Varian DS102 1Ph, DS202 1Ph, 949-9350, 949-9351, DS302 1Ph Nstruction Manual

...

DS102 1Ph

DS202 1Ph

DS302 1Ph

Dual Stage Rotary

Vane Pumps U.K.

Model 949-9350

Model 949-9351

Model 949-9352

MANUALE DI ISTRUZIONI

BEDIENUNGSHANDBUCH

NOTICE DE MODE D’EMPLOI

INSTRUCTION MANUAL

87-900-943-01(E)

JANUARY 2006

DS102 – DS202 – DS302

ISTRUZIONI PER L’USO ....................................................................................................1

GEBRAUCHSANLEITUNG .................................................................................................3

MODE D’EMPLOI................................................................................................................5

INSTRUCTIONS FOR USE.................................................................................................7

TECHNICAL INFORMATION ..............................................................................................9

SECTION I .....................................................................................................................................9

TECHNICAL DESCRIPTION.........................................................................................................9

LUBRICATION...............................................................................................................................9

VACUUM SEALS...........................................................................................................................9

GAS BALLAST VALVE................................................................................................................10

ANTI-SUCKBACK DEVICE..........................................................................................................10

TECHNICAL DATA......................................................................................................................14

DIMENSIONS....................................................................................................................15

SAFETY PRECAUTIONS............................................................................................................17

TRANSPORT AND INSTALLATION............................................................................................17

PRELIMINARY OPERATIONS....................................................................................................17

SECTION II ..................................................................................................................................18

ELECTRICAL MOTORS..............................................................................................................18

Single phase universal motors...........................................................................................18

CONNECTIONS TO THE INLET AND EXHAUST FLANGES ....................................................20

STARTING AND RUNNING THE PUMP.....................................................................................20

STOPPING THE PUMP...............................................................................................................21

SAFETY RULES..........................................................................................................................21

WARNING NOTES ,..................................................................................................21

CAUTION NOTES ....................................................................................................22

MAINTENANCE ACTIONS..........................................................................................................22

LUBRICANTS ..............................................................................................................................23

SCHEDULED MAINTENANCE CARDS......................................................................................25

UNSCHEDULED MAINTENANCE CARDS.................................................................................30

TROUBLESHOOTING AND CORRECTIVE ACTION.................................................................57

SPARE PARTS LIST ...................................................................................................................59

ISTRUZIONI PER L’USO

1 87-900-943-01(E)

INFORMAZIONI GENERALI

Questa apparecchiatura è destinata ad uso professionale. L'utilizzatore deve leggere attentamente il presente manuale di istruzioni ed ogni altra informazione addizionale fornita dalla

Varian prima dell'utilizzo dell'apparecchiatura. La Varian si ritiene sollevata da eventuali responsabilità dovute all'inosservanza

totale o parziale delle istruzioni, ad uso improprio da parte di

personale non addestrato, ad interventi non autorizzati o ad uso

contrario alle normative nazionali specifiche.

Le pompe DS102 1Ph, DS202 1Ph, DS302 1Ph sono delle

pompe rotative bistadio a palette, a tenuta in bagno d'olio, azionate da motore elettrico mono o trifase.

Queste pompe da alto vuoto sono adatte al pompaggio di gas

non corrosivi.

Nei paragrafi seguenti sono riportate tutte le informazioni necessarie a garantire la sicurezza dell'operatore durante l'utilizzo

dell'apparecchiatura. Informazioni dettagliate sono fornite nell'appendice “Technical information”.

Questo manuale utilizza le seguenti convenzioni:

,

PERICOLO!

I messaggi di pericolo attirano l'attenzione dell'operatore su una

procedura o una pratica specifica che, se non eseguita in modo

corretto, potrebbe provocare gravi lesioni personali.

ATTENZIONE!

I messaggi di attenzione sono visualizzati prima di procedure

che, se non osservate, potrebbero causare danni all'apparecchiatura.

NOTA

Le note contengono informazioni importanti estrapolate dal testo.

IMMAGAZZINAMENTO

Durante il trasporto e l'immagazzinamento delle pompe non

devono essere superate le seguenti condizioni ambientali:

− temperatura: da -20 °C a +70 °C

− umidità relativa: 0 - 95% (non condensante)

PREPARAZIONE PER L'INSTALLAZIONE

La pompa viene fornita in un imballo protettivo speciale; se si

presentano segni di danni, che potrebbero essersi verificati durante il trasporto, contattare l'ufficio vendite locale.

Il peso dell’imballo, comprensivo della pompa, è, al massimo, di

circa 27 [Kg].

Durante l'operazione di disimballaggio, prestare particolare attenzione a non lasciar cadere la pompa e a non sottoporla ad

urti o vibrazioni.

Non disperdere l'imballo nell'ambiente. Il materiale è completamente riciclabile e risponde alla direttiva CEE 85/399 per la

tutela dell'ambiente.

NOTA

La pompa non può essere danneggiata rimanendo semplicemente esposta all'atmosfera. Si consiglia comunque di mantenerla chiusa fino al momento dell'installazione sul sistema onde

evitare eventuale inquinamento da polvere.

INSTALLAZIONE

Non installare e/o utilizzare la pompa in ambienti esposti ad

agenti atmosferici (pioggia, gelo, neve), polveri, gas aggressivi,

in ambienti esplosivi o con elevato rischio di incendio.

Durante il funzionamento è necessario che siano rispettate le

seguenti condizioni ambientali:

− temperatura: da +12 °C a +40 °C

− umidità relativa: 0 - 95% (non condensante).

ATTENZIONE!

Prima di avviare la pompa, occorre procedere al rifornimento di

olio lubrificante, poichè la pompa viene fornita scarica.

,

PERICOLO!

Togliere i tappi di protezione posti sulle flange di aspirazione e

scarico prima di ogni successiva operazione. L’aria contenuta

all’interno della pompa, in caso di accensione involontaria, può

proiettarli contro l’operatore.

,

PERICOLO!

Durante l'installazione prestare la massima attenzione che la

flangia di aspirazione sia collegata alla camera da evacuare e

che la flangia di scarico non sia tappata (vedere la figura

seguente).

La pompa non deve essere usata come compressore.

La massima pressione interna al contenitore dell'olio non deve

superare 1,5 bar (abs).

L'inosservanza di queste precauzioni può causare danni alla

macchina ed all'operatore.

ISTRUZIONI PER L’USO

2 87-900-943-01(E)

ATTENZIONE!

Controllare che la tensione di alimentazione corrisponda a quella indicata sul cartellino del motore.

Collegare la pompa all’alimentazione.

ATTENZIONE!

Nel caso di motore trifase, una inversione di polarità provoca

l'inversione del verso di rotazione della pompa, con conseguenti possibili danni di natura meccanica.

USO

Prima di mettere la pompa in servizio effettivo è necessario, per

il raggiungimento del vuoto limite, far marciare per circa un’ora

la pompa con zavorra aperta allo scopo di eliminare l’umidità

nell’olio.

L'accensione della pompa non richiede particolari manovre; è

sufficiente collegarla all’alimentazione elettrica agendo

sull’interruttore bipolare (versione con motore monofase) o onnipolare (versione con motore trifase).

,

PERICOLO!

La pompa è progettata per operare con fluidi neutri o non corrosivi. È assolutamente vietato l'impiego con sostanze potenzialmente esplosive o infiammabili.

Lo spegnimento della pompa non richiede particolari manovre;

è sufficiente scollegarla dall’alimentazione elettrica agendo

sull’interruttore bipolare (versione con motore monofase) o onnipolare (versione con motore trifase).

MANUTENZIONE

Il personale addetto alla condotta ed alla manutenzione della

pompa deve essere ben addestrato e deve avere un'approfondita conoscenza delle norme antinfortunistiche.

,

PERICOLO!

Le alte tensioni possono causare morte al contatto. Operare

sempre con la massima cautela e secondo le norme antinfortunistiche in vigore.

,

PERICOLO!

Quando la macchina è alimentata prestare attenzione per la

presenza di parti in movimento e di alta tensione.

,

PERICOLO!

Nel caso si debba procedere ad operazioni di manutenzione

della pompa al termine di un periodo di esercizio, è necessario

lasciarla raffreddare, poichè la temperatura esterna può superare i 60 °C.

,

PERICOLO!

Escludere sempre l'alimentazione della pompa prima di compiere operazioni di manutenzione. Apporre specifici cartelli di

avvertenza: APPARECCHIATURA IN MANUTENZIONE - NON

INSERIRE L'ALIMENTAZIONE, in corrispondenza dell'interruttore di alimentazione. Al termine ripristinare i dispositivi di sicurezza.

,

PERICOLO!

Non effettuare la sostituzione dell’olio subito dopo l’arresto della macchina, in quanto la temperatura dello stesso può essere

elevata.

ATTENZIONE!

In fase di sostituzione di pezzi, operare con attenzione. In particolare nel caso di adozione di motore trifase, una inversione di

polarità provoca l'inversione del verso di rotazione della pompa,

con conseguenti possibili danni di natura meccanica.

NOTA

Prima di rispedire al costruttore una pompa per riparazioni è

indispensabile compilare e far pervenire al locale ufficio vendite

la scheda "Sicurezza e Salute" allegata al presente manuale di

istruzioni. Copia della stessa deve essere inserita nell'imballo

della pompa prima della spedizione.

Qualora una pompa dovesse essere rottamata, procedere alla

sua eliminazione nel rispetto delle normative nazionali specifiche.

GEBRAUCHSANLEITUNG

3 87-900-943-01(E)

ALLGEMEINE HINWEISE

Dieses Gerät ist für den professionellen Gebrauch bestimmt.

Vor dem Gebrauch soll der Benutzer dieses Handbuch sowie

alle weiteren von Varian mitgelieferten Zusatzinformationen

genau lesen. Bei vollständiger bzw. teilweiser Nichtbeachtung

der enthaltenen Hinweise, unsachgemäßem Gebrauch durch

ungeschultes Personal, nicht autorisierten Eingriffen und

Benutzung unter Mißachtung der nationalen Bestimmungen

übernimmt Firma Varian keinerlei Haftung.

Die Pumpen DS102 1Ph, DS202 1Ph, DS302 1Ph sind dichte

ölbadgeschmierte zweistufige Flügelzellenpumpen, die von

einem Ein- oder Dreiphasenstrommotor betätigt werden.

Diese Hochvakuumpumpen eignen sich für das Pumpen von

nicht korrosiven Gasen.

In den folgenden Abschnitten sind alle erforderlichen

Informationen für die Sicherheit des Bedieners bei der

Verwendung des Geräts aufgeführt. Detaillierte technische

Informationen sind im Anhang "Technical Information"

enthalten.

In dieser Gebrauchsanleitung werden Sicherheitshinweise

folgendermaßen hervorgehoben:

,

GEFAHR!

Die Gefahrenhinweise richten die Aufmerksamkeit des Bedieners auf eine spezielle Prozedur oder Praktik, die bei unkorrekter Ausführung schwere Personenschäden zur Folge haben

könnte.

ACHTUNG!

Die Warnhinweise vor bestimmten Prozeduren machen den

Bediener darauf aufmerksam, daß bei Nichteinhaltung Schäden

am Gerät entstehen können.

ANMERKUNG

Die Anmerkungen enthalten wichtige Informationen, die aus

dem Text hervorgehoben werden.

LAGERUNG

Während des Transports und der Lagerung der Pumpen sollen

die folgenden Umgebungsbedingungen gegeben sein:

− Temperatur: -20 °C bis +70 °C

− Relative Feuchtigkeit: 0 - 95% (niederschlagsfrei)

VOR DER INSTALLATION

Die Pumpe wird in einer speziellen Schutzverpackung geliefert.

Eventuelle Transportschäden sind der zuständigen örtlichen

Verkaufsstelle zu melden.

Das Verpackungsgewicht beträgt, einschließlich der Pumpe,

maximal 27 Kg.

Beim Auspacken ist darauf zu achten, daß die Pumpe nicht

fallengelassen oder Stößen oder Vibrationen ausgesetzt wird.

Das Verpackungsmaterial ist ordnungsgemäß zu entsorgen. Es

ist vollständig recyclebar und entspricht der EG-Richtlinie

85/399 für den Umweltschutz.

ANMERKUNG

Die Pumpe kann, wenn sie einfach der Atmosphäre ausgesetzt

ist, nicht beschädigt werden. Sie sollte jedoch bis zur

Installation an der Anlage geschlossen bleiben, um

Verunreinigungen durch Staub zu vermeiden.

INSTALLATION

Die Pumpe darf nicht in Umgebungen installiert und/oder

benutzt werden, die ungeschützt vor Witterungsbedingungen

(Regen, Frost, Schnee), Staub und aggressiven Gasen sind

und in denen Explosions- oder erhöhte Brandgefahr besteht.

Während des Betriebs sollen die folgenden

Umgebungsbedingungen gegeben sein:

− Temperatur: +12 °C bis +40 °C

− Relative Feuchtigkeit: 0 - 95% (niederschlagsfrei).

ACHTUNG!

Die Pumpe ist vor ihrer Inbetriebnahme mit Schmieröl zu füllen,

da sie leer geliefert wird.

,

GEFAHR!

Vor Aufnahme jeglicher Arbeiten sind die Schutzkappen an den

Saug- und Druckflanschen zu entfernen. Die im Pumpeninnern

enthaltene Luft könnte diese bei unbeabsichtigter Einschaltung

gegen den Bediener schleudern.

,

GEFAHR!

Bei der Installation ist unbedingt darauf zu achten, dass der

Saugflansch an die zu entleerende Kammer angeschlossen ist

und der Ablassflansch nicht verschlossen ist (siehe nachstehende Abbildung).

Die Pumpe darf nicht als Verdichter verwendet werden.

Der Druck im Ölbehälter darf nicht größer als 1,5 bar (abs) sein.

Bei Nichtbeachtung dieser Anweisungen besteht

Schadensgefahr für das Gerät und die Bedienperson.

GEBRAUCHSANLEITUNG

4 87-900-943-01(E)

ACHTUNG!

Kontrollieren, daß die Versorgungsspannung mit der

Spannungsangabe auf dem Typenschild des Motors

übereinstimmt.

Die Pumpe an das Versorgungsnetz anschließen.

ACHTUNG!

Bei Dreiphasenstrommotoren bewirkt eine Polumkehrung die

Umkehrung des Drehsinns der Pumpe, was Schäden an der

Mechanik zur Folge haben kann.

GEBRAUCH

Vor der eigentlichen Inbetriebnahme der Pumpe ist es zur

Erreichung des Grenzvakuums erforderlich, die Pumpe

ungefähr eine Stunde mit geöffnetem Ballast laufen zu lassen,

um die Feuchtigkeit aus dem Öl zu entfernen.

Die Einschaltung der Pumpe erfordert keine speziellen Schritte,

sie braucht nur durch Betätigung des zweipoligen (Version mit

Einphasenstrommotor) oder des allpoligen Trennschalters

(Version mit Dreiphasenstrommotor) an die elektrische

Energieversorgungsquelle angeschlossen werden.

,

GEFAHR!

Die Pumpe ist für den Betrieb mit neutralen und nicht

korrosiven Fluiden konzipiert. Der Einsatz mit potentiell

explosions- oder feuergefährlichen Substanzen ist streng

verboten.

Die Ausschaltung der Pumpe erfordert keine speziellen

Schritte, sie braucht nur durch Betätigung des zweipoligen

(Version mit Einphasenstrommotor) oder des allpoligen

Trennschalters (Version mit Dreiphasenstrommotor) von der

elektrischen Energieversorgungsquelle getrennt zu werden.

WARTUNG

Das für den Betrieb und die Wartung zuständige Personal soll

geschult sein und über eine solide Kenntnis der

Unfallschutzvorschriften verfügen.

,

GEFAHR!

Hochspannungen können bei Kontakt tödliche Folgen haben.

Es ist stets mit größter Vorsicht und gemäß der geltenden

Unfallschutzvorschriften vorzugehen.

,

GEFAHR!

Bei eingeschaltetem Gerät ist auf Bewegungs- und

Hochspannungsteile zu achten.

,

GEFAHR!

Falls die Pumpe im Anschluß an den Betrieb gewartet werden

soll, ist abzuwarten, bis sie abgekühlt ist, da ihre Oberfläche

eine Temperatur von 60°C überschreiten kann.

,

GEFAHR!

Vor Wartungsarbeiten ist die Pumpe stets energiefrei zu

schalten. Am Netzschalter sind spezielle Warnschilder

“INSTANDHALTUNG AM GERÄT – NICHT EINSCHALTEN”

anzubringen. Nach Abschluß der Arbeiten sind die

Sicherheitseinrichtungen wieder zu aktivieren.

,

GEFAHR!

Keine Ölwechsel unmittelbar nach Stillsetzung des Gerätes

vornehmen, da die Öltemperatur sehr hoch sein kann.

ACHTUNG!

Bei Ersatz von Teilen ist mit Vorsicht vorzugehen.

Insbesondere bei der Version mit Dreiphasenstrommotor

bewirkt eine Polumkehrung die Umkehrung des Drehsinns der

Pumpe, was Schäden an der Mechanik zur Folge haben kann.

ANMERKUNG

Bevor dem Hersteller eine Pumpe zur Reparatur zurückgesandt

wird, ist das Formular “Sicherheit und Gesundheit” in der

Anlage zum vorliegenden Handbuch auszufüllen und der

lokalen Verkaufsstelle zuzustellen. Eine Kopie des Formulars

ist der Pumpenverpackung vor dem Versand beizulegen.

Bei eventueller Verschrottung einer Pumpe ist diese

entsprechend der einschlägigen nationalen Vorschriften zu

entsorgen.

MODE D'EMPLOI

5 87-900-943-01(E)

INDICATIONS GÉNÉRALES

Cet appareillage a été conçu en vue d'une utilisation professionnelle. Il est conseillé à l'utilisateur de lire attentivement

cette notice d'instructions ainsi que toute autre indication fournie par Varian avant d'utiliser l'appareil. Varian décline par

conséquent toute responsabilité en cas de non-respect total ou

partiel des instructions fournies, d'utilisation incorrecte de la

part d'un personnel non formé, d'opérations non autorisées ou

d'un emploi contraire aux réglementations nationales spécifiques.

Les pompes DS102 1Ph, DS202 1Ph, DS302 1Ph sont des

pompes rotatives à deux stades à palettes, étanches en bain

d'huile, actionnées par un moteur électrique mono ou triphasé.

Ces pompes à vide poussé sont adaptées au pompage de gaz

non corrosifs.

Les paragraphes suivants fournissent toutes les indications

nécessaires pour garantir la sécurité de l'opérateur pendant

l'utilisation de l'appareillage. Des renseignements plus détaillés

se trouvent dans l'appendice “Technical information”.

Cette notice utilise les signes conventionnels suivants :

,

DANGER!

Les messages de danger attirent l'attention de l'opérateur sur

une procédure ou une manœuvre spéciale dont la mauvaise

exécution risque de provoquer de graves lésions.

ATTENTION !

Les messages d'attention apparaissent avant certaines procédures dont le non-respect peut endommager sérieusement

l'appareillage.

NOTE

Les notes contiennent des renseignements importants, extrapolés du texte.

EMMAGASINAGE

Pendant le transport et l'emmagasinage des pompes, il faut

veiller à respecter les conditions environnementales suivantes :

− température: de -20 °C à +70 °C

− humidité relative: 0 - 95% (non condensante)

PRÉPARATION POUR L'INSTALLATION

La pompe est fournie dans un emballage de protection spécial;

si l'on constate des marques de dommages pouvant s'être produits pendant le transport, contacter aussitôt le bureau de vente

local.

Le poids total de l'emballage et de la pompe est au maximum

de 27 Kg.

Pendant l'opération d'ouverture de l'emballage, veiller tout particulièrement à ne pas laisser tomber la pompe et à ne lui faire

subir aucun choc ni aucune vibration

Ne pas jeter l'emballage dans la nature. Le matériel est entièrement recyclable et il est conforme à la directive CEE 85/399

en matière de protection de l'environnement.

NOTE

La pompe ne peut être endommagée en restant simplement

exposée à l'atmosphère. Il est de toute façon conseillé de la

garder dans son emballage jusqu'au moment de sa mise en

fonction afin d'éviter toute pollution due à la poussière

INSTALLATION

Ne pas installer et/ou utiliser la pompe dans des milieux exposés aux agents atmosphériques (pluie, gel, neige), à des poussières, à des gaz agressifs ainsi que dans des milieux explosifs

ou à risque élevé d'incendie.

Pendant le fonctionnement, il est nécessaire de respecter les

conditions environnementales suivantes :

− Température: de +12 °C à +40 °C

− Humidité relative : 0 - 95% (non condensante).

ATTENTION !

Avant toute utilisation de la pompe, il est impératif de procéder

à son remplissage en huile de lubrification car elle est livrée

vide.

,

DANGER!

Avant toute autre opération, retirer les bouchons de protection

placés sur les brides d'aspiration et de vidange. En cas de mise

en marche inopinée de l'appareillage, l'air contenu à l'intérieur

de la pompe peut les projeter contre l'opérateur.

,

DANGER!

Pendant l'installation, faire très attention que la bride d'aspiration soit reliée à la chambre à vider et que la bride d'évacuation

ne soit pas bouchée (voir la figure ci-après).

La pompe ne doit pas être utilisée comme un compresseur.

La pression maximale à l'intérieur du réservoir d'huile ne doit

pas dépasser 1,5 bar (abs).

Le non-respect de ces précautions peut entraîner un danger

pour l'opérateur et l'endommagement de la machine.

MODE D'EMPLOI

6 87-900-943-01(E)

ATTENTION !

Contrôler que la tension d'alimentation correspond à la tension

indiquée sur la plaquette du moteur.

Brancher la pompe à la source d'alimentation.

ATTENTION !

En cas de moteur triphasé, une inversion de polarité provoque

l'inversion du sens de rotation de la pompe et peut entraîner

des dommages de nature mécanique

UTILISATION

Avant la mise en service de la pompe, il est nécessaire, pour

atteindre le vide maximum, de faire fonctionner la pompe pendant environ une heure avec le reniflard ouvert afin de supprimer l'humidité de l'huile.

La mise en marche de la pompe ne requiert aucune manœuvre

particulière ; il suffit de la brancher à l'alimentation électrique et

d'agir sur l'interrupteur bipolaire (version avec moteur monophasé) ou unipolaire (version avec moteur triphasé).

,

DANGER!

La pompe a été conçue pour fonctionner avec des fluides neutres ou non corrosifs. L'emploi de substances potentiellement

explosives ou inflammables est strictement interdit.

L'arrêt de la pompe ne requiert aucune manœuvre particulière ;

il suffit de la débrancher de l'alimentation électrique en agissant

sur l'interrupteur bipolaire (version avec moteur monophasé) ou

unipolaire (version avec moteur triphasé).

MAINTENANCE

Le personnel chargé de la conduite et de la maintenance de la

pompe doit avoir reçu la formation nécessaire et posséder une

connaissance approfondie des normes de prévention des accidents du travail.

,

DANGER!

Les hautes tensions peuvent entraîner la mort par contact. Veiller à toujours opérer avec le maximum de prudence et dans le

respect des normes de prévention des accidents du travail en

vigueur.

,

DANGER!

Lorsque la machine est sous alimentation, faire attention à la

présence d'organes en mouvement et de haute tension.

,

DANGER!

En cas de nécessité de procéder à des opérations de maintenance de la pompe au terme d'une période de fonctionnement,

il est indispensable de la laisser refroidir car sa température

extérieure peut être supérieure à 60°C.

,

DANGER!

Avant toute opération de maintenance, il est impératif de toujours couper l'alimentation de la pompe. Placer les pancartes

spécifiques d'avertissement : APPAREILLAGE EN COURS DE

MAINTENANCE – NE PAS BRANCHER L'ALIMENTATION,

près de l'interrupteur d'alimentation. Au terme des opérations

de maintenance, restaurer les dispositifs de sécurité.

,

DANGER!

Ne pas effectuer la substitution d'huile immédiatement après

l'arrêt de la machine car la température de cette dernière peut

être élevée.

ATTENTION !

En phase de substitution de pièces, opérer avec le maximum

d'attention. En particulier, en cas de moteur triphasé, une inversion de polarité provoque l'inversion du sens de rotation de

la pompe et peut entraîner des dommages de nature mécanique.

NOTE

Avant de retourner une pompe au constructeur pour réparation,

il est indispensable de remplir et d'adresser au bureau local de

vente la fiche "Sécurité et Santé" jointe à la présente notice

d'instructions. Une copie de celle-ci devra être mise dans l'emballage de la pompe avant expédition.

En cas de mise au rebut de la pompe, procéder à son élimination conformément aux réglementations nationales en la matière.

INSTRUCTION MANUAL

7 87-900-943-01(E)

GENERAL INFORMATION

This equipment is destined for use by professionals. The user

should read this instruction manual and any other additional

information supplied by Varian before operating the equipment.

Varian will not be held responsible for any events occurring due

to non-compliance, even partial, with these instructions, improper use by untrained persons, non-authorized interference

with the equipment or any action contrary to that provided for by

specific national standards.

The DS102 1Ph, DS202 1Ph, DS302 1Ph pumps are dualstage, rotary vane pumps oil sealed, driven by a single-phase

or three-phase electric motor.

These high vacuum pumps are suitable for pumping non corrosive gases.

The following paragraphs contain all the information necessary

to guarantee the safety of the operator when using the equipment. Detailed information is supplied in the appendix "Technical Information".

This manual uses the following standard protocol:

,

WARNING!

The warning messages are for attracting the attention of the

operator to a particular procedure or practice which, if not followed correctly, could lead to serious injury.

CAUTION

The caution messages are displayed before procedures which,

if not followed, could cause damage to the equipment.

NOTE

The notes contain important information taken from the text.

STORAGE

When transporting and storing the pumps, the following environmental requirements should not be exceeded:

− temperature: from -20° to +70 °C

− relative humidity: 0 - 95% (non-condensing)

PREPARATION FOR INSTALLATION

The pump is supplied in a special protective packing. If this

shows signs of damage which may have occurred during transport, contact your local sales office.

Total weight of the pack, including the pump, is approx. 27 Kg.

When unpacking the pump, be sure not to drop it and avoid any

kind of sudden impact or shock vibration to it.

Do not dispose of the packing materials in an unauthorized

manner. The material is 100% recyclable and complies with

EEC Directive 85/399.

NOTE

Normal exposure to the environment cannot damage the pump.

Nevertheless, it is advisable to keep it closed until it is installed

in the system, thus preventing any form of pollution by dust.

INSTALLATION

Do not install or use the pump in an environment exposed to

atmospheric agents (rain, snow, ice), dust, aggressive gases,

or in explosive environments or those with a high fire risk. During operation, the following environmental conditions must be

respected:

− temperature: from +12 °C to +40 °C

− relative humidity: 0 - 95% (non-condensing)

CAUTION

Before starting the pump, fill up with lubricating oil as the pump

is delivered empty.

,

WARNING!

Take out the protective caps on the suction and exhaust

flanges before doing anything else. In the event of an accidental start-up, the air inside the pump could violently expel the

protective caps and harm the operator.

,

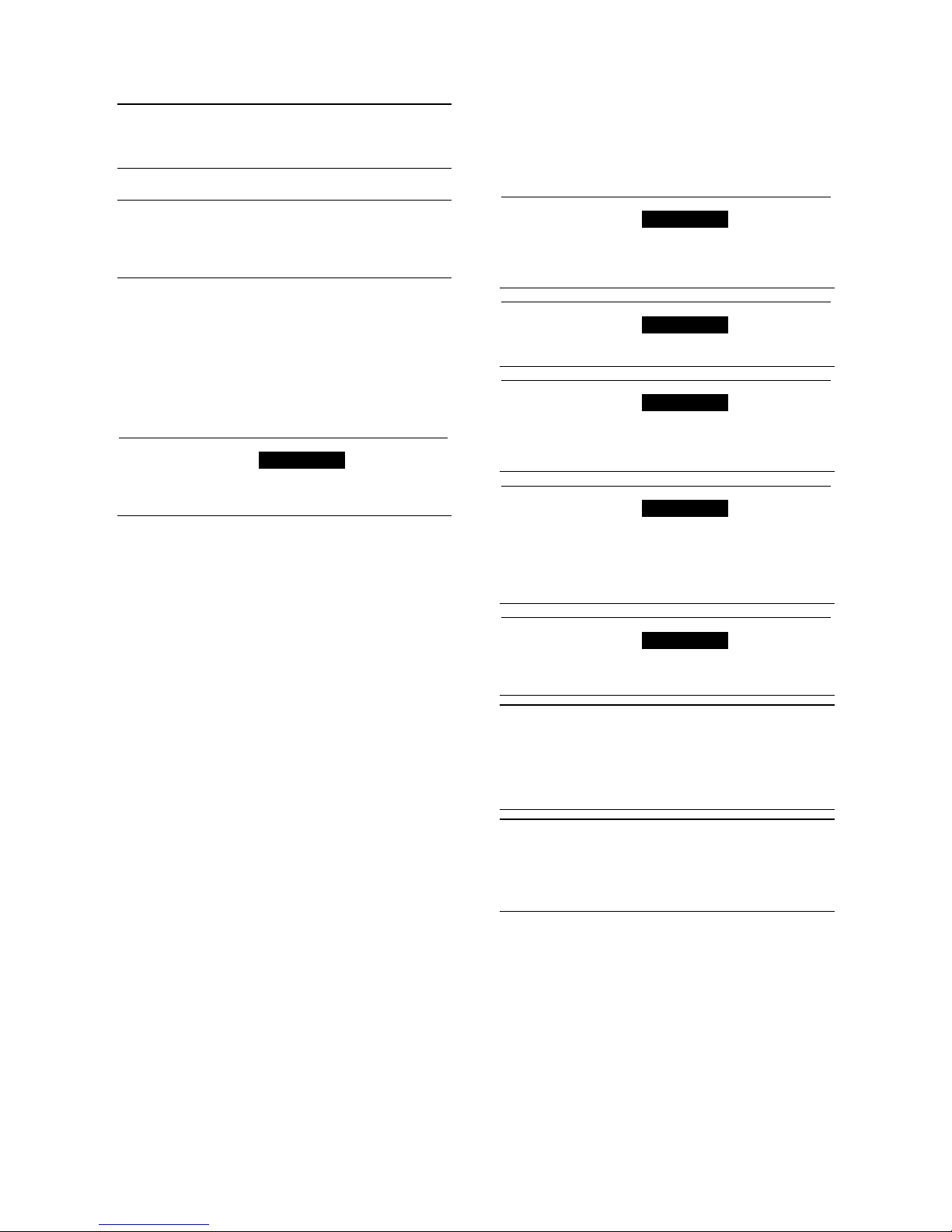

WARNING!

During installation, pay maximum attention that the suction

flange is connected to the vacuum chamber and the exhaust

flange is not closed (see the following figure).

The pump must not be used as a compressor.

Maximum pressure inside the oil container must not exceed 1.5

bar (abs.)

Non-observance of these precautions may be dangerous for

the machine and the operator.

INSTRUCTION MANUAL

8 87-900-943-01(E)

CAUTION

Check that your electrical mains voltage corresponds to that

indicated on the motor’s plate.

Connect the pump to the power supply.

CAUTION

Pay special attention to the three-phase motor, where an inversion of polarity causes inversion of the direction of rotation of

the pump with consequent possibilities of mechanical damage.

USE

Before being put into service, in order to reach maximum vacuum, the pump must be left running for about an hour with the

gas ballast valve open. This will eliminate any humidity from the

oil.

There are no special procedures for switching the pump on; it

needs only to be connected to the electric power by means of

the bipolar switch (version with single-phase motor) or of the

multipolar switch (version with three-phase motor).

,

WARNING!

The pump is designed for operation with neutral or noncorrosive fluids. It is absolutely forbidden to use potentially explosive or flammable substances.

There are no special procedures for switching the pump off; it

needs only to be disconnected from the electric power by

means of the bipolar switch (version with single-phase motor)

or of the multipolar switch (version with three-phase motor).

MAINTENANCE

Personnel responsible for pump operation and maintenance

must be well-trained and must be aware of the accident prevention rules.

,

WARNING!

Death may result from contact with high voltages. Always take

extreme care and observe the accident prevention regulations

in force.

,

WARNING!

When machine is powered take care on account of moving

parts and high voltages.

,

WARNING!

If you have to perform maintenance on the pump after a considerable time in operation, leave it to cool as temperature of

the outer surface may be in excess of 60 °C.

,

WARNING!

Always disconnect the power supply to the pump before starting maintenance work. Place a special warning signs over the

power supply breaker switch: MACHINE UNDERGOING

MAINTENANCE - DO NOT POWER ON. When finished, remove the safety warning.

,

WARNING!

Do not change the oil immediately after stopping the machine

as the oil temperature may still be high.

CAUTION

When replacing a part, take great care. Pay special attention to

the three-phase motor, where an inversion of polarity causes

inversion of the direction of rotation of the pump with consequent possibilities of mechanical damage.

NOTE

Before returning the pump to the constructor for repairs the

"Health and Safety" sheet attached to this instruction manual

must be filled-in and sent to the local sales office. A copy of the

sheet must be inserted in the pump package before shipping.

If a pump is to be scrapped, it must be disposed of in accordance with the specific national standards.

TECHNICAL INFORMATION

SECTION I

TECHNICAL DESCRIPTION

The DS102 1Ph, DS202 1Ph and DS302 1Ph

pumps are dual-stage, rotary vane pumps oil

sealed, driven by a single-phase or three-phase

electric motor.

These vacuum pumps are suitable for pumping

non corrosive gases.

The main features are:

- all parts in direct contact with the fluid pumped

are free of copper alloys;

- all materials are carefully selected to provide

extended life;

- a high capacity gas ballast device allow to

pump condensable vapors;

- all the parts composing the pump are fully replaceable due to the close machining tolerances and to the centering obtained by using

reference pins;

- due to its design features and low number of

gaskets, the pump requires little maintenance,

disassembly and reassemble are easy and

require minimal time.

The pump works with force-feed lubrication, provided by an auxiliary gear-pump driven by the rotor

of the vacuum pump itself. This ensures proper

lubrication even when pressures are close to

atmospheric

.

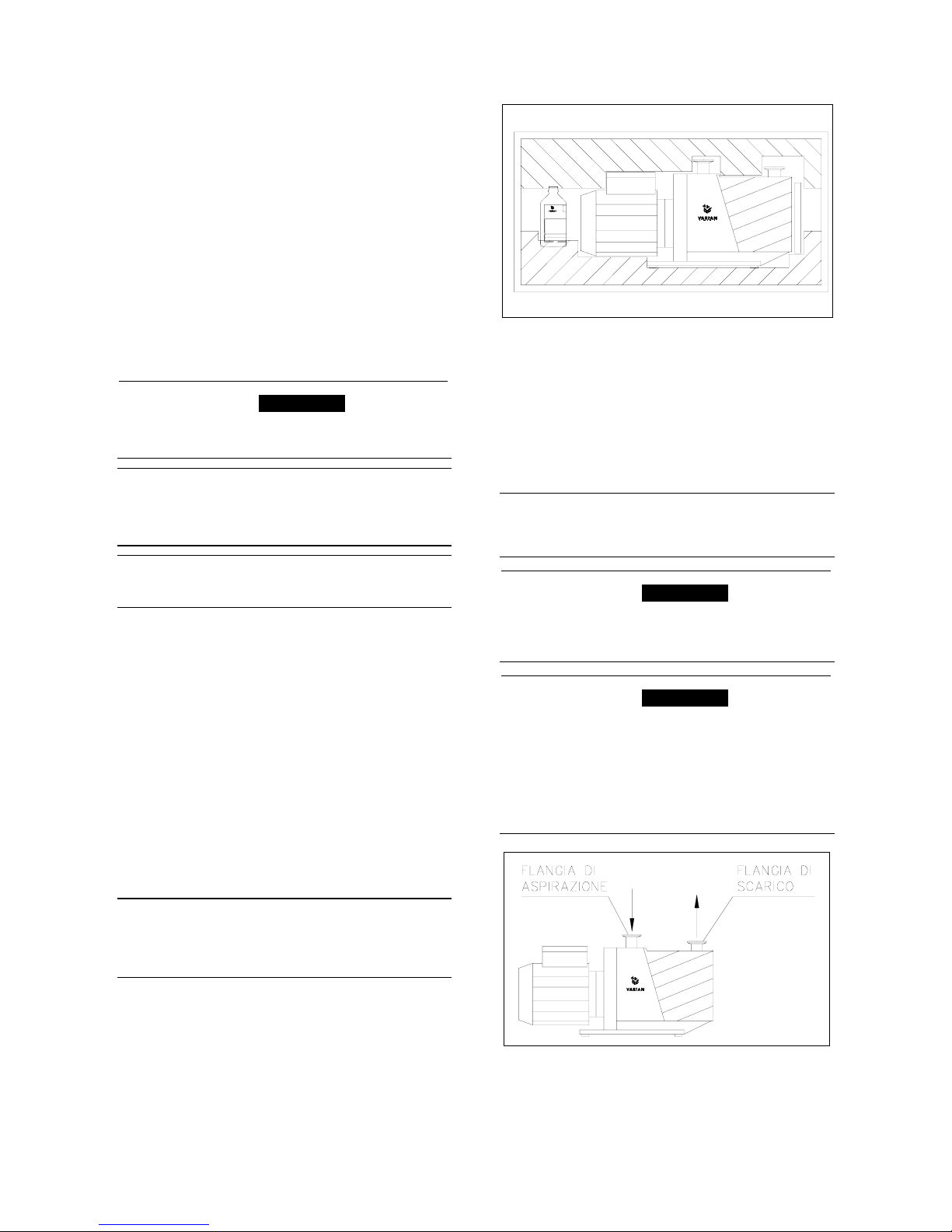

The entire pump functional block is immersed in

the oil contained in the casing. The oil guarantees

perfect sealing of the discharge valves, enters the

pump to ensure lubrication and sealing of the parts

inside, facilitates heat dissipation and reduces

pump noise.

The pump is equipped with a special antisuckback device which automatically isolates the

vacuum system when the pump stops. This avoids

rises in pressure or oil flow in the vacuum system

while air is allowed back into the stator chambers.

The air entering the pump after the anti-suckback

device has closed prevents the oil in the casing

from filling the stator chambers.

The inner seals are achieved by the lubricating oil,

thanks to the close machining tolerances.

The vacuum pumps are connected directly to the

electric motor through a flexible coupling, so that

motion is transmitted even in case of poor alignment.

A fan fitted on the joint and housed in the pump

support produces a forced air flow over the finned

surfaces of the casing to avoid oil overheating.

LUBRICATION

The pump’s lubricating system is force-feed type.

Oil circulation is obtained by means of a gear

pump connected to the rotor shaft.

The oil is sucked through a gauze filter to prevent

any foreign bodies from entering the pump.

Shunt-mounted on the delivery line is a hydraulic

piston which, besides actuating the anti-suckback

device (see ANTI-SUCKBACK DEVICE), also

regulates pressure by discharging excess oil flow

directly into the tank.

The required flow of oil under pressure passes

through ducts that are drilled in the walls of the

pump and lubricates the bushings and the inside

parts.

VACUUM SEALS

A special feature of this pump is the low number of

gaskets that are employed.

The seals in the circuit are obtained by means of

VITON gaskets.

The careful surface finish of the various parts of

the pump means that vacuum sealing of the functional block is ensured by the film of oil separating

metal surfaces. Sealing of the rotor shaft is guaranteed by a rotating gasket with dust-guard lip.

The suction flange and duct are sealed by mean of

OR gaskets.

INLET PORT

OUTLET PORT

9 87-900-943-01(E)

TECHNICAL INFORMATION

GAS BALLAST VALVE

When the pump sucks in vapors, these condense

during compression and mix with the oil, forming

an emulsion (an aqueous vapor, for example) or a

solution (organic solvent vapors, for example).

A number of problems arise from this, such as the

impossibility of obtaining high vacuums, the alteration of the properties of the oil, could cause scaling

on parts of the pump.

To avoid this, during compression at the second

stage, atmospheric air is let into the pump through

an adjustable valve, or “gas ballast valve”, located

at the top of the pump.

In this way, the discharge valve of the second

stage opens through the effect of the atmospheric

air before the partial pressure of the vapor reaches

saturation point, thus preventing condensation

from occurring. The vapors are expelled mixed

with air.

ANTI-SUCKBACK DEVICE

The pump is equipped with a special antisuckback device to avoid air pressure rises and/or

oil backflow towards the evacuated vessel when

the pump is switched off. This device has a shutter

which automatically closes the suction duct.

In this way the pump and vacuum system are

completely isolated from each other and air can

enter the pump without any risk for the vacuum

produced in the system.

The device includes some special features,

namely:

- drive obtained avoiding any form of contamination of the inlet duct by fluids (oil and/or air)

used to command the shutter. Thanks to this,

when the pump is started again, the pumpdown to vacuum conditions is extremely fast

as these contaminants are not present and no

degassing is therefore required;

- suction flange maintained closed even when

the pump is idle, so that pollutants cannot enter from the environment and no oil can overflow from the pump.

10 87-900-943-01(E)

TECHNICAL INFORMATION

View of the pump

11 87-900-943-01(E)

TECHNICAL INFORMATION

Legend (cf. figure View of the pump)

N° Description DS 102 DS202 DS302

1 Electric motor SR03700702 SR03700702 SR03700702

1A Electric motor 370-450W SR03700865 SR03700865 SR03700865

1B Three phase electric motor SR03700922 SR03700922 SR03700922

2 Rubber foot

3 Screw

4 Screw

5 Screw

7 Spacer

8 Motor support

9 Handle

10 Screw

11 Right sideplate

12 Board

14 Screw

15 Support plate

16 Cylindrical pin (3) - (1) (3) - (2) (3) - (2)

17 Screw

18 Rubber crown (3) - (1) (3) - (2) (3) - (2)

19 Half-joint with fan

20 Half-joint (pump side)

21 Oil-seal ring (3) - (1) (3) - (2) (3) - (2)

22 Special screw

23 OR gasket (3) - (1) (3) - (2) (3) - (2)

24 Gas Ballast Valve knob SR03700219 SR03700219 SR03700219

25 Half-plate

26 Inlet screen SR03700237 SR03700237 SR03700237

27 OR gasket (3) - (1) (3) - (2) (3) - (2)

28 Suction flange

29 Anti-suckback shutter (3) - (1) (3) - (2) (3) - (2)

30 Piston

31 OR gasket (3) - (1) (3) - (2) (3) - (2)

32 Casing gasket (3) - (1) (3) - (2) (3) - (2)

33 Inner plate SR03700260 SR03700260 SR03700260

34 Pump support

35 Anti-wear bushing

36 OR gasket (3) - (1) (3) - (2) (3) - (2)

37 Kei motor side SR8999980101 SR8999980101 SR8999980101

38 First stage vane (1) (2) (2)

39 First stage rotor SR03700273 SR03700319 SR03700319

40 Spring (3) - (1) (3) - (2) (3) - (2)

41 Tongue SR8999980001 SR8999980001 SR8999980001

42 Second stage vane (1) (2) (2)

43 Second stage rotor SR03700269 SR03700269 SR03700269

44 Tie-rod SR03700209 SR03700308 SR03700308

45 OR gasket (3) - (1) (3) - (2) (3) - (2)

46 Bracket

47 Screw

49 Valve cover plate

50 Valve spring (3) - (1) (3) - (2) (3) - (2)

12 87-900-943-01(E)

TECHNICAL INFORMATION

13 87-900-943-01(E)

N° Description DS 102 DS202 DS302

51 Valve gasket (3) - (1) (3) - (2) (3) - (2)

52 First stage stator SR03700261 SR03700316 SR03700495

53 Middle plate SR03700262 SR03700262 SR03700262

56 GasBallast Valve shutter (3) - (1) (3) - (2) (3) - (2)

57 GasBallast Valve spring (3) - (1) (3) - (2) (3) - (2)

58 Second stage stator SR03700321 SR03700321 SR03700321

59 Oil pump joint SR03700280 SR03700280 SR03700280

60 Special screw

61 End plate SR03700285 SR03700285 SR03700285

62 Tongue

63 Washer

64 Nut

69A External oil pump gear SR03700281 SR03700281 SR03700281

69B Internal oil pump gear SR03700277 SR03700277 SR03700277

70 Oil pump cover

71 Screw

73 Plate

74 Filter

75 Casing

76 Exhaust flange

77 OR gasket (3) - (1) (3) - (2) (3) - (2)

78 Oil fill plug 03.701218 03.701218 03.701218

79 Oil drain plug SR03700256 SR03700256 SR03700256

80 Oil drain plug gasket SR03700256 SR03700256 SR03700256

81 Left sideplate

83 Spring

84 Filter

85 Flange

86 Sight glass 03.701326 03.701326 03.701326

87 OR gasket (3) - (1) (3) - (2) (3) - (2)

99 Special screw

100 Piston

101 Arm

102 Spring (1) (2) (2)

103 OR gasket (3) - (1) (3) - (2) (3) - (2)

104 OR gasket (3) - (1) (3) - (2) (3) - (2)

105 Sleeve

106 Spring (1) (2) (2)

107 Ring (3) - (1) (3) - (2) (3) - (2)

108 Arm

109 Insert

110 Special washer

111 Screw

NOTES

(1) Part of DS 102 Major Maintenance Kit (P/N 9499380)

(2) Part of DS 202-302 Major Maintenance Kit (P/N9499381)

(3) Part of DS 102-202-302 Minor Maintenance Kit (P/N 9499370)

TECHNICAL INFORMATION

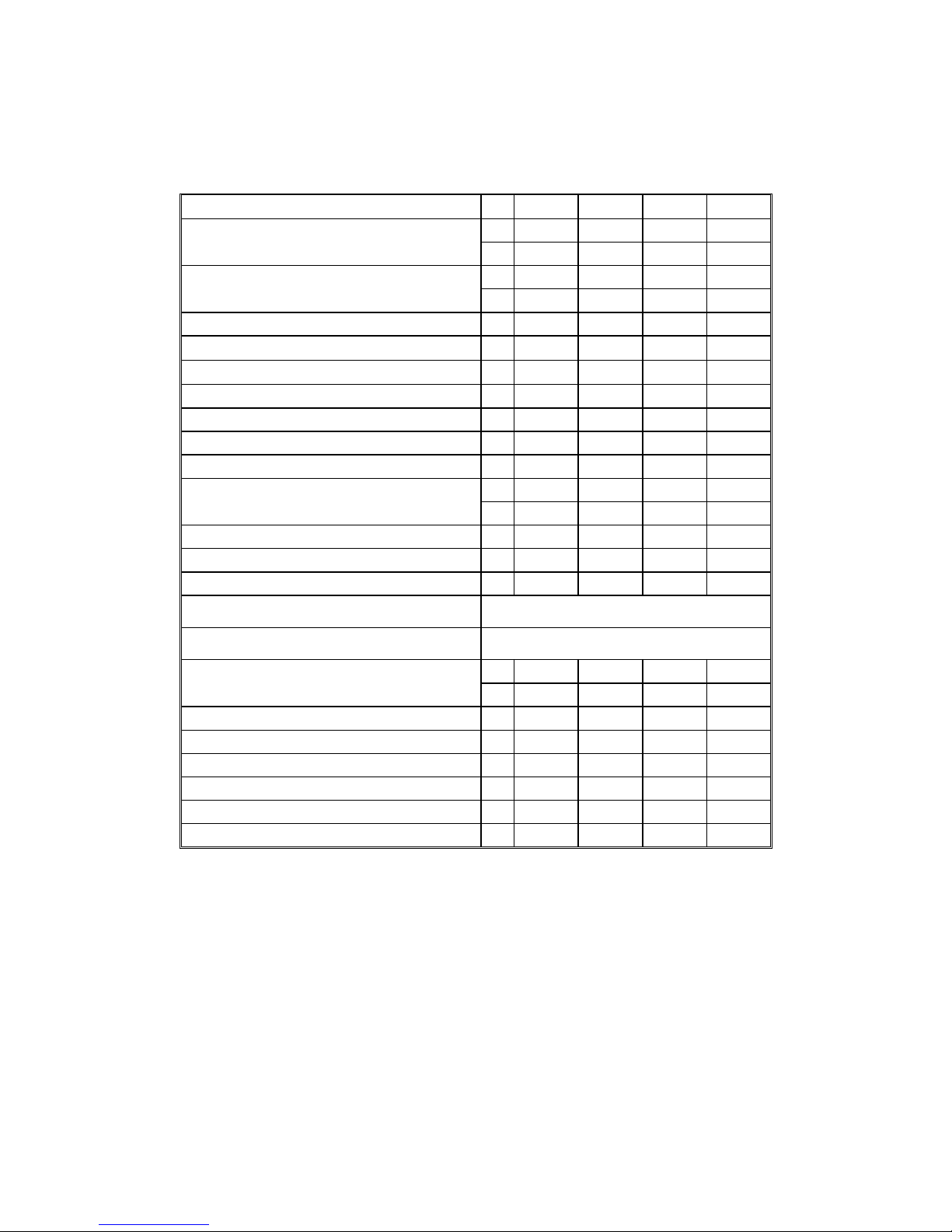

TECHNICAL DATA

The following table lists the main technical data of the DS102 1Ph, DS202 1Ph and DS302 1Ph pumps.

TECHNICAL DATA Hz UNITS DS102 DS202 DS302

60 l/min (cfm) 114 (4) 192 (6,8) 285 (10)

FREE AIR DISPLACEMENT

50 l/min (m

3

/h) 95 (5,7) 160 (9,6) 237 (14,2)

60 cfm 3,5 5,8 8,2

PUMPING SPEED *

50 m

3

/h 5 8,3 11,6

ULTIMATE PARTIAL PRESSURE * mbar 10

-4

10

-4

10

-4

ULTIMATE TOTAL PRESSURE *

mbar

2⋅10

-3

2⋅10

-3

2⋅10

-3

ULTIMATE TOTAL PRESSURE WITH GAS BALLAST *

mbar

2⋅10

-2

2⋅10

-2

2⋅10

-2

WATER VAPOR TOLERANCE mbar 15 15 20

WATER VAPOR CAPACITY g/h 60 100 160

OIL CAPACITY min/max l 0,3/0,5 0,4/0,6 0,4/0,6

MOTOR RATING 1ph 50/60 kW 0,37/0,45 0,37/0,45 0,37/0,45

50 rpm 1500 1500 1500

NOMINAL ROTATION SPEED

60 rpm 1800 1800 1800

OIL TEMPERATURE °C 50 50 52

(pump operating) ** °F 122 122 126

OPERATING TEMPERATURE RANGE °C 12 - 40 12 - 40 12 - 40

Installation category II

Pollution degree 2

Kg 22 24 24

WEIGHT

lb 48 53 53

INLET FLANGE DN 25KF 25KF 25KF

EXHAUST FLANGE DN 25KF 25KF 25KF

Dimensions (cf. also next table):

- length, 1ph mm 454 491 491

- width mm 134 134 134

- height mm 212 212 212

* According to PNEUROP 6602

** At ultimate total pressure, 20 °C (68 °F) room temperature

14 87-900-943-01(E)

TECHNICAL INFORMATION

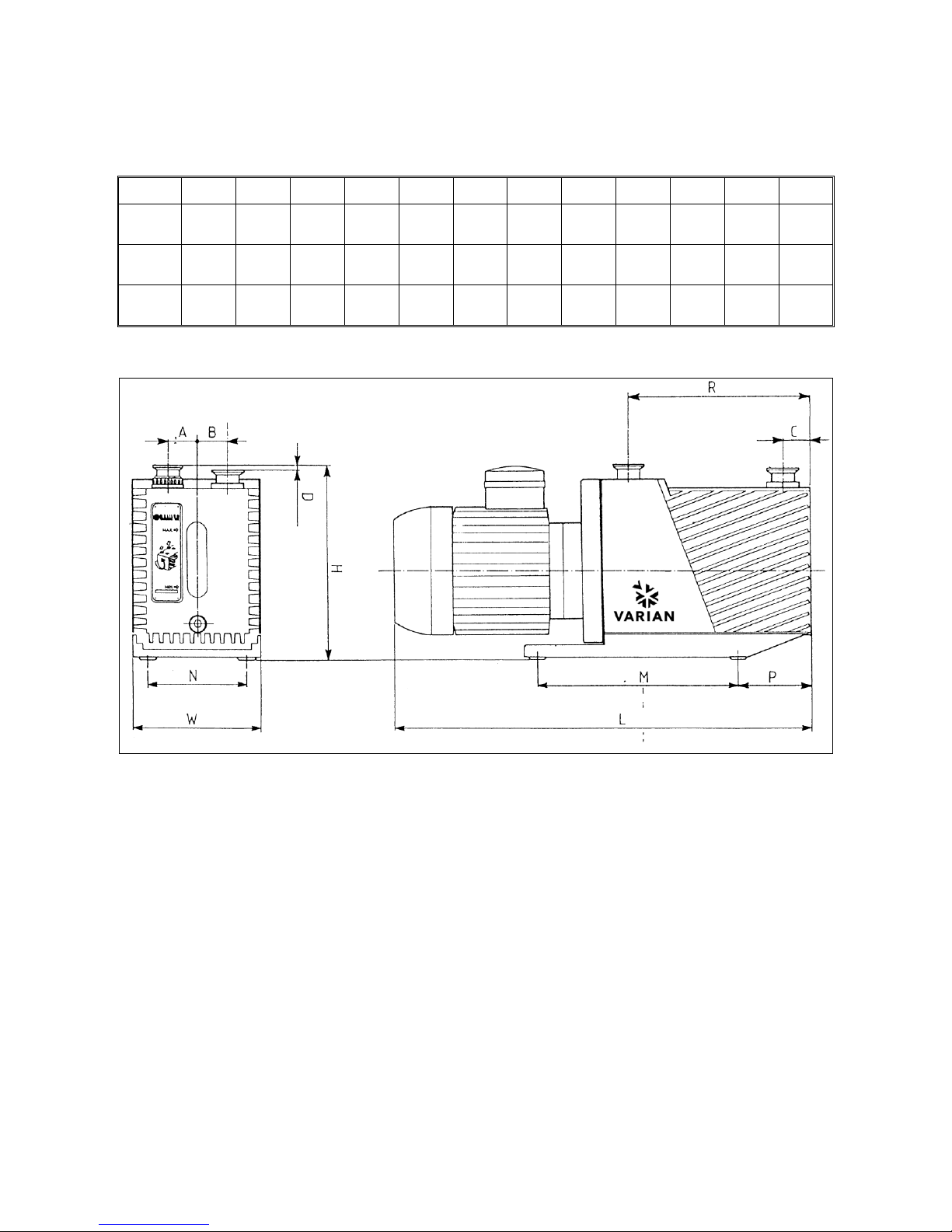

DIMENSIONS

MODEL UNITS A B C D H L M N P R W

DS102

mm

inch

30

1,18

30

1,18

35

1,38 3 0,12

212

8,3

430

16,9

250

9,8

100

3,9

105

4,1

165

6,5

132

5,2

DS202

mm

inch

30

1,18

30

1,18

35

1,38 3 0,12

212

8,3

467

18,4

250

9,8

100

3,9

105

4,1

205

8,1

132

5,2

DS302

mm

inch

30

1,18

30

1,18

35

1,38 3 0,12

212

8,3

467

18,4

250

9,8

100

3,9

105

4,1

205

8,1

132

5,2

Pump dimensions

15 87-900-943-01(E)

TECHNICAL INFORMATION

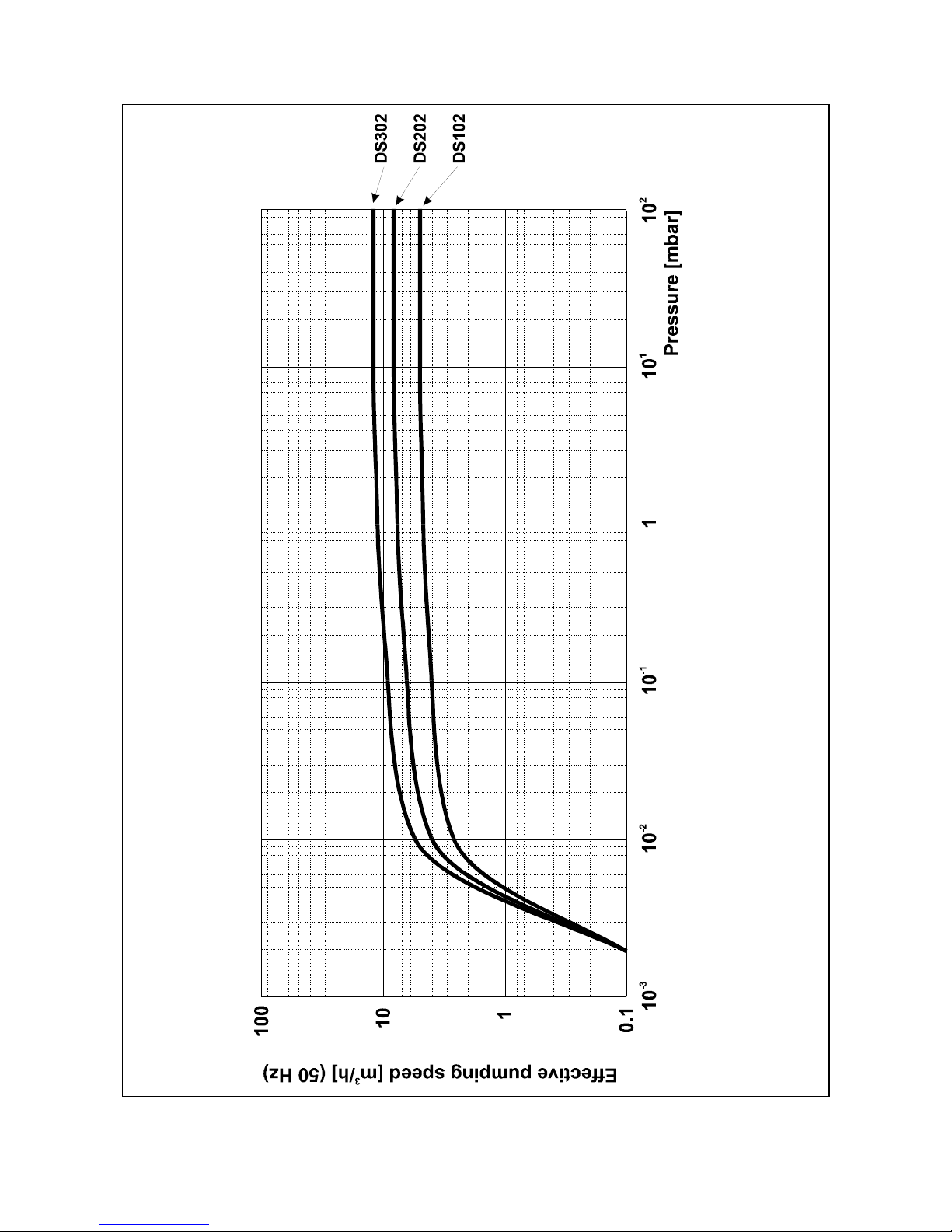

Typical Performance Curves

16 87-900-943-01(E)

TECHNICAL INFORMATION

SAFETY PRECAUTIONS

- Always carry the pump by means of the handles provided.

- The pump must be set in position taking the

upmost care in order to avoid accidental falls.

,

WARNING!

In case of a need to handle the pump after a period of operation, it must be left to cool first as the

external surface temperature may be in excess of

60 °C.

TRANSPORT AND INSTALLATION

The pumps are shipped to the customer inside

cardboard boxes.

Total weight of the pack, including the pump, is between 25 and 27 Kg according to the different

pump models.

The case must be handled with care, using appropriate lifting equipment.

CAUTION

When moving the case, ensure that it is securely

bound to the lifting equipment and that the equipment is strong enough to support the weight.

The pump’s working environment is a traditional

industrial environment. Naturally sites with corrosive vapors or excessive heat are best avoided.

Room temperature should ideally be between 12

°C and 40 °C.

If the temperature is not inside this range, consult

Varian technical service for the changes required.

Setting the pump in position should be performed

as follows:

- Pump laid on the ground. There are no special instructions for this type of installation, except that the floor should be as flat as

possible and suited to bear the weight of the

pump (it should ideally be a concrete floor)

and of any accessories mounted on it. Note

that the pump is stable on its base plate and it

should not be necessary to anchor it to the

floor with bolts and screws; also vibrations to

and from the pump are greatly reduced by the

use of rubber feet.

- Pump off the ground. In this case, the user

must design a suitable support structure, remembering the following points:

* the plane supporting the pump must be

perfectly horizontal;

* the structure should be adequately rigid;

* the relevant safety precautions should be

applied.

Note also that the pump should be attached to

the supporting structure after replacing the

rubber feet with special anti-vibration feet,

which should be screwed to the pump base

and to the supporting plane.

After taking the pump out of its packing case, you

are advised to make the following checks:

a. Ensure that the pump has not suffered any

damage during shipping.

b. Check that the guards are mounted correctly

(side plates, refs. 11 and 81 in fig. View of the

pump) and that there are no uncovered or

loose parts.

PRELIMINARY OPERATIONS

Before starting the pump, fill up with lubricating oil

as the pumps are delivered empty.

NOTE

A tin of oil is included in the packing.

For details on how to fill up, see Scheduled Maintenance Card 01.

CAUTION

Oil must be poured into the casing through the

special threaded plughole and NOT through the

suction line.

,

WARNING!

Take out the protective caps on the suction and

exhaust flanges before doing anything else. In the

event of an accidental start-up, the air inside the

pump could violently expel the protective caps and

harm the operator.

17 87-900-943-01(E)

TECHNICAL INFORMATION

The motor has a main on/off bipolar switch.

SECTION II

ELECTRICAL MOTORS

The motor includes a thermal protection against

overloads. If the motor is switched off by this relay,

it can be started again after a few minutes.

Single phase universal motors

They are world wide motors, dual voltages and

dual frequencies, and they are in accordance with

major international standards (UL, CSA, CE). On

the table below are shown the technical specifications of the motor.

Consult the trouble shooting section in order to

understand and remove the overload cause.

NOTE

If fuses are installed on the power line, they must

be in accordance with the table below.

CAUTION

If you start a pump at low temperature, the current

absorbed by the motors will be for several seconds

higher than the nominal one, for this reason the

fuse on the line must be of the slow-blow type.

Before connecting to the mains, check the position

of the voltage selector situated inside the electrical

box (see next paragraph).

200 to 240 V,

50/60 Hz

100 to 120 V,

50/60 Hz

Voltage selector

Motor specifications for different pumps

PUMP NOMINAL

VOLTAGE [V]

Hz RPM kW START UP

CURRENT [A]

FULL LOAD

CURRENT [A]

MAXIMUM FUSE

RATING [A]

100 50 1450 0.37 31 6.3 8

100 to 120 60 1730 0.45 33 6.5 8

200 to 240 50 1450 0.37 19 3.5 6

DS 102

DS 202

DS 302

200 to 230 60 1730 0.45 17 3.7 6

18 87-900-943-01(E)

TECHNICAL INFORMATION

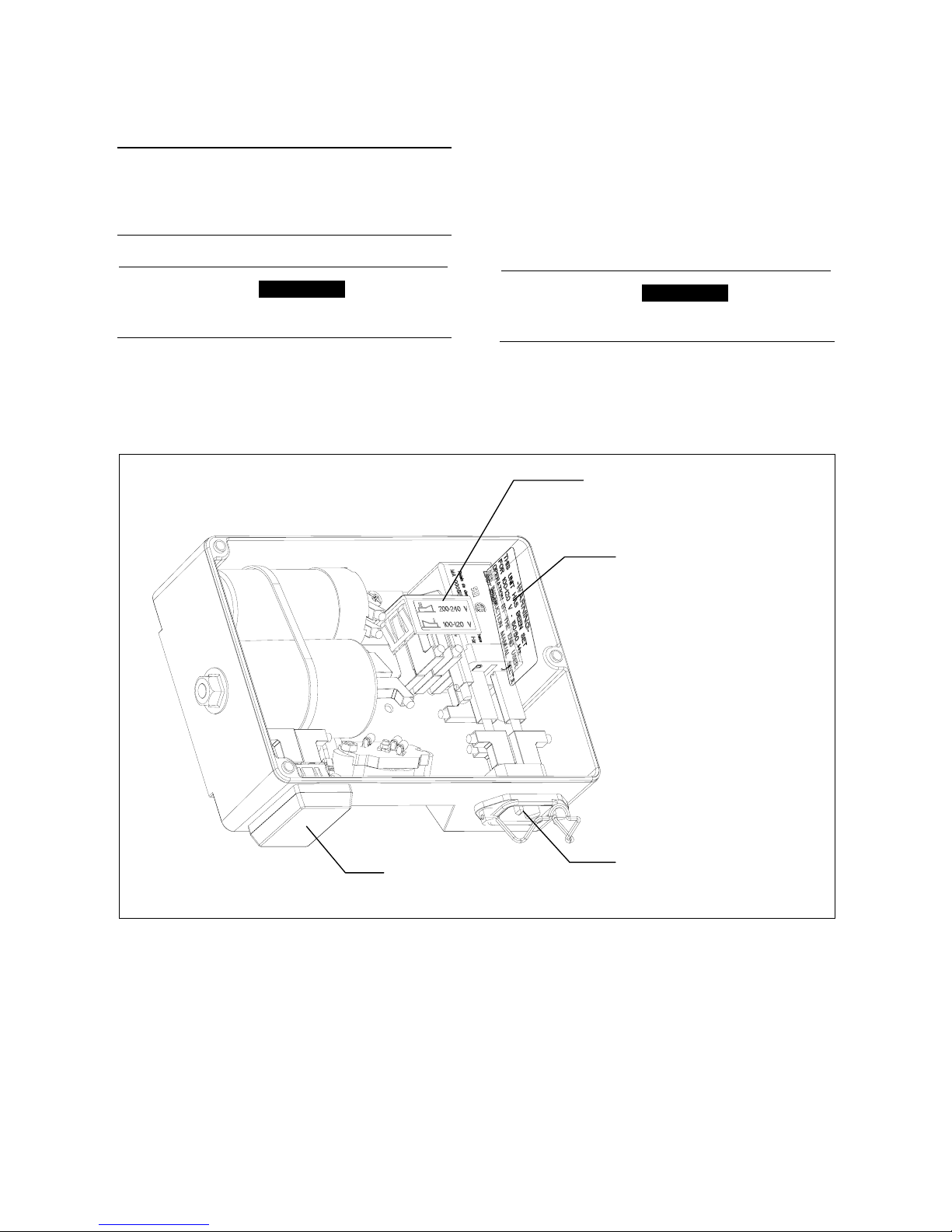

Single-Phase Universal Motors Voltage Setting

CAUTION

Before connecting to the mains, check that your

electrical mains voltage corresponds to the motor

voltage setting.

,

WARNING!

Disconnect the motor from the mains before opening the electrical box.

The motors are factory set to operate at 200-240 V

(50/60 Hz) nominal voltages.

To modify the voltage setting, change the position

of the voltage selector situated inside the motor

electrical box.

To confirm the change of the voltage setting from

High Voltage to Low Voltage, glow the orange label above the yellow label positioned on the electrical box cover.

,

WARNING!

Close the motor electrical box cover before connecting to the main.

Voltage Selector

Orange label (100 to 120 V)

IEC 320 main socket

On/off switch

Motor Electrical box

19 87-900-943-01(E)

Loading...

Loading...