VASTEX E-100-2128, E-100-2331, E-100, E-1000, E-1-4731 Assembly And Operation Instructions Manual

...

Doc. # 01-04-021E

Year of Manufacture: 20____

Fluorescent Exposing Units

Original Instructions

E-100 & E-1000

Assembly and Operation Instructions

E100-2128

E1-4731

E100-2331

Vastex International, Inc.

1032 N. Irving St.

Allentown, Pa. 18109 USA

Phone# 610 434-6004 Fax# 610 434-6607

Contents Pg. #

Introduction, Machine Specifications 2

Safety Information 3

Assembly Instructions 4-5

Operating Instructions 6

Troubleshooting 7

Maintenance 8-9

Emulsion Tip 10-11

01-00-005/015 Warranty/Terms and Conditions 12

Electrical Drawing #: Revision:

Serial Number: VTX

(Please log your machine's serial number and date of purchase for future reference.)

Date: / /

Web Site www.vastex.com

Authorized Representative in Europe:

Certification Experts BV

Nieuwstad 100 1381 CE Weesp,

The Netherlands

Tel : + 31 (0) 294 – 48 33 55

Fax : + 31 (0) 294 – 41 46 87

Vastex E-mail assistance

Purchasing & Product Info:

sales@vastex.com

Electrical Support:

stech@vastex.com

Tech Support, Mechanical Setup, and Operation:

techsupport@vastex.com

Screen Printing Issues & Support:

printech@vastex.com

Doc. # 01-04-021E

Pg. 2

Introduction

Vastex Exposing Units

(Ultraviolet Exposure Systems)

Thank you for purchasing your printing equipment form Vastex International Inc.

Vastex has been designing and building printing equipment since 1960. We have knowledge and

experience, and are proud to supply the printing industry with quality equipment at an affordable price. You

can be confident your purchase will give you years of trouble free service.

Machine Specifications & Part Numbers

Overall Size (lid closed)

Depth x Width x Height

Weight

Screen Capacity

Power Requirements

Vacuum Pump

Vacuum Timer

Exposure Timer

Glass Reorder Numbers

Light Source

Vacuum Blanket

Lid Seal

E100-2128 E100-2331 E1-4731

32.75” x 37.75” x 14”

(83 x 88 x 36 cm)

151 lbs. (68.5kg) 174 lbs. (78.9kg) 273 lbs. (123.8kg)

21" x 28" 23” x 31” (2) 23" x 31" or a 31" x 47"

120v: 60Hz @ 3.5 Amps

240v: 50/60Hz @ 2 Amps

1/16 HP Diaphragm Pump

(120V P/N: 04-02-040)

(240V P/N: 04-02-041)

Analog P/N 04-01-085 Analog P/N 04-01-085 Analog P/N 04-01-085

Analog P/N 04-01-085 Analog P/N 04-01-085 Digital P/N: 04-01-083

P/N: 04-08-060 P/N: 04-08-048 P/N: 04-08-049

(4) 24" Black UV Bulbs

P/N: 04-08-006

P/N: EUB-2128 P/N: EUB-2331 P/N: EUB-4731

P/N: 04-08-039 P/N: 04-08-039 P/N: 04-08-039

36.5” x 41.75” x 14”

(93 x 106 x 36 cm)

120v: 60Hz @ 3.5 Amps

240v: 50/60Hz @ 2 Amps

1/16 HP Diaphragm Pump

(120V P/N: 04-02-040)

(240V P/N: 04-02-041)

(6) 28" Black HO UV Bulbs

P/N: 04-08-050

(106.7 x 132.1 x 114.3 cm)

240v: 50/60Hz @ 4 Amps

(120/240V—P/N: 04-02-060)

(12) 28" Black HO UV Bulbs

42” x 52” x 45”

120v: 60Hz @ 5 Amps

1/4 HP Rocking Piston

Pump

P/N: 04-08-050

Floor Model/Tabletop

Warranty

Table Top, optional stand

1 Year; Manufacturer

Essential Characteristics of tools which may be fitted to this machinery: This equipment is

not designed to be used with any additional attachments or tools, other than as specifically listed

available

defects

Table Top, optional stand

available

3 Years; Manufacturer

Defects

Floor model only

3 Years; Manufacturer

Defects

Doc. # 01-04-021E

Pg. 3

Safety

Intended Use:

This equipment is intended for the purpose of exposing screens and films with UV light in conjunction with

UV sensitive emulsions.

Safety:

The operator should read and understand this manual before operating this equipment. Store manual

and safety information near equipment for easy

access to operators.

Never leave equipment unattended while in operation.

Children and pets must be kept clear of the work area.

Do not store any objects on top of the exposing unit.

Unplug power cord before removing glass or entering control box.

Do not operate if any guard or cover has been removed.

Do not operate if power cord is damaged.

Safe Operating Temperature (Ambient): 55°F-100°F (13°C-38°C)

Do not attempt to defeat safety interlocks.

Noise and Vibration: This noise level produced by this equipment does not exceed 70 dB(A).

** WARNING HANDLE GLASS WITH CARE **

Wear gloves when handling the glass

Lay glass only on a flat protected surface

Tempered glass, although strong, can shatter if the edges are subject to an impact

General Information

Exposing Unit must be on a flat surface to

eliminate stress on the glass.

Caution! Screens must be free of sharp edges.

All surfaces coming in contact with vacuum

blanket should be rounded and smooth.

If installing onto the Vastex utility cart, see the

utility cart manual for

attachment procedure. (E-1000 Only)

Black UV light bulbs are used in Vastex exposing

units. Ultraviolet output of bulbs will lessen over

time. Replacing of bulbs is recommended if

longer exposure times are noticed. Changing

bulbs every 1 to 2 years is recommended. See

the Lamp Maintenance section of this manual for

details.

Keep the lid in the raised position when not in

use. It will increase the life of lifting cylinders

and the rubber blanket.

Tools Required

Philips Head Screw Driver

7/16”, 1/2”, 9/16" & 5/8” Wrenches

OR METRIC: 11mm, 13mm, 15mm, 16mm

Doc. # 01-04-021E

Pg. 4

Assembly

Getting started:

Your Exposing Unit has been fully assembled and tested in our factory. Both lid lifting

cylinders have been removed from their upper mounting stud and secured to the side of the

cabinet. Follow the steps in this manual to reattach them. Be careful not to damage the

rubber vacuum blanket when removing the Exposing Unit from it's crating.

It is best to keep the lid locked closed when lifting the exposing unit. Carefully remove the

unit from its crate and place it on a suitable surface. It is important that the surface be flat, an

uneven surface can put stress on the glass causing it to crack.

Placing the equipment into service and operating the equipment:

To place equipment into service, follow steps 1-4 (if applicable to your unit) and 5 on page 5.

To operate your exposure unit, follow the instructions on page 6 and the troubleshooting and maintenance

instructions on pages 7-9.

Stability during use, transportation, assembling, dismantling when out of service, testing, and

foresee able breakdowns:

This equipment is designed to be stable under all foreseeable conditions if the instructions provided

herein are followed. Do not place the units into positions not shown in this manual (e.g., on their sides) and

do not operate with any parts removed unless necessary for troubleshooting.

Safe transport, handling, storage: when the equipment is transported, it should moved by two or more

people. No other special precautions are required. Refer to page 2 for unit masses.

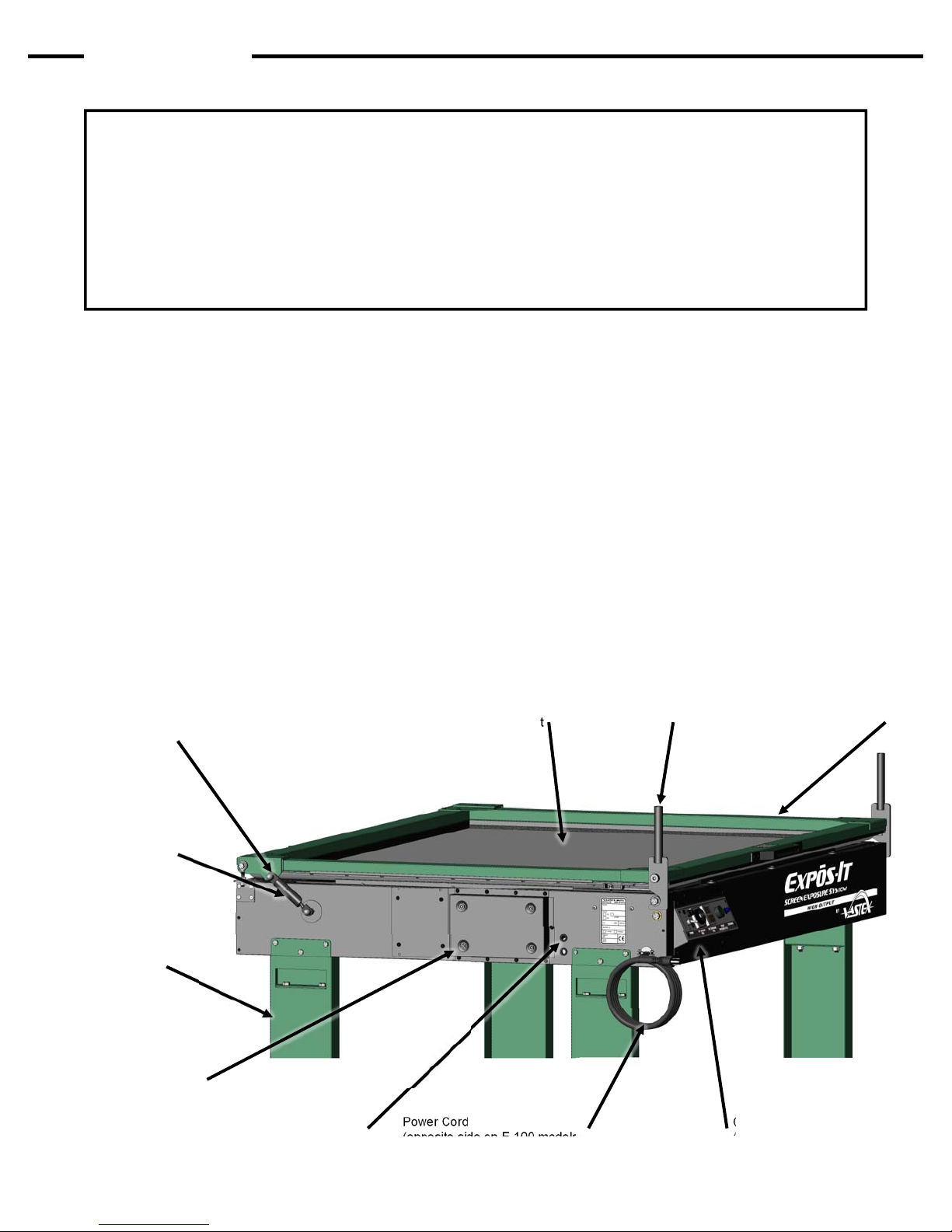

Acorn Nut & Upper

Cylinder Mounting Stud

(2) Lid Lifting Cylinders

(one on each side)

(2) Leg Assembly

(E1-4731 Only)

(2) Lid Locking HandleRubber Vacuum Blanket

Lid

Vacuum Pump Access Panel

(E1-4731Only)

Pump Exhaust

(opposite side on E-100 models)

Power Cord

(opposite side on E-100 models)

Control Panel

(opposite side on E-100 models)

Loading...

Loading...