Page 1

QUICK REFERENCE GUIDE

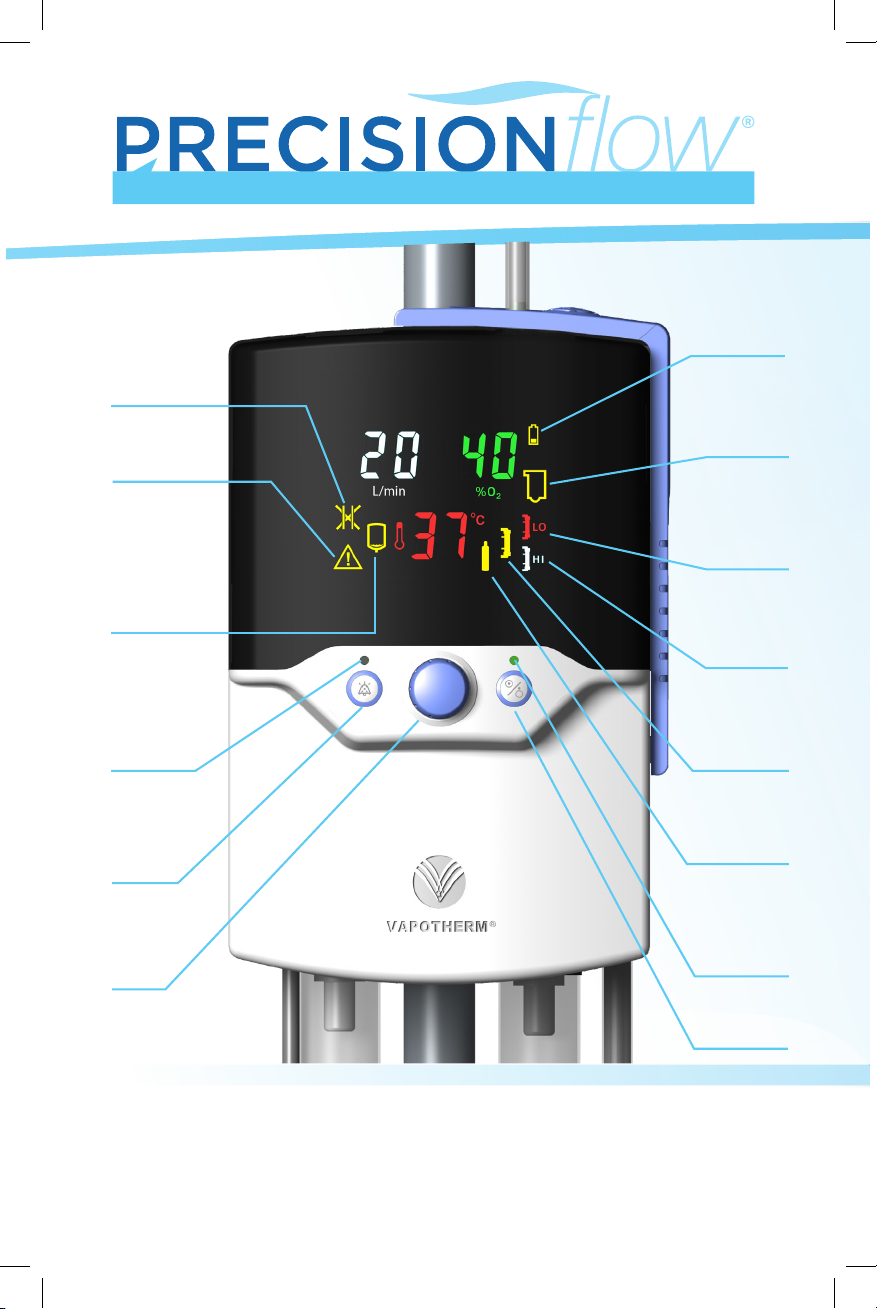

Battery low

or charging

(not indicative of

charge level)

Blocked tube

General fault

Water out

Alarm mute

LED

Alarm mute

button

Setting

Control

Knob

Disposable

Water Path

faulty or

absent

Low Flow

Circuit

Installed

High Flow

Circuit

Installed

Vapor Transfer

Cartridge fault

Gas supply

fault

Run/Stop

Status LED

Run/ Standby

button

This guide provides you with basic instructions on how to set up and operate

the Precision Flow®. Before operating the Vapotherm Precision Flow®, please

review the Instructions For Use which can be found at our website

www.vapotherm.com and on the USB drive provided in the Start-Up Kit.

Page 2

ALARM ICON WARNING INDICATES CAUSE ACTION

ALARM ICON WARNING INDICATES CAUSE ACTION

Primary Indications:

Precision Flow® is intended for use to add warm moisture to breathing gases from an external source for

administration to a neonate/infant, pediatric and adult patients in the hospital, subacute institutions, and home

settings. It adds heat and moisture to a blended medical air/oxygen mixture and assures the integrity of the

precise air/oxygen mixture via an integral oxygen analyzer. The ow rates may be from 1 to 40 liters per minute

via nasal cannula.

Contraindications: General:

• Not appropriate for patients who are not spontaneously breathing, are unable to protect their airway or have anatomic or

injury induced blockage of the nasal pathway to the nasopharyngeal space

• Not for treating OSA and snoring

• The Precision Flow® is not for eld transport

• The Precision Flow® is MRI unsafe. Do not use it in an MR environment.

Additional patient monitoring including pulse oximetry is necessary if the Precision Flow® is used to give

supplementary oxygen.

Precision Flow® Packaging contains:

Precision Flow® Unit

Power Cord

US ONLY - Air and Oxygen Hoses

Check gas supply. If not

GENERAL FAULT

and

– – IN FLOW

(FLASHING)

Malfunction of

sensor or control

system

Internal

component failure

corrected, disconnect patient.

Unplug AC power, press and

hold Run/Standby button for

3 seconds to clear the alarm,

send for service.

GENERAL FAULT

and

– – IN 0

2

(FLASHING)

O₂ sensor fault

Depleted or

defective O₂ sensor

Unplug AC power, press and

hold Run/Standby button for

3 seconds to clear the alarm.

Replace O2 sensor. Restart unit.

Cannot be corrected by user:

GENERAL FAULT

and

– – IN TEMP

(FLASHING)

Temperature

out of range.

Overheating or

temperature sensor

malfunction.

disconnect patient. Unplug AC

power, press and hold Run/

Standby button for 3 seconds

to clear the alarm, send for

service.

No water in dispos-

WATER OUT

able

water path. Gas ow

continues without

heating or water

Sterile water empty,

or obstructed inlet

tube.

Replace water bag or straighten

inlet tube. Restart unit. If alarm

persists, disconnect patient

from therapy.

circulation.

If disposable water path is

present, place unit into

Standby, remove and replace

disposable patient circuit to

reset detector. Restart unit.

DISPOSABLE

WATER PATH

(FLASHING)

BATTERY

CHARGING

(STEADY)

Disposable water

path faulty or not

detected. Unit will

not run.

Disposable water

path defective, not

properly seated or

not installed.

The internal battery backup is not fully charged. The unit would not run on

battery for the full rated time in the event of a power failure. No action is

necessary.

The unit is running

BATTERY

(FLASHING)

in BATTERY mode.

Gas ow and

blending continues

without heat or

water circulation.

AC power is

disconnected

Reconnect AC power.

Obstructed or

BLOCKED TUBE

(FLASHING)

High back pressure

kinked cannula/

delivery tube, incorrect cannula for

Clear obstruction, check

cannula type, re-install DPC

ow rate or DPC

improperly seated

GENERAL FAULT ALARMS:

indicated by this icon accompanied by the Temp display showing numbers between 50 & 84 (error codes) and

dashes in O₂ and Flow displays. When an error code is displayed, gas delivery is stopped. The user needs to monitor

the treatment and respond to general fault alarms. General Fault alarms cannot be silenced with the mute button.

To reset, rst disconnect the unit from AC power and then press the Run/Standby Button. With the exception of O₂

sensor replacement, the unit must be repaired by an approved service facility.

Failures in the control or measurement systems will cause a General Fault alarm

CANNULA FLOW RATES

CARTRIDGE CANNULA TYPE OPERATIONAL FLOW RATES

High Flow Adult, Pediatric/Adult Small, Pediatric Small* 5-40 liters per minute (L/min)

Low Flow Premature, Neonatal, Infant, Intermediate Infant,

Solo, Pediatric Small*

*Pediatric Small cannula is intended to deliver ow rates of 1-20 L/min

1-8 liters per minute (L/min)

Page 3

ALARM ICON WARNING INDICATES CAUSE ACTION

LO HI

CARTRIDGE

FAU LT

CARTRIDGE

TYPE

GAS SUPPLY

(FLASHING)

GAS SUPPLY

(CONTINUOUS

AND FLOW

RATE NUMERIC

DISPLAY

FLASHES)

TEMPERATURE

NUMERIC

DISPLAY

FLASHES

Disconnect patient. Remove

Cartridge and/or DPC not

detected. Unit will not run.

RUN mode: faulty

sensor or cartridge

not detected.

disposable patient circuit.

Check cartridge installation.

Check sensor windows are

clean.

Disconnect patient. Place

Gas bubbles in water

circulation. Unit

continues to operate.

Excessive gas

diusion through

cartridge bers.

unit into Standby. Replace

disposable patient circuit

including water path,

cartridge & delivery tube.

Cartridge and/or DPC

not detected.

STANDBY mode:

missing cartridge.

Remove disposable

patient circuit. Check

cartridge installation.

Indicates type of cartridge installed (low or high ow). Not an alarm.

Gas supply pressure

outside 4-85 psi

(28-586 kPa) range.

Unit will not operate.

Selected ow can not

be provided from current

gas supply.

Gas supply is

disconnected or

exhausted.

Inlet gas pressure

too low for selected ow rate.

Check gas supply and correct

as necessary.

Increase gas pressure or

decrease ow setting.

User enters set

Temperature 2° > set point

point much lower

than previous

Silence alarm and wait for

temperature to drop.

temperature.

Temperature 2° < set point

Very low water

temperature after

bag replacement.

Silence alarm and wait for

temperature to rise.

INDICATIONS, WARNINGS AND CAUTIONS

Primary Indications:

Precision Flow® is intended for use to add warm moisture to breathing gases from an external source for

administration to a neonate/infant, pediatric and adult patients in the hospital, subacute institutions, and home

settings. It adds heat and moisture to a blended medical air/oxygen mixture and assures the integrity of the

precise air/oxygen mixture via an integral oxygen analyzer. The ow rates may be from 1 to 40 liters per minute

via nasal cannula.

Contraindications: General:

• Not appropriate for patients who are not spontaneously breathing, are unable to protect their airway or have anatomic or

injury induced blockage of the nasal pathway to the nasopharyngeal space

• Not for treating OSA and snoring

• The Precision Flow® is not for eld transport

• The Precision Flow® is MRI unsafe. Do not use it in an MR environment.

Additional patient monitoring including pulse oximetry is necessary if the Precision Flow® is used to give

supplementary oxygen.

Precision Flow® Packaging contains:

Precision Flow® Unit

Power Cord

US ONLY - Air and Oxygen Hoses

Instructions For Use on USB Quick Reference Guide

Air & Oxygen Inlet Particulate Traps with Connectors O2 Sensor cell

Delivery Tube clip

Page 4

DISPOSABLE PATIENT CIRCUIT

• Assemble Disposable Patient Circuit according to provided instructions.

• Open door and install Disposable Water Path into docking station so there is no gap

between bottom of the Disposable Water Path and the Docking Station Floor

• Hang sterile water bag or bottle

• Wipe water spike with alcohol pad or equivalent and insert into sterile water bag

• Allow a minimum of 200ml of water to ll into the Disposable Patient Circuit

• Precision Flow is ready for start up

START UP AND ADJUSTING PARAMETERS

• Install oxygen sensor. Replace sensor annually

• Install gas inlet lters on back with lter bowls vertical (glass side down). Replace gas

inlet lters every six months

• Attach air & O₂ hoses. Plug in power cord

• Rotate the blue Setting Control Knob to illuminate display

• Press in Setting Control Knob to select the parameter and rotate to adjust the value

• Press and release (do not hold) the Run/Standby button once to start

A GREEN light indicates RUN mode (AMBER light indicates STANDBY mode, No Flow)

• Green light will stop ashing once temperature is reached

CONNECT TO PATIENT

• The ashing green LED becomes steady when the set variables are reached

• Place the cannula on the patient. Once the unit has reached at least 33°C, connect to

delivery tube

• The unit should not be placed in Standby mode for extended periods of time. For

pauses in therapy, keep unit in RUN mode, remove cannula from the patient, and set

the parameters to the lowest available setting. To reinitiate therapy, before cannula is

placed on patient, clear accumulated condensate

INTERNAL BATTERY BACK-UP

• The back-up battery is designed for temporary use only, when AC power to the unit

has been interrupted

• The unit will enter into battery mode and will maintain ow and oxygen percentage

for at least 15 minutes

• The battery icon will ash

• Replace battery every two years

• Battery recharges in two hours

SHUT DOWN

• Press the Run/Standby button. Unit will enter Standby mode (No Flow), indicated by

the AMBER light

• Clamp the water inlet tube. Open the door, remove the Disposable Patient Circuit

(includes delivery tube & cartridge) by sliding it upwards out of the docking station

• Discard all disposables according to hospital guidelines

• Disconnect unit from AC power

• Wipe down with Super Sani-Cloth®. In addition, if hospital procedures require, the

following may be used: 70-90% Isopropyl Alcohol, 2% (maximum) chlorine cleaning

solution, 6% (maximum) Hydrogen Peroxide cleaning solution, CaviWipesTM, AF3

Germicidal, Incidin® OxyWipe, Bacillol® 30 Tissues, Clinell® Alcohol Wipes, or Tue

Disinfectant Wipes

VAPOTHERM, INC.

100 Domain Drive

Exeter, NH 03833

T: 603-658-0011

USA

3101540 Rev. A

May be patented. www.vapotherm.com/patents

Technical Support

T: 855 557 8276 Domestic

+1 (603) 658-5121 International

ts@vtherm.com

0297

RMS-UK Ltd.

28 Trinity Road

Nailsea, North Somerset

BS48 4 NU

United Kingdom

Loading...

Loading...