c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

1/16

Adaptive Pressure Controller

PM-4 & 5 for Gate Valve Control System

This manual is vali d for product with the

product identification numbe r

FABR. NO. 641PM - . 6 . . - . . . .

configured with Software Version

64PM.3I.00

The product identification is sp ecified on the rear panel of each PM controller:

Made in Switzerland in 20 . .

Patented

641P . - . 6 . . - . . . . - . . . .

Read these «Installation, Operating and Maintena nce Instructions» (IOMI) and the enclosed

«General Safety Instructions» carefully before you start any other action.

Table of content

1 Intended Use of Product.............. . ....... . ....... . ....... . . ....... . ...... .. .............. ....... . . ....... . ....... . ....... ....................2

1.1 Technical Data............................................................................................................................. ....2

2 Installation...............................................................................................................................................2

2.1 Content of VAT PM Controller Delivery ................ ...... ... ..... ...... .. ...... ... ..... ... ...... .. ...... ... ..... ...... ... ......2

2.2 Hardware Installation................................................................................................................... ....2

2.3 PM Configuration (setup sequence) ... . ... . .. ... . .. .. . .. ... . .. .. . .. ... . .. .. . .. ... . .. .. . .. ... . .. .. . ... .. . .. .. . ... .. . .. .. . ... .. .......4

3 Operation......................................................................................................................... .......................5

3.1 Local Mode (PM-4 with Service Box only) ........................................................................................5

3.2 Remote Mode (PM-5 if Interface installed only) ............. . ....... . . ....... . ....... . ....... . . ....... . ....... . ....... . . .......5

3.3 Power Failure / Power Failure Option (PFO)..................................................................................... 5

4 Preventive Maintenance...................................................................................................................... ....6

5 Spare Parts / Retrofit Options..... ... ..... ... ..... ... ...... ... ..... ... ..... ... ...... ... ..... ...... ... ..... ... ..... ... ...... ..... ............... 7

6 Trouble Shooting .................................................................................................................... ................. 7

7 Repairs................................................................................................................................ ....................8

8 Warranty............................................................................................................................. .. .................. 8

9 Engineering Information......................................................................................................... .................. 9

9.1 Wiring of Connectors ........................................................................................................ ............... 9

9.2 RS232C Interface Configuration..................................................................................................... 12

9.3 RS232C Communication................................................................................................................ 12

9.4 User Information and Recommendat io ns............. ............. . .............. ............. . ....... . ............. . ...........16

PM-5

PM-4

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

2/16

1 Intended Use of Pr od uc t

This product is an adaptive pressure controller for VAT series 64 control valves. The product may only be operated within the ranges

specified below:

1.1 Technical Data

Mains volta ge

100 - 240 VAC (±10%), 50/60 Hz

Temperature

0 - 50 °C

Sensor input signal 0 - 10 VDC max.

Sensor power supply

+ 15 VDC (±5%), 1400 mA max. (total current for sensor 1 and 2)

- 15 VDC (±5%), 1400 mA max. (total current for sensor 1 and 2)

Operation only with VAT series 64 control valve

Additional technical information see chapter ‚9 Engineering Information‘

2 Installation

2.1 Content of VAT PM Controller Delivery

Adaptive Pressure Controller PM-4 or PM-5

Plug for mains connection of controller

Plug for interface cable

Plug for cable of pressure sensor 1 (standard) and 2 (option)

2.2 Hardware Installation

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

3/16

Confirm that hardware is complete (picture 1)

(1) Adaptive Pressure Controller PM-4 or PM-5, hereafter referred to as PM controller.

For PM controller with power failure option confirm that battery life has not expired (see chapter ‚4 Preventive Maintenance‘)

(2) Connection cable valve - PM controller: VAT part number 640CV-99L .

(3) VAT Series 64 control valve

(4) Mains connection, wiring information see chapter ‚9.1.2 Connector for mains‘

(5) Interface cable, wiring information see chapter ‚9.1.3 Connector for interface‘

(6) Sensor 1 (standard) and 2 (option)

(7) Cable for sensor 1 and 2, wiring information see chapter ‚9.1.1 Connector for sensor 1 and sensor 2‘

Install hardware

PM controller must be switched off during installation.

- Install VAT control valve (3) according to the Installation, Operating and Maintenance Instruction Manual of the VAT Series 64 control

valve.

- Install sensor(s) (6) according to the recommendations of the sensor manufacturer

- Install PM controller (1) into control rack.

- Connect valve cable (2) to control valve and then to PM controller (connector: valve)

- Connect sensor cable (7) to sensor(s) and then to PM controller (connector: sensor 1 / sensor 2)

- For remote operation, connect interface cable (5) to PM controller (connector: interface)

- Connect mains cable (4) to PM controller

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

4/16

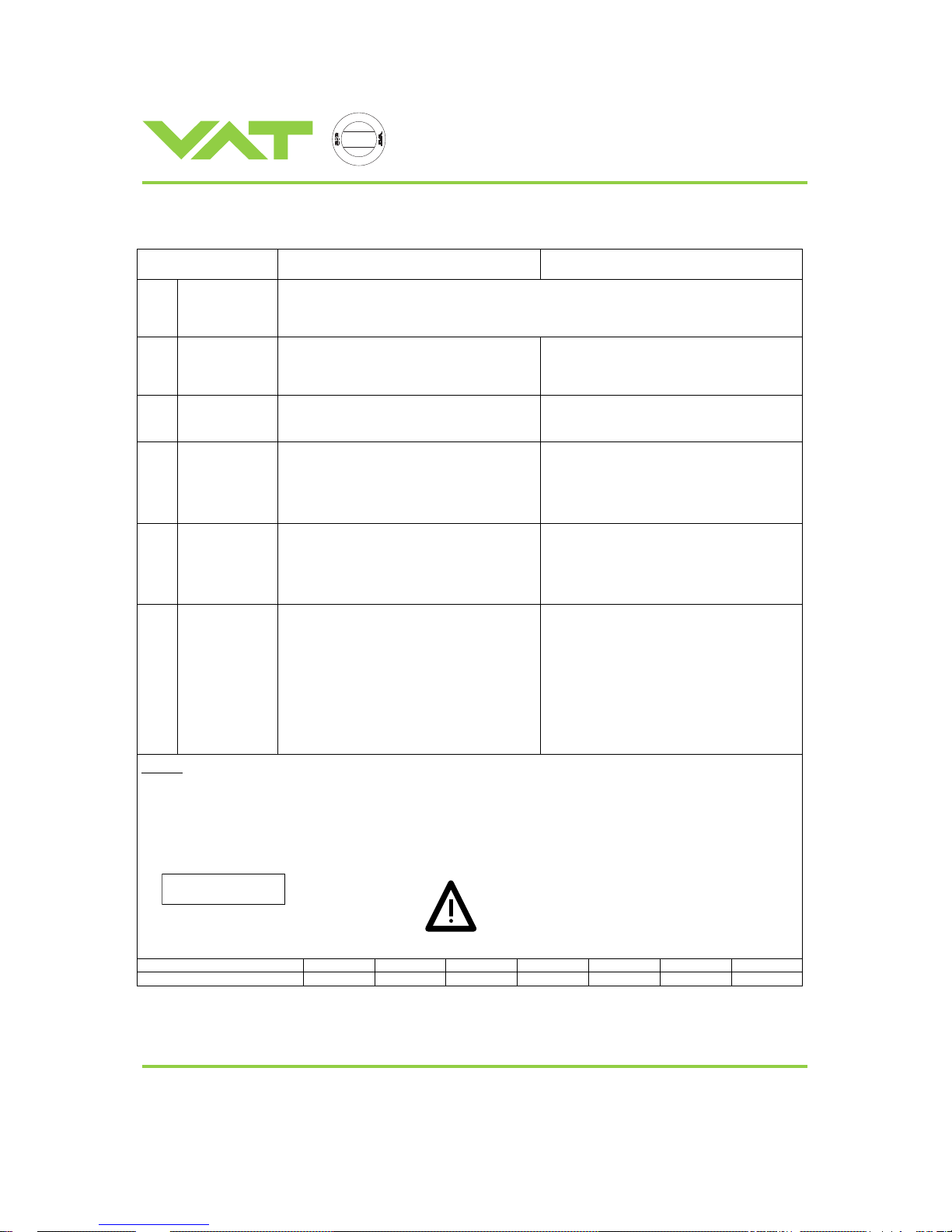

2.3 PM Configuration (setup sequence)

STEP

LOCAL MODE (PM-4 in comb ination with

Service Box only)

REMOTE MODE (PM-5 if interface i nstalled

only)

1

POWER ON

1. PM contr oller: Turn on power switch at the rear pane l of the PM controller. Note: Valve wi l l clos e, if not in

closed position

2. On PM-5 or Service Box start-up display (Software version, type of interface, etc.) appears, until valve is in

closed position

3. CLOSE(D) is displayed, otherwise please refer to chapter ‘6 Trouble Shooting’.

2

SELECT

MODE

Select LOC AL operation by pressing «LOCAL» key for 2

seconds.

Select REMOTE oper a ti on by pres si n g «REMO T E» key

on front panel or Service Box for 2 seconds or select

remote operation through RS232 (see ‚9.3.1 Control

commands’) or logic interface (see ‚9.1. 3.1 Logic

interface‘)

3

AUTOMATIC

SIZE

ADJUSTMENT

Press simultaneously «OPEN» and «CLOSE» keys for 2

seconds. The controller will perform an automatic size

adjustment procedure to determine open and closed

position and the range between the two positions.

Send RS232 co mmand:

J:<CR><LF> (see ‚9.3.1 Control commands’)

or use Logic command (see ‚9.1.3.1 Logic interface‘)

4

SENSOR

SETUP

1)

Press simultaneously «LEARN» and «ZERO» key for 2

seconds (notation used her eafter: «&», e.g. «LEARN» &

«ZERO»). Then, use «↑» and «↓» key to change

parameters (VOLTAGE RANGE; DISPLAY RANGE;

DISPLAY UNIT; GAIN FACTOR; SENSOR TYPE; ZERO

ADJUST) for each sensor. T oggle with «F1» key to the

next setup parameter. Press «F2» , when fini shed.

See ‚9.3.3 Sensor setup command‘

Example:

Sensor 1, Voltage Range: 0-10V; Display Range: 0- 10;

Display Unit: Torr; Gain Factor: 1; Sensor Type: Torr;

Zero Adjust: enabled;

s:1332010<CR><LF>

Mind: Not possible to do by a log ic interface.

5

ZERO ADJUST

(Offset

compensation of

sensor output)

Evacuate process chamber to high vacuum. When the

base pressure is reached, press «ZERO» key for 2

seconds to reset the offset of the pressure sensor.

Disable ZERO function in SENSOR SETUP, if the base

pressure of your system is higher than 1‰ of sensor full

scale.

Evacuate process chamber to high vacuum. When the

base pressure is reached send RS232 command:

Z:<CR><LF> (see ‚9.3.1 Control commands’)

or use Logic command (see ‚9.1.3.1 Logic interface‘).

Disable ZERO function in SENSOR SETUP, if the base

pressure of your system is higher than 1‰ of sensor full

scale.

6

LEARN

2)

(Determination of

control

characteristi cs o f

your process

chamber)

Process chamber at high vacuum, control valve is open:

Open gas inlet and set gas fl ow (s ee reco mmendation

below). Press «LEARN» key for 3 seconds to perform

the autolear ning routine of the PM controller. The

autolearning routine ma y take several minutes and can

be aborted by pressing the «F1» key. A single full run of

the autolearning routine is required to ensure fast and

accurate pressure control.

Note: It is not necessary to repeat LEARN, if the

sensor setup is changed, or if t he second

sensor is selected for pressure control. The

controller covers 5% to 5000% of the gasflow

which was us e d at LEARN.

Process chamber at high vacuum, control valve is open:

Open gas inlet and set gas fl ow (s ee reco mmendation

below). Then send RS232 LEARN command:

L:001000<CR><LF> (‚9.3.1 Contro l co mman d s ’)

or Logic command (see ‚9.1.3.1 Logic interf ace‘).

The autolearning ro utine may take several minutes. A

single full run of the autolearning routi ne is required t o

ensure fast and accurate pressu re con trol.

Note: It is not necessary to repeat LEARN, if the

sensor setup is changed, or if t he second

sensor is selected for pressure control. The

controller covers 5% to 5000 % of the gasflow

which was used at LEARN.

Legend:

1)

The default GAIN FACTOR is 1.00. See chapter ‚9.3.3 Sensor setup command‘ if resetting is necessary.

gain factor > 1 means: faster contr ol but higher overshoot of pressure

gain factor < 1 means: slower cont rol but lower overshoot of pr essure

Just 98% of sensor pressure range can be used during control.

If no sensor is used, select as display parameter ‘POS’.

2)

Ideal gasflow for autolearning

Q = 40 • p

SFS

• L

min

Q...........gasflow for autolearning [sccm]

p

SFS

.......sensor full scale pressure [Torr]

L

min

........min. controllable conductance [l/s]

Do not use a different gasflow than

recommended for aut olearning otherwi se

pressure control performance may be insu fficient.

valve size DN63 DN100 DN160 DN200 DN250 DN320 DN400

min. controllable conductance 0.6 l/s 1 l/s 1.6 l/s 2 l/s 2.5 l/s 3.2 l/s 4 l/s

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

5/16

3 Operation

For user information and recommendations for pressure control please refer to ch0r ‘9.4 User Information and Recommendations’

Display Information: (PM-4 with Service Box only)

‘P1:’/’P2:’ for actual p res su re , ‘SP:’ for set point pressure, ‘Pos:’ for valve position (0000 = closed, 1000 = open)

Errors:

‘E’ on display for position error, ‘P‘ for parameter error (refer to section ‘6 Trouble Shooting’)

Power-fail option:

‘D’, if power-fail option disabled temporarily (only in local mode possible)

Logic Inputs:

‘M’, if Logic Inputs disabled by RS232C command

3.1 Local Mode (PM-4 with S ervice Bo x on ly)

Acti vate ke yboar d :

Press «LOCAL» key for 2 seconds to enable keyboard. LED on «LOCAL» key will turn green.

Open valve:

Press «OPEN». LED on «OPEN» key will turn green.

Close valve:

Press «CLOSE». LED on «CLOSE» key will turn green.

Select sensor: (for double sensor version)

Press «F2» & «↑» key to toggle between sensor 1 and sensor 2. As an alternative, the sens or setup may be used to select the sensor for

pressure control.

Pressure control:

Press «PRESSURE MODE» key, then press one of the four «SET POINT» keys. Use «↑» or «↓» key to change set point value. Store the

set point value by pressing one of the four «SET POINT» keys for at least 2 seconds.

Freeze valve position, interrupt pressure control:

While in PRESSURE MODE, press «F1» key to interrupt pressure control and free ze the actual valve position. ‘HOLD’ wil l appear on

display. Press «PRESSURE MODE» key to continue pressure control.

Valve position control:

Press «POSITION MODE», then press one of the four «SET POINT» keys. Use «↑» or «↓» key to change the posi tion value. Stor e set

point value by pressing «SET POINT» key for at least 2 seconds.

Note: Commands «ZERO », «LOCAL», «REMOTE», «LEARN», «F1» & «F2» require that the ke ys are pressed for 2 seconds, befor e

the commands are accepted to prevent that the settings are changed accidentally.

Contrast of the display can be adjusted by pressing «F1» & «F2» & «↑», or «F1» & «F2» & «↓» key.

3.2 Remote Mode (PM-5 if Interface installed only)

Press «REMOTE» key for 2 seconds or select remote operation through RS 232C or LOGIC interface for remote control. For details about

interface wiring and remote commands refer to chapter ‘9 Engineering Information’.

3.3 Power Failure / Power Failure Option (PFO)

All parameters will remain stored during a power failure.

If a power-fail battery is installed (check VAT part number of PM controller: 641PM- . 6B

. - . . . .), the PM controller has to be hooked up to

power for at least 10 hours to assure repeated valve closures in case of a power failure.

Note: By pressing the «F2» key for 2 seconds, the Power Fail Option will be disabled for 1 minute. A ‘D’ will be displayed on the

control panel.

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

6/16

4 Preventive Maintenance

ESD Precaution!

All work on the controller has to be done under ESD protected envi ronment to prevent el ectronic

components from damage!

SRAM (see chapter ‚5 Spare Parts / Retrofit Options‘ part number.)

When the battery life expires (typical life time is 5 years, check date specified on label on the rear panel of PM controller) , the SRAM

memory needs to be exchanged.

Procedure:

- Turn off power to PM controller, disconnect powe

r cable and wait for

60 seconds.

- Disconnect sensor cable, valve cable and interface cable.

- Open top cover of PM controller.

- Exchange SRAM (IC3 on master board), confirm SRAM is installed correctly.

Check mark for pin 1 [{] on SRAM. First row of socket contacts must be left

empty.

- Reattach cover.

- Attach label with new expiration date on back panel of PM controller.

- Perform PM configuration routine

(SENSOR SETUP, AUTO SIZE ADJUST, ZERO, LEARN).

IC 3

SRAM (IC3) Socket

Power-fail battery

(this is an option which is installed if controller part-no. is 641PM- . 6B . - ...., see chapter ‚5 Spare Parts / Retrofit Options‘ part number.)

When the PFO battery life expires, PFO battery needs to be exchanged. Production date is specified on label on the rear panel of PM

controller. Life time of NiCd-battery is specified with 20'000 hours if surrounding temperature is not higher than 30°C . A significant

decrease is directly linked with higher temperatures. The following diagram shows the influence on life time at various ambient

temperatures.

PFO duration of life

0

10

20

30

40

50

20° 25° 30° 35° 40° 45° 50°

Environment temperature [°C]

Exp. of life

[month]

PM-4, PM-5

Procedure:

- Turn off power to PM controller, disconnect power cable and wait for 60 seconds

- Disconnect sensor cable, valve cable and interface cable

- Open bottom and top covers

- Disconnect connector J5 of battery pack from the bottom side

- Remove the battery pack from the top side

- Install new battery pack and plug in connector J5 of battery pack

- Reattach covers

- Attach label with new production date on rear panel

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

7/16

5 Spare Parts / Retrofit Options

Description Ordering No.

Preventive maintenance kit for PM controller with power-fail option, consisting of: SRAM, battery pack, label 86705-R1

Preventive maintenance kit for PM controller without power-fail option, consisting of: SRAM, label 86706-R1

Battery pack for power-fail option, for retrofit 67786-R1

LOGIC interface 207806

RS232C interface 75944-R1

Service Bo x f o r PM-4 600BS-29NN

6 Trouble Shooting

Problem Recommendation

Front panel:

LED’s and LCD display inactive

- Check, if mains switch is on, mains cable is connected, mains supply is on

- Check fuses at rear panel of PM controller

Control does not respond to keyboard

commands

- Control in REMOTE, switch PM controller to LOCAL

No or weak text on LCD display

- Adjust brightness; «F1» & «F2» & «↑» key

‘PAR:ER’ or flashing ‘P’ displayed

- New auto learning should be performed

- If error occurs after new auto learning and

power disruption, replace battery powered

SRAM memory

‘ROM:ER’ displayed - EPROM defective, to be changed

LED on «CLOSE» key is flashing, valve

is closed and does not respond to RS 232

or keyboard commands

- Logic CLOSE input on RS 232 interface is active

Pressure reading is wrong

Negative pressure reading

- Confirm that sensor setup is correct, press «LEARN» & «ZERO»

- When base vacuum is reached and pressure reading is off, perform ZERO command

ZERO command does not work - Valve is not in open position, OPEN valve and bring chamber to high vacuum

- ZERO command is disabled, check sensor setup («LEARN» & «ZERO»)

Display not ‘0’ after ZERO command - Sensor offset voltage is larger than ±1.4V

- System not pumped to base pressure

Pressure control not optimal after LEARN

command

- The PM controller reoptimizes the parameters for each set point, repeat pressure

control command after adaption is completed

- ZERO command was not performed before LEARN command

- LEARN command was performed with different gas flow, repeat LEARN sequence

- Make sure sensor range is suited for application (>3% of f.s.)

- Noise on sensor signal, check sensor voltage, make sure a shielded sensor cable is

used

Valve open or in control mode

‘E’ displayed on front panel

- Pendulum plate does not reach end position because of mechanical obstruction.

- Check valve installation (torque on valve flange mounting screws too high, see

Installation and Operating Instruction for valve!). Check and clean valve

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

8/16

Problem Recommendation

LOGIC interface installed:

Controller does not respond to logic

inputs

- Switch to «REMOTE»

- Verify that logic Interface is installed correctly

‘LOGIC’ is displayed on front panel during start-up.

LOGIC interface installed:

Controller does not respond to analog

position or pressure setpoint

- One of the 4 setpoints, OPEN or CLOSE digital inputs are activated

RS232C interface installed:

Controller does not respond to

RS 232 commands

- Verify settings of the switch S1 on the RS232C interface are correct

- Confirm that RS232C interface is installed correctly

‘MIXED’ is displayed on the LCD display during start-up

- Confirm that PM controller is in REMOTE

- Logic inputs on RS232C interface override RS232 commands

RS232C interface installed:

Controller responds with error message

- Wrong command or transmission error, see chapter ‚9.3 RS232C Communication‘

7 Repairs

Contact VAT for repair. Please check first the fabri cation No. 641P . - . . . . . - . . . . - . . . .) marked o n the rear panel of the

PM controller. Your VAT representative will discuss with you how the repair can be carried out best.

8 Warranty

Each product sold by VAT Vakuumventile AG (VAT) is warranted to be free from the manufacturing defects that adversely

affect the normal functioning thereof during the one-year period immediately following delivery thereof by VAT, provided

that the same is properly operated under conditions of normal use and that regular, periodic maintenance and service is

performed or replacements made, in accordance with the instructions provided by VAT. The foregoing warranty shall not

apply to any product or component that has been repaired or altered by anyone other than an authorized VAT

representative or that has been subject to improper installation or abuse, misuse, negligence or accident. VAT shall not be

liable for any damage, loss, or expense, whether consequential, special, incidental, direct or otherwise, caused by, arising

out of or connected with the manufacture, delivery (including any delay in or failure to deliver), packaging, storage or use of

any product sold or delivered by VAT shall fail to conform to the foregoing warranty or to the description thereof contained

herein, the purchaser thereof, as its exclusive remedy, shall upon prompt notice to VAT of any such defect or failure and

upon the return o f the product, part or component in question to VAT at i ts factory, with transportation charges prepaid, and

upon VAT's inspection confirming the existence of any defect inconsistent with said warranty or any such failure, be entitled

to have such defect or failure cured at VAT's factory and at no charge therefor, by replacement or repair of said product, as

VAT may elect. VAT MAKES NO WARRANTY OR REPRESENTATION OF ANY KIND, EXPRESS OR IMPLIED,

(INCLUDING NO WARRANTY OR MERCHANTABILITY), EXCEPT FOR THE FOREGOING WARRANTY AND THE

WARRANTY THAT EACH PRODUCT SHALL CONFORM TO THE DESCRIPTION THEREOF CONTAINED HEREIN, and

no warranty shall be implied by law.

Furthermore, the «Terms of sal e» at the back of the price l ist are applicable.

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

9/16

9 Engineering Information

9.1 Wiring of Connectors

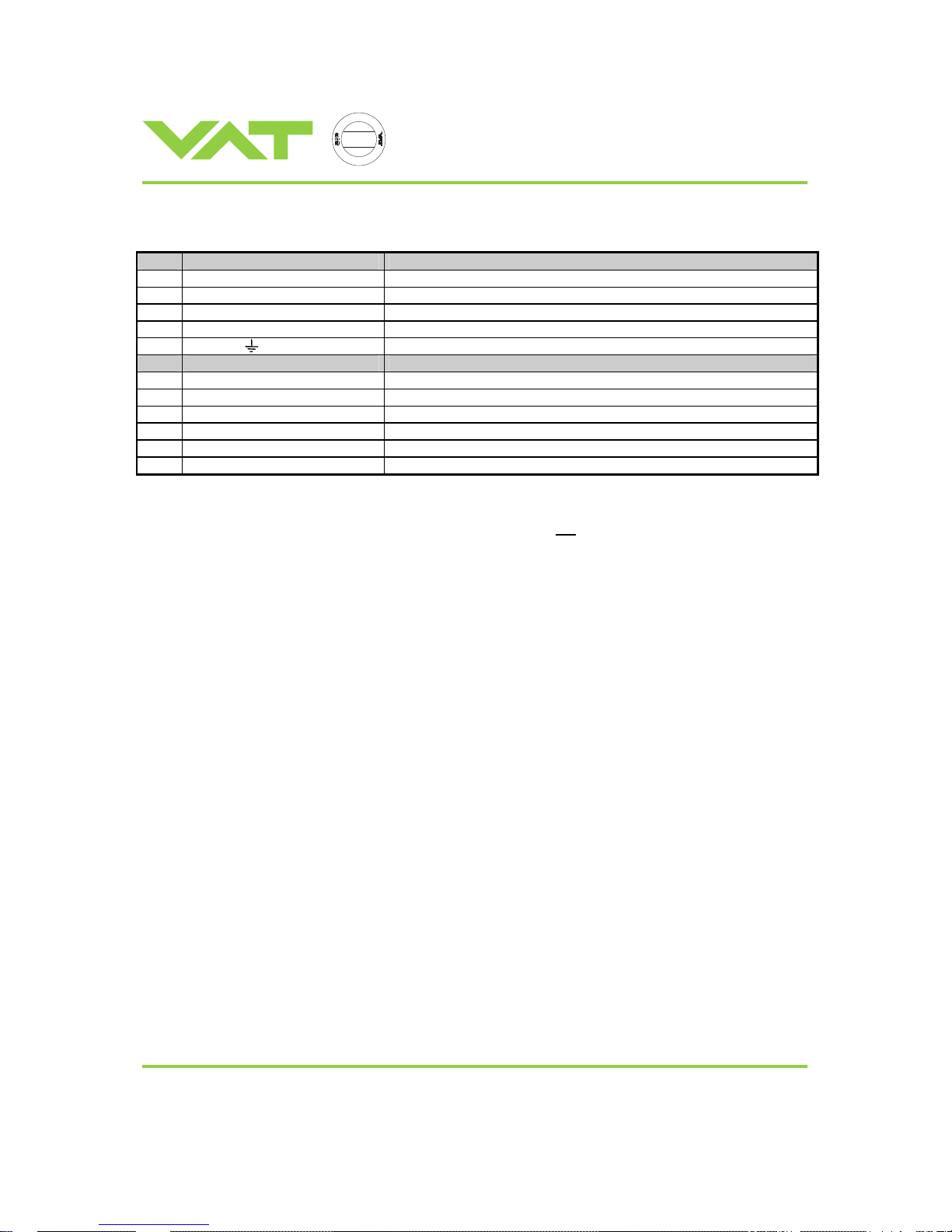

9.1.1 Connector for sensor 1 and sensor 2

PIN Description

1 Connect shield of sensor cable

7 (-) Sensor signal

8 (+) Sensor signal

10

+ 15 VDC, max., ±5%, 1400 mA max. *

12 0 VDC

14

- 15 VDC, max., ±5%, 1400 mA max. *

*) total current for both sensors is 1400mA

Mind: Do not connect other Pins than indicated in the table above!

Recommendations:

- Use only shielded sensor cables

- Keep cable as short as possible, but locate it away from noise sources

- Use power supply of the PM controller for the sensor

- Mount the sensor, especially capacitance diaphragm gauges, at a place free of mechanical shock and/or vibrations

- Observe recommendations of sensor manufacturer

9.1.2 Connector for mains

PIN Description

L Phase (100 - 240 VAC +/-10%, 50/60Hz, 150 VA max.)

N Neutral

Ground

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

10/16

9.1.3 Connector for interface

PM controller may be equipped with a Lo gic, RS232C or no interface.

9.1.3.1 Logic interface

Connection via 25-pole D-subminiature socket INTERFACE located on the rear of the PM controller. A counter plug is

attached to each control unit.

PIN Function Description

Digital Inputs Inputs to PM controller

6 Common (-) Common for all external inputs. Use relay or optocoupler.

7 Control mode Contact closed = pressure control mode

Contact open = position control mode

14

2

1

4

1, 4

Set point 1

Set point 2

Set point 3

Set point 4

Auto size adjust

If no set point is selected, the PM controller uses the analog signal on PIN 24 (if position mode is

selected) or PIN 25 (if pressure mode is selected) as set point.

Mind: Do not select set point 3 and set point 4 at the same time (see below).

This function will be started by connecting PIN 1 and PIN 4 to PIN 6 at the same time for at least

1 second.

3 ZERO Automatic zero adjustment for pressure sensor. Contact to be closed for 0.5 s min.

19 LEARN Contact closed = auto learning as long as contact is closed

Contact open = auto learning is interrupted

15

17

CLOSE valve

OPEN valve

Contact closed = valve closes

Contact closed = valve opens

Notice: The valve remains closed or open as long as the contact is closed. Close has higher

priority than open.

5 DISABLE LOCAL Contact closed = PM controller is switched into remote mode, key pad LOCAL is

disabled as long as contact is closed

Contact open = key pad LOCAL enabled, PM control unit remains in remote mode

16 Hold Contact closed = hold

Digital Outputs Outputs from PM control unit to host controller

20 Common Common for Digital Outputs

8 Valve in OPEN position Contact closed = valve is in open position

9 Valve in CLOSED position Contact closed = valve is in closed position

21 PM in REMOTE mode Contact closed = PM controller unit is in REMOTE operation

22 Deviation Contact closed during zero adjust, learn procedure, in position mode while actual valve position

exceeds 0.1 % of position setpoint, in pressure mode while actual pressure exceeds 2 % of

pressure setpoint

Analog Signals

13 Common Analog ground

24 Position setpoint input The voltage is proportional to the rotation angle of the rotary feedthrough

10V = 1000 = open, 0V = 0000 = closed but not yet isolated, R

i

> 100kOhm

(Use digital input for isolation function)

25 Pressure setpoint input The voltage is proportional to the pressure set point

10V = FS of pressure range, 0V = 0, R

i

> 100kOhm

11 Position output The rotation angle of the rotary feedthrough is proportional to the voltage

10V = 1000 = open, 0V = 0000 = closed, 1mA max.

(Use digital output for isolation function monitoring)

12 Pressure output The voltage is proportional to the actual pressure

10V = FS of pressure range, 0V = 0, 1mA max.

10

23

potentiometer supply 1

potentiometer supply 2

Auxiliary voltage +15V, Ri = 3.9kOhm

Auxiliary voltage +15V, R

i

= 3.9kOhm

Mind: Do not connect other Pins than indicated in the table above!

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

11/16

9.1.3.2 RS232C interface

PIN Function Description

RS232C

2 TxD Transmitted data from the PM control

3 RxD Received data by the PM control

7 GND Signal Ground

1 Ground Chassis Ground

Digital Inputs / Outputs

15 CLOSE VALVE input Valve will close when contact PIN 15 to 23 is closed

17 OPEN VALVE input Valve will open when contact PIN 17 to 23 is closed

23 Common for digital input Use relay or optocoupler

8 OPEN VALVE output Valve is open when contact between PIN 8 and 10 is closed, 70V / 0.5 A max.

9 CLOSE VALVE output Valve is cl osed w hen cont act bet ween PI N 9 an d 10 i s close d, 70V / 0.5 A max .

10 Common for digital output 70V , 0.5A max.

Mind: Do not connect other Pins than indicated in the table above!

Note: Logic inputs CLOSE valve and OPEN valve are executed in REMOTE and LOCAL operation. These signals have priority

(CLOSE is higher than OPEN) and they are executed immediately.

Local operation:

- The controller remains in OPEN or CLOSE after the logic input is reset.

Remote operation:

- The controller will resume the previous command after the logic input is reset.

- In case a RS232 command is received while a logic input is active this will be accepted by the PM controller and executed

after the logic input is reset.

A flashing LED on the «OPEN» or «CLOSE» key indicates that the logic input OPEN valve, resp. CLOSE valve is activated.

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

12/16

9.2 RS232C Interface Configuration

9.2.1 Options

OPTION:

Default:

RANGE / DESCRIPTION:

- Baud rate:

4800 110 to 19200

- Parity bi t:

Even even, odd, “1“, or “0“

- Data length:

7 bits 7 or 8 bits

- Stop bit/s:

1

Note: If 2 stop bits are required, parity bit has to be set to “1“ and it will then

serve as additi onal (second) stop bit.

- 2nd acknowledgement

(Answer) enabled

Yes/No

NO Immediately after receipt of the command, the PM controller will send an

acknowledgement that the command has been received. Please refer to section

‘9.3 RS232C Communication’ for details. If 2

nd

command acknowledgement is

enabled, the PM controller will send a second acknowledgement after the

command has been executed.

Example: "C:<CR><LF>" command will close valve. The PM controller will

reply immediately afterwards with "C:<CR><LF>". The valve will start to

close. If 2

nd

acknowledgement is enabled, then the PM controller will send in

addition "C:<CR> <LF>" when the valve is in CLOSED position.

- Logic inputs

- No function

9.2.2 Microswitch configuration

Note: Your PM controller may be ordered with a customized factory configuration.

s...default configuration

Default setting for 64PM.3 I.0 0: «1010 000 1»

Change of the con figuration: Switch off mains supply, disconnect mains connector, wait for 60 s, open top cover and set

DIL switches to the desired setting.

9.3 RS232C Communication

Logic inputs CLOSE a nd OPEN are executed in R EMOTE and

LOCAL operation.

These signals have priority (CLOSE is higher than OPEN) and they are executed immediately

(see chapter ‚9.1.3.2 RS232C interface‘ for details)

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

13/16

9.3.1 Control commands

Note:

<CR> = Carriage Return (0D hexadecimal); <LF> = Linefeed (0A hexadecimal); _ = Space (20 hexadecimal)

Control commands starting with ‘U:’ are accepted in REMOTE and LOCAL mode. All other control commands are accepted only, when the

PM controller is in REMOTE mode.

Control commands are acknowledged by one or two acknowledgements:

1st acknowledgement: Confirmation that command has been received, within 40 ms

2nd acknowledgement: If enabled, confirmation that command has been executed

Please refer to chapter ‚9.2 RS232C Interface Configuration‘ to select 1 or 2 command acknowledgements.

Description Commands

Acknowledgements

2nd acknowledgement in

parenthesis

Examples / Explanation

Remote Operation

U:01<CR><LF> U:<CR><LF>

= switch to Remote

Local Operation

U:02<CR><LF> U:<CR><LF>

= switch to Local

Close valve

C:<CR><LF> C:<CR><LF>

(C:<CR<<LF>)

= close

Open valve

O:<CR><LF> O:<CR><LF>

(O:<CR<<LF>)

= open

Select valve position

in 1/1000 of stroke

(0000 = closed, 1000 = open)

R:xxxxxx<CR><LF> R:<CR><LF>

(R:<CR><LF>)

R:000428<CR><LF>

= 428 * 1/1000 of stroke

Zero adjust

Sensor offset adjustment

Z:<CR><LF> Z:<CR><LF>

Automatic zero adjustment

Learn

up to maximum pressure to be

learned in 1/1000 of sensor

full scale

L:00xxxx<CR><LF> L:<CR><LF> L:001000<CR><LF>

= up to sensor full scale

L:000100<CR><LF>

= up to 100 * 1/1000 = 10%

Pressure command: ‘S:’

Standard command

xxxx = 0000 to 1000 Pressure

in 1/1000 of full scale

S:00xxxx<CR><LF>

S:<CR><LF>

(S:<CR><LF>)

S:000119<CR><LF>

= 119 * 1/1000 of sensor full

scale

Select Sensor 1

U:12<CR><LF> U:<CR><LF>

Default, after power on

Select Sensor 2

U:13<CR><LF> U:<CR><LF>

Hold mode

Freeze valve position

H:<CR><LF>

K:<CR><LF>

H:<CR><LF>

K:<CR><LF>

= start hold

= change to pressure mode

Note: Command can be used in

pressure and position mode.

Reduced positioning speed

in 1/1000 of maximum speed

(remains stored until next

speed is given and is set to

1000 after mains is switched

off) Function is active for R:

V:xxxxxx<CR><LF>

V:<CR><LF>

V:000200<CR><LF>

R:000428<CR><LF>

= Actuator speed is 200* 1/1000

= 20% of maximum speed,

while gate is moved to

position 428* 1/1000 = 428

Auto size adjust

J:<CR><LF> J:<CR><LF>

Automatic adjustment to valve

size

Disable Power Failure Option

Enable Power Failure Option

U:14<CR><LF>

U:15<CR><LF>

U:<CR><LF>

U:<CR><LF>

After power-up, PFO is always

enabled.

Interlock front panel keys

U:03<CR><LF>

U:04<CR><LF>

U:<CR><LF>

U:<CR><LF>

= interlock Local/Remote

buttons

= release Local/Remote buttons

Disable LOGIC INPUT

Enable LOGIC INPUT

U:16<CR><LF>

U:17<CR><LF>

U:<CR><LF>

U:<CR><LF>

= Disable LOGIC INPUT

= Enable LOGIC INPUT

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

14/16

9.3.2 Inquiry commands

Note:

<CR> = Carriage Return (0D hexadecimal); <LF> = Linefeed (0A hexadecimal); _ = Space (20 hexadecimal)

Inquiry commands are accepted in REMOTE and LOCAL mode. After receipt of an inquiry command, the PM controller sends back the

corresponding acknowledgement within a maximum of 40 ms.

Description Commands Acknowledgements Examples / Explanation

Actual valve position

in 1/1000 of stroke

A:<CR><LF> A:xxxxxx<CR><LF>

A:000428<CR><LF>

= 428 * 1/1000 of stroke (0 = closed,

1000 = open)

Actual pressure

in 1/1000 of sensor

full scale

P:<CR><LF>

P:xxxxxx<CR><LF>

P:000119<CR><LF>

= 119 * 1/1000 of sensor full scale

P: -00004<CR><LF>

= -4 * 1/1000 of sensor full scale

(-0.4%(sensor offset))

Pressure setpoint

value

W:<CR><LF>

W:xxxxxx<CR><LF>

W:000119<CR><LF>

= 119 * 1/1000 of sensor full scale

Operating mode

I:<CR><LF> I:LOCAL<CR><LF>

I:REMOTE<CR><LF>

I:LOCKED<CR><LF>

= LOCAL mode

= REMOTE mode

= logic inputs from RS232 are active

Control mode

M:<CR><LF> M: POS<CR><LF>

M: PRESS<CR><LF>

= POSITION MODE

= PRESSURE MODE

Self te st

T:<CR><LF> T:____OK<CR><LF>

T:PAR-ER<CR><LF>

T:ROM-ER<CR><LF>

= memory o.k.

= parameter error

= EPROM error

(see section ‚6 Trouble Shooting‘ if

«PAR-ER» or «ROM-ER» appears)

Sensor zero offset

in 1/1000 of sensor

full scale

z:<CR><LF>

z:xxxxxx<CR><LF>

z:000015<CR><LF>

= 15 * 1/1000 of sensor full scale

c:<CR><LF> c:xxxxxxxxxx<CR><LF> c:0000125013<CR><LF>

= 125’013 cycles

Valve cycle counter

n:<CR><LF> n:<CR><LF>

= set counter to zero

Software versio n

i:01<CR><LF> i:01xxxxxxxx<CR><LF>

i:0164PM3I00<CR><LF>

= software version 64PM.3I.00

Read current

sensor 1 setup

i:02<CR><LF> i:02sabcdef<CR><LF>

Current sensor 1 setup; for abcdef refer to

setup commands:

Read current

sensor 2 setup

i:03<CR><LF> i:03sabcdef<CR><LF>

Current sensor 2 setup; for abcdef refer to

setup commands:

p:<CR><LF> p:____OK<CR><LF>

p:POS-ER <CR><LF>

= position o.k.

= plate position error

Position error

f:<CR><LF> f:<CR><LF>

= reset error flag

Valve position

i:05<CR><LF> i:05V1:aV2:b<CR><LF>

a = 0 (valve 1 open)

a = C (valve 1 closed)

a = N (valve 1 in intermediate pos.)

b = - (not connected)

Upload of learned

data

u:mmm<CR><LF> u:mmmdddddddddddd

<CR><LF>

Download of learned

data

d:mmmdddddddddddd

<CR><LF>

d:mmm<CR><LF>

mmm = index 000-082

to up-/download complete data all indices

have to be used

ddd.. = data in hexadecimal format

(0...9, A...F)

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

15/16

9.3.3 Sensor setup command

Note:

<CR> = Carriage Return (0D hexadecimal); <LF> = Linefeed (0A hexadecimal); _ = Space (20 hexadecimal)

Sensor setup commands are accepted only, when the PM controller is in REMOTE mode.

Description Commands Acknowledgements Examples / Explan ation

Sensor Setup s:xabcdef<CR><LF> s:<CR><LF> s:2332010<CR><LF>

x = Sensor nr. 1 = sensor 1

2 = sensor 2

2 = sensor 2

a = Voltage Range

0 = 0 - 1 V , 1 = 0 - 2 V, 2 = 0 - 5 V, 3 = 0 - 10 V

3 = 0 - 10 V input signal

b = Display Range

0 = 0 - 1.000, 1 = 0 - 2. 000, 2 = 0 - 5.000, 3 = 0 - 10.00, 4 = 0 - 20.00

5 = 0 - 50.00, 6 = 0 - 100.0, 7 = 0 - 200.0, 8 = 0 - 500.0, 9 = 0 - 1000

A = 0 – 2000, B = 0 – 5000, C = 0 - 2.500, D = 0 - 25.00, E = 0 - 250.0

F = 0 - 2500

3 = 0 - 10.00 full scale

c = Display Unit 0 = mbar, 1 = µbar, 2 = Torr, 3 = mTorr, 4 = Pa, 5 = kPa, 6 = V, 7 = %

8 = 0001-1000, 9 = none, A = Position Mod e on ly

2 = pressure display in Tor r

d = Gain Factor 0 = 1.00, 1 = 1.33, 2 = 1.78, 3 = 2.37, 4 = 3.16, 5 = 4.22, 6 = 5.62

7 = 7.50, 8 = 0.1, 9 = 0.13, A = 0.18, B = 0.23, C =0.32, D = 0.42, E = 0.56

F = 0.75

0 = Gain factor 1.00

e = Sensor Type 0 = mbar / Pa, 1 = Torr 1 = Torr sensor

f = Zero Adjust 0 = enable, 1 = disable Zero adjust enable

9.3.4 Error messages

Error messages Description

E:000001<CR><LF>

Pari ty error

E:000002<CR><LF>

<CR> or <LF> is missing

E:000003<CR><LF> «:» is missing

E:000004<CR><LF>

Wrong letter code

E:000005<CR><LF>

Numerica l value not given in 6 digits

E:000006<CR><LF>

Numerical value larger 1000

E:000007<CR><LF>

PRESSURE MODE, ZERO or LEARN have been selected with no sensor connected (display

format set for no sensor)

E:000008<CR><LF>

Instruction given in operating mode LOCAL

E:000009<CR><LF>

RS232 commands Z:, L:XXXXXX or J: given while a logic input is activated

E:000101<CR><LF>

Error with LEARN

Pressure at closed valve is smaller than 5% of the sensor full scale

E:000200<CR><LF>

Error with ZERO

- valve is not in open position

- PM controller is switched in control mode PRESSURE MODE

- function ZERO blocked (= DISABLED)

c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Op erating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

16/16

9.4 User Information and Recommendati ons

9.4.1 Operation sequence of PM controller

Initialization

Prior to pressure control the setup sequence needs to be performed. Please refer to chapter ‚2.3 PM Configuration (setup sequence)‘

Pressure Control Sequence in LOCAL mode or with ‘S:’ Command

Pressure control starts after «PRESSURE MODE» and a «SET POINT» is selected or after a pressure control command is sent to the PM

controller.

9.4.2 How to opt i m iz e se nsor signa l r eso l ut i on

Full scale signal of the sensor is converted by a 12bit AD converter. The resolution depends therefore on the Voltage Range.

Example: Sensor: 1 Torr full scale, 0 to 10 VDC output;

Required pressure range: 0 to 120 mT

Standard sensor setup on PM: Voltage Range: 0-10V, Display Range: 1, Display Unit: Torr

→ Resolution of PM controller: 1Torr * 0.03% = 0.3mT

Recommended for sensor setup: Voltage Range: 0-2V, Display Range: 0-200, Display Unit: mTorr

→ Resolution of PM controller: 200mTorr * 0.03% = 0.06mT

Valve

Position

Control Mode

Pressure

Valve

OPEN

Gas flo w

Loading...

Loading...