Year of Manufacture: 20____

D-100 and D-1000 Series Dryer

Assembly and Operating Instructions

Doc. # 01-23-001E

Contents Page#

Safety Information 2

General Information 3

Package Contents 4-5

Component Identification 6

Assembly 7-10

Electrical Requirements/Controls 11

Operation 12

Chain Drive Adjustment 13

10” Extension 14

Warranty 15

Electrical Drawing #:

Serial Number:

(Please log your machine's serial number and date of purchase for future reference.)

VTX

Rev:______

Date:____/____/______

Vastex International, Inc.

7 Emery Street

Bethlehem, PA 18015-1982 USA

Phone# 610 625-2702 Fax# 610 625-2775

Web Site www.vastex.com

Authorized Representative in Europe:

Certification Experts BV

Nieuwstad 100 1381 CE Weesp,

The Netherlands

Tel : + 31 (0) 294 – 48 33 55

Fax : + 31 (0) 294 – 41 46 87

Vastex E-mail assistance

Purchasing, product and printing Info:

sales@vastex.com

Electrical Support:

stech@vastex.com

Tech Support, Mechanical Setup, and Operation:

techsupport@vastex.com

Introduction

Pg. 2

Congratulations, you have chosen a VASTEX conveyor cur ing system. VASTEX has been designing and building dryers

since 1960 and has the knowledge and expertise to supply a quality dryer an d help you keep it running for years to come. VASTEX

has innovated many of the features found in conveyor ovens today from control methods, modular features, air movements and belt

tracking.

Vastex Infrared Dryer have been Factory tested and burned in for a period of 2-8 hours. All components are tested to be

sure they work correctly when the Dryer leaves our factory.

Inspect all packages and notify the shipping company if

any damages are detected.

Safety

The Instruction Manual and Safety Instructions must be read and understood by anyone operating

the Vastex Conveyor Drying System.

The operator should read and understand the instru ction manual before operating this equipment. Store instruction manual

and safety instructions near equipment for easy access to operators.

VASTEX Conveyor Drying System is intended for the curing of non-fla mmable inks on screen printed materials. Do not use

for any other purpose unless authorized by Vastex International, Inc. Use of this equipment for any other purpose can be dangerous and may cause damage to this equipment, voiding the warranty.

It is recommended that the area around this equipment be designated as a work area and only authorized employees be al-

lowed in the area.

Children and pets must be kept clear of the work area.

Do not place any objects on top of the drying chamber. Surfaces are hot!

Never leave equipment unattended.

Do not operate conveyor or dryer with any cover or guard removed.

Operator must be familiar with controls of the dryer and conveyor.

Never put excessive load on the conveyor belt.

Before starting production, the operator must check that all covers and guards are in place, no material has been left on the

conveyor, and the work area is clear of obstructions.

Switch on and verify conveyor belt is moving before turning on the heat.

Allow dryer to cool to 300°F (149°C) or turn off heat for 10 to 15 minutes before switching off conveyor.

Always turn off power at the main disconnect at the end of production.

In case an abnormal symptom occurs, for example excessive vibration, noise, and strong smell or smoke development, turn

off the VASTEX Conveyor Curing System and contact a qualified technician.

Immediately turn off the VASTEX Conveyor Curing System if products become jammed in the drying chamber or conveyor

belt.

Do not remove any cover or guard until power at the main disconnect is switched off and locked out. No unauthorized per-

sons are to be allowed inside the control boxes.

Turn off and lock out power at the main disconnect before any cleaning or maintenance.

Only qualified technicians should be allowed to make repairs on the VASTEX Conveyor Drying System.

Stability during use, transportation, assembly, testing, and foreseeable breakdowns:

Pg. 3

The D-100 and D-1000 dryers are designed and expected to be inherently stable under all foreseeable conditions of use, assembly, testing, etc., so long as the procedures listed in this manual are followed. Be certain that your workbench, table, or stand can safely support the weight of your ma-

Safe handling, transport, and storage:

Unplug your dryer and allow it to cool before storing. When handling or transporting your machinery, be aware of the following weights and dimensions:

D-100: Assembled — 89 lbs (40.4 kg); 46” x 24” x 24” (119 x 61 x 61 cm)

Boxes: #1 – 57 lbs (25.9 kg); #2 – 14 lbs (6.4 kg); #3 – 18 lbs (8.2 kg); Boxes on skid: 115 lbs

(52.2 kg)

D-1000: Assembled — 116 lbs (52.6 kg), 46” x 32” x 24” (119 x 81 x 61 cm)

Boxes: #1 – 38 lbs (17.2 kg); #2 – 43 lbs (19.5 kg); #3 – 35 lbs (15.9 kg); Boxes on skid: 137 lbs

(62.1 kg)

Safety during adjustment and maintenance

Before beginning any maintenance or adjustment procedures on your dryer:

If the machine’s heater has been ON, shut the heat control OFF, but allow the belt to continue

running for 10 -15 minutes, or until the heater has cooled to 300°F (149°C) or lower . If the belt

is stopped while the heater is hot, belt damage will occur.

Switch machine OFF and disconnect from power before beginning any adjustment or mainte-

nance.

Do not attempt any maintenance while machine is powered.

Do not run machine with panels or guards removed.

Adjustment and Maintenance:

Periodically check ink temperature on garments exiting machine. See page 11, “Operation

Tips.” Readjust temperature control as necessary to maintain correct temperature for your application.

Occasionally, check belt tracking and adjust if necessary. See page 9, step 12.

Chains in chain drives can loosen over time; occasionally check the tension on the chain in your

machine.

In the event of a malfunction or breakdown:

Allow heater to cool, then shut off machine and disconnect from power as described above in

“Safety during adjustment and maintenance.”

Follow the troubleshooting chart below

If the chart does not resolve the trouble, contact Vastex for additional assistance.

Symptom Possible Cause Solution

No functions operate Machine unplugged

Building wiring fault

Belt does not move Belt circuit fuse(s) blown

Speed control faulty

Belt motor faulty

Make sure machine is plugged in.

Have wiring checked.

Check or replace fuse(s).

Replace. Contact Vastex.

Replace. Contact Vastex.

No heat Faulty heater control

Faulty heater assembly

Replace. Contact Vastex.

Replace. Contact Vastex.

Package Contents D-100 only

Pg. 4

3 Separate Cartons

Carton #1 Conveyor Components

Conveyor Assembly

Conveyor Belt

16 x 16 Infrared Heater

Hardware Package Contains

(36) Black #8 Sheet Metal Screws

(4) Heater Mounting Pins

(4) 3/8” Flat Metal Washers

(2) 3/8” Flat Plastic Washer

1) Chain Guard

1) Hardware package with:

6 screws and 2 belt guards.

Carton #3 Chamber Components Carton #2

Side Panel

Back Panel

Front Panel

Side Panel

Knobs

Wire Cover

Top Cover

Package Contents D-1000 only

Pg. 5

3 Separate Cartons

Carton #1 Front Conveyor Components

Front conveyor with belt

aligner and front pulley.

Carton #3 Chamber and heater Components

Carton #2 Rear Conveyor Components

Rear conveyor with Drive

motor, controls and

rear pulley

Additional items above:

1) Belt, 1) Chain guard, and 1) Hardware

package with: 18 screws and 2 belt guards.

#8 sht

metal screw

16 x 20 Infrared Heater

Hanger

Install hanger with provided #8

sht metal screws as shown above

Back Panel

Front Panel

Side Panel

Side Panel

Wire Cover Knobs

Top Cover

Hardware Package Contains

(36) Black #8 Sht Metal Screws

(4) Heater Mounting Pins

(4) 3/8” Flat Metal Washers

(2) 3/8” Flat Plastic Washer

Component Identification

Pg. 6

Heater Height Adjustment Knob

Conveyor Assembly

(one each side)

1 pc D100

Heat / Belt Speed

Controls & Fuses

Belt Tracking Adjustor

(one each side)

Chamber Assembly

Heater Assembly

Conveyor Assembly

2 pc D1000

Belt Guards

(one each side)

Conveyor Drive,

under chain

Chamber Components

IR Heater The infrared heaters in VASTEX dryers emit medium wave infrared heat, perfect for curing many

HI-16-D100-120

HI-16-D100-240

HI-1620-D1000-120

HI-1620-D1000-240

types of fabric inks. The heater height and tilt is adjusted by knobs located on the sides of the chamber.

A heater height scale allows for accurate height adjustment.

Conveyor Components

Belt The conveyor belt is made of Teflon coated fiberglass. It is joined together with an alligator

D100 p/n 04-06-065

D1000 p/n 04-06-131

D1000 extension belt

p/n 04-06-132

Aligner

The aligner is a device for tracking the belt and keeping it on the pulley. As the belt moves from

lace using a steel pin to connect each side. The belt will not burn under normal conditions but

the dryer should always have the belt moving while the heater is hot. The belt should remain

tracked in the center of each pulley. (See Belt Installation and Tracking for adjustment instructions.)

side to side the aligner is used for adjustments to keep it centered. The belt does not have to be

perfectly centered on the pulley but should not be hanging over either edge.

Pulley The pulleys at either end of the conveyor are made by VASTEX of 4 ½ inch tubing with ¾ inch

center shaft. They are mounted on self aligning flange bearing blocks for precision rolling.

Gear Motor A 90 Volt DC gear motor is located to the rear of the conveyor. It drives the rear pulley and belt

P/N 04-02-005

with a roller and a #25 chain.

Belt Speed Control Rotate knob clockwise to increase, counter clockwise to decrease belt speed. Turn knob counter

P/N 04-01-004 (120V)

P/N 04-01-005 (240V)

clockwise until it clicks for off position.

Heat Control Turns power on/off and varies heater temperature.

P/N 04-01-008 (120V)

P/N 04-01-009 (240V)

Fuses Protects the belt drive control circuit.

P/N 04-03-057

One required for 120V Dryers, two required for 240V Dryers

(Fuse AGC 1 amp)

Assembly D1000 conveyor only

Pg. 7

The D1000 conveyor comes in two sections. Slide them

together while interlocking the joiner plates and insert six (6)

screws on each side as shown below.

Inner and outer joiner plates go

together as shown above.

Install 6 screws on each side.

NOTE: D100 conveyor come shipped as one piece.

Optional 10” Conveyor Extension D1000

The optional d-1000 conveyor extension comes complete. Instruction for installation are as follows: Disconnect

all power. Remove dryer chamber via 3 or 4 sheet metal screws on each side. Separate conveyor belt. Remove

front and back halves of the conveyor via 6 screws.

Front

Back

Remove 6 screws on each side. Sht metal screws (3 or 4 each side)

Separate front and rear conveyor sections. Insert the 10” conveyor extension noting th e position of the inner and

outer joiner plates. Attach extension to front and rear conveyor section with screws provided. Splice the conveyor

belt extension piece. Replace dryer chamber into conveyor via the sheet metal screws. Reconnect power.

Assembly

Pg. 8

Tools Required:

Note: A 1/4” and 7/16” Flat Plate Wrench is supplied.

Or use

1/4” Nut Driver (recommended) or 1/4” Socket and Ratchet (6.5mm)

7/16” Wrench Open End (11mm), for belt aligner adjustm e nt .

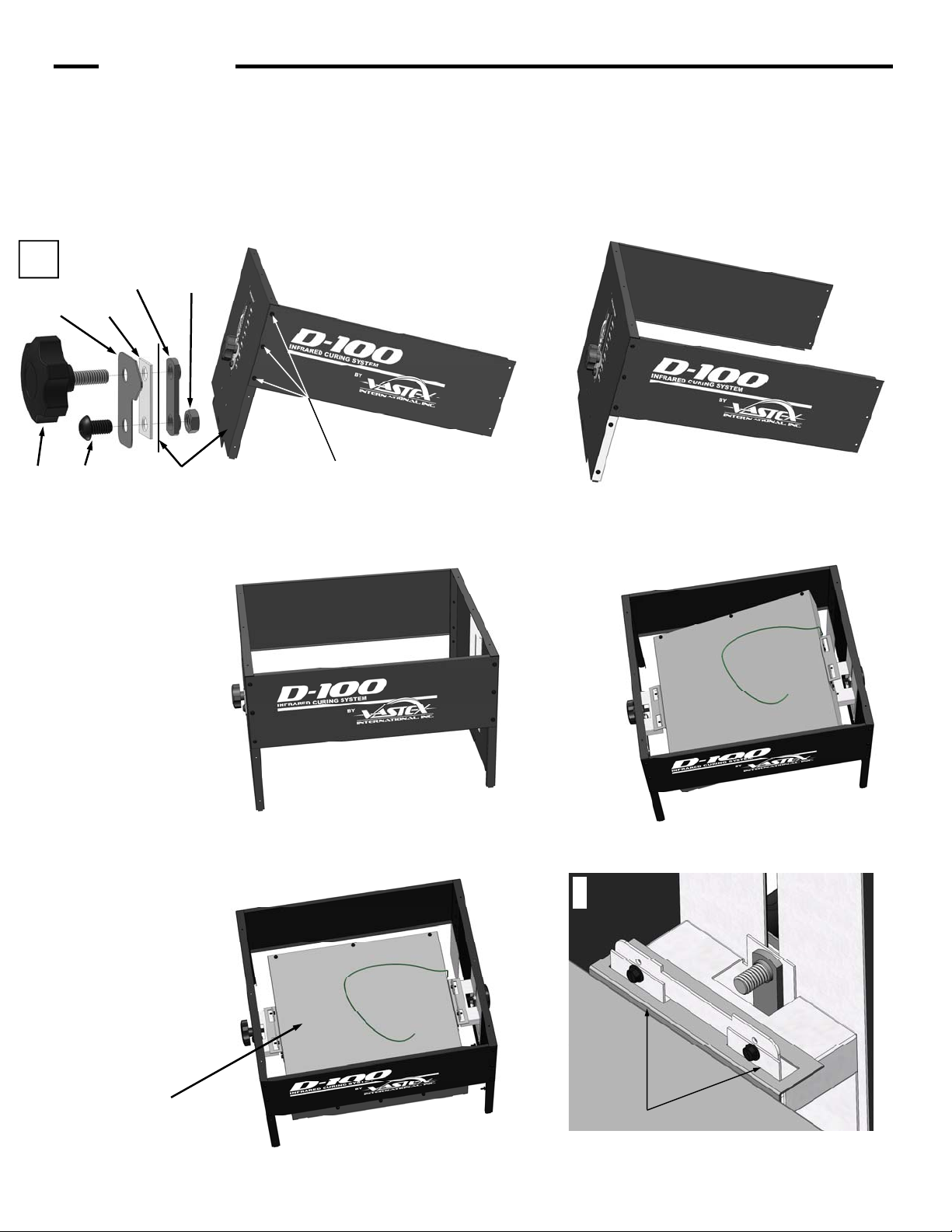

Chamber Assembly and Heater Installation

1A

Weldnut Hexnut

Pointer

Knob Bolt

Spacer

Side Panel

1B

Front Panel

Install (3) Sheet Metal Screws

(each corner)

Attach Front Panel to Left Side Panel

1A) Install knob and bolt through

pointer and spacer outside of

both side panels. Connect to

weldnut and hexnut on other

side as shown above.

Do not over tighten fasteners.

2

Attach Back Panel to Left Side Panel

Back Panel

3

Attach Front & Back Panel to Right Side Panel

5

4

Heater wires are towards back of chamber

6

See Pg. 5 for

heater assembly

Install (4) heater mounting

screws (2 each side)

Assembly Cont.

Pg. 9

Connecting Chamber To Conveyor

7

Front

Chamber alignment tabs

at four corners.

Printed Side

8

Install Sheet Metal Screws

(3 or 4 each side)

Pass the three wires,

one at a time, thru

the hole in the conveyor bed.

Tan wires first then

the green wire.

Pull wire thru to

make the connections.

Heater Mounting screws

(2 each side)

Back

Note: Power cord must be unplugged and

belt removed to make heater connections.

Do not operate dryer without belt installed.

Heater and mounting pins installed,

wires toward the back.

Position chamber onto conveyor.

Corner alignment tabs on chamber

slide into cutouts in conveyor. Note

heater wires are towards back of

conveyor. Attach chamber to conveyor with (6) screws, 3 each side.

9

Check that the heater mounting pins are

installed before proceeding. Carefully lay

the conveyor on its side as shown.

Assembly

Pg. 10

Heater Wire Connections

10A

See photo

Ground Wire Connection

Push any extra slack in the wires, back

up thru the hole in the conveyor bed.

10B

10B for

!

Heater Wires (tan wires) have

push on connectors. Attach

either wire onto either open

terminal (indicated on the left)

on the heat control.

It does not matter which wire

to which terminal. Align the

connector with the tab on the

heat control and push firmly

until fully seated. It should be

hard to push them on, we want

a tight connection. Pull gently

on each connector, it should be

held firmly onto the tab.

10B. Ground Wire Connection

Remove the wingnut and lock washer.

Place the green ground wire with the ring

terminal oriented as shown, onto the

grounding stud. Secure with lock washer

and wingnut.

Tighten nut securely.

Grounding Stud

Ring Terminal

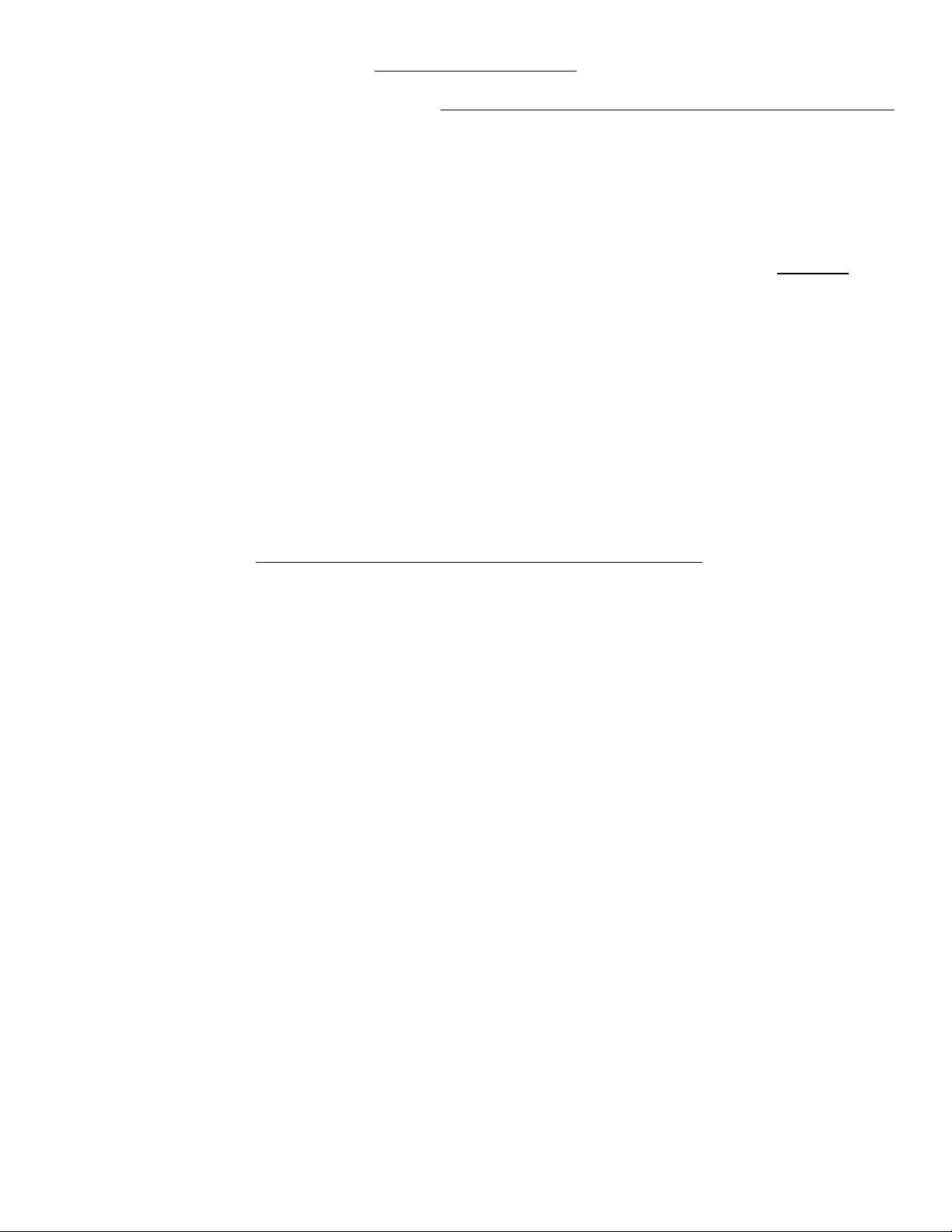

Belt Installation and Tracking

Belt Installation

1) While dryer is on its side, pass the belt over the aligner

bar and both braces.

2) Carefully lay the dryer back onto its feet.

3) Align the edges of the belt and insert the belt connecting

pin. See enlarged view below.

4) Center belt on both rollers. Raise both sides of the belt

aligner equally approximately 1-1/2”.

Do Not over tension belt, tension only enough to eliminate

any belt slip on drive pulley.

11

11

Align the edges of the belt.

Insert the belt connecting pin.

Pin ends can be trimmed if desired

Braces Aligner Bar

Assembly

Pg. 11

Belt Tracking

Adjuster Bolts

13

12

Left Side

Right Side

Belt Tracking

Perform after assembly is complete and dryer is on a flat surface.

Maintain belt as close to centered as possible on both rollers.

Do Not leave conveyor unattended during tracking process.

1) While conveyor is running at full speed, observe

position on both rollers.

2) Raising the belt aligner on one side moves the belt

in the opposite direction. Lowering the bar moves

the belt toward that side.

3) Make small adjustments, 1/4 turn of adjuster bolts.

Allow the belt to respond to the adjustment.

Never allow the belt to track off the rollers, belt damage

can result. Make belt tracking adjustments as needed.

High Temp.

PlasticTY-Wrap

(2) Sheet

Metal Screws

14

15

(6) Sheet Metal

Screws (3 each side)

Gently pull up on wires to remove any

excess wire from below the conveyor bed.

Place the high temperature plastic ty-wrap

as shown to control wire movement. Cut

extra material off ty-wrap.

Installing Chain Guard and Belt Guards

Chain Guard must be installed before

operating the dryer.

bottom of the guard into the slots below the

drive chain. Pivot the guard up, secure to the

Belt Guards are to be installed at both sides

on the rear of the conveyor. Secure to conveyor with (2) sheet metal screws.

Hook tabs on the

Install top cover after all heater

wire connections are completed.

Carefully position wires

behind wire cover, attach cover with (2) screws.

16

Belt Guards (both sides)

Chain Guard

Do Not operate dryer with chain guard removed.

Electrical Requirements

Pg. 12

Models: Plugs and receptacles listed are for domestic (USA) models. International models are sup-

plied with the appropriate power cords.

D-100 / 120Volts, 12.5Amps, 1.63KW

Requires dedicated 15 amp circuit with a NEW commercial duty 5-15R receptacle.

D-1000 / 120Volts, 16.5Amps, 2.05KW

Requires dedicated 20 amp circuit with a NEW commercial duty 5-20R receptacle.

D-100-240 / 240Volts, 6.3 Amps, 1.63KW

D-1000-240 / 240Volts, 8.6 Amps, 2.05KW

Requires good quality 6-15R receptacle. (Some international plugs available)

(North America Standard Receptacles)

D-100

120 Volt 15 Amps

Nema 5-15R Receptacle

D-1000

120 Volt 20 Amps

Nema 5-20R Receptacle

Controls

- Variable Heat Control

The control has positions LO-2-3-4-5-6 and HI. The

controller turns the power to the heater on and off to

vary the temperature. The higher the number on the

control the longer the on cycle and shorter the off cycle is. The “HI” position is full power.

- Heat On Light

This RED light is wired to the controller. It will illuminate when the control is turned on, even if the controller has failed.

- Belt Speed Control

Rotate clockwise to increase, counter clockwise to decrease belt speed.

- Fuses

Protects belt control circuit, (1) Amp AGC fast blow

One (1) fuse for 120 volt.

Two (2) fuses for 240 volt.

D-100 and D-1000

240 Volt 15 Amps

Nema 6-15R Receptacle

Control Plate

Dryer Operation

Pg. 13

Startup Procedure

Plug in Dryer:

Check belt path: Remove any objects from the conveyor and belt.

Turn on Conveyor: Set belt speed with the Belt Speed Control on the conveyor, near the motor.

Turn on the Heat

Curing Plastisol with infrared:

Plastisol ink can fully cure in approximately 20-30* seconds. Most inks must achieve 320°-330 F (160°-165°C) throughout to

cure and fuse to the garment. The thicker the ink the hotter the top skin has to be in order to be cured completely to the garment.

Discharge or water based: (A powered exhaust is recommended)

Water based products require more time than plastisol to cure due to the fact that the water/moisture must be evaporated before

the ink can cure. We have seen cure times from 50 to 90* seconds to achieve a full cure or discharge and not damage the garment. Please note as the time is increased the temperature must be decreased to protect the garment from scorching.

*Actual cure times can vary depending on conditions such as garment moisture and color, ink color, ink thickness, and

environmental conditions. All three variables should be used to maximize production while insuring a proper cure.

Set the Heat: With the dryer plugged in, rotate the Variable Control Timer to the desired setting. Often times, it is

: Turn the Variable Heat Control dial on HI for 10-15 minutes to allow the dryer to warm up.

Be sure the breaker and dryer controls are switched off. Plug the dryer into a properly

rated outlet and turn the breaker on.

best to run the dryer on HI and adjust your belt speed and heater height to achieve a proper cure.

Set the Heater Height: Set the desired heater height for your job. On each side of the heating chamber, there is a knob to

raise and lower the heater. It is recommended to run the heater height at about 2” - 3” above the

garment. The heater can be run at an angle for curing non-flat sub-straights such as hats.

Set the Belt Speed: Rotate the Belt Speed Control Knob clockwise to increase speed and counter-clockwise to

decrease it. For Plastisol inks, a good starting point is 20-25 seconds in the chamber. The

dial numbers are for reference only. They do not represent seconds in the chamber.

Operation Tips

While machine is in operation, it is necessary to have the belt moving while the heater is above 300°F (149°C).

Allow approximately 15 minutes for dryer to reach Ful l temperature.

If no garments are being run through the dryer for more than 10 minutes, it is recommended to lower the dryer

heat control to “4” or lower. It will take approximately 10 minutes to return to operating temperature.

Periodically check ink temperature at the exit of the dryer. It is recommended that you check the temperature of

the ink towards the outside of the printed image.

When checking temperature with a laser gun, shoot the ink while it is still under the heating elements.

Shut Down Procedure

Turn off Heat: Turn the Heat Control off. Allow the heaters to cool for 10-15 minutes before shutting the

conveyor off. Belt damage may result from stopping the conveyor with hot elements.

Turn off Conveyor: Once the dr yer cools down to 300°F (149°C) or lower, turn the Belt Speed down to the off

position. Skip this step if leaving the conveyor belt speed set for the following shift.

Turn off Breaker: Turn off the breaker controlling the dryers at the end of each shift and unplug them from

their outlets.

Chain Tension measured and why it is important

Pg. 14

The proper chain tension is critical to achieving acceptable service life as excessive tension can cause accelerated wear or

chain overload and excessive slack can cause rough chain operation and possibly result in the chain skipping a sprocket

tooth, resulting in a catastrophic failure. For Vastex drives, the total movement in the slack span of the chain (up and

down total movement) should be .25 to .38 inch. Please see below for picture.

This is the slack in the down position.

This is the slack in the up position.

Total slack is .25

to .38 inch. This is

total up and down

movement.

Vastex Warranty

Pg. 15

(1.) Vastex, hereinafter referred to as “seller” warrants only to its original “purchaser”, who holds a copy of the original invoice and is the original end user of the equipment in question, its

new equipment against manufacturer defects in materials or workmanship on a pro-rated basis. Warranty period begins from date of shipment to the buyer and will on l y apply to customers

paid in full. Warranty periods are as follows: one (1) year for E-1000, three (3) years for all other complete machines (including F-Flash), fifteen (15) years for infrared heaters (excluding FFlash) installed by Vastex in a new dryer, three (3) years for replacement infrared heaters, and one (1) year for replacement parts. Rubber blankets, light bulbs and glass on exposure units

are particularly subject to wear while in use. Wear is not covered by this warranty but as stated above only manufacturers defects are covered. All sales made through Vastex dealers must

be certified by that dealer before a warranty replacement is issued. All equipment is thoroughly tested and inspected before packaging. This warranty does not cover minor cosmetic

damages that occur during shi pment that do not affect the functionality of the equipment.

(2.) This warranty is expressly contingent upon the buyer delivering to seller, at the address below, with all transportation charges prepaid, the part o r parts claimed to be

defective within the above mentioned warranty periods stated in paragraph one. The defective part or parts will be repaired or replaced at the discre ti on of Vastex International,

Inc. If the equipment in question is less than one (1) year old, it will be shipped to the customer at no charge, with an RGA issued by Vastex for the defective part. The defective

part must be shipped back to Vastex freight prepaid within 30 d ays or the account will be billed. If the equipment is more than a year old, the part will be shipped after we

receive the defective part. If it’s necessary to expedite the movement of parts and to minimize down time to the buyer, the replacement part shall be supplied on a C.O.D. basis. If

testing and analysis of said part by the seller or its supplier discloses that said part is defective, the cost of said part will be refunded to the buyer on a prorated ba s i s.

(3.) Except as otherwise provided herein, the equipment is being s old “as-is”. Final determination of the suitability of the equipment for the use contemplated by the buyer, is the sole

responsibility of buyer, and seller shall have no responsibility in connection with the suitability.

(4.) All warranties implied by law, including the implied warranties of merchantability and fi tness are hereby limited t o manufacturer defects in materials or workmanship during the

warranty period stated in paragraph one. The express warranty and remedies contained herein and such implied limited warranties are made solely to the sole warranties and remedies and

are in lieu of all other warranties, guarantees, agreements, and other liabilities, w hether express or implied, and all other remedies for breach of warranty or any other liability of seller, in no

event shall seller be liable for consequential damages.

No person, agent, distributor, or service representative is authorized to change, modify or extend the terms hereof in any manner whatsoever.

These terms and conditions are an essential part of the transaction between the parties and constitute the entire agreement between them with respect to the same.

Some states do not allow lim i t ation on how long an implied warranty lasts of the exclusion or limitation of incidental, or consequential damages, so the above limitation may not

apply to you.

This warranty gives you speci f i c legal rights, and you may al so have other rights which vary from state to state.

Infrared heaters are the only replacement parts covered for a period of (3) years from date of shipment and contingent to receipt of payment in full.

Electrical components cannot be returned once installed unless proven defective.

Please refer to doc. 01-00-015 for specific terms and conditions of sale and the limited warranty.

Please refer to doc. 01-00-017 for V-2000HD printer warranty.

Updates: V1000 to 3 year warranty 01/09/12, Heater warranty to 15 years 01/02/2012.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

TERMS AND CONDITIONS OF SALE AND LIMITED WARRANTY Doc.#01-00-015

1. Buyer’s order will constitut e an offer in accordance with the terms hereof and such offer, upon acknowledgment of Sell er, will constitute the agreement between Buyer and Seller.

Buyer’s order after such acknowledgment by Seller will not be subject to canc ellation, change or reducti on in amount, or suspension by Buyer of deliveries, unless prior to such

action Buyer has obtained Seller’s written consent. Notwithstanding anything to the contrary in B uyer’s Purchase Order or other communications, the partie s agree to be bound by

these Terms and Conditions. Acceptance of the product by t he Buyer shall be deemed to c onst i tute unconditional acc eptance of these Terms and Condi t i ons.

2. Any of these terms, conditions and provisions of Buyer’s order which are inconsistent with Seller’s acknowledgm ent and these Terms and Conditions of Sale shall not be bindi ng on

the Seller and shall be considered not applicable to any sale so made. No waiver, alteration or modification of any of the provisions on either side of the document shall be binding

upon Seller unless agreed to in writing by Seller.

3. (a) All prices are F.O.B. Seller’s Plant and method of delivery and routing shall be at Seller’s discretion, unless specifically otherwise stated herein. Notwithstanding any agreement

4. It is understood that deliveries will be made in accordance with Seller’s regular production schedule. Every reasonable effort will be made to meet the Buyer’s required delivery

5. Seller reserves the right to increase the prices prior to Seller’s acceptance of order and/or after expiration of any price quoted by Seller.

6. Unless otherwise stated in writing, Seller’s prices do not include sales, excise, value-added or other taxes. Consequently, in addition to the price specified herein, the amount of any

7. Seller reserves the right, at any time, to revoke any credit extended to Buyer because of Buyer’s failure to pay for any products when due or for any other reason deemed good and

8. (a) SELLER’S LIABILITY SHALL BE LIMITED TO SELLER’S STATED SELLING PRICE PER UNIT OF ANY DEFECTIVE GOODS AND SHALL IN NO EVENT

9. The remedies herein reserved by Seller shall be cumulative and in addition to any other legal remedies. No waiver of a breach of any portion of this contract shall c ons t itute a waiver

10. These Terms and Conditions constitute the entire agreement of the parties. No amendments, changes, revisions or discharges hereof in whole or in part shall have any force or effect

11. This contract shall be governed and shall be construed according to the domestic laws of the Com monwealth of Pennsylvania.

12. Anything herein to the contrary notwithstanding, any action for alleged breach by Seller of the contract between the parties, including but not limited to any action for breach of the

13. This agreement shall inure to the benefi t of and be binding upon the parti es hereto, their respecti ve successors and permitted assigns.

14. All notices required by this contract to be given by either party shall be sent in writi ng or by facsimile and shall be addressed to the last known address of such other

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

to pay freight, delivery of products purchased hereunder to a common carrier or licensed trucker shall constitute delivery to Buyer and be determinative of the date and time of

shipment and all risk of lossor damage in transit shall be borne by Buyer. If the Buyer fails to accept the goods from the common carrier or licensed trucker, the Seller shall be

entitled to claim payme nt f romthe Buyer. Seller shall arrange for storage, the risk and the cost, includi ng insurance costs, to be borne by the Buyer (and Buyer agrees to pay

such amounts upon demand) e xcept if the failure to acce pt delivery is due to any of the exc eptions noted in Paragraph 4.

(b) Terms of payment shall be as stated on invoice.

dates but Seller will not be liable for damages or be deem ed t o be in default by reason of any failure to deliver or delay in delivery due to any preference, priority, allocation or

allotment order issued by the Government, whether Federa l , State or local, or causes beyond its control including but not limited to, Acts of God or a public enemy, acts of

Government, fires, floods, epidemics, quarantine restrictions, strikes, lockouts, freight embargoes, severe weather, unavailability of materials or shipping space, delays of carriers or

suppliers or delays of any subcontractors. Should delay in delivery be caused by any of the circumstances mentioned in this paragraph, such extension of the delivery period shall be

granted as is reasonable under the circumstanced of the case. Should delay be caused by an event not specif i cally mentioned in this par agraph, damages will be limited to

cancellation of the purchase order without penalty, and refund of any monies deposited or prepaid on the purchase order with no liability for any consequential or incidental damages.

present or future sales, use, excise, value-added or other tax applicable to the manufacture, sale, purchase or use of the products hereunder shall be paid by Buyer, or in lieu thereof,

Buyer shall provide Seller with a valid tax exemption certificate acceptable to the taxing authorities.

sufficient by Seller and in such event, all subsequent shipments shall be paid for prior to at delivery at Seller’s option.

INCLUDE BUYER’S MANUFACTURING COSTS, LOST PROFITS, GOODWILL, OR ANY OTHER SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, ARISING OUT OF THE AGREEMENT, THIS CONTRACT, THE SALE OF THE PRODUCTS TO THE BUYER OR THE USE OR THE PERFORMANCE

OF THE PRODUCTS. Seller may at its discretion repair, replace or give the Buyer credit (pro-rated) for such defective products.

(b) Notwithstanding anything herein to the contrary, Seller shall have no liability for alleged defects with the products which are not specified in written notice from the Buyer to the

Seller within thirty-six (36) months fro m the date of shipment of machine s . Seller shall pass to Buyer any warranty received by Seller from the manufacturer of Limited Life

Components, which in most cases is 12 to 18 months.

(c) Seller shall have no liability under this Limited Warranty unless Buyer has paid in full for the products. Further, this Limited Warranty is expressly contingent on Buyer’s

delivery to Seller, all costs prepaid, the defective part(s ) w ithin thirty-six (36) months of shipment to Buyer, together with a written statement specifying the alleged defect(s).

Any replacement part(s) shall be shipped to Buyer on a C.O.D. basis.

(d) SELLER SPECIFICALLY EXCLUDES ALL WARRANTIES, EXPRESSED, IMPLIED OR OTHERWISE, EXCEPT AS STATED EXPLICITLY IN THESE TERMS AND

CONDITIONS OF SALE. SELLER DISCLAIMS THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

of continuing or future breach of such provision or of any other provisions hereof.

unless set forth in writing and s i gned by the parties hereto. This contract shall not be assignable by Buyer voluntarily by operation of law or otherwise without Seller’s written

consent.

warranties herein set forth, shall be barred unless commenced by Buyer within one (1) year from the date such cause of action accrued.

party. Notices shall be deemed to have been received on the fifth business day following deposit in the mail.

Doc#01-00-005D Revised 2/20/2018

VASTEX 7 EMERY ST

INTERNATIONAL BETHLEHEM, PA. 18015 USA

Loading...

Loading...