Page 1

VHS-4, VHS-6 and

VHS-250

Diffusion Pumps

vacuum technologies

INSTRUCTION MANUAL

Part No. 699901024

Revision A

February 2005

Page 2

VHS-4, VHS-6 and VHS-250

Diffusion Pumps

Copyright 2005

Vacuum Technologies

Page 3

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Warranty

Products manufactured by Seller are warranted against defects in materials and workmanship for twelve (12) months

from date of shipment thereof to Customer, and Seller’s liability under valid warranty claims is limited, at the option of

Seller, to repair, replacement, or refund an equitable portion of the purchase price of the Product. Items expendable in

normal use are not covered by this warranty. All warranty replacement or repair of parts shall be limited to equipment

malfunctions which, in the sole opinion of Seller, are due or traceable to defects in original materials or workmanship.

All obligations of Seller under this warranty shall cease in the event of abuse, accident, alteration, misuse, or neglect of

the equipment. In-warranty repaired or replaced parts are warranted only for the remaining unexpired portion of the

original warranty period applicable to the repaired or replaced parts. After expiration of the applicable warranty period,

Customer shall be charged at the then current prices for parts, labor, and transportation.

When products are used with toxic chemicals, or in an atmosphere that is dangerous to the health of humans, or is

environmentally unsafe, it will be the responsibility of the Customer to have the product cleaned by an independent

agency skilled and approved in handling and cleaning contaminated materials before the product will be accepted by

Vacuum Technologies for repair and/or replacement.

Reasonable care must be used to avoid hazards. Seller expressly disclaims responsibility for loss or damage caused by

use of its Products other than in accordance with proper operating procedures.

Except as stated herein, Seller makes no warranty, express or implied (either in fact or by operation of law), statutory or

otherwise; and, except as stated herein, Seller shall have no liability under any warranty, express or implied (either in

fact or by operation of law), statutory or otherwise. Statements made by any person, including representatives of Seller,

which are inconsistent or in conflict with the terms of this warranty shall not be binding upon Seller unless reduced to

writing and approved by an officer of Seller.

Disclaimer

Operation and maintenance of this equipment involves serious risk. It is the responsibility of the user to maintain safe

operating conditions at all times. Vacuum Technologies assumes no liability for personal injury or damage resulting

from operation or service of the equipment.

Vacuum Technologies has no control over the use of this equipment and is not responsible for personal injury or

damage resulting from its use. The safe use and disposal of hazardous or potentially hazardous materials of any kind is

the sole responsibility of the user. Observe all WARNINGS and CAUTIONS to minimize the serious hazards involved.

It is the sole responsibility of the users of Vacuum Technologies equipment to comply with all local, state and federal

safety requirements (laws and regulations) applicable to their system. Employ the services of an industrial hygienist

and/or a qualified chemical safety engineer in order to ensure safe installation and use.

Warranty Replacement and Adjustment

All claims under warranty must be made promptly after occurrence of circumstances giving rise thereto, and must be

received within the applicable warranty period by Seller or its authorized representative. Such claims should include

the Product serial number, the date of shipment, and a full description of the circumstances giving rise to the claim.

Before any Products are returned for repair and/or adjustment, written authorization from Seller or its authorized

representative for the return and instructions as to how and where these Products should be returned must be obtained.

Any Product returned to Seller for examination shall be prepaid via the means of transportation indicated as acceptable

by Seller. Seller reserves the right to reject any warranty claim not promptly reported and any warranty claim on any

item that has been altered or has been returned by non-acceptable means of transportation. When any Product is

returned for examination and inspection, or for any other reason, Customer shall be responsible for all damage resulting

from improper packing or handling, and for loss in transit, notwithstanding any defect or non-conformity in the Product.

In all cases, Seller has the sole responsibility for determining the cause and nature of failure, and Seller’s determination

with regard thereto shall be final.

If it is found that Seller’s Product has been returned without cause and is still serviceable, Customer will be notified and

the Product returned at Customer’s expense; in addition, a charge for testing and examination may be made on Products

so returned.

3/1/00

iii

Page 4

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

This page intentionally left blank.

Page 5

Declaration of Conformity

Declaration of Conformity

Konformitätserklärung

Déclaration de Conformité

Declaración de Conformidad

Verklaring de Overeenstemming

Dichiarazione di Conformità

We

Wir

Nous

Nosotros

Wij

Noi

declare under our sole responsibility that the product,

erklären, in alleniniger Verantwortung, daß dieses Produkt,

déclarons sous notre seule responsabilité que le produit,

declaramos, bajo nuestra sola responsabilidad, que el producto,

verklaren onder onze verantwoordelijkheid, dat het product,

dichiariamo sotto nostra unica responsabilità, che il prodotto,

Varian, Inc.

Vacuum Technologies

121 Hartwell Avenue

Lexington, MA, 02421-3133 USA

VHS-4, VHS-6 and VHS-250 Diffusion Pump

to which this declaration relates is in conformity with the following standard(s) or other normative documents.

auf das sich diese Erklärung bezieht, mit der/den flogenden Norm(en) oder Richtlinie(n) übereinstimmt.

auquel se réfère cette déclaration est conforme à la (auz) norme(s) ou au(x) document(s) normatif(s).

al que se refiere esta declaración es conforme a la(s) norma(s) u otro(s) documento(s) normativo(s).

waamaar deze verklaring verwijst, aan de volende norm(en) of richtlijn(en) beantwoodt.

a cui se rifersce questa dichiarazione è conforme alla/e sequente/I norma/o documento/I normativo/i.

VMF-11 VHS-6 VHS-400 NHS-35

AX-65 VHS-250 HS-16

AX-150 VHS-4 HS-20

HS-2 VHS-10 HS-32

73/023/EEC . . . . . . . . . . . . . . . . . . . Low Voltage Directive

EN 61010-1. . . . . . . . . . . . . . . . . . . “Safety requirements for electrical equipment for measurement, control and

laboratory use”, incorporating amendments, numbers 1 and 2.

Frederick C. Campbell

Operations Manager

Vacuum Technologies

Varian, Inc.

Lexington, Massachusetts, USA

October 2000

Page 6

VHS-4, VHS-6 and VHS-250 Diffusion Pump

This page intentionally left blank.

Page 7

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Contents

Introduction ............................................................................................................................... 1-1

Pump Specifications ........................................................................................................................... 1-1

Installation ............................................................................................................................... 1-10

Unpacking ........................................................................................................................................ 1-10

Pump Oil Installation ........................................................................................................................1-10

Vacuum System Connections ........................................................................................................... 1-11

Cooling Water Connections ..............................................................................................................1-11

Electrical Connections ...................................................................................................................... 1-12

Thermal Switch ................................................................................................................................ 1-13

Startup ....................................................................................................................................... 2-1

Shutdown .................................................................................................................................. 2-2

General Maintenance ................................................................................................................3-1

Inspection Requirements ............................................................................................................ 3-1

Cleaning .................................................................................................................................... 3-2

VHS-4 and VHS-6 Cold Cap Removal/Installation ......................................................................3-3

VHS-250 Cold Cap Removal/Installation ....................................................................................3-4

Jet Assembly Removal/Installation ..............................................................................................3-5

Heater Replacement ..................................................................................................................3-8

Pump Fluid Charge ..................................................................................................................3-10

Leakage .....................................................................................................................................4-1

Outgassing ................................................................................................................................. 4-1

Poor Pump or System Performance ............................................................................................ 4-2

vii

Page 8

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

This page intentionally left blank.

Page 9

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Figures

1-1 VHS-4 Speed and Throughput Curves.................................................................................. 1-4

1-2 VHS-4 Wiring Information ................................................................................................... 1-4

1-3 VHS-6 Speed and Throughput Curves.................................................................................. 1-6

1-4 VHS-6 Wiring Information ................................................................................................... 1-6

1-5 VHS-250 Speed and Throughput Curves..............................................................................1-8

1-6 VHS-250 Wiring Information ............................................................................................... 1-8

3-1 VHS4 and VHS-6 Cold Cap Removal/Installation................................................................. 3-3

3-2 VHS-250 Cold Cap Removal/Installation..............................................................................3-4

3-3 VHS-4 Diffusion Pump Jet Assembly.................................................................................... 3-6

3-4 VHS-6 and 250 Diffusion Pump Jet Assembly ...................................................................... 3-7

3-5 VHS-6 and VHS-250 Heater Mounting ................................................................................3-8

3-6 VHS-4 Heater Mounting ......................................................................................................3-9

ix

Page 10

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

This page intentionally left blank.

Page 11

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Tables

1-1 Pump Operational Specifications........................................................................................ 1-1

1-2 VHS-4 Dimensions ............................................................................................................. 1-5

1-3 VHS-6 Dimensions ............................................................................................................. 1-7

1-4 VHS-250 Dimensions ......................................................................................................... 1-9

4-1 Troubleshooting.................................................................................................................. 4-2

5-1 VHS-4 Models .................................................................................................................... 5-1

5-2 VHS-4 Replacement Parts ................................................................................................... 5-1

5-3 VHS-6 Models .................................................................................................................... 5-2

5-4 VHS-6 Replacement Parts ................................................................................................... 5-3

5-5 VHS-250 Models ................................................................................................................ 5-4

5-6 VHS-250 Replacement Parts ............................................................................................... 5-4

xi

Page 12

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

This page intentionally left blank.

Page 13

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Preface

Instructions for Use

This equipment is designed for use by professionals. Read this instruction manual and any

other additional information supplied by Vacuum Technologies before operating the

equipment. Vacuum Technologies will not be held responsible for any events that occur due

to non-compliance with these instructions, improper use by untrained persons,

non-authorized interference with the equipment, or any action contrary to that provided for

by specific national standards.

Documentation Standards

This manual uses the following documentation standards:

WARNING Warnings are for attracting the attention of the operator to a

particular procedure or practice which, if not followed

correctly, could lead to serious injury.

CAUTION Cautions are displayed before procedures, which if not

followed, could cause damage to the equipment.

NOTE Notes contain important information.

xiii

Page 14

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Safety

Diffusion Pump Hazards

Designers of systems utilizing diffusion pumps must design out hazards wherever possible.

For hazards that cannot be designed out, warnings, procedures, and instructions on proper

use and servicing are provided. Please use guards, safety features, and interlocks as

recommended.

Refer to the following tables for a list of general hazards and recommended actions, a list of

prohibited actions that can result in explosions, and a list of pressurization hazards that can

result in damage to equipment.

THE INSTALLATION, OPERATION, AND SERVICING OF DIFFUSION PUMPS INVOLVES

ONE OR MORE OF THE HAZARDS LISTED IN THIS SECTION, ANY ONE OF WHICH IN

THE ABSENCE OF SAFE OPERATING PRACTICES AND PRECAUTIONS, COULD

POTENTIALLY RESULT IN DEATH OR SERIOUS HARM TO PERSONNEL.

xiv

Page 15

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

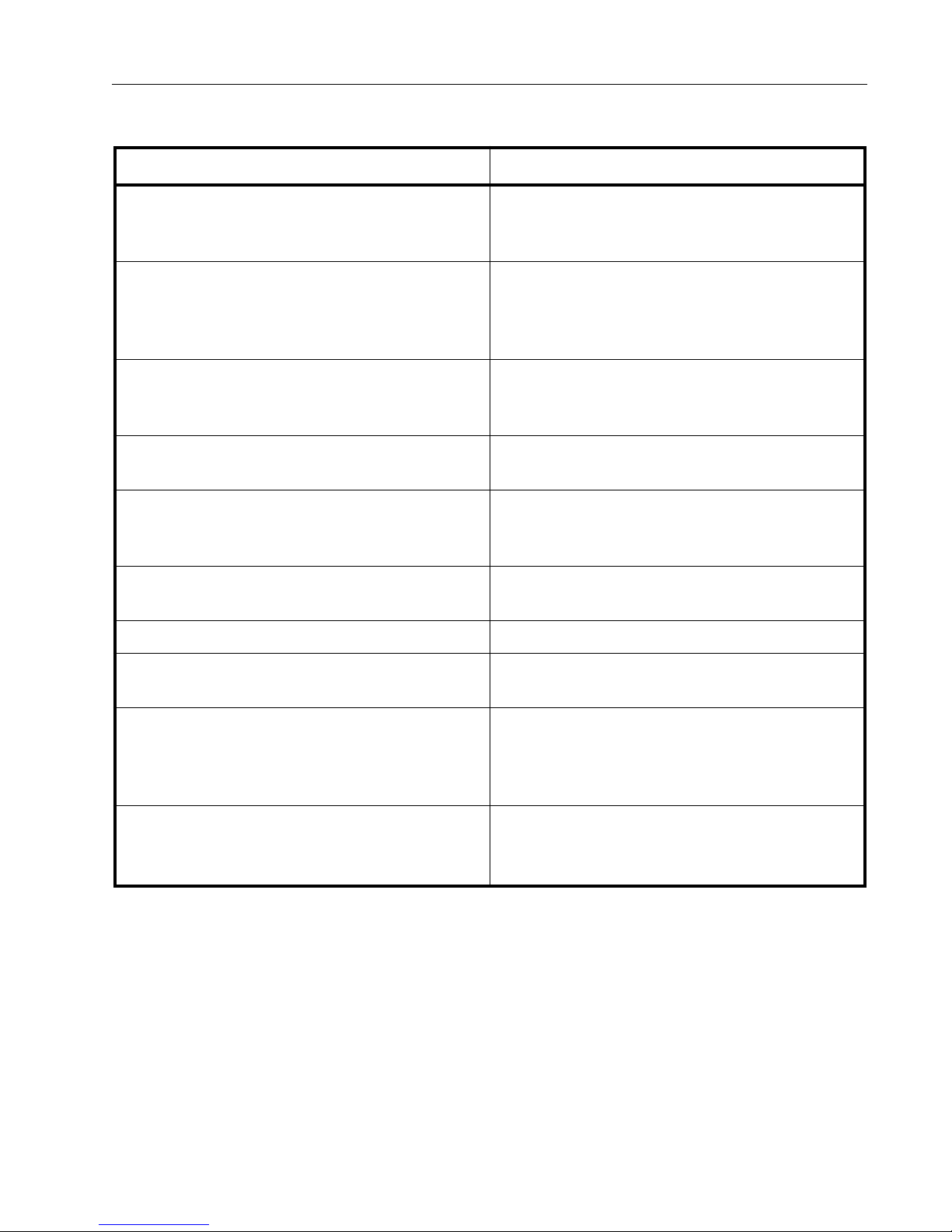

General Hazards

Hazard Suggested Corrective Action

Loss of utility: water and/or electricity Provide sufficient backup water and power

supply as necessary to effect a safe shutdown

under worst case conditions.

Overpressure in foreline Provide an interlock to ensure that the power

supply to the pump heater cannot be activated

if the foreline pump is not running and/or the

pressure in foreline is above 0.5 Torr (0.67 mbar).

Overtemperature Fit temperature sensors and pump fluid level

sensors with feedback to an interlock on the

heater power supply.

Insufficient water flow through main cooling coils Use water flow sensor and feedback to interlock

the heater power supply.

Water trapped between inlet and outlet of

Quick Cool Coil, or liquid nitrogen trapped

Provide vent or pressure relief valves for both

Quick Cool Coil and liquid nitrogen trap.

between inlet and outlet of liquid nitrogen trap

Loss of electrical ground integrity Incorporate ground fault interrupt circuit into

heater power supply.

Positive pressure in pumping system Integrate pressure relief valve in vacuum system.

High voltage Prevent personnel contact with high voltages;

design and attach warnings.

Toxicity and Corrosivity Toxic and/or corrosive gases must be vented

to a safe location, ensuring adequate dilution or

scrubbing to safe levels, taking all action required

to meet air quality standards.

Explosion Integrate pressure relief valves in all systems

using pumps 10” or larger in diameter.

Do not use hydrocarbon-based pumping oils.

xv

Page 16

Explosion

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Operation of the diffusion pump without continuous evacuation below 0.5 Torr (0.67 mbar)

or without coolant, and then introducing a strong oxidizer (such as air), explosive vapors,

powders, or materials which may react with pumping fluids in a hot pump (above 300 °F or

150 °C) can cause an explosion. Such an explosion would violently expel valves and other

hardware, slam open doors that are not designed for appropriate pressure relief, or burst

other components of the vacuum system. Serious injury or death could result from expelled

parts, doors, shrapnel, and shock waves.

Avoid the implementing the following three elements that could result in an explosion:

❑ Fuel

❑ Oxidizer

❑ Ignition

A combination of temperature and pressure can be a source of ignition. Most diffusion

pump fluids, except mercury, are fuels. Hydrocarbon oils are more prone to oxidize and

explode than synthetic silicone-based oil. The oxidizer can be air, which is a strong oxidizer

that is introduced by a leak, deliberately brought in via a process, or inadvertently admitted

by an operator or by a process controller error.

Explosion and Fire from Acetone and Alcohol

Diffusion pumps are typically cleaned with acetone and alcohol. When combined with

air, oxygen, and other oxides, alcohol and most other solvents are very flammable and

explosive. Never permit any trace of these cleaners to remain in or on the pump. Remove

all traces of alcohol and acetone and other cleaners with clean, dry, oil-free compressed air.

Oxygen and other strong oxidizers are even more dangerous than air. Certain conditions

of temperature and pressure can cause a combustible mixture to explode. The larger the

diffusion pump, the greater the risk of explosion and the greater the risk of damage and

injury. Never operate large diffusion pumps utilizing hydrocarbon oils without a complete

safety analysis for the entire system and for the application.

Never operate a large diffusion pump under the conditions listed in the following table.

Any of these situations increases the probability of an explosion.

xvi

Page 17

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Explosive Conditions

Prohibited Action Explosion-Causing Condition

Do not run pump without cooling water. Overtemperature

Do not run pump with low level of pump fluid. Overtemperature

Do not run pump without proper backing or holding pump. Overpressure

Do not run pump when not evacuated below 0.5 Torr

Overpressure

(0.67 mbar).

Do not admit air to, or rough through, a pump with hot boiler. Overpressure plus strong oxidizer

Do not open drain or fill plug while pump is under vacuum,

Overpressure plus strong oxidizer

especially when it is hot.

Do not contaminate pump with explosive vapors. Lower explosive threshold

of gas mixtures

Do not remove, defeat, or override safety counter-measures such

as pressure and thermal switches and valve sequencer interlocks.

Do not machine or weld any part of the pump without removing

Overtemperature, overpressure,

more combustible mixtures

Source of ignition

all oil or solvent residue in pump in large pumps.

Do not use unsuitable pumping fluid, especially hydrocarbon oil. Lower explosive threshold

of gas mixture

xvii

Page 18

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Pressurization Hazards

Large vacuum pumps and their components are designed for vacuum service. They are not

designed to be pressurized, which can cause them to burst and possibly expel shrapnel at

lethal velocities. Serious accidents have been caused by intentional pressurization of

vacuum systems and their components.

❑ Never pressurize any part of a vacuum system for test or any other purpose.

❑ Always provide pressure relief when designing diffusion pumps into systems and

ensure that pressure relief motion is limited to safe envelopes.

❑ Never permit any of the hazards in the table below to develop.

Pressurization Hazards

Prohibited Action Result

Do not block inlet or vent of liquid nitrogen trap and lines. LN2 trap and/or lines burst

Do not close isolation valves at inlet and discharge of main

Water turns to steam and bursts coils

water cooling coils when pump is reheated.

Do not pressurize the pump body. Body of pump bursts

Do not make a hole through the vacuum wall. Loss of structural integrity of wall

Pressure Relief Devices

Systems larger than 10”, such as this pump, must be designed with pressure relief devices to

provide safe pressure relief from internal explosions. Always recognize that safety devices

can fail or malfunction; provide redundant protection by installing devices having different

failure modes, failure mechanisms, and failure causes. Be certain that exhaust duct

materials are capable of withstanding the corrosivity, temperature, and pressure of

exhausted products.

xviii

Page 19

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Dangerous Substances

Chemical Dangers of Acetone and Alcohol

Diffusion pumps are typically cleaned with acetone or alcohol. Acetone, alcohol, and most

other solvents are irritants, narcotics, and depressants, and/or carcinogenic. Their inhalation

and ingestion may produce serious effects. Even absorption through the skin can result in

moderate toxicity.

Ensure that cleaning operations are always performed in large, well-ventilated rooms. The

use of a self-contained breathing apparatus may be necessary depending upon the solvent

type and vapor concentration in surrounding air.

Poisonous and Corrosive Compounds

When pumping poisonous, reactive, and/or corrosive gas, vapors, or chemicals, proper

operation and regeneration do not always ensure that all hazardous materials have been

totally removed.

If hazardous gas, vapors, chemicals, or combustible mixtures are pumped, sufficient

quantities may exist during operation or remain after regeneration to cause severe injury or

death.

Pump Fluids

Overheating the pump fluid, exposing it to air or reactive materials, or overpressurizing it

above the normal operating range (approximately 1 x 10

decomposes the fluid and possibly makes it toxic. This is especially true of backstreamed

mechanical pump oils which are more volatile (unstable). Overheating of accidentally

introduced or backstreamed mechanical pump oils cannot be protected against by thermal

switches which are set for diffusion pump oil.

Process Gasses

These gasses are frequently toxic, flammable, corrosive, explosive, or otherwise reactive.

Vacuum Technologies has no control over the types of gasses passing through your diffusion

pump as these are entirely under the control of the process user and/or the hardware

systems integrator. Since these gasses can cause serious injury or death, it is very important

to plumb the exhaust of the pump to the facility’s hazardous gas exhaust system which

incorporates appropriate filters, scrubbers and similar components to ensure that the

exhaust meets all air and water pollution control regulations.

−3

Torr / 1.3 x 10−3 mbar)

xix

Page 20

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

High Temperatures

Hot Surfaces

Boiler temperatures reach 530 °F (275 °C) which can cause serious burns. Always ensure

that surfaces have cooled to near room temperature before touching them.

Hot Cooling Water and Steam

The water used to cool the pump can reach scalding temperatures. Touching or rupturing

the cooling surface can cause serious burns. Water left inside Quick Cool Coils from

previous use turns to steam when the pump is reheated. This steam must be allowed to

escape without coming into contact with personnel. Whenever possible, design the water

system with interlock valves so that power cannot be applied to the pump unless water is

flowing in the main cooling coils (not the Quick Cool Coils).

High Voltages

Diffusion pump heaters operate at voltages high enough to kill. Design systems to prevent

personnel contact with high voltages. Securely attach prominent hazard warnings. Always

break the primary circuit to the power supply when direct access to the heater or wiring is

required.

xx

Page 21

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Section 1. Introduction and Installation

1.1 Introduction

Before unpacking and installing a VHS-4, VHS-6 or VHS-250 diffusion pump, thoroughly

familiarize yourself with this instruction manual and the diffusion pump operational

specifications (Table 1-1). Examine all other technical material supplied in order to gain a

better understanding of the operating principles, limitations, correct application, and

hazards involved with the operation of this equipment.

1.1.1 Pump Specifications

Table 1-1 lists the specifications for the VHS-4, VHS-6 and VHS-250 pumps.

Table 1-1 Pump Operational Specifications

Power Rating VHS-4: 1450 Watts

VHS-6: 2200 Watts

VHS-250: 2200 Watts

−3

Optimum Operating Range (Torr) VHS-4 and VHS-6: 1x10

(1.3 x 10-3 to < 6.6 x 10-9 mbars)

−4

VHS-250: 7x10

Maximum Pumping Speed (l/s) VHS-4: Air – 1200 with std cold cap; 950 with extended cold

cap

Helium –1500 with std cold cap; 1200 with extended

cold cap

VHS-6: Air – 2400 with std cold cap; 1600 with extended cold

cap

Helium –3000 with std cold cap; 2000 with extended

cold cap

VHS-250: Air – 3700 with std cold cap; Helium –4600

Maximum Throughput (Torr-l/s) VHS-4: 1.2 (1.6 mbar-l/s) in operating range

2.5 (3.2 mbar-l/s) @0.01 Torr

VHS-6: 2.4 (3.2 mbar-l/s) in operating range

3.5 (4.5 mbar-l/s) @0.01 Torr

VHS-250: 2.6 (3.5 mbar-l/s) in operating range

to < 5x10

to < 5x10

−9

(9 x 10-4 to < 6 x 10-9 mbars)

−9

DRAFT 3/9/05

Maximum Forepressure No Load – 0.65 Torr (.87 mbars)

3.5 (4.5 mbar-l/s) @0.01 Torr

Full Load – 0.55 Torr (.73 mbars)

1-1

Page 22

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 1-1 Pump Operational Specifications (Continued)

Backstreaming Rate at Pump Inlet 5x10−4 mg/cm2/minute (with std cold cap)

Electrical Requirements 120, 208, 240; 50/60 Hz; single phase

Warm-up Time 10 minutes

Cooldown Time

(using Quick Cool Coil)

Fluid Charge VHS-4: 300 cc

Cooling Water Requirements Maximum inlet temperature – 60/80 °F (15 - 26 °C)

Pressure drop across coils VHS-4: 4 psi

Backing Pump Size VHS-4: ≥ 10 cfm for maximum throughput

Recommended Jet Assembly 4-stage, self-aligning, stainless steel

Foreline Baffle Stacked half moon

Cold Cap Nickel-plated copper

Water Connections 1/8" FPT

10 minutes

VHS-6 and VHS-250: 500 cc

Maximum outlet temperature at foreline – 120 °F (48.9 °C)

Flow rate – VHS-4: 0.15 gpm

VHS-6 and VHS-250: 0.25 gpm

VHS-6 and VHS-250: 15 psi

VHS-6 and VHS-250: 17 cfm for maximum throughput

Thermal Switches Manual reset at 300 °F

DRAFT 3/9/05

1-2

Page 23

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 1-1 Pump Operational Specifications (Continued)

Heater circuit resistance (ohms) VHS-4: 1450 watts

120 V – 10

208 V – 29.8

240 V – 39.7

VHS-6 and VHS-250: 2200 watts

120 V – 6.5

208 V – 19.6

240 V – 26.1

Clearance (for heater removal) 6" minimum

Materials Body, Flanges, Foreline, Baffle – stainless steel

Jet Assembly – stainless steel

Body Cooling Coils – copper

Quick Cooling Coil – stainless steel

Cold Cap – nickel-plated copper

Shipping Weight VHS-4: 55 pounds

VHS-6 and VHS-250: 75 pounds

DRAFT 3/9/05

1-3

Page 24

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Figure 1-1 shows the VHS-4 speed and throughput curves.

Speed with standard cold cap

Speed with extended cold cap

1800

5

1200

900

600

Air Speed (//sec)

300

0 0

−10

10

INLET PRESSURE — TORR

*Note: Speed curves were generated according to AVS Standards 4.1

10

−9

10

−4

10

−7

10

−10

10

−5

10

−4

10

−3

10

Figure 1-1 VHS-4 Speed and Throughput Curves

NOTE Speed curves were generated according to AVS Standard 4.1.

Figure 1-2 gives the VHS-4 wiring information.

4

3

2

Throughput (Torr-//sec)

1

−2

10

−1

DRAFT 3/9/05

1-4

Figure 1-2 VHS-4 Wiring Information

Page 25

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 1-2 lists the VHS-4 dimensions.

Table 1-2

in mm in mm in mm

Height 18.05 458 18.05 458 18.05 458

Centerline to Centerline 10.62 270 10.62 270 10.62 270

Flange Face to Flange Face 5.03 128 5.03 128 5.03 128

EIectrlc8I Box Height 8.63 219 8.63 219 8.63 219

Sight Glass,

Degrees from Foreline

Electrical Box,

Degrees from Foreline

Inlet Flange, Nominal Size 4” ASA ISO -160K 8” CFF

Inlet Flange, OD 9.00 229 7.09 180 7.96 202

Inlet Flange, ID 5.91 150 5.78 147 5.91 150

Inlet Flange, Thickness 0.50 13 0.47 12 0.93 24

90° clockwise 90° clockwise 90° clockwise

30° counterclockwise 30° counterclockwise 30° counterclockwise

VHS-4 Dimensions

ASA ISO Conflat

Inlet Flange, Bolt Circle 7.50 191 N/A N/A 7.12 181

Inlet Flange, Number of Holes 8 N/A 20

Inlet Range, Hole Size 0.69 18 N/A N/A .33 8

O-ring Groove ID 6.06 154 N/A N/A N/A N/A

O-ring Groove Width 0.18 4 N/A N/A N/A N/A

Foreline Flange, Nominal Size KF40 KF-40 2¾ CFF

OD 2.16 55 2.16 55 2.73 69

ID 1.38 35 1.38 35 1.38 35

Thickness 0.20 5 0.20 5 1.38 35

Bolt Circle N/A N/A N/A N/A 2.31 59

Number of Holes N/A N/A N/A N/A 6

Hole Size N/A N/A N/A N/A 0.27 7

O-ring Groove ID N/A N/A N/A N/A N/A N/A

O-ring Groove Width N/A N/A N/A N/A N/A N/A

DRAFT 3/9/05

1-5

Page 26

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Figure 1-3 shows the VHS-6 speed and throughput curves.

Figure 1-3 VHS-6 Speed and Throughput Curves

Figure 1-4 gives the VHS-6 schematic and wiring information.

DRAFT 3/9/05

1-6

Figure 1-4 VHS-6 Wiring Information

Page 27

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 1-3 lists the VHS-6 dimensions.

Table 1-3 VHS-6 Dimensions

ASA ISO Conflat

in mm in mm in mm

Height 21.92 557 21.92 557 21.92 557

Centerline to Centerline 13.38 340 13.38 340 13.38 340

Flange Face to Flange Face 8.62 219 8.62 219 8.62 219

EIectrlc8I Box Height 9.12 232 9.12 232 9.12 232

Sight Glass,

Degrees from Foreline

Electrical Box,

Degrees from Foreline

Inlet Flange, Nominal Size 6” ASA ISO -200K 10” CFF

90° clockwise 90° clockwise 90° clockwise

30° counterclockwise 30° counterclockwise 30° counterclockwise

Inlet Flange, OD 11.00 279 9.45 240 9.97 253

Inlet Flange, ID 7.88 200 7.72 196 7.88 200

Inlet Flange, Thickness 0.75 19 0.47 12 0.96 24

Inlet Flange, Bolt Circle 9.50 241 N/A N/A 9.12 232

Inlet Flange, Number of Holes 8 N/A 24

Inlet Range, Hole Size 0.81 21 N/A N/A .33 8

O-ring Groove ID 8.20 208 N/A N/A N/A N/A

O-ring Groove Width 0.18 4 N/A N/A N/A N/A

Foreline Flange, Nominal Size 1½" ASA KF-50 3

OD 5.00 127 2.05 75 3.38 86

ID 1.95 50 1.95 50 1.95 50

Thickness 0.63 16 0.24 6 0.62 16

Bolt Circle 3.88 99 N/A N/A 2.85 72

Number of Holes 4 N/A N/A 8

3/8" CFF

DRAFT 3/9/05

Hole Size 0.62 16 N/A N/A 0.33 8

O-ring Groove ID 2.22 56 N/A N/A N/A N/A

O-ring Groove Width 0.30 8 N/A N/A N/A N/A

1-7

Page 28

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Figure 1-5 shows the VHS-250 speed and throughput curves.

Figure 1-5 VHS-250 Speed and Throughput Curves

DRAFT 3/9/05

Figure 1-6 gives the VHS-250 schematic and wiring information.

Figure 1-6 VHS-250 Wiring Information

1-8

Page 29

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 1-4 lists the VHS-250 dimensions.

Table 1-4 VHS-250 Dimensions

Height 22.79 579

Centerline to Centerline 13.38 340

Flange Face to Flange Face 9.56 243

Electrical Box Height 9.12 232

Sight Glass,

Degrees from Foreline

Electrical Box,

Degrees from Foreline

Inlet Flange, Nominal Size ISO - 250F

ISO

in mm

90° clockwise

30° counterclockwise

Inlet Flange, OD 13.19 335

Inlet Flange, ID 10.75 273

Inlet Flange, Thickness 0.63 16

Inlet Flange, Bolt Circle 12.205 310

Inlet Flange, Number of Holes 12

Inlet Range, Hole Size 0.44 11

O-ring Groove ID 10.95 278

O-ring Groove Width 0.14 4

Foreline Flange, Nominal Size 1½ ASA

OD 5.00 127

ID 1.88 48

Thickness 0.62 16

Bolt Circle 3.88 99

Number of Holes 4

DRAFT 3/9/05

Hole Size 0.62 16

O-ring Groove ID 2.22 56

O-ring Groove Width 0.30 8

1-9

Page 30

1.2 Installation

Installation consists of:

❑ Section 1.2.2 “Unpacking”

❑ Section 1.2.3 “Pump Oil Installation”

❑ Section 1.2.4 “Vacuum System Connections” on page 1-11

❑ Section 1.2.5 “Cooling Water Connections” on page 1-11

❑ Section 1.2.6 “Electrical Connections” on page 1-12

❑ Section 1.2.7 “Thermal Switch” on page 1-13

1.2.2 Unpacking

When unpacking the pump:

1. Inspect the pump to ensure that no damage has occurred during shipping.

Do not discard any evidence of rough handling; report any damage to the carrier and to

Vacuum Technologies without delay.

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Diffusion pumps are factory-packed to permit prolonged storage in suitably protected

areas without special precautions.

2. Remove flange covers and protective plugs from water connections being careful not to

scratch the inlet and foreline flanges O-ring seal surfaces.

3. Inspect the internal jet assembly. It should be concentric and firmly seated on the

bottom of the diffusion pump and the ejector nozzle must be directly in line with the

foreline.

DRAFT 3/9/05

The location of the jet is controlled by an indexing pin located on the bottom of

the pump.

NOTE The pump requires no initial cleaning if the required vacuum

4. Charge the pump with the diffusion pump oil shipped with the pump.

1.2.3 Pump Oil Installation

The recommended oil charge for the:

level is above 10

6

Torr. For pressure below 10

−

6

Torr (1.3x10-6

−

mbar), follow the cleaning procedure in Section 3.3 “Cleaning”

on page 3-2.

❑ VHS-4 is 300 cc

❑ VHS-6 and VHS-250 is 500 cc

❑ Pour the oil is normally into the pump inlet or foreline, or remove the fill plug and

pour it into the fill and drain assembly.

1-10

Page 31

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

1.2.4 Vacuum System Connections

WARNING Utility failure can cause damage to the equipment, overheating,

and explosions. Diffusion pump equipment designers must take

appropriate system design action to protect personnel and

property from possible hazards. Read the safety section at the

beginning of this manual.

1. Install the diffusion pump with the body vertical and plumb.

2. Ensure that the pump inlet mating flange on the system is horizontal within ±1°. The

boiler plate must be horizontal to prevent an uneven fluid level.

CAUTION Failure to meet this requirement could result in overheating of

the diffusion pump boiler plate.

3. Prepare the inlet and foreline O-rings by wiping them with a clean, lint-free cloth.

A small amount of diffusion pump oil may be used to clean the O-rings.

4. Install the O-rings in the O-ring grooves, being careful not to damage or scratch the

sealing surface.

5. Check the fill and drain plugs for tightness and apply light to medium torque, enough to

compress the O-rings.

6. Using an appropriate lifting apparatus, align the bolt holes of the inlet flange with the

bolt holes of the mating flange.

7. Using the appropriate mounting hardware, tighten the bolts evenly until the O-ring is

compressed and the flanges make light, metal-to-metal contact.

8. Ensure the integrity of the connections: Check the vacuum connections for leaks using a

helium mass spectrometer leak detector before operating the vacuum system.

1.2.5 Cooling Water Connections

1. Connect the inlet water fitting (near the inlet flange at the top of the pump) to a

continuously running water supply at 0.15 gpm (VHS-4) or .25 gpm (VHS-6 and 250)

and at a temperature of 60 to 80 °F.

CAUTION In the following step, discharge connections must be installed

in accordance with all Federal State and local laws and

regulations.

If the diffusion pump is being cooled by a recirculating water

system:

❑ Ensure the exit water temperature does not exceed 120 °F.

❑ The outlet or discharge (nearest the foreline) should be

DRAFT 3/9/05

connected to an open drain.

1-11

Page 32

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

2. Connect the quick cool drain to an open drain which is below the inlet connection of

the Quick Cool Coil to ensure that the Quick Cool Coil is completely drained when the

cooling water supply is turned off and the pump is vented to atmosphere.

1.2.6 Electrical Connections

WARNING Diffusion pump heaters operate at voltages high enough to kill

❑ The minimum rating of this system should be 85% of the

maximum power rating of the diffusion pump.

❑ The Quick Cool Coil feed line, located at the boiler plate,

should be controlled by a separate three-way valve (open,

closed, and vent to atmosphere).

through electrical shock.

❑ During installation, check the drawings and be sure to attach

all hazard warning and caution labels.

❑ Always break the primary circuit of the power supply when

direct access to the heater or wring is required.

Read the safety section in the front of this manual.

DRAFT 3/9/05

The diffusion pump has been designed to operate at a specific voltage. The voltage is

specified on the label that is mounted on the side of the pump.

1. Verify the heater rating by measuring the resistance of the heater circuit and comparing

it to the values in Table 1-1 on page 1-1.

2. Make the electrical connections in the junction box located near the foreline. The

electrical supply should not be more than ±5% of the rated voltage.

CAUTION All electrical connections should be made in accordance with

all applicable state, local, and/or industrial codes.

1-12

Page 33

1.2.7 Thermal Switch

The pump has been fitted with a manually-resettable thermal switch that is preset at the

factory. This switch is located in a box near the bottom of the pump and provides protection

to the pump in the event of excessive fluid loss, the loss of cooling water, or high inlet

pressure.

WARNING Failure to properly connect the thermal switch circuit can result

❑ Connect the thermal switch in series with the heater.

In the event of overtemperature. the thermal switch opens and shut off the power to the

pump.

Reset the thermal switch by pressing the button located at the center of the thermal switch.

Do this only after the root cause of a problem has been determined and the appropriate

corrective action taken.

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

in catastrophic injury to personnel and major damage to the

pump or vacuum system.

1-13

DRAFT 3/9/05

Page 34

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

DRAFT 3/9/05

This page intentionally left blank.

Page 35

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Section 2. Operation

CAUTION ❑ Before turning on the heater, ensure there is fluid in the pump.

Running the heater without fluid can ruin the heater and

damage the pump.

❑ Do not air-release the pump while the boiler is hot. Most

diffusion pump fluids are heat sensitive and breaks down under

these conditions.

❑ Do not operate the pump without the internal splash baffle or

foreline baffle in place. If the splash baffle is omitted, the pump

may be unstable and operate at a low speed. If the foreline

baffle is omitted, there may be excessive fluid loss.

❑ Do not operate the pump for extended periods at inlet pressures

above 1 mTorr (1.3x10

cause excessive backstreaming.

❑ Do not operate the pump heater unless cooling water is

circulating. It causes the pump fluid to overheat.

-3

mbars). High-pressure operation can

2.1 Startup

During initial operation of the diffusion pump, a fresh charge of diffusion pump oil may go

through a degassing process. This can result in inlet and foreline pressure fluctuations.

These pressure fluctuations are normal.

1. Visually inspect the sight glass assembly to ensure that the diffusion pump has been

charged with the proper amount of diffusion pump fluid.

When properly filled, the oil level (when the pump is cold) is even with the FULL/COLD

mark on the oil level indicator.

2. Evacuate the diffusion pump (rough pump) with a mechanical backing pump

(customer supplied).

The pressure must be reduced to less than 0.5 Torr (.66 mbars). The backing pump

should remain connected to the foreline of the diffusion pump.

3. Turn on the cooling water supply to the pump body and verify that the cooling water is

not being supplied to the Quick Cool Coil at this time.

4. Turn on the power to the diffusion pump heater.

DRAFT 2/24/05

2-1

Page 36

5. Monitor inlet and foreline pressures.

During operation of the diffusion pump:

❑ The gas load at the inlet should not exceed the maximum throughput capability of

the pump.

❑ The forepressure should not exceed the specified tolerable forepressure.

2.2 Shutdown

1. Turn off the power to the diffusion pump and continue to back the diffusion pump with

the appropriate mechanical pump.

2. Allow cooling water to flow through the diffusion pump until the pump body

temperature, located just above the boiler plate, has cooled to a temperature of

approximately 130 °F.

After isolating the backing pump, the diffusion pump can be vented to atmosphere.

If faster cooling is desired, the pump can be cooled using the Quick Cool Coil at the

bottom of the diffusion pump.

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

DRAFT 2/24/05

2-2

Page 37

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Section 3. Maintenance and Service

3.1 General Maintenance

Diffusion pumps generally require little attention when operated correctly. It is advisable to

perform some periodic inspections to ensure trouble-free operation. By performing simple

preventive maintenance, costly downtime can be avoided. A day-to-day log of pump and

system performance helps indicate the condition of the pump and the need for corrective

action.

3.2 Inspection Requirements

The frequency of inspections depends on the type of system, its operation, and its use.

The maximum interval between inspections is established on the basis of experience.

Vacuum Technologies recommends that you examine the following items regularly:

✔ When the pump is cold, check the condition and level of the fluid.

❑ Withdraw a fluid sample through the drain and visually check the level of the fluid

through the sight glass. A slight discoloration of the fluid does not affect

performance.

NOTE Always use new O-rings when replacing

fill plugs or the sight glass.

Loss of fluid can be caused by any of the following conditions:

❑ Incorrect venting procedures and/or admittance of excessive air or other gas to a

hot pump

❑ Inadequate water cooling

❑ Prolonged operation at inlet pressures above 10

❑ Failure to reinsert the foreline baffle in the pump assembly

−3

Torr (1.33x10-3 mbar)

✔ Check the total heater power input.

❑ When the pump is cold and the power is off, ensure that the heater is bolted

snugly to the boiler plate.

DRAFT 3/9/05

❑ Verify that all heater terminal connections at the heater and inside the junction

box are tight and in good condition.

3-1

Page 38

3.3 Cleaning

Complete cleaning of the pump may be required due to the gradual deterioration of pump

fluids. Removal of the pump from the system is necessary.

To clean the pump:

1. Turn off the power and disconnect the power supply plug.

2. Allow the pump to cool, then turn off the cooling water and disconnect the cooling

lines.

3. Unbolt the inlet flange and foreline connections.

4. Remove the pump from the system.

5. Drain the diffusion pump of all fluid.

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

❑ Ensure that the cooling water flow is adequate and unobstructed. In areas where

the mineral content of the water is high or where there is considerable sediment,

it may be advisable to install water filters.

DRAFT 3/9/05

6. Remove all O-rings, then remove the cold cap assembly, the jet assembly, and the

foreline baffle from the pump.

7. Thoroughly clean the diffusion pump body interior and the jet assembly using acetone

followed by an isopropyl alcohol rinse.

8. Dry the pump and the jet assembly with clean, dry, oil-free compressed air.

9. Install the foreline baffle, the jet assembly, and the cold cap assembly in the pump body.

❑ Verify that the ejector nozzle is properly aligned with the foreline.

❑ Verify that the cold cap is properly installed on the jet assembly. The space between

the underside of the cold cap and the outside of the jet cap should be uniform.

10. Reinstall the diffusion pump in the system using all new O-rings.

11. Charge the pump with the proper amount of fluid.

12. Reconnect the water cooling lines and the power supply.

13. Evacuate the diffusion pump with the appropriate mechanical pump and turn on the

cooling water.

14. After the pump has been evacuated to a pressure below 0.5 Torr (.66 mbars), turn on the

power to the diffusion pump.

3-2

Page 39

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

3.4 VHS-4 and VHS-6 Cold Cap Removal/Installation

To remove the cold cap:

1. Remove the spring (1) (Figure 3-1) attached by round head screw (2), a flat washer (3)

and a lock washer (4). The screw types are:

❑ VHS-4: no. 8-32x3/16

❑ VHS-6: no. 6-32x3/16

2. Loosen the nut (5) holding the cold cap bracket (6) to the copper bar (A) and remove the

cold cap (7) from the top of the jet cap (8).

3. Unscrew the no. 8-32x

1/4 socket head cap screw (9) from the top of the ceramic standoff

(10).

4. Remove the ceramic standoff (10) and the no. 8-32x

1/2 stud (11).

To install the cold cap:

1. Thread the 8-32 stud (11) into the ceramic bushing (10) until it bottoms (finger tight).

2. Thread the 8-32 hex socket head screw (9) into top of ceramic bushing (10) until it

bottoms.

3. Install the ceramic bushing assembly onto the top of the jet cap (8) by threading stud

(11) into the tapped hole in the top jet cap. Install finger tight.

4. Attach spring clip (1) to cold cap (7) with 6-32 screw (2) and washers (3 and 4) so that

the clip rests on top of sleeve (12).

5. Lower the cold cap assembly carefully onto the top of the jet cap assembly (8). The

ceramic bushing fits in sleeve (12) and the clamp bar (6) straddles the body bar (A).

6. Lower the cold cap until the horizontal portion of the spring clip (1) touches the head of

screw (9). Ensure that the clearance between the cold cap and the top jet cap is even

around the periphery and that the cold cap assembly is level with the pump inlet flange.

7. Carefully tighten the captive bolt (5) ensuring that there is no strain on the ceramic

bushing and no shift in the position of the cold cap.

DRAFT 3/9/05

Figure 3-1 VHS4 and VHS-6 Cold Cap Removal/Installation

12

1

7

5

6

10

A

2, 3, 4

9

11

8

3-3

Page 40

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

3.5 VHS-250 Cold Cap Removal/Installation

To remove the cold cap:

1. Remove the spring (J) attached by the 6-32x

a lock washer (Figure 3-2).

2. Loosen the nuts (L) holding the cold cap bracket (E) to the copper bar (C) and remove

the cold cap (B) from the top of the jet cap (A).

3. Unscrew the no. 8-32x

standoff (D).

4. Remove the ceramic standoff (D) and the no. 8-32x

To install the cold cap:

1. Thread the 8-32 stud (F) into the ceramic bushing (0) until it bottoms (finger tight).

2. Thread the 8-32 hex socket head screw (G) into top of ceramic bushing (0) until it

bottoms.

3. Install the ceramic bushing assembly onto the top of the jet cap (A) by threading stud (F)

into the tapped hole in the top jet cap. Install finger tight.

4. Attach spring clip (J) to cold cap (8) with 6-32 screw (H) so that the clip rests on top of

sleeve (K).

5. Lower the cold cap assembly carefully onto the top of the jet cap assembly (A). The

ceramic bushing fits in sleeve (K) and the clamp bars (E) straddle the body bar (C).

1/4 socket head cap screw (G) from the top of the ceramic

3/16 round head screw (H), a flat washer and

1/2 stud (F).

DRAFT 3/9/05

6. Lower the cold cap until the horizontal portion of the spring clip (J) touches the head of

screw (G). Ensure that the clearance between the cold cap and the top jet cap is even

around the periphery and that the cold cap assembly is level with the pump inlet flange.

7. Carefully tighten the captive bolts (L) ensuring that there is no strain on the ceramic

bushing and no shift in the position of the cold cap.

Figure 3-2 VHS-250 Cold Cap Removal/Installation

3-4

Page 41

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

3.6 Jet Assembly Removal/Installation

To remove the jet assembly:

1. Remove the cold cap from the pump (Figure 3-3).

2. Unscrew the top cap from the jet assembly.

3. Lift out each section of the jet assembly, being careful not to dent or otherwise damage

the jet assembly during disassembly or cleaning.

4. Remove the splash baffle from the pump.

To install the jet assembly:

1. Place the splash baffle in the bottom of the pump and verify that it is located in the outer

boiler groove.

2. Insert the jet base, making sure the ejector is aligned with the foreline and that the slot in

the jet base locks onto the alignment pin.

3. Assemble the remaining stages of the jet.

❑ Verify that all the stages are firmly seated.

❑ Verify that all the drip shields are in place.

4. Install the cold cap assembly.

DRAFT 3/9/05

3-5

Page 42

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Jet Cap

Jet Plug

Inner Rod

2nd Stage Drip Shield

3rd Stage Jet

3rd Stage Drip Shield

Jet Tube Assembly

Jet Base

DRAFT 3/9/05

Ejector

4.00 Flat

Splash Baffle

Boiler Plate

Jam Nut

Figure 3-3 VHS-4 Diffusion Pump Jet Assembly

3-6

Page 43

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Figure 3-4 VHS-6 and 250 Diffusion Pump Jet Assembly

DRAFT 3/9/05

3-7

Page 44

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

3.7 Heater Replacement

Refer to Figure 3-5 (VHS-6 and VHS-250) and Figure 3-6 (VHS-4) for this procedure:

1. Turn off the power to the diffusion pump and disconnect the power supply.

2. Remove the heater cover and the insulation from the bottom of the diffusion pump.

3. Label the heater wires for proper location during installation.

4. Disconnect the terminal leads.

Use two wrenches when loosening (one on each nut) to prevent excessively torquing

and possibly breaking the heater terminals.

5. Remove the nut holding the heater clamp.

6. Lower the entire heater unit from the pump and replace the defective heater.

7. Coat the boiler stud with an anti-seize compound such as FEL-PRO C5A or common

milk of magnesia.

8. Support the heater unit by the heater clamp, line up the hole with the boiler stud, and

push the unit up against the boiler plate.

DRAFT 3/9/05

9. Finger-tighten the nut to hold it in place.

10. Tighten the heater clamp bolt to a torque of 250 inch-pounds.

11. Replace the heater insulation and cover.

Heater Element

647306125 2200 W, 120 V

647306175 2200 W, 208 V

647306225 2200 W, 240 V

Figure 3-5 VHS-6 and VHS-250 Heater Mounting

3-8

Page 45

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Heater Element

647304205 1450 W, 120 V

647304210 1450 W, 208 V

647304250 1450 W, 240 V

Figure 3-6 VHS-4 Heater Mounting

DRAFT 3/9/05

3-9

Page 46

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

3.8 Pump Fluid Charge

The recommended fluid charge is:

❑ 300 cc for the VHS-4

❑ 500 cc for VHS-6 and VHS-240

The fluid charge will gradually be depleted through use, but the pump will continue to

operate normally.

When the charge is reduced to approximately 60% of the initial fill amount, the boiler plate

temperature may begin to rise. Under this condition, the thermal switch, when properly

connected, is designed to open the heater circuit.

To add pump fluid:

1. Turn off power to the pump and allow the pump to cool until the temperature of the

pump body (measured 1" above the heater skirt) has cooled to 130 °F.

2. Turn off the backing pump.

DRAFT 3/9/05

3. Vent the pump to atmosphere.

4. Loosen and remove the fill plug located at the top of the sight glass assembly.

5. Add pump fluid until the fluid level is even with the FULL/COLD mark on the

sight glass.

6. Replace the O-ring in the fill plug and lubricate it with pump fluid.

7. Install the fill plug and tighten it moderately.

8. Evacuate the diffusion pump and start the pump as according to Section 2.1 “Startup”

on page 2-1.

3-10

Page 47

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Section 4. Troubleshooting

4.1 Leakage

Analysis of general operational experience with diffusion pumps indicates that certain

locations are more prone to vacuum leaks. The following locations should be checked first

if leakage is the suspected cause of poor system performance:

❑ Inlet and foreline connections

❑ Drain and fill plugs

❑ Other compression fittings, such as high vacuum gauges in the system

❑ Threaded connections, such as foreline gauge

4.2 Outgassing

High vacuum systems, even without external leakage, can also exhibit high gas loads due to

outgassing from internal surfaces or processes. The pressure in the system is a result of gas

load divided by pumping speed (P = Q/S). If the gas load (Q) exceeds the maximum

throughput capability of the diffusion pump, the diffusion pump will not function and the

pumping action will essentially be performed by the mechanical backing pump.

To estimate gas load:

After evacuation, isolate the system from all pumps and measure the rate of pressure

rise. The gas load created by the system can be estimated as:

Q = V x ∆P

∆t

Where:

V is the isolated volume

∆P is the pressure rise, and

∆t is the time period of measurement

DRAFT 3/9/05

4-1

Page 48

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

4.3 Poor Pump or System Performance

Before proceeding with a step-by-step troubleshooting program, check the performance and

accuracy of the vacuum gauges used on the system. Table 4-1 shows the most frequent

faults, their probable causes, and specific repair actions required for each.

Table 4-1 Troubleshooting

Symptom Probable Cause Repair Action

Poor system pressure Leak in system — virtual or real. Locate and repair.

High process gas load. Measure gas load,

and eliminate the cause.

System dirty. Clean system to reduce

outgassing.

Poor ultimate pressure Contaminated pump fluid. Examine, clean pump,

and replace fluid.

DRAFT 3/9/05

Slow pumpdown (prolonged

cycle after checking gas load

conditions)

Low heat input. Check voltage.

Check for continuity, burned out

element, poor thermal contact.

Inadequate cooling water flow. Check water pressure. Check

tubing for obstructions or

backpressure.

Excessive or too cold

cooling water.

High forepressure. Check for leak in foreline, poor

Water in Quick Cool Coil. Check and remove water.

Low heat input. Check heaters.

Low oil level. Add oil.

Malfunctioning pump assembly

Improperly located jets.

Damaged jet system.

Check temperature, adjust flow.

mechanical pump performance,

breakdown of mechanical pump

fluid.

Check and repair or replace.

4-2

Page 49

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 4-1 Troubleshooting (Continued)

Symptom Probable Cause Repair Action

Inlet pressure surges Incorrect heater voltage. Check and correct voltage.

Fluid outgassing. Condition pump fluid by

operating pump for a few hours.

Leak in system ahead of

pump inlet.

High chamber contamination Forepressure too high. Check for leak in foreline, poor

Prolonged operation at high

throughput at pressure above

−3

10

Torr (1.33x10-3 mbar).

Improper system operation

air-release procedures.

Pump will not start Safety circuits and/or protective

devices prevent contactor from

staying closed.

Check and correct.

mechanical pump performance,

breakdown of pump fluid, and

incorrect valve operation.

Review operating procedures.

Review operating procedures

Check utilities, flow switches,

interlocks, and thermostat

operation.

4-3

DRAFT 3/9/05

Page 50

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

DRAFT 3/9/05

This page intentionally left blank.

Page 51

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Section 5. Replacement Parts

Table 5-1 lists the VHS-4 models.

Table 5-2 lists the VHS-4 replacement parts available from Vacuum Technologies.

Table 5-1 VHS-4 Models

Part Number

Flange Type

Pump Voltage

Standard cold cap 120 V 86460301 L6256301 L6188301

Extended cold cap 120 V 86460311 L6256311 L6188311

Standard cold cap 208 V 86460306 L6256306 L6188306

Extended cold cap 208 V 86460316 L6256316 L6188316

Standard cold cap 240 V 86460302 L6256302 L6188302

Extended cold cap 240 V 86460312 L6256312 L6188312

Table 5-2 VHS-4 Replacement Parts

Part Number Description

86488301 Standard Cold Cap Assembly

F6898301 Extended Cold Cap Assembly

L8908301 Sight Glass Repair Kit

F4785301 Jet Assembly

F4780 301 Splash Baffle

ASA ISO Conflat

DRAFT 3/9/05

86754 301 Foreline Baffle Assembly

642906025 Switch

699006025 Standoff, ceramic insulating, Cold Cap

647304205 120 V / 1450 watt Heater Element

647304210 208 V / 1450 watt Heater Element

647306250 240 V / 1450 watt Heater Element

656179100 Wire, No. 10 stranded, nickel

648056680 Lugs, Replacement, nickel

5-1

Page 52

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 5-2 VHS-4 Replacement Parts (Continued)

88164301 Heater Clamp

Commercial Heater Clamp Nut,

31/48-16, Hex, stainless steel

694492156 Baffle Retaining Ring

K0377183 O-Ring Kit includes:

❑ 3 Butyl inlet flange O-ring, Parker No. 2-258

❑ 10 Viton fill and drain O-rings (old style), Parker No. 2-112

❑ 10 Viton fill and drain O-rings (new style, Parker No. 2-113

❑ 1 Sight glass O-ring, Parker No. 2-226

❑ 1 Teflon gasket

K6948301 NEOVAC SY Diffusion Pump Fluid (1000 cc)

695474005 DC-704 Diffusion pump Fluid (500 cc)

695475005 DC-70S Diffusion Pump Fluid (500 cc)

695405005 Santovac 5 Diffusion Pump Fluid (500 cc)

86715001 Spring, Cold Cap

Commercial Screw, Rd hd machine, no. 8-32x

31/416, stainless steel

Commercial Stud, no. 8-32 x 1~2, stainless steel

Commercial Screw, Socket hd cap, no. 8-32x

11/44, stainless steel

Table 5-3 lists the VHS-6 models.

Table 5-4 lists the VHS-6 replacement parts available from Vacuum Technologies.

DRAFT 3/9/05

Pump Voltage

Table 5-3 VHS-6 Models

Part Number

Flange Type

ASA ISO Conflat

Standard cold cap 120 V 85826301 L6193301 L6200301

Extended cold cap 120 V 85826311 L6193311 L6200311

Standard cold cap 208 V 85826306 L6193306 L6200306

Extended cold cap 208 V 85826316 L6193316 L6200316

Standard cold cap 240 V 85826302 L6193302 L6200302

Extended cold cap 240 V 85826312 L6193312 L6200312

5-2

Page 53

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 5-4 VHS-6 Replacement Parts

Part Number Description

86488301 Standard Cold Cap Assembly

F6455301 Extended Cold Cap Assembly

F3365301 Jet Assembly

F3373301 Splash Baffle

L9172301 Foreline Baffle Assembly

642906025 Thermoswitch Kit

699006025 Standoff, ceramic insulating, Cold Cap

647306125 120 V / 2200 watt Heater Element

647306225 208 V / 2200 watt Heater Element

647306175 240 V / 2200 watt Heater Element

656179100 Wire, No. 10 stranded, nickel

648056680 Lugs, Replacement, nickel

86087001 Heater Insulator

86086301 Heater Clamping Plate

86088301 Heater Cover Plate

L8998001 Heater Insulating Blanket

L8997001 Heater Cover

K0377184 O-Ring Kit includes:

❑ 3 Butyl inlet flange O-ring, Parker No. 2-267

❑ 3-Butyl-N foreline flange O-ring, Parker No. 2-332

❑ 10 Viton fill and drain O-rings (old style), Parker No. 2-112

❑ 10 Viton fill and drain O-rings (new style, Parker No. 2-113

❑ 1 Teflon gasket

❑ 1 Sight glass O-ring, Parker No. 2-226

K6948301 NEOVAC SY Diffusion Pump Fluid (1000 cc)

695474005 DC-704 Diffusion pump Fluid (500 cc)

DRAFT 3/9/05

695475005 DC-70S Diffusion Pump Fluid (500 cc)

695405005 Santovac 5 Diffusion Pump Fluid (500 cc)

86715001 Spring, Cold Cap

Commercial Screw, Rd hd machine, no. 6-32x

3/16, stainless steel

5-3

Page 54

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 5-4 VHS-6 Replacement Parts (Continued)

Commercial Washer, flat, no. 6, stainless steel

Commercial Washer, lock, no. 6, stainless steel

Commercial Stud, no. 8-32 x 1/2, stainless steel

Commercial Screw, Socket hd cap, no. 8-32x

1/4, stainless steel

Table 5-5 lists the VHS-250 models.

Table 5-6 lists the VHS-250 replacement parts available from Vacuum Technologies.

Table 5-5 VHS-250 Models

Pump Voltage

Standard cold cap 120 V K0543301

Standard cold cap 208 V K0543306

Standard cold cap 240 V K0543302

Table 5-6 VHS-250 Replacement Parts

Part Number Description

F9584301 Standard Cold Cap Assembly

Part Number

Flange Type

ISO

F9548301 Jet Assembly

DRAFT 3/9/05

F3373301 Splash Baffle

L9172301 Foreline Baffle Assembly

642906025 Thermoswitch Kit

699006025 Standoff, ceramic insulating, Cold Cap

647306125 120 V / 2200 watt Heater Element

647306225 208 V / 2200 watt Heater Element

647306175 240 V / 2200 watt Heater Element

656179100 Wire, No. 10 stranded, nickel

648056680 Lugs, Replacement, nickel

86087001 Heater Insulator

86086301 Heater Clamping Plate

5-4

Page 55

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

Table 5-6 VHS-250 Replacement Parts (Continued)

86088301 Heater Cover Plate

L8998001 Heater Insulating Blanket

L8997001 Heater Cover

K0377178 O-Ring Kit includes:

❑ 3 Butyl inlet flange O-ring, Parker No. 2-332

❑ 3-Butyl-N foreline flange O-ring, Parker No. 2-379

❑ 10 Viton fill and drain O-rings (old style), Parker No. 2-112

❑ 10 Viton fill and drain O-rings (new style, Parker No. 2-113

❑ 1 Teflon gasket

❑ 1 Sight glass O-ring, Parker No. 2-226

K6948301 NEOVAC SY Diffusion Pump Fluid (1000 cc)

695474005 DC-704 Diffusion pump Fluid (500 cc)

695475005 DC-70S Diffusion Pump Fluid (500 cc)

695405005 Santovac 5 Diffusion Pump Fluid (500 cc)

86715001 Spring, Cold Cap

Commercial Screw, Rd hd machine, no. 6-32x

3/16, stainless steel

Commercial Washer, flat, no. 6, stainless steel

Commercial Washer, lock, no. 6, stainless steel

Commercial Stud, no. 8-32 x 1/2, stainless steel

Commercial Screw, Socket hd cap, no. 8-32x

1/4, stainless steel

DRAFT 3/9/05

5-5

Page 56

VHS-4, VHS-6 and VHS-250 Diffusion Pumps

DRAFT 3/9/05

This page intentionally left blank.

Page 57

Request for Return

Request for Return Health and Safety Certification

ISO

REGISTERED

9001

Health and Safety Certification

1. Return authorization numbers (RA#) will not be issued for any product until this Certificate is completed and returned to a

Varian, Inc. Customer Service Representative.

2. Pack goods appropriately and drain all oil from rotary vane and diffusion pumps (for exchanges please use the packing

material from the replacement unit), making sure shipment documentation and package label clearly shows assigned

Return Authorization Number (RA#) VVT cannot accept any return without such reference.

3. Return product(s) to the nearest location:

North and South America Europe and Middle East Asia and ROW

Varian, Inc.

Vacuum Technologies

121 Hartwell Ave.

Lexington, MA 02421

Fax: (781) 860-9252

For a complete list of phone/fax numbers see www.varianinc.com/vacuum

4. If a product is received at Varian, Inc. in a contaminated condition, the customer is held responsible for all costs incurred to

ensure the safe handling of the product, and is liable for any harm or injury to Varian, Inc. employees occurring as a result of

exposure to toxic or hazardous materials present in the product.

CUSTOMER INFORMATION

Company name: ......................................................................................................................................................................

Contact person: Name: ...................................................................................... Tel:............................................................

Fax: .......................................................................................... E-mail: .....................................................

Ship method: Shipping Collect #: .................................. P.O.#: .......................................................

Europe only: VAT Reg Number: ........... USA only: ❒Taxable ❒ Non-taxable

Customer ship to: .................................................................... Customer bill to: .................................................................

.................................................................... .................................................................

.................................................................... .................................................................

Varian S.p.A.

Via F.lli Varian, 54

10040 Leini (TO) – ITALY

Fax: (39) 011 997 9350

Varian Vacuum Technologies

Local Office

PRODUCT IDENTIFICATION

Product Description Varian, Inc. Part Number Varian, Inc. Serial Number

TYPE OF RETURN (check appropriate box)

❒ Paid Exchange ❒ Paid Repair ❒ Warranty Exchange ❒ Warranty Repair ❒ Loaner Return

❒ Credit ❒ Shipping Error ❒ Evaluation Return ❒ Calibration ❒ Other

HEALTH and SAFETY CERTIFICATION

ACUUM TECHNOLOGIES CANNOT ACCEPT ANY BIOLOGICAL HAZARDS, RADIOACTIVE MATERIAL, ORGANIC METALS, OR

V

MERCURY AT ITS FACILITY. CHECK ONE OF THE FOLLOWING:

❒ I confirm that the above product(s) has (have) NOT pumped or been exposed to any toxic or dangerous materials in a

quantity harmful for human contact.

❒ I declare that the above product(s) has (have) pumped or been exposed to the following toxic or dangerous materials in a

quantity harmful for human contact (Must be filled in):

Print Name................................................ Signature ................................................... Date ...............................

PLEASE FILL IN THE FAILURE REPORT SECTION ON THE NEXT PAGE

Do not write below this line

Notification (RA) #:...................................

Customer ID #: ........................................ Equipment #:............................................

August 2003 — Page 1 of 2

Page 58

Request for Return

ISO

REGISTERED

9001

Health and Safety Certification

FAILURE REPORT

(Please describe in detail the nature of the malfunction to assist us in performing failure analysis):

TURBO PUMPS AND TURBOCONTROLLERS

Claimed Defect Position Parameters

❒ Does not start ❒ Noise ❒ Vertical Power: Rotational Speed:

❒ Does not spin freely ❒ Vibrations ❒ Horizontal Current: Inlet Pressure:

❒ Does not reach full speed ❒ Leak ❒ Upside-down Temp 1: Foreline Pressure:

❒ Mechanical Contact ❒ Overtemperature ❒ Other

❒ Cooling defective ❒ Clogging Operation Time:

Describe Failure:

Turbocontroller Error Message:

ION PUMPS/CONTROLLERS VALVES/COMPONENTS

❒ Bad feedthrough ❒ Poor vacuum ❒ Main seal leak ❒ Bellows leak

❒ Vacuum leak ❒ High voltage problem ❒ Solenoid failure ❒ Damaged flange

❒ Error code on display ❒ Other .............................. ❒ Damaged sealing area ❒ Other ...............................

Describe failure: Describe failure:

................................

Temp 2: Purge flow:

Customer application: Customer application:

LEAK DETECTORS INSTRUMENTS

❒ Cannot calibrate ❒ No zero/high background ❒ Gauge tube not working ❒ Display problem

❒ Vacuum system unstable ❒ Cannot reach test mode ❒ Communication failure ❒ Degas not working

❒ Failed to start ❒ Other ............................... ❒ Error code on display ❒ Other ...............................

Describe failure: Describe failure:

Customer application: Customer application:

ALL OTHER VARIAN, INC. DIFFUSION PUMPS

❒ Pump doesn’t start ❒ Noisy pump (describe) ❒ Heater failure ❒ Electrical problem

❒ Doesn’t reach vacuum ❒ Overtemperature ❒ Doesn’t reach vacuum ❒ Cooling coil damage

❒ Pump seized ❒ Other ............................... ❒ Vacuum leak ❒ Other ...............................

Describe failure: Describe failure:

Customer application: Customer application:

August 2003 — Page 2 of 2

Page 59

Page 60

Sales and Service Offices

Sales and Service Offices

Canada

Central coordination through:

Varian, Inc.

121 Hartwell Avenue

Lexington, MA 02421

USA

Tel: (781) 861 7200

Fax:(781) 860 5437

Toll Free: (800) 882 7426

China

Varian Technologies - Beijing

Room 1201, Jinyu Mansion

No. 129A, Xuanwumen Xidajie

Xicheng District

Beijing 1000031

P.R. China

Tel: (86) 10 6608 1031

Fax:(86) 10 6608 1541

France and Benelux

Vari an s.a .

7 avenue des Tropiques

Z.A. de Courtaboeuf – B.P. 12

Les Ulis cedex (Orsay) 91941

France

Tel: (33) 1 69 86 38 13

Fax:(33) 1 69 28 23 08

Germany and Austria

Vari an Deu tsc hl and Gmb H

Alsfelder Strasse 6

Postfach 11 14 35

64289 Darmstadt

Germany

Tel: (49) 6151 703 353

Fax:(49) 6151 703 302

India

Varian India PVT LTD

101-108, 1st Floor

1010 Competent House

7, Nangal Raya Business Centre

New Delhi 110 046

India

Tel: (91) 11 5548444

Fax:(91) 11 5548445

Italy

Vari an , In c.

Via F.lli Varian, 54

10040 Leini, (Torino)

Italy

Tel (39) 011 997 9 111

Fax (39) 011 997 9 350

Japan

Varia n, In c.

Sumitomo Shibaura Building, 8th Floor

4-16-36 Shibaura

Minato-ku, Tokyo 108

Japan

Tel: (81) 3 5232 1253

Fax:(81) 3 5232 1263

Korea

Varian Technologies Korea, Ltd.

Shinsa 2nd Building 2F

966-5 Daechi-dong

Kangnam-gu, Seoul

Korea 135-280

Tel: (82) 2 3452 2452

Fax:(82) 2 3452 2451

Mexico

Varia n S.A.

Concepcion Beistegui No 109

Col Del Valle

C.P. 03100

Mexico, D.F.

Tel: (52) 5 523 9465

Fax:(52) 5 523 9472

Russia

Central coordination through:

Varian, Inc.

via F.lli Varian 54

10040 Leini, (Torino)

Italy

Tel: (39) 011 997 9 252

Fax: (39) 011 997 9 316

Ta i w a n

Varian Technologies Asia Ltd.

18F-13 No.79, Hsin Tai Wu Road

Sec. 1, Hsi Chih, Taipei Hsien

Taiwan, R.O.C.

Tel: (886) 2 2698 9555

Fax:(886) 2 2698 9678

UK and Ireland

Varia n Ltd.

28 Manor Road

Walton-On-Thames

Surrey KT 12 2QF

England

Tel: (44) 1932 89 8000

Fax:(44) 1932 22 8769

United States

Varia n, In c.

121 Hartwell Avenue

Lexington, MA 02421

USA

Tel: (781) 861 7200

Fax:(781) 860 5437

Other Countries

Varian , I nc.

Via F.lli Varian 54

10040 Leini, (Torino)

Italy

Tel: (39) 011 997 9 111

Fax:(39) 011 997 9 350

Customer Support and Service:

North America

Tel: 1 (800) 882-7426 (toll-free)

vtl.technical.support@varianinc.com

Europe

Tel: 00 (800) 234 234 00 (toll-free)

vtl.technical.support@varianinc.com

Japan

Tel: (81) 3 5232 1253 (dedicated line)

vtj.technical.support@varianinc.com

Korea

Tel (82) 2 3452 2452 (dedicated line)

vtk.technical.support@varianinc.com

Ta i w a n

Tel: 0 (800) 051 342 (toll-free)