Page 1

Subject to modification! Updated 10/2017 Version 09

INSTRUCTION MANUAL

VARTA element

VARTA Storage GmbH

Page 2

2

Subject to modification! Updated 10/2017

The first part of this manual contains general

information on how to use the VARTA element

energy storage system.

Further information can be found in the

“Installation”, “Operation in the passwordprotected area” and “Maintenance” sections.

Congratulations!

You have opted for an energy storage system from VARTA Storage

GmbH! We are pleased that in doing so, you chose a durable

system for which we considered quality paramount. Please read

through these instructions carefully. They describe how to operate

and use the battery.

Have fun storing power!

Guidance for the qualified electrician

Page 3

Subject to modification! Updated 10/2017

3

Legal notice

Original Instruction Manual VARTA Storage GmbH

VARTA Storage GmbH

Nürnberger Straße 65

86720 Nördlingen

Germany

www.varta-storage.de

Tel.: 0049 9081 240 86 60

info@varta-storage.com

Technical service:

technical.service@varta-storage.com

Tel.: 0049 9081 240 86 44

Document number: OM_850_809

Updated 10/2017

Version 09

Page 4

4

Subject to modification! Updated 10/2017

Contents

General ........................................................................................... 12

1 Information about this manual ............................................ 12

1.1 Explanation of symbols .............................................. 12

1.1.1 Safety instructions .............................................. 12

1.1.2 Warning levels .................................................... 13

1.1.3 General safety signs ........................................... 14

1.1.4 Warning signs ..................................................... 15

2 Safety ................................................................................. 16

2.1 General information on safety .................................... 16

2.2 Intended use ............................................................... 18

2.3 Requirements regarding qualified electricians ........... 19

2.4 General hazard sources ............................................. 20

2.4.1 Danger of electrical voltage ................................ 20

2.4.2 Danger from water .............................................. 21

2.4.3 Danger from oxidising and corrosive

substances ......................................................... 21

2.4.4 Danger from heat ............................................... 22

2.4.5 Danger from misbehaviour ................................. 23

2.5 Safety devices ............................................................ 24

3 Function, scope of delivery and technical parameters ....... 25

3.1 Function ...................................................................... 25

3.2 Scope of delivery ........................................................ 26

3.3 Front view VARTA element ........................................ 28

3.4 System overview ........................................................ 29

Page 5

Subject to modification! Updated 10/2017

5

3.5 Rating plate ................................................................ 30

3.6 Technical parameters ................................................ 31

Operation ....................................................................................... 34

4 Switching on and off, web interface ................................... 34

4.1 Switching on and off .................................................. 35

4.2 LED ring indications ................................................... 36

4.3 Web interface ............................................................. 37

4.3.1 Access to the web interface ............................... 37

4.3.2 Information on the welcome page (Home) ........ 38

4.3.3 External relays (optional) ................................... 39

4.4 Portal (optional) ......................................................... 40

5 Maintenance and cleaning ................................................. 41

5.1 Maintenance work...................................................... 41

5.2 Cleaning ..................................................................... 42

6 Malfunction/event of damage ............................................ 43

6.1 Malfunction indicators ................................................ 44

6.1.1 Malfunction indicators of the LED ring ............... 44

6.1.2 Malfunction indicators on the web interface ...... 44

6.2 Behaviour in the event of damage ............................. 44

Installation...................................................................................... 46

7 Transport and storage ....................................................... 46

7.1 Transport ................................................................... 46

7.2 Transportation regulations and safety instructions .... 47

7.3 Packaging/transport control ....................................... 49

7.4 Storage ...................................................................... 51

Page 6

6

Subject to modification! Updated 10/2017

8 Assembly and installation ................................................... 52

8.1 Check the components ............................................... 52

8.2 Requirements for the installation location .................. 53

8.3 Installation location ..................................................... 54

8.3.1 Dimensions and features .................................... 54

8.3.2 Environmental conditions ................................... 55

8.3.3 Non-permissible locations and environmental

conditions ........................................................... 56

8.4 Warranty ..................................................................... 56

8.5 Warranty registration .................................................. 59

8.5.1 Warranty registration by the installation

engineer ............................................................. 59

8.5.2 Warranty registration by the customer ............... 64

8.6 Preparation of the electrical connection ..................... 68

8.6.1 Connections to the distributor box ...................... 70

8.6.2 Preparation of the AC port for the building

grid ..................................................................... 71

8.6.3 Current sensor .................................................... 74

8.7 Preparation of assembly ............................................. 76

8.8 Installing and connecting the storage cabinet ............ 77

8.9 Battery module assembly ........................................... 79

8.9.1 Opening the storage cabinet .............................. 80

8.9.2 Checking the battery modules ............................ 81

8.9.3 Behaviour in the event of damage ..................... 82

8.9.4 Installing and connecting battery modules ......... 84

8.9.5 Closing the storage cabinet ................................ 93

Page 7

Subject to modification! Updated 10/2017

7

8.10 Initial commissioning ................................................. 94

8.10.1 Checking the activation of the battery modules . 94

8.10.2 Switching on ...................................................... 94

8.10.3 Password entry .................................................. 96

8.10.4 Entering serial numbers of the battery modules 97

8.10.5 Portal connection ............................................... 99

8.10.6 Setting the grid parameters for GS protection . 100

8.10.7 Reboot ............................................................. 101

8.10.8 Checks on the welcome page ......................... 101

8.10.9 Checks on the "System" page ......................... 103

8.10.10 Exiting the password-protected area ........... 104

8.11 Quick Install ............................................................. 105

Operation in the password-protected area .................................. 108

9 The password-protected area.......................................... 108

9.1 Access to the web interface - password entry ......... 108

9.2 System ..................................................................... 109

9.3 Version ..................................................................... 109

9.4 Settings .................................................................... 110

9.4.1 Basic settings ................................................... 111

9.4.2 Network ............................................................ 112

9.4.3 Service settings ............................................... 113

9.4.4 Grid parameters for GS protection .................. 115

9.4.5 Reactive power compensation ........................ 117

9.5 Power limitation ....................................................... 124

9.6 Logging out .............................................................. 124

Page 8

8

Subject to modification! Updated 10/2017

Maintenance ................................................................................. 125

10 Maintenance basics ...................................................... 125

10.1 Safety instructions .................................................... 125

10.2 Scope of maintenance work ..................................... 127

11 Service and repair work ................................................ 128

11.1 Checking the storage cabinet from outside .............. 128

11.2 Checking the system parameters (Service) ............. 128

11.2.1 Checking the online status ............................... 129

11.2.2 Error lists .......................................................... 129

11.2.3 Checking the software version ......................... 130

11.2.4 Software update ............................................... 130

11.2.5 Air filter change: Resetting the time ................. 131

11.2.6 Checking the fan .............................................. 131

11.3 Checking the system parameters ............................. 133

11.3.1 Checking the current sensor values ................. 133

11.3.2 Checking the battery charger ........................... 134

11.3.3 Checking the battery modules .......................... 135

11.4 Service and repairs: Cabinet interior ........................ 136

11.4.1 Opening the cabinet ......................................... 137

11.4.2 Removing the battery inverter .......................... 138

11.4.3 Removing and installing the battery charger .... 138

11.4.4 Removing and installing battery modules ........ 142

11.4.5 Replacing/cleaning the air filter ........................ 144

11.4.6 Disassembling the storage cabinet cover ........ 144

11.4.7 Cleaning/replacing the fan ................................ 145

Page 9

Subject to modification! Updated 10/2017

9

11.5 Completion of service and repair work .................... 148

11.5.1 Checking the operating state ........................... 149

11.6 Cleaning ................................................................... 151

12 Malfunctions................................................................. 152

12.1 Malfunction indicators of the LED ring ..................... 152

12.2 Malfunction indicators on the web interface ............ 152

13 Disassembly and disposal ........................................... 153

13.1 Planning disassembly .............................................. 153

13.2 Disassembling ......................................................... 153

13.3 Disposal ................................................................... 154

14 Relocation .................................................................... 155

14.1 Planning a relocation ............................................... 155

14.2 Relocating ................................................................ 156

Page 10

10

Subject to modification! Updated 10/2017

About this manual

Please read this instruction manual carefully before beginning any

kind of work. It contains important information, in order to ensure

trouble-free functioning of the VARTA element energy storage

system.

The manual is structured in a way, so all work must be carried out

by a qualified electrician certified by VARTA Storage GmbH.

Storage of the manual

The instruction manual should be kept in close proximity to the

VARTA element and must be permanently available to all

individuals involved in working on the energy storage system.

If the owner changes, the instruction manual has to be handed

over.

Target groups

This manual is intended for different target groups:

End customers

Qualified electricians who are responsible for installation,

commissioning and maintenance.

Scope

This manual is part of the system and corresponds to the state-ofthe-art at the time of publication. This applies to the product VARTA

element in the expansion stages element 3, element 6, element 9,

or element 12 from serial number 125 XXXXXX onwards (rating

plate).

Page 11

Subject to modification! Updated 10/2017

11

i

Please keep in mind that this instruction manual

also refers to optional components, which are not

included in the scope of delivery as standard.

These parts or components are designated

"optional" in this manual. Just skip these parts of

the manual if your energy storage is not equipped

with them.

ATTENTION

Energy storage system switched off!

Potential damage to the battery module due

to deep discharge!

The energy storage system may be

switched off temporarily only for

maintenance purposes.

Limitation of liability

VARTA Storage GmbH accepts no liability for personal injuries,

material damage, damages at the product, as well as consequential

damages arising from non-observance of this manual, improper

use of the product, during repairs, opening of the storage cabinet

and other activities carried out by unqualified electricians who were

not certified by VARTA Storage GmbH. This limitation of liability

also applies to the use of non-approved spare parts, as well as

non-observance of the stated maintenance intervals.

It is prohibited to carry out unauthorised modifications or technical

changes at the product.

© VARTA Storage GmbH 2017

Special attention required

Page 12

12

Subject to modification! Updated 10/2017

i

Indicates tips for handling the device.

Signal word

Type and source of the hazard

Potential consequence(s) in case of nonobservance!

Measures and restraints for

avoiding the hazard.

General

1 Information about this manual

1.1 Explanation of symbols

This instruction manual uses the following types of safety

instructions and tips:

1.1.1 Safety instructions

In this manual, the safety instructions are structured as follows:

Table 1: Safety instructions

Page 13

Subject to modification! Updated 10/2017

13

General

Operation

Installation

Operation (Service)

Maintenance

Warning colour/signal

word

Consequences

warns of an immediately dangerous

situation, which might lead to death or

serious injuries and/or fire.

DANGER

warns of a potentially dangerous

situation, which might lead to death or

serious injuries and/or fire.

WARNING

warns of a potentially dangerous

situation, which might lead to minor

injuries and/or material damages.

CAUTION

warns of a potential situation, which might

lead to material and environmental

damages, and which might interrupt the

operating sequence.

ATTENTION

1.1.2 Warning levels

Signal word and warning colour indicate the warning level and give

immediate information on type and severity of the consequences if

measures for avoiding the hazard are not taken.

Table 2: Warning levels

Page 14

14

Subject to modification! Updated 10/2017

Symbol

Meaning

Prohibition symbols are circular, showing a

black pictogram on a white background

surrounded by a red edge with a crossbar.

Mandatory action symbols are circular,

showing a white symbol on a blue

background.

Warning signs are triangular, showing a black

symbol and edge on a yellow background.

Environmental regulations are information on

statutory requirements, which have to be

complied with, especially during disposal.

1.1.3 General safety signs

Table 3: Safety signs

Page 15

Subject to modification! Updated 10/2017

15

General

Operation

Installation

Operation (Service)

Maintenance

General warning sign

Warning of electrical voltage

Warning of oxidising substances

Warning of hand injuries

Warning of cut injuries

Warning of hazards due to batteries

Warning of non-observance of the

discharge time:

3 minutes!

1.1.4 Warning signs

Table 4: Warning signs

Page 16

16

Subject to modification! Updated 10/2017

WARNING

Non-observance of the safety instructions!

Improper use can lead to fatal injuries.

Prior to use, ensure that all protective

devices are functioning.

Read the instruction manual.

2 Safety

2.1 General information on safety

Any person being in charge of carrying out work at the system must

have read and understood this manual, especially the Chapter

Safety.

By observing the safety instructions and complying with the

instructed health and safety measures, the risk will be limited.

This manual cannot describe every conceivable situation, therefore

the currently applicable standards as well as the appropriate

regulations for industrial safety and health protection always have

priority.

Furthermore, the use of the energy storage system is associated

with residual risks under the following circumstances:

Installation and maintenance work is not performed

correctly.

Page 17

Subject to modification! Updated 10/2017

17

General

Operation

Installation

Operation (Service)

Maintenance

Installation and maintenance work is performed by

personnel who have not been trained and not been

instructed.

The safety instructions provided in this manual are not

observed.

All safety instructions have to be strictly followed, the observance is

for your safety. The device must not be modified in any way.

Page 18

18

Subject to modification! Updated 10/2017

WARNING

Possible mortal danger due to wrong use!

Possible mortal danger

The device accommodates parts

carrying hazardous voltages. Contact

with these parts can be fatal.

Any usage beyond or other than the

intended use of the energy storage

system or individual parts of it might

lead to life threatening situations.

Do not use VARTA element:

for mobile use at land, water or air.

for use at medical devices.

2.2 Intended use

VARTA element as well as the components thereof, is built to stateof-the-art technology and to product-specific standards. This

product is designed for storing electricity from renewable energy

generating plants, such as photovoltaic systems or other energy

sources. Any other use must be agreed in consultation with the

manufacturer and the local energy supplier.

Page 19

Subject to modification! Updated 10/2017

19

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Insufficient qualification of the electrician!

Personal injuries and material damage!

Work at the VARTA element system

(e.g. installation and maintenance

work) may only be carried out by

qualified electricians who are certified

by VARTA Storage GmbH!

i

The “Installation”, “Operation in the password-

protected area” and “Maintenance” sections

contain further information for qualified

electricians.

2.3 Requirements regarding qualified electricians

Page 20

20

Subject to modification! Updated 10/2017

DANGER

Contact with electrical voltage!

Risk of fatal injury from electric shock!

Keep the energy storage system

always closed.

Pay attention to damages of the

electrical equipment! Eliminate defects

immediately!

Only the electrician is allowed to open

the energy storage system when it is

switched off.

Respect the waiting times.

2.4 General hazard sources

If the following instructions for handling the device are not

observed, this might lead to personal injury or material damage at

the device, for which VARTA Storage GmbH will accept no liability.

2.4.1 Danger of electrical voltage

Page 21

Subject to modification! Updated 10/2017

21

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Entry of water into electrical systems!

Possible mortal danger and material damage!

Do not use water for cleaning the

energy storage system.

Never put down containers with fluids

(beverage containers and the like) on

electrical systems.

The relative humidity inside the room

must not exceed 80%.

WARNING

Storage and use of oxidising and

corrosive substances

Increases the risk of fire and the risk of

electric shocks.

Store the above mentioned substances

only at places that are intended for

them.

Do not clean the system with agents

containing acid, lye or solvents.

2.4.2 Danger from water

2.4.3 Danger from oxidising and corrosive substances

Page 22

22

Subject to modification! Updated 10/2017

ATTENTION

Insufficient ventilation of the system!

Overheating of the system possible!

Keep the ventilation openings clear.

Ensure sufficient ventilation.

ATTENTION

Heat input due to direct sunlight or

devices emitting heat!

Overheating and damage of the system

possible!

Protect the system against direct

sunlight.

Do not use fan heaters or the like near

the system.

2.4.4 Danger from heat

Page 23

Subject to modification! Updated 10/2017

23

General

Operation

Installation

Operation (Service)

Maintenance

ATTENTION

Energy storage system switched off!

Potential damage to the battery module due

to deep discharge!

The energy storage system may be

switched off temporarily only for

maintenance purposes.

ATTENTION

Objects on the system!

Risk of injury due to falling objects, and the

system might be damaged!

Do not put any objects on the energy

storage system.

ATTENTION

Blocked access!

In the event of damage, the system cannot be

switched off!

The access to the energy storage

system must always be ensured.

2.4.5 Danger from misbehaviour

Page 24

24

Subject to modification! Updated 10/2017

WARNING

Defective safety devices!

Possible mortal danger!

Safety devices must not be damaged,

modified, removed, or

decommissioned.

The proper functioning of the safety

devices must be tested by qualified

electricians who are certified by VARTA

Storage GmbH after completion of

installation and commissioning.

2.5 Safety devices

The VARTA element energy storage system has multiple safety

devices. Including grid and system protection to VDE-AR-N 4105,

closed electrical operating area, overtemperature cutout and a door

contact switch. This switches off the system if an attempt is made

to open the storage cabinet before it has been de-energised.

Furthermore it is recommended to install a smoke detector in the

installation room of the VARTA element.

Page 25

Subject to modification! Updated 10/2017

25

General

Operation

Installation

Operation (Service)

Maintenance

3 Function, scope of delivery and technical

parameters

3.1 Function

The VARTA element battery storage system is a storage system for

operation in a 3-phase building grid, which offers the option of

connecting a separate grid-connected photovoltaic system. This

must be a generating unit which supplies to surplus rather than to

full feed. There is also provision for storing renewable energy, for

example from small wind turbines or other CHP system energy

sources.

The VARTA element system is used to increase the share of

private consumption and the efficiency of a photovoltaic system. If

the photovoltaic system generates more electricity than

immediately needed, it can be stored temporarily in the energy

storage system. The electricity will be fed into the building grid, as

soon as the consumption rises again above the electricity

generated by the photovoltaic system.

The VARTA element system is integrated into the building grid as a

3-phase AC connection and operates independently of the

photovoltaic system. A current sensor controls the charge and

discharge processes of the energy storage system. It is mounted in

the fuse box, directly behind the consumption/feed-in meter, and

measures all incoming and outgoing currents.

If the current sensor measures outgoing currents in case of

available free charge capacity of the energy storage system, it will

be charged. During the process, the battery inverter inside the

VARTA element system converts AC to DC and charges the

battery modules. If the maximum charge capacity is reached, or the

solar electricity exceeds the maximum charging current, the surplus

solar electricity is fed into the public grid. If the photovoltaic system

Page 26

26

Subject to modification! Updated 10/2017

is not able to cover the current electricity demand inside the

building, the current sensor measures incoming currents. As a

result, the energy storage system gives output into the building

grid, in order to minimise the external electricity consumption and

the associated costs.

Before installing the VARTA element energy storage system, the

appropriate energy provider has to be asked, whether it is

necessary to register the system.

3.2 Scope of delivery

The VARTA element energy storage system consists of:

Storage cabinet with integrated energy and battery

management

Battery module(s)

Battery inverter

Expansion stage element 3:

1 x Battery charger,

1 x Communication cable set,

1 x Power cable

Expansion stage element 6:

1 x Battery charger,

1 x Communication cable set,

1 x Power cable

Expansion stage element 9:

2 x Battery charger,

2 x Communication cable set,

2 x Power cable

Page 27

Subject to modification! Updated 10/2017

27

General

Operation

Installation

Operation (Service)

Maintenance

Expansion stage element 12:

2 x Battery charger,

2 x Communication cable set,

2 x Power cable

Extra items:

Current sensor (50 A) with sensor board,

20 m sensor cable RJ11,

1 x AC connector,

8 x mounting screws for battery module(s),

Instruction Manual

Customer folder

accompanying letter,

return envelope,

commissioning report,

service booklet,

warranty records,

Online Portal Agreement

Page 28

28

Subject to modification! Updated 10/2017

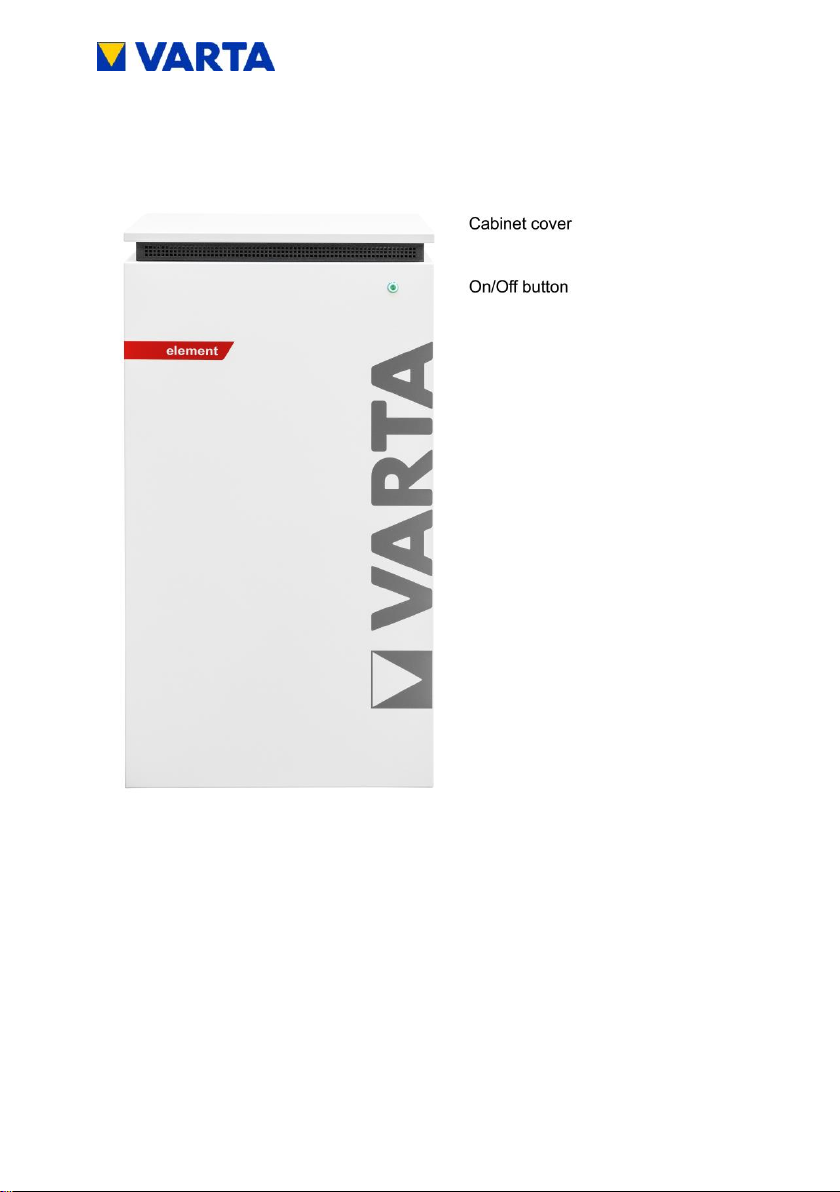

3.3 Front view VARTA element

Figure 1: Front view VARTA element

Page 29

Subject to modification! Updated 10/2017

29

General

Operation

Installation

Operation (Service)

Maintenance

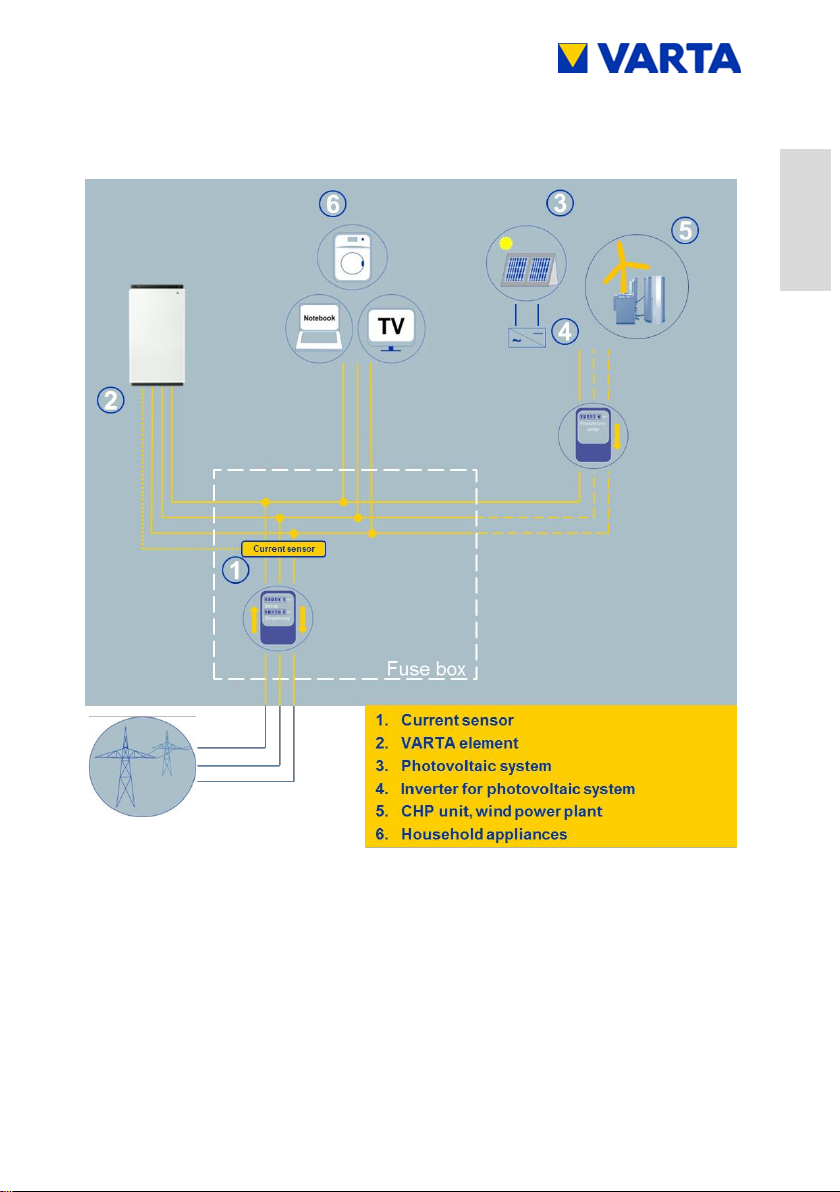

3.4 System overview

Figure 2: System overview VARTA element

Page 30

30

Subject to modification! Updated 10/2017

Figure 3: Rating plate VARTA element

Figure 4: Cryptocode

3.5 Rating plate

Page 31

Subject to modification! Updated 10/2017

31

General

Operation

Installation

Operation (Service)

Maintenance

EXPANSION STAGE ELEMENT 3

Nominal capacity

AC charge power

AC discharge power

Battery inverter structure

Dimensions in mm (W x H x D)

Weight (incl. battery module)

Installation location

Grid connection

Make current

Maximum output residual current

Internal consumption

optimisation

Power measurement

System transport

Packaging in mm (W x H x D)

Grid system fusing

3.3 kWh

1.8 kW

1.6 kW

without isolation transformer

600 x 1,176 x 500

95 kg

inside the building

400 V AC, 3-phase, 50 Hz

< max. operating current

for input and output

max. 6 A for 100 μs

3-phase, regulated

3-phase, via current sensor

vertical on a pallet

700 x 1,325 x 600

16 A (B-character)

EXPANSION STAGE ELEMENT 6

Nominal capacity

AC charge power

AC discharge power

Battery inverter structure

Dimensions in mm (W x H x D)

Weight (incl. battery modules)

Installation location

Grid connection

Make current

Maximum output residual current

Internal consumption

optimisation

Power measurement

System transport

Packaging in mm (W x H x D)

Grid system fusing

6.5 kWh

2.2 kW

1.8 kW

without isolation transformer

600 x 1,176 x 500

115 kg

inside the building

400 V AC, 3-phase, 50 Hz

< max. operating current

for input and output

max. 6 A for 100 μs

3-phase, regulated

3-phase, via current sensor

vertical on a pallet

700 x 1,325 x 600

16 A (B-character)

3.6 Technical parameters

Table 5: Technical parameters – expansion stage element 3

Table 6: Technical parameters – expansion stage element 6

Page 32

32

Subject to modification! Updated 10/2017

EXPANSION STAGE ELEMENT 9

Nominal capacity

AC charge power

AC discharge power

Battery inverter structure

Dimensions in mm (W x H x D)

Weight (incl. battery modules)

Installation location

Grid connection

Make current

Maximum output residual current

Internal consumption

optimisation

Power measurement

System transport

Packaging in mm (W x H x D)

Grid system fusing

9.8 kWh

3.4 kW

3.0 kW

without isolation transformer

600 x 1,176 x 500

145 kg

inside the building

400 V AC, 3-phase, 50 Hz

< max. operating current

for input and output

max. 6 A for 100 μs

3-phase, regulated

3-phase, via current sensor

vertical on a pallet

700 x 1,325 x 600

16 A (B-character)

EXPANSION STAGE ELEMENT 12

Nominal capacity

AC charge power

AC discharge power

Battery inverter structure

Dimensions in mm (W x H x D)

Weight (incl. battery modules)

Installation location

Grid connection

Make current

Maximum output residual current

Internal consumption

optimisation

Power measurement

System transport

Packaging in mm (W x H x D)

Grid system fusing

13 kWh

4 kW

3.7 kW

without isolation transformer

600 x 1,176 x 500

165 kg

inside the building

400 V AC, 3-phase, 50 Hz

< max. operating current

for input and output

max. 6 A for 100 μs

3-phase, regulated

3-phase, via current sensor

vertical on a pallet

700 x 1,325 x 600

16 A (B-character)

Table 7: Technical parameters – expansion stage element 9

Table 8: Technical parameters – expansion stage element 12

Page 33

Subject to modification! Updated 10/2017

33

General

Operation

Installation

Operation (Service)

Maintenance

BATTERY MODULE (VKB 56461701100)

Electrochemical cell

Nominal module capacity

Discharge depth

Useful module capacity

Connection

Cell monitoring

Dimensions in mm (W x H x D)

Weight

Packaging in mm (W x H x D)

Li-ion

3.3 kWh

90%

3.0 kWh

touch safe

integrated

445 x 110 x 339

25 kg

800 x 460 x 600

BATTERY MODULE (VKB 56462701100)

Electrochemical cell

Nominal module capacity

Discharge depth

Useful module capacity

Connection

Cell monitoring

Dimensions in mm (W x H x D)

Weight

Packaging in mm (W x H x D)

Li-ion

6.5 kWh

90%

5.9 kWh

touch safe

integrated

445 x 110 x 587

45 kg

800 x 460 x 600

ENVIRONMENTAL RATING DATA

Environmental category

Classification of wet rooms

Degree of contamination

Ingress protection

Ambient temperature

Relative humidity

Max. altitude

Overvoltage category

Protection class

Air-conditioned indoors*

No wet rooms allowed

2

IP22

+5 °C to +30 °C

< 80%

2000 m ASL

III

1

*The energy storage system is completely enclosed by a building or housing. This protects the

energy storage system against sunlight, dust and other external influences. Additionally, the

building or housing is air-conditioned with regard to temperature, air humidity and air filtering.

Table 9: Technical parameters – battery modules

Table 10: Technical parameters – environmental rating data

Page 34

34

Subject to modification! Updated 10/2017

DANGER

Contact with electrical voltage!

Risk of fatal injury from electric shock!

Keep the energy storage system

always closed.

Pay attention to damages of the

electrical equipment!

Eliminate defects immediately!

Only the electrician is allowed to open

the energy storage system when it is

switched off.

Respect the waiting times.

ATTENTION

Energy storage system switched off!

Potential damage to the battery module due

to deep discharge!

The energy storage system may be

switched off temporarily only for

maintenance purposes.

Operation

4 Switching on and off, web interface

Page 35

Subject to modification! Updated 10/2017

35

General

Operation

Installation

Operation (Service)

Maintenance

The On/Off button on the front of the cabinet is pressed by the

certified installation engineer during commissioning and for service

work. In case of damage (see Chapter 6.2), the system can be

shut-down using the On/Off button.

Figure 5: On/Off button with LED ring

4.1 Switching on and off

Page 36

36

Subject to modification! Updated 10/2017

LED ring

colour

LED action

Operating state

Green

Flashes every second

(approx. 90 s)

System check

Green

Steady light

Ready

Green

Flashes every 3 s

Standby

Green

Pulses with increasing

intensity

Charge

Green

Pulses with decreasing

intensity

Discharge

Green

-red

Flashes

Update

Red

Steady light

Error*

Red

Flashes every second

Current sensor

check failed

*The i-button on the welcome page of the web interface displays

information about current errors (see Chapter 4.3.2).

4.2 LED ring indications

The LED ring at the On/Off button indicates the states and events

which occur while the energy storage system is in operation.

Table 11: LED ring indications at the On/Off button

Page 37

Subject to modification! Updated 10/2017

37

General

Operation

Installation

Operation (Service)

Maintenance

i

Access to the web interface might require

the browser to be refreshed.

4.3 Web interface

The web interface offers the option of configuring settings, as well

as monitoring and controlling the energy storage system functions.

4.3.1 Access to the web interface

To access the web interface, you will need the serial number of the

energy storage system. The serial number can be found on the

rating plate on the outside of the cabinet (top). See Figure 3: Rating

plate VARTA element

Connect your storage cabinet to the router of your home network

by means of the network cable. The port (RJ45 socket) is located at

the rear of the cabinet. See Figure 16.

Enter the serial number of the energy storage system

behind http://varta in the address line of your browser.

e.g.: http://varta125023456

The welcome page of the web interface will appear.

The web interface is factory-tested with the following browsers:

Firefox, Internet Explorer, Chrome and Opera.

Page 38

38

Subject to modification! Updated 10/2017

Figure 6: Web interface: Welcome page

4.3.2 Information on the welcome page (Home)

The welcome page provides an overview of the current power

values and the states of the energy storage system:

(1) Charge power of the battery inverter in watt (W):

The energy storage system is charged with this power

(power of the generating units, e.g. PV system, CHP,

minus the direct internal consumption).

(2) Discharge power of the battery inverter in watt (W):

The energy storage system is discharged with this power.

(3) Power of the grid supply/grid draw (W): The power

supplied into the public grid or drawn from the public grid

is displayed.

Page 39

Subject to modification! Updated 10/2017

39

General

Operation

Installation

Operation (Service)

Maintenance

(4) Operating state of the energy storage system: The

operating state, e.g. standby, charging, error is displayed.

(5) The charging state of the energy storage system in

%: The charge level of the energy storage system is

displayed.

(6) WWW: Indicates whether the energy storage system is

connected to the VARTA server (green = online, red =

offline).

(7) Info button (i): Displays information about the storage

system, e.g. IP address, energy counter, or the most

recent grid faults.

To see further explanations, move the cursor over the symbols.

4.3.3 External relays (optional)

Via the web interface, up to four external relays can be individually

programmed for controlling special functions, such as switching

consumers or generating units on/off. Clicking the Ext. relay button

shows the corresponding page.

A download available from www.varta-storage.com provides further

information.

Page 40

40

Subject to modification! Updated 10/2017

i

The data displayed on the VARTA Storage

portal cannot be used for billing purposes.

4.4 Portal (optional)

The www.varta-storage-portal.com portal serves to monitor and

visualise energy storage systems. To ensure continuous data

transmission, the Internet connection must not be interrupted for

longer than five days.

Access to the portal is activated if the option "I wish to use the

VARTA Storage Online Portal", which appears during online login

to the storage system, has been checked. A download is available

from www.varta-storage.com for the online login to the storage

system and for using the portal (see Chapter 8.5 Warranty

registration).

Alternatively, you can tick the "I wish to use the VARTA Storage

Online Portal" box on the warranty card, which you return to

VARTA Storage GmbH.

Use of the Online Portal is free-of-charge. The Internet connection

costs must be borne by the customer. However, there is no

entitlement to access the portal (see the Terms and Conditions for

the Online Portal in the download area).

Page 41

Subject to modification! Updated 10/2017

41

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Improper execution of maintenance and

cleaning work

Possible mortal danger!

Ensure that only qualified electricians

certified by VARTA Storage GmbH

carry out maintenance and cleaning

work!

Only original parts are to be used for

maintenance work.

5 Maintenance and cleaning

5.1 Maintenance work

Maintenance of the energy storage system includes:

Service (= inspection and maintenance)

Repair and technical improvements and any additions

To maintain the warranty entitlement (outside of Germany, Austria

and Switzerland: to safeguard any warranty claims), the first

service must be carried out within two years of the installation date.

Subsequent servicing must be at three year intervals.

Page 42

42

Subject to modification! Updated 10/2017

i

Retain the service booklet together with

the instruction manual.

WARNING

Entry of water into electrical systems!

Possible mortal danger!

Do not use water for cleaning the

energy storage system

Never put down containers with fluids

(beverage containers and the like) on

electrical systems.

Cleaning agents

Do not use any cleaning agents containing acid, lye or

solvents!

Cleaning the outside of the housing

clean with a vacuum cleaner.

wipe with a damp, not wet, cloth.

The extent of the maintenance work is described in the Chapter

Maintenance.

5.2 Cleaning

Page 43

Subject to modification! Updated 10/2017

43

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Improper elimination of malfunctions!

Possible mortal danger!

Ensure that only qualified electricians

certified by VARTA Storage GmbH

carry out work at the energy storage

system!

i

In case of a malfunction, contact the qualified

electrician.

6 Malfunction/event of damage

Page 44

44

Subject to modification! Updated 10/2017

WARNING

Improper handling in case of fire and

flooding!

Possible mortal danger!

If possible, switch off the system and

disconnect the fuses.

Leave the hazard zone.

In case of fire, call the fire brigade

immediately.

Inform the fire brigade about the

lithium-ion batteries inside the energy

storage system.

6.1 Malfunction indicators

6.1.1 Malfunction indicators of the LED ring

The LED ring of the On/Off button on the front of the cabinet

indicates malfunctions. See Table 11 in Chapter 4.2.

6.1.2 Malfunction indicators on the web interface

Malfunctions are displayed on the welcome page of the web

interface.

To do this, click on the i icon.

A window will open. Any pending system errors and the

previous five grid faults can be read from this window.

6.2 Behaviour in the event of damage

Page 45

Subject to modification! Updated 10/2017

45

General

Operation

Installation

Operation (Service)

Maintenance

i

In the event of a fire or flooding, prudent

behaviour can limit the damage.

WARNING

Damaged battery module due to technical

defect!

Pungent smell

Avoid contact with possibly leaking

fluid!

Avoid contact with possibly escaping

vapours!

If possible, switch off the system and

disconnect the fuses.

Avoid sparks and open flames.

Ventilate the installation room.

In case of a malfunction, contact the

qualified electrician.

Page 46

46

Subject to modification! Updated 10/2017

This section is intended for the qualified

electrician.

Installation

7 Transport and storage

7.1 Transport

Lithium-ion batteries are hazardous goods. The battery modules

are constructed and tested in a way, so they are allowed to be

transported up to a total weight of 333 kg by complying with the

conditions of ADR 1.1.3.6 (transport not subject to labelling, as long

as there are no other hazardous goods on or inside the vehicle).

The other requirements of GGVSEB (ordinance on the national and

international carriage of hazardous goods by road, rail, and inland

waterways) and ADR (Agreement on Dangerous Goods by Road)

also have to be fulfilled. Delivery is made in tested hazardous

goods packaging.

Lithium-ion batteries were successfully tested according to

UN 38.3 transport test (UN Manual of Tests and Criteria, Part III,

subsection 38.3) and have passed.

The storage cabinet is packaged separately from the battery

modules.

Page 47

Subject to modification! Updated 10/2017

47

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Improper transport due to lack of

professional knowledge.

Possible mortal danger and material damage!

The transportation of the energy storage

system and its components is only

allowed to be carried out by the

manufacturer and the electricians

qualified and certified by him.

Be prudent during transport.

Adhere to the transportation regulations!

The housing and the battery module

must not be temporarily stored in the transport vehicle.

the energy storage system must not be transported if a

battery module has already been installed.

driver or co-driver are not allowed to open the outer

packaging of a battery module.

instructions

7.2 Transportation regulations and safety

Page 48

48

Subject to modification! Updated 10/2017

The housing and the battery module

a tested ABC fire extinguisher with a minimum capacity of

2 kg has to be carried along.

observe the symbols on the packaging.

Transport the parts only in enclosed vehicles.

the load has to be properly secured.

transport the battery module only in its intended transport

packaging.

adhere to the requirements according to GGVSEB and

ADR!

Use your personal protective equipment.

This reduces the risk of injuries during the mechanical work.

WARNING

Components are heavy!

This might lead to overburdened

intervertebral discs, bruises and crushings!

Carry out the work described in this

chapter with 2 persons or suitable

equipment.

Page 49

Subject to modification! Updated 10/2017

49

General

Operation

Installation

Operation (Service)

Maintenance

i

When exchanging a battery module, request

new hazardous goods packaging if required,

pack the battery module and have it picked up

by the supplier.

DANGER

Installation of damaged components!

Mortal danger!

Do not accept clearly damaged

packaging.

Contact VARTA Storage GmbH!

7.3 Packaging/transport control

Storage cabinet and battery module (individually packaged) are

delivered in separate and tested packaging units on pallets. The

disposal of the packaging will be taken over by the installation

engineer. Please examine the deliveries on completeness and

damages:

If damages are already visible at the packaging, please

note this down on the delivery documents and have the

driver confirm this by signature.

If the packaging is severely damaged, reject the deliveries.

In order to identify improper handling during transport, a

ShockWatch® sticker is attached to the outside of the cardboard

packaging of the storage cabinet. If the shock indicator is red, the

consignment has been exposed to strong vibrations.

Page 50

50

Subject to modification! Updated 10/2017

i

Remove the packaging not until immediately

before the installation. This avoids damages.

Keep the packaging material, so the system

can be properly packaged in case of a

subsequent transport (relocation).

The storage cabinet may be damaged.

Do not reject the consignment!

Enter "Indicator red" on the transport note.

Leave all parts packed in the original packaging and

request a damage inspection by the shipper immediately.

Figure 7: ShockWatch®sticker

Page 51

Subject to modification! Updated 10/2017

51

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Entry of water into electrical systems!

Short-circuit and corrosion due to condensation!

Adhere to the storage conditions.

The housing and the battery module

must not be temporarily stored in the transport vehicle.

must not be stored outdoors.

avoid sudden temperature changes.

The housing and the battery module

are to be stored dry, at a humidity of < 80%.

are to be stored at a temperature of 5 30 °C

(optimum: +18 °C).

ATTENTION

Material damage due to overstorage!

Deep discharge of the battery module!

Adhere to the storage conditions.

The battery module

must be commissioned by the manufacturer or a qualified

electrician certified by VARTA Storage GmbH within

eleven weeks of being delivered.

7.4 Storage

Page 52

52

Subject to modification! Updated 10/2017

This section is intended for the

qualified electrician.

WARNING

Entry of water into electrical systems!

Short-circuit and corrosion due to condensation!

Start the assembly not until the

components have room temperature.

WARNING

Installation of damaged components!

Possible mortal danger!

Check all components on visible

damages.

Do not install damaged components.

Contact VARTA Storage GmbH.

8 Assembly and installation

8.1 Check the components

Page 53

Subject to modification! Updated 10/2017

53

General

Operation

Installation

Operation (Service)

Maintenance

This section is intended for the

qualified electrician.

WARNING

Entry of water into electrical systems!

Mortal danger from electric shock!

Install the storage cabinet only inside

buildings.

Observe all requirements for the

installation location.

CAUTION

Personal injury and material damage due

to wrong installation and lack of space!

Crush injuries of limbs!

Place the cabinet, so a safe installation,

operation, maintenance and

disassembly are possible when used

properly.

8.2 Requirements for the installation location

Page 54

54

Subject to modification! Updated 10/2017

8.3 Installation location

The following dimensions and framework conditions have to be

complied with at the installation location.

8.3.1 Dimensions and features

For the room, in which the VARTA element will be installed, a

volume of at least 30 m³ is recommended. A horizontal, even floor

with a minimum surface of 70 cm x 55 cm (width x depth). The floor

must be able to take the load.

Weight of the energy storage system Chapter 3.6 Technical

parameters.

If necessary, have the statics tested.

The ground, the adjacent walls and ceiling must not

consist of heat-sensitive material.

The distance to the adjacent installations must be approx. 5 cm to

the right and approx. 10 cm to the left. A clear space of approx. 120

cm depth is required in front of the device, in order to carry out

installation and maintenance work via the front door. In order to

secure the means of escape, doors must not swing into this clear

space.

Page 55

Subject to modification! Updated 10/2017

55

General

Operation

Installation

Operation (Service)

Maintenance

Sufficient rodent protection must be provided.

Smoking is not allowed at the installation

location!

The screws for opening the storage cabinet on the left next to the

front door must be accessible.

A minimum clearance of 30 cm must be left above the storage

cabinet. The distance between the wall and the rear of the cabinet

must remain free to enable cooling air to escape from the device

unhindered.

8.3.2 Environmental conditions

The installation location must match a pollution degree 2.

A continuous air exchange, possibly via forced ventilation, e.g.

window, air-conditioning system, ventilation or the like, has always

to be ensured. The distance to the ventilation must be at least

100 cm.

The room temperature always has to be between 5 30 °C

(optimum +18 °C), the relative humidity must be < 80%.

Recommendation: well ventilated room without external heat

sources

Page 56

56

Subject to modification! Updated 10/2017

8.3.3 Non-permissible locations and environmental

conditions

Altitudes above 2,000 metres,

Garages, carports or other places, at which the environmental

conditions are not complied with.

Locations:

with explosive atmosphere

at which flammable or oxidising substances are stored

Wet rooms

with high fluctuations of the ambient temperature

with direct sunlight

with a humidity above 80% and condensation

in which the temperature might be below the freezing point

in which salty humidity might enter

with ammonia containing environment

8.4 Warranty

For the warranty to be effective (to safeguard any warranty claims

outside Germany, Austria and Switzerland), VARTA Storage GmbH

must be in possession of the following data:

Commissioning report (including date of commissioning)

Serial number (SN number) of the VARTA system.

The ID label (rating plate) of the system is affixed inside

the storage cabinet.

Serial number(s) of the battery module/battery modules.

The ID label of the battery module is enclosed in the

packaging.

The installation engineer enters these data in the VARTA Storage

GmbH installation engineer portal. Within four weeks of the

Page 57

Subject to modification! Updated 10/2017

57

General

Operation

Installation

Operation (Service)

Maintenance

Figure 8: ID label (rating plate) of the system

(inside the storage cabinet)

address, email address, telephone number) at www.varta-storageportal.com and enter the serial number (SN number) of the VARTA

element system and the activation code. The installation engineer

can also register the data, subject to the customer's consent.

The activation code label (Unlock Code) is affixed to the

inside of the storage cabinet door. This label is provided

for the customer's personal documents.

As an alternative to this procedure, the completed and signed

warranty records (commissioning report and warranty card,

together with the affixed ID label for the VARTA system and battery

modules) can be sent to VARTA Storage GmbH within four weeks

of the installation date.

installation date, the customer must register their data (name,

Page 58

58

Subject to modification! Updated 10/2017

Figure 9: ID label of the battery module (example)

Figure 10: Activation code label (example)

Page 59

Subject to modification! Updated 10/2017

59

General

Operation

Installation

Operation (Service)

Maintenance

8.5 Warranty registration

This online-based warranty registration consists of two parts:

Part 1: Registration of the energy storage system by the installation

engineer incl. commissioning report (Chapter 8.5.1)

Part 2: Warranty registration by the end customer incl. registration

for the web portal (Chapter 8.5.2)

8.5.1 Warranty registration by the installation engineer

Open page www.varta-storage.com

Change to "energy storage systems"

Registration in the B2B area with login and password

On the welcome page, click on "Start VARTA-Portal"

Change to "energy storage registration"

Entering the data for the battery storage:

Initial installation/retrofit

Date

Installation engineer

Serial number

Activation code

The system's serial number and the activation code can be found

on the stickers on the inside of the battery cabinet.

Page 60

60

Subject to modification! Updated 10/2017

i

If the storage is connected to the Internet, the

serial number or the serial numbers of the

installed battery modules will be transmitted

automatically.

The battery module has to be registered at the

latest 11 weeks after delivery.

Call up the next screen "battery modules" with "next".

Enter the serial number(s).

NOTE: This applies to all battery modules which have not yet been

registered.

Page 61

Subject to modification! Updated 10/2017

61

General

Operation

Installation

Operation (Service)

Maintenance

Call up the next screen "customer data" with "next".

Determine whether the customer agrees that the

installation engineer completes the following fields and

transmits them to VARTA Storage GmbH.

If "Yes", continue with the next screen

If "No", the screen "customer data" will be skipped. In this

case, the end customer has to enter these data in the 2nd

part of the warranty registration himself.

Entering the customer data.

Mandatory fields are marked with an *.

Call up the next screen "commissioning" with "next".

Page 62

62

Subject to modification! Updated 10/2017

Details of the commissioning report

Page 63

Subject to modification! Updated 10/2017

63

General

Operation

Installation

Operation (Service)

Maintenance

Confirmation of the registration

Completion of the registration with "close"

These data can be viewed in the B2B area:

Open under "warranty registration" or save as a PDF.

Page 64

64

Subject to modification! Updated 10/2017

8.5.2 Warranty registration by the customer

Open page www.varta-storage.com

Change to "energy storage systems"

Registration in the portal

Under: "No access yet? Register now"

with serial number and activation code.

Enter the following details

Battery storage,

Contact data

Declaration for contacting via telephone

Declaration for the use of the online services plus

contacting via telephone

Cancellation right information

Voluntary consents of the customer

Page 65

Subject to modification! Updated 10/2017

65

General

Operation

Installation

Operation (Service)

Maintenance

Click the button "Send registration".

Page 66

66

Subject to modification! Updated 10/2017

After completion of the entries, the details of the warranty

registration are displayed.

Correct the entries or send the registration now.

Page 67

Subject to modification! Updated 10/2017

67

General

Operation

Installation

Operation (Service)

Maintenance

Confirmation with the warranty registration as a PDF.

Final screen with the warranty documents as a PDF.

After registration, the customer receives an email with the access

data.

Alternatively, the customer can register with the enclosed warranty

card (sheet 1, 2 and 4).

Page 68

68

Subject to modification! Updated 10/2017

This section is intended for the

qualified electrician.

Use your personal protective equipment.

This reduces the risk of injuries during the mechanical work.

Observe the safety rules!

Disconnect

Lockout

Check for absence of voltage

Before connecting up the power supply, make sure

that no persons are in the hazard zone.

8.6 Preparation of the electrical connection

Page 69

Subject to modification! Updated 10/2017

69

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Improper installation!

Personal injury and material damage

Design the fuse ahead of the energy

storage system with three poles!

It must fulfil the requirements of a

separator.

Fuse the device connection at the

energy storage system with a 16 A fuse

type B.

Observe the disconnect conditions in

accordance with VDE 0100-410.

Never connect the energy storage

system without a PE and N connection!

A suitable separator must be installed

between power grid and customer

system (e.g. selective automatic cut-out

'SAC'), which can be used for all-poles

disconnection of the customer system

from the grid during maintenance work.

Observe the specified conductor crosssections!

For the position of the separators, see the connection

diagrams (Figures 1a/1b and 2a/2b) in the Appendix.

Page 70

70

Subject to modification! Updated 10/2017

i

1. Do not allow any mechanical load on the

sensor cable.

2. In order to minimise losses, the wiring

section between storage and connection

should not be longer than 20 m.

8.6.1 Connections to the distributor box

The following connections must be prepared:

Device connection: 5 x 1.5 - 2.5 mm²

Sensor cable: RJ12

LAN connection

Page 71

Subject to modification! Updated 10/2017

71

General

Operation

Installation

Operation (Service)

Maintenance

Figure 11: Stripping cables

i

A flexible plastic-sheathed cable facilitates

assembly work.

8.6.2 Preparation of the AC port for the building grid

To connect to the building grid, the 5-wire AC cable must be

connected to the supplied AC connector.

Strip the cable 40 mm at the end.

The PE conductor must be 5 mm longer than the other

four conductors (L1, L2, L3, N). Shorten these conductors

accordingly.

Strip the wires for the building connection approx. 8 mm at

the ends.

Ferrules must be used for fine-stranded conductors.

Screw off the union nut of the strain relief.

Take off the connector housing: To do so, release the

catch by pressing on the two side lugs at the same time.

Push union nut and connector housing over the cable.

Page 72

72

Subject to modification! Updated 10/2017

Figure 12: AC connector

1

Opening for locking when inserting

To release: Push in snap-in nose

2

Union nut for strain relief

3

Connector housing

4

Opening for snap-in nose (on both sides).

For locking when mounting the connector

5

Contact insert

i

Ensure that the conductor is tightly fixed in the

connections.

Insert the wires according to Figure 13: Assignment AC-

connector (connection side) into the screw connections in

the contact insert and screw tight.

Insert the contact insert into the connector housing. Both

parts must audibly snap into the snap-in noses at the

sides.

Page 73

Subject to modification! Updated 10/2017

73

General

Operation

Installation

Operation (Service)

Maintenance

Figure 13: Assignment AC-connector (connection side)

Tighten the union nut for strain relief.

Page 74

74

Subject to modification! Updated 10/2017

ATTENTION

Reversed phases!

Charging and discharging malfunction!

Conductors L1, L2, L3 for building

connection, current sensor and AC

connector must have the same phase

assignment.

Executing the connection as a righthand phase rotation is not sufficient!

8.6.3 Current sensor

If the energy storage system to be installed is to be cascaded with

further energy storage systems, the following step will not be

carried out. Instead, see instruction manual for cascading.

(Optional add-on package required)

In order to ensure the internal consumption optimisation, the

current sensor must capture all values of consumption and infeed.

Therefore, it is located directly behind the consumption and feed

meter. The current sensor is intended for top-hat rail mounting and

designed for a maximum current of 50 A per phase.

Page 75

Subject to modification! Updated 10/2017

75

General

Operation

Installation

Operation (Service)

Maintenance

Figure 14: Current sensor - direction of installation

When installing the current sensor, it is important that the sensor

board points in the direction of the sub-distribution (see Figure 14:

Current sensor - direction of installation). Conductors L1, L2, L3 for

building connection, current sensor and AC connector must have

the same phase assignment.

Current sensor and energy storage system are connected with the

supplied sensor cable. See position of socket "current

measurement " in Figure 16.

For the connection diagram, see Figures 1a and 1b, and also

2a and 2b in the Annex.

Page 76

76

Subject to modification! Updated 10/2017

This section is intended for the

qualified electrician.

Read the instruction manual.

WARNING

Components are heavy.

This might lead to overburdened

intervertebral discs, bruises and

crushings.

Carry out the work described in this

chapter with 2 persons or suitable

equipment.

At the installation location, tilt the cabinet by

max. 30° Risk of slipping away!

8.7 Preparation of assembly

Page 77

Subject to modification! Updated 10/2017

77

General

Operation

Installation

Operation (Service)

Maintenance

8.8 Installing and connecting the storage cabinet

Plug the AC connector into the AC port. The catch audibly

engages.

Figure 15: AC port (rear of the storage cabinet)

Insert the sensor cable and the network cable into the

corresponding sockets.

Figure 16: Sockets (rear of the storage cabinet)

Page 78

78

Subject to modification! Updated 10/2017

i

Changes to the factory settings require a

network connection.

Position the cabinet at the installation location.

Screw your storage cabinet to the rear wall using

appropriate fasteners. To do so, turn the mounting bracket

outwards by 90°.

Figure 17: Wall mounting VARTA element

Set the height-adjustable feet (see Figure 21: Installation

positions of the battery modules) to a height of approx.

4 cm (max. 5 cm).

Align the storage cabinet using a spirit level. You can

make fine adjustments with the height-adjustable feet.

Page 79

Subject to modification! Updated 10/2017

79

General

Operation

Installation

Operation (Service)

Maintenance

This section is intended for the

qualified electrician.

DANGER

Contact with live parts!

Mortal danger!

Adhere to the waiting times.

Make sure that the battery modules are

switched off and no LED indicator is lit.

The energy storage system must not

be transported if a battery module has

already been installed.

Keep unauthorised persons away.

WARNING

Contact with sharp-edged parts!

Cut injuries!

Wear your personal protective

equipment.

8.9 Battery module assembly

Page 80

80

Subject to modification! Updated 10/2017

Figure 18: Opening the storage cabinet

8.9.1 Opening the storage cabinet

To open the cabinet, undo the screws to the side near the

door.

Aid: Torx 25 screwdriver

Page 81

Subject to modification! Updated 10/2017

81

General

Operation

Installation

Operation (Service)

Maintenance

WARNING

Damaged battery module!

Personal injuries and material damage!

Unpack the battery module carefully.

Check the battery module for damages

and cleanness.

Never install and commission are

damaged or contaminated battery

module.

Transport the battery module carefully.

Do not put any parts on the battery

module.

Keep unauthorised persons away.

Cleaning agents

Do not use any cleaning agents containing acid, lye or

solvents!

8.9.2 Checking the battery modules

Page 82

82

Subject to modification! Updated 10/2017

WARNING

Improper handling in case of damaged

battery module!

Personal injuries and material damage!

Do not open the battery module.

Do not attempt to repair it!

Avoid contact with possibly leaking

fluid!

Avoid contact with possibly escaping

vapours!

Damaged or contaminated battery module

Contact VARTA Storage GmbH.

First aid in case of contact with electrolyte

When inhaling: Leave the room.

Get medical attention immediately.

In case of skin contact: Thoroughly wash the affected area

with water and soap.

Get medical attention immediately.

In case of eye contact: Rinse eyes with running water for at

least 15 minutes.

Get medical attention immediately.

8.9.3 Behaviour in the event of damage

Page 83

Subject to modification! Updated 10/2017

83

General

Operation

Installation

Operation (Service)

Maintenance

Figure 19: VARTA element battery module

Page 84

84

Subject to modification! Updated 10/2017

ATTENTION

Two battery modules at one battery charger!

Material damage due to too high current!

Always connect only one battery module to

one battery charger.

ATTENTION

Overstorage of the battery module!

Deep discharge of the battery module!

Once you started commissioning, it has to be

carried out until finished.

ATTENTION

Reversed wires of error and warning messages!

Wrong error message to the control!

Observe the given colour-coding.

8.9.4 Installing and connecting battery modules

Page 85

Subject to modification! Updated 10/2017

85

General

Operation

Installation

Operation (Service)

Maintenance

Figure 20: Clamped connections of battery module (DRY contact)

Depending on the model, up to two battery modules will be

installed. The battery modules are placed in accordance with

Figure 21: Installation positions of the battery modules.

Lift the battery module/battery modules onto the two mounting rails

using the handles.

Page 86

86

Subject to modification! Updated 10/2017

Figure 21: Installation positions of the battery modules

1 - 4

Height-adjustable feet

5

Battery connections

6

Fastening screws for battery modules

Page 87

Subject to modification! Updated 10/2017

87

General

Operation

Installation

Operation (Service)

Maintenance

-blank page-

Page 88

88

Subject to modification! Updated 10/2017

Installing a battery module (expansion stage element 3/6)

Figure 22: Connections – expansion stage element 3/6

Page 89

Subject to modification! Updated 10/2017

89

General

Operation

Installation

Operation (Service)

Maintenance

Expansion stage element 3/6

Place the battery module in the storage cabinet according to

Figure 21: Installation positions of the battery modules.

Connections at the battery module according to Figure 22:

Connections – expansion stage element 3/6:

Battery power connection:

Plug on both connectors with correct polarity.

Communication 1:

Insert the four communication cables into the openings in

the clamping connector.

The connections are self-clamping.

For the pin assignment, see Figure 20: Clamped

connections of battery module (DRY contact)

Communication 2:

Plug in communication cable 2 (red, CAN).

Fixation:

Slide the battery module towards the rear.

Fix at the fastening holes of the mounting rails by using

the supplied screws.

Aid: Allen key, size 4

Switching on the battery module:

Press the activation button on the battery module.

The LED indicator at the battery module indicates the

standby mode.

Page 90

90

Subject to modification! Updated 10/2017

Installing two battery modules (expansion stage element 9/12)

Figure 23: Connections – expansion stage element /12

Page 91

Subject to modification! Updated 10/2017

91

General

Operation

Installation

Operation (Service)

Maintenance

Expansion stage element 9/12

Place the battery modules in the storage cabinet according to

Figure 21: Installation positions of the battery modules.

Connections at the battery modules according to Figure 23:

Connections – /12

Battery charger -left-

o Battery power connection:

Plug both connectors with correct polarity at the

rear battery module.

o Communication 1:

Insert the four communication cables into the

openings of the clamping connector.

The connections are self-clamping.

For the pin assignment, see Figure 20: Clamped

connections of battery module (DRY contact)

o Communication 2:

Plug in the communication cable (red, CAN).

o Fixation:

Fix the rear battery module at the fastening holes

by using the supplied screws.

Aid: Allen key, size 4

o Switching on the battery module:

Press the activation button at the rear battery

module.

The LED indicator at the battery module indicates

the standby mode.

Page 92

92

Subject to modification! Updated 10/2017

Battery charger -right-

o Battery power connection:

plug both connectors with correct polarity at the

front battery module.

o Communication 1:

Insert the four communication cables into the

openings of the clamping connector.

The connections are self-clamping.

For the pin assignment, see Figure 20: Clamped

connections of battery module (DRY contact)

o Communication 2:

Plug in the communication cable (red, CAN).

o Fixation:

Fix the rear battery module at the fastening holes

by using the supplied screws.

Aid: Allen key, size 4

o Switching on the battery module:

Press the activation button at the rear battery

module.

The LED indicator at the battery module indicates

the standby mode.

Page 93

Subject to modification! Updated 10/2017

93

General

Operation

Installation

Operation (Service)

Maintenance

8.9.5 Closing the storage cabinet

Before you close the energy storage system, please check:

all tools removed?

is the interior clean?

o no loose parts in the interior?