Page 1

Varian Analytical Instruments

2700 Mitchell Drive

Walnut Creek, CA94598-1675/USA

Purge and Trap AutoSampler System

Operator’s Manual

©Varian, Inc. 1999 Printed in U.S.A. 03-914642-00:6

Page 2

Contents

1 Introduction 1-1

1.1 Product Description 1-1

1.2 Design Features 1-2

1.3 Specifications 1-3

1.4 Component Description 1-3

1.4.1 Front Panel 1-3

1.4.2 Rear Panel 1-4

1.4.3 Interior 1-5

1.5 Vial Types 1-6

2 Site Preparation / Installation 2-1

2.1 Materials Needed 2-1

2.2 Unpacking the Archon 2-1

2.3 Parts and Materials Included in the Accessory Kit

2.4 Lab and Bench Space Requirements 2-2

2.5 Gas Connections 2-3

2.6 Electrical Connections 2-4

2.7 Electronic I/O Signal Connections 2-4

2.7.1 Purge and Trap Sync Cable Connector 2-4

2.7.2 Personal Computer Connection 2-4

2.8 Water and Waste Lines Setup 2-4

2.8.1 Blank / Wash Bottle Setup 2-4

2.8.2 Waste Lines Setup 2-6

2.9 Sample Tray Setup 2-6

2.10 Sample Tray Coolant Setup (Optional) 2-7

2.11 Archon Soil Transfer Line Installation 2-7

2.11.1 Archon to Tekmar 3000 2-8

2.11.2 Archon to Tekmar 2000 2-14

2.11.3 Archon to OI 4560 2-18

2.12 Soil Helium Purge Gas Flow Adjustment 2-22

2.13 Loop Calibration for Internal Standard 2-23

2.14 Installation Checklist 2-23

(DY-505224-90)

2-2

03-914642-00:6

i

Page 3

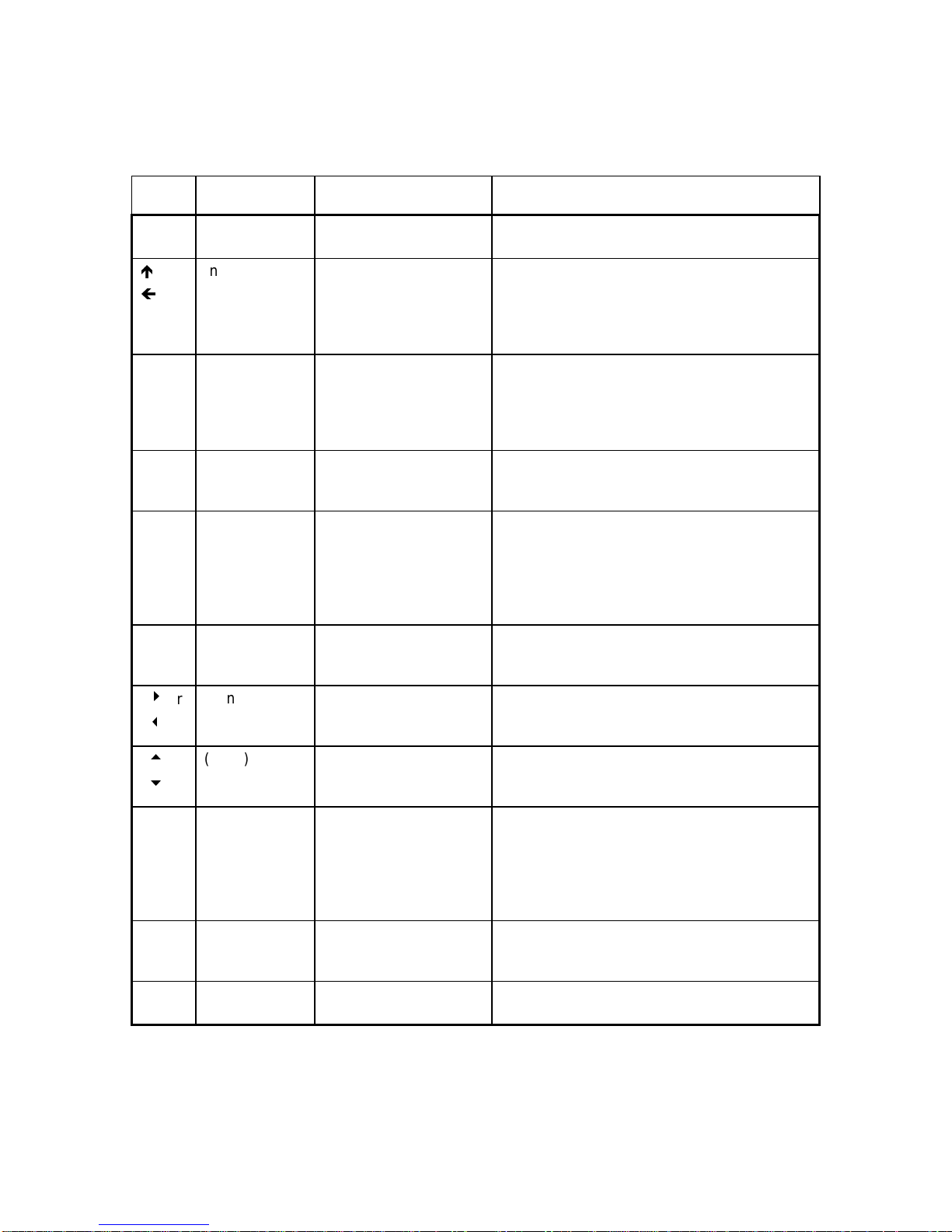

3 Keypad Definition & Layout / Screen Display 3-1

3.1 General 3-1

4 Operation Keys 4-1

4.1 Auto Key 4-1

4.2 Manual / Priority Sample Key 4-2

4.2.1 Running a Priority Sample During an AutoRun. 4-2

4.3 Flush Key 4-3

4.3.1 Drain Sparge Tube 4-4

4.3.2 Flush Syringe 4-4

4.3.3 Rinse Sparge Tube 4-4

4.3.4 Backflush Water Probe 4-5

4.4 Pause / Stop Key 4-5

4.5 System Hold 4-5

5 Method Setup 5-1

5.1 Method Editing 5-1

5.2 Sample Method Parameters 5-1

5.3 Blanks After Vial Editing 5-5

5.4 Method Programming Guidelines 5-6

5.4.1 Water Method Program 5-6

5.4.2 Soil Method Program 5-6

5.4.3 Blank Method Program 5-7

5.5 Equilibrium Count and Equilibrium Time 5-7

5.6 Operating Sequence Steps 5-8

5.6.1 Water Sample Sequence 5-8

5.6.2 Soil Sample Sequence 5-10

5.6.3 Blank Sample Sequence 5-11

6 System Setup 6-1

6.1 Front Park 6-1

6.2 System Status 6-1

6.3 Maintenance 6-2

6.3.1 Standard Control 6-2

6.3.2 Adjust Counters 6-3

6.3.3 Shipping Position 6-3

6.3.4 Clean Syringe 6-4

6.3.5 Elevator up/down 6-4

6.4 System Calibration 6-4

6.4.1 Calibration Test 6-4

6.4.2 Auto Calibrate 6-5

6.4.3 Vial 22 Position 6-8

6.4.4 Water Probe Vial Position 6-8

ii

Page 4

6.4.5 Equilibrium Block 6-9

6.4.6 Knockoff Clearance 6-9

6.4.7 Standard Clearance 6-10

6.4.8 Manual Calibration: Coordinate Settings Menu Items 6-11

6.5 System Diagnostics 6-12

6.6 System Settings 6-14

6.7 System Options 6-16

7 Maintenance 7-1

7.1 Removal and Replacement of the Needle Sparge or SoilVial Probe 7-1

7.2 Removal and Replacement of the Water Probe 7-3

7.3 Cleaning the Soil Transfer Line Frit (PN DY-505599-00) 7-4

7.4 Replacement of the Water Line Screen (P/N DY-505598-00). 7-4

7.5 Replacement of the Soil Transfer Line (Nickel Line Only) (DY-505745-00) 7-4

7.6 Replacement of the Soil Purge Gas Needle (DY-505463-00) 7-5

7.7 Cleaning the Vial Gripper 7-5

7.8 Leak Check Helium Purge Gas Flow 7-5

7.9 Replacement of the Heated Upper Soil Valve 7-6

7.10 Sample Stir Motor Speed Adjustment 7-7

7.11 Drip Pan Cleaning 7-8

7.12 Cleaning or Replacing the Syringe Plunger O-ring 7-8

7.13 Cleaning the Internal Standard Valve and Lines 7-10

7.14 Installation of the Internal Standard Vials 7-11

7.15 Shipping Instructions 7-12

8 Remote I/O Cable Hookup Instructions 8-1

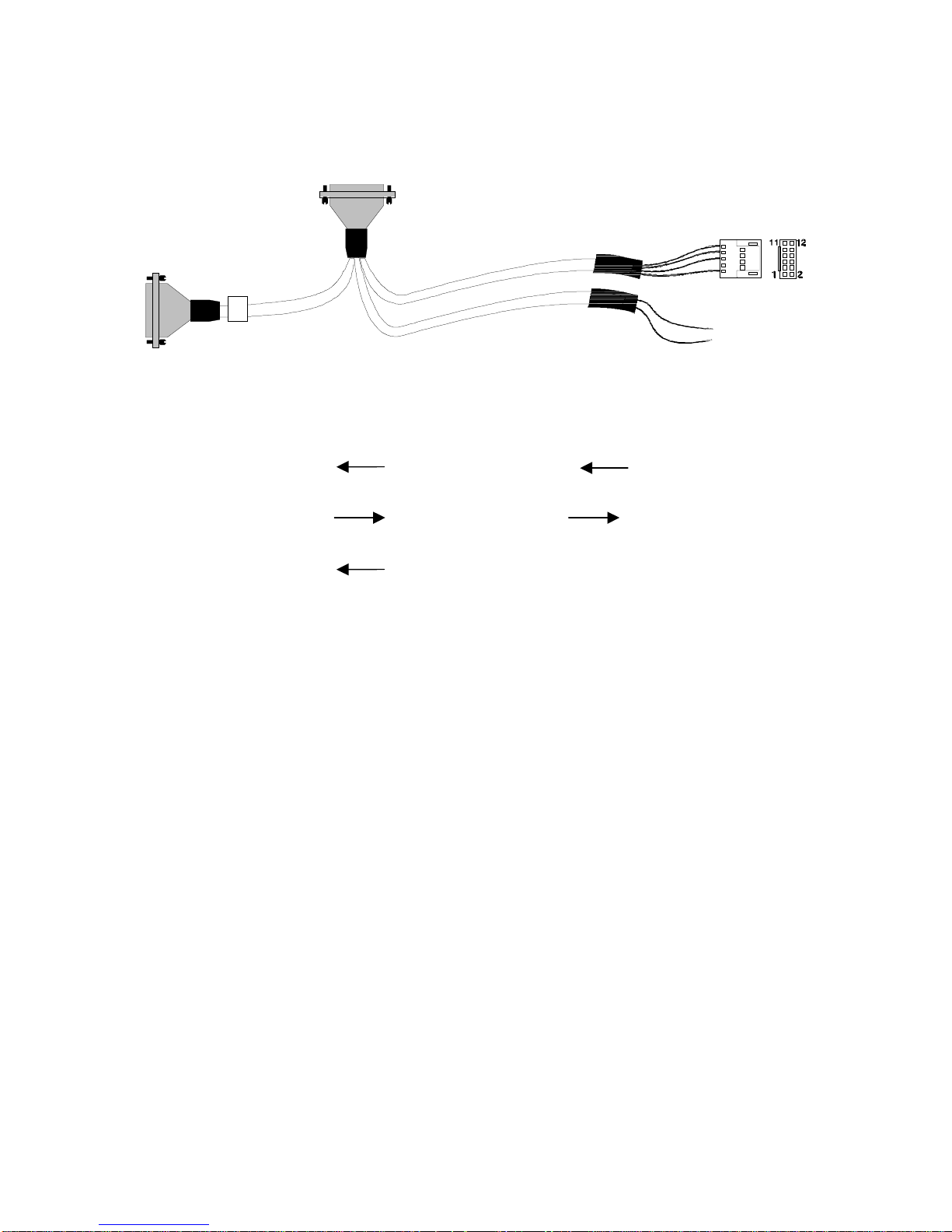

8.1 Archon to Tekmar LSC-2000 and 3000, P/N DY-505872-00 8-2

8.2 Archon to Tekmar 3000 with HP 5890, P/N DY-505869-00 8-3

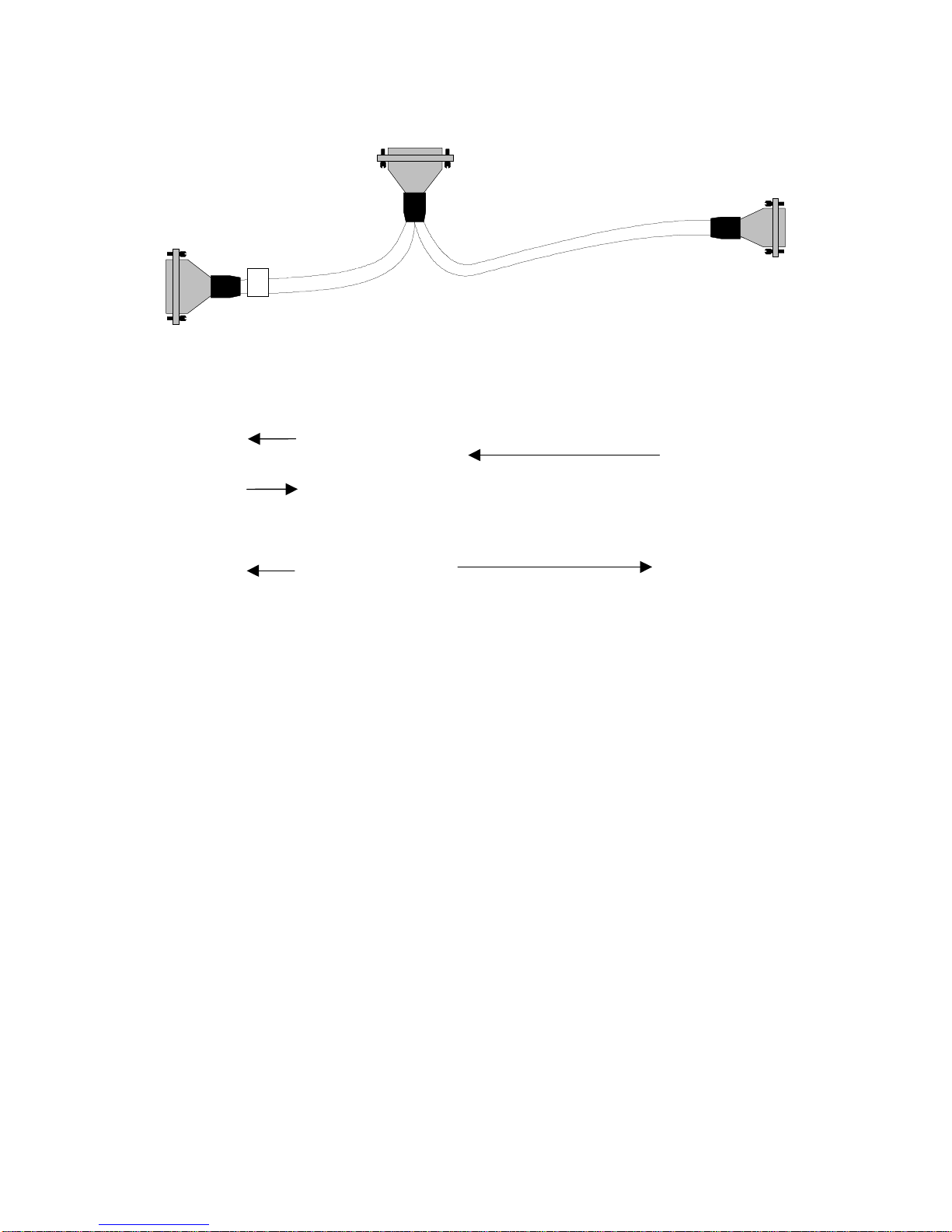

8.3 Archon to Tekmar LSC 2000/3000 with Varian 3400/3600 8-4

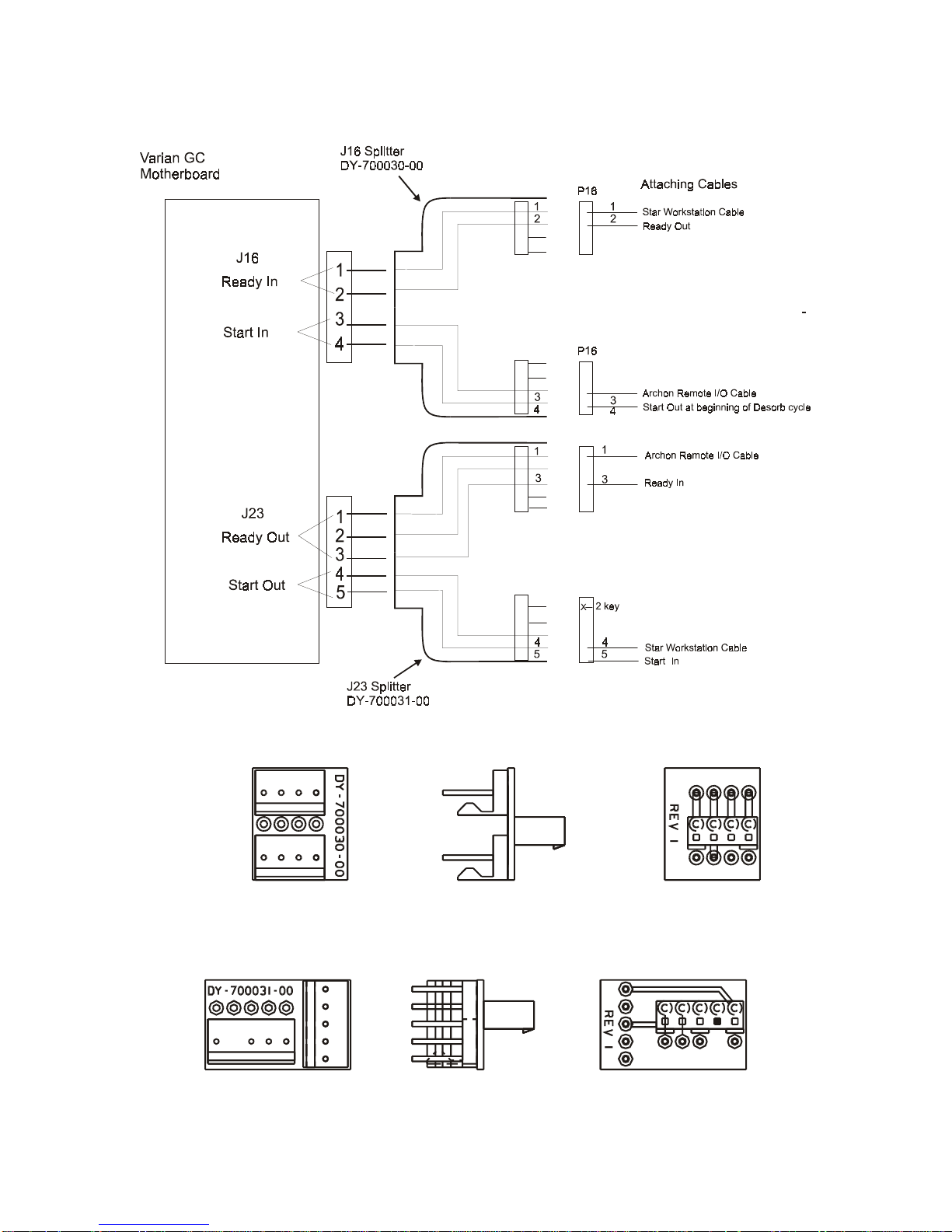

8.3.1 Varian GC Motherboard Attachments – J16 and J32 8-5

8.3.2 J-16 Splitter DY-700030-00 8-5

8.3.3 J-23 Splitter DY-700031-00 8-5

8.4 Archon to Tekmar LSC 2000 / 3000 with HP 5895/96/85/87/88/92 8-7

8.5 Archon to Tekmar LSC 2000 / 3000 with HP 5890 w/5970/71/72 8-9

8.6 Archon to Tekmar LSC 2000 / 3000 to HP 6890, P/N DY-505873-00 8-10

8.7 Archon to OI 4460/4560 with HP 5890, P/N DY-505871-00 8-11

8.8 Archon to OI 4460 / 4560 with Varian 3400/3600, P/N DY-505870-00 8-12

8.9 Archon to OI 4460 / 4560 to HP 5890, RTE HP 1000 GC / MS Software 8-13

8.10 Archon to Tekmar 2000/3000 with Varian 3800, PN 03-925673-01 8-14

03-914642-00:6

iii

Page 5

9 Error Code Screen Messages 9-1

10 Spare Parts and Service Information 10-1

11 Technical Assemblies 11-1

11.1 Front Panel 11-1

11.2 Syringe Plate 11-2

11.2.1 Internal Standard Valve Assembly 11-3

11.2.2 Mixing Solenoids / 26 mL Syringe Assembly 11-4

11.2.3 Probe Section 11-5

11.2.4 Vial Sample Stations 11-6

11.3 Interface / Transfer Line, Purge Gas Solenoid 11-7

11.4 Rear Panel 11-8

11.5 Robotic Arm 11-9

11.6 Interconnect Diagram 11-10

12 Flow Diagrams 12-1

iv

Page 6

1.1

Product Description

The Archon Purge and Trap AutoSam pler is designed to automate the tedious

sample handling procedures associated with purge and trap analysis for volatile

organic compounds (VOC's) under current EPA methods. The Archon can be

used for drinking water, waste water, soil analysis, and solids. The Archon is

designed as a stand-alone unit for retrofit to purge and trap instruments.

The Archon is a state-of-the art robotic, X-Y-Z axis autosampler. The

AutoSampler utilizes a 51 position sam ple tray that allows water or soil samples

to be run. The tray can be cooled if an optional chiller kit is ins talled. The Archon

has a unique "gripper" arm which moves the sample vial to diff erent pos itions that

will bar code read (optional), identify the vial type, stir the sample, equilibrate to

room temperature, and transfer the sample to the water or soil probe position.

When running s oil samples, the Archon automates heated purge and trap. The

soil sample may be placed in the patented SoilVial, or if the Archon is s etup for

needle sparging, a standard 40 mL VOC vial. A stirring bar (optional) is added,

the cap with a low bleed septum is replaced, and the entire vial placed in the

sample tray. The robotic arm transfer s the vial to the vial identification step, and

then lifts the vial into the heated chamber where water is added, with one or both

standards, the sample is then purged directly onto the trap of the concentrator.

1 Introduction

If a water sample is to be run, the sample is placed in a 40 mL VOC vial and a stir

bar (optional) is placed in the vial and the vial is placed in the tray. The Ar chon

robotic arm moves the vial to the vial ID station and then to the pr obe location

where it is lifted onto the sample probe, and a program med volume of water is

transferred to the purge vessel. It is during the transfer that one or both of the

standards are added to the sample. It will also drain and c lean the needle, s parge

tube, and transfer lines.

The operating modes of the Archon are the Automatic, Manual, and Flush

modes. Automatic mode allows for complete unattended operation. Manual mode

operation allows for single sample operation of the unit, priority sampling, and

running blanks. The Flush m ode perform s the flushing with hot water and helium

for the cleanup of the system. All modes perform per their programmed method.

The Archon is easily programmed through its own color-coded keypad.

Programming is m enu driven and displayed on an LCD screen. Parameters can

be read and altered and the screen displays the function in progress during the

run.

The Archon interfaces directly with the Tekmar LSC 2000, 3000, OI 4460A, 4560

and other purge and trap units.

03-914642-00:6 1-1

Page 7

1.2

Design Features

Large 51 position removable sample tray for water or soil samples.

Runs blanks from its own blank/wash water reservoir.

Programmable sample dilution using blank H

directly from the 40 mL vial.

Water sample volumes programmable in 1-25 mL increments.

Programmable mechanical stirring of water samples containing sediment prior to

sampling.

All sample pathways are chemically inert, manufactured from PEEK®, Stainless Steel,

glass, or electroformed nickel.

Programmable dual standards allow for 1 or 2 different standards to be injected with the

sample, prior to purging.

Soil samples may be purged via needle sparge option utilizing disposable 40 mL vials or

by the patented SoilVial®.

The heated soil chamber can accept matrices consisting of solids, sludges, and liquids

from SoilVials or 40 mL EPA VOC vials.

Optional sample tray cooling capability. Optional refrigerated chiller is required.

O from reservoir, e.g., 0, 2, 5, 10, and 20,

2

Priority Sample feature allows the current analysis to be interrupted for RUSH samples.

Easily readable back lit LCD display.

Fast easy programming from the touchpad keyboard.

30 programmable methods may be stored for various method configurations.

A sample may be run from any position in the tray.

Easy hook up and installation to all purge and trap systems.

Back flushes the VOC soil probe pathway with line pressure helium.

Hot water rinse utilizes a cartridge heater to heat blank water to 90C prior to flushing

sample pathways and the purge vessel.

Intelligently determines if a temperature zone exceeds its set point.

Archon utilizes a 5-position temperature equilibrium chamber that ensures samples are

equilibrated at room temperature prior to sampling.

Positively identifies programmed SoilVials and water vials prior to placement into

sampling positions.

A heated upper soil valve to eliminate cold spots in the sample pathway of samples

purged in the soil chamber.

1-2

Page 8

1.3

Specifications

Introduction

Tray Capacity:

Sample Volume:

Flush Volume:

Indoor Use

Altitude:

Operating Temperature:

Relative Humidity:

Line Voltage:

Fuse:

Installation Category:

Pollution Degree:

Heat Dissipation:

Weight:

Size:

Gas Requirements:

51 sample vials. 40 mL EPA VOC or SoilVials

0-25 mL

0-25 mL

Up to 2000 m

15C to 35C; Storage Temperature 5C to 85C

10 to 90%

115 Vac 15%, 230 Vac 15%, 50/60 Hz 3 Hz

6A, 250 Vac, SB (115V); 3.15A, 250 Vac, T-Type (230V)

II

2

2500 BTU/Hr. Max. Worst Case

Approximately 80 lbs; 36.5 Kilograms

21.5W x 17H x 20D inches

54.6W x 43.2H x 53.3D centimeters

Helium 60-90 PSI 99.999% GC/MS grade purity

1.4

Component Description

The Archon consists of a base unit with a 51 position sample tray. The s ample

tray is removable from the front. A description of components follows.

1.4.1

Front Panel

Keypad & Screen:

screen. The keypad allows for

entering or editing all information. The

LCD screen displays the information.

Keypad with LCD

Figure 1-1

03-914642-00:6

1-3

Page 9

1. Regulator: A regulator is provided for accurate

adjustment of the soil purge gas pressure and for

pressurizing the 40 mL vial during a water sample.

2. Pressure Gauge: A pressure gauge is located

above the regulator to monitor the purge gas and

to pressurize gas pressure.

3. Flow Controller: A flow controller is mounted on

the front panel to adjust the flow of purge gas

during the soil purge process.

4. Sample Tray Cover/ Door: The tray access cover

lifts up and locks to access the sample tray and

interior. The cover has a sensor mounted on the

right allowing the Archon to detect if the cover is

open. Additionally, there is a door at the bottom of

the Archon which allows the sample tray to be

removed / installed. Press the latch button and the

door will drop down.

1.4.2 Rear Panel

Power Module: The power access module has a detachable power cord and

contains the incoming line fuse, power selector and voltage selector card.

2

1

+

PURGE GAS

+

PRESSURE

_

PURGE GAS FLOW

3

Figure 1-2

Gas Input: A 1/8" Swagelok® bulkhead is used for He gas input ranged for 60-90

PSI.

Drain Line: The drain line is provided to attach to a waste bottle or a sink drain.

Remote I/O: All communication to the purge and trap and GC are m ade via the

25 pin, "D" connector. Custom built cables are des igned for each purge and trap

system to ensure correct handshaking.

Remote RS-232: A 9 pin, RS-232 "D" Connector will allow for operation via a

computer with a Windows® compatible program.

Water Connections: A water input connection is provided for supplying blank

runs, flush rinses and dilutions. A gas connection press ures the water reservior

to aid in water delivery and to ensure water cleanliness.

PAT Purge Cut Off Valve: T he Archon uses a valve to shut off the purge gas

supplied from the purge and trap concentrator during the soil purge. In this

mode, the Archon supplies the purge gas.

Sample Tray Coolant: The Archon will allow the sample tray to be cooled. An

optional recirculating bath (P/N DY-505627-00) must be purchased. Plumbing

connections for the bath are located on the lower, right rear side of the cabinet in

units shipped before March 1,1999. After that date, the plumbing kit

(DY-700085-90) must be purchased if a chiller option is installed. The liquid

coolant specifications are as follows: 10 PSI maximum pressure; temperature

range, -10 to 60C; Coolant liquid, 50/50% mix Ethylene Glycol / water, or 100%

water.

1-4

Page 10

1.4.3 Interior

Introduction

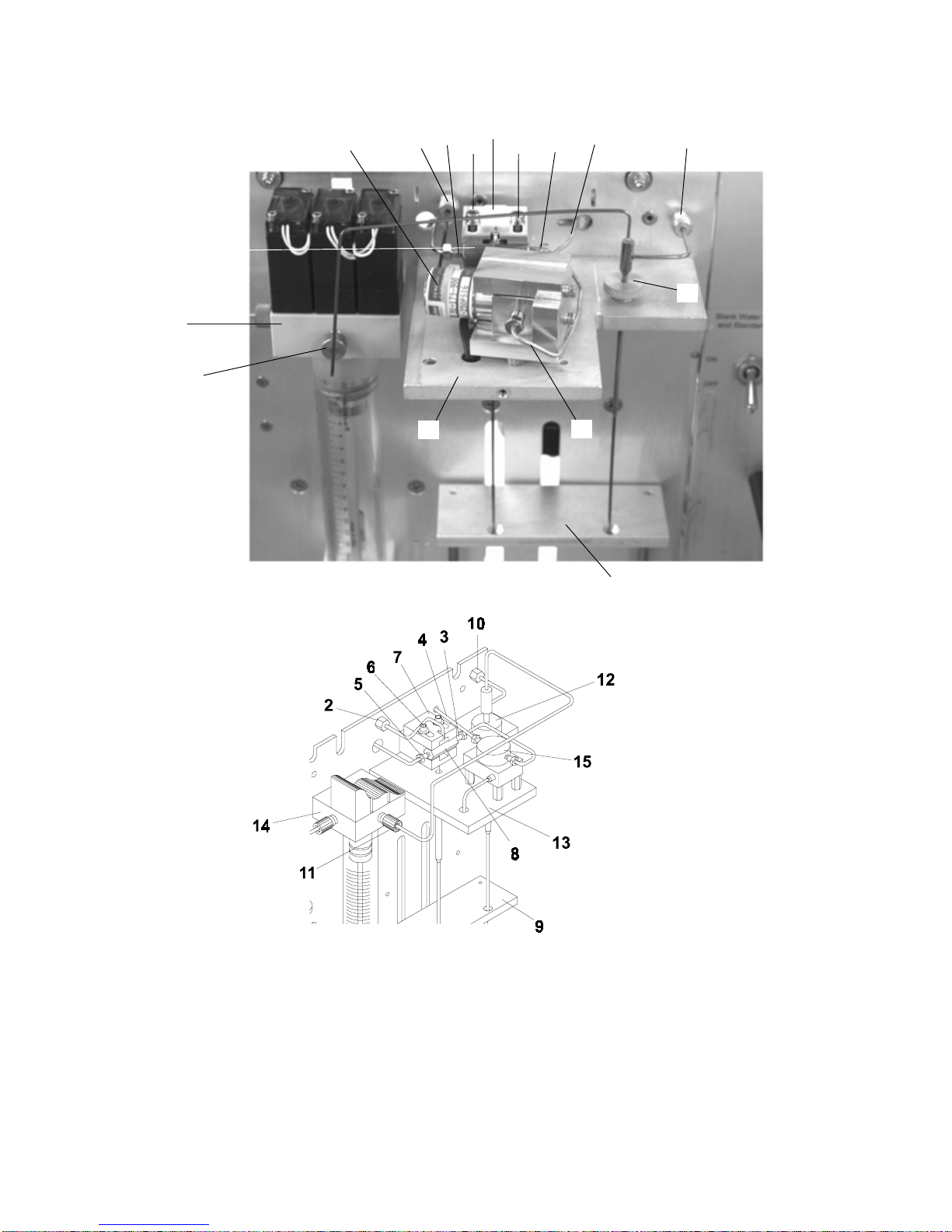

Refer to Figure 1-3.

Sample Tray (not shown): A 51 position, all aluminum, sam ple tray is provided

to hold sample vials. The tr ay is removable, and when installed, rests on top of

the aluminum tray cooler for cooling the samples.

1. Robotic Arm: The robotic arm is used to move the sample vials. A vial

gripper is used to remove the vials from the tray and place them in the

appropriate sampling positions.

2. Water Probe: The water probe is a patented concentric needle to puncture

water vials, pressurize, and displace water samples to the syringe. After

sampling, the probe is rinsed in a chamber that prevents sample from

spraying onto the instrument components.

3. Soil Probe: The patented soil probe and the Needle Sparge probes

incorporate a "T" fitting design for attachment of water and heated transfer

line. The probe is installed in a heated oven and easily removable for

cleaning or replacement.

4. 26 mL Syringe: A 26 mL syringe is used to move sam ple, blank, flush and

waste water. The syringe is mounted upright, directly into the valve manifold.

5

4

7

6

8

9

2

3

1

Figure 1-3

5. Standard Valve: The standar d injection station uses a 6 port valve with a 1

µL internal loop. The internal standard groove is filled by pressurizing the

standard reservoir and rotating the valve to positions 1 & 2, (Std. 1, Std.

2).Water samples or dilution water passes through the loop to deliver the

03-914642-00:6

1-5

Page 11

1.5

standard. Approximately 15 µL of standard solution is flushed during each

cycle.

6. Equilibrium Zone: The Archon utilizes a 5 position tem perature Equilibrium

station. If a sample has been cooled or heated, it can be cycled for an

equilibrium time in minutes, prior to analysis.

7. Vial Identification: The equilibrium station also contains the positive vial

identification sensor located in the first position from the left. This sensor

distinguishes between a SoilVial and a standard 40 mL water vial. The

second position contains the optional bar code reader used for sample

tracking.

8. Sample St ir Motor: The Archon allows the sam ple (both water and solid) to

be stirred. The motor is located below the vial sample stations. The motor

rotates a magnet which will spin a m agnetic spin bar placed in the vial. See

Section 7.11 for motor speed adjustment instructions.

9. Overflow Drip Pan: The Archon has a drip pan to collec t water in the event

of spillage. The pan has a fitting on the bottom to attach a 1/4" ID hose. Lift

the edge of the Archon and slide the 1/4" ID hose over the fitting. Route the

other end to a drain.

Vial Types

The Archon may use two different types of sample vials, depending on the

sampling type option installed. The two types of vials are shown below.

Patented SoilVial®

This vial is used if the Archon is pur chased with the

SoilVial Option installed. This double-ended vial

contains a frit at the bottom end and vial complies

with USEPA Method 5035.

use of the

on

both

ends.

bleed septum (P/N DY-504104-00)

low

This vial

requires

StanStandard 40 mL VOC vial

This is the standard USEPA approved glass vial. It

is used for water samples and for purging soil or

solid samples if the Archon is purchased with the

Needle Sparge option. When this vial is used for

purging a soil or solid sample, you

bleed septum (P/N DY-504104-00).

Vial types are NOT interchangeable. NEVER place a SoilVial in a

CAUTION

water vial location and NEVER use a SoilVial if the Archon is

configured with the Needle Sparge Option! Additionally,

permanent markers are recommended for labeling vials. If paper

labels are used, no more than two labels should be applied to

vials for reliable operation.

must

use a

the

low

Patented Standard

SoilVial 40 mL VOC

Figure 1-4

1-6

Page 12

Please read this section carefully before you begin to assemble the Archon.

2.1

Materials Needed

Regulator, single, two-stage with stainless steel diaphragm

In line on/off valve

Gas supply line tubing, minimum 1/8" diameter

Helium gas, 99.999% purity

Tools, 1/4", 1/16" open end wrenches; 3/16" blade screwdriver, Phillips screwdriver

Remote I/O Cable for communication to concentrator, see Section 8.

2.2

Unpacking the Archon

Each Archon is shipped in two cartons. The sample tray, accessory kit and

installation kit, with any optional spare parts, are shipped in a separate carton

from the Archon.

WARNING

Carefully open the shipping cartons. Lifting from the bottom remove the

Archon from its carton (the largest box). Place it on the bench to the left side

of the concentrator.

2 Site Preparation / Installation

Avoid back strain or injury by following all safety precautions

when lifting heavy objects.

Remove the sample tray, interface kit, interface cable, and any accessory or

spare items from the second carton.

Inspect for possible shipping damage or shortages. If damage is discovered,

immediately notify the carrier and Varian.

Varian Analytical Instruments

2700 Mitchell Drive

Walnut Creek, California 94598-1675

Attention: Manager of Customer Service

925-939-2400

Outside the U.S.A., notify the nearest Varian office.

Store the shipping cartons and all packing material for possible future use.

Inspect the contents against the packing list to determine if all items ordered

were received.

Locate the shipping, locking screw with spacer, on the left side of the cabinet.

This screw and spacer must be removed prior to turning the Archon on. Use a

small screwdriver to remove the screw. Save the screw and spacer for

possible future use.

03-914642-00:6

2-1

Page 13

CAUTION

If the Archon is to be shipped for any reason, the shipping screw

and spacer must be installed or serious damage will occur! See

Section 7.15

Before turning the instrument on: Check the eight blue reverse ferrule

fittings located in the sample area behind the rear panel (Section 11,

para. 11.2 and 11.4). Unscrew each fitting. Verify that the ferrule is

pushed over the tubing until the end of the tubing can be seen.

Replace and snugly tighten the nut.

Remove back panel. Locate the waste lines. Route lines through slot.

Parts and Materials Included in the Accessory Kit

2.3

The following items are included with the Archon Accessory Kit. Note: Remote I/O

cables are not included with the Archon, they must be purc hased separately. See

Section 10 for a list of cables and kits.

Operator's Manual

Blue aluminum nut

Tefzel® flange-free, ferrule, 1/16”

6 x 15 mm stir bars, pkg. of 6

1 ea. 80 oz. safety coated bottle

22 mm low-bleed septa, pkg. of 60

EPA 40 ml water vials and caps, pkg. of 12

51 position sample tray (note this is shipped in a separate box)

Composite warning labels

Water Transfer Line, SS, 1/16” x 5’ long

Stir bars (soil), pkg. of 6 (supplied with SoilVial® version only)

2 ea. SoilVial® (supplied with the SoilVial version only)

2 ea. Standard reservoir

(DY-505224-90)

Lab and Bench Space Requirements

2.4

The Archon requires bench space behind the instrument for the electrical and

helium gas connections. An additional 17” overhead clearance is required to allow

the cover to be opened.

From the rear of the Arc hon extend f lexible tubing (approx im ately 60”/1.5M) to be

connected to a blank water reservoir (80 oz./2L bottle) and to a user-supplied

waste receptacle(s). The waste receptacles must be located at or below the

height of the Archon base for proper drainage. Typically, both the blank water

reservoir and waste receptacle are placed on the floor behind the laboratory

bench.

2-2

Page 14

Site Preparation / Installation

The Archon dimensions are: 21.5W x 17H x 21D inches; 54.6W x 43.2H x 53.3D

centimeters (see Figure 2-1), and weighs approximately 80 lbs./36.5 kilograms.

17”H

21”D 21.5”W

2.5

Gas Connections

Figure 2-1

Ultra high purity helium (99.999% GC/MS grade) is required for purging soil

samples and operation of the vial gripper arm. The input supply pressure m ust be

60-90 PSI.

The helium gas line m ust be connected to the bulkhead fitting labeled “

.” Gas line must be 1/8” diam eter copper tubing and fittings mus t be 1/8"

Input

Swagelok®. Use a single, two-stage, high quality pressure regulator with a

stainless steel diaphragm. Consult your supplier for the proper type and size of

cylinder valves. An on-off, shut off valve, s hould be inst alled in the line to f ac ilitate

installation. Gas line tubing should be generous. Allow enough length, in a c oil, to

be able to move the Archon around to access the rear panel. Tighten and leak

test all connections using propanol and water.

Avoid any pipe thread connections in the supply line. If any fitting requires a

sealant, use an instrument-grade Teflon tape.

Helium

03-914642-00:6

2-3

Page 15

2.6

Electrical Connections

The Archon uses a grounded, three-pronged receptacle. Make certain the

electrical voltage is a constant source with no severe drops or spikes in the

voltage. If the power source is not certain, install a power conditioner on the

electrical line. Verify the correct fuse value and voltage selection for the line

voltage to be used.

Attach the power cord to the power receptacle on the rear panel. Check the

power switch located next to the receptacle to be certain it is OFF, plug the power

cord into a three-prong grounded outlet.

2.7

Electronic I/O Signal Connections

2.7.1 Purge and Trap Sync Cable Connector

The Archon comm unicates with the purge and trap concentrator and GC via a

cable specific to each m ake and m odel purge and trap and G C. Section 8 details

the Archon to purge and trap connections. The cable plugs into the 25-pin D

connector located on the rear of the Arc hon, labeled

of the cable attach to the purge and trap and the GC. See Section 8 for

installation instructions.

I/O signals vary; some GCs and purge and traps use normally-close contact

closures of active-high TTL logic; others us e normally-open contact closures or

active-low TTL logic. Refer to the operator's manual for each system for signal

information.

Remote IO

. The other ends

The Archon signal input configuration must be es tablished to properly receive the

purge and trap's output signals for Standby, Desorb and Stop. “

details the parameter configur ations for each of the signals. The factory default

setting for each signal is

CLOSED

2.7.2 Personal Computer Connection

The Remote RS-232 port on the Arc hon rear panel allows connection to external

computing devices. Specific software and cables are required for these

connections. Contact your sales representative for these products.

2.8

Water and Waste Lines Setup

2.8.1 Blank / Wash Bottle Setup

The Archon is supplied with an 80 oz. bottle and lines f or the blank, wash, and

dilution water. Remove the bottle from the accessory kit box. The clear line will

attach to the barbed fitting labeled “Helium” and the PEEK line will attach to the

fitting labeled “W ater.” See Figure 2-2, The Archon should be supplied with the

same high purity water (free of volatile organic c ompounds) that is used with the

purge and trap system. Rinse the bottle with purge and trap quality water then fill

it about 2/3 full with DI water. The bottle can be placed either on the bench top or

on the floor behind the Archon.

System Settings

.

”

2-4

Page 16

Figure 2-2

Site Preparation / Installation

Insert the cap, with the PEEK pickup line, into the bottle, screw the cap onto the

bottle.

NOTE: DO NOT OVERTIGHTEN THE CAP. SLOWLY TURN THE CAP

ONLY UNTIL SNUG. OVERTIGHTENING WILL SPILT THE CAP.

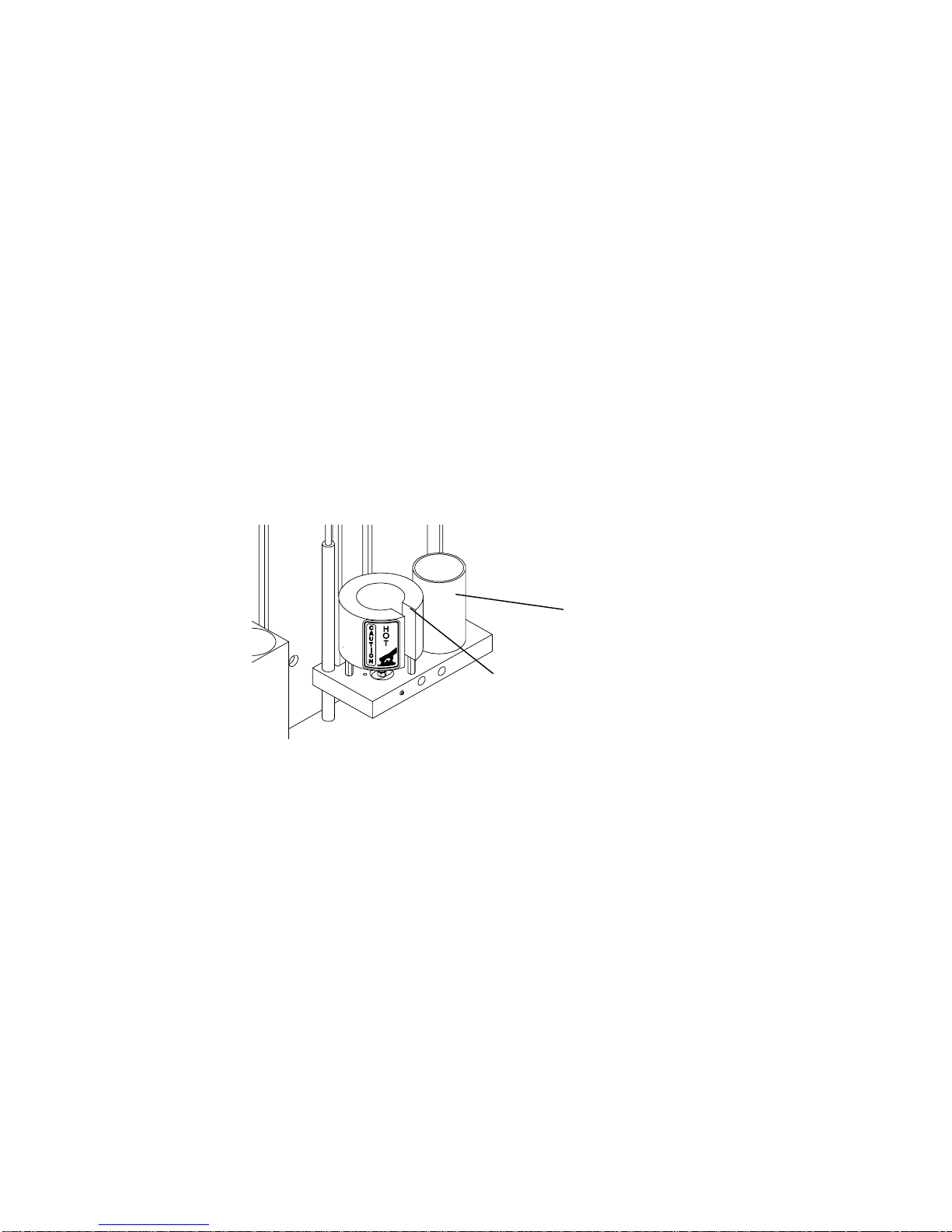

Verify the helium is turned on at the source. Turn the toggle valve for blank water

reservoir and standard helium to the ON position. The valve is located inside the

cabinet on the right rear wall, see Figure 2-3.

To test for a pressurized bottle, depress the vent button located on the blank

waste bottle plug. You should hear the release of pressure. T o refill the bottle,

turn the toggle switch OFF and vent the bottle by depressing the chrome button.

When the pressure is completely vented, remove the cap. Fill the bottle as

described above.

03-914642-00:6

2-5

Page 17

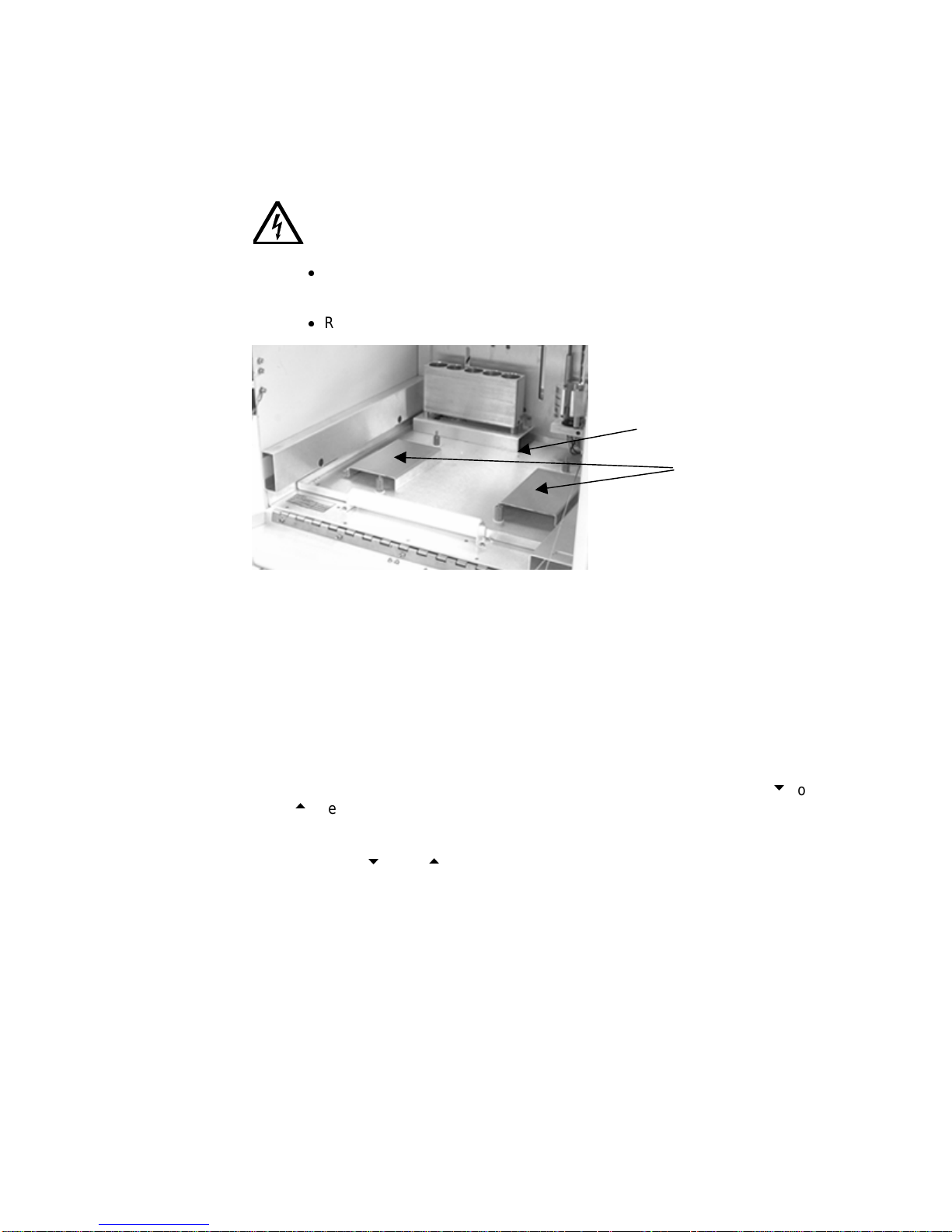

Toggle Switch

2.8.2 Waste Lines Setup

Cap

Figure 2-3

Chrome Vent

Button

2.9

Sample Tray Setup

WARNING:

SHOCK HAZARD

Remove the rear panel of the Archon and r oute the bundle of four plastic lines

through the slot in the chassis labeled “W aste Lines.” These waste lines should

empty into the user-supplied receptacles that are plac ed at a height equal to or

lower than the base of the Archon to provide proper drainage. Note that the

colored waste lines expel exces s standard solutions while the clear lines empty

waste water. The user may want to use separate waste containers f or the color ed

versus clear lines to allow different disposals.

Note: Instructions for two PEEK lines are found on page 2-12.

Remove the tray from its shipping carton. The tray is installed in the Archon

behind the lower door. Notice the tray has 51 positions and each location is

numbered. Raise the large tray cover and secure the arm loc k by gently pushing

it in the center and then lowering the cover. Press the latch button on the top

edge of the lower door and pull the door down.

Grasp the handles on the tray and insert the tray into the Archon with the number

1 position to the front left. The tr ay will rest on rollers as it is being inserted. Onc e

the tray is all the way in, it will “lock down” onto four posts. This will align the tray.

Dangerous voltages exposed when covers

are removed. Unplug power cord.

The tray must be pushed all the way to the rear most position in the

Note:

cabinet.

To remove the tray, lift the front of the tray, then slide the tray out the front on the

rollers.

The tray should be loaded by grouping the vials per the sample method chosen in

Section 5, e.g., water sample vials grouped together and soil sample vials

2-6

Page 18

grouped together. The method param eters, “First Vial - Las t Vial”, will determine

what vial numbers are run together.

The Archon vial gripper calibration coordinate settings m ust now be checked as

factory settings may have changed during shipping, therefore run the

“Calibration Test” procedure as described in Section 6.4.

Note: If any error messages appear while runing the Calibration Test, refer to

Drip Pan Drain

Site Preparation / Installation

Section 9-1. Refer to Section 6.4 for detailed calibration instructions.

Tray Posts

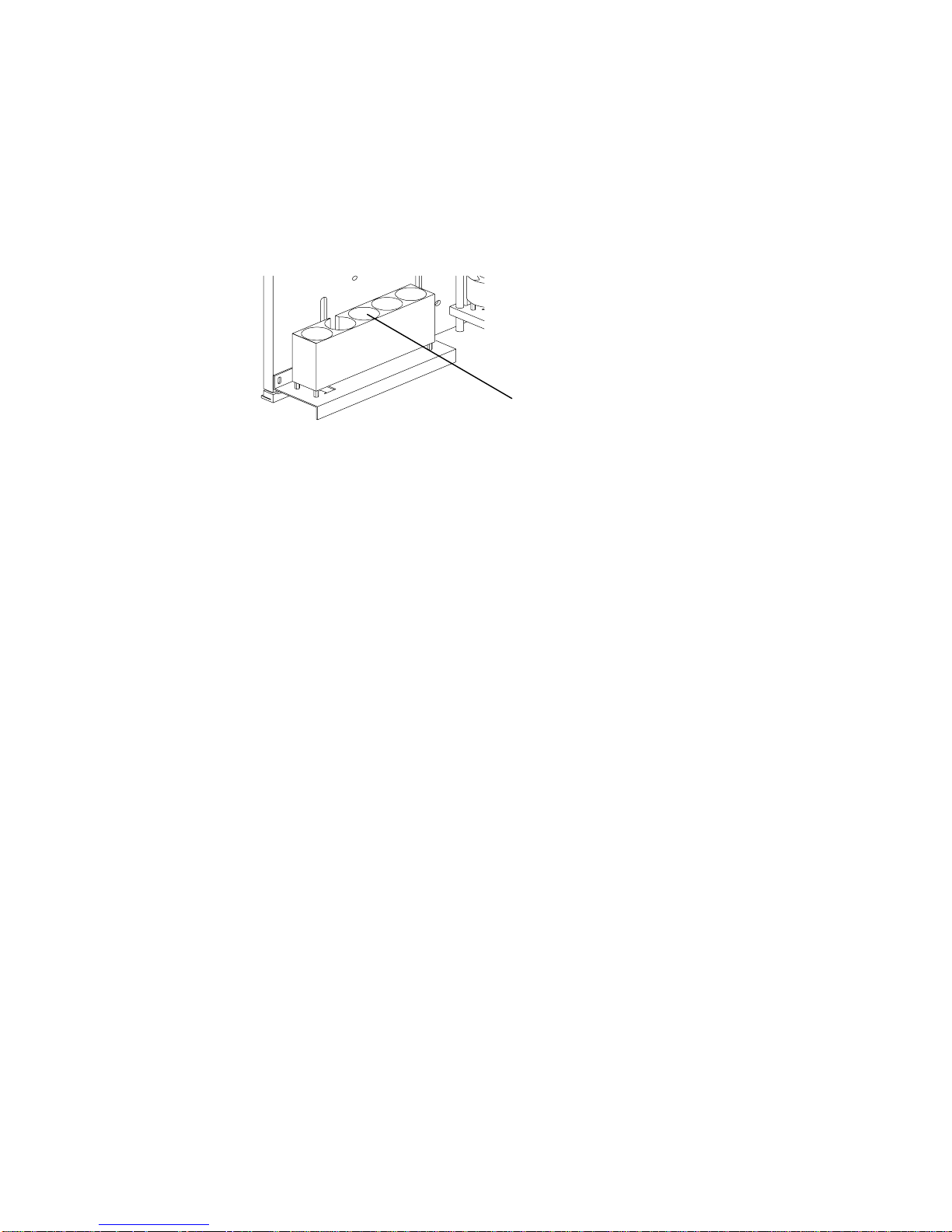

2.10

Sample Tray Coolant Setup (Optional)

The Archon sample tray can be cooled by an optional, refrigerated chiller bath

(P/N DY-505627-00), and plumbing kit (DY-700085-90) that c an be attached to

the coolant coil. It is located inside the cabinet under the tray. The tray rests on

top of the coil allowing conductive transfer of tem peratures. See Figure 2-4. The

coolant connections are located on the rear panel at the lower right cor ner and

are labeled “Tray Coolant, IN - OUT.” The tubing is 3/8" Duro. Refer to the

instructions included with the coolant and plumbing installation kit.

When the sam ple tray cooler is used, the drip pan drain MUST have a 1/4" ID

hose attached and be routed to a suitable drain. See Section 7.12 for cleaning the

drip pan.

2.11

Archon Soil Transfer Line Installation

This section will discus s the installation of the Archon sample transfer lines and

purge gas cut off solenoid valve lines to the purge and trap. This section will

explain the installation to the Tekmar 3000, 2000, and OI 4560.

Door Latch

Tray Rollers

Figure 2-4

03-914642-00:6

2-7

Page 19

Tools required are: 1/4", 2 ea. 5/16" open end wrenches, small flat blade

screwdriver, 9/64" and 3/32" Allen wrenches, and small needle nose pliers.

The installation of the Archon involves four primary steps. Note: All steps do not

apply to every purge and trap. Installation to each instrument is explained in detail

in later sections.

1. Installation of the four way “cross” fitting in the 2000 and 3000 valve oven.

2. Installation of the Archon heated soil transfer line.

3. Installation of the PEEK tubing for purge gas cut off.

4. Installation of the water transfer line.

The Archon installation kit c ontains various nuts, ferrules, and f ittings shipped in

the smaller carton with the Archon. Exam ine the c ontents of the carton to c onfirm

that all items are correct. Refer to Sections 2.1 through 2.3 for unpacking and

component details.

The installation of the Archon will require the use of two different types of nuts

and ferrules. See Figure 2-5.

28-694029-00

Valco nut with

one piece ferrule

2.11.1 Archon to Tekmar 3000

WARNING:

SHOCK HAZARD

The Tekm ar 3000 valve oven may be configured with one of two different

Note:

“tee” fittings. A 3-port on Serial Number units < 95073002 and a 4-port on units >

95073002. A 4-port cross fitting, P/N DY-505716-00 is supplied in the T ekmar

installation kit.

Replacing the 3-Port Fitting with the 4-Port Cross Fitting

in the Tekmar 3000 Valve Oven

1/8 “brass compression

nut with two piece ferrule.

28-694028-01

28-694027-01

Figure 2-5

Dangerous voltages exposed when covers

are removed. Unplug power cord.

Refer to Figure 2-6. The early Tekmar 3000 instruments (Serial numbers <

95073002) were shipped with 3-port fittings within the valve oven; c onsequently,

2-8

Page 20

Site Preparation / Installation

this does not allow the Archon to be installed. Therefore, the 3-por t f itting must be

replaced with a 4-port cross fitting.

1. Remove the top, left side and valve oven covers from the Tekmar 3000.

2. Using a screwdriver, loosen the screw which secures the thermocouple and

the clamp on the three-port fitting to the cabinet.

3. Using a 1/4" open end wrench, loosen the nuts in all three ports.

4. Loosen the two screws, which secure the sparge tube mount to the cabinet.

5. Pull the sparge tube mount and tubing, out of the 3- port fitting and off the

instrument.

6. Pull each of the other two lines out.

7. Replace the original fitting with the new 4-port cross fitting.

8. Attach all of the lines into the new fitting. Replace the sparge tube, with

mount, back on the cabinet.

Refer to Figure 2-6 for correct line placement in the new fitting.

03-914642-00:6

2-9

Page 21

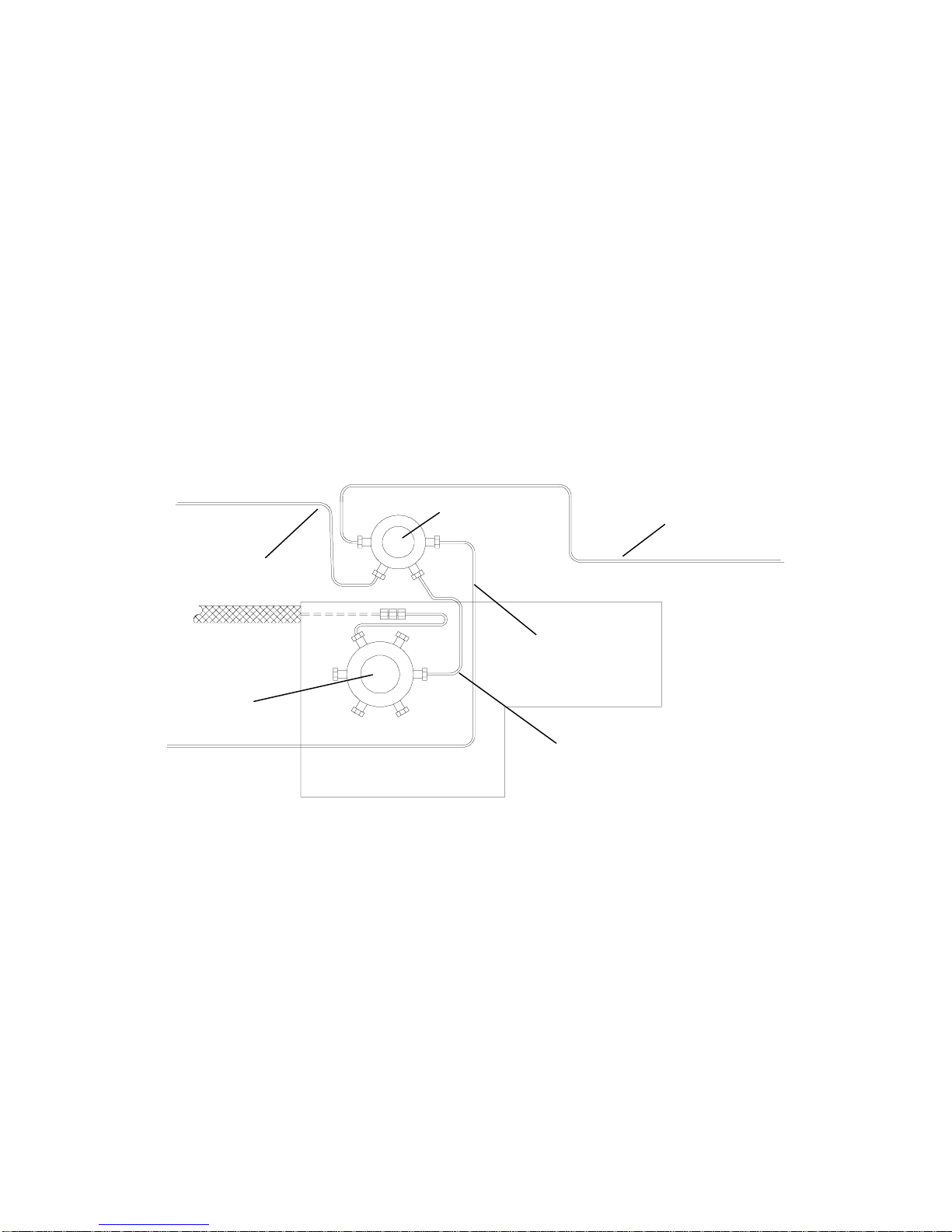

Archon Heated

Transfer Line

Assembly

DY-700001-01/02

Bolt with spacer

Transfer Line Sheath Clamp

with Standoff for GC

Transfer Line Only

GC Transfer

Line

Six Port Valve

Archon E-Form

Nickel transfer

Line

DY-505745-00

Figure 2-6

Four Port Cross Fitting

DY-505716-00

Oven

Thermocouple

Clamp

Sparge Tube Mount

Sparge Tube

2-10

Page 22

Site Preparation / Installation

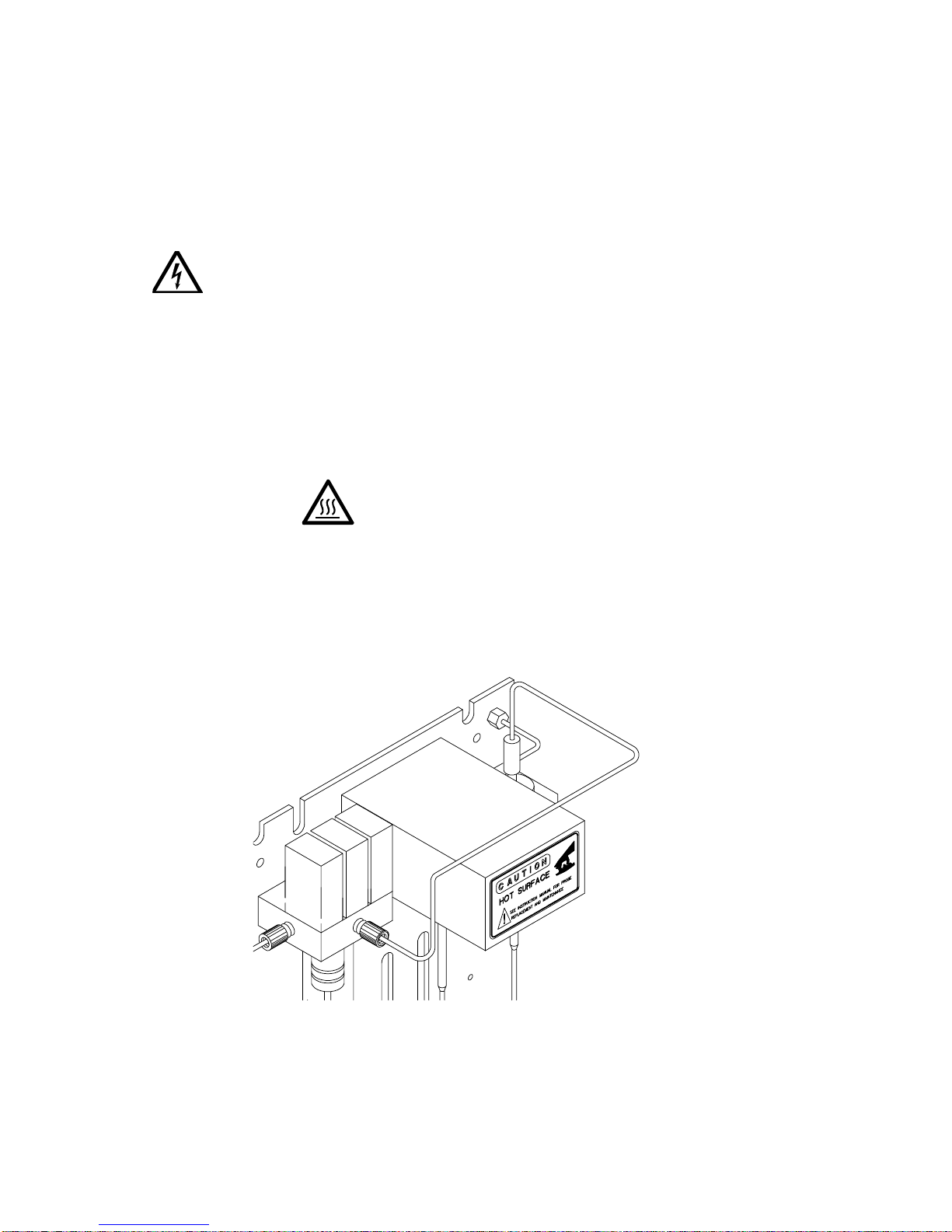

Installation of the Heated Soil Transfer Line Assembly to the Purge and Trap

Refer to Figure 2-7 and Figure 2-8. Rem ove the accessory kit from the shipping

carton. Examine the contents and verify all items are correct. Remove the top, left

side and valve oven covers from the Tekmar 3000. Refer to the Tekm ar 3000

manual. Remove the rear panel from the Archon. Remove the Archon heated

transfer line and the water transfer line from the accessory kit.

1. Remove the plug in the Tekmar 3000 valve oven, 4-port cross fitting. This

fitting contains the lines to the six port valve, s parge tube and dry purge, the

fourth port contains the plug. Note: If your Tek mar 3000 does not have a 4port fitting see paragraph 2.11.1.

2. Insert the Archon transfer line assembly into the rear of the 3000. Fit the

Archon line assembly into the Tekmar 3000 transf er line channel. The Archon

line will rest on the top of the Tekmar 3000 GC transfer line.

3. Bend the end of the Archon nickel transf er line, so it will fit into the open port

on the 4-port cross fitting. Using a 1/4" open end wrenc h, tighten the nut. See

Figure 2-6. Be careful not to kink the line.

4. Push the two lines down into the channel.

Installation of the Heated Transfer Line to the Archon

1. Inside the Archon, use an Allen wrench to loosen the screw securing the

probe and upper soil valve cover. Rem ove the cover. Remove the ins ulation

block.

2. Insert the free end of the transfer line into the rear of the Archon, the line will

pass the open slot. Attach the transfer line bracket to the panel with the two

#4 socket head screws already installed in the rear panel.

3. Attach the transf er line to the upper soil valve using a 1/4" open end wrench.

See Figure 2-8.

4. Reinstall the insulation block and the probe cover and screw.

Note: On units =>12146, Heated Transfer Line is already installed on the

Archon.

03-914642-00:6

2-11

Page 23

Archon Heated

Transfer Line

Heated

Transfer Line

Channel

Tekmar Heated

GC Transfer

Line Assembly

Figure 2-7

Assembly

Installation of Purge Gas Lines

Soil

Transfer

Line

Upper Soil

Valve

Cap Screw

(cover removed)

Figure 2-8

See Figure 2-9.

1. Remove the current purge

gas line from the “Purge”

fitting on the 3000 and the

sparge tube.

2. Connect the blue PEEK

tube to the “purge” out fitting

on the 3000. Use 1/16” nut

and ferrules for this

connection.

3. Connect the red PEEK tube

to the sparge tube fitting.

Use 1/16” nut and ferrules

for this connection.

4. Route the peek tubing lines

through the notch in the rear

panel of the Archon labeled

“waste lines”.

Water

Transfer

Line

Blue PEEK

Tube Connects

Here

Red PEEK

Tube Connects

Here

Sparge Tube

Fitting

Reverse

Ferrule

Fitting

Figure 2-9

½” SS

Nut

2-Way

Sample

Valve

Water Transfer Line Installation

The Archon transfers , cleans, and dilutes liquid sam ples to the sparge tube via a

five-foot stainless steel line and attaches to the 2-way valve on the top of the

sparge tube. Refer to Figure 2-9.

2-12

Page 24

1. Locate the nut and ferrule and the line from the accessory kit.

2. Uncoil the line. Locate the tan-colored PEEK valve body manifold inside the

right rear of the Archon. Slide the line into the fitting on the left. T ighten the

fitting by hand.

3. Route the line through the “notch” in the rear panel of the Archon labeled

“Waste Lines.” Route the line to the purge and trap.

4. The line will attach to the black 2-way valve on the top of the sparge tube.

5. T urn the handle so the valve is open toward the Ar chon trans fer line. Look in

the port to ensure the holes are aligned.

6. Slide the nut and reverse ferrule over the line and insert into the port on the

left side of the toggle valve. Tighten the nut.

7. Replace the rear door panel.

8. Remove sparge vessel. Make a slight bend about 3” (7.2 cm ) from end of

needle. (This maximizes the rinse ability of the Archon.)

Note: Make sure needle is not touching frit.

Tekmar 3000 Setup Specifications

After the Archon is installed, the T ekmar 3000 MUST be properly configured for

the I/O switch closures and method parameters to function correctly. This will

enable the Archon and the purge and trap to properly communicate.

Site Preparation / Installation

Use the hand held controller and press:

1. Conf

<A>= GC I/O port

B =Gas Flows

C =Installed Option

Select <A>

GC Port (standard/user) select “standard”*

GC Type=(63/31) Select “63”

GC Handshaking - (ON/OFF) Select “ON”*

Use the (-) key to toggle.

Press “Enter” after selection is made

*Note: Refer to cable hook-ups (pages 8-2 to 8-12).

2. Sched

A=Sample status

C=Commands

<E>=Edit Schedules

Select <E>

Start Stop Meth RPS

1) 0 0 14 1

2)

3)

03-914642-00:6

2-13

Page 25

To move cursor across page, Enter a “number” (0) and press Enter.

3. Meth

Method 14

Type Aquatek 50

Note: If Aquatek 50 is not selected the purge and trap will not send a

ready signal.

C=Command <E>=Edit

Enter the number 14 and press “Enter”. Select the “type” (63/31)

according to GC selection. Now, Select <E>.

Press “next page” until

Line Temp _____

Valve Temp _____

Then press “next page” until:

Sample fill - 0

Purge TIme 11.0

Then press “next page” until:

Sample Drain ON

Then press “next page” until:

BGB OFF Delay 0

4. Sched

A=Sample Status

<C>=Commands

E=Edit Schedule

Select <C>

<A>=Run Schedule

B=Update Schedule

C=Clear Schedule

Select <A>

This will load “New” method. To ver ify look in the upper right hand corner of the

key pad, “Display”, “M” and the new method selected should be displayed.

2.11.2 Archon to Tekmar 2000

WARNING:

SHOCK HAZARD

Remove the mounting hardware fr om the ac cessory kit shipping c arton. Exam ine

the contents and verify all items are correct.

To properly interface the Archon to the Tekmar 2000, a 4-way fitting must be

installed in the 2000 valve oven. Note the following installation procedures.

Verify that both the Archon and the Tekmar 2000 are turned

OFF and the power cords are disconnected before starting

the installation.

2-14

Page 26

Site Preparation / Installation

Installation of the 4-port Cross Fitting and the Heated Soil Transfer Line in the

Tekmar 2000 Valve Oven

Refer to Figure 2-10. Remove the trap c over, left side panel, right side panel, top

and the valve oven cover from the Tekmar 2000 as described in the Tekmar 2000

manual.

1. Using a 1/4" open end wrench, remove the three lines attached to the tee

inside the Tekmar 2000 valve oven. Remove the tee. Refer to the Tekmar

2000 plumbing diagram to confirm line locations.

2. Attach to the bottom right port of the new 4-way fitting, the short line attached

to the 6-port valve.

3. Attach the line from the sparge tube (previously removed from the Tekmar

2000 tee) to the upper left port on the new fitting.

4. Insert the Archon heated transfer line into the rear of the 2000, through the

hole labeled “ALS.” Attach the line to the bottom left port on the new fitting.

5. Attach the line from the “Dry Purge” valve (previously removed f rom the 2000

tee) to the top right port of the new fitting.

6. Check all fittings to ensure they are tight.

Transfer Line to

Archon

2000 6 Port

Valve

LSC 2000 Valve Oven

Figure 2-10

Installation of the Heated Soil Transfer Line

1. Inside the Archon, use an Allen wrench to loosen the screw securing the

probe and upper soil valve cover. Rem ove the cover. Remove the ins ulation

block.

2. Insert the free end of the transfer line into the rear of the Archon, the line will

pass the open slot. Attach the transfer line bracket to the panel with the two

#4 socket head screws already installed in the rear panel.

3. Attach the transf er line to the upper soil valve using a 1/4" open end wrench.

See Figure 2-12.

New 4 Port Tee

Sparge Tube Line

Line to Dry

Purge Valve

Line to 6 Port

Valve

4. Reinstall the insulation block and the probe cover and screw.

03-914642-00:6

2-15

Page 27

Hole

Soil

Transfer

Line

Bracket

Archon Heated

Transfer Line

GC Transfer Line

Figure 2-11

Installation of the Purge Gas Lines

Refer to Figure 2-13.

1. Remove the purge gas supply line at the fitting on the LSC 2000.

2. Connec t the blue PEEK tube to the purge gas supply fitting on the 2000. Use

1/16” nut and ferrules for this connection. Refer to Figure 2-13.

3. Connect the red PEEK tube to the sparge tube fitting. Use 1/16” nut and

ferrules for this connection. Refer to Figure 2-13.

4. Route the peek tubing lines thr ough the notch in the rear panel of the Archon

labeled “waste lines”.

Archon Water

Transfer Line

Upper Soil

Valve

Cap Screw

(cover removed)

Figure 2-12

2-way Sample Valve

Red PEEK Tube

Connects here

Sparge Tube Fitting

2-16

Blue PEEK Tube

Connects here

Purge Gas Supply Fitting

Figure 2-13

Page 28

Water Transfer Line Installation

The Archon transfers, cleans and dilutes liquid samples to the sparge tube via a

five-foot stainless steel line and attaches to the 2-way valve on the top of the

sparge tube. Refer to Figure 2-13.

1. Locate the nut and ferrule and the line from the accessory kit.

2. Uncoil the line. Locate the tan-colored PEEK valve body manifold inside the

right rear of the Archon. Slide the line into the fitting on the left. T ighten the

fitting by hand.

3. Route the line through the “notch” in the rear panel of the Archon labeled

“Waste Lines.” Route the line to the purge and trap.

4. The line will attach to the black 2-way valve on the top of the sparge tube.

5. T urn the handle so the valve is open toward the Ar chon trans fer line. Look in

the port to ensure the holes are aligned.

6. Slide the nut and reverse ferrule over the line and insert into the port on the

left side of the toggle valve. Tighten the nut.

Site Preparation / Installation

7. Replace the rear door panel.

8. Remove sparge vessel. Make a slight bend about 3” (7.5 cm ) of needle. ( T his

maximizes the rinse ability of the Archon.)

Tekmar 2000 Setup Specifications

After the Archon is installed, the Tekmar 2000 MUST be properly configured to

allow the I/O switch closures and method parameters to func tion correct ly. These

settings will cause the Archon and the purge and trap to properly communicate.

Confirm the following setpoint parameters have been established:

Set the bake gas bypass to: OFF.

Set the U012 DIP switch to: 3 open, other closed.

Turn the Autodrain: ON

Confirm the Desorb Time; be certain the Archon and

the purge and trap times match.

03-914642-00:6

2-17

Page 29

2.11.3 Archon to OI 4560

Remove the installation and accessory kits f rom the shipping carton. Examine the

contents and verify all items are correc t. The Archon m ay be positioned on either

the right or left side of the OI 4560.

WARNING:

SHOCK HAZARD

Remove the accessory kit from its shipping carton. Examine the contents and

verify all items are correct.

Be certain both the Archon and the OI 4560 are turned OFF

and the power cords are disconnected before starting the

installation!

Installation of the Heated Soil Transfer Line to the OI 4560

Refer to Figure 2-14.

1. Remove the plug installed in the AS port on the side of the OI 4560 spar ge

tube mount.

2. Slide the heated transf er line assembly through the two clamps. Attach the

clamps, with line, to the bracket us ing the #6-32 x 1/2" screws with nuts and

lock washers.

3. Slide the spec ial fitting (P/N DY-505727-00), provided in the Installation Kit,

onto the transfer line. Carefully bend the line and insert it, with the f itting, into

the AS port on the OI 4560. W ith a 5/16" wrench, tighten the larger nut first.

Push the line into the fitting and tighten the 1/4" nut.

4. Check all fittings and screws to ensure they are tight.

Installation of Purge Gas Lines

Refer to Figure 2-14.

1. Rem ove the OI 4560 purge gas line from the sparge tube and the outlet port

on the front of the 4560.

2. Connect the blue PEEK tube to the purge gas outlet on the OI 4560. Use

1/16” nut and ferrules for this connection.

3. Connect the red PEEK tube to the sparge tube fitting. Use 1/16” nut and

ferrules for this connection.

4. Route the peek tubing lines thr ough the notch in the rear panel of the Archon

labeled “waste lines.”

2-18

Page 30

Water transfer Line

Site Preparation / Installation

Heated Transfer

Line Assembly

From Archon

(red PEEK tube)

Purge Gas Outlet

(Blue PEEK tube connects here)

Compression Nut on

Sample Valve for

Water Transfer Line

Clamp

VOC

Transfer Line

Special 4560 Fitting

Sparge Tube

Fitting

Figure 2-14 Installation of soil transfer line to O.I. 4560

03-914642-00:6

2-19

Page 31

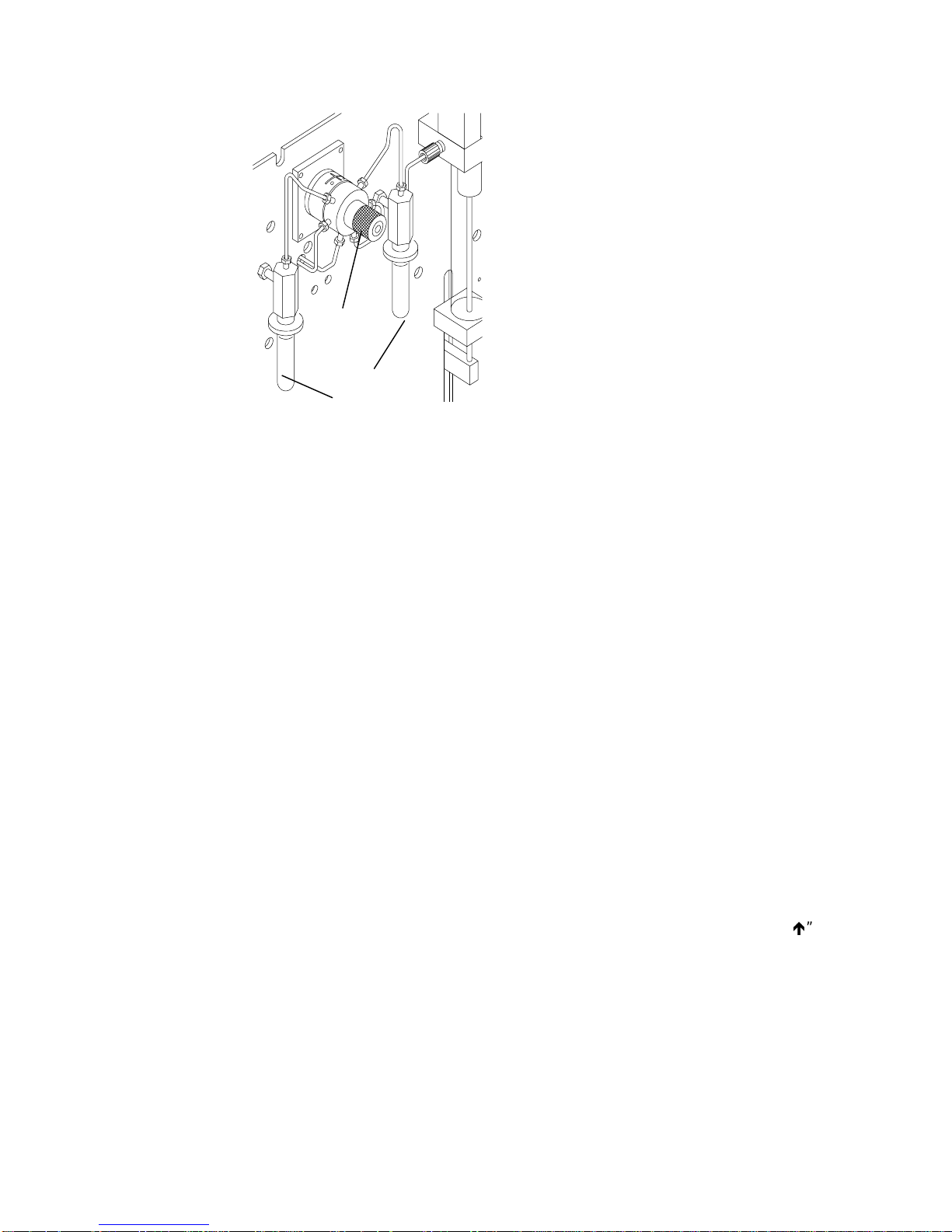

Installation of the Heated Transfer Line to the Archon

Refer to Figure 2-15.

1. Inside the Archon, use an Allen wrench to loosen the screw securing the

probe and upper soil valve cover. Rem ove the cover. Remove the ins ulation

block.

2. Insert the free end of the transfer line into the rear of the Archon, the line will

pass the open slot. Attach the transfer line bracket to the panel with the two

#4 socket head screws already installed in the rear panel.

3. Attach the transfer line to the upper soil valve using a 1/4" open end wrench.

4. Reinstall the insulation block and the probe cover and screw.

Soil Transfer

Line

Upper Soil

Valve

Figure 2-15

Cap Screw

(cover removed)

2-20

Page 32

Water Transfer Line Installation

Refer to Figure 2-16. The Archon transf ers, cleans and dilutes liquid samples to

the sparge tube via a five-foot stainless steel line and attaches to the 2-way valve

on the top of the sparge tube. Remove the rear panel of the Archon.

1. Locate the nut and ferrule and the line from the accessory kit.

2. Uncoil the line. Locate the tan-colored PEEK valve body manifold inside the

right rear of the Archon. Slide the line into the fitting on the left. T ighten the

fitting by hand.

3. Route the line through the “notch” in the rear panel of the Archon labeled

“Waste Lines.” Route the line to the purge and trap.

4. The line will attach to the black 2-way valve on the top of the sparge tube.

5. Rotate the two-way valve above the sparge tube so the ports are facing left

and front. The Luer fitting should be to the front. Remove the drain line. Us ing

a 5/16” wrench, install the modified Swagelok union with rubber washer to the

port on the left side. Route the line around the left side of the purge and trap

to the sample valve.

Site Preparation / Installation

6. T urn the handle so the valve is open toward the Ar chon trans fer line. Look in

the port to ensure the holes are aligned.

7. Slide the nut and reverse ferrule over the line and insert into the modified

Swagelok union. Tighten using two 5/16” wrenches.

8. Replace the rear door panel.

9. Remove sparge vessel. Make a slight bend about 3” (7.5 cm ) from end of

needle. (This maximizes the rinse ability of the Archon.)

Sample Valve Handle

Sample Valve

Modified Union

Water Transfer Line

Figure 2-16

03-914642-00:6

2-21

Page 33

OI 4560 Setup Specifications

These Parameter settings will ensure handshaking of the OI 4560 and the

Archon.

Note: The sample mount heater cartridge option should be installed to

minimize carryover.

1. From the keypad on the OI 4560, select: 2nd function - Configure and select

“STATES”, then press ENTER; Use the keys to select INPUTS or

OUTPUTS, then press ENTER.

2. Select INPUTS PRG - RDY or

Desorb RDY: If PRG - RDY is selected, set, Wait For Start, ON, then

ENTER; If Desorb RDY is selected, set, Wait For RDY, ON, then ENTER.

3. Press the “Clear” key.

4. Select OUTPUTS, then ENTER; Select Desorb - Output at Start ON

5. Press the “Clear” key.

6. Select Flows, then ENTER; Config. Desorb then Bake. First, Desorb -

Sample Drain ON, then ENTER, second, Config. Bake - Sample Purge ON,

then ENTER.

7. Press the “Clear” key to exit.

Soil Helium Purge Gas Flow Adjustment

2.12

Before running a soil sample the helium purge gas f low rate s hould be se t. T his is

accomplished by the helium purge gas flow controller (1), pressure adjustment

regulator (2), and gauge (3) located on the front right side of the Archon, see

Figure 2-17.

1. Adjust the purge gas regulator until the gauge

reads 20 -25 psi.

2. Load a clean vial with a new septum in the tray

and run a manual soil sample using this vial (see

Section 4.2).

3. Once the soil purge begins, check the f low rate at

the purge vent on the host purge and trap. Adjust

the helium purge gas flow controller on the Ar chon

to give the desired purge gas flow rate through the

purge and trap unit (typically 40 mL/min for m any

methods).

Note:All units are set to 40mL/min prior to

shipping.

+

PURGE GAS

PRESSURE

_

+

PURGE GAS FLOW

Figure 2-17

3

2

1

2-22

Page 34

2.13

Loop Calibration for Internal Standard

The absolute volume of the internal loop of the standard valve must be

determined to achieve accurate sample data. The stated 1 µL volume is

approximated within the stated tolerance from the valve manufacturer. For

absolute internal standard accuracy, use the following calibration procedure

before beginning your sample analysis.

1. Prepare a reference standard equivalent to a 1 µL volume injection via the

valve.

2. Run the calibration standard by hand (put 5 mL directly into the sparge tube.

Site Preparation / Installation

3. Run blanks in the Archon manual mode.

4. Calibrate the internal standard data by comparing the Archon data to the

2.14

Installation Checklist

Verify the following during and after installation of the Archon.

Be sure the manual mode

Note:

program calls for internal standard when running the blanks.

hand standard.

Be certain the sample tray is pushed all the way to the rear most

position in the cabinet.

Confirm the supply helium pressure is between 70-90 PSI 5 PSI.

Be certain the handle, on the black sample valve located on top of the

sparge vessel, is rotated in the position of the water transfer line.

Do not overtighten the cap on the blank/wash bottle. To properly

tighten the cap, turn it until snug, then stop.

Be certain the septum used for the soil samples is

P/N DY-504104-00. It is extremely important that this low bleed

septum is used because it is formulated for maximum sealing ability

with minimum bleed of siloxane compounds that might interfere with

chromatographic results.

This procedure will check all of the new fittings installed at the 4-way

03-914642-00:6

The caps, when used on SoilVials, must be tightened 1/4 turn past

finger tight to prevent leakage. A slight depression can be observed in

the septum when the cap is properly tightened.

Please review Sections 7.3 and 7.4, in this manual, “Cleaning the Soil

Transfer Line Frit and Replacement of the Water Line Screen.”

Perform system leak check on the purge and trap as specified in the

Tekmar LSC 2000, 3000, OI 4460 and OI 4560 manuals.

cross in the Tekmar 3000 & 2000 and at the external upper soil valve

supplied with the Archon.

2-23

Page 35

Lines attached to the upper soil valve must be installed with a Valco

stainless nut, P/N 28-694501-00 and a set of Swagelok stainless

ferrules, P/N 28-693996-00 and 28-693997-00.

Perform a soil purge leak check by checking and balancing flows at

the soil probe gas outlet bulkhead Swagelok fitting. Record flow rates.

Also, check flow at the vent fitting on the host purge and trap. (Flow

should be within 2 ml per minute.) Record flow rates.

Check vial calibration settings. The vial MUST move freely in and out

of the tray without resistance. Refer to Section 6.4.

Permanant marker pens are recommended to label sample vials.

Otherwise, no more than two labels should be applied to the vials.

MUST

The waste bottle or drain

be placed at a location which is equal

to or lower than the base of the Archon.

Make sure the sample needle in the sprage tube does not sit centered

or flush on the glass frit. The needle should touch the side of the

glass and sit slightly above the frit.

Review Sections 3, 4, 5, and 6.

Run a water method program (Section 5.4.1).

Run a soil method program (5.4.2).

Note: Use 7-10 mLs of clean H

0 for (Install Samples) on soil.

2

2-24

Page 36

3.1

General

3 Keypad Definition & Layout / Screen Display

The keypad provides a complete numeric pad as well

as a motion operation pad for the X -Y-Z axis arm. The

keypad is coupled with a 4 line, 20 character LCD

screen for displaying programming and status

information. The inf ormation will include the current vial

number, sample process sequence, temperatures,

remaining time in a run, Auto or Manual sample

indications, method parameters, warning indicators, and

general status information.

The keypad can be segmented into three key types:

See Section 4,

Figure 3-1

Operational, Setup, and Special.

Operation Keys, for a complete description of

operational key functions.

Numeric keys are used to enter numeric values 0-9 for

entering numeric information such as time or

temperature programming.

Operational Keys

Auto

Manual

Flush

Pause/Stop

Setup Keys

Method

System

Starts the autosampling procedure, see Section 4.1.

Starts a single sampling procedure or runs a Priority Sample,

see Section 4.2.

Performs the water/helium gas flush sequence of the sample

path, see Section 4.3.

Provides a pause in the current operation and/or a complete

abort of the current operation.

Selects a Method for editing and modifies the various Method

parameters.

Provides access to System Operation, Configuration,

Maintenance and System Diagnostics menus.

03-914642-00:6

3-1

Page 37

Special Keys

Enter

4, 6,

8, 2

—

Used to terminate the entry of a numeric or menu item selection.

It also serves as a scroll down key when selecting the Method

parameter setting.

Used to scroll up within the Method Parameter setting. Also used

to toggle the current motor selection and place the Archon in

“SYSTEM HOLD.”

Acts as a “backspace key.” Allows erasure of the current value of

any data entry item.

These keys have dual functions. They are numeric as well as

directional keys. These keys are used to scroll up or down for

menu selection and operation of motors in “System Calibration.”

This is an Escape Key. It can be used to exit a menu.

3-2

Page 38

4.1

Auto Key

The AUTO key starts the Archon autosampling sequence. When the AUTO key is

pressed the screen displays three lines:

The Method Number line will be in brackets (< >). Enter the correct Method

number using the numeric keypad, press ENTER. The BACKSPACE (

allows changing the Method number if nec essar y. Note: Pressing ENT ER without

changing the current Method Number will accept the default to the last Method

used. Pressing the UP

the method is selected, press ENTER. The 'START AUTORUN' will now be

bracketed, press ENTER, the AutoRun operation will now begin.

To start the Archon at a later tim e, use the 'DELAYED ST ART ' feature. Using the

"2" key, scroll down to the <DELAYED START> command line. Press ENT ER .

The screen will now display a menu line <Delay xx.xx hours>. Use the num eric

keypad to enter the amount of time delay before starting the AutoSampler

sequence. Note: The time entered will be in hours and hundredths of an hour.

Once the value is entered press ENT ER. The scr een will display time rem aining

before start, <Delayed Start xx.xx>.

4 Operation Keys

Keypad Display Entry Range

AutoSampler Start *

<Method Number: xx>

START AUTORUN

DELAYED START

(

) key, will backup the cursor to the previous line. Once

1-30

)

key

While the AutoRun is in progress, the Run-Time Screen will be displayed.

Keypad Display Entry Range

*Method xx * Auto

Vial = xx Soil (Water, Blank)

Vol = xx xx: 1 STD = 1 2

Current Status

* AutoSampler Start *

Exit

AUTORUN has been started, only the PAUSE / STOP key can be used to

interrupt the run. If a priority sample (additional sample to be run outside the

AutoRun sequence) is to be run, refer to Section 4.2

menu by pressing the AUTO key. However, once

Status only

(No user entries)

03-914642-00:6

4-1

Page 39

4.2

Manual / Priority Sample Key

The MANUAL key starts a single sam ple or Priority run. When the MANUAL key

is pressed the screen displays four entry selections:

Keypad Display Entry Range

*Manual Sample*

<Sample Vial #>

Method Number xx

Sample Type: Soil > (Water, Blank)

<START RUN>

The “Sample Vial#” (this is ignored if it is a BLANK) is now bracketed. Note, the

vial position number displayed is the last position entered. Using the numeric

keypad enter the correct vial position number. Press ENTER.

An incorrect vial type will cause severe damage to probes, needles

CAUTION

Using the numeric keypad enter the Method number containing the correct

Sample / Blank param eters, press ENTER. T he Sample Type will be updated to

the method’s sample type. If no change is made the method num ber defaults to

the last one used.

or vials. The sample vial location number entered contains the

correct vial type for the sample method to be run. If the “vial type”

is not turned on in Section 6.7, System Options, the Archon will not

identify a vial type automatically.

1-51

1-30

Soil, water blank

The “Sample Type: Soil” (W ater or Blank m ay be displayed depending on the last

sample type run). The sample type will be determined by the method selected.

The ‘”START RUN” is now brack eted, press ENTER. The MANUAL run will now

begin.

4.2.1 Running a Priority Sample During an AutoRun.

The Manual key is also used to interrupt an AutoRun to process a Priority

Sample. When the Manual key is pressed during the AutoRun, the screen will

display the following menu lines.

Keypad Display Entry Range

*Priority Sample*

<Sample Vial # = xx>

Method Number xx

Sample Type: Water, Soil

<PRIORITY RUN>

1. Enter the vial position number of the Priority Sample then press ENTER.

1-51

1-30

(Determined by method)

4-2

Page 40

Operation Keys

2. ENTER the Method Number for the type of sample to be run. Press ENTER.

3. Press ENTER again sc heduling the Priority Sample. A “P” will appear in the

upper left corner informing the user a Priority Sample has been scheduled.

The Priority Sample will begin after the current sample in progress is

completed, including any programmed blanks.

4. After c ompletion of the Priority Sample, the Pause Message will appear on

the screen.

Keypad Display Entry Range

4.3

System Paused

Enter to resume

Stop to reset

The Manual, Method, or Flush key may be pressed to perform additional

functions, or the ENTER key may be pressed to resume the AutoRun.

To cancel out of the Priority Sample menu, press the Manual key again.

Flush Key

The system is automatically flushed between samples. However, you may want to

manually flush the system if contamination or carryover occurs. The Flush Key

offers four options to decontaminate the water and soil sample pathways.

The FLUSH key displays the following menu. This key is only operational in

Manual mode. If an AutoRun is in operation the key will be ignored.

Keypad Display Entry Range

STATUS ONLY

(no user entries)

1. Drain the sparge tube

2. Flush the 26 ml syringe

3. Rinse the sparge tube

4. Backflush the water probe with helium

*Manual Flush*

<Drain Sparge Tube>

Flush Syringe

Rinse Sparge Tube

<Backflush W Probe>

Enter to resume

Stop to reset

Select the desired menu line by scrolling through the selections with the “ 2 “ or

“8 “ keys.

03-914642-00:6

4-3

Page 41

4.3.1 Drain Sparge Tube

The DRAIN SPARGE TUBE menu line will be highlighted with brackets (< >).

Press ENTER to initiate draining the sparge tube. A two-line menu appears:

Keypad Display Entry Range

* Drain Sparge Tube*

<Drain Volume: xx>

Drain Sparge Tube*

Enter a drain volume from 1-25 ml. Pres s ENTER. T he “Drain Sparge Tube” line

will now be in brackets. Press ENTER to start the drain.

4.3.2 Flush Syringe

To initiate the “Flush Syringe” sequence use the “2 ” Key to scroll down to the

“Flush Syringe” menu line. The command line will now be bracketed. Press

ENTER. The screen will display a menu with three selections:

Keypad Display Entry Range

*Flush Syringe*

<Flush #Times: xx>

Flush Volume: xx

Flush Syringe

1-25

1-20

1-25

Using the numeric keypad enter the desired num ber of flushes , from 1- 20. Press

ENTER, scrolling to the next menu line, “Flush Volume.”

Enter a value from 1-25 ml. Press ENTER key scrolling to the next menu line,

“Flush Syringe.” Press ENTER again to initiate the Flush Syringe sequence. Note,

this Flush sequence will only flush the 26 ml sample syringe.

4.3.3 Rinse Sparge Tube

The Manual Flush mode will also allow rinsing of the sparge tube and the 26 ml

syringe simultaneously. Use the “2” or “8” keys to scroll to the menu line

“Rinse Sparge Tube.” Press ENTER, the screen will display three menu lines.

Keypad Display Entry Range

*Rinse Sparge Tube*

<Rinse # Times: xx>

Rinse Volume: xx

Rinse Sparge Tube

1-20

1-25

4-4

Page 42

4.3.4 Backflush Water Probe

This function allows the water probe to be flushed with hot blank water and

helium. W ith the “2 ” or “8 “ keys scroll to the “<Backf lush W Probe>” menu

line, press ENTER. The flush process will begin immediately. The waste block will

be lifted then the probe flushed with hot blank water followed by helium. This

Backflush will occur each time the menu line is selected.

Keypad Display Entry Range

*Running* BACKFLUSH

Vial = NA Sam=NA

Vol=

Backflush W Probe

4.4

Pause / Stop Key

The “Pause / Stop” key is a multif unction key. Pressing the key once during an

AutoRun performs a PAUSE function.

Keypad Display Entry Range

System paused. Press

Enter to resume

Stop to reset

Operation Keys

4.5

System Hold

After the key is pressed the screen will display an “S” in the upper corner

indicating the Pause / Stop has been pressed. Onc e the sam ple run is c omplete

the “S” is removed, then the following message appears on the screen. The

Manual, Flush, Method and System keys are now functional.

Methods may be edited, Manual Sample may be perform ed, or any of the System

parameters can be changed. Press ENTER to resume the AutoRun from the

point it was paused.

Pressing the key twice will cause an abort /stop run, the Archon will then return to

a Standby state after going through the start-up sequence.

The Archon may be placed in a “HOLD” state by pressing . Once the key is

pressed, the Archon will HOLD the sequence it is cur rently running and display

“SYSTEM HOLD” on the bottom of the screen. Note, it does not effect the

robotic arm, standard motor, syringe motor or elevator motor. These movem ent

items must stop before the “SYSTEM HOLD” will tak e effect. To continue from

HOLD, press any key but the Pause/Stop key.

During SYSTEM HOLD, the timers will continue to run.

Note:

03-914642-00:6

4-5

Page 43

4-6

Page 44

5.1

Method Editing

The Archon allows 30 methods to be edited and saved into a battery backed

memory. To edit these parameters, press the Method key. The * Method * m enu

will be displayed. Enter the method number from 1-30, and press ENTER.

The menu line <EDIT METHOD> will now be bracketed. Press ENTER again.

The menu for editing parameters will now be displayed.

5.2

Sample Method Parameters

Pressing ENTER will cycle through each parameter to allow changes to be made.

Use the numeric keys to enter new values or the “2” and “8” and “4” “6”

keys as scroll keys. To scroll up in the menu use .

If an invalid entry is made, the system will change the value to be within the

allowable range.

5 Method Setup

Keyboard Display Entry Range

*Method* 1-30

<Method: XX>

EDIT METHOD

EDIT BLANK VIALS

To exit * Method Parameters * press the Method key again. Any changes will be

automatically saved.

Methods can be built for water, soil, or blank samples using the following

procedures. Although all parameters are listed below, only certain ones apply to

each method type. Recommended parameters for blank water and soil sample

are described in Section 5.4.

Parameter Range Default Description

Sample Type Soil, Water,

Blank

First Vial 1-51 01

Water

This selection will establish the type of

sample or blank to be run. A blank

method allows a series of blanks to be run

between other methods.

This is the first to be run using the

method. If

selected enter 1. (The First Vial, Last Vial,

parameter indicates the number of blanks

to be run. It does not indicate the vial

positions as in the water and soil

methods.)

BLANK

sample type is

03-914642-00:6

5-1

Page 45

Parameter Range Default Description

Last Vial 1-51 01

Sample Volume

Dilution

Factor

0-25 ml

0,2,5,10,

20,50,100

05

NO

This is the last vial or blank number to be

run. If BLANK sample type is selected,

enter the last number of blank to be run.

For example if you want two blank to be

run enter first vial=1 and last vial =2.

If the sample Type selected is Water or

Blank, this is the volume removed from

the sample vial or Blank/Wash bottle and

transferred to the sparge vessel. Note: If

the sample type selected is Soil, a

minimum of 3 ml of dilution water must be

selected in order for Standards to be

accurately added. The volume may be set

in 1 ml increments

The dilution factor shows the ratio of the

total volume of water sample and blank

water blended together to the volume of

24.3 mls., DF-NO is no dilution, DF-2 is 1

volume sample blended with 1 volume

blank water (50% dilution), DF-50 is 1

volume sample blended with 49 volumes

blank water (98% dilution). The “4” key

is used to change the dilution factor.

Rinse Volume 0-25 ml 05

#Rinses 0-20 01

Standard 1 YES/NO NO

Standard 2 YES/NO NO

S. PreHeat

YES/NO NO

Stir

Volume of rinse water used to flush the

PAT sparge tube during the bake mode.

The volume may be set in 1 ml

increments.

Number of times the sparge tube will be

flushed, using the rinse volume above,

during bake mode.

This parameter will enable or disable the

addition of 1 µl of standard #1 to the

Sample or Blank or into the Soil vial.

This parameter will enable or disable the

addition of 1 µl of standard #2 to the

Sample or Blank or into the Soil vial.

This parameter turns the stirring motor on

or off during the Soil PreHeat cycle. It can

be used to break up the solid sample.

Note: This is a soil only parameter.

5-2

Page 46

Parameter Range Default Description

Method Setup

Stir YES/NO NO

W. Stir Time

(min.)

W. Settle

0-9.9

0.0 min

minutes

0-99 seconds 00sec

Time (sec)

Syringe Flush 0 -20 YES

PreHeat YES / NO YES

PreHeat Temp

amb/140C40

This parameter turns the Soil mechanical

stirrer on during purge time, or the water

mechanical stirrer on for a sample mixing

prior to sampling.

The Stir motor will run for the length of

time entered for this parameter.

Note: This is a water method only

setting.

This time allows particulates in the

sample to settle back to the bottom of the

vial after the Stir process. This time is

used after stirring a Water sample.

This parameter allows hot water to be

flushed in the 26 mL syringe and out to

waste.

This parameter will allow the sample to

heat prior to purging. The heating will

occur after the water is added. Note: This

is a soil method only setting.

C

This parameter sets the temp for the

preheating of the sample. Note: This is a

soil method only setting.

PreHeat Time 0-99.9 min. 3-0 min.

Purge Time

(min.)

Desorb Time

(min)

0-999.9

minutes

0-99.9

minutes

11.0 min

2.0 min

This parameter sets the time for

preheating of the sample. Note: This is a

soil method only setting.

This is the time the sample will be purged.

This parameter must match the time

programmed on the purge and trap

concentrator. Note: This is a soil

method only setting.

This parameter must match the time

programmed on the purge and trap

concentrator. The purge vessel is auto

drained back to the Archon waste bottle

during desorb.

03-914642-00:6

5-3

Page 47

Parameter Range Default Description

Operate Mode Local /

Remote

Remote

Cycle Timer 0-99.9 min. 00.0 min.

This Mode determines if the Archon will

depend on switch signals from the purge

and trap to advance, or be dependent on

the Cycle Timer. In the “Local” Mode,

the Archon will start when the Cycle

Timer parameter, set in the method has

elapsed. NOTE: In Local, the Ar chon will

NOT respond to switch signals from the

purge and trap, i.e. Standby (Ready) and

Desorb Ready. In the “Remote” Mode,

the Archon responds to the switch signals

given by the purge and trap and the Cycle

Timer parameter. Once the purge and

trap reaches its Standby mode, a signal

output will start the Archon, provided the

Cycle Timer has reached 0.0.

This will advance the Archon from a ready

to sample mode. T he Archon starts when

a purge ready signal is received from the

purge and trap, in the standby mode. The

cycle includes the purge time, plus the

GC run time and cool down. The cycle

time is normally used to ensure that the

GC will be ready to receive the next

sample. In the case of short GC run

times, cycle time will not be effec tive, and

should be set to "0.”

Auxiliary

Timer

Link to

Method

0-99.9 min. 00-0 min.

0-30 0-00

This is a timed event output used to start

or stop additional external equipment.

The timer starts af ter the s ample goes out

the sparge tube for a water or a blank

sample or at the start of the purge for a

soil sample.

The Archon will continue the sampling

sequence for this method upon

completion of the current selected

method. Any combination of methods

may be linked together providing for

continuous operation. Note: Circular

linkage of a method is allowed, i.e.,

linking a method to itself to continually

cycle through one method. Set the

parameter to "0" to stop the autosampler

after the last vial in the method.

5-4

Page 48

5.3

Blanks After Vial Editing

Single blank runs can be programmed after specific sample vials within a

particular method. These are known as "Method Blanks" and complement the

alternative of creating a whole method where all of the runs are blanks.