Page 1

Varian BV

Herculesweg 8

4330 EA Middelburg

The Netherlands

CP-4900 Micro-GC

User Manual

North/South America

2700 Mitchell Drive

Walnut Creek

94598 California, USA

Tel: ++(1)9259392400

Fax: ++(1)9259452360 or

++(1)9259452344

© 2002-2009 Varian, Inc. All Rights Reserved Printed in the Netherlands CP501265 Rev:7 August 2009

Europe

P.O. Box 8033

4330 EA Middelburg

The Netherlands

Tel: ++(31)118671000

Fax: ++(31)118623193

Australia/East Asia

679 Springvale Road

Mulgrave, Victoria 3171

Australia

Tel: ++(61)395607133

Fax: ++(61)395607950

Page 2

Varian Analytical Instrument Warranty

HARDWARE PRODUCTS

All analytical instruments sold by Varian are warranted to be free from defects in material and workmanship for the

periods specified and in accordance with the terms on the face of Varian's quotation or as otherwise agreed upon in

writing between Varian and the Customer. The warranty period begins on the date of shipment from Varian to the

original Customer. However, where installation is paid for by the Customer or included in the purchase price, the

warranty period begins upon completion of installation. If the Customer schedules installation to start later than 30 days

after delivery or if such delay is caused through the Customer's inability to provide adequate facilities or utilities or

through failure to comply with Varian's reasonable pre-installation instructions or through other omissions by Customer,

then the warranty period starts on the 31st day from date of shipment. Moreover Varian will charge the Customer for

labor and other expenses involved in making multiple or follow-up installation service calls.

SOFTWARE PRODUCTS Where software is provided within the frame of a license agreement concluded between the Customer and Varian, any

warranty shall be strictly in accordance with the terms of such agreement.

In the absence of a license agreement and unless an alternate warranty period is agreed upon in writing between Varian

and the Customer, the warranty period is as specified on the face of Varian's quotation. Varian warrants such software

products, if used with and properly installed on Varian hardware or other hardware as specified by Varian to perform as

described in the accompanying Operator's Manual and to be substantially free of those defects which cause failure to

execute respective programming instructions; however, Varian does not warrant uninterrupted or error-free operation.

REMEDIES

The sole and exclusive remedy under hardware warranty shall be repair of instrument malfunctions which in Varian's

opinion are due or traceable to defects in original materials or workmanship or, at Varian's option, replacement of the

respective defective parts, provided that Varian may as an alternative elect to refund an equitable portion of the

purchase price of the instrument or accessory.

Repair or replacement under warranty does not extend the original warranty period.

Repair or replacement under warranty claims shall be made in Varian's sole discretion either by sending a Customer

Support Representative to the site or by authorizing the Customer to return the defective accessory or instrument to

Varian or to send it to a designated service facility. The Customer shall be responsible for loss or damage in transit and

shall prepay shipping cost. Varian will return the accessory or instrument to the Customer prepaid and insured. Claims

for loss or damage in transit shall be filed by the Customer. To correct software operation anomalies, Varian will issue

software revisions where such revisions exist and where, in Varian's opinion, this is the most efficient remedy.

LIMITATION OF WARRANTY

This warranty does not cover software supplied by the Customer, equipment and software warranted by another

manufacturer or replacement of expendable items and those of limited life, such as but not limited to: Filters, glassware,

instrument status lamps, source lamps, septa, columns, fuses, chart paper and ink, nebulizers, flow cells, pistons, seals,

fittings, valves, burners, sample tubes, probe inserts, print heads, glass lined tubing, pipe and tube fittings, variable

temperature dewars, transfer lines, flexible discs, magnetic tape cassettes, electron multipliers, filaments, vacuum

gaskets, seats and all parts exposed to samples and mobile phases.

This warranty shall be void in the event of accident, abuse, alteration, misuse, neglect, breakage, improper operation

or maintenance, unauthorized or improper modifications or tampering, use in an unsuitable physical environment, use

with a marginal power supply or use with other inadequate facilities or utilities. Reasonable care must be used to avoid

hazards.

This warranty is expressly in lieu of and excludes all other express or implied warranties, including but not

limited to warranties of merchantability and of fitness for particular purpose, use or application, and all other

obligations or liabilities on the part of Varian, unless such other warranties, obligations or liabilities are

expressly agreed to in writing by Varian.

LIMITATION OF REMEDIES AND LIABILITY

The remedies provided herein are the sole and exclusive remedies of the Customer. In no case will Varian be

liable for incidental or consequential damages, loss of use, loss of production or any other loss incurred.

.

Page 3

Declaration of Conformity

We hereby Declare that the equipment listed below complies with the requirements of:

The Low Voltage Directive 73/23/EEC (93/68/EEC)

LVD

The EMC Directive 89/336/EEC (92/31/EEC and 93/68/EEC)

APPLICABLE STANDARDS

EN 61010-1 CSA 22.2 No. 1010.1-92 UL 3101-1

EMC

Type of Equipment:

EN 61326-A1 47CFR part 15 ANSI C63.4-1992

Micro Gas Chromatograph

Print Name: G. A. Wassink

Signed:

Position: Quality Manager

Date: November 28, 2001

AUTHORIZED REPRESENTATIVE – USA

Print Name: Martin O’Donoghue

Signed:

Position: General Manager

Date: November 28, 2001

Model:

MANUFACTURER - EU

Company Name:

Address:

Telephone:

Company Name:

Address:

Telephone:

Varian B.V.

Herculesweg 8

P.O. Box 8033

4330 EA Middelburg

The Netherlands

+31(0) 118 671 000

Varian, Inc.

2700 Mitchell Drive

Walnut Creek, California 94598

USA

925-939-2400

CP-4900

Page 4

.

Page 5

Page 6

Page 7

Safety Information

Safety Information

INFORMATION

In accordance with Varian’s commitment to customer service and safety, this instrument and its

accompanying documentation (NEN 5509) complies with the CE specifications and the safety

requirements for electrical equipment for measurement, control, and laboratory use

CSA

(CEI/IEC 1010-1),

This device has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable pro tection

against harmful interference when the equipment is operated in a commercia l environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio

communications.

Operation of this equipment in a residential area is likely to case harmful inter ference in witch c ase

the user will be required to correct the interfer ence at his own e xpense.

To prevent any injury to the user or any damage to the instrument it is essential that you read the

information in this chapter.

If this manual is not in your native language and if you have problems understanding the text, we

advise you to contact your Varian office for assistance. Varian cannot accept responsibility for any

damage or injury caused by misunderstanding of the information in this manual.

c

and FCC-b.

us

OPERATING INSTRUCTIONS

This instruction manual is provided to help you establish operating conditions, which will perm i t

safe and efficient use of your equipment.

Special considerations and precautions are also described in the manual, which appear in the

form of NOTES, CAUTIONS, and WARNINGS as described belo w (next pag e).

It is important that you operate your equipment in accordance with this instruction manual and

any additional information, which may be provided by Varian. Address any questions regarding

the safe and proper use of your equipment to your local Varian office.

Varian, Inc. User Manual CP-4900 Micro-GC Page:I

Page 8

Safety information

CAUTION

WARNING

Information to aid you in

obtaining optimal performance

from your instrument.

Alerts you to situations that

may cause moderate injury

and/or equipment damage,

and how to avoid these

situations.

Warning Symbol Warning Description

WARNING:

Shock hazard

WARNING:

Burn hazard

Instruction

Manual

Protective

Conductor terminal

Radioactive

hazard

Skin puncture

Static discharge

Warning

Do not touch

Indicates dangerous voltage: (terminals fed from the interior

by voltage exceeding 1000V must be so marked).

Indicates parts that may cause burns when touched.

Indicates that the user should refer to the manual before

operating the equipment.

For protection against electrical shock in case of a fault. Used

with field wiring terminals to indicate the terminal, which must

be connected to ground before operating equipment.

Indicates that the inst rum ent co ntai ns ra dioac tive

components, which may cause personal injury when handled

incorrectly.

Indicates sharp or suddenly moving parts such as injection

needles that may cause injury.

Indicates instrument contains parts that can be damaged by

electrostatic discharge. Take care for proper grounding

before handling.

Touching this item may result in damage to the instrument

or personal injury.

Alerts you to potentially

hazardous situations that

could result in serious injury,

and how to avoid these

situations.

Page II User Manual CP-4900 Micro-GC Varian, Inc.

Page 9

Safety Information

GENERAL SAFETY PRECAUTIONS

Follow these safety practices to ensure safe equipment operation.

• Perform periodic leak checks on all supply lines and pneumatic

plumbing.

• Do not allow gas lines to become kinked or punctured. Place lines

away from foot traffic and extreme heat or cold.

• Store organic solvents in fireproof, vented and clearly labeled

cabinets so they are easily identified as toxic and/or flammable

materials.

• Do not accumulate waste solvents. Dispose of such materials

through a regulated disposal program and not through municipal

sewage lines.

NOTICE:

This instrument has been tested per applicable requirements of EMC

Directive as required to carry the European Union CE Mark. As such, this

equipment may be susceptible to radiation/interference levels or

frequencies, which are not within the tested limits.

This instrument is designed for chromatographic anal ysis of appropriately

prepared samples. It must be operated using appropriate gases and/or

solvents and within specified maximum ranges for pressure, flows, and

temperatures as described in this manual. If the equipment is used in a

manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

It is the responsibility of the Customer to inform Varian Customer Support

Representatives if the instrument has been used for the analysis of

hazardous biological, radioactive, or toxic samples, prior to any

instrument service being performed or when an instrument is being

returned to the Service Center for repair.

CAUTIONS

1. Disconnect the instrument from all power sources before removing protective panels to

avoid exposure to potentially dangerous voltages.

2. When it is necessary to use a non-original power cord plug, make sure the replacement

cord adheres to the color-coding and polarity described in the manual and all local

building safety codes.

3. Replace faulty or frayed power cords immediately with the same type and rating.

4. This instrument should be placed in a suitable location with sufficient ventilation to

remove gases and vapors. Space around the instrument must be sufficient to

enable cooling of the instrument.

Varian, Inc. User Manual CP-4900 Micro-GC Page:III

Page 10

Safety information

5. Before plugging the instrument in or turning the power on, always make sure that

the voltage and fuses are set appropriately for your local power source.

6. Do not turn on the instrument if there is a possibility of any kind of electrical damage.

Instead, disconnect the power cord and contact your Varian office.

7. The supplied power cord must be inserted into a power outlet with a protective earth

ground connection. When using an extension cord, make sure that the cord is also

properly grounded.

8. Do not change the external or internal grounding connections as this could

endanger you and/or damage the instrument.

9. The instrument is properly grounded when shipped. You do not need to make any

changes to the electrical connections or to the instrument chassis to ensure safe

operation.

10. When working with this instrument, follow the regulations for GLP (Good Laboratory

Practice). Take care to wear safety glasses and appropriate clothing.

11. Do not place containers with flammable liquids on this instrument. Spillage of the

liquid over hot parts may cause fire.

12. This instrument may use flammable or explosive gases e.g. hydrogen under

pressure. Be sure to be familiar with and to follow accurately the operation

procedures prescribed for those gases before operating the instrument.

13. Never try to repair or replace any component that is not described in this manual

without the assistance of a Varian service engineer. Unauthorized repairs or

modifications will result in rejection of warranty claims.

14. Always disconnect the AC power cord before attempting any type of maintenance.

15. Use proper tools when working on the instrument to prevent danger for you and/or

damage to the instrument.

16. The customer should not attempt to replace battery(s) or fuse(s) in this instrument

other then specified in the manual.

17. Damage can result if the instrument is stored under unfavorable conditions for

prolonged periods (e.g., subject to heat, water, etc.).

18. Do not shut off column flow when the oven temperature is high this may damage

the column.

19. This unit has been designed and tested in accordance with recognized safety

standards and designed for use indoors.

20. If the instrum ent is used in a manner not specified by the manufacturer, the

protection provided by the instrument may be impaired.

21. Substituting parts or performing any unauthorized modification to the instrument

may result in a safety hazard.

22. Changes or modifications not expressl y approved by the responsible party for

compliance could void the user’s authority to operate the equipment.

Page IV User Manual CP-4900 Micro-GC Varian, Inc.

Page 11

Safety Information

SPARE PARTS AVAILABILITY

It is the policy of Varian to provide operational spare parts for any instrument and

major accessory for a period of five (5) years after shipment of the final production

run of that instrument. Spare parts will be available after this five (5) year period

but on an as available basis. Operational spare parts are defined as those

individual electrical or mechanical parts that are susceptible to failure during their

normal operation. Examples include relays, lamps, temperature probes, detector

elements, motors, etc. Sheet metal parts, structural members or assemblies and

castings, printed circuit boards, and functional modules are normally capable of

being rebuilt to like-new condition throughout their useful life and therefore will be

supplied only on an as available basis after the final production run of the

instrument.

SERVICE AVAILABILITY

Varian provides a variety of

services to support its customers

after warranty expiration. Repair

service can be provided by

attractively priced service

contracts or on a time and

material basis. Technical

support and training can be

provided by qualified personnel

on both a contractual or asneeded basis.

Varian Analytical Instruments Sales Offices

For Sales or Service assistance and to order Parts and Supplies, contact your local Varian

office.

Argentina

Buenos Aires

Tel. +54.11.4.783.5306

Australia

Mulgrave, Victoria

Tel. +61.

Austria

Poettelsdorf

Tel. +43.2626.20090

Benelux

Middelburg

Tel. +31.118.671500

Brazil and Latin America (S)

São Paulo

Tel. +55.11.3845.0444

Canada

Mississauga, Ontario

Tel. 800.387.2216

China

Beijing

Tel. +86.106310.8550

Europe

Middelburg, The Netherlands

Tel. +31.118.671.000

3.9560.7133

France

Les Ulis Cédex

Tel. +33.1.6986.3838

Germany

Darmstadt

Tel. +49.6151.7030

India

Mumbai

Tel.

+91.22.2570.8595/97

Italy

Torino

Tel. +39.011.997.9111

Japan

Tokyo

Tel. +81.3.5232.1239

Korea

Seoul

Tel. +82.333.665.5171

Mexico and Latin

America (N)

Mexico City

Tel.

+52.5.55.5239465/026

Russian Federation

Moscow

Tel. +7.095.937.4280

Spain

Madrid

Tel. +34.91.472.7612

Sweden

Solna

Tel. +46.8.445.1620

Switzerland

Steinhausen

Tel. +41.848.803.800

Taiwan

Shih-Chi

Tel. +886.22.698.9555

United Kingdom and

Ireland

Oxford

Tel. +44.1865.291500

Venezuela

Caracas

Tel.

+58.212.285.0320/2494

United States

Walnut Creek, California,

USA

Tel. +1.800.926.3000

(GC and GC/MS)

Tel. +1.800.367.4752 (LC)

http://www.varianinc.com/

Varian, Inc. User Manual CP-4900 Micro-GC Page:V

Page 12

Page 13

Table of contents

Table of contents

VARIAN ANALYTICAL INSTRUMENT WARRANTY.................................................................. II

HARDWARE PRODUCTS ............................................................................................................... II

SOFTWARE PRODUCTS................................................................................................................ II

REMEDIES................................................................................................................................... II

LIMITATION OF WARRANTY...........................................................................................................II

LIMITATION OF REMEDIES AND LIABILITY.......................................................................................II

DECLARATION OF CONFORMITY............................................................................................III

APPLICABLE STANDARDS............................................................................................................ III

MANUFACTURER - EU.................................................................................................................III

AUTHORIZED REPRESENTATIVE – USA........................................................................................III

SAFETY INFORMATION...............................................................................................................I

INFORMATION............................................................................................................................... I

OPERATING INSTRUCTIONS...........................................................................................................I

GENERAL SAFETY PRECAUTIONS................................................................................................III

CAUTIONS...............................................................................................................................III

SPARE PARTS AVAILABILITY.........................................................................................................V

SERVICE AVAILABILITY.................................................................................................................V

TABLE OF CONTENTS................................................................................................................ 1

PRE-INSTALLATION REQUIREMENTS .....................................................................................7

Environmental requirements.................................................................................................7

Space requirements..............................................................................................................7

Power source........................................................................................................................7

Gas supply............................................................................................................................8

- External gas supply .................................................................................................8

- Safety regards ......................................................................................................... 8

GAS SAMPLES .............................................................................................................................8

CP-4900 MICRO-GC INSTALLATION.........................................................................................9

INSPECTION ................................................................................................................................ 9

UNPACKING.................................................................................................................................9

PACKING LIST............................................................................................................................10

CP-4900 Micro-GC.............................................................................................................10

Accessories ........................................................................................................................11

INSTALLATION............................................................................................................................12

Install Gas Regulators and Set pressures.......................................................................... 12

Carrier gas..........................................................................................................................12

Connect to Power...............................................................................................................12

Connect data handling peripherals.....................................................................................12

Sample................................................................................................................................ 13

Varian, Inc. User Manual CP-4900 Micro-GC Page 1

Page 14

Table of contents

Heated Sample line........................................................................................................13

Turn power ON...................................................................................................................13

Factory default states and settings.....................................................................................13

INSTRUMENT OVERVIEW ........................................................................................................ 14

FRONT VIEW.............................................................................................................................. 14

BACK VIEW ..............................................................................................................................15

INSIDE VIEW..............................................................................................................................16

CARRIER GAS CONNECTION........................................................................................................17

SAMPLE GAS .............................................................................................................................18

Handling a sample.............................................................................................................. 18

Unheated Injector Systems ...................................................................................18

Heated Injector Systems................................................................................................19

HEATED SAMPLE LINE ................................................................................................................20

Connect a heated sample line............................................................................................20

POWER..................................................................................................................................... 22

SHUT DOWN PROCEDURE........................................................................................................... 22

LONG STORAGE RECOVERY PROCEDURE ...................................................................................23

INITIAL OPERATION .................................................................................................................... 24

INITIAL RUN...............................................................................................................................24

SETTING UP THE TEST METHOD ..................................................................................................24

INJECTING THE SAMPLE..............................................................................................................24

COLUMN CP-SIL 5 CB 6 METER UNHEATED................................................................................ 25

COLUMN CP-SIL 5 CB 4 METER HEATED ....................................................................................26

COLUMN CP-SIL 5 CB 8 METER HEATED ....................................................................................27

COLUMN CP SIL13CB TBM 12 METER HEATED ......................................................................... 28

COLUMN HAYESEP 40CM HEATED .............................................................................................29

COLUMN MOLSIEVE 5Å 20 METER UNHEATED.............................................................................30

Conditioning of Molsieve columns......................................................................................31

COLUMN PPQ 10 METER HEATED ..............................................................................................32

REFERENCE ..............................................................................................................................33

INSTRUMENT DESCRIPTION...................................................................................................33

CARRIER GAS............................................................................................................................33

MICRO ELECTRONIC GAS CONTROL (EGC)..................................................................................34

INJECTOR..................................................................................................................................34

COLUMN ...................................................................................................................................35

DETECTOR................................................................................................................................36

TCD.....................................................................................................................................36

DMD.................................................................................................................................... 36

IN/OUTPUTS............................................................................................................................... 37

EXTERNAL DIGITAL I/O...............................................................................................................38

Ready/not ready signal....................................................................................................... 38

COMMUNICATION PORTS (COM)................................................................................................39

EXTERNAL ANALOG I/O..............................................................................................................40

DIFFERENCE BETWEEN WORKSTATION SOFTWARE PACKAGES.................................................... 41

Page 2 User Manual CP-4900 Micro-GC Varian, Inc.

Page 15

Table of contents

THE DIFFERENTIAL MOBILITY DETECTOR........................................................................... 42

GENERAL................................................................................................................................42

General functionality........................................................................................................... 42

CP-4900 Micro-GC DMD Channel .....................................................................................44

GENERAL OPERATION................................................................................................................45

Tuning the DMD..................................................................................................................45

NETWORKING BASICS.............................................................................................................46

THE NETWORKING MODELS ........................................................................................................46

Peer-to-peer........................................................................................................................46

Client/Server.......................................................................................................................46

Different types of networks.................................................................................................46

Star Topology.................................................................................................................46

Bus Topology .................................................................................................................47

Ring Networks................................................................................................................47

DIFFERENT CABLE TYPES.......................................................................................................... 47

Coaxial............................................................................................................................47

Coaxial RG-58................................................................................................................48

Twisted Pair....................................................................................................................48

PROTOCOLS..............................................................................................................................49

Different Types of Protocols:.......................................................................................... 49

The Internet Protocol Suite.............................................................................................49

IP Addresses..................................................................................................................49

The Internet protocol suite..............................................................................................49

NETWORKING DEVICES (HUBS, SWITCHES, AND ROUTERS)......................................................... 50

Hubs and switches are… ............................................................................................... 50

Hubs...............................................................................................................................50

Switches.........................................................................................................................51

Routers...........................................................................................................................52

CP-4900 MICRO-GC AND NETWORKS .......................................................................................53

Network Requirements of the CP-4900 Micro-GC......................................................... 53

FAQ (FREQUENT ASK QUESTIONS)............................................................................................54

GLOSSARY OF NETWORK TERMS ................................................................................................55

BNC connector ...................................................................................................................55

Crossover Cable.................................................................................................................55

Domain................................................................................................................................55

Ethernet Address................................................................................................................ 55

Gateway..............................................................................................................................55

Host name ..........................................................................................................................55

Hub .....................................................................................................................................55

IP Address..........................................................................................................................55

Patch Cable........................................................................................................................56

RJ45 Connector..................................................................................................................56

TCP/IP ................................................................................................................................56

WORKSTATION SOFTWARE....................................................................................................57

CONTROL INSTRUMENT.............................................................................................................. 57

CP-MAITRE ELITE .....................................................................................................................58

Varian, Inc. User Manual CP-4900 Micro-GC Page 3

Page 16

Table of contents

SERIAL COMMUNICATION ...........................................................................................................59

ETHERNET COMMUNICATION......................................................................................................60

Peer-to-peer: single instrument..........................................................................................60

Multiple instrument (local network)..................................................................................... 61

Global network: Multiple instruments..................................................................................62

INSTRUMENT CONFIGURATION ...................................................................................................63

MODULES CONFIGURATION........................................................................................................65

MICRO-GC CONFIGURATION SETUP............................................................................................66

COMMUNICATION SETUP............................................................................................................ 67

Serial communication ......................................................................................................... 67

Ethernet communication..................................................................................................... 67

EHTERNET CONNECTION SETUP .................................................................................................68

FIND INSTRUMENTS ON THE NETWORK........................................................................................69

ASSIGN NEW IP ADDRESS VIA ETHERNET CONNECTION ...............................................................70

ASSIGN NEW IP ADDRESS VIA SERIAL CONNECTION .................................................................... 71

UPLOAD INSTRUMENT CONFIGURATION ......................................................................................72

HARDWARE TAB........................................................................................................................72

USER SETTINGS TAB..................................................................................................................74

CP-MAITRE ELITE TAB............................................................................................................... 75

AUTOMATION TAB ......................................................................................................................76

VICI VALVE...............................................................................................................................80

INFO TAB ..................................................................................................................................81

REMOTE FIRMWARE UPDATE .....................................................................................................82

PRESSURE SENSOR CALIBRATION..............................................................................................83

RESET MPU-CP-49000............................................................................................................83

UPLOAD METHOD......................................................................................................................84

DOWNLOAD METHOD.................................................................................................................84

DOWNLOAD METHOD TAB.......................................................................................................... 84

INSTRUMENT STATUS ................................................................................................................ 85

Extension Box status (optional).......................................................................................... 86

SHOW AUTOSAMPLER TRAY.......................................................................................................87

START SINGLE RUN...................................................................................................................87

EVENT CONFIGURATION.............................................................................................................88

START SEQUENCE.....................................................................................................................89

PREVIEW RUN...........................................................................................................................89

MICRO-GC METHOD SETUP.......................................................................................................90

CP-4900 TAB ...........................................................................................................................90

AUX TRACES MAIN TAB..............................................................................................................91

TRIGGER TAB............................................................................................................................92

COMMON TAB ...........................................................................................................................93

Stabilization Time ...............................................................................................................94

ALARM EVENTS TAB..................................................................................................................95

Remote control external relays...........................................................................................96

UserDataStore Address...................................................................................................... 96

Activate Relay if..................................................................................................................96

CHANNEL TABS .........................................................................................................................98

CHANNEL TAB DMD................................................................................................................ 101

SAMPLER TAB.........................................................................................................................102

AUX TRACES TAB.................................................................................................................... 103

Page 4 User Manual CP-4900 Micro-GC Varian, Inc.

Page 17

Table of contents

ELITEEXPORT.DLL USER FILE ...................................................................................................104

STANDARD CONTROL ..............................................................................................................106

EXTERNAL STARTED................................................................................................................ 106

AUTO SAMPLER CONTROL .......................................................................................................107

ALARM SETUP (CONTACT CLOSURES).......................................................................................107

External Pump Control......................................................................................................108

ACQUIRE EXTERNAL ANALOG SIGNALS.....................................................................................108

EXTERNAL DEVICE SYNCHRONIZATION......................................................................................109

CP-4900 AND SAMPLER EXTERNAL STARTED...........................................................................109

REMOTE ACCESS INSTRUMENT STATUS ...................................................................................110

GENERAL ERROR STATE..........................................................................................................112

VARIAN USERLINK APPLICATIONS .............................................................................................114

CP-4900 External Relays .................................................................................................114

CP-4900 instrument status including analog inputs.........................................................115

UserDataStore addresses of Varian userlink applications...............................................115

EXTERNAL DEVICES.................................................................................................................117

CYCLE WITH STATIC (ELECTRONIC) PRESSURE..............................................................119

CYCLE WITH ELECTRONIC PRESSURE CONTROL............................................................120

COLUMN MODULE CONDITIONING ......................................................................................121

BACKFLUSH OPTION.............................................................................................................122

Description........................................................................................................................123

Tuning...............................................................................................................................124

SHIPPING INSTRUCTIONS.....................................................................................................125

CLEANING INSTRUCTIONS....................................................................................................125

DISPOSAL INSTRUCTIONS.................................................................................................... 125

ERROR LIST............................................................................................................................. 126

ERROR HANDLING....................................................................................................................126

ERROR LIST: ........................................................................................................................... 127

Varian, Inc. User Manual CP-4900 Micro-GC Page 5

Page 18

Introduction and Initial Operation

Introduction

Congratulations and thank you for purchasing the Varian, Inc. CP-4900 Micro-G C.

The CP-4900 Micro-GC is a powerful single or dual or quad channel high speed Micro GC

suited for analyses of gaseous samples. This instrument is tailored to meet your needs. The

columns are installed and the instrument as a whole has been thoroughly tested at our factory.

The CP-4900 Micro-GC incorporate technical advancements in Micro electronic gas control

(EGC). The unique advantages of the CP-4900 allow column head pressure settings to become

part of the GC method and can be programmed electronically.

The Varian, Inc. CP-4900 Micro-GC with Micro EGC allows you to optimize your analysis. Apart

from the constant pressure mode, the Micro EGC in the CP-4900 allows you also to program

the pressure over your column. Pressure programming improves not only the speed of the

analysis, but it will give you the opportunity to run new and more extended applications.

The CP-4900 Micro-GC analytical channels can optionally be equipped with backflush and

Micro-Gasifier capabilities thus optimizing the analysis even further.

For problems or questions about your CP-4900 Micro-GC, please contact your

nearest Varian, Inc. subsidiary or Varian, Inc. representative.

Page 6 User Manual CP-4900 Micro-GC Varian, Inc.

Page 19

Introduction and Initial Operation

Pre-installation requirements

In order to assure a quick, safe and uncomplicated installation, we kindly request you to

make provisions as stated below before our Varian, Inc. service engineer will install

your instrument(s).

Environmental requirements

- Pollution degree: 2.

- Humidity: 0% to 95% RH.

- Temperature: +0° to +50°C operating.

- The CP-4900 Micro-GC is intended for indoor use and certified for operation up

to an altitude of 2000 meter.

- The CP-4900 Micro-GC should be protected from corrosive chem icals or gases,

dust/particulate accumulation, and direct venting of air conditioners, heaters,

furnaces or fans.

Space requirements

- Allow sufficient bench space to permit installation of workstations, integrators

and other Micro-GC equipment. The table below lists the physical dimensions

and weight of the CP-4900 Micro-GC and the peripheral instruments which may

be installed near it.

- Allow 10-20 cm of space at the sides and rear of the CP-4900 Micro-GC to

permit free air circulation.

Instrument

Height Width Depth Weight

Inch. Cm Inch. Cm Inch. Cm Lb. Kg

CP-4900 Micro-GC 2-CH 11 28 6.5 16 12 30 14 6

CP-4900 Micro-GC 4-CH 11 28 6.5 16 21.5 55 22 10

Power supply 2-CH 2.5 6.4 4 9.5 7 17.8 2 1

Field case 2-CH 15 38 12 30 16 41 35 16

Field case 4-CH (with trolley) 18.5 47 15 38 28.5 73 68 30

Chromatography Workstation

(computer with monitor, approximate

values)

Power source

- Voltage of 12 VDC.

- Installation Category (overvoltage category) II.

For more details refer to the Micro-GC CP-4900 power supply user manual

(CP501267).

Varian, Inc. User Manual CP-4900 Micro-GC Page 7

17 43 17 43 21 53 35 16

Page 20

Introduction and Initial Operation

Gas supply

Gas quality specifications are listed in the reference document “Pre-Installation

requirements CP-4900 Micro-GC CP501289”.

- External gas supply

• Carrier gas pressure: Gas bottle provided wit a proper working two-stage

pressure assembly to adjust the carrier gas pressure to 550 ± 10 % (80 ± 10

%).

• DMD Transport Gas(ses): DMD (Differential Mobility Detector) transport

gas(ses) only Nitrogen or Zero Air. Gas bottle provided wit a proper working

two-stage pressure assembly to adjust the carrier gas pressure to 550 ± 10

% (80 ± 10 %).

Never use Helium as DMD Transport Gas(ses), this will damage the

detector permanent.

- Safety regards

Gas bottles must be fixed to a table or to a wall.

GAS SAMPLES

- Do not introduce liquid samples into your CP-4900.

- Type of samples: non-condensing gas

- Samples other than non-condensing gases (wet, vapors, particles and

polymers) must be filtered in advance.

- Sample conditions: Non condensing gas between 0 and 110°C.

- Sample pressure between 0 and 100 kPa (1 bar, 15 psi)

- Outlet of sample container must fit to a stainless steel capillary of 1/16"

outside diameter, provided with a Swagelok

Page 8 User Manual CP-4900 Micro-GC Varian, Inc.

® female nut.

Page 21

Introduction and Initial Operation

CP-4900 Micro-GC Installation

INSPECTION

The CP-4900 Micro-GC will arrive packed in one large box and one or more sm aller

cartons. Inspect the cartons carefully for damage or signs of rough handling. Report

damage to the carrier and to your local Varian office.

UNPACKING

Unpack the CP-4900 Micro-GC and accessories carefully and transfer to the work area,

using proper handling techniques. Inspect the CP-4900 Micro-GC and accessories

carefully for damage or signs of rough handling. Report damage to the carrier and to

your local Varian office.

Avoid back strain or injury by following all safety precautions when

lifting (heavy) objects.

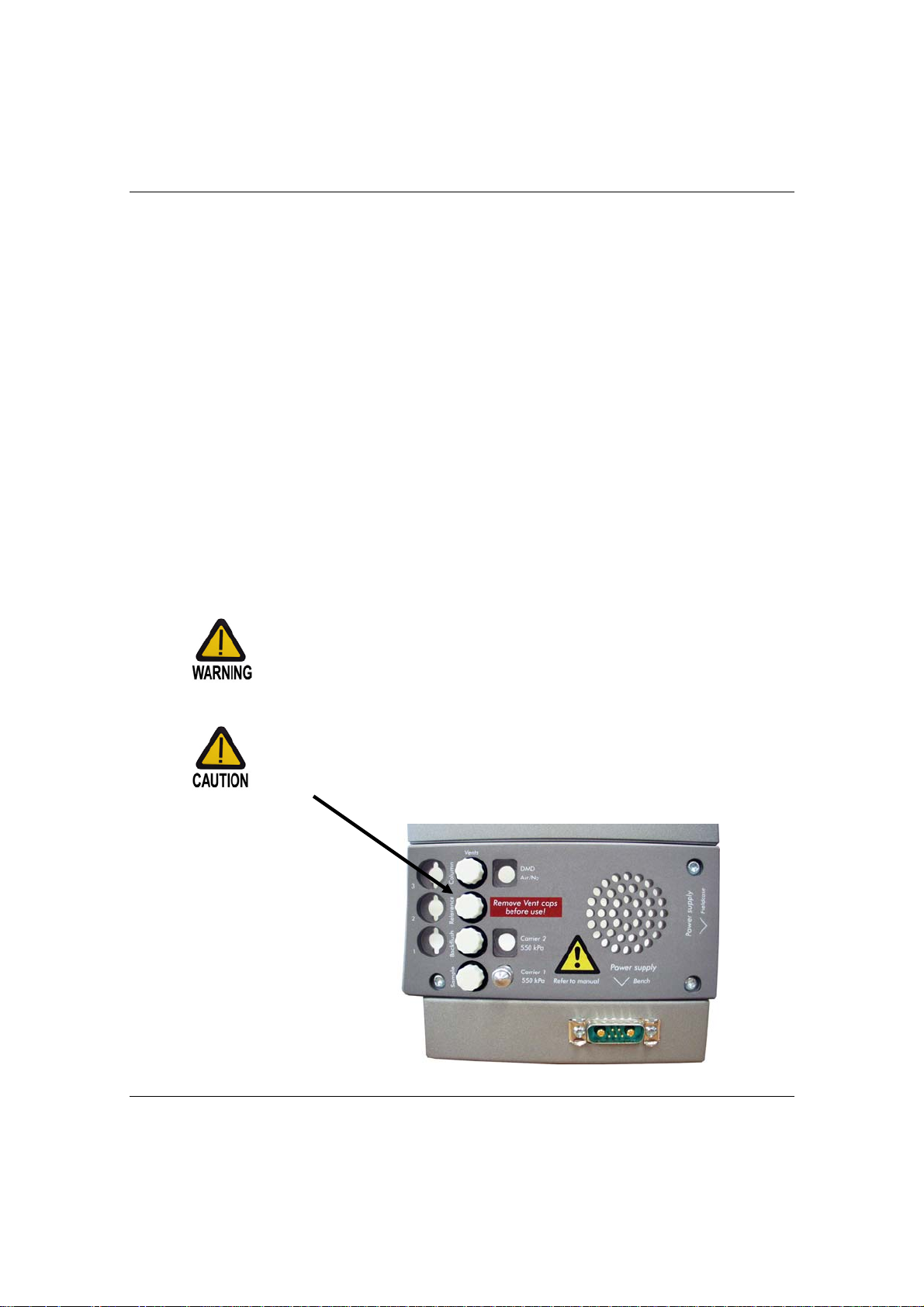

The instrument has been protected during shipment by protection caps.

Prior to operating, remove:

• At the back of the system all (plastic) caps (see picture below).

Varian, Inc. User Manual CP-4900 Micro-GC Page 9

Page 22

Introduction and Initial Operation

PACKING LIST

CP-4900 Micro-GC

Check the packing list to see if you have received all that you require.

Item Part number

External sample filter kit CP736729

Filters 5x for external filter assy. CP736467

CD-ROM user manual CP-4900 Micro-GC CP505532

Cable Dsub9 Male-Female 3 meter CP177138

Locking nut

CP420200 x 4

Male Luer

Front and back ferrule 1/16” SS x 2 CP4417

Capillary tubing SS 1/16” x 1.0 mm, 10 cm CP4008

Power supply 110V or CP49PWR110

Power supply 220V or CP49PWR220

Power supply 240V CP49PWR240

CP420100 x 4

Page 10 User Manual CP-4900 Micro-GC Varian, Inc.

Page 23

Introduction and Initial Operation

Accessories

Item Qty Part number

Spare filters (5 pieces) for external filter 5 CP736467

Manual CP-4900 Micro-GC (hard copy) 1 CP501265

Manual CP-4900 Micro-GC power supply (hard

copy)

Heated sample inlet elbow with frit 5 CP740434

Ethernet crossover cable 10 meter 1 CP740293

Ethernet crossover cable, 2 meter 1 CP740292

Combo card (Ethernet and Com ports), including 3

meter crossover cable (not for HUB)

Aux power car cigarette lighter DC adapter 1 CP740291

Charger for CP-4900 battery pack 1 CP740427

Battery pack NiMH (rechargeable) 1 CP740328

1 CP501267

1 CP740292

Micro Gasifier 110 Volt 1 CP740431

Micro Gasifier 220 Volt 1 CP740432

Micro Gasifier 240 Volt 1 CP740433

Genie 170 BTU filter complete 1 CP739535

Genie 101 BTU filter complete 1 CP739534

Genie 170 standard filter complete 1 CP739536

Genie 170 BTU membrane 1 CP739531

Genie 170 standard membranes 5 392590004

Genie 101 BTU standard membranes 5 392590005

Varian, Inc. User Manual CP-4900 Micro-GC Page 11

Page 24

Introduction and Initial Operation

INSTALLATION

Install Gas Regulators and Set pressures

Carrier gas supplied from cylinders should have a two-stage pressure assembly to

adjust the carrier gas pressure to 550 ± 10 % (80 ± 10 %). Set cylinder regulator

pressure to match the CP-4900 Micro-GC gas inlet pressure

Carrier_gas_connection on page 17).

(see

Carrier gas

The most commonly used carrier gas for the CP-4900 Micro-GC is either He or N2. The

recommended purity for carrier gas is 99.995% minimum.

Carrier_gas_connection on page 17

See

Connect to Power

First, connect the power connector to the CP-4900 Micro-GC, then plug the power cord

into an appropriate source of power.

Connect data handling peripherals

The CP-4900 Micro-GC must be connected to an external Workstation both to set up

the method and to acquire data.

Workstations and other data handling devices are connected to the cable connectors

inside the CP-4900 Micro-GC (see

• If CP-Maître Elite Workstation software with CP-4900 Micro-GC control is being

installed, follow the software installation instructions in the Workstation section of

this manual (see

• Hardware connection between the Workstation (computer) and CP-4900 Micro-GC

may be made via serial (RS232, standard) or Ethernet (optional). For additional

information, follow the links:

Cable_connectors on page 16.

Workstation_software on page 57).

Cable_connectors on page 16 for more details).

Communication_setup on page 67 and

Page 12 User Manual CP-4900 Micro-GC Varian, Inc.

Page 25

Introduction and Initial Operation

Sample

Connect the sample to the CP-4900 using the sample-in connector situated at the front

of the instrument (

chapter Sample Gas on page 18 for more important information!

Read

see front view on page 14).

Heated Sample line

To connect heated sample lines refer

to Heated Sample line chapter on page

20.

Turn power ON

Turn on the CP-4900 Micro-GC using the power switch on the lower front of the

instrument. The “READY” LED should light (after two minutes) when ready. (see

Front_view on page 14).

Factory default states and settings

Your CP-4900 Micro-GC is shipped from the factory with default settings. The following

is relevant information on the factory default states and settings:

• When the CP-4900 Micro-GC is turned on, the power LED will light up and the

system will begin the Flush cycle procedure. The Flush cycle is a 2-minute cycle in

which the various valves are activated and deactivated in order to flush the

entrapped air from the manifold, valves, and tubing.

• After the flush cycle is finished, the method (the default method in this case), which

was last active before the instrument was shutdown, is activated:

• All heated zones will be set at 30°C.

• The Detector filaments will be set to OFF.

If your system is supplied with a DMD (Differential Mobility Detector) detector all

settings are factory installed. The complete DMD method for the instrument (customer)

specific application is tested en installed inside the DMD.

Varian, Inc. User Manual CP-4900 Micro-GC Page 13

Page 26

Introduction and Initial Operation

INSTRUMENT OVERVIEW

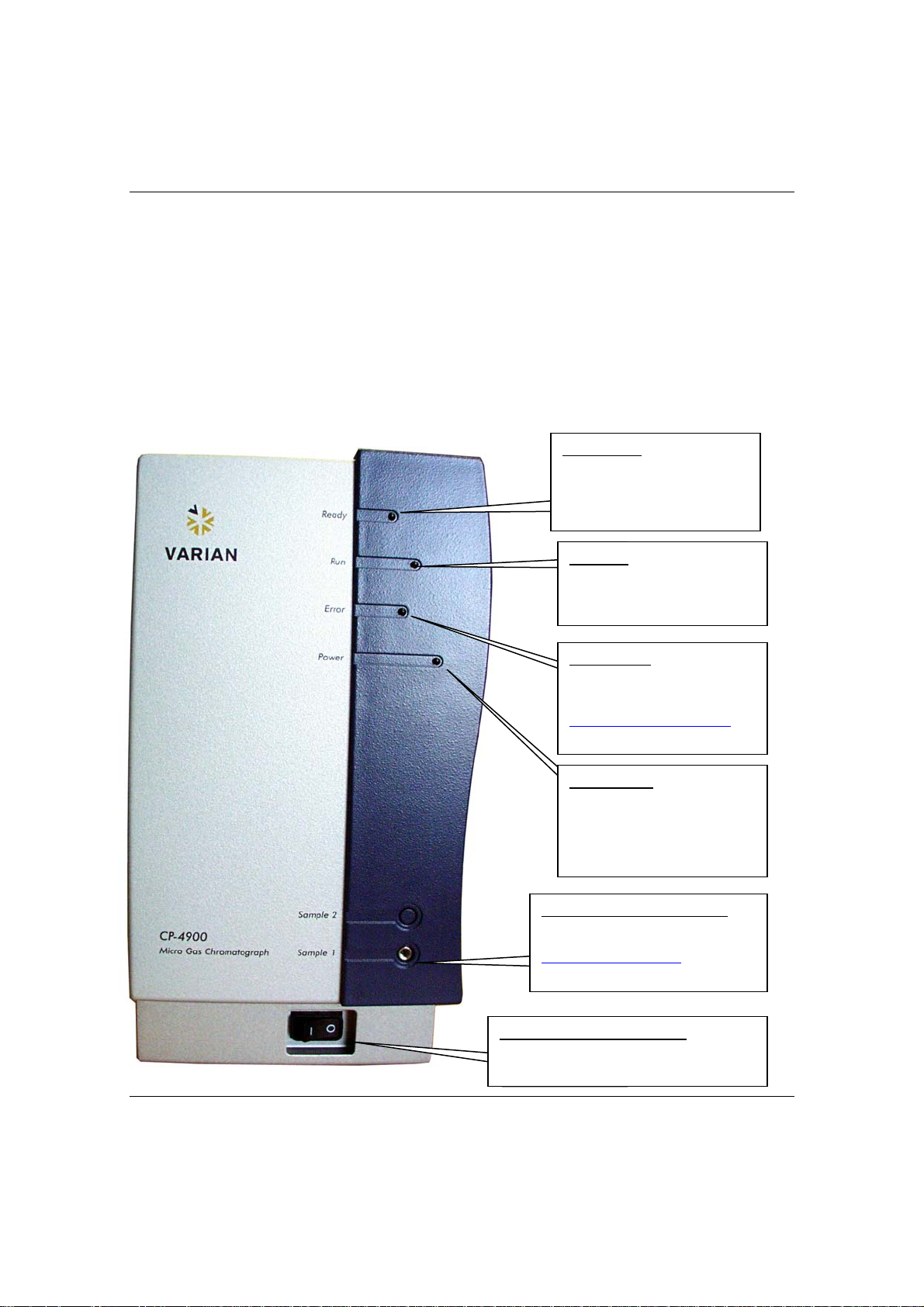

FRONT VIEW

READY led

Led OFF: System NOT ready

Led ON: System ready

RUN led

Led OFF: No run

Led blinking: Run in progress

ERROR led

Led OFF: No error

Led blinking: Error present

See here for the complete list on

page 126

POWER led

Led OFF: No power

Led ON: Power OK

Led blinking: Voltage < 10 Volt

SAMPLE 1 and SAMPLE 2

Sample gas inlet connector

See here for more details on page 18

POWER ON/OFF SWITCH

Switch the CP-4900 Micro-GC ON or OFF

Page 14 User Manual CP-4900 Micro-GC Varian, Inc.

Page 27

Introduction and Initial Operation

BACK VIEW

VENTS

DMD CONNECTOR

In DMD channel used as connector for

transport gas.

See here for more details on page 8

It is possible to connect long vent lines to these fittings in order to safely

guide hazardous fumes to a fume hood or other appropriate vent.

CARRIER 1 CONNECTOR

Carrier gas input connector

See here for more details on page 17.

POWER CONNECTOR

Power IN connector (male).

See here for more details on page 22

Varian, Inc. User Manual CP-4900 Micro-GC Page 15

Page 28

Introduction and Initial Operation

INSIDE VIEW

Open the cover and the cable connectors will be visible.

ASSIGN IP-ADDRESS BUTTON

Holding down this button during power-up will set

the “assign IP-address mode”

Assign_new_IP_address on page 70

See

ETHERNET

Ethernet RJ45 connector for Ethernet

installations.

See here for more details on page 60

COM 2 & COM 3

Optional RS232 (2-wire) and RS485 (4wire)- communication interface, only

available if Combo card is present.

See here for more details on page 39

Red led: Transmit data

Green led: Receive data

COM 1

RS232-communication interface.

See here for more details on page 39

ANALOG I/O

External Analog I/O signals.

See here for more details on page 40

DIGITAL I/O

Digital in and output signals, like start_stop,

ready_out, start_in and much more.

See here for more details on page 38

Page 16 User Manual CP-4900 Micro-GC Varian, Inc.

Page 29

Introduction and Initial Operation

CARRIER GAS CONNECTION

The carrier gas line is connected from a carrier gas connection to the CP-4900 MicroGC at the rear panel CARRIER GAS 1 or 2 port.

Do not use any kind of plastic tubing since air will diffuse through the tubing,

which may cause noisy baselines and decreased sensitivity. The metal

tubing should be clean for GC use. Buy either flamed or chromatographically

clean tubing.

Specifications for the carrier gas used on CP-4900 Micro-GC:

Pressure: 550 ± 10 % (80 ± 10 %)

Purity: 99.995% minimum

Dry and free of particles: CP-Gas Clean filters are recommended

CP-Gas Clean filters are recommended to remove any traces of moisture and oxygen.

For low-level analysis a better grade of carrier gas should be considered. The type of

analysis you want to perform determines the type of carrier gas used. The difference

between the relative thermal conductivity of the carrier gas and the sample components

should be as high as possible. Refer to the table for several relative thermal

conductivities.

Hydrogen 47.1 Ethane 5.8

Helium 37.6 Propane 4.8

Methane 8.9 Argon 4.6

Oxygen 6.8 Carbondioxide 4.4

Nitrogen 6.6 Butane 4.3

Carbon monoxide 6.4

Your CP-4900 Micro-GC is configured either for carrier gas He (or H

is configured for N

(or Ar). Make certain that the carrier gas selection in

2

the controlling Workstation corresponds to the carrier gas connected to

your CP-4900. Use carrier gas corresponding this configuration.

Changing type of carrier gas must only be carried out using the

mandatory procedure in the

Workstation software on page 74

If you are using hydrogen as carrier gas, pay particular attention to

possible leaks at connections inside and outside the CP-4900 Micro-GC

(use an electronic Leak Tester).

CP-Gas Clean filters are filled with nitrogen. If you are not using nitrogen

as the carrier gas, flush filters and gas lines after installation of a new

filter.

) or it

2

Varian, Inc. User Manual CP-4900 Micro-GC Page 17

Page 30

Introduction and Initial Operation

SAMPLE GAS

The CP-4900 Micro-GC is an analyzer built for the analysis of gases and vapors only.

You are advised to prepare a non-condensing gaseous samples standard sample for

routine check up of the instrument. Sample pressure should be between 0-100 kPa (015 psi), the temperature between 0 and 40°C ± 5°C of the analyzer ambient

temperature and it must be filtered, preferably through a 5 μm filter. Varian, Inc.

ALWAYS recommends the use of the external filter kit part number CP736729.

Click here for more

Liquids will seriously damage the instrument and should be avoided!

Handling a sample

If possible, filter and dry the sample before introducing it to the Micro-GC. It is advised

to use an External Sample Filter Unit between the injector and the sampling device.

The Filter, male must be hand tightened into the Filter Female, followed by a 1/8th turn

with a 7/16" wrench. The arrow on the Filter Female should be directed towards the

Fingertight Fitting.

Whenever possible remove moisture from samples introduced to the

CP-4900 Micro-GC.

Unheated Injector Systems

details about the heated sample line on page 20.

Replace the External Filter Unit on page 11 dat regular intervals.

Page 18 User Manual CP-4900 Micro-GC Varian, Inc.

Page 31

Introduction and Initial Operation

Heated Injector Systems

Varian, Inc. User Manual CP-4900 Micro-GC Page 19

Page 32

Introduction and Initial Operation

HEATED SAMPLE LINE

A heated sample line is always combined with a heated injector.

A heated injector and sample line is an option for a channel unit and is chosen in case

condensable samples need to be analyzed and condensation in th e sample lines needs to be

prevented.

The heated sample and injector can be controlled between 30°C and 110°C (see also

Maître Elite on page 98 Workstation).

Connect a heated sample line

Before connecting a heated sample line, allow the sample line heater to cool

down to ambient temperature. The metal surfaces of the sample line heater

are very hot and could burn your skin.

- Open the side panel, the heater will be visible.

Sample line heater

- Remove the insulation.

CP-

Page 20 User Manual CP-4900 Micro-GC Varian, Inc.

Page 33

Introduction and Initial Operation

- The sample line connector will be visible.

- Connect the sample line.

Insulate the sample line coming into the CP-4900, this to prevent damage to the

in/out coming cables.

Must be insulated

Varian, Inc. User Manual CP-4900 Micro-GC Page 21

Page 34

Introduction and Initial Operation

POWER

The CP-4900 Micro-GC requires 12.0 VDC, 130W maximum.

Refer to the User manual power supply for more information part number CP501267.

Only use the power supply that has been supplied with the instrument.

SHUT DOWN PROCEDURE

When the instrument is shut down for more then a few days please,

carry out the procedure mentioned below

Create a method for all channels with the following settings:

• Filaments switched OFF.

• Column temperature set at 30°C.

• Injector temperature set at 30°C.

• Pressure set at 50 KpA.

• Wait until the temperature of the column and injector is < 40°C (to protect the column),

before switching off the Micro-GC.

• Remove the carrier gas tubing and plug all the vents/carrier gas connections with 1/8”

brass nut or plastic cap.

• When the instrument is going to be used again then follow the procedure

on page 23

Page 22 User Manual CP-4900 Micro-GC Varian, Inc.

Page 35

Introduction and Initial Operation

LONG STORAGE RECOVERY PROCEDURE

Follow the recovery procedure below if your CP-4900 Micro-GC has been

stored for a long period of time

• Remove the 1/8” brass nuts & plastic caps from all the vents/carrier gas

connections.

• Connect carrier gas tubing and apply pressure on the CP-4900 Micro-GC,

according the pre-installation requirements.

• Wait, at least 10 minutes, before switching ON the Micro-GC.

• Check immediately if the detector filaments are switched OFF, switch OFF if

necessary (see

• Set the column(s) temperature to the maximum allowed temperature

(160 °C or 180 °C depending on the column module).

• Condition the column module, preferably overnight. This will ensure that all

the water has been removed from the column module and no damage will

occur to the TCD filaments.

Method_setup on page 90 for more details).

Varian, Inc. User Manual CP-4900 Micro-GC Page 23

Page 36

Introduction and Initial Operation

INITIAL OPERATION

A test method has been provided. This method has been designed to determine if the

instrument is functioning properly and comes together with test chromatograms on

which the test conditions are stated.

If you ordered a Molsieve column, make sure it is conditioned before use.

conditioning_Molsieve_columns on page 31 for parameters.

See

INITIAL RUN

SETTING UP THE TEST METHOD

To enter the method parameters, refer to the

data-handling package manual.

Send the instrument parameters from the data-handling package software to the MicroGC. You can watch the CP-4900 Micro-GC status in the

85.

method set-up portion on page 90 of the

instrument status tab on page

INJECTING THE SAMPLE

Connect the sample by means of a 1/16" line

to the CP-4900 Micro-GC. You are advised

to put an external 5 μm filter between the

sample and the CP-4900 Micro-GC for

additional filtering (see

18 for more details).

Press the START button to begin analysis.

Following are a few results on commonly

used columns. CP-Sil 5 CB and CP-Sil 19

CB, HayeSep A and Molsieve. The sample is

natural gas, which provides a convenient

standard for testing the instrument in any

configuration of these columns.

Sample_Gas on page

0.77 % Nitrogen

N

2

CH4 89 % Methane

C2H6 8 % Ethane

C3H8 1 % Propane

IC4H10 0.14 % Isobutane

NC4H10 0.2 % N-butane

IC5H12 0.007 % Isopentane

NC5H12 0.001 % N-pentane

Page 24 User Manual CP-4900 Micro-GC Varian, Inc.

Page 37

Introduction and Initial Operation

y

COLUMN CP-SIL 5 CB 6 METER UNHEATED

Instrument parameters

Column temperature : 50°C

Injector temperature : NA

Column pressure : 150kPa (21PSI)

Sample time : 30s

Injection time : 40ms

Run time : 60s

Detector sensitivit

: Auto

ID Component Concentration

Peak identification

1 Composite Balance

2 Ethane 8.1%

3 Propane 1.0%

4 i-Butane 0.14%

5 n-Butane 0.20%

The natural gas components, mostly hydrocarbons, separate in the same order on the

non-polar and medium-polar CP-Sil CB columns. Nitrogen, methane, carbon dioxide,

and ethane are not separated on these columns. They produce a composite peak. For

separation of these components a HayeSep A column is advised.

Varian, Inc. User Manual CP-4900 Micro-GC Page 25

Page 38

Introduction and Initial Operation

y

COLUMN CP-SIL 5 CB 4 METER HEATED

Instrument parameters

Column temperature : 50°C

Injector temperature : 110°C

Column pressure : 150kPa (21PSI)

Sample time : 30s

Injection time : 40ms

Run time : 30s

Detector sensitivit

: Auto

ID Component Concentration

1 Composite Balance

2 Ethane 8.1%

3 Propane 1.0%

4 i-Butane 0.14%

5 n-Butane 0.20%

Peak identification

Page 26 User Manual CP-4900 Micro-GC Varian, Inc.

Page 39

Introduction and Initial Operation

y

COLUMN CP-SIL 5 CB 8 METER HEATED

Instrument parameters

Column temperature : 50°C

Injector temperature : 110°C

Column pressure : 150kPa (21PSI)

Sample time : 30s

Injection time : 40ms

Run time : 60s

Detector sensitivit

: Auto

ID Component Concentration

1 Composite Balance

2 Ethane 8.1%

3 Propane 1.0%

4 i-Butane 0.14%

5 n-Butane 0.20%

Peak identification

Varian, Inc. User Manual CP-4900 Micro-GC Page 27

Page 40

Introduction and Initial Operation

y

COLUMN CP SIL13CB TBM 12 METER HEATED

Instrument parameters

Column temperature : 40°C

Injector temperature : 50°C

Column pressure : 250kPa (38PSI)

Sample time : 30s

Injection time : 255ms

Run time : 80s

Detector sensitivit

Page 28 User Manual CP-4900 Micro-GC Varian, Inc.

: Auto

ID Component Concentration

1 Methane Balance

2 TBM 6.5ppm

Peak identification

Page 41

Introduction and Initial Operation

y

COLUMN HAYESEP 40CM HEATED

Instrument parameters

Column temperature : 50°C

Injector temperature : 110°C

Column pressure : 150kPa (21PSI)

Sample time : 30s

Injection time : 40ms

Run time : 60s

Detector sensitivit

: Auto

ID Component Concentration

Peak identification

1 Nitrogen 0.77%

2 Methane Balance

3 Ethane 8.1%

The HaySep A column separates oxygen, methane, carbon dioxide, ethane, acetylene,

ethylene, and selected sulfur gases. Nitrogen coelutes with oxygen. Components with a

higher molecular weight than propane have long retention times on this column.

Maximum allowable column temperature: 160 °C

Varian, Inc. User Manual CP-4900 Micro-GC Page 29

Page 42

Introduction and Initial Operation

y

COLUMN MOLSIEVE 5Å 20 METER UNHEATED

Instrument parameters

Column temperature : 40°C

Injector temperature : NA

Column pressure : 200kPa (28PSI)

Sample time : 30s

Injection time : 40ms

Run time : 210s

Detector sensitivit

: Auto

ID Component Concentration

1 Neon 18ppm

2 Hydrogen 1.0%

3 Argon 0.2%

4 Oxygen 0.2%

5 Nitrogen 0.2%

Peak identification

The Molsieve 5Å column is designed to separate: hydrogen, carbon monoxide,

methane, nitrogen, oxygen, and some noble gases. Higher molecular weight

components have much higher retention times on this column.

Page 30 User Manual CP-4900 Micro-GC Varian, Inc.

Page 43

Introduction and Initial Operation

Conditioning of Molsieve columns

On a properly activated column nitrogen and oxygen will be very well separated.

However, in time you will find that these two peaks will start to merge together. This is

caused by water, present in the sample or carrier gas, adsorbing to the stationary

phase. To restore the columns efficiency it will suffice to raise the oven temperature to

180 °C (max. column oven temperature) and, with the normal operating pressure on the

column head, leave it to condition for about an hour. You are advised to switch the

detector filaments off during this period. After reconditioning you can test the column

performance by injecting plain air. If you have a proper separation between nitrogen

and oxygen again the column separation power has been restored. If the CP-4900

Micro-GC's frequency of use is very high, you might adopt a standard reconditioning

procedure of leaving the instrument with the oven temperature at 180°C overnight. The

longer the re+onditioning period the better the column performance without damage.

Varian, Inc. User Manual CP-4900 Micro-GC Page 31

Page 44

Introduction and Initial Operation

y

COLUMN PPQ 10 METER HEATED

Instrument parameters

Column temperature : 150°C

Injector temperature : 110°C

Column pressure : 150kPa (21PSI)

Sample time : 30s

Injection time : 40ms

Run time : 50s

Detector sensitivit

: Auto

ID Component Concentration

1 Composite Balance

2 Ethane 8.1%

3 Propane 1.0%

4 i-Butane 0.14%

5 n-Butane 0.20%

Peak identification

Page 32 User Manual CP-4900 Micro-GC Varian, Inc.

Page 45

Reference

REFERENCE

INSTRUMENT DESCRIPTION

CARRIER GAS

The Varian, Inc. CP-4900 Micro-GC is configured for the use with either He (or H

(or Ar).

Having chosen one option definitely rules out the use of the other without the

instrument undergoing internal changes prior to any switching of carrier gas

type.

It is recommended to use gases with a minimum purity of 99.995%. Since the injection

valve is operated pneumatically, there is a limit of 550 ± 10 % (80 ± 10 %) to the main

gas supply.

Your CP-4900 Micro-GC is configured either for carrier gas He (or H

configured for N

(or Ar). Use the carrier gas type, for which your instrument

2

is configured, otherwise the detector filaments can be damaged.

) or N2

2

) or it is

2

Varian, Inc. User Manual CP-4900 Micro-GC Page 33

Page 46

Reference

GAS CLEAN UNIT

(OPTIONAL)

Micro-

electronic

gas control

(EGC)

Injector Column &

reference

Detector

(TCD)

CARRIER GAS

SAMPLE

IN OUT

MICRO ELECTRONIC GAS CONTROL (EGC)

The CP-4900 Micro-GC has built-in Micro EGC regulators that can be adjusted to get a

constant or programmed pressure control, which result in a constant or programmed

flow through the injector, column and detector. The pressure range of the Micro EGC is

between 50-350 kPa (7 - 49 Psi). This pressure sets a continuous flow of carrier gas of

about 0.2-4.0 mL/min.

A typical pressure rise is 200 kPa/min, which will give a significant pressure increase

during the run, without excessive baseline disturbance. In most cases baseline

subtraction may improve the quality of chromatograms that suffer from baseline drift.

INJECTOR

The injector has a built-in 10μl sample loop that is filled with the gaseous sample. The

pressure of the sample should be between 0-100 kPa (0-15 psi) and the sample

temperature within 5-40 °C ±5 °C of the analyzer.

By activating the START option within the data-handling package, a vacuum pump will

draw the gas sample through the loop and then the injector will inject the gas sample

from the sample loop into the gas stream. The minimum pressure required by the

injector is 550 ± 10 % (80 ± 10 %). A typical injection time is 40 milliseconds (ms). This

equals an average injection volume of 200 nL. Injection time will be rounded to a

multiple of 5 ms. A practical minimum value is 40 ms.

In most cases a value of 0 - 20 milliseconds will result in no injection.

COLUMN/REFERENCE

VENT

Page 34 User Manual CP-4900 Micro-GC Varian, Inc.

Page 47

Reference

COLUMN

A variety of column configurations are possible on the CP-4900. The columns you

require for your specific analysis have been installed at our factory. Other configurations

are, of course, possible, but changing the column modules is a delicate matter that can

only be handled by one of our service engineers. Table I shows several standard

columns as supplied in the CP-4900 Micro-GC and selected applications. Other

columns are available by contacting Varian, Inc.

Column Main applications

Molsieve 5Å PLOT Hydrogen (H2), oxygen (O2), nitrogen (N2), methane (CH4),

carbon monoxide (CO), noble gases (Kr, Xe, Ne)

HayeSep A Air, methane (CH4), carbon dioxide (CO2), ethylene (C2H4),