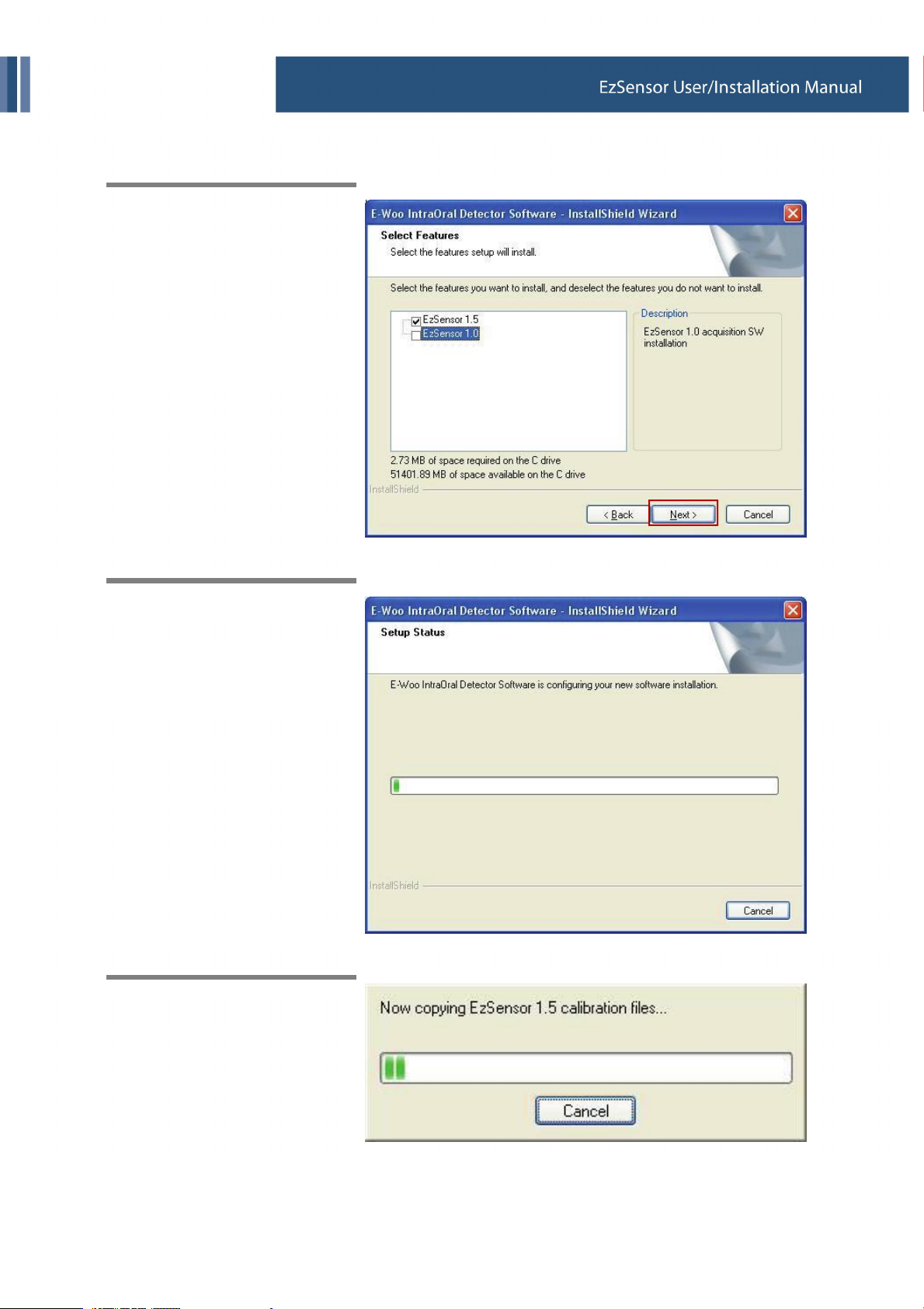

Step 3

Select the EzSensor feature that

you want to install. Check

‘EzSensor 1.5’ or ‘EzSensor 1.0’

and then click the ‘Next’ button.

Step 4

The Installshield Wizard will start

configuring the installation

parameters you have chosen.

Step 5

The InstallShield wizard will copy

the EzSensor calibration files to

your workstation(PC).

13

2. Hardware Installation

2.3. Cable Connection & Driver Installation

Do not connect the EzSensor and USB cable to your computer until you

have successfully installed the setup program.

Be sure to connect the EzSensor module to the control box before

connecting the USB cable to your computer.

Step 1

Connect the EzSensor Module to

the Control box.

Step 2

Connect the USB Cable to the

Control box.

14

2. Hardware Installation

Step 3

Connect the USB cable

connector to the USB 2.0 port on

the PC.

Step 4

After connecting the USB Cable

to the USB 2.0 port on the PC,

the ‘Found New Hardware

Wizard’ will appear.

If the ‘Found New Hardware

Wizard’ does not appear,

reconnect the USB Cable

connector to the PC.

Select ‘Install from a list or

specific location (Advanced)’, and

then click ‘Next’.

15

2. Hardware Installation

Step 5

Select ‘include this location in the

search’.

Click ‘Browse’, and then select

‘EzSensor100’ or ‘EzSensor150’

Folder.

And then click ‘Next’ button.

Step 6

If the ‘Hardware Installation’

window appears, click

‘Continue Anyway’

16

2. Hardware Installation

Step 7

Driver Installation has been

completed successfully.

Click the ‘Finish’ button.

Step 8

Confirmation of Driver installation at the Device Manager.

Method of Confirmation : Settings → Control Panel → System → Hardware → Device manager

Select the ‘Vatech HDS Driver’, located under Imaging Devices. You should see the message, “This

device is working properly”.

17

2. Hardware Installation

18

2. Hardware Installation

2.4. Installation of the EzSensor Holder

The EzSensor holder is used for mounting the EzSensor to the wall when it is not in use.

When choosing where to install the EzSensor, locate an area that offers easy access and visibility during

patient examination.

① Position the holder on a stable, flat surface. Using the holes at the back of the holder as guides,

fasten the holder securely to the wall using 2 dry wall screws (included).

② Remove the tape from the backside of the silicon holder. Attach the silicon holder to the sensor holder.

19

3. Software Setup and Usage

3. Software Setup and Usage

3.1. Installation of EasyDent V4

Step 1

Insert the EasyDent installation

CD in the CD-ROM drive.

Setup should start automatically.

If it does not, click Start → Run,

and type

D:\EasyDentV4\setup.exe.

Press ‘Enter’.

Step 2

Select the language you want to

install and then click ‘Next’.

20

3. Software Setup and Usage

Step 3

Preparing the installation.

Step 4

The ‘EasyDent V4 InstallShield

Wizard’ will appear. Click ‘Next’

button.

21

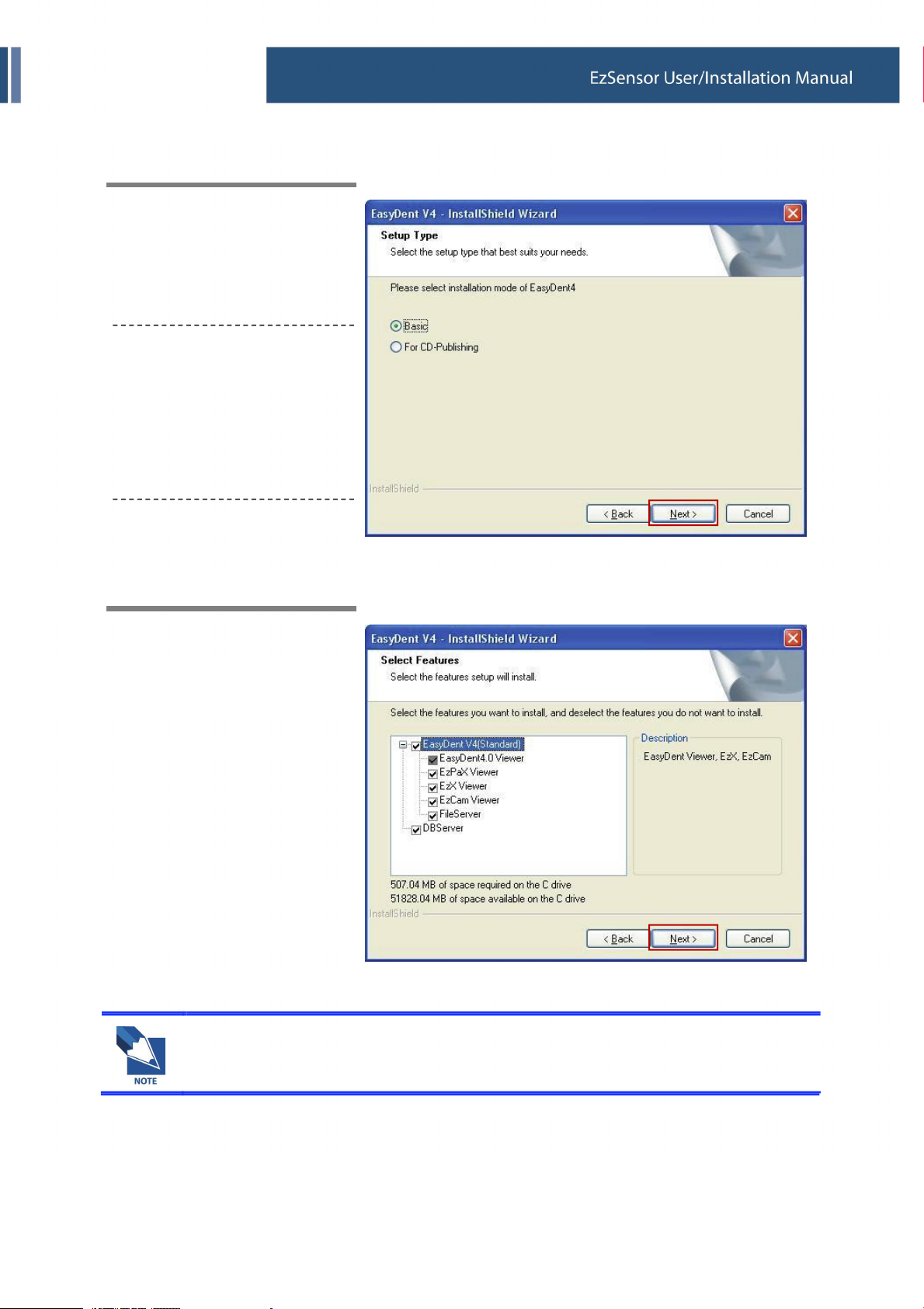

3. Software Setup and Usage

Step 5

Select the setup type that best

suits your needs.

Click ‘Next’ button.

Basic : Installs the basic version

of Easydent V4

CD-Publishing : Installs the

basic version of EasyDent V4

along with CD-Publishing

capabilities. (optional)

Step 6

Select the features that you want

to install. Click ‘Next’ button.

For the EasyDent server, select all items. For PC being used for viewer :

Select only the items except for DB & File servers.

22

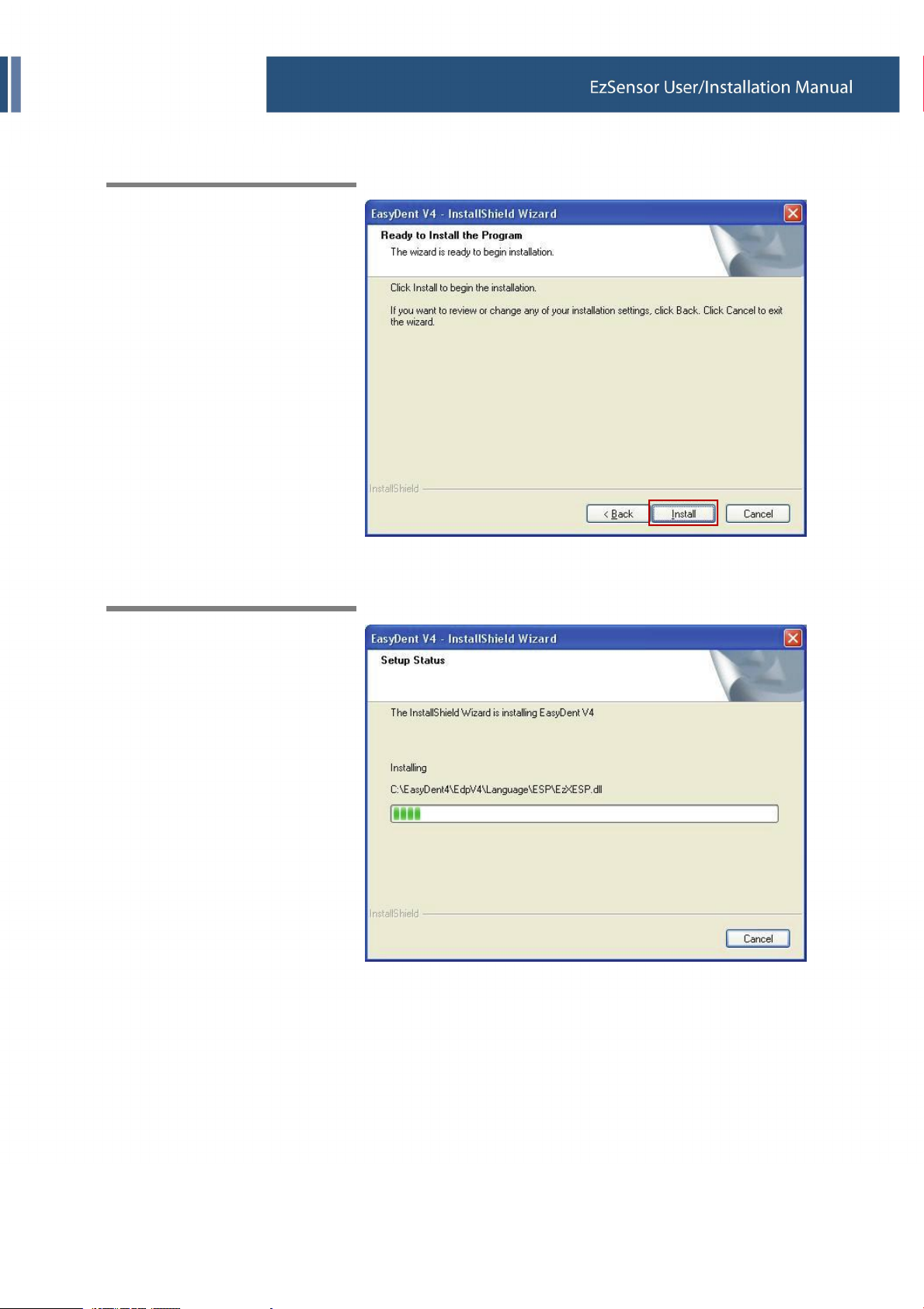

3. Software Setup and Usage

Step 7

Now you are ready to install.

If you would like review any of

your installation settings, click

‘Back’, To proceed with the

installation, click ‘Install’.

Click ‘Cancel’ to exit the wizard.

Step 8

Installing EasyDent V4.

23

3. Software Setup and Usage

Step 9

MSDE(Microsoft SQL server

Desktop Engine) is installed

automatically.

Step 10

Choose ‘No, I will restart my

computer later’, and then click

‘Finish’.

24

3. Software Setup and Usage

3.2. Image Acquisition with EzSensor

① Turn on the computer that has the EzSensor software installed (EasyDent v4 – Refer to 3.2).

② Set the required X-ray parameters (exposure time, etc.) on the X-ray source.

Put a new disposable cover on the EzSensor.

③ Position the EzSensor at the appropriate area of the mouth

The sensor must be positioned with the flat side facing the X-ray source.

The use of a cone indicator is recommended to guarantee that the sensor is parallel to the tooth and

at the proper angle for exposure.

④ The use of the parallel technique with a cone indicator, if possible, is highly recommended.

⑤ After preparing the sensor for exposure in EasyDent v4, acquire an image by pressing the exposure

button for your X-ray source.

<Using the EzSensor with EXS intraoral X-ray> <Using the EzSensor with a Cone Indicator (optional)>

25

3. Software Setup and Usage

3.3. Running the EasyDent V4

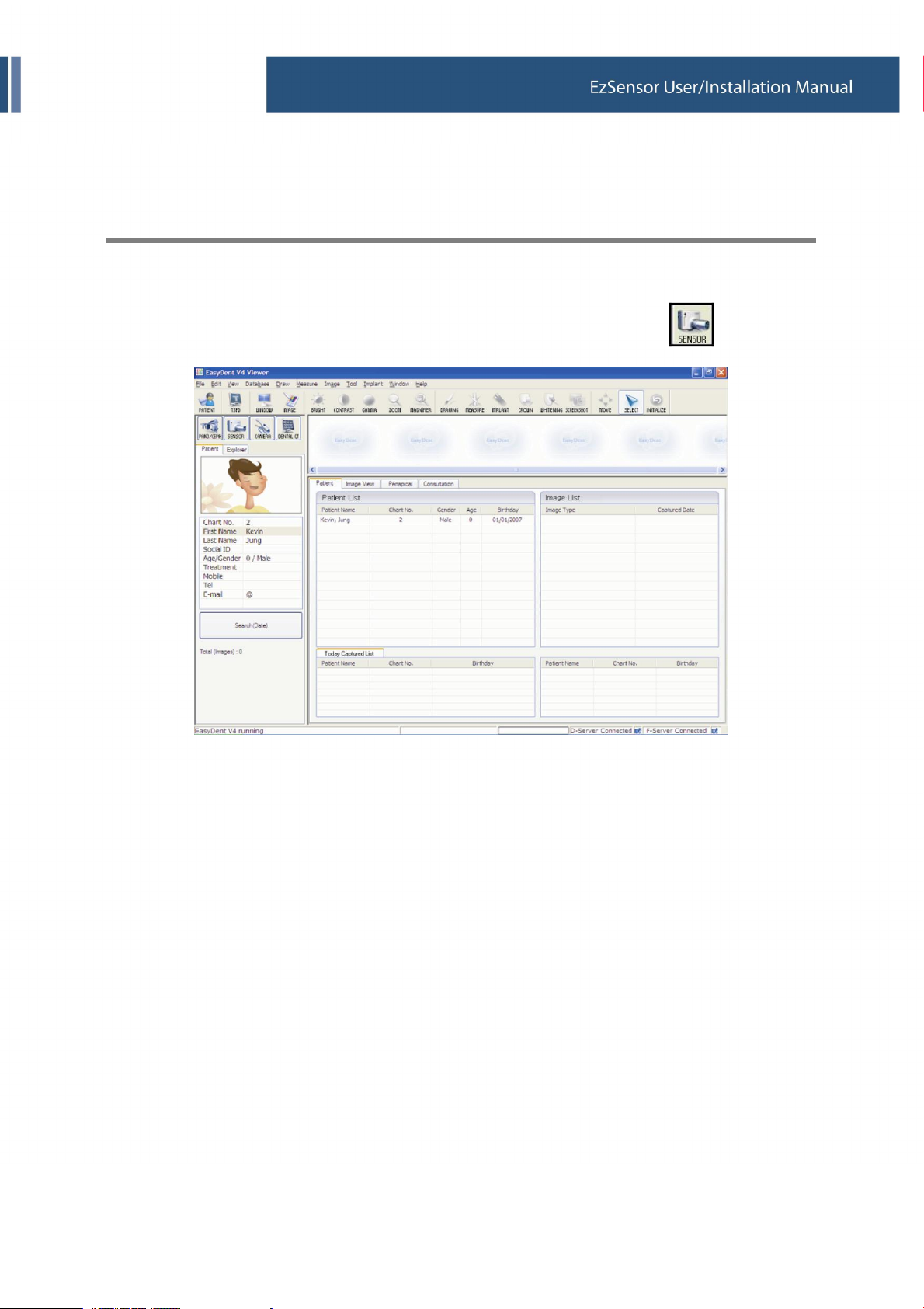

3.3.1. Patient Registration

Step 1

Turn on the PC.

Run EasyDent V4. Click ‘Patient (

)’ icon to register a new patient.

26

3. Software Setup and Usage

3.3.2. Normal Mode

Step 1

Start EasyDent by clicking the EasyDent V4 Viewer on the desktop.

Search and enter the appropriate patient information and then click the ‘Sensor(

27

)’ button.

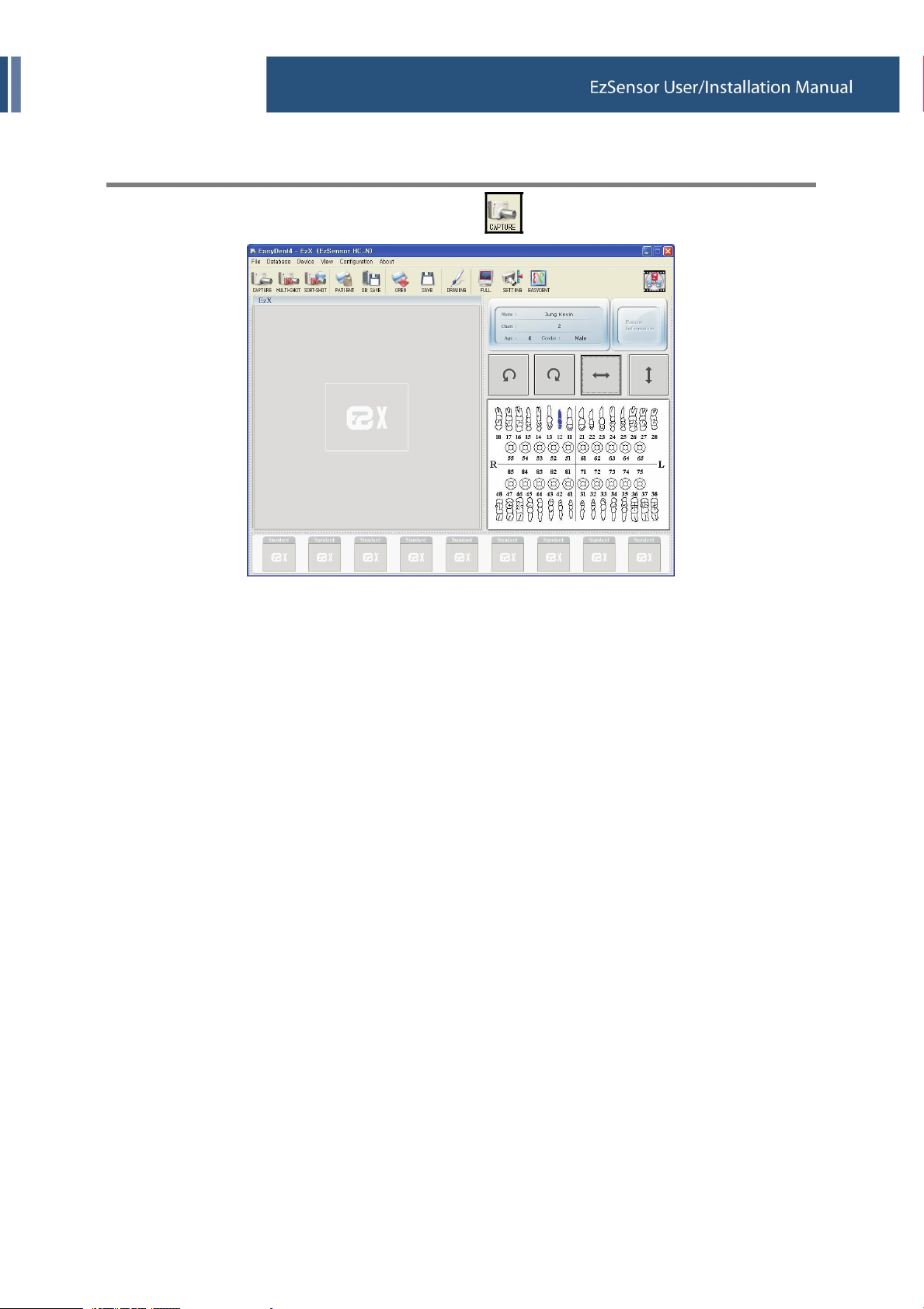

3. Software Setup and Usage

Step 2

Select your capture device. Please click ‘EzSensor 1.5’ then choose the image type.

① HC (Default) : High Contrast

② MC : Middle Contrast

③ LC : Low Contrast

④ HC_N : High Contrast (New Image processing)

⑤ MC_N : Middle Contrast (New Image processing)

⑥ LC_N : Low Contrast (New Image processing)

⑦ NI : Normal Image

If the capture device is not selected, you will get the following error message.

28

3. Software Setup and Usage

Step 3

Select the tooth position and then click the ‘Capture’(

29

) button.

3. Software Setup and Usage

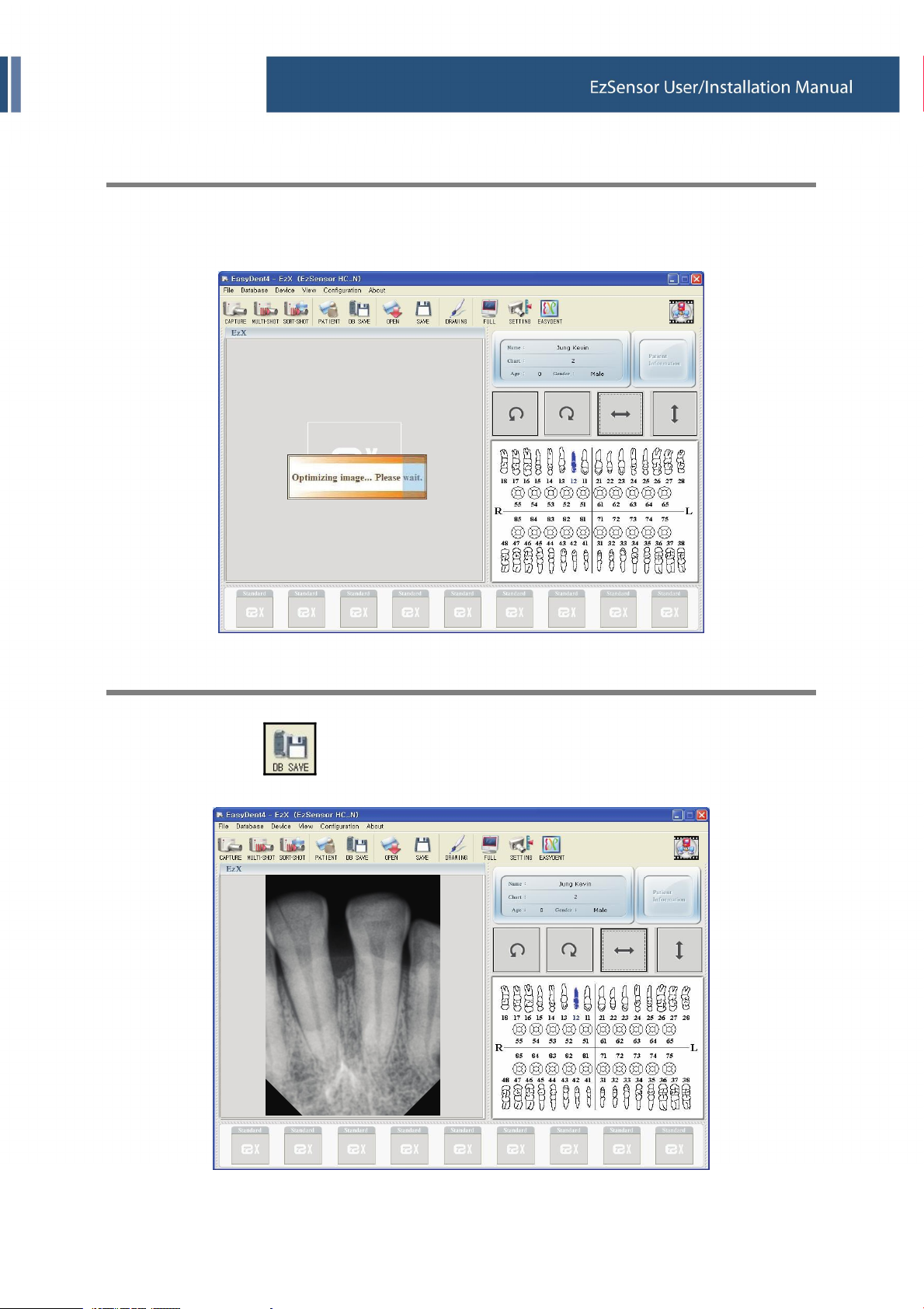

Step 4

Expose the X-ray after the “Please expose X-ray” message appears.

The message, “Optimizing Image… Please wait” appears momentarily while the image is being

optimized. The image will appear after optimization is complete.

Step 5

Click the ‘DB SAVE(

)’ button to save the image.

30

3. Software Setup and Usage

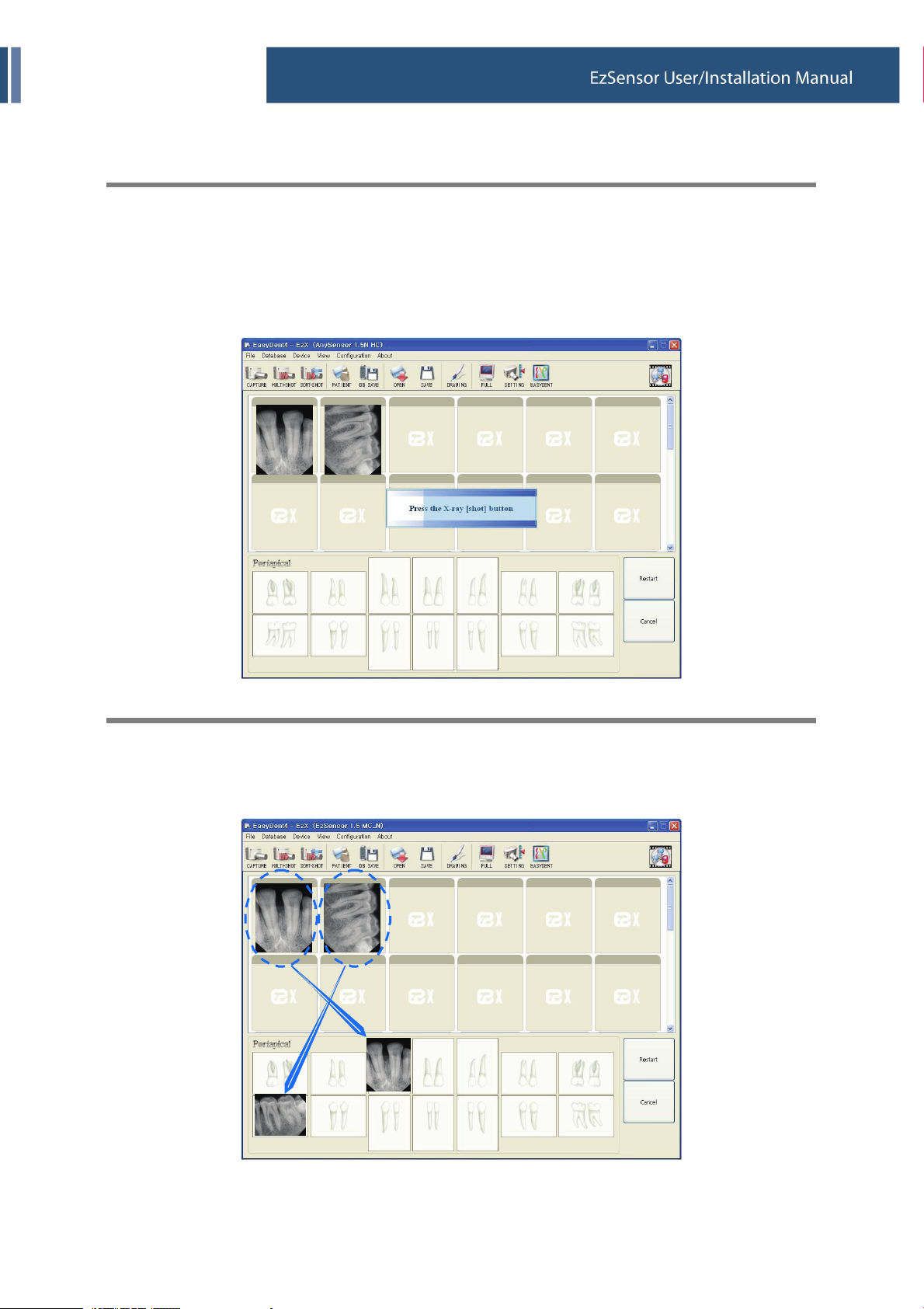

3.3.3. Multi-Shot

Step 1

Click the ‘MULTI-SHOT (

)’ button.

The system will get ready to acquire an X-ray image.

Step 2

Expose the X-ray after the “Press the X-ray (shot) button” message appears.

31

3. Software Setup and Usage

Step 3

The message, ‘Optimizing Image… Please wait’ will appear momentarily while the image is being

optimized. The image will appear after optimization is complete.

Step 4

Expose the X-ray again for a subsequent shot.

32

3. Software Setup and Usage

Step 5

If you want to acquire more images, continue to expose the x-ray when the ‘Press the X-ray (shot)

button’ message appears.

If you want to finish, click the ‘Finish’ button.

Step 6

Click and drag the image to its appropriate position.

33

3. Software Setup and Usage

Step 7

Click ‘DB SAVE (

Step 8

)’ to save the images.

Click the ‘MULTI-SHOT(

)’ button again to exit the Multi-shot Mode.

34

4. Maintenance

4. Maintenance

4.1. Visual Inspection

Like all electrical systems, EzSensor requires not only correct usage, but also visual inspection prior to

operation, Along with routine checks at regular intervals. These precautions will help ensure that the system

operates accurately, safely, and efficiently.

Before using, the operator should check the system for any signs of physical damage or defect. If

something is detected, contact your local distributor of VATECH & E-WOO products for further instructions

on what to do.

4.2. Periodic Maintenance

Periodic maintenance should be performed if needed, but at least once a month. It must consist of various

checks performed by the operator or by a qualified service technician.

● Check that all cables connected to the EzSensor are undamaged

● Check for external damage to the EzSensor that could compromise its ability to operate safely.

4.3. Cleaning

To clean the EzSensor, use either of the following solutions listed below and observe the noted precautions.

● Mild soap and water

● Isopropyl alcohol (70%)

Do not soak or immerse the system and be sure to dry it completely afterwards.

Clean the surface of the system by moistening it with a soft cotton swab dipped in either of the cleaning

solutions listed above. Gently wipe the surface from end-to-end in lines without applying pressure. Make

sure that the liquid will not penetrate the system through the USB cable or the sensor cable connectors.

After cleaning the surface of the EzSensor, use a clean lint-free cloth to dry the system, as needed, until the

surface is clean.

35

5. Warranty

5. Warranty

The EzSensorTMis warranted to be free from sensor defects in sensor and workmanship from the date of

installation for a period of 12 months.

In the event that the product is returned by the dealer or the end-user after the warranty has expired, we

reserve the right to collect a reasonable fee from the end user for services mutually agreed upon.

Any item returned to the factory, through an authorized dealer VATECH & E-WOO, will be repaired or

replaced at our option at no charge provided that our inspection indicates it to have been defective.

Dealer’s labor cost, shipping and handling charges are not covered by this warranty.

This warranty does not apply to damages due to shipping, misuse, or careless handling. Warranty is void if

the system is installed, repaired, or serviced by anyone other than authorized service personnel, as dictated

by VATECH & E-WOO.

36

Appendix

Appendix

1. LED Indicators

The EzSensor Hardware Controller has two LED indicators that show its functional status.

The location of the LED lights is shown in the following illustration and described in Table 3.

LED 1

LED 2

< Table 3. Description of LED Indicators >

Operational State

LED State

LED 1 LED 2

Functional Status

Confirmation

Initial State

Standby

Trigger (X-ray On)

Data Transmission

with USB cable

Image acquisition

Green

Green

Orange

Green Orange

Green

Off

Green

Green

Off

37

USB Connection

Board On

X-ray On and Sensor Trigger On

Confirm data transmission

with sensor board

Completion of data transmission

with PC-board

Appendix

2. X-ray Exposure Guide

< Table 4. Detailed Exposure Guidance Table>

Ref.

Exposure condition Dose

Signal Level

60kvp

2mA

60kVp

6mA

65kVp

5mA

Patient

Cone to skin

Section

-

-

No

Filter

-

-

4mm

Al filter

--Adult

8cm

AnyRay

Adult

8cm

VX 70

Adult

8cm

ESX-

Series

Upper

Approximate Exposure Time

Upper

Lower

Jaw/

Anterior

Upper

Jaw/

Canine

Upper

Jaw/

Posterior

Lower

Jaw/

Anterior

Lower

Jaw/

Canine

Lower

Jaw/

Posterior

2800

2800

3200

2400

2400

2800

1800

1800

2100

1400

1400

1800

160 0.20 0.16 0.22

160 0.20 0.16 0.22

200 0.25 0.20 0.27

130 0.15 0.12 0.18

130 0.15 0.12 0.18

160 0.20 0.16 0.22

For larger body types : increase the source current by 25%

For children : reduce the source current by 20%

For edentulous patients : reduce the source current by 20%

38

Appendix

The X-ray dose required for image acquisition can vary depending on the X-

ray source and environmental circumstances. You must maintain the

exposure time and change the kVp and mA values according to the signal

level. In addition, if the X-ray source and the distance to the sensor were

changed during the initial installation, the distance (from cone to detector)

must be changed to the 80mm setting.

To reduce an initial measuring error, you should use a 4mm Al filter to

maintain a distance that is identical to the conditional circumstances of the

test.

The exposure time may vary depending on the age, gender and bone

density of the patient.

39

Appendix

How to optimize the exposure conditions?

Position the EzSensor and the X-ray source, as shown below. The distance between the cone and the

detector should be 80mm (8cm). Please align the X-ray source over the sensor.

1. Distance: 80mm(8cm) (from cone to detector)

2. Added filter: 4mm Al filter (or No filter )

3. Signal level: after calibration of image

Run program ‘_EzSensor150’ located in C:\EzSensor150

40

Appendix

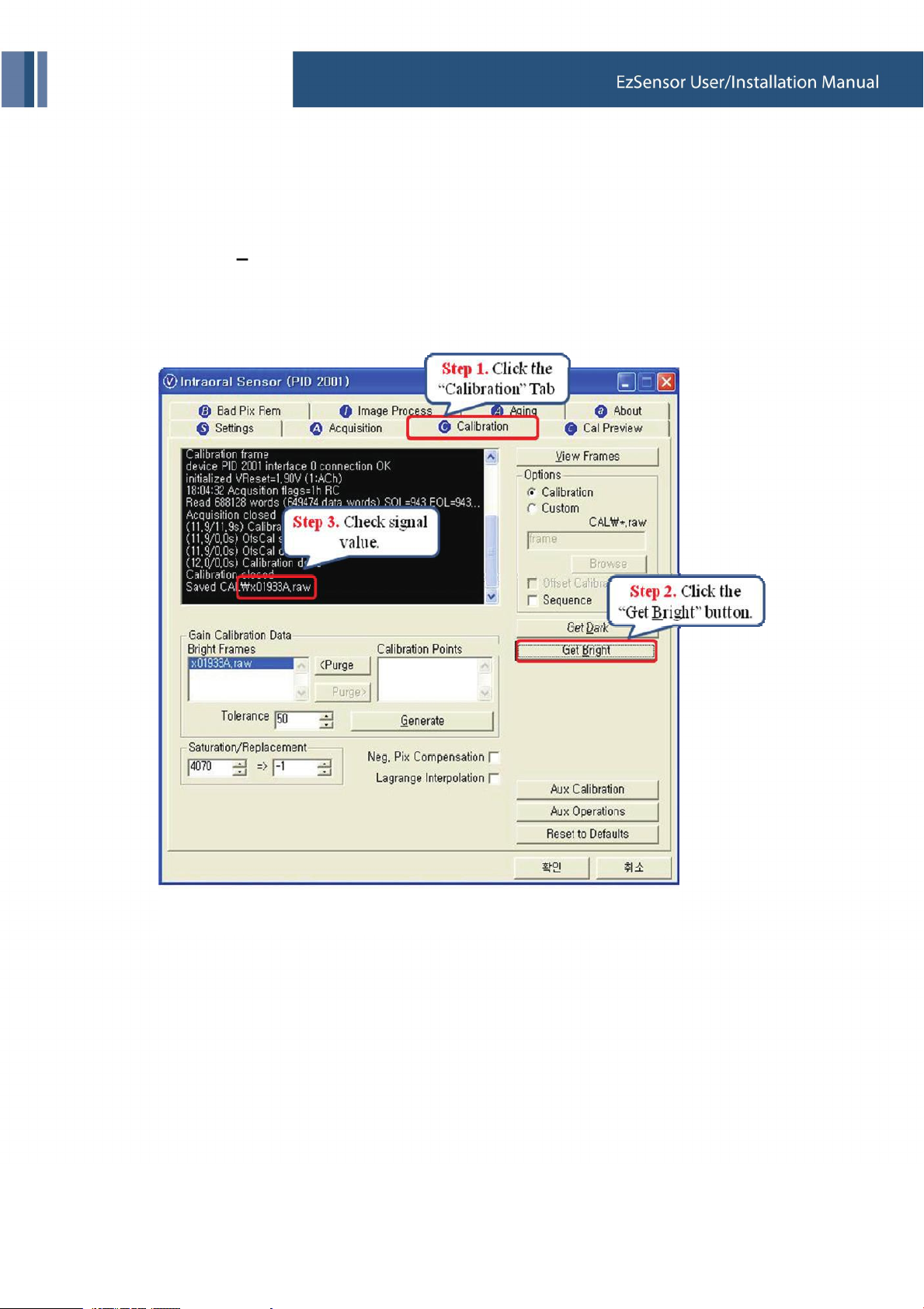

Follow the steps below:

[Step 1] Click the ‘Calibration’ tab.

[Step 2] Click the ‘Get Bright’ button for the exposure time.

; Refer to ‘Table 4. Detailed Exposure Guidance Table’.

[Step 3] Check the command window.

41

Appendix

3. Error Code

1. Code 0

● Message : USB device driver is not installed.

● Solution : Please install device driver again.

2. Code 1

● Message : USB driver can't detect connected sensor device. Check connection.

● Solution : Check and re-connect USB cable.

3. Code 2

● Message : USB device driver is not working properly.

● Solution : Re-install the driver.

4. Code 3

● Message : Capture program is already running.

● Solution : Please close other program.

5. Code 4

● Message : Detector's response time-out.

● Solution : Check and re-connect USB cable. Contact Customer Service.

6. Code 5

● Message : Data communication error.

● Solution : Re-connect USB cable.

7. Code 6

● Message : Data communication error.

● Solution : Re-connect USB cable.

8. Code 7

● Message : Canceled image capturing.

● Solution : User canceled image capture. Please try again.

42

Appendix

9. Code 8

● Message : Bad Pixel's map correction error.

● Solution : Restore the EzSensor’s calibration data from the installation CD or re-calibrate the sensor.

Contact Customer Service.

10. Code 9

● Message: Bad Pixel's map correction error.

● Solution: Restore the EzSensor’s calibration data from the installation CD or re-calibrate the sensor.

Contact Customer Service.

11. Code 10

● Message :. Can't find dark frame.

● Solution : Restore the EzSensor’s calibration data from the installation CD or re-calibrate the sensor.

Contact Customer Service

12. Code 11

● Message: Can't find bright frames for calibration

● Solution: User canceled image capture. Please try again.

13. Code 12

● Message: Canceled image capturing.

● Solution : User canceled image capture. Please try again.

14. Code 13

● Message: Wrong image processing parameters.

● Solution: Check X-ray source.

15. Code 14

● Message: Error in configuration file.

● Solution: Please re-instal acquisition software.

16. Code 15

● Message: Image process library was damaged.

● Solution: Please re-instal acquisition software.

43

Appendix

17. Code 16

● Message: Image process library was damaged.

● Solution: Please re-instal acquisition software.

18. Code 17

● Message : Can't load 'EzSensor150.dll'.

● Solution : Please re-install acquisition software.

19. Code 18

● Message : Requre 'EzSensor150.DLL' was damaged.

● Solution : Please re-install acquisition software.

20. Code 19

● Message : Canceled image processing.

● Solution : Please try again.

44

Appendix

4. Troubleshooting

In case you experience any problems regarding the EzSensor system during operation, please refer to the

troubleshooting table below for corrective actions. If the problem persists, please contact your local

distributor of VATECH & E-WOO products.

< Table 5. Troubleshooting Table >

Item

1

2

3

4

Description

LED 1 on the control box doesn’t illuminate

after installing the device.

LED 1 on the control box continuously

illuminates an ORANGE light during image.

acquisition

LED 2 on the control box continuously

illuminates a RED light during image

acquisition.

A ‘PID 2001 NO; interface #0 (Check

Connection)’ error message is displayed.

45

Corrective Action

Check that the USB cable is plugged in

correctly at the Control box and on the console

PC.

Check that the Sensor is properly connected.

Unplug the USB cable from the control box and

then reconnect it.

Unplug the USB cable from the control box and

then reconnect it.

Open the Windows Device Manager and check

that the device is installed correctly.

Alternately, try another USB port on your

computer.

Unplug the USB cable from the control box and

then reconnect it.

Open the Windows Device Manager and check

that the device is installed correctly.

Alternately, try another USB port on your

computer..

Appendix

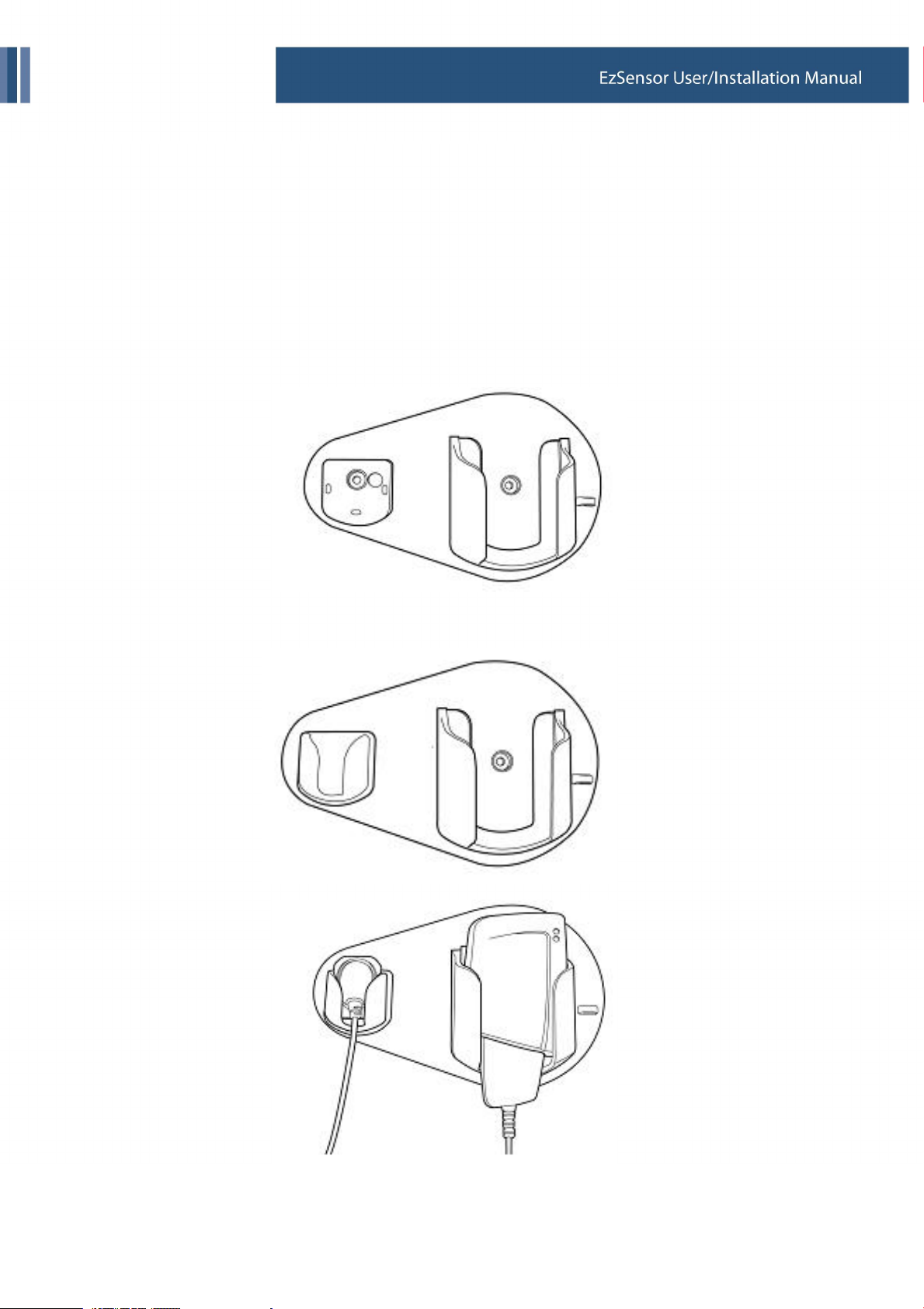

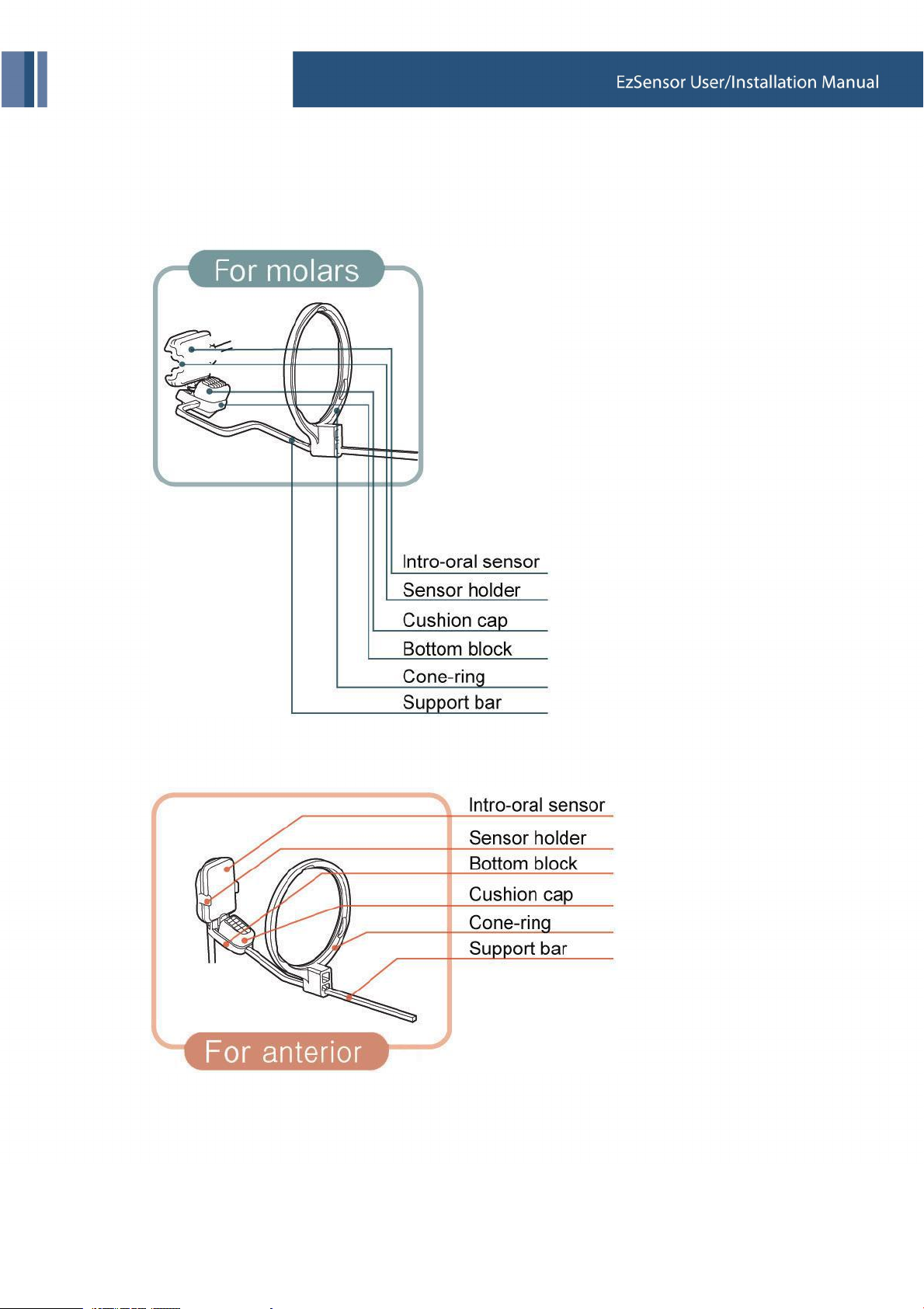

4.1. How to use the cone indicator

① Cone indicator for molars

② Cone Indicator for anterior

46

Appendix

● Usage

① Insert the sensor into the disposal bag provided.

② Pass the sensor through the cone ring, into the sensor holder.

③ Fix the sensor firmly to the sensor holder.

④ Put the sensor cable in the cable-holder, located at the side of the bottom block.

47

Appendix

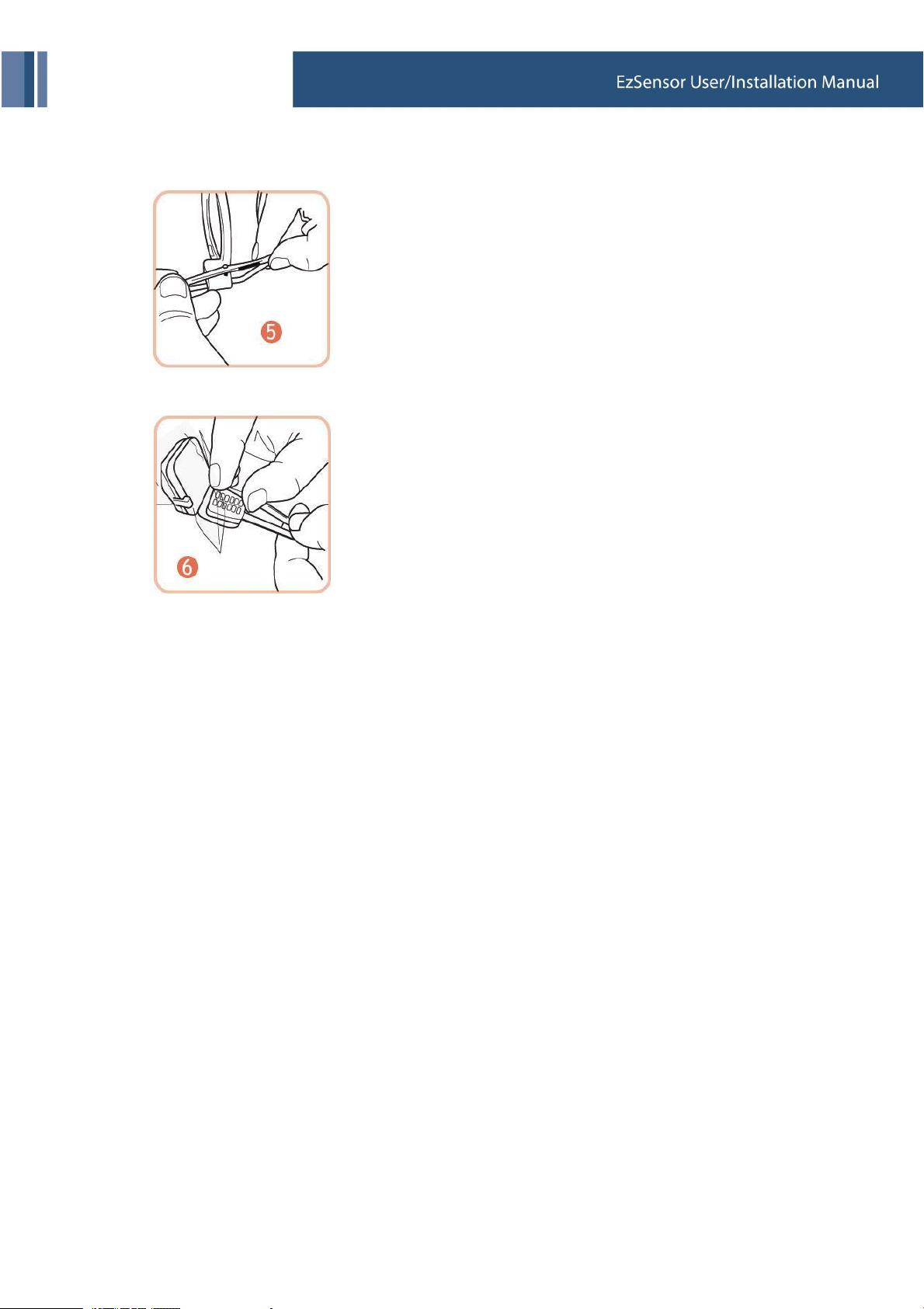

⑤ Fasten the sensor cable on the cone ring with the cable hook.

⑥ Put the cushion cap on the top of the bottom block.

48

Loading...

Loading...