Page 1

NOTICE: Varian, Inc. was acquired by Agilent

Technologies in May 2010. This document is provided

as a courtesy but is no longer kept current and thus

will contain historical references to Varian. For more

information, go to www.agilent.com/chem.

Varian, Inc.

2700 Mitchell Drive

Walnut Creek, CA 94598-1675/USA

Saturn® 2000 GC/MS

MS Workstation

Version 6

Operation Manual

©Varian, Inc. 2003-2009 Printed in U.S.A. 03-914979-00:5

Page 2

Page 3

Contents

Getting Started........................................................................................................................11

About this Manual/Help ............................................................................................................................................11

Additional Manuals/Help...........................................................................................................................................11

MS Workstation Toolbar ........................................................................................................13

Overview...................................................................................................................................................................13

Elements of the MS Workstation Toolbar.................................................................................................................14

Launching Applications from the MS Workstation Toolbar

Using the Application Icon Buttons...........................................................................................................................19

Using the Data File and Method Quick Link buttons................................................................................................19

................................................19

MS Workstation Toolbar Options..........................................................................................21

Moving the MS Workstation Toolbar........................................................................................................................21

The MS Workstation Toolbar Options Menu............................................................................................................21

2000 MS Module Control........................................................................................................25

Starting System Control the First Time ....................................................................................................................25

Configuring the Instrument.......................................................................................................................................25

Configuring the 3800 or 3900 GC Communication (No Company Network) ...........................................................32

Configuring the GC for a Company Network............................................................................................................34

Using a Password to Protect BOOTP Settings ........................................................................................................39

Adding a GC and Varian MS to the Instrument in System Control ..........................................................................41

2000 MS Instrument Control Command Reference

Saturn Module Dialogs.............................................................................................................................................47

2000 Module Window...............................................................................................................................................48

2000 MS Instrument Window

The 2000 MS Instrument Window............................................................................................................................59

Status and Control Window......................................................................................................................................73

.................................................................................................59

.............................................................47

3800 GC System Control Window.........................................................................................99

The Instrument Window............................................................................................................................................99

The 3800 GC Status and Control Window.............................................................................................................100

Documenting Module Information ..........................................................................................................................104

3800 GC Injecting a Single Sample.....................................................................................107

Overview.................................................................................................................................................................107

Using the Inject Single Sample Dialog Box............................................................................................................107

Specifying the Data File Name and Path ...............................................................................................................108

1

Page 4

Specifying Per-Sample Data Handling Parameters ...............................................................................................109

Specifying a RecalcList ..........................................................................................................................................110

Monitoring the Status of the Run............................................................................................................................110

Using QuickStart.....................................................................................................................................................111

3800 GC Injecting Multiple Samples ...................................................................................113

Introduction.............................................................................................................................................................113

Using a SampleList in System Control...................................................................................................................113

Specifying the Data File Name and Path ...............................................................................................................115

Specifying Per-Sample Data Handling Parameters ...............................................................................................116

Specifying a RecalcList ..........................................................................................................................................116

Changing Default SampleList Entries.....................................................................................................................117

Reading Vial Positions from an 8200 AutoSampler ...............................................................................................117

Monitoring the Status of Runs................................................................................................................................118

Saving SampleLists for Later Use..........................................................................................................................119

Using More Than One Method for Injections..........................................................................................................119

3900 GC System Control Window.......................................................................................123

The Instrument Window..........................................................................................................................................123

The 3900 GC Status and Control Window.............................................................................................................124

Documenting Module Information ..........................................................................................................................128

3900 GC Injecting a Single Sample.....................................................................................131

Overview.................................................................................................................................................................131

Using the Inject Single Sample Dialog Box............................................................................................................131

Specifying the Data File Name and Path ...............................................................................................................132

Specifying Per-Sample Data Handling Parameters ...............................................................................................132

Specifying a RecalcList ..........................................................................................................................................133

Monitoring the Status of the Run............................................................................................................................133

Using QuickStart.....................................................................................................................................................134

3900 GC Injecting Multiple Samples ...................................................................................137

Introduction.............................................................................................................................................................137

Using a SampleList in System Control...................................................................................................................137

Specifying the Data File Name and Path ...............................................................................................................139

Specifying Per-Sample Data Handling Parameters ...............................................................................................140

Specifying a RecalcList ..........................................................................................................................................140

Changing Default SampleList Entries.....................................................................................................................141

Monitoring the Status of Runs................................................................................................................................141

Saving SampleLists for Later Use..........................................................................................................................142

Using More Than One Method for Injections..........................................................................................................142

System Control Menus.........................................................................................................145

File Menu................................................................................................................................................................145

Edit Menu................................................................................................................................................................146

Inject Menu.............................................................................................................................................................147

Automation Menu....................................................................................................................................................147

Recalculate Menu...................................................................................................................................................148

Instrument Menu.....................................................................................................................................................148

Windows Menu.......................................................................................................................................................149

Help Menu ..............................................................................................................................................................150

2

Page 5

System Control Toolbar.......................................................................................................151

Main Toolbar...........................................................................................................................................................151

2000 MS Method Basic Scan Functions .............................................................................153

Introduction.............................................................................................................................................................153

2000 MS Method Chemical Ionization.................................................................................155

Introduction.............................................................................................................................................................155

The Chemical Ionization Scan Function.................................................................................................................155

Ion Formation By Chemical Ionization....................................................................................................................157

The CI Parameters .................................................................................................................................................158

Chemical Ionization Using Fixed Parameters ........................................................................................................162

Using Liquid CI Reagents.......................................................................................................................................162

Adjusting the CI Reagent Gas Pressure for Gases Other Than Methane.............................................................165

Tuning for CI Operation..........................................................................................................................................166

Low-Pressure CI vs. High Pressure CI...................................................................................................................166

Recommended Reading.........................................................................................................................................167

2000 MS Method Command Reference...............................................................................169

Spreadsheet editing................................................................................................................................................169

The CI Parameters .................................................................................................................................................175

CI Fixed Parameters...............................................................................................................................................176

Ion Storage (SIS) Parameters................................................................................................................................177

Customize SIS........................................................................................................................................................177

The MS/MS Ion Prep Method.................................................................................................................................178

The MS “q” Calculator ............................................................................................................................................178

Ion Preparation MS/MS..........................................................................................................................................183

MSn.........................................................................................................................................................................185

2000 MS Method Electron Ionization ..................................................................................189

The Electron Ionization Scan Function with Automatic Gain Control (AGC) .........................................................189

Ion Formation..........................................................................................................................................................190

AGC Prescan..........................................................................................................................................................190

Mass Scanning.......................................................................................................................................................191

Basic Equation of the AGC Software .....................................................................................................................192

Software Parameters..............................................................................................................................................193

2000 MS Method Ion Preparation

The Ion Preparation Method...................................................................................................................................199

Theory of Operation of the SIS Option...................................................................................................................201

Selected Ion Storage (SIS) Parameters.................................................................................................................202

Customize SIS........................................................................................................................................................203

Tips for Using SIS...................................................................................................................................................205

The MS “q” Calculator ............................................................................................................................................205

........................................................................................199

2000 MS Method MS/MS Option: Theory of Operation.....................................................207

Overview.................................................................................................................................................................207

The MS/MS Ion Prep Method.................................................................................................................................212

The MS “q” Calculator ............................................................................................................................................214

Customize Non-resonant Method...........................................................................................................................214

Customize Resonant Method................................................................................................................................217

3

Page 6

Tandem Mass Spectrometry (MS/MS)...................................................................................................................219

Automated Methods Development.........................................................................................................................221

MS/MS....................................................................................................................................................................224

Unit Resolution Selected Ion Storage ....................................................................................................................224

MS/MS/MS..............................................................................................................................................................224

2000 MS Method Section......................................................................................................227

Overview.................................................................................................................................................................227

Using Star Assistant to Create a New Method.......................................................................................................227

The Method Builder Window ..................................................................................................................................230

The 2000 MS Method Windows .............................................................................................................................231

The Flow Sampling Segment .................................................................................................................................233

2000 MS Method System Control

The Startup Method................................................................................................................................................235

Editing Methods from the Saturn Status and Control Window...............................................................................236

Changing Method End Time from the Saturn Control and Status Window............................................................236

Importing Method Sections.....................................................................................................................................237

Deleting Method Sections.......................................................................................................................................238

Printing the Method ................................................................................................................................................239

Password Protecting a Method ..............................................................................................................................239

........................................................................................235

3800 GC Method Command Reference...............................................................................241

3800 GC AutoSampler ...........................................................................................................................................241

3800 GC Sample Delivery......................................................................................................................................248

3800 GC Injector ....................................................................................................................................................249

3800 GC Flow/Pressure.........................................................................................................................................253

3800 GC Column Oven..........................................................................................................................................256

3800 GC Detector...................................................................................................................................................257

3800 GC Output......................................................................................................................................................265

3800 GC Data Acquisition......................................................................................................................................266

3800 GC Method Section......................................................................................................267

Overview.................................................................................................................................................................267

Using Star Assistant to Create a New Method.......................................................................................................267

The Method Builder Window ..................................................................................................................................270

The 3800 GC Method Windows .............................................................................................................................271

Sample Delivery Window........................................................................................................................................274

Injector Window......................................................................................................................................................276

Flow/Pressure Window...........................................................................................................................................281

Column Oven Window............................................................................................................................................285

Detector Window ....................................................................................................................................................286

Output Window.......................................................................................................................................................294

Data Acquisition Window........................................................................................................................................295

Autosampler Window..............................................................................................................................................296

Auto-Configuring the Method to Match the 3800 GC Hardware ............................................................................297

Uploading the Method from the 3800 GC...............................................................................................................297

The Startup Method................................................................................................................................................298

Editing Methods from the 3800 Status and Control Window..................................................................................298

Importing Method Sections.....................................................................................................................................299

Deleting Method Sections.......................................................................................................................................300

Printing the Method ................................................................................................................................................301

Password Protecting a Method ..............................................................................................................................301

4

Page 7

3800 GC System Control Command Reference.................................................................303

Status and Control Window....................................................................................................................................303

Setup Ethernet Ports Dialog Box............................................................................................................................327

8400/8410 SampleList Window Extensions...........................................................................................................330

3900 GC Method Command Reference

3900 GC AutoSampler ...........................................................................................................................................333

3900 GC Injector Section .......................................................................................................................................341

3900 GC Flow/Pressure Section............................................................................................................................343

3900 GC Column Oven Section.............................................................................................................................344

...............................................................................333

3900 GC Method Section......................................................................................................345

Overview.................................................................................................................................................................345

Using Star Assistant to Create a New Method.......................................................................................................345

The Method Builder Window ..................................................................................................................................348

The 3900 GC Method Windows .............................................................................................................................349

GC Control Window................................................................................................................................................352

Autosampler Window..............................................................................................................................................356

Auto-configuring the Method to Match the 3900 GC Hardware.............................................................................357

Uploading the Method from the 3900 GC...............................................................................................................357

The Startup Method................................................................................................................................................358

Editing Methods from the 3900 Status and Control Window..................................................................................358

Importing Method Sections.....................................................................................................................................359

Deleting Method Sections.......................................................................................................................................360

Printing the Method ................................................................................................................................................362

Password Protecting a Method ..............................................................................................................................362

3900 GC System Control Command Reference.................................................................363

Status and Control Window....................................................................................................................................363

Setup Ethernet Ports Dialog Box............................................................................................................................377

8200 AutoSampler Instrument Control Command Reference .......................................... 381

8200 AutoSampler Status and Control Window.....................................................................................................381

8200 SampleList Window Extensions....................................................................................................................385

8200 Method Command Reference

8200 Configuration Window ...................................................................................................................................389

Automated MS Report Generation

Overview.................................................................................................................................................................393

.....................................................................................389

......................................................................................393

Automation File Editor Command Reference ....................................................................395

Menus.....................................................................................................................................................................395

Main Toolbar...........................................................................................................................................................397

Open Automation File Dialog Box ..........................................................................................................................398

Save Automation File As Dialog Box......................................................................................................................399

Print Setup Dialog Box ...........................................................................................................................................400

Edit Notes Dialog Box.............................................................................................................................................401

RecalcList Window.................................................................................................................................................402

SampleList Window................................................................................................................................................408

5

Page 8

Sequence Window..................................................................................................................................................414

Automation File Editor.........................................................................................................415

Overview.................................................................................................................................................................415

Accessing the Automation File Editor.....................................................................................................................415

Editing or creating a RecalcList..............................................................................................................................415

Editing or creating a SampleList.............................................................................................................................417

Specifying the Data File Name and Path ...............................................................................................................419

Specifying Per-Sample Data Handling Parameters ...............................................................................................420

Specifying a RecalcList ..........................................................................................................................................421

Changing Default SampleList Entries.....................................................................................................................421

Using More Than One Method for Injections..........................................................................................................422

Editing or Creating a Sequence .............................................................................................................................423

GC Batch Report...................................................................................................................425

Overview.................................................................................................................................................................425

Method Selection....................................................................................................................................................426

Generating Reports................................................................................................................................................427

Changing Report Commands.................................................................................................................................427

GC Data Handling Calibration .............................................................................................429

Types of Calibration................................................................................................................................................429

Preparing the Method for Calibration .....................................................................................................................429

Automated Calibration............................................................................................................................................430

Inspecting Calibration Curves ................................................................................................................................431

Generating Calibration Block Reports....................................................................................................................433

Calibration Verification............................................................................................................................................434

GC Data Handling Fundamentals........................................................................................435

Introduction.............................................................................................................................................................435

Performing a Pilot Run ...........................................................................................................................................435

Peak Detection .......................................................................................................................................................436

Identifying Peaks ....................................................................................................................................................439

Building a Calibration Curve...................................................................................................................................439

External Standard Calibration.................................................................................................................................440

Internal Standard Calibration..................................................................................................................................441

Normalized Percent Calibration..............................................................................................................................441

Choosing a Calibration Type..................................................................................................................................441

GC Data Handling Method Command Reference

Integration Parameters...........................................................................................................................................443

Peak Table..............................................................................................................................................................445

Calibration Setup....................................................................................................................................................447

Calibration Curve Window......................................................................................................................................450

Verification Setup....................................................................................................................................................454

Time Events Table..................................................................................................................................................455

...............................................................443

GC Interactive Graphics Dialog Boxes...............................................................................459

Open Multiple Data Files Dialog Box......................................................................................................................459

Open Method File Dialog Box.................................................................................................................................462

Open Original/Recalc Dialog Boxes.......................................................................................................................463

6

Page 9

Save Method As Dialog Box...................................................................................................................................464

Saturn Printer Setup Dialog Box.............................................................................................................................465

Preferences Dialog Box..........................................................................................................................................465

Reintegration List Dialog Box.................................................................................................................................471

Fill Peak Table Window..........................................................................................................................................473

Exact View Dialog Box ...........................................................................................................................................474

GC Interactive Graphics Menus ..........................................................................................475

File Menu................................................................................................................................................................475

Edit Menu................................................................................................................................................................476

View Menu..............................................................................................................................................................476

Results Menu..........................................................................................................................................................477

Edit Method Menu...................................................................................................................................................478

Help Menu ..............................................................................................................................................................479

GC Interactive Graphics Toolbars.......................................................................................481

Toolbar Overview ...................................................................................................................................................481

Main Toolbar...........................................................................................................................................................481

Method Quick Link Toolbar.....................................................................................................................................482

Chromatogram Toolbar ..........................................................................................................................................482

GC Interactive Graphics Window........................................................................................485

Locator Window......................................................................................................................................................485

Main Window..........................................................................................................................................................486

Info-Panels..............................................................................................................................................................489

Visual Method Edit Window....................................................................................................................................491

GC Interactive Graphics .......................................................................................................497

Viewing Chromatograms in Interactive Graphics...................................................................................................497

Elements of the Interactive Graphics Window........................................................................................................498

Changing Viewing Options.....................................................................................................................................501

Selecting a Method.................................................................................................................................................504

Changing the Data Handling Parameters...............................................................................................................507

Filling the Peak Table.............................................................................................................................................510

Interactive Editing of Timed Events........................................................................................................................511

Moving Peak Start and End Points.........................................................................................................................513

Calculating Results.................................................................................................................................................513

Viewing Results......................................................................................................................................................515

Viewing Calibration Curves ....................................................................................................................................516

Printing and Copying the Chromatogram Display..................................................................................................517

GC Standard Report Method Command Reference

Print Options...........................................................................................................................................................519

Results Format .......................................................................................................................................................521

Chromatogram Format...........................................................................................................................................522

Calibration Block Report Format ............................................................................................................................524

...........................................................519

Generating GC Standard Reports .......................................................................................525

The Standard GC Reports Method Section............................................................................................................525

Automated Report Generation................................................................................................................................528

Automated Printing to Multiple Printers..................................................................................................................529

7

Page 10

Batch Report Printing without Recalculating..........................................................................................................530

Viewing a Report for a Single Run .........................................................................................................................531

Method Builder Dialog Boxes..............................................................................................535

Create/Open Method File Dialog Box.....................................................................................................................535

Open Method File Dialog Box.................................................................................................................................536

Save Method File As Dialog Box............................................................................................................................537

Add Password Dialog Box......................................................................................................................................538

Change Password Dialog Box................................................................................................................................539

Print Method Sections Dialog Box..........................................................................................................................540

Star Printer Setup Dialog Box.................................................................................................................................541

Delete Method Sections Dialog Box.......................................................................................................................542

Import Method File Sections Dialog Box................................................................................................................543

Star Assistant Wizard .............................................................................................................................................543

Method Builder Menus.........................................................................................................549

File Menu................................................................................................................................................................549

Edit Menu................................................................................................................................................................550

View Menu..............................................................................................................................................................550

Window Menu.........................................................................................................................................................550

Help Menu ..............................................................................................................................................................551

Method Builder Toolbars .....................................................................................................553

Overview.................................................................................................................................................................553

Main Toolbar...........................................................................................................................................................553

Directory Toolbar....................................................................................................................................................554

Window Toolbar......................................................................................................................................................555

Method Builder Window.......................................................................................................557

Overview.................................................................................................................................................................557

Method Directory ....................................................................................................................................................558

Method Parameters................................................................................................................................................559

Module Information Editor...................................................................................................561

Module Information Editor ......................................................................................................................................561

Creating a Section..................................................................................................................................................562

Deleting a Section ..................................................................................................................................................562

Renaming a Section...............................................................................................................................................562

Adding an Entry to a Section..................................................................................................................................563

Deleting an Entry from a Section............................................................................................................................563

Editing an Entry or Renaming an Item ...................................................................................................................563

Creating a Default Module Information Template ..................................................................................................564

Designing Documentation Structures.....................................................................................................................564

Retrieving Information from Data Files...................................................................................................................565

Commands .............................................................................................................................................................565

Dialog Boxes...........................................................................................................................................................566

Security Administration.......................................................................................................569

Overview.................................................................................................................................................................569

Passwords..............................................................................................................................................................569

Application Locking.................................................................................................................................................571

8

Page 11

File Revision Settings.............................................................................................................................................572

Standard GC Reports Command Reference ......................................................................575

File Menu................................................................................................................................................................575

Search Menu ..........................................................................................................................................................575

Font Menu...............................................................................................................................................................575

View Menu..............................................................................................................................................................576

Options Menu .........................................................................................................................................................576

Windows Menu.......................................................................................................................................................576

Help Menu ..............................................................................................................................................................577

Standard GC Reports Dialog Boxes....................................................................................579

Open Data File Dialog Box.....................................................................................................................................579

Print Dialog Box......................................................................................................................................................580

Printer Setup Dialog Box........................................................................................................................................581

Title Dialog Box.......................................................................................................................................................581

Chromatogram Options Dialog Box........................................................................................................................582

Results Options Dialog Box....................................................................................................................................584

Find Dialog Box ......................................................................................................................................................585

Standard GC Reports Format Descriptions .......................................................................587

Results Report........................................................................................................................................................587

Verification Report..................................................................................................................................................593

Standard GC Reports Toolbar.............................................................................................595

Main Toolbar...........................................................................................................................................................595

9

Page 12

10

Page 13

Getting Started

About this Manual/Help

This manual/help system contains information about how to acquire data, build

methods, and operate the Saturn GC/MS through the Varian MS Workstation.

This manual also describes the configuration of the 3800 and 3900 GCs for

standard Ethernet communication with the Saturn 2000 and MS Workstation’s

System Control application. Use this manual in conjunction with the other

manuals supplied with your MS Workstation and your 3800 GC or 3900 GC. All

of the information included in this manual is also available in the On-Line Help

section of the software.

Additional Manuals/Help

Other sources of information are available to help you get the most from this

product.

2000 GC/MS Hardware Reference Manual/Help

The Hardware Reference Manual/Help system provides the necessary

information for installing, maintaining, using and repairing your Saturn GC/MS

System. All of the information included in this manual is also available in the OnLine Help section of the software.

MS Workstation Manual/Help

This Manual/Help provide a practical way to quickly learn how to perform basic

tasks using the MS Workstation Software. While these tutorials use Saturn 2000

ion trap files, they can easily be adapted to your instrument configuration.

3800 and 3900 GC Operator’s Manuals

These manuals are included on the Varian MS Workstation CD-ROM and

describe the GC Method, instrument operation, and the process of connecting

your GC to a PC or to an existing network.

Context Sensitive Help

The MS Data Review, Method Builder and System Control sections of the

software contain Context Sensitive Help. Help can be obtained simply by

positioning the mouse pointer on the item of interest, clicking the right mouse

button and selecting "What's This".

11

Page 14

12

Page 15

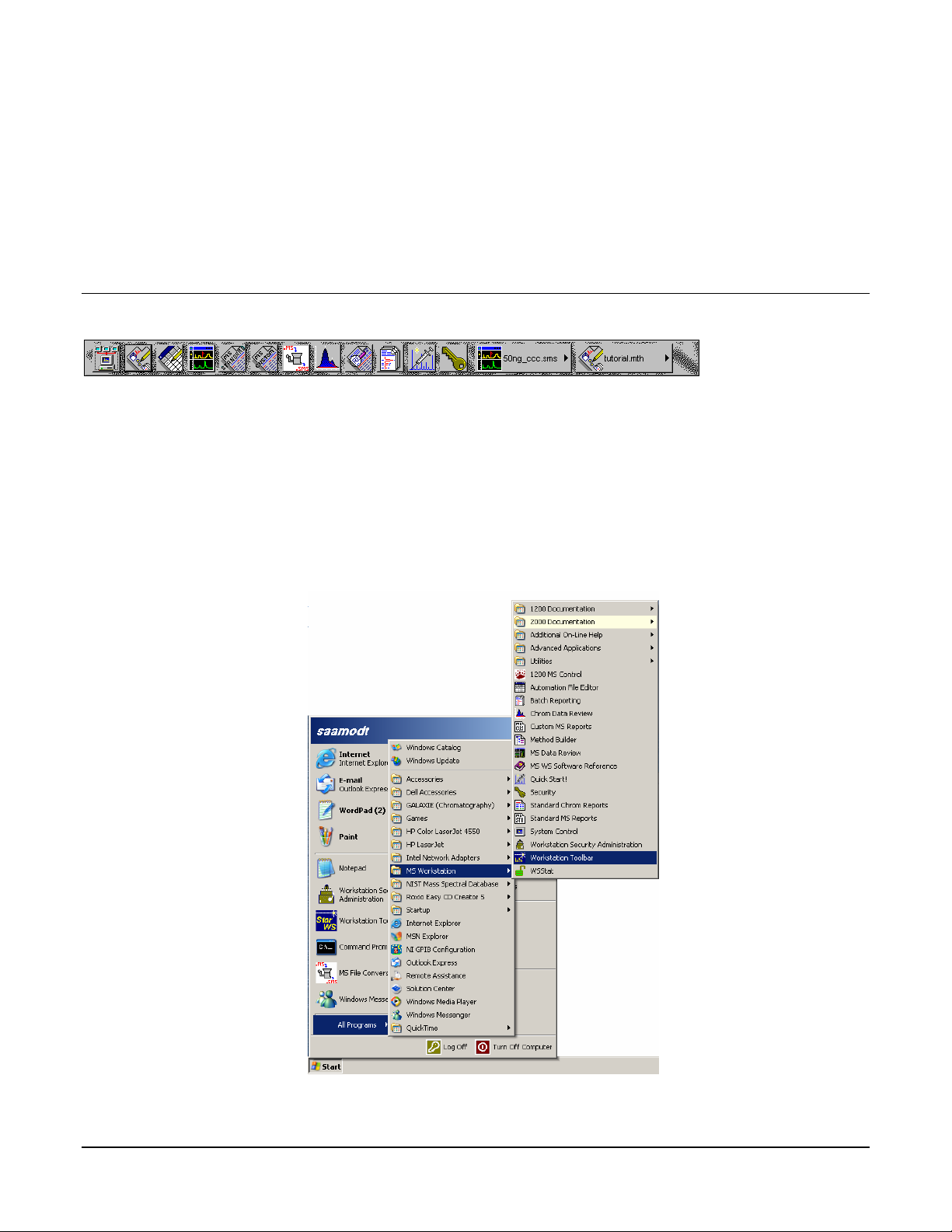

MS Workstation Toolbar

Overview

Saturn GC/MS Workstation is a suite of applications for controlling

chromatographs, collecting data from chromatograph detectors, and analyzing

those data. The MS Workstation Toolbar provides quick and easy access to the

Saturn GC/MS Workstation applications. When activated, the MS Workstation

Toolbar behaves very much like the Windows Taskbar. It can be docked on any

of the four sides of the display screen and other Windows programs will not

cover or go behind it when they are opened in full screen mode.

If the MS Workstation Toolbar is not already opened on your Saturn GC/MS

Workstation, you can start it from the Windows Start Menu.

13

Page 16

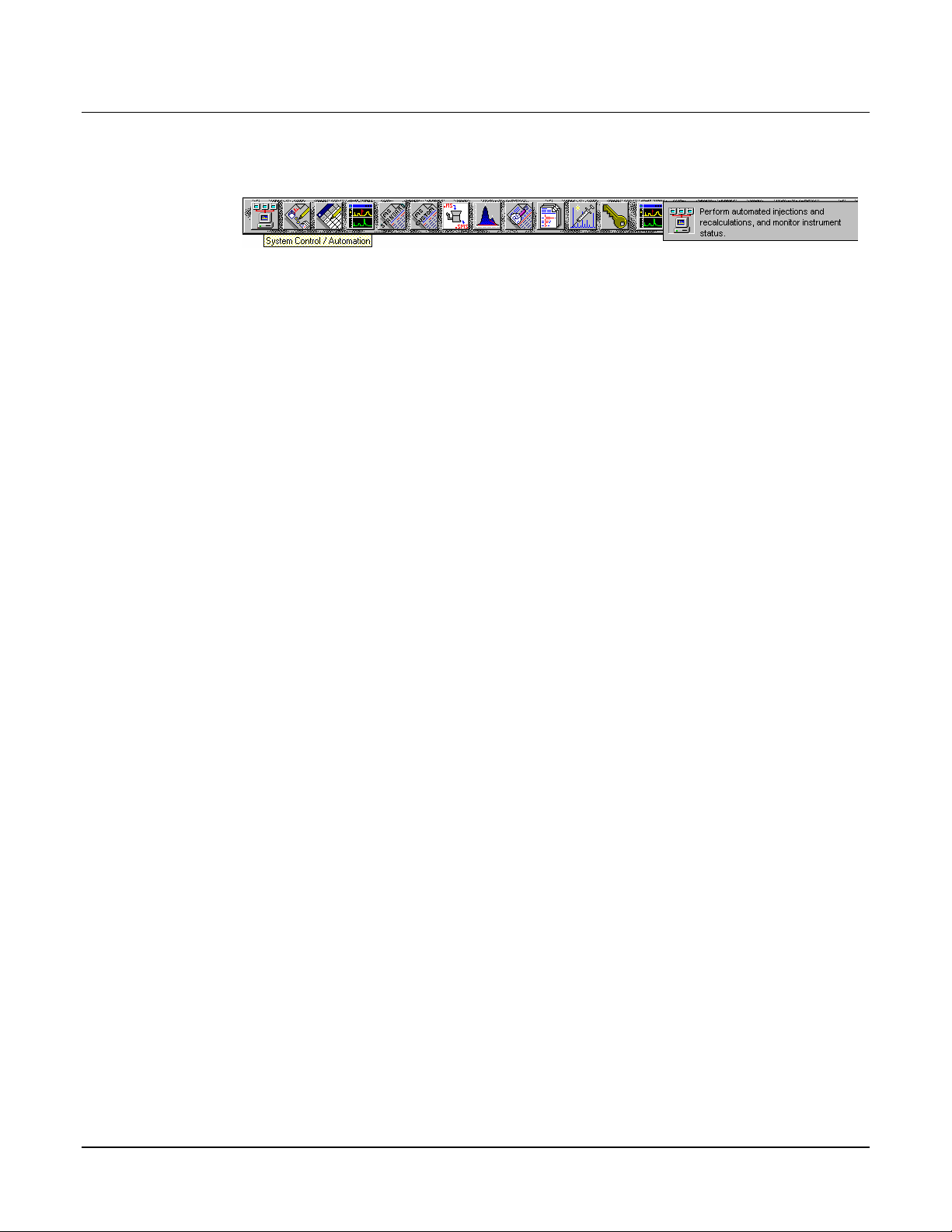

Elements of the MS Workstation Toolbar

Application Buttons for immediate access to the selected application.

Tooltip shows the application name when the cursor rests on the Application

Button.

Quick Link Buttons provide menu selections of operations to be performed on the

listed file.

Application Descriptions give a brief description of the application that will be opened

when the cursor rests on the Application Button.

14

Page 17

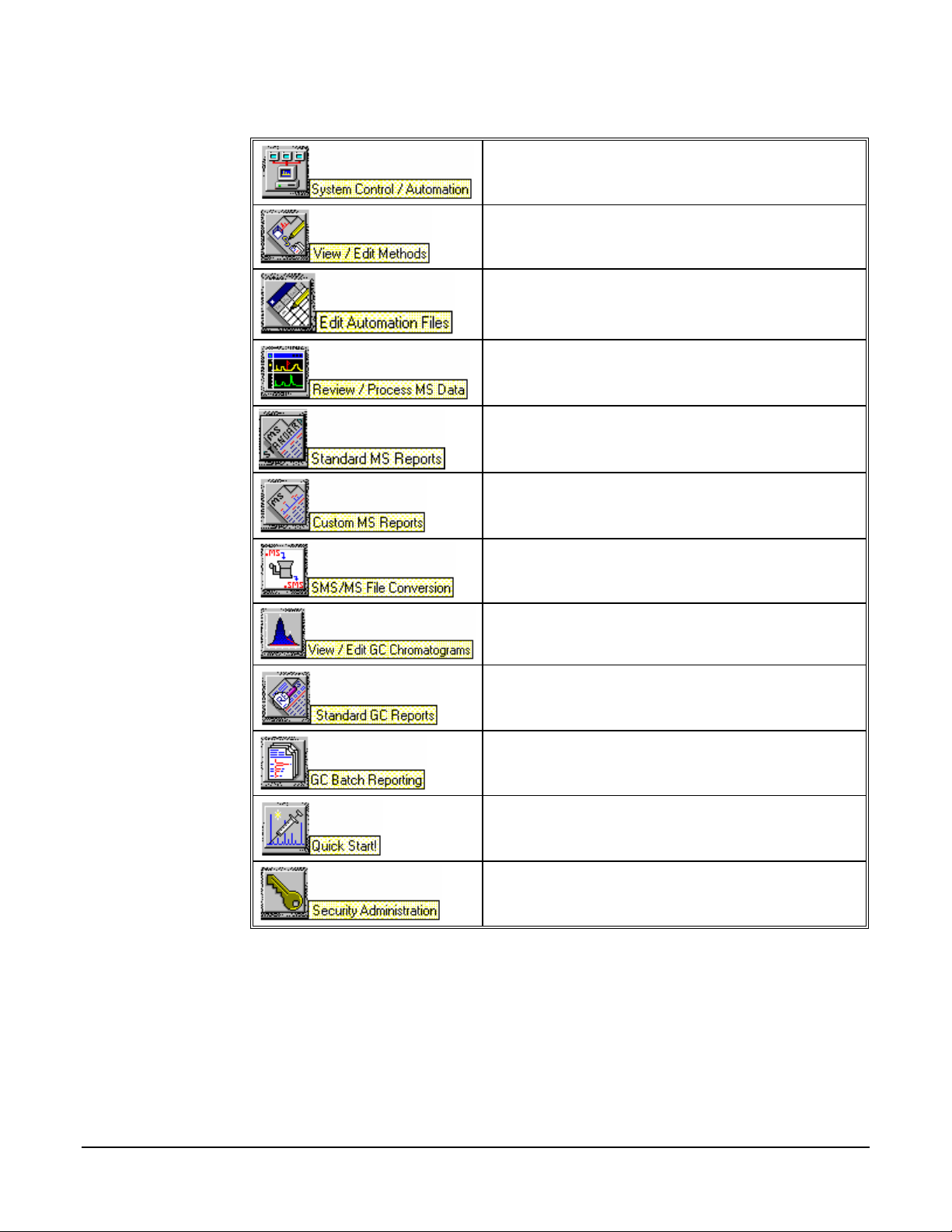

Application Buttons

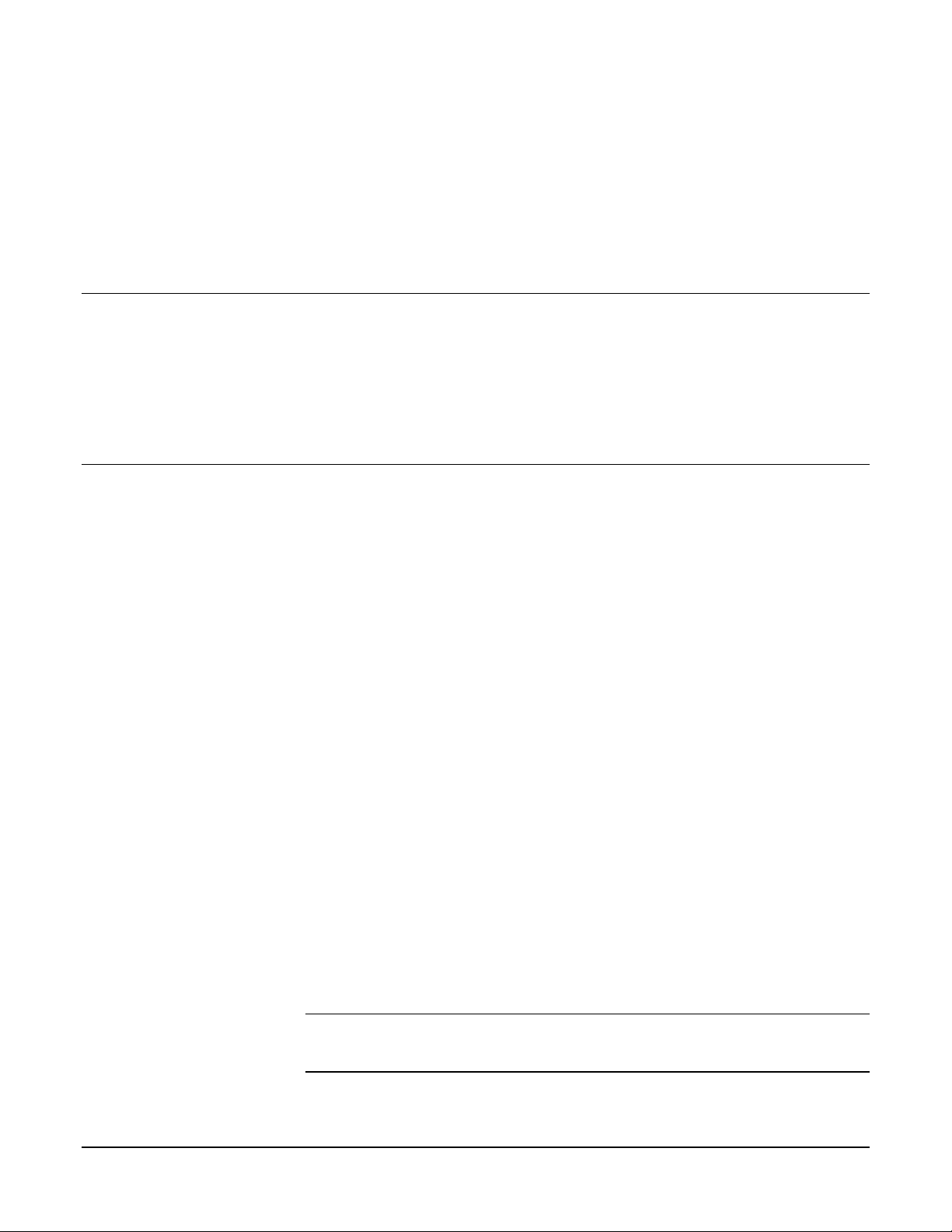

Used to monitor instrument status, perform automated

injections, and perform batch recalculations.

Used to view and edit instrument operation, data

acquisition, and data handling methods.

Used for off-line editing of SampleLists, RecalcLists and

Sequences.

Used to review chromatograms and spectra, perform library

searches, and review and process quantitation results.

Used to create, edit, and view standard MS reports.

Used to create, edit, and view customized MS reports.

Used to convert data files between DOS and Windows

formats.

Used to review standard GC chromatograms, interactively

edit data handling parameters, and recalculate results.

Used to preview standard chromatogram and results

reports.

Used to generate standard reports for a group of Data Files

by dragging and dropping them on the Batch Report

Window.

Used to run a sample without a Sample List.

Used to set Saturn GC/MS Workstation security options and

passwords.

In addition, other application buttons may be added to the MS Workstation

Toolbar when you install additional Saturn GC/MS Workstation options, such as

StarFinder and Star Custom Report Writer.

15

Page 18

Quick Link Buttons

Most Recently Used Data File. A menu of operations that can be performed on

the Most Recently Used Data File are displayed when the button is pressed. A

different data file can be selected from a list of most recently used files.

Most Recently Used Method. Menu of operations that can be performed on the

Most Recently Used Method will be displayed when the button is pressed. A

different method can be selected from a list of most recently used methods.

16

Page 19

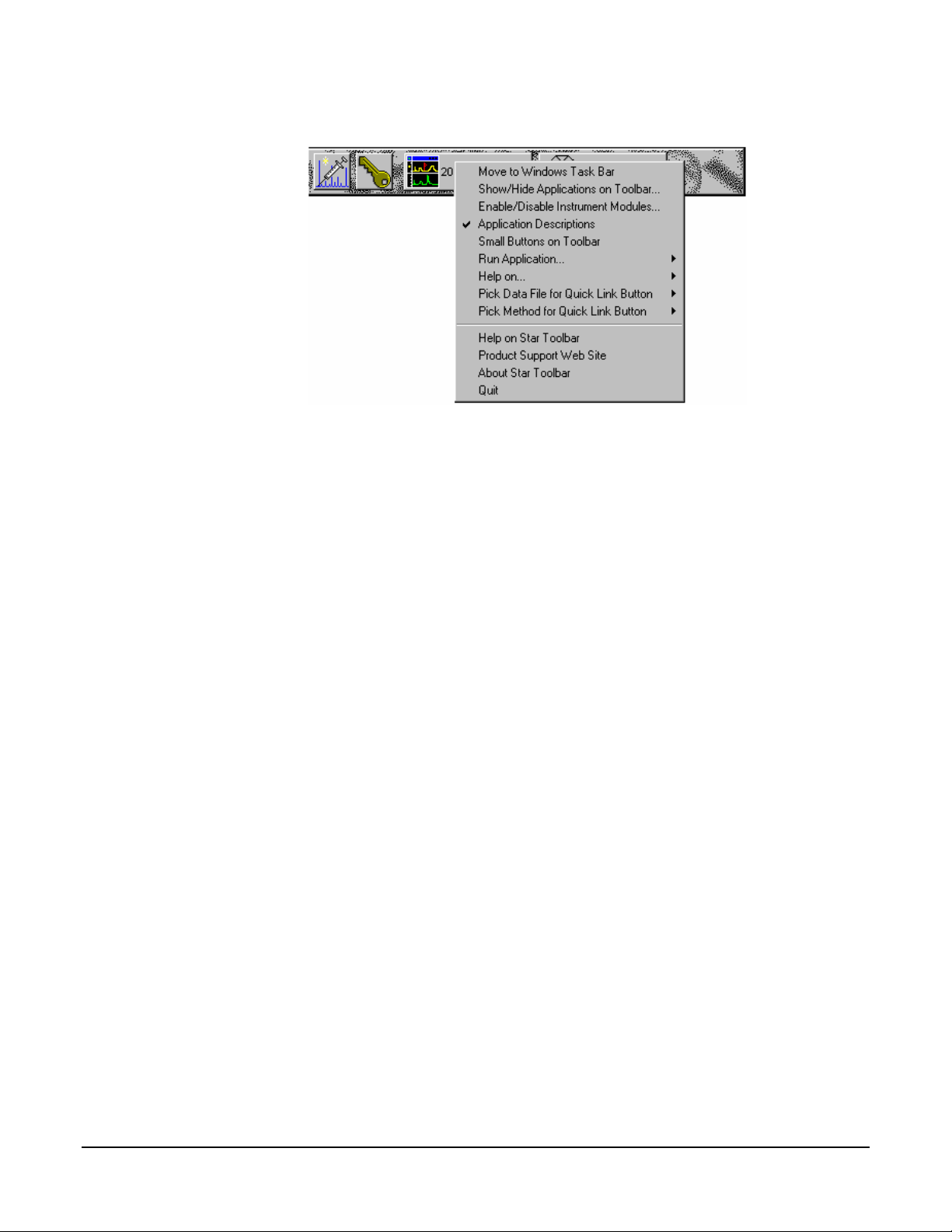

MS Workstation Toolbar Options

Right-click the bar to display the Toolbar Options. A menu of MS Workstation

Toolbar configuration options and operations that may be performed will be

shown.

17

Page 20

18

Page 21

Launching Applications from the MS Workstation Toolbar

Using the Application Icon Buttons

Saturn GC/MS Workstation applications appear as icon buttons on the MS

Workstation Toolbar. As you move the mouse over these buttons, the name of

the application is shown in a tooltip window below the cursor.

Click any icon in the MS Workstation Toolbar to launch the corresponding

application.

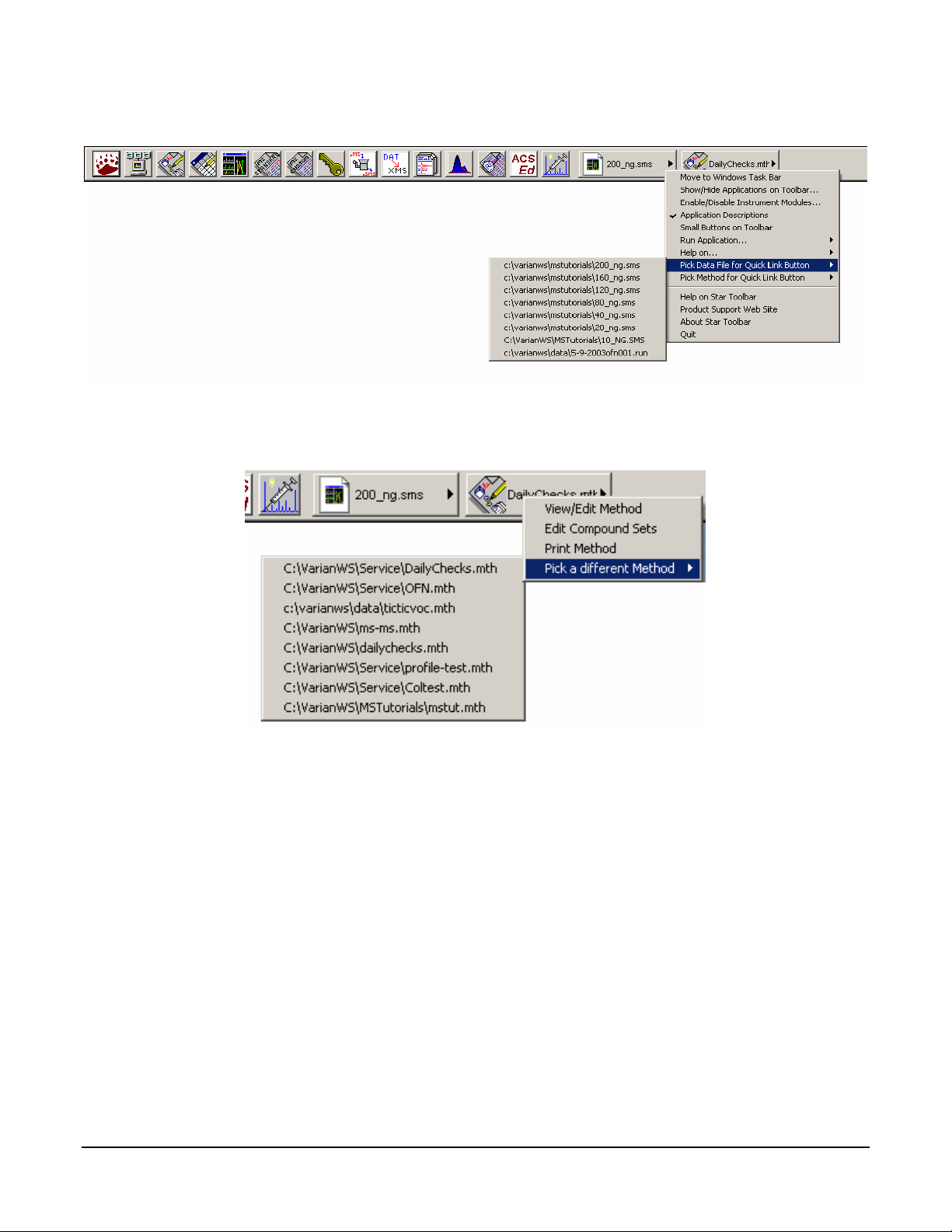

Using the Data File and Method Quick Link buttons

The two buttons to the right of the application buttons are Quick Link buttons.

These two Quick Link buttons correspond to recently used Data Files and

Methods. On each Quick Link button is the name of the file associated with that

button. When you click the Quick Link button, a menu is displayed showing

operations that can be performed on the corresponding file.

The Quick Link buttons in the MS Workstation Toolbar are always updated with

the most recently used Data File and Method. If the Data File or Method you wish

to use is not displayed in the Quick Link button, you can choose from the eight

most recently used files by selecting “Pick a different Data File (or Method)” from

Quick Link button’s menu.

19

Page 22

20

Page 23

MS Workstation Toolbar Options

Moving the MS Workstation Toolbar

The MS Workstation Toolbar can be moved to any edge of the Windows screen.

Click a portion of the MS Workstation Toolbar that does not contain application or

Quick Link buttons and drag the toolbar to the edge of the screen that you desire.

When you release the mouse, the toolbar will remain on that edge. The MS

Workstation Toolbar remembers its location the next time it is started.

Additionally, you can display the MS Workstation Toolbar as a Windows Taskbar

icon. To do so, select “Move to Windows Taskbar” from the MS Workstation

Toolbar options menu. Taskbar icons appear in the lower right (or bottom) of the

Windows Taskbar (the bar on which the “Start” button appears). When displayed

as a Taskbar icon, the toolbar no longer takes up space on the screen. When

you click the MS Workstation Toolbar icon, the options menu is displayed.

The MS Workstation Toolbar Options Menu

When you move the mouse over an area of the MS Workstation Toolbar not

containing application or QuickLink buttons, you may right-click to display an

option menu.

21

Page 24

Move to Windows Taskbar

You can display the MS Workstation Toolbar as a Windows Taskbar icon.

Taskbar icons appear in the lower right (or bottom) of the Windows Taskbar (the

bar on which the “Start” button appears). When displayed as a Taskbar icon, the

toolbar no longer takes up space on the screen. When you click the MS

Workstation Toolbar icon, the options menu is displayed.

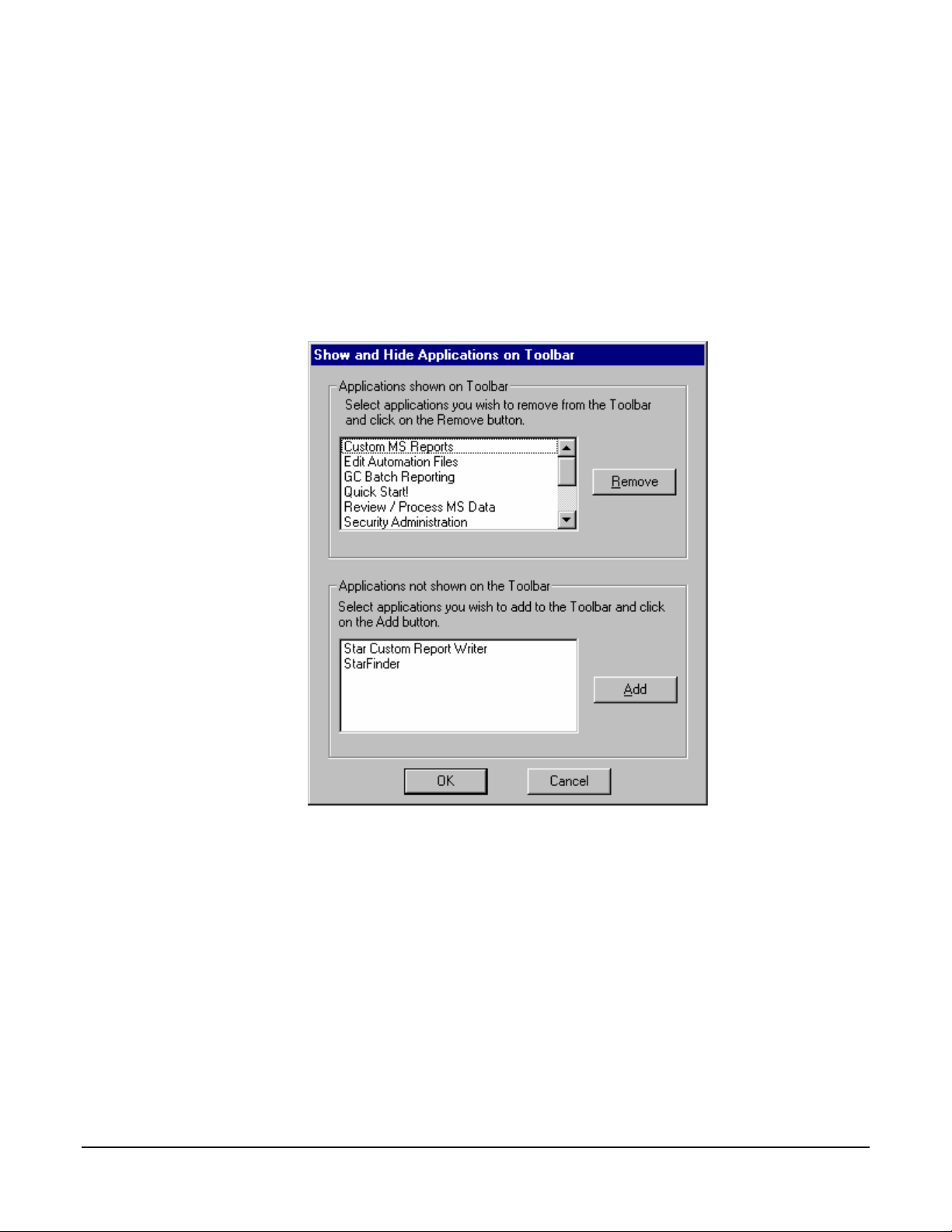

Show/Hide Applications on Toolbar

Selecting this option displays the Show and Hide Applications on Toolbar dialog

box.

This dialog box allows you to select which Saturn GC/MS Workstation

applications are represented by icons on the MS Workstation Toolbar. The top

list box shows all applications that are currently displayed in the toolbar. The

bottom list shows all applications that are installed but not displayed in the

toolbar. To remove an icon from the toolbar, select it from the top list and click

Remove. To add an icon to the toolbar, select it from the bottom list and click

Add.

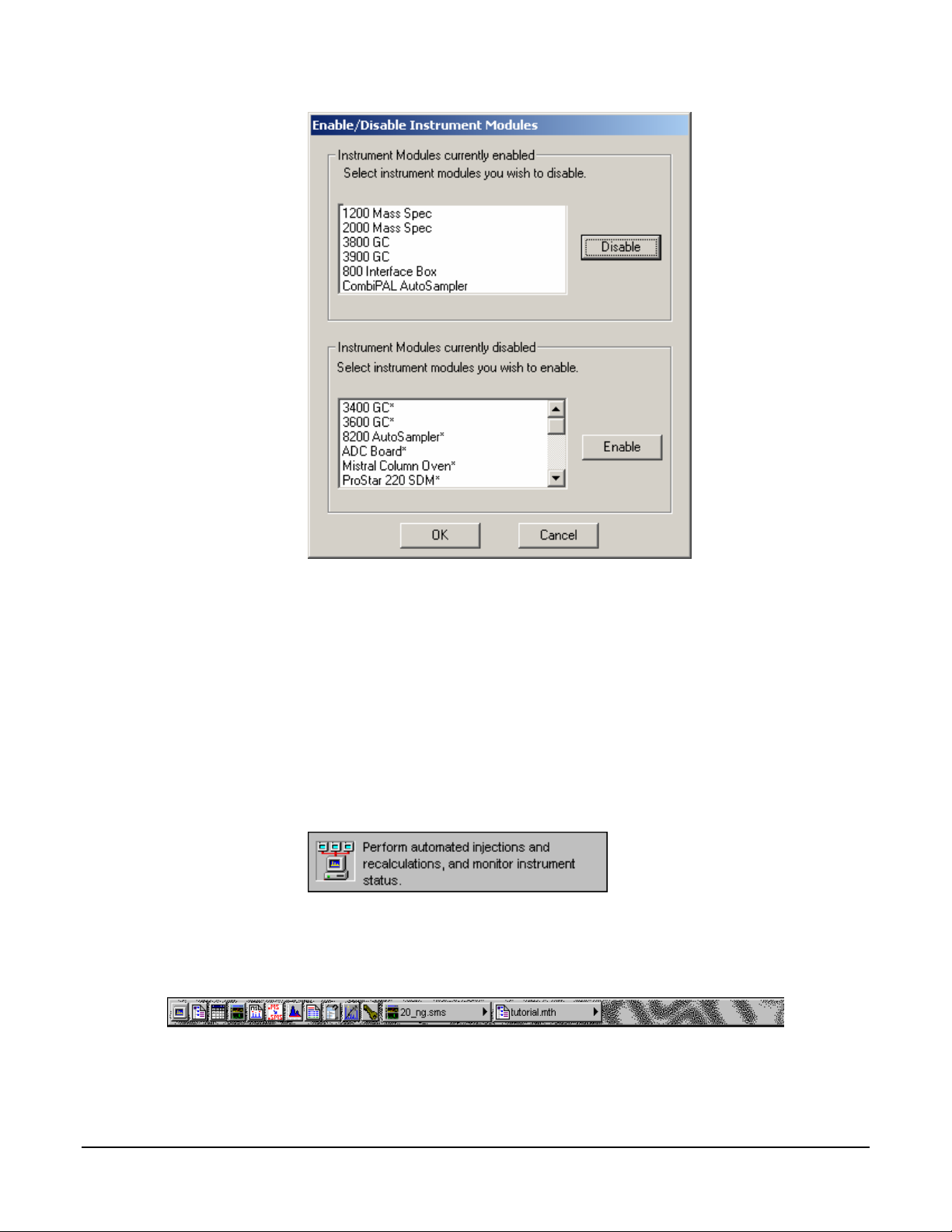

Enable/Disable Instrument Modules

Selecting this option displays the Enable/Disable Instrument Modules dialog box.

22

Page 25

This dialog box allows you to select which Saturn GC/MS Workstation instrument

modules are available from this Workstation. When an instrument module is

available, it will appear in System Control if the corresponding instrument is

connected and powered-on, you will be able to create a Method section for it,

and you will be able to format reports for it.

The top list box shows all instrument modules that are currently installed and

enabled in the Saturn GC/MS Workstation. The bottom list shows all instrument

modules that are installed but not enabled. To disable an instrument module,

select it from the top list and click Disable. To enable an instrument module,

select it from the bottom list and click Enable.

Application Descriptions

When this menu item is checked, application descriptions are displayed when

you move the mouse over application buttons in the MS Workstation Toolbar.

Small Buttons on Toolbar

When this menu item is checked, the MS Workstation Toolbar is reduced in size.

23

Page 26

Run Application

This hierarchical menu item lists all applications showing on the MS Workstation

Toolbar. When you select an item from this list, the corresponding application is

launched.

Help on

This hierarchical menu item lists all applications showing on the MS Workstation

Toolbar. When you select an item from this list, the online help corresponding to

the application is displayed.

Pick Data File for Quick Link Button

This hierarchical menu item lists the eight most recently used Data Files in order

of use. When you select a Data File from this list, the Data File currently

displayed in the Quick Link button is changed to the selected file.

Pick Method for Quick Link Button

This hierarchical menu item lists the eight most recently used Methods in order of

use. When you select a Method from this list, the Method currently displayed in

the Quick Link button is changed to the selected file.

Help on MS Workstation Toolbar

Displays the help you are now using.

Product Support Web Site

If you have Internet access and a web browser installed on your computer, this

option will automatically open the Saturn GC/MS Workstation Product Support

Web Site. Here you will find the latest software and documentation updates for

the Saturn GC/MS Workstation suite of products, along with additional notes,

tips, and answers to frequently asked questions.

You may wish to visit this site periodically to see if new information is available

that may be pertinent to you.

About MS Workstation Toolbar

Displays the About Box for the MS Workstation Toolbar. The About Box contains

information about the software version, installation information, and a list of the

instrument control modules that you have installed.

Quit

Quits the MS Workstation Toolbar application. If you elected to run the MS

Workstation Toolbar automatically when Windows starts, the MS Workstation

Toolbar will reappear the next time you start Windows.

24

Page 27

2000 MS Module Control

Starting System Control the First Time

Before you enter System Control for the first time, confirm that the proper

instrument modules have been enabled and that any instrument modules that

are not part of the system have been disabled. To enable or disable instrument

modules refer to the section of the MS Workstation Toolbar, Enable/Disable

Instrument Modules.

Configuring the Instrument

Before beginning the configuration process, you should know whether you will be

attaching your Workstation and 3800 or 3900 GC to a company network or an

isolated network only used for instrument control. If you have a Network

Administrator on site, you may wish to ask which configuration is recommended.

Use this table to determine the order in which you should read the following

sections.

1. If an Ethernet card has not been installed and configured on your PC, read

Installing and Configuring the Ethernet Card in Your PC and one of the

following:

No Company Network: Configuring TCP/IP Parameters with no

Company Network.

Company Network: Configuring TCP/IP Parameters for a Company

Network.

2. Read Connecting Your 3800 or 3900 GC to Your PC or Network.

If you have not already installed the Varian MS Workstation, do so before

3.

proceeding.

No Company Network: Read Configuring the 3800 or 3900 GC

Communication (No Company Network).

Company Network: Read Configuring the GC for a Company Network.

Continue reading the rest of the sections, starting with Adding a GC and

4.

Varian MS to the Instrument in System Control.

Installing and Configuring the Ethernet Card in Your PC.

5.

NOTE: The following section describes a procedure that is relatively generic;

consult your Windows documentation and that of the Ethernet card’s

manufacturer for more detailed explanations.

25

Page 28

Refer to the installation instructions packaged with your Ethernet card for

information on installing the Ethernet card in your computer. Before proceeding,

your Ethernet card should be recognized by your Windows version. When done,

the Network Neighborhood icon should appear on your Windows desktop.

NOTE: For the following procedure, the use of disks other than the ones that

were used for the original Windows installation may result in a Ethernet driver

version mismatch that keeps Windows from starting. Should this occur, it may be

necessary to remove the Ethernet Board from the computer to remove the

incorrect Ethernet drivers.

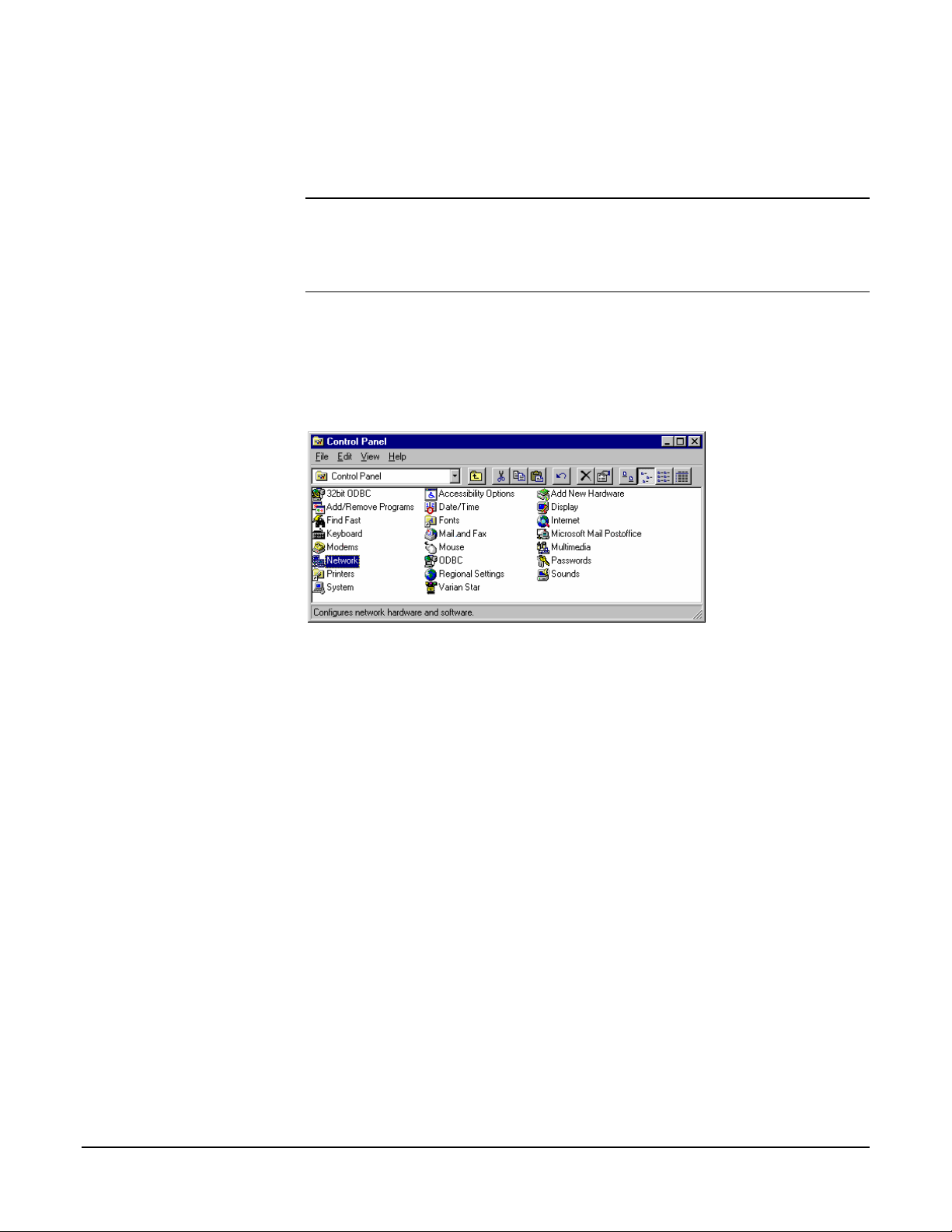

You must configure your computer’s network settings to allow communication

with the 3800 or 3900 GC. You do so by running the Windows Control Panel.

1. Run the Control Panel by selecting it from the Start menu (under Control

Panel or Settings).

The Control Panel window is displayed.

2. Double-click the Network icon to set your Network options.

26

Page 29

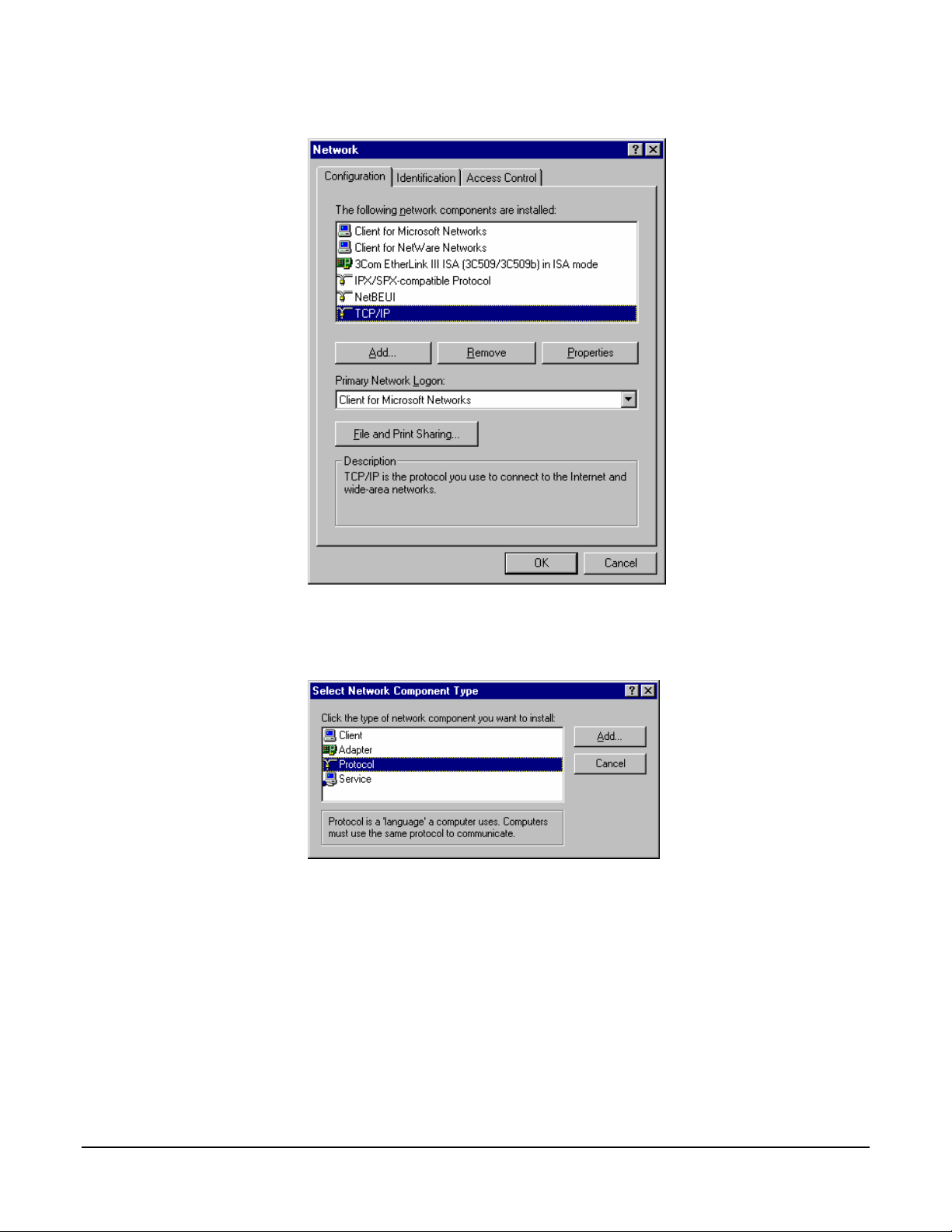

The Network dialog box is displayed.

3. If TCP/IP is already listed in the list of network components, skip to the Note

after step 5, otherwise, click Add.

The Select Network Component Type dialog box is displayed.

4. Select Protocol and click Add.

27

Page 30

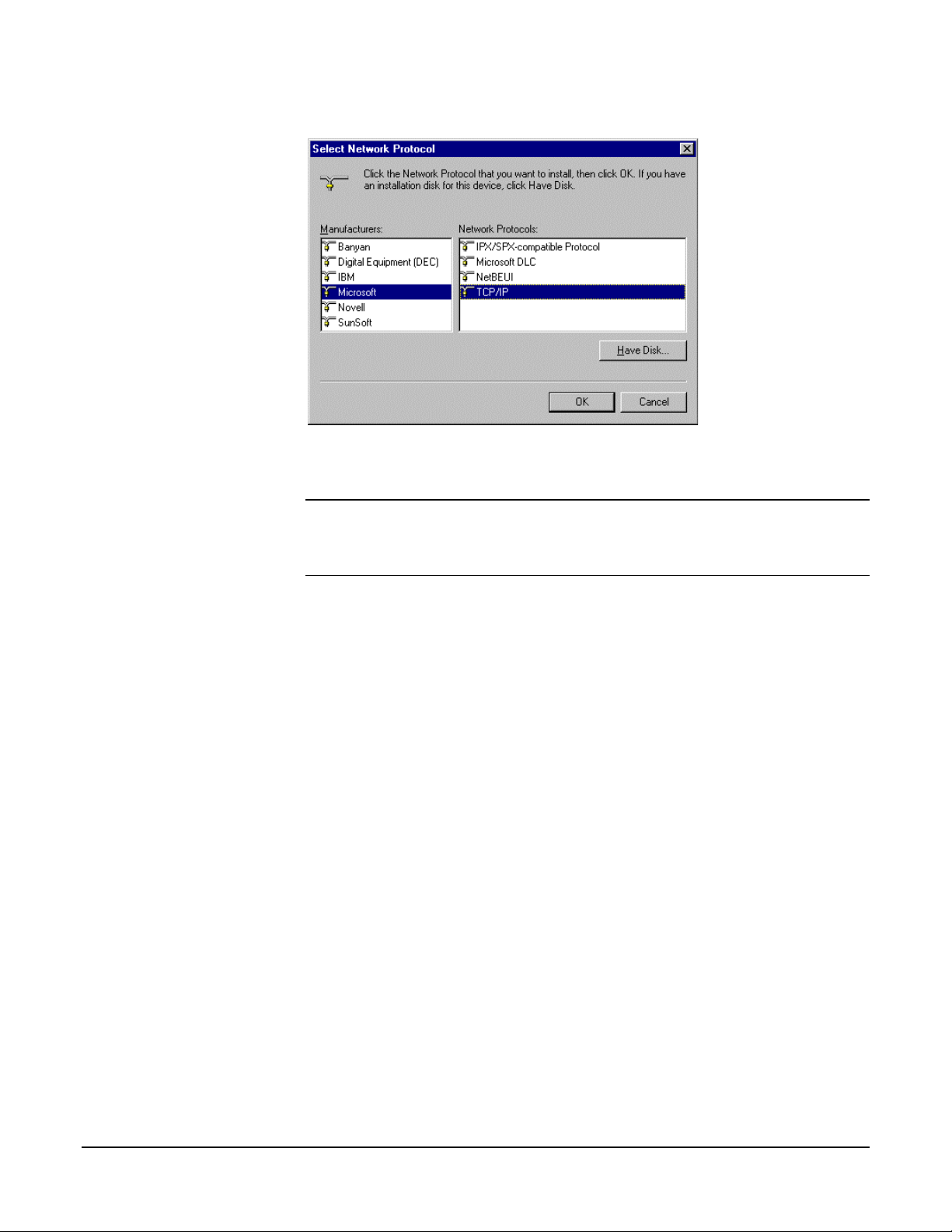

The Select Network Protocol dialog box is displayed.

5. Select Microsoft as the manufacturer. Select TCP/IP as the protocol. Click

OK. The protocol is added to your installed network Component list.

NOTE: If you are not connecting your Workstation to a company network (that

is, you are not assigned an IP address by a Network Administrator), follow the

next three steps. If you are connecting your Workstation to a company network,

skip to Configuring the GC for a Company Network.

Configuring TCP/IP Parameters with no Company Network

The following three steps assume you have completed steps 1 through 5 from

the previous procedure.

1. Select TCP/IP from the network components list and click Properties. The

TCP/IP properties dialog box is displayed.

28

Page 31

Enter an IP address in the range 10.2.128.1 through 10.255.255.254. Note that if you

are adding more than one Workstation to this network, each Workstation PC must

have a unique IP address within this range. The Subnet Mask will be automatically

set to 255.0.0.0. Do not change this value.

29

Page 32

Ensure that no entries have been made in your Gateway, and that Domain Name

Server (DNS) and WINS Configuration have been disabled. These entries are not

used in an isolated network and may cause problems if they are present. Delete

any settings that may have been entered from a previous configuration.

2. Click OK. Reboot Windows for the changes to take affect.

NOTE: Refer to Communication Problems in the Diagnostic and

Troubleshooting section for information about diagnostic tools to verify that your

network installation is correct.

Configuring TCP/IP Parameters for a Company Network

The following three steps assume you have completed steps 1 through 5 from

the previous table.

3. Select TCP/IP from the network components list and click Properties. The

TCP/IP properties dialog box is displayed.

Enter the IP address to be used by this Workstation. Contact your Network

Administrator (or whoever assigns IP addresses in your network) to get the

appropriate address. Note that each Workstation PC must have a unique IP

address. Enter the appropriate Subnet Mask to be used with this IP address.

4. Your Network Administrator may instruct you to obtain an IP address

automatically by selecting the appropriate radio button.

30

Page 33

Contact your Network Administrator (or whoever assigns IP addresses for your

network) to see what the appropriate settings are for your Gateway, and whether

Domain Name Server (DNS) and WINS Configuration are needed.

5. Your Network Administrator may also instruct you to specify parameters in

the Bindings and Advanced tabs.

6. Click OK. Reboot Windows for the changes to take affect.

NOTE: Refer to Communication Problems in the Diagnostic and