Page 1

1

Installation— and

User guide

Revision 3

Varde Vision

Page 2

2

Congratulation on purchasing your new stove

Varde Ovne A/S is a Danish company specializing in functional, environmentally friendly and

designed quality stoves.

Index

Welcome and index Page 2

Technical specifications Vision 11 Page 3

Technical specifications Vision 1 Page 4

Regulations and approval Page 5

Flooring and distance Page 6

Chimney Page 7

Air supply Page 8

Operation Page 9

How to light and stoke a fire Page 10

List of accessories Page 11

Vermiculit e Page 12

How to choose the wood Page 13

Maintenance Page 14

Troubleshooting Page 15

Spare Parts Page 16

Fresh Air supply Page 17

Test certificate (Teknologisk Institut) Page 18

Warranty Page 19

Page 3

3

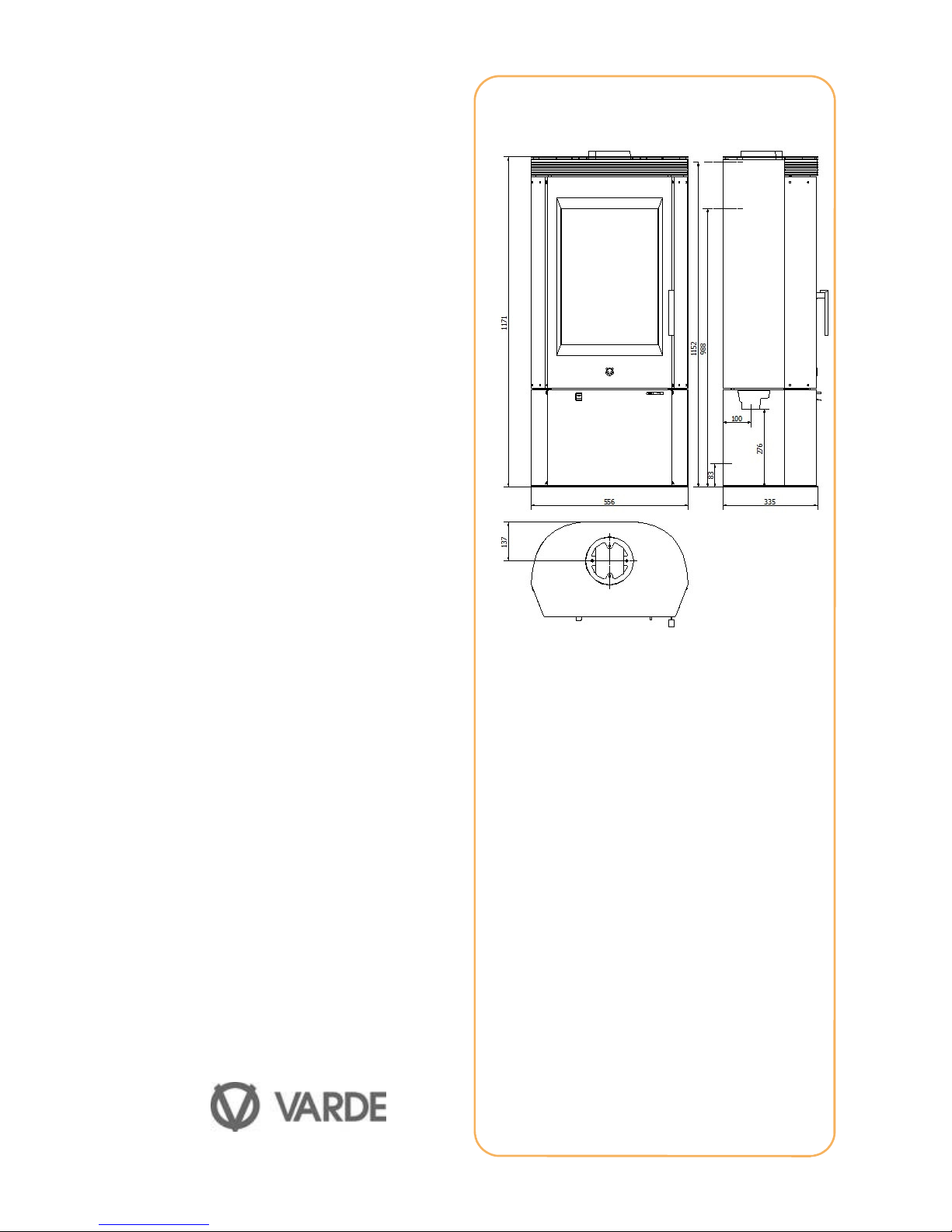

Varde Vision 11

Hight (mm) 1171

Wide (mm) 556

Depth (mm) 335

Weight (kg) 110

Effect 5,3-6W

Nominal Output 6 Kw

Heated area 45-120m2

Efficiency 79 %

Flue gas data: 5,8g/sek., 265°C 20°C, 12 pa.

Combustion chamber: (H x W x D):

380 x 352 x 215mm

Flue outlet Ø 15 cm (Mounting hight top:

~1032cm)

Distance to non-flammable: : 5-10cm

(recommended)

Distance to flammable materials:

Rear = 25cm, Sides = 25cm, In front = 100cm

Technical Specifications

Vision

Page 4

4

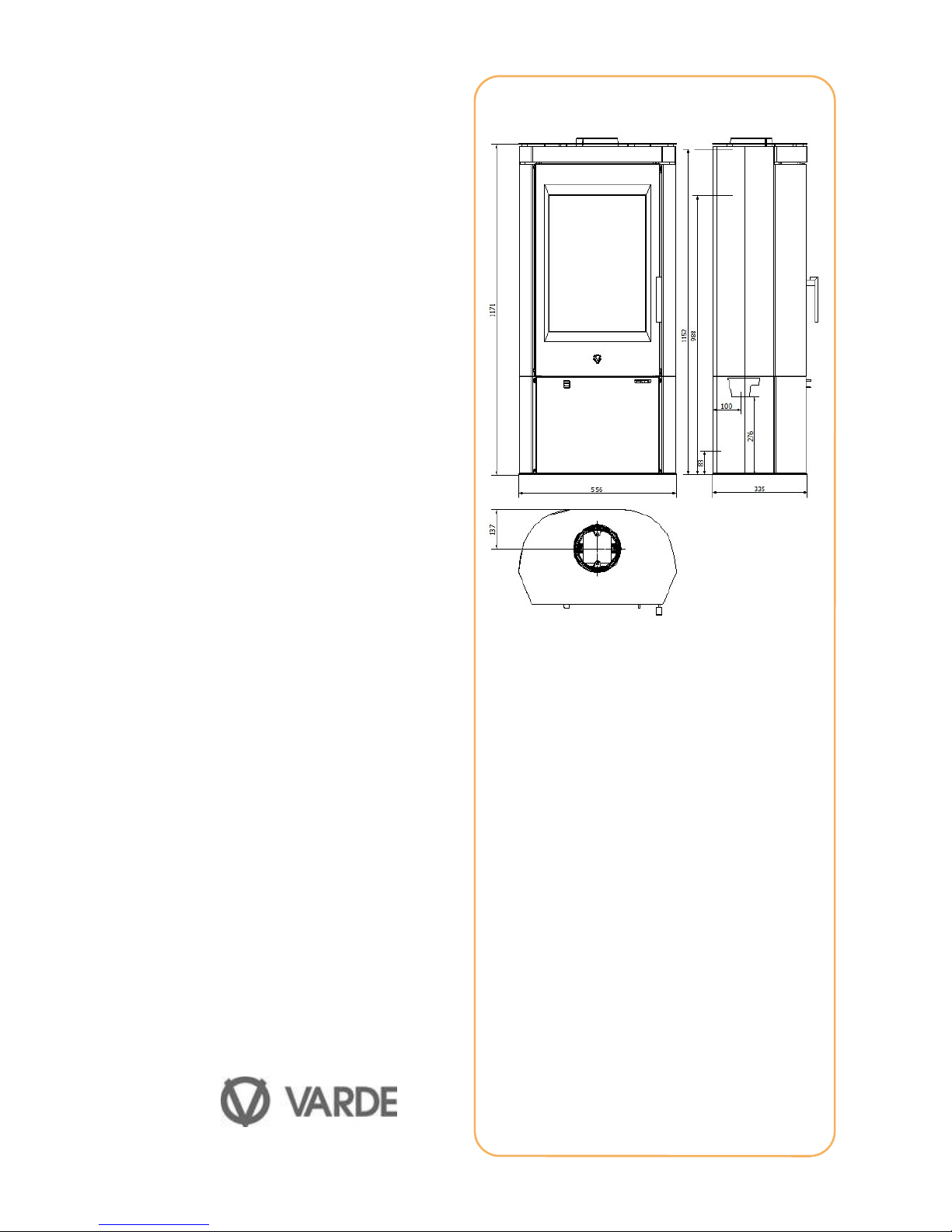

Varde Vision 1

Hight (mm) 1171

Wide (mm) 556

Depth (mm) 335

Weight (kg) 110

Effect 5,3-6 W

Nominal Output 6 kW

Heated area 45-120m2

Efficiency 79 %

Flue gas data: 5,8g/sek., 265°C , 20°C, 12 pa.

Combustion chamber: (H x W x D):

440 x 360 x 242 mm

Flue outlet Ø 15 cm (Mounting hight top:

~1152cm)

Distance to non-flammable: : 5-10cm

(recommended)

Distance to flammable materials:

Rear = 25cm, Sides = 25cm, In front = 100cm

Technical Specifications

Varde Vision

Page 5

5

Important!

Before lighting up your Varde Stove for the

first time, we recommend that you read these

instructions carefully and contact your local stove

vendor or building authoorities to inquire about

existing regulations regarding the intallation of

stoves. Please follow these regulations closely.

Inspection of installation

It is very important that the installation is inspected by a qualified chimney sweeper before

the stove is used the first time.

Regulations

All local regulations as well as National and

European, should be adhered to when installing your stove.

All Varde Ovne stoves are closed fireplaces.

The stove is designed for intermittent combustion and can be connected to a chimney

used by other fireplaces, as long as the appropriate rules and regulations are adhered to.

This Varde Stove

Has passed the

Danish /European Standard DS/EN 13240

Norwegian (NS), Austrian §15a Art. B-VG tests

and the

German (Stufe 2) test , and have thereby proved

to be a environmentally friendly product.

Proffesional installation

We recommend that you consult with the

dealer where you purchased the stove or an

other competent installer, as there may be

specific things to consider during the installation. You should also reseive the applicable

rules for installing the stove and follow them.

Please Note!

You are by law required to register your stove at the local chimney-sweeper.

Until installation keep the stove dry and not to cold. The stove cannot stand moisture.That an

existing chimney, not necessarily is effective enough for a new modern stove.Vermiculite is a

very porous material, therefore handle with care. When refilling the stove, put the wood carefully, use the glove.

EC declaration of confirmaty.

MANUFACTURER

Name: Varde Ovne A/S

Adress Soldalen 12, DK-7100 Vejle, Danmark

Product Varde Vision 1 and 11

Product type Vision

Type code Heating stove, suitable for intermittent combustion

Standard Costruction products (89/106/EC/) standard used

EN 13240

Application Residential Heating

Fuel Wood

Special conditions Non

CE-Markning

Issued 2014

Nominal Output 6 kW

Fuel type Wood

Fluegas temperature 265 °C

Efficiency 79 %

Co-release 0,07

%

Page 6

6

Flooring:

If the floor on which the stove is to be placed is inflammable, the floor must be covered with non

-flammable material, such as steel or glass plate, floor tiles or artifical slate, covering an area of

at least 15 cm from the sides of the stove and at least 30 cm from the front of it. Regarding the

front, however, we recommend 50 cm. Also, the Floor construction must be capable of carrying

the combined weight of stove and chimney.

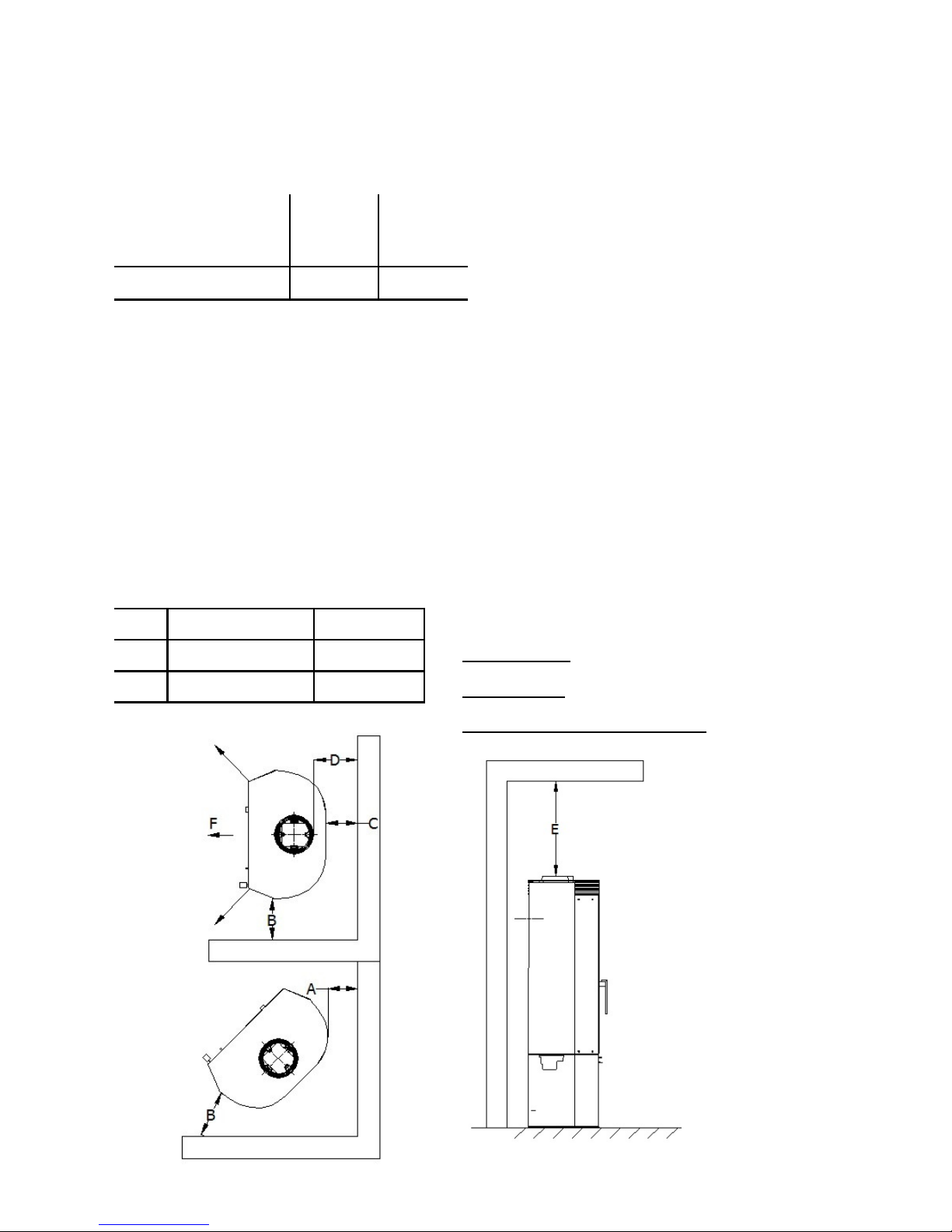

Installation distance:

If walls are non-inflammable, the stove can be placed closer to them. However, we recommend

a minimum distance of 5-10 cm, to allow for cleaning behind the stove. The cleanout gate must

be accessible. Optimal combustion can only be obtained if fresh air is constantly admitted. It is

important, therefore, to ensure that this is the case. The best way to provide a steady flow of

fresh air is by installing 1-2 air vent’s in the room where the stove is situated. (One in each side

of the room).

According to existing regulations, stoves must be placed with the following minimum distances

in mm to inflammable walls and materials.

The safety distance from a non-insulated chimney pipe to inflammable walls and materials must

be at least 450mm.

The stove must in accordance with applicable

rules comply with the following minimum distances from inflammable walls and materials:

Sides : 25 cm

Rear : 25 cm

Distance to furniture : 100 cm

Weight Steel

With

Soapstone

Varde Vision 110 kg 120 kg

A 200 mm C 250 mm

B 200 mm D 300 mm

Varde Vision

F 1000 mm E 600 mm

Page 7

7

Connection of Flue pipe:

The Stove is mounted with Flue adaptor on top or on the rear side.

When mounting on the rear side the

Flue adaptor and cover switch places.

The cast iron cover is placed in the

hole on top of the cast iron top.

The chimney:

Always use a chimney with a diameter of at least 15 cm. This corresponds to a clear of 175

cm2. Make sure the chimney is of a sufficient height, that it draws well and that smoke does not

bother your neighbours.

We recommend that you fit your chimney with a damper, allowing for draft control. This may

prove particularly important on windy days.

Note: the damper must never shut off draught completely – always allow at least 20 cm² free

passage through the chimney.

With nominal usage the stove has tested a flue gas flow of 5,8g/second and with a flue gas temperature of 265°C and at a room temperature of 20 °C.

Varde stoves are always fitted with a smoke plate which redirects smoke to make its way to the

chimney as effectively as possible. This ensures that the heat from the smoke is emitted inside

your home rather than outside it. The smoke plate is moveable and placed in top of the Combustion Chamber. You should make sure that it is pushed all the way back against the back wall

of the combustion chamber.

Draught conditions

Consult your local stove dealer about how best to adjust the draught in your chimney.

Hight of chimney

If in doubt, contact your local stove dealer. He will be able to inform you of the correct hight.

Information about the new cast iron adapter, Part no.: 134

Your stove is equipped with the new cast iron adapter from Varde Ovne.

The adapter is suitable for smoke pipes with inner diameter on 150 mm.

If you need it, it’s now possible for you to make a condensate drain-hole in the adapter.

Carefully punch a chisel or the like through the bottom of the outer groove (at the

arrow mark). This way you can establish a condensate drain hole in the adapter if

needed

Arrow mark for the hole.

Now the condensate – hole is

ready.

Carefully punch a hole with a

chisel or the like.

Page 8

8

Continual fresh air

A continual supply of fresh air is required in the

room in wich the stove is situated. This can be

achieved by installing 1-2 vents, whilst also ensurring that these can not be blocked. The quantity

of air used for burning,

is approx. 20

m³ / h.

Overheating

Occors if too much wood is placed in the

stove or if the combustion receives too

much air.

The Shake grate

The Shake grate is situated at the

bottom of the combustions chamber.

By turning the lower handle the

ashes will be shaken into the ashpan.

Combustion Air Throttel

Turn the Throttel towards left for Air Inlet.

Turn towards right to close.

The Shake grate

Operate by moving the handle inn and out.

Normaly operation of the Stove.

The handle should be in the inner position. The grate must be open.

Page 9

9

How it works —

Operation

The Shake grate is

operated by moving

the handle inn and

out .

Normaly operation

of the Stove.

The handle should

be in the inner position. The grate must

be open.

Ignition/ Lighting your

Varde Ovne stove

1.:

Open the Ignition Air by

turning the handle 1 down.

2.:

Push the Combustion air

Throttle 2 towards left for

Air Inlet.

Your stove is now in ignition position.

Once the fire has caught

properly, push handle 1 up.

Your stove is now in operating position.

Wait until the fire burns

bright and clear.

Regulate the fire/heating by

pushing the Throttle from

left towards right.

Combustion Air Throttel

Turn the Throttel towards left for Air

Inlet. Turn towards right to close.

Ignition Air-is closed when the handle is

pushed up.

1

2

1

L

R

2

Page 10

10

How to light and stoke a fire

The first time you light up the stove, the enamel will temper and give off some smoke and a

slightly burnt smell. We recommend that you leave doors and windows open, as airing the room

will make the smell disappear.

This tempering softens the enamel, making it susceptible to damage. Therefore exercise caution

and avoid touching the enamel. We also recommend opening the door to the stove at regular

intervals during the first couple of hours to prevent the rope seal from sticking to the enamel.

Never use highly flammable liquids such as methylated spirit or petrol for lighting up!

We recommend using ‘top-down’ lighting, where you light the wood at the top of the combustion

chamber and not at the bottom. This is the most environmentally friendly method to light a fire.

The method will also help keep the glass clean. Place two small logs parallel in the bottom plate

of the combustion chamber (approx. 1.3 kg) with a small distance between each log. Place 10 –

15 smaller sticks (approx. 1.3 kg) in a cross on top of the logs, and 2 – 3 firelighters at the top

and in between the sticks.

A thin layer of ash at the bottom of the stove makes it easier to light the fire.

Before lighting the stove, open the ignition air (See page 10 for how)

Once the fire burns, remember to close the ignition air vent and shaking grate again. Otherwise,

the stove and chimney might become overheated, which would invalidate the warranty.

A slight amount of soot may build up on side glass during the start-up fire. This is normal and

vanishes after a period.

Once the kindling has reduced to embers, we recommend opening the door slightly for a couple

of seconds to neutralise the negative pressure in the combustion chamber before opening the

door completely.

Place 2 logs parallel on top of the embers (approx. 1.3 kg) and close the door again. To make

sure the wood ignites quickly, we recommend briefly opening the ignition air vent and make

sure you remember to close it again once the fire gets going. You can then adjust the combustion air according to your heating requirements.

Take care not to shut off the air supply completely, otherwise the fire will die. The fire should

always burn bright and clear.

In most instances, however, you will have to identify the best combustion air settings yourself, as the height and draught of your chimney as well as the quality of the firewood are decisive factors in determining the best settings for your particular stove.

If the nominal heat output of your stove is too high compared to your heating requirements, you

can reduce the output as follows:

- Stoke a smaller amount of wood than usual, for example 1 kg, preferably consisting of 3 – 4

smaller pieces of wood. Apply full air to ignite the wood properly before reducing the combustion

air, perhaps down to approx. 60%. Be careful not to reduce the air supply to the point that the

fire dies. The fire should always burn bright and clear.

With this method it is possible, depending on the chimney, wood quality, etc., to reduce the

stove’s heat output from a nominal 5 kW down to perhaps 3 kW.

Please be aware that it can lead to poor combustion if you reduce the combustion air too much,

resulting in a lower efficiency and increased emission levels (increased pollution).

When refilling the stove with wood, we recommend opening the stove door once only embers

are left in the combustion chamber. Opening the door while flames are still burning and producing smoke and gas might cause smoke to escape into the room.

If you have problems lighting or operating the stove, see the section on Troubleshooting.

Page 11

11

Operation

1. Shake grate

2. Vermiculit plates

3. Ash tray

4. Ignition Air

5. Combustion Air

6. Throttel for Shake grate

7. Cast iron Door

8. Top Steel cover

8

7

1

3

2

4

5

6

Page 12

12

Vermiculite

The plates in the combustion chamber are called vermiculite plates and will eventually

become worn, as will the smoke guide plate. Accidental breakage of a plate, for instance by

hitting it hard with a piece of wood, will not affect the quality of the combustion. You do not

need to replace the plate until the gap is approx. 5 mm wide.

Vermiculite

A special, non-flammable material that looks like chipboard. The plates act as insulation and at

the same time protect the stove against wear and tear. The vermiculite plates and the smoke

guide plate are not covered by the warranty.

Vermiculite is a very porous material and should be handled with care. When refilling the

stove, stoke the wood carefully and use a glove.

Only use original parts from Varde Ovne A/S

How too replace the Vermiculite

1. Lift the left side plate slightly and rotate outwards.

2. Lift the right side plate and rotate outwards.

3. Lift the rear plate up and out of the stove.

4. Air Guide, tilt and remove.

5. Lift the smoke guide slightly, tilt the rear end forward and remove.

When fitting the new vermiculite plates, begin with the Smoke guide and repeat the steps in the

reverse order, finishing with step 1

Vermiculit set,

Item no.: 1501506

1. Smoke guide

2. Air guide

3. Left side plate

4. Right side plate

5. Rear

2

1

4

3

5

Max height of firewood

= 220 mm above grate

Page 13

13

The new stove

The first time you light up the stove the enamel will temper, and give off some smoke and

a slight smell. We recommend that you leave

doors and windows open, as airing the room

will make the smell disappear. This tempering

softens the enamel making it susceptible to

damage. Therefore exercise caution and avoid

touching the enamel. Likewise we recommend

opening the door to the stove at regular intervals for the first hours to prevent the insulations rope from sticking to the enamel.

What kind of wood to use?

Generally, beech wood is considered the best

type of wood for burning. It burns evenly

without producing much smoke and ashes are

clean and take up little space. Ash, birch and

maple wood are fine alternatives.

How big the firewood?

Split firewood with a diameter larger than 10

cm. Use firewood with a length on 20-25 cm.

The use of larger quantities of fuel than recommended in the tabel belove will overtax the

stove and resulte in increased temperatures in

the chimney as well as a lowered efficiency.

This may cause damage to both chimney and

stove, and the annulment of the warranty. Also,

never use toxic materials such as chipboard,

painted or impregnated wood.

What to burn.

This Varde Stove is tested and approved for

the burning of wood. Only dry wood with a

moisture content of maximum 20 percent and

the size to fit into the combustion chamber

should be used. The burning of moist wood

will result in an increased amount of tarry

soot, pollution and uneconomic fuel consumption. Newly chopped wood contains about 6070 percent moisture, which makes it completely unsuitable as fuel. Allow newly chooped

firewood to dry in a open shed for a couple of

years before using it in the stove.

Do not use! - Consider the environment

Also, never use toxic materials such as

chipboard, painted or impregnated wood.

The use of larger quantities of fuel than recommended in the tabel belove will overtax

the stove and resulte in increased temperatures in the chimney as well as a lowered efficiency. This may cause damage to both chimney and stove, and the annulment of the warranty.

Fuel Quanti-

ty

[kg]

Primary Air

open

[%]

Combustion

Air open

[%]

Nominal

Output

[kW]

Chimney

Draught

[PA]

Efficiency

[≥ i %]

Refill interval at

nominal output

[minuts]

1,3

0 (closed) 50 % 6,1 12 79 % ca. 45

The following optimal register and fuel quanitty settings are recommended(in case of similar chimney

draught):

Kindling

Lenght: 25 –30 cm

Diameter: 2-5 cm

Amount per firing: 1,3 kg

(approx. 10-12 finely chopped pieces)

Feeding Wood: Chopped wood

Lenght: 25-30 cm

Diameter: 7-9 cm

Normal amount: 1.3 kg/hour (2 pieces)

Max amount: 2.0 kg/hour (max 3 pieces per insertion. Max 1.5 kg

per insertion)

Topdown lightning

Page 14

14

Maintenance

Like any piece of equipment in daily use, your stove needs maintenance.

The stove should only be cleaned when cold. Use a dry cloth for cleaning the exterior of the

stove.

Clean the interior regularly by removing ashes, soot and tar from the combustion chamber. The

smoke deflector plate should be removed for cleaning, as the reverse side will be covered in dirt

and soot. Finally check that the smoke pathway through the flue pipe and chimney is completely

clear. You should also inspect the rope seals in the door and ash pan for signs of wear. Replace

them if they no longer seal properly. Also, remember to lubricate the door hinges as required.

Glass pane

The glass pane should be cleaned using Varde Glas Cleaner, which is available at all DIY centres

selling Varde Ovne stoves.

Empty the Ash pan regularly. It can be emptied into your dustbin, as long as you make sure it

does not contain any hot embers. If in doubt about how to clean your stove, contact the dealer

where you bought your stove, or your chimney sweeper.

It is especially important to check the stove and the chimney for blockages after a long period of

non-use.

The enamelled surface of the stove may wear down in certain places if the stove is overheated. Worn surfaces can, however, be repaired with a special Senotherm® spray paint, available

from your local dealer.

The plates in the combustion chamber are vermiculite plates and will eventually become

worn, as will the smoke deflector plate. Accidental breakage of a plate, for instance by hitting it

hard with a piece of wood, will not affect the quality of the combustion. You do not need to replace the plate until the gap is 5 mm wide.

Only use original parts from Varde Ovne A/S

The door is equipped with a spring, which pulls the gate closed. This is a legal requirement in

many countries. The spring is fitted to the hinged side of the door but can be removed if you

prefer the door not to be spring-loaded.

Do not make any unauthorised changes to the stove.

All external parts of the stove become hot during use, and you should therefore exercise due caution.

IMPORTANT!!

Chimney fires

Should your chimney catch fire, cut off the air supply to the stove’s combustion chamber and

contact the emergency service. (The majority of fires die out after the oxygen supply is cut off.)

You should subsequently contact your chimney sweeper, who will check your stove and chimney

for damage

Page 15

15

Troubleshooting.

Smoke enters the room

• Not enough draught in the chimney.

• Inspect the flue pipe or the chimney for blockage.

• Make sure the height of the chimney is correct.

The glass or the chimney soots up

• The wood is too moist.

• Not enough secondary air is supplied to the combustion process.

• You may have shut off the supply of ignition air too soon when lighting the stove.

• There should be clear flames in the combustion chamber at all times.

No heat is emitted from the stove

• The wood is too moist (all energy is spent on drying it) or of a poor quality.

• Inspect the position of the smoke deflector plate and make sure there is free passage for the smoke.

• The amount of combustion (secondary) air is insufficient.

Combustion is too intense

• Rope seals in the door or the ash pan are no longer tight and need replacement.

• The chimney draught is too strong; install a damper in the chimney.

• Check that the ignition air is shut off.

The shaking grate is stuck

• Inspect the grate for jammed wood, nails or the like.

• Make sure the lever is placed correctly.

Recycling

Packaging

For environmental reasons, the packaging should be disposed of together with household waste.

The packaging is 100% recyclable.

Ceramic glass

Ceramic glass should be deposited at the local recycling centre (together with pottery and porcelain).

Vermiculite

Vermiculite plates from the stove should be deposited at the local recycling centre.

Page 16

16

Spare Parts

If Spare parts at any time should be needed, please chech the list below.

Vermiculit Set, Item no.: 1501506

Glas, Item no.: 1501503

Locking system, Item no.: 1501565

Sealings—Door , Item no.: 10014+10008

Shake Grate, Item no.: 65

Glass spring with screws, Item no.: 10024

Page 17

17

Continual fresh air.

A contiual supply of fresh air is reguired in the room in witch the stove is situated. This can be

achived by installing 1 or 2 vents, whilst also ensuring that these can not be blocked.

Combustion air supply (extra)

When a stove is installed in a room, the requirements to air supply increase. The air can be supplied through a vent in the outer wall or through a duct from the outside that is attached to the

connector underneath the stove. The quantity of air needed for combustion is approx. 20 m³/h.

The spigot has an outer diameter on 67 mm. With pipes longer than 1 m the pipediameter has

to be increased to 100 mm, and equivalent larger wall vent is chosen.

Leave a 40 mm

gap between the

condensation insulation and the bottom

of the stove.

Indirectly through the exterior wall

Through the exterior wall

Through the floor and foundation

Through the floor and

crawl space

Page 18

18

Page 19

19

Warranty

All Varde stoves go through a close quality inspection, and we take

pride in always delivering products of a consistent quality. This being

so, manufacturing faults may still occur, and on these we offer a 5

year warranty.

The warranty does not include:

· wearing parts, such as the Vermiculite plates in the combustions

chamber, the smoke plate, glass, gaskets, cast iron bottom and

shacking grate.

· Damages whichs occur as a consequence of misuse, such as overheating, incorrect installation, missing or wrong maintenance etc. (see

instructions earlier)

·Damages caused by external influence of a physical character.

·Cost of transportation in connection with warranty repairs.

·Assembling/reassembling in connection with warranty repairs.

·Compensation for following damages, including damage on other

objects.

Warranty conditions:

These instructions for use are also your proff of warranty. The warranty will not take effect until vendor’s stamp, information about model, registration numer and date of purchase (invoice if possible)have

been applid below. In case of claims, please bring this proof of warranty to your local vendor.

Model:

Reg.no.:

Date of

purchase:

Vendor’s stamp and signature

Page 20

20

Soldalen 12, 7100 Vejle, Danmark, Tel. +45 7482 0003. vardeovne.dk

Loading...

Loading...