Page 1

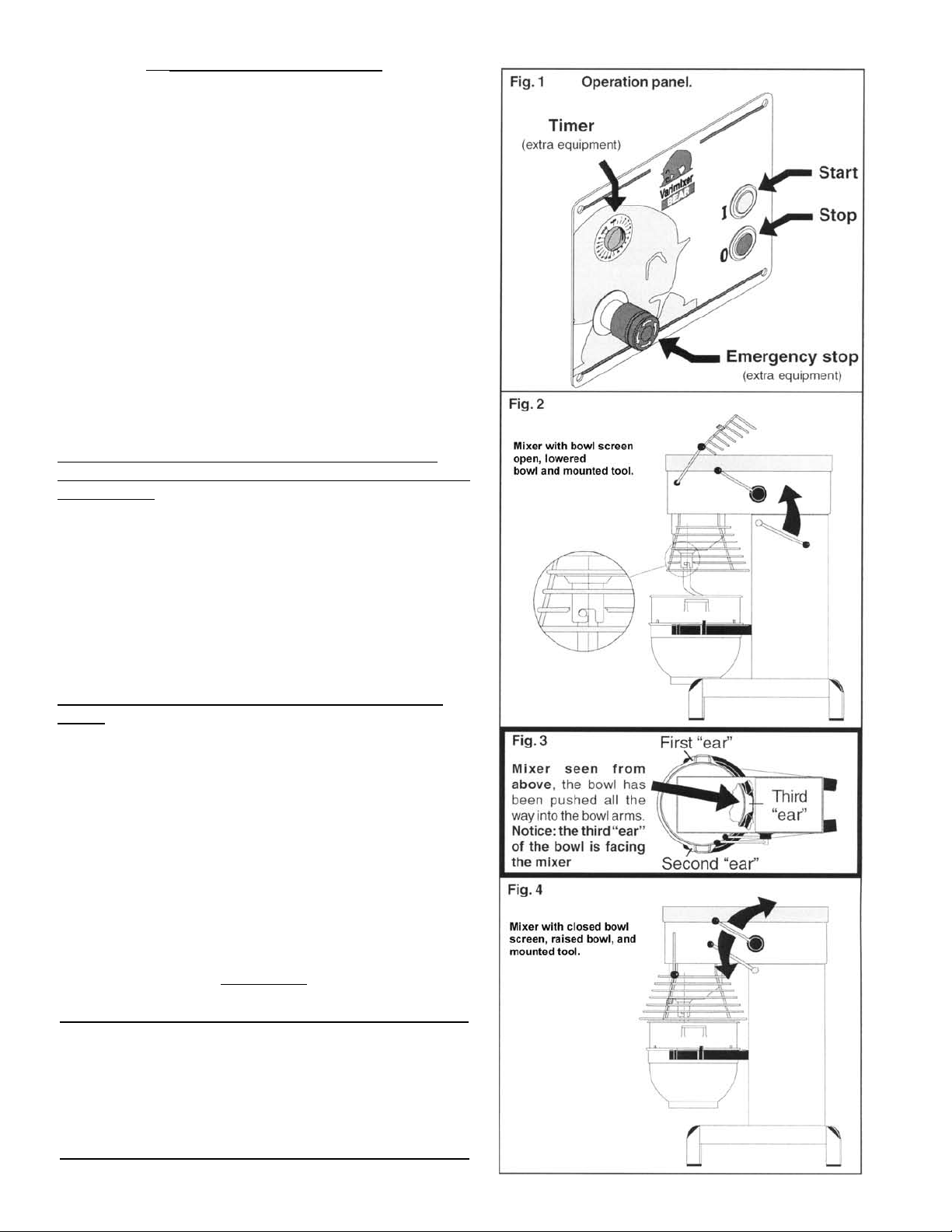

OPERATION OF THE MIXER:

A) Open the bowl screen and place the bowl in the bowl

arms. Note: The bowl arms must be in lowest position and

the bowl must be pushed all the way into the bowl arms.

(Fig.3).

B) Place the mixing tool in the bayonet shaft. The pin on

the tool must be turned into the bayonet hole (fig.2).

C) The bowl is raised to working position, ensure that the

bowl is placed correctly. Close the bowl screen. If the mixer

is equipped with a timer, set the mixing time required by

turning the timer (fig 1) clockwise. The mixer will stop automatically, when the time runs out. When the mixer has

timed out, the "procedure for starting after emergency stop"

is used before the mixer is re-started.

D) Start the mixer by pressing the green start button

(fig.1)

The mixer will only start when the bowl is in the "up"

position, the bowl screen is "closed", and the timer is set to

time or "hold".

E) Turn the speed selector lever (fig. 4) to the rear until

the required speed has been obtained, (notice the recommended maximum speeds on page 3).

F) Before the mixer is stopped, the speed selector lever

must be moved back to lowest speed (fig.4).

G) Stop the mixer by pressing the red stop button (fig.1)

PROCEDURE FOR STARTING AFTER EMERGENCY

STOP:

1) This procedure must be used in cases where the mixer

has been interrupted in high speed.

2) Lower the bowl and remove the tool from the bayonet.

3) Raise the bowl arms, either empty or with the bowl.

4) Close the bowl screen, start the mixer and move

the speed selector lever back to lowest speed. Switch off

the mixer. Now the mixer can be started as usual.

OVERLOAD

Do not overload the mixer. Sticky and heavy doughs may

reduce the capacity of the bowl by 75%. The capacity is

further reduced if the speed of the mixing tool is increased

beyond recommended values or if an incorrect mixing tool

is used. Large lumps of fat or cooled ingredients MUST be

cut into small parts before they are placed into the bowl or

damage can occur to the mixing tool(s).

3

Page 2

Correct use of tools:

Whips should never be struck

against hard objects, this will

decrease the life of the tool.

Recommended applications for tools:

Whip Beater Hook

Cream

Egg Whites

Mayonnaise

and the like.

Cakes

Waffles

Muffins

and the like.

Doughs and

the like.

Cleaning:

Pizza

Bread

Donut

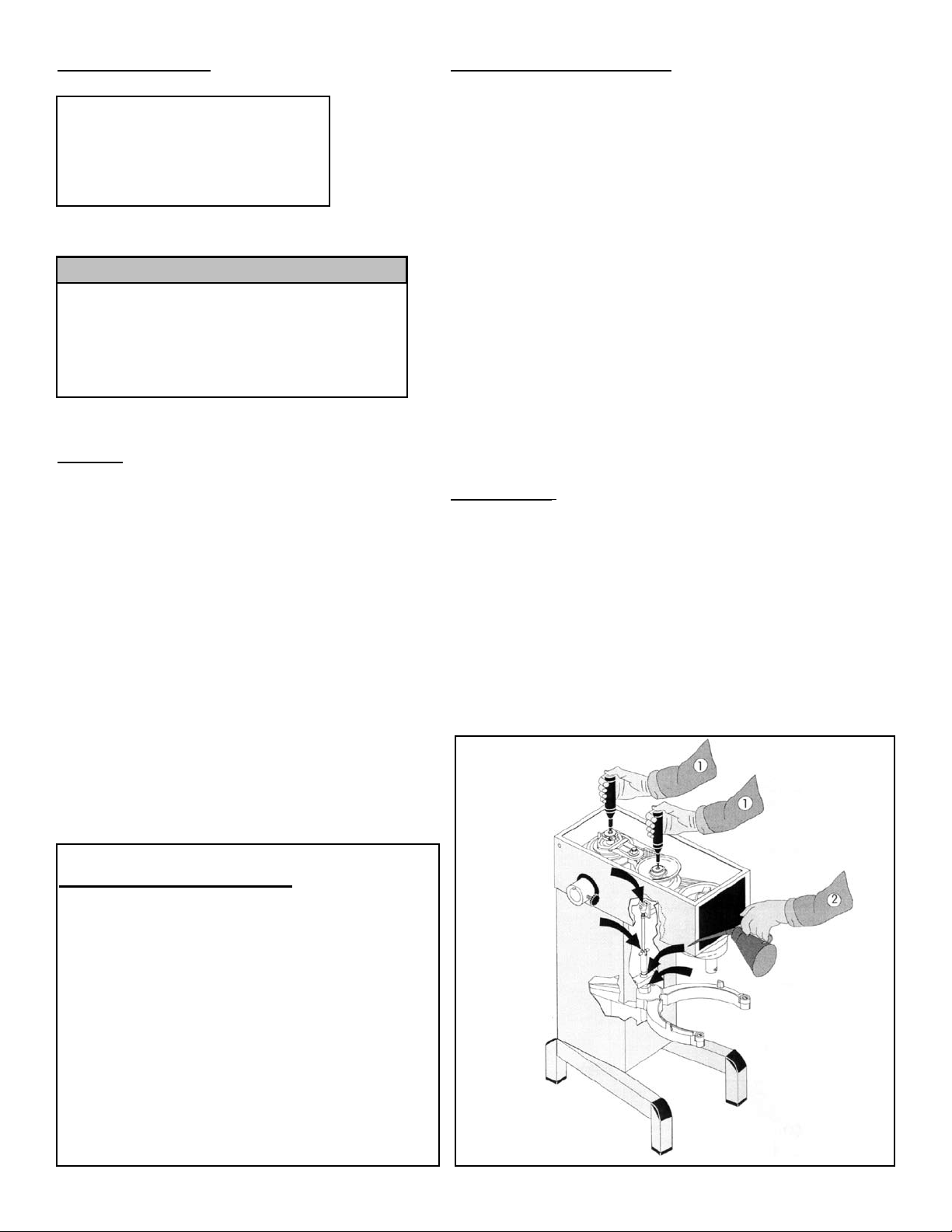

Maintenance and Lubrication:

The variable speed pulleys must be lubricated regularly, i.e. a

lubrication interval of approx. 60 hours of operation.

Lubrication of variable speed pulleys:

-Start the mixer and increase the speed to approx. 50%. Stop

the mixer and open the lid on the top of the mixer. On the top of

each of the two pulley set shafts is a grease nipple (fig. 5 point

1). Press grease through the grease nipples until the grease

gun feels hard to press or until grease comes out between the

shaft and the pulleys.

-Start the mixer, and set the speed back to low ..speed.

-Stop the mixer and fill the grease gun with new grease so that

it is ready for next time.

Lubrication of other movable parts:

The movable parts of the bowl arms, the shaft and the lifting

rod must also be lubricated with oil. Remove the rear covering

and lubricate the marked points with an oil can. (fig.5 pkt.2)

The mixer should be cleaned daily or after use.The

mixer should be cleaned with a soft cloth and clean

water. Sulphonated soaps should be used with caution

as they destroy the mixer's lubricants.

Never use high pressure cleaning for the mixer.

Bowls and tools of aluminium must not be washed with

strong alkaline detergents (pH not larger than 9.0).

The soap suppliers can recommend the correct type of

soap.

The mixer should be unplugged before cleaning to prevent accidental starting while cleaning.

The inside of the beater shaft should be cleaned once

a day with warm, soapy water.

Dough hook Cleaning: Special care

should be given to cleaning the dough

hook. We recommend that it be

cleaned and sanitized in a commercial

dish machine. An alternate cleaning

procedure is to vigorously scrub the

hook with a hot.water and detergent

solution. Use a heavy bristled brush.

After cleaning, sanitize the hook by

rinsing it with a 50 ppm solution of

sodium hypochlorite.

Grease Types:

-Grease for the pulley set shafts: Lubriplate # 1200-2

-On repair of the planetary head: Grease the toothed wheel and

the toothed rim with Nye Gel 868VH,(PN 868VH), the needle

bearings in the planetary head must not be lubricated with this

type of grease, they should be lubricated with PN Sapphire 2.

Do not use any another type of grease than the one stated

here.

-On repair of the attachment drive: Fill the attachment drive with

Tribol Molub 860/150-0, (PN 860/150-0).

Fig.5

4

Loading...

Loading...