Page 1

1

VZ-MC50

Pan and Tilt Controls Diagram

Page 2

2

VZ-MC50

PLEASE READ THOROUGHLY BEFORE STARTING! SAFETY PRECAUTIONS: *Keep fingers

and loose clothing away from gears and moving parts. *Always unplug VZ-MC50 Pan and

Tilt Head when not in use. *Mount only on stable surfaces.

***TURN OFF YOUR CAMERA’S OPTICAL IMAGE STABILIZER (OIS) WHILE IT IS MOUNTED TO THE PAN/TILT

HEAD. OIS DOES NOT REACT WELL TO PAN/TILT SYSTEMS.***

Pan and Tilt Head - Set-Up and Operating

Instructions

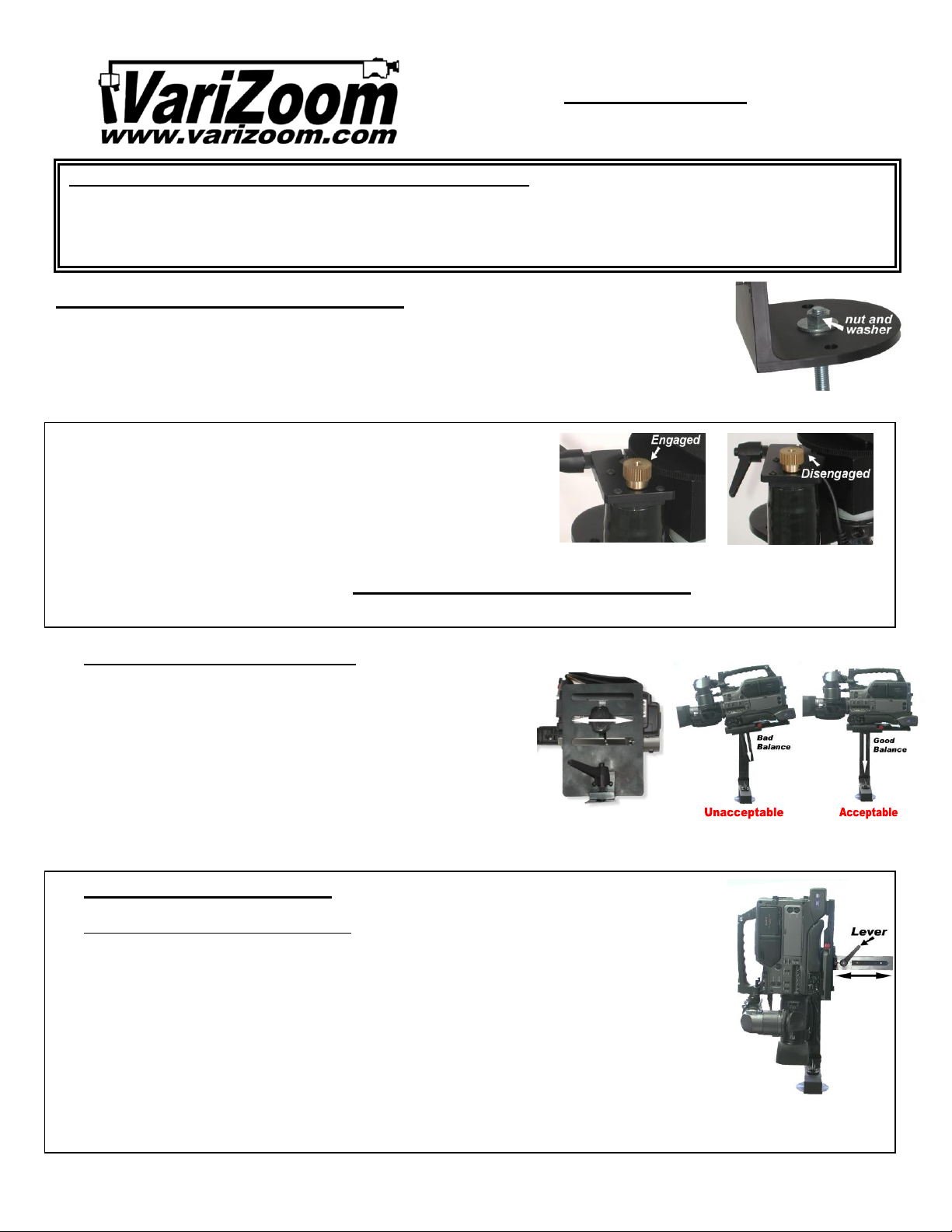

SETTING UP YOUR NEW PAN AND TILT HEAD – In addition to the parts shown on the first

page, the MC50 comes with a 20’ video cable, 20’ extension for LANC controls, and mounting

screws/washers for the head and camera.

1. Bolt the base plate of the VZ-MC50 head securely to jib or tripod mount. The base is

designed to mount on a flat surface or 100mm bowl, so an adapter may be necessary for

other sizes (consult jib or tripod maker). The mounting plate on the MC50 has a threaded

hole, but it should never be used without the included nut and washer to ensure that the head does not fall!

Pan and Tilt Motor Attachment

2. There are two motors included, one for Panning left/right (to place

at the base of the MC50), and one for Tilting up/down (to place at

the top). The motor w/ larger gear will turn the head faster, so

use the larger gear on the axis that needs more speed. The

motors are easily attached by a.) connecting the male stereo plug from the motor to the

female plug on MC50 head and b.) loosening the clamp lever and sliding the clamp onto the stainless steel post

adjacent to the large black arm gears. For initial setup, leave the motors disengaged (the small brass motor gears

should be pulled away from the large black gears).

HORIZONTAL CAMERA BALANCING

3. Securely attach the camera to the mounting plate with bolt and

washer. After tightening the bolt, slightly loosen it again so

that the camera may slide forward and backward on the

mounting plate. Move the camera so that gravity allows it to

rest on the plate without tilting up or down, balancing the

camera horizontally. The tilt arm that holds the adjustable

mounting plate should be exactly parallel to the main arm

(straight up). Now you can thoroughly tighten the camera

mounting bolt(s) so that the camera doesn’t slide when tilting

(you may want to use multiple bolts for large cameras with tripod mounting plates).

CAMERA MUST BE PROPERLY BALANCED FOR OPERATION.

VERTICAL CAMERA BALANCING

4. With the camera horizontally balanced, rotate the tilt arm so the camera is exactly vertical.

Be sure to keep the gears disengaged. If the camera stays vertical, it may be nearly

balanced, but if it swings up or down, you need to adjust the position of the mounting plate

on the tilt arm. To adjust, loosen the lever under the mounting plate. This will allow the

mounting plate to slide freely back and forth.

-Slide the mounting plate in either direction until the camera is balanced vertically. If the tilt arm

swings down, slide the mounting plate upward; if the tilt arm swings up, slide the mounting

plate downward. Adjust until the camera stays perfectly vertical (see picture right). Tighten the

lever. NOW TILT THE CAMERA AT VARIOUS ANGLES ALL THE WAY AROUND – IT

SHOULD HOLD ANY POSITION IF PROPERLY BALANCED. YOU MAY NEED TO TWEAK

THE HORIZONTAL AND VERTICAL POSITIONS TO GET IT EXACTLY RIGHT. THE

CAMERA MUST BE THOROUGHLY BALANCED FOR PROPER OPERATION.

Page 3

3

5. Engage the brass motor gears to the black arm gears and tighten.

Be sure the levers are pointing away from the rotating arm.

-NOTE: Once tightened, you can adjust the position of the lever by

simply pulling out on it and then rotating the lever until it faces away.

This will NOT loosen the fastener. Failure to aim lever away will

impede the movement of the MC50.

Connecting the Cables

1. Connect the locking 4-pin control cable to the 4-pin motor cord at the

base of the MC50.

2. Connect the other end of the 4-pin control cable to the

MC50 Control Unit at the locking 4-pin connector.

The additional 3-pin port located beneath the motor cable port

will provide 24VDC power output.

3. Connect the 4-pin XLR power cable from the AC adapter to the

4-pin XLR power connector located on the MC50 Control Unit.

OPERATION OF MC50 CONTROL UNIT

1. The joystick controls camera movement in a fashion similar to airplane

controls. Joystick Forward: camera points down; Joystick Backward:

camera points up; Joystick Left: camera points to the left; Joystick Right:

camera points to the right.

*NOTE: The UP/DOWN joystick directions will depend on how the

camera is mounted – you can reverse the UP/DOWN by turning the

camera 180 degrees to face the opposite direction. For normal operation,

mount the camera so that the left side (viewfinder/LCD panel side) faces

out away from the rotating arm.

Page 4

4

Speed

dials

Underslung Operation

toggle switch

1a. When the camera is underslung, your left / right controls are

reversed, however the up/down controls remain consistent

when MC50 is underslung. You can change this up/down

control scheme by remounting the camera 180° from the

original position. The silver toggle switch will reverse the

direction of pan input on the joystick. Try flipping this switch if

you are having trouble framing your shot while in the

underslung position.

underslung

2. In addition to the joystick, which is pressure-sensitive for speed control, these

dials enable the operator to set the maximum speed of each motor, allowing

for a higher degree of control. Turn the dials completely clockwise for maximum speed. The

most effective way to vary the speed of the panning and tilting is by using the joystick, but

you can also preset the maximum speed using the dials.

****The control box operates most effectively with the speed dials turned up at least

1/3 of the way (“10 o’clock”). We don’t recommend turning the dials all the way down.

You may experience drifting issues with the dials turned too far down.***

IMPORTANT NOTES *

* STORAGE

We recommend removing the motors from the Pan/Tilt head when storing the MC50 unit in the case. You can do this by

loosening the clamp levers and sliding the motors off the stainless steel mounting posts – they can be placed in one of the

supplied compartments of the MC50 case. Likewise, you should disconnect all extension cables from the unit and store

them in a properly coiled position. When storing the unit, do not subject it to excessive heat, moisture or dust – store in a

cool, dry place for optimal long-term performance.

* TRIPOD MOUNTING

We recommend mounting the MC50 on a 100mm bowl-type tripod since it will fit snugly and enable you to thread the

supplied bolt through the MC50 mounting plate and down through the bowl of the tripod. Using the supplied oversize

washer and nut, you can securely bolt the MC50 onto the tripod bowl. Although the MC50 can be mounted to a standard

center-post tripod, the mounting bolt on such tripods isn’t long enough to enable you to secure the mount with a washer

and nut. If the tripod/MC50 mount were suddenly jarred or disrupted, there is a possibility the mounting bolt might bend or

shear, so be very cautious about this type of setup. VARIZOOM DOES NOT RECOMMEND MOUNTING THE MC50 ON

ANY TRIPOD OTHER THAN A 100 mm BOWL TRIPOD.

* 360-DEGREE PANS AND TILTS

The MC50 is capable of 360-degree turns on either axis, and the only limitation is in the twisting of your cables. Typically,

you can go at least 360 degrees before the cables become severely entwined, but you should always be aware of the

stress you place on the cables when going past 360 degrees – cable damage may result. Furthermore, improper cable

management may result in damage to the camera’s connectors, so be aware of cable twist when rotating beyond 360

degrees of movement.

Page 5

5

* FOR PROFESSIONAL CAMERAS

A.1.

A.2.

Since professional shoulder-mount cameras typically use a quick-release tripod plate of some sort, it is important to note

that in some cases the friction between the camera’s mounting plate and the mounting plate of the VZ-MC50 may not be

sufficient to ensure a secure mount when tilting. You may want to line one or both of the surfaces with electrical tape,

gaffer’s tape, or something to provide a more slip-resistant contact. Of course, you’ll want to securely tighten the

mounting bolts, as well. Some quick-release tripod plates also have a lot of ‘play’, so you may need to shim or even

eliminate the plate to sustain proper balance, because if the camera shifts at all it will throw off the balance.

TROUBLESHOOTING: UNWANTED CAMERA MOVEMENT

1-TURN OFF YOUR CAMERA’S OPTICAL IMAGE STABILIZER (OIS) WHILE IT IS MOUNTED TO THE PAN/TILT

HEAD. OIS DOES NOT REACT WELL TO PAN/TILT SYSTEMS.

2-TURN THE SPEED DIALS UP

3-MAKE SURE your camera is perfectly balanced by disengaging your motors and tilting the camera at various angles – it

should not move at all if the camera is in balance (if necessary, re-balance – see Page 1).

4- IF SOLUTIONS 1-3 DON’T WORK, you may have motor drift - do not worry! To find out if you have motor drift, do the

following: *** turn the speed dials all the way up for both pan and tilt, and with all of the power and control cables

connected (a mounted camera is not necessary), disengage the motors so that the brass gears on the motors can spin

freely. If the brass gears turn on their own, without your command, the motor control joystick needs to be calibrated (if

they don’t move, the drifting must be attributed to bad balance).

If Motors Drift:

With the motors disengaged from the head so

they can spin freely, remove the large black threaded

plug on the side of the control box (A.1.) and you will

see two dials for calibrating the pan and tilt (A.2).

Carefully use a small tip Phillips or flat screwdriver to

turn the dials until the motors stop moving. Try to

center the dials between the points where the motors

begin moving in each direction. * Do not press hard

on these dials or damage may result. *

TROUBLESHOOTING: ERRATIC CONTROL UNIT

Erratic control unit behavior may also result from damaged cables or bad power connection.

MAINTENANCE:

The MC50 should not require much maintenance, but over time wear and tear may take its toll. The most common wear

and tear issue is damaged cables, which are relatively easily replaced. After much use, the bearings in the base may

need light lubrication. These bearing are the two sets of thin triple washer-like assemblies above and below the base

block (where the rotating shaft fits). If you lubricate these bearing, just use light oil and don’t add very much or you will

simply attract more dust. As long as the unit pans smoothly, you shouldn’t worry about this.

Most other maintenance should be performed by the factory.

REMINDER: KEEP FINGERS, LOOSE CLOTHING, AND

HAIR AWAY FROM MOVING PARTS AND GEARS! ALWAYS UNPLUG MC50 PAN

AND TILT HEAD WHEN NOT IN USE! WHEN IN DOUBT ABOUT SAFETY, ASK

QUESTIONS FIRST!!! 888-826-3399 / www.varizoom.com

Loading...

Loading...