Page 1

Cinema Pro JR-K5

Operations Manual

Page 2

BEFORE YOU START, READ THESE WARNINGS

1) NEVER PLUG POWER DEVICES OTHER THAN THOSE SUPPLIED BY

VARIZOOM INTO THE SYSTEM. ONLY USE VARIZOOM POWER SOURCES

AND CABLES. USING DIFFERENT POWER COMPONENTS CAN LEAD TO

SEVERE DAMAGE TO THE HEAD AND EVEN THE CAMERA. THIS TYPE

OF DAMAGE IS NOT COVERED UNDER WARRANTY.

2) DO NOT MODIFY THE SUPPLIED CABLES OR ATTEMPT TO

DISASSEMBLE THE HEAD.

3) LENS CONTROL CABLES MUST ONLY BE PLUGGED INTO THE

SPECIFIED INPUT JACK ON THE LENS ITSELF – NEVER PLUG A 12-PIN

CONNECTOR ON A VARIZOOM LENS CONTROL CABLE INTO THE 12PIN

JACK ON THE CAMERA BODY. WHEN IN DOUBT, CONSULT VARIZOOM

OR YOUR LENS MANUAL.

4) THE ADVANCED CONTROLLER DOES NOT REQUIRE SEPARATE POWER,

IT RECEIVES POWER THROUGH THE GREEN-CODED CONTROL CABLE

THAT CONNECTS TO THE HEAD. THE “AUX” POWER JACK ON THE

ADVANCED CONTROLLER IS ONLY UTILIZED IN WIRELESS

CONFIGURATIONS AND SHOULD ONLY BE CONNECTED TO A

VARIZOOM POWER SUPPLY.

5) DO NOT OPERATE THE HEAD WITH AN UNBALANCED LOAD (i.e., with

the camera’s weight extremely off-center either horizontally or

vertically).

6) DO NOT GET THE SYSTEM WET – IT IS NOT WATERPROOF.

7) ALWAYS MAKE SURE YOUR LENS AND POWER CABLES HAVE ENOUGH

SLACK RUNNING THROUGH THE TILT AXIS TO PREVENT TWISTING

AND TEARING OF THE CABLES.

8) MAKE SURE YOUR LENS CLEARS THE BASE OF THE HEAD WHEN

TILTING. IF THE LENS DOES NOT CLEAR THE BASE, SET SOFT LIMITS

(SECTION 7) TO PREVENT THE LENS FROM STRIKING THE BASE OF

THE HEAD WHEN TILTING.

9) WHEN USING THE CP JR’s ONBOARD LENS CONTROLS TO CONTROL

YOUR CAMERA, ALWAYS POWER THE CAMERA UP LAST. OTHERWISE,

THE RECORD START/STOP FEATURE MAY FALL OUT OF SYNC. TO

AVOID THIS ISSUE, JUST MAKE SURE TO CONNECT XLR POWER TO

THE HEAD BEFORE YOU TURN YOUR CAMERA ON.

Page 3

General Description

The CinemaPro JR is a lightweight, two-axis motion control head for film

and video cameras. It has a wide variety of operating modes: manual operation

from joystick, motion control style record and playback, “go to mark” preset

framing*. Software upgrade options are also available for additional features

such as intervalometer, camera sync, PC data share, and additional recorded

takes and mark points.

The Cinema Pro JR’s optional advanced Controller can give the user all

input and programming capabilities and has a joystick for pan & tilt control.

The Advanced Controller also works in concert with two optional control input

devices: Pan Bars for broadcast-style operation or Hand Wheels for cinemastyle operation.

The Jibstick remote is a simpler, less expensive controller designed for

one-man jib operation. The jibstick only offers joystick pan & tilt with

smoothing and speed control.

The Cinema Pro JR’s lens interface controls zoom and focus. It handles

several control signals: RS-232 for Fujinon digital lenses or Varizoom (TOC)

motor drives, RS-422 for Canon digital lenses or Preston motor drives, position

or speed based analog, pulse width type RC servos, and LANC.

*Go to marks and presets are only available when using the advanced controller.

Page 4

1. Basic Setup

-Secure the head to crane, tripod, or solid mounting beam

-Plug the FACTORY POWER SUPPLY into AC mains

-Connect XLR cable between head and FACTORY POWER

SUPPLY

-Plug green control cable into the head and the jack marked

“CTRL” on the Advanced Controller (or Jibstick, if applicable)

-If applicable, connect camera power (red) and lens control cables

(orange) and route the cables through the tilt axis port hole to connect to your camera

-Make sure to turn camera power on as the LAST step.

Feeding External Cables through the Head

In some cases, you will need to feed video or other

cables through the head. To do so, simply remove the

cable covers (pictured at right, covers may differ

slightly in appearance). 4 screws secure the long

vertical cable cover, while only 2 screws secure the

short horizontal cover. Run the cables through the pan

base and tilt arm with enough slack, and reattach the

cable covers.

If using the TOC system

Connect the TOC 3A (3 axis lens drive box) between the

orange 16-PIN lens control connector located on the

head, and the grey “control” connector located on the

TOC 3A. Connect the Lens drive motors to the

appropriate connection according to their function (zoom, focus, iris)

Page 5

Balance the Camera – Although the head will hold position very well, it operates best when the camera

Center of Mass

is balanced on the mounting platform. With heavier cameras, it is essential, as an out-of-balance load

will cause the servos to constantly fight to hold position. Make sure that the motor power is turned off

before balancing. This will allow you to move the tilt axis by hand. To balance the camera

horizontally, you need to place the camera’s front-to-back center of mass at the center of the mounting

platform slot. You can do this by trial and error, sliding the camera front-to-back on the mounting

platform until it stays level. The simplest accurate way to find the camera’s center of mass is to lay a

pencil/pen on a table and try to balance the camera on it front-to-back. The spot on the camera where

it comes closest to balancing on the pencil is the center of mass. Place the camera’s center of mass at

the center of the mounting slot and secure the camera with mounting screws (2 if possible). When

horizontally balanced, the platform should stay level.

To get the vertical balance right, raise or lower the platform to get the

camera’s vertical center of mass located on the center of tilt rotation. To

adjust, loosen the platform locking lever about ½ turn. Turn the black knob

on the underside of the platform to precisely raise or lower it – you can use

a hex key. Try to get the camera’s center of mass right on the center of tilt

rotation. Rotate the platform to various angles and adjust until it holds

position at any angle. If it falls down, you need to adjust the platform

upward. If it drifts upward, you need to lower the platform. When balance

is achieved, tighten the platform locking lever.

After all connections have been made and the camera is balanced, the head is

ready to be powered up.

Connect the power supply to AC power. Plug in the green communication

connector to the head, and the other end to the jibstick. The jibstick should now power up. Once the

Sync light is illuminated, you may then turn on the motor power switch.

Page 6

Joystick deadband

2. Jibstick layout and functions

Pan Speed

Pan direction

Communication Connector

Tilt direction

Tilt Speed

Smoothing

Pan/Tilt

Control joystick

Communication connector (Green)- Connect this to the communication cable, and connect the other

end of the communication cable to the green connector on the CinemaPro Head. This cable runs

communication as well as power, so make sure that there is XLR power connected to the CinemaPro

Pan direction and Tilt direction- Reverses the response direction for each axis

Page 7

Joystick for pan and tilt operation- Move the joystick in the direction you wish the head to move. The

response direction can be changed with the response direction switches.

Smoothing- Adjusts the amount of smoothing for both the pan and tilt axes. The higher the smoothing

is set the more “delay” there will be in response to the joystick.

Pan speed and Tilt Speed- Adjusts the maximum speed for the pan motor and tilt motor.

Deadband- Adjusts the amount the joystick must be moved before pan and tilt will respond.

3. Troubleshooting

No Response from head

1) Make sure that the motor power switch is turned on, and the light above it is green.

2) Check to make sure that there aren’t any soft limits set too close together. Disable all soft limits, and

then try again.

3) Power down the system, unplug the XLR connector, wait for a few seconds, re-plug everything back

in, power it back up, then try again.

Pan and Tilt moves too slowly or PanBar range is limited

1) Check both speed settings. If the speed is dialed too slowly it will appear to have no response at all.

Head is “jerky” or too responsive

1) Turn down motor speed.

5) If you have been using the advanced controller, check to make sure that the servo tuning in the

“tuning” menu is set to the factory setting. Selecting “reset all” will return this to the factory preset.

Note: When the jibstick is plugged into the head, it will default to the servo tuning of the last

advanced controller that used with the head.

My jib or crane sways, swims, moves around when the head is rotating

1) This is a problem of imbalance in rotational inertia. If the jib moves when panning, you need to

attach the optional counterweight. If the jib move around when tilting, you need to adjust the

vertical balance (adjust the camera platform until the camera’s center of gravity is on the center

of tilt rotation.

Page 8

4. Options and Specs

Additional Software- The controller can be upgraded to have more position marks, intervalometer

mode, and additional recorded moves.

Additional Head options-

The Head can be fitted with either a 100mm half ball or Mitchell mount. A Mitchell ring adapter is

available for old style Mitchell mount.

An adapter is also available to adapt Mitchell mount to Jimmy Jib style mount.

Wireless control is available, and operates up to ¼ mile. (1 mile with line of sight).

Additional controller cables are available in 50’, 100’, or 150’ increments. A coupler is available to join

the cables, or we will make a cable of any reasonable length as a custom item on request.

Head XLR power cables are available in standard 30’ or 75’ increments, or longer as a custom item on

request.

External Lens Drive Motors available for separate purchase

Page 9

Specs-

Head construction: Primarily Aluminum, with carbon fiber platform rails and some stainless steel, steel,

brass, bronze and delrin components

Height: 20.5”

Width: 11.3”

Depth: 6”

Weight: 13lbs

Camera weight limit: 35lbs

Maximum speed: 130 deg/sec (limited for optimal performance)

Power Supply (included): 24VDC, 5A

Head Power Requirements: 24 VDC regulated, 120 watts max

WARNING: Do not connect the head to any power supply other than the one supplied. If you must

power the head another way, make sure you clear it with VariZoom first.

Page 10

Connectors-

Head Base connectors

Controller - 7pin LEMO (green)

XLR 4-pin Head/Camera Power

Passageway for external cables (video, lens control, etc.)

Head Top connectors

Lens Control Out to camera/lens/lens drive - 16pin LEMO (orange)

Camera Power Out - 2pin LEMO (red)

Controller connectors

CTRL - 7Pin LEMO – Head control cable (green)

SERIAL - 8pin LEMO – TOC or Preston Lens Drive Hand Units (gray)

ANALOG - 5pin LEMO – Pan Bars zoom & focus controls (white)

Page 11

Jib Counterweight Option

(1)

(2)

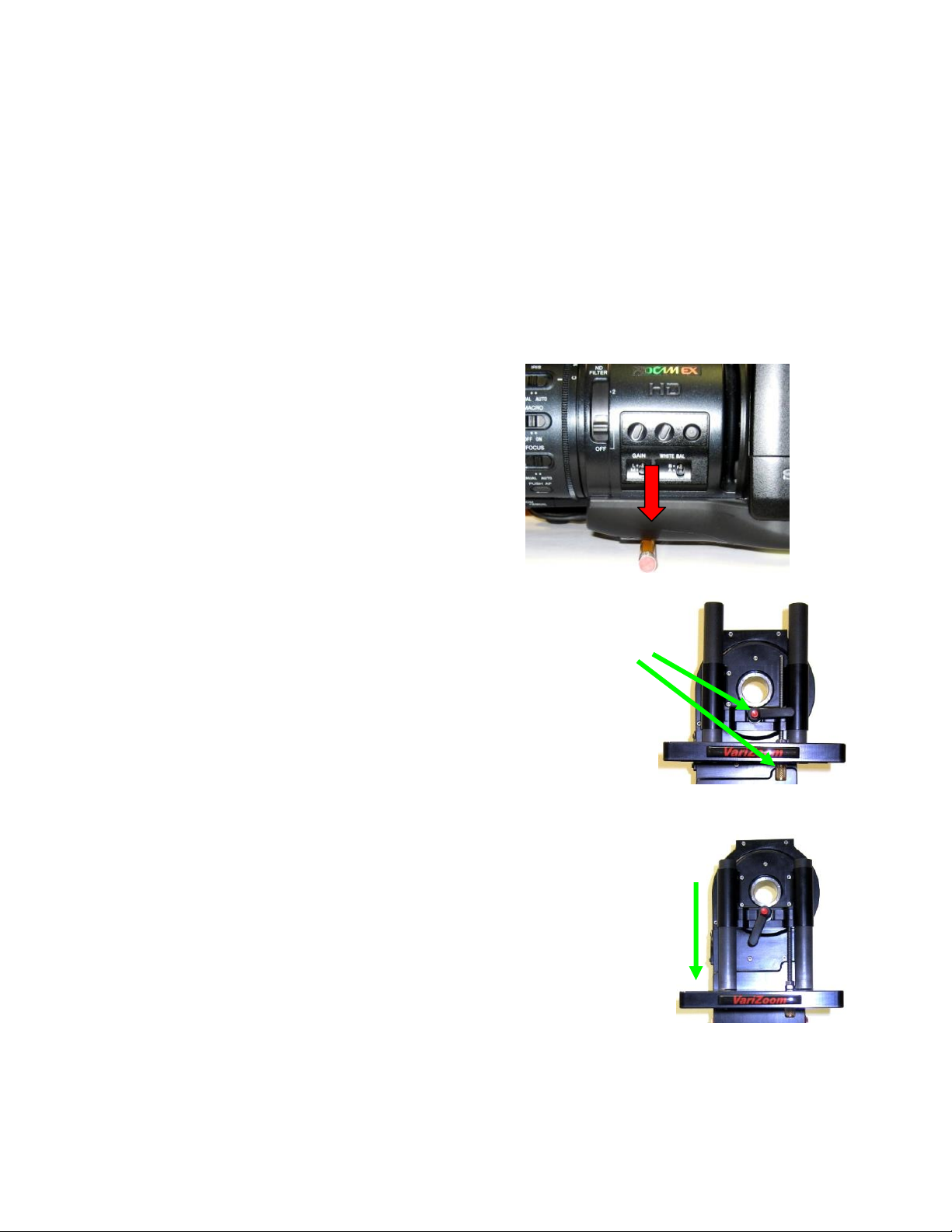

Some lightweight jibs may not have enough mass to neutralize the high acceleration and torque of the

CP Jr head. If the motion of the head causes your jib to sway from side to side in a way you want to

eliminate, we have a counterweight option that will effectively eliminate the problem.

Heavier jibs will not be affected much, and the effect is only significant during sudden moves. Adding

our counterweight to the CP Jr balances out the rotational inertia so even lightweight jibs will not be

susceptible to the swaying effect caused by sudden moves.

Attaching the counterweight is simple. Before

attaching the counterweight, fix the head to your

jib.

(1) Start by attaching the interface plate to the

head with the 4 small screws (supplied). Now fix

the support arm to the interface plate using the

supplied thumbscrews, lockwashers, and flat

washers. Put the flat washers between the

support arm and the lockwashers to prevent

scratching. Tighten the thumbscrews thoroughly.

(2) Now attach the square weight to the support arm,

using the same type of thumbscrews, lockwashers and

washers. Tighten the thumbscrews thoroughly.

The counterweight adds about 7 lbs total weight to the

system, so if you don’t need it, try operating without it

first. Also note that some swaying may be caused by the

camera platform being out of vertical balance – remedy

this by adjusting the camera platform up or down so the

camera’s center of mass is on the center of tilt rotation.

Page 12

Appendix

24VDC Power Supply Connector

1) Power Supply Connector – XLR 4-pin Female

Pin Function Wire Color

1 N.C.

2 CP JR Neg. Black & Green

3 CP JR Pos. White & Red

4 N.C.

* 2) Optional XLR Y-adapter for running head AND camera power through single XLR extension

Y-1 “Camera” Power Input Male XLR Connector

Pin Function

1 Camera Neg.

2 N.C

3 N.C.

4 Camera Pos.

Y-2 “Head” Power Input Male XLR Connector

Pin Function

1 N.C.

2 CP JR Neg.

3 CP JR Pos.

4 N.C.

Y-Single Female XLR Output Connector (combines Camera & Head Power into one XLR cable run

– connect to 30’ XLR extension that plugs into CP JR head)

Pin Function

1 Camera Neg.

2 CP JR Neg.

3 CP JR Pos.

4 Camera Pos.

Page 13

CP JR Head - Base Connectors

1) Head Control Connector (Green) – LEMO EGG1B307CLL

Pin Function Wire Color (Cable)

1 Common Brown

2 RS-422 RXD Red

3 RS-422 RXD! Orange

4 RS-422 TXD Yellow

5 RS-422 TXD! Green

6 24 VDC + Blue Power to Remote or Jibstick

7 24 VDC - Violet Power to Remote or Jibstick

2) Power Input Connector – XLR 4-pin Male

Pin Function Wire Color

1 Camera Neg. Black

2 Cinema Pro Neg. White

3 Cinema Pro Pos. Red

4 Camera Pos. Green

*** WARNING: DO NOT POWER THE CINEMAPRO JR WITH ANYTHING OTHER THAN

THE INCLUDED FACTORY POWER SUPPLY OR YOUR WARRANTY MAY BE VOIDED.

THE UNIT MAY BE SEVERELY DAMAGED AND CAUSE DAMAGE TO YOUR CAMERA IF

YOU USE A NON-APPROVED POWER SUPPLY. IF YOU MUST POWER IT USING A

BATTERY SYSTEM, MAKE SURE THE SETUP IS APPROVED BY VARIZOOM AND

EXECUTED BY A QUALIFIED TECHNICIAN.

CP JR Head - Top Connectors

1) Camera Power (Red) – LEMO EGG2B302CLL

Pin Function

1 Camera Power +

2 Camera Power -

Page 14

2) Lens Control (Orange) – LEMO EGG2B316CLL (Final Version)

Pin Function Lens Connection

1 RS-232 RXD Fuji Digital

2 RS-232 TXD Fuji Digital

3 +5 VDC – Iso Fuji Digital

4 Common – Iso Fuji Digital

5 RS-422 RXD Canon Digital

6 RS-422 RXD! Canon Digital

7 RS-422 TXD Canon Digital

8 RS-422 TXD! Canon Digital

9 Common

10 +5 VDC

11 Analog #1 Focus

12 Analog #2 Zoom

13 RC Servo #1 Focus

14 RC Servo #2 Zoom

15 24 VDC +

16 24 VDC –

Page 15

Lens Connection Table

Lens Control, 16 pin LEMO FGG2B316CLAD

Fujinon Digital

Fujinon Analog

Fujinon Telecon

Canon Digital

Canon Analog

HR10A-10P-10P

HR10A-10P-12P

HR10A-10J-12P

HR25-9P-20P

HR25-9P-20P

1

RS-232 RXD 3

2

RS-232 TXD 2

3

Iso Vcc 4

4

IsoCom & IsoCom3

5

19 & 20 - Green

5

RS-422 RXD

17 - Orange

6

RS-422 RXD!

18 - Yellow

7

RS-422 TXD

15 - Brown

8

RS-422 TXD! 16 - Red

9

Common 2 3

20

10

Vcc (5 volts)

11

Analog #1 out

7 (If zoom)

9 (Zoom)

2

12

Analog #2 out

7 (If focus)

8 (focus) 3

13

RC Servo Out 1

14

RC Servo Out 2

15

Head power + out

16

Head power - out

Tie pins 1 & 2 to 7

for position control

Page 16

Advanced Controller Connectors (if applicable)

1) Auxiliary power input

1 Center 18 to 36 volts input

2 Common

2) “CTRL” - Head Control (Green) – LEMO EGG1B307CLL

Pin Function Wire Color (Cable)

1 Common Brown

2 RS-422 RXD Red

3 RS-422 RXD! Orange

4 RS-422 TXD Yellow

5 RS-422 TXD! Green

6 24 VDC + Blue Power from Cinema Pro

7 24 VDC - Violet Power from Cinema Pro

2) “SERIAL” - Peripheral Connector (Gray) – EGG1B308CLL

Pin Function

1 Common

2 #1 RS-232 RXD

3 #1 RS-232 TXD

4 +5 VDC

5 24 VDC -

6 #2 RS-232 RXD

7 #2 RS-232 TXD

8 24 VDC +

3) “ANALOG” - Panbars Option Zoom & Focus Input (White) – EGG1B305CLL

1 Common

2 Motor disable

3 Zoom analog signal

4 Focus analog signal

5 +5 VDC

Page 17

4) “WHEELS” - Wheels and Panbars Option Input (Blue) – EGG1B306CLL

1 Common

2 +5 VDC

3 Pan encoder signal “A”

4 Pan encoder signal “B”

5 Tilt encoder signal “A”

6 Tilt encoder signal “B”

5) “BLOOP” - Sync & Bloop – Fischer D103A056-130

1 Common – Isolated

2 +5 VDC – Isolated

3 Sync In

5 Bloop out #1

7 Bloop out #2

6) “VIDEO SYNC” - BNC

1 BNC signal

2 Isolated common

Jibstick Connectors (if applicable)

1) Cinema Pro Control (Green)– LEMO EGG1B307CLL

Pin Function Wire Color (Cable)

1 Common Brown

2 RS-422 RXD Red

3 RS-422 RXD! Orange

4 RS-422 TXD Yellow

5 RS-422 TXD! Green

6 24 VDC + Blue Power from Cinema Pro

7 24 VDC - Violet Power from Cinema Pro

2) Focus Input – Fischer D103A054-130

1 Common

2 +5 VDC

3 Focus analog signal

4 Zoom analog signal (unused)

Common

Loading...

Loading...