These instructions contain operating information and should be left with the unit.

Resistance Heater Units

Installation & Operation Manual

Edition 6

(For use with Software version 8.0 and subsequent issues)

Installation in countries covered by EC Directives:

This product meets the requirements of the RoHS Directive 2002/95/EEC

This product will meet the requirements of the Low Voltage Safety Directive 2006/95/EEC and the

EMC Directive 2004/108/EEC when installed in accordance with the instructions contained in this

manual.

Failure to comply with these instructions may invalidate the manufacturer's warranty or any

certificate/declaration of conformance requested to be supplied with the unit.

CONTENTS

1.0 Installation. ................................................................................................................................ 4

1.1 Positioning the Vapac LR unit ................................................................................................... 4

1.1.1 Vapac LR unit dimension layout ............................................................................................ 4

1.1.2 LR weights ............................................................................................................................. 7

1.2 Positioning the steam pipes ...................................................................................................... 7

1.2.1 General .................................................................................................................................. 7

1.2.2 Steam Hose Connection ....................................................................................................... 7

1.3 Plumbing Considerations. ......................................................................................................... 8

1.4 Electrical Connections .............................................................................................................. 9

1.4.1 Important E.M.C. Considerations ......................................................................................... 9

1.4.2 Power Supply Connection ................................................................................................... 10

1.4.2.1 Volt free alarm outputs ........................................................................................................ 10

1.4.2.2 Unit control terminals ........................................................................................................... 10

1.4.3 Electrical Connections ......................................................................................................... 11

1.4.4 Cable Entry Provision .......................................................................................................... 11

1.4.5 Vapac Control Circuit Transformer ...................................................................................... 11

1.4.6 RDU Connection.................................................................................................................. 11

1.4.7 Cylinder Electrical demand loads ........................................................................................ 12

1.5 Control Circuit Connections .................................................................................................... 13

1.5.1 Control Circuit Wiring .......................................................................................................... 13

1.5.2 Proportional Control ............................................................................................................ 13

1.5.3 Control Signal Selection ...................................................................................................... 13

1.5.4 On/Off Control ..................................................................................................................... 13

1.5.6 Security Circuit / E.P.O. Shutdown ...................................................................................... 14

1.5.7 Load Shed Option................................................................................................................ 14

1.5.8 Master/Slave System .......................................................................................................... 15

2.0 Start-Up / Operation ................................................................................................................ 16

2.0.1 Start-up check list ................................................................................................................ 16

2.0.2 Start-Up Instructions ............................................................................................................ 17

2.0.3 Commissioning/Start-Up ..................................................................................................... 17

2.0.4 Features of VAPANET Resistance Heater Unit .................................................................. 17

2.1 Service Advice ........................................................................................................................ 18

2.1.1 Cylinder Inspection. ............................................................................................................. 18

2.2.1 Feed Valve with Strainer ..................................................................................................... 19

2.2.2 Drain Pump .......................................................................................................................... 19

3.0 Location of Indicators and Controls ....................................................................................... 20

3.1 Positioning of Indicators and controls on Vapac ® Vapanet ® LR Units. ............................... 20

3.2 Initial Set-up ............................................................................................................................ 21

3.3 Normal Run / Standby / Start-up – No User Intervention Required ........................................ 22

3.4 Fault / Service Indications – Requiring Operator Intervention. ............................................... 23

3.4.1 To Postpone the Sevice: ..................................................................................................... 24

3.4.2 To Service the unit: ............................................................................................................. 24

3.5 Other Options .......................................................................................................................... 25

3.6 Use with LRO unit................................................................................................................ 25

4.0 Trouble-shooting Check List ................................................................................................... 26

5.0 Wiring Diagram ....................................................................................................................... 27

Appendix 1.

A Guide to Positioning Steam Pipes: ................................................................................................. 41

Appendix 2.

A Guide to Positioning Multipipes: ..................................................................................................... 43

Important Installation Points

The unit must be installed to comply with national regulations and/or codes of practice. A qualified

electrician must carry this out.

Ensure at least 1000 mm clear front access to the electrical and steam sections of the cabinet.

Do not locate the cabinet where the ambient temperature around the unit could exceed 35ºC or fall

below 5ºC e.g., an unventilated roof mounted enclosure – see minimum space / ventilation

requirements page 5.

Do not locate the cabinet where a ladder is required for service access as this could make

servicing and cylinder service or exchange hazardous.

Make sure steam line(s) have adequate slope (min 12%) for condensate drainage and use

condensate separators if the pipe is lower than the unit.

Provide adequate support to prevent sags developing in flexible steam lines, w hich can fill w ith

water and create a "trap".

Do not locate vented drain directly under the cabinet.

It is important to select the correct water type, see table on page 8, your water supply company

should be able to provide the required information free of charge.

Important Electrical Connection Items

Before commissioning the unit, check that all electrical (power) connections - including those at

the terminals and contactor are tight.

Check that the transformer primary winding connection is correct for the supply voltage at Vapac

terminals A1 & A2.

The Vapac transformer must not be used to power other equipment.

To comply with EMC aspects see recommendations on page 9.

Use a high-limit humidistat to ensure positive interruption of unit operation when over-

humidification is detected (see p14).

It is important that the control signal connected to terminals 5 & 6 must be referenced to ground at

the control PCB – this can be done by linking either terminal 5 or 6 to terminal 7.

NB if the controller output is referenced to ground, it is important that the “leg” which is

connected to ground at the controller is also connected to ground at the Vapac unit. Grounding

the opposite “leg” will cause damage to the controller and/or the Vapac control PCB.

Important Maintenance Items

Only a qualified electrician should carry out maintenance.

The boiler contains hot water, and must be drained before any maintenance is carried out on the

steam section. This should be done prior to isolating the power, and removing the front access

panel

ESD SENSITIVE DEVICES USED ON PCB. ENSURE ANTI-STATIC PRECAUTIONS ARE TAKEN

WHEN REMOVING OR REPLACING PCB’S.

1.0 Installation.

1.1 Positioning the Vapac LR unit

1.1.1 Vapac LR unit dimension layout

Do’s

Do mount the unit as close to the steam distribution

pipe(s) as possible.

Do mount the unit at a height convenient for reading the

display window.

Do ensure adequate side ventilation (min 80 mm).

Do ensure adequate service access to the front of the unit

(min 1000 mm).

Do ensure adequate service access below the unit (min

1000 mm).

Do ensure that the holes in the rear top panel remain

unobstructed to allow a free flow of air see fig 1.

Do use the marking on the side of the carton as a template

to mark the mounting hole positions.

Do remove the cylinder, if necessary, to access the

mounting holes in the back of the steam section.

Do use M6 projecting type wall bolts or equivalent to

mount the unit in position.

Do mount units with RDU’s so that steam pipe discharge is

above head height.

Do leave minimum gap between the top of an RDU and

the ceiling as per table in fig 3.

6

165

Don’ts

Don’t mount the unit close to sources of strong electro-

magnetic emissions e.g. variable speed lift motor

drives, kVa transformers etc.

Don’t mount the unit in an unventilated enclosure.

Don’t mount in a position requiring ladder access to the

unit.

Don’t mount the unit behind a false ceiling or other

situation where an unusual malfunction (e.g. water

leak) would cause damage.

Don’t mount the unit in an area which will be hosed down.

Don’t install the unit where the ambient temperature can

exceed 35oC; or fall below 5oC.

Don’t mount the unit inside a cold-room or other place

where temperature and humidity conditions can cause

condensation on electrical components.

Don’t mount the unit where the sound of a contactor

opening/closing and water flow in a pipe would be

unacceptable e.g. libraries, private apartments, etc.

Don’t position an RDU to discharge directly over

expensive equipment, desks or stored materials

305

6

.

Gland Plate

120 x 120

NB Entry hole for

Gland Plates approx

105 x 90

299

360

55

810

62

186

Steam Outlet

330

165

305

70

520

73555

Wall mounting

fixing centres

D = Drain discharge 35mm pipe.

D

F

F = Water feed ¾” BSP male

connection

Fig 1 LR5 & LR5P to LR 30 &

LR30P units with or without

RDU fitted.

52

90

Fig 2 LR5 & LR5P to LR 30 & LR30P RDU

Within the area of H1 or H2 above the unit nothing must protrude out from the

wall, as this will effect the natural ventilation path of the Unit.

Fig 3 Clearances around LR units.

LR UNIT A B L H min H1 H2

LR5 & LR5P 377 205 80 1000 500 200

LR10 & LR10P 377 205 80 1000 500 250

LR20 & LR20P 435 205 80 1000 500 500

LR30 & LR30P 602 205 80 1000 500 750

Fig 4 LR40 & LR40P to LR 60 & LR60P

610

190

360

55

6

176

346

6

55

360

322

Steam outlet pipes position.

610

990

810

505

190

73555

31.1"(790)

70 850

Gland Plate

120 x 120

NB Entry hole for

Gland Plates approx

105 x 90

152

D = Drain discharge

35mm pipe.

F = Two water feed ¾”

BSP male connection

Note:- RDU units

cannot be fitted to LR40 &

LR40P to LR60 and

LR60P units

20.5"(520)

468

62

FF

D

237

343

343

LR40, LR40P, LR50, LR50P, LR60, and LR60P units

have the same minimum recommended dimension as

follows:

Note:

L, H & H1 refer to dimensions shown in Fig 3 on page 5.

Wall mounting

fixing centres

Gland Plate

120 x 120

NB Entry hole for

Gland Plates approx

105 x 90

L 100

H 1000

H1 600

7

1.1.2 LR weights

The unit dry weight is the delivered unit with no

water in unit, the wet weight is the operational

weight when the unit is running . The RDU weight

must be added to the unit weight if fitted on top of

the Resistive unit.

Resistive model Dry Kg Wet Kg RDU Kg

LR5 and LR5P 34 48 6

LR10 and LR10P 35.5 49.5 10

LR20 and LR20P 39 65.5 12

LR30 and LR30P 40 66.5 14

LR40 and LR40P 72.5 125.5 NA

LR50 and LR50P 73.5 126,5 NA

LR60 and LR60P 74.5 127.5 NA

1.2 Positioning the steam pipes

1.2.1 General

Steam pipes should be positioned as shown below,

allowing a minimum rate of fall back to the unit of

12% to allow the free flow of condensate back to the

unit. If the above fall is not possible, then

condensate separators must be fitted as shown in

figure 1.

The position of the steam pipe or multipipe in a airconditioning system relative to other items such as

bends, filters, heat exchangers, etc., is critical. The

steam pipe must not be located closer to such item,

than the entrainment distance, and must be decided

by the design engineer responsible for the project.

Do's

Do obtain project engineer's instruction/drawing for

chosen location of pipe

Do obtain project engineer's instruction/drawing for

pipe position relative to the top & bottom of the

duct (or sides if airflow is vertical.

Do check if alternative slope of Ø35mm pipe has

been specified requiring rotation of pipe in its

socket before installation.

Do use bracket/lug on the end of Ø54mm pipes for

extra support.

1.2.2 Steam Hose Connection

Do's

Do use Vapac steam hose or well insulated copper

pipe.

Do keep steam hose as short as possible (under 2m

for max efficiency).

Do arrange to have a vertical rise immediatel y over

the unit of 300mm.

Do use the full height available between the unit and

steam pipe to provide maximum slope (min 1220% for condensate to drain back to the steam

cylinder (or down to a condensate separator).

Always provide a continuous slope.

Do provide adequate support to prevent sagging

a) fit pipe clips every 30-50cm

or b) support straight lengths on cable trays or

in heat resistant plastic pipe.

Do ensure radius hose bends are fully supported to

prevent kinks developing when in service.

Do add extra insulation to steam hose for longer

runs (2m-5m) and in cold ambient conditions to

avoid excess condensate and reduction in

delivered output.

Don'ts

Don't allow steam hose to develop kinks or sags.

Don't include horizontal runs or 90

steam line.

o

elbows in the

Steam Distribution Pipe requirement

Resistance Heater

Unit Model

35mm ∅ Pipe No.

54mm ∅. Pipe No.

* Duct Pressure Pa. +2000

* For systems with a duct pressure over +1000 Pa. It may

be necessary to fit a suitably sized trap in the water feed

line between the Vapac tundish and the feed drain

manifold to ensure water can enter the cylinder when it is

empty.

LR05

LR10

LR05P

LR10P

1

-

LR20

LR30

LR20P

LR30P

-600

LR40

LR50

LR60

LR40P

LR50P

LR60P

-

1

+2000

-600

Flexible Steam

Pipe.

-

2

No Sags!

Flexible Steam

Pipe.

Distance to first

bend.

R min for 35 ∅ Pipe = 250mm

R min for 54 ∅ Pipe = 500mm

VAPAC

HUMIDIFIER

35 or 54 mm

copper or

stainless steel

steam pipe with

Insulation.

Flexible pipe coupling to

connect Steam pipe to Duct

pipe coupling length to allow

for line movement and

expansion. Coupling clamp

with Hose clips each end.

Fig 6

35mm ∅ Pipe Selection

Duct width

B mm

320-470

470-620

620-770

770-920

920-1070

1070-1200

In-duct Length

L mm

300

450

600

750

900

1050

For guidance on positioning of steam pipes see

Appendix 1.

For guidance on use of Multipipes see Appendix

2.

54mm ∅ Pipe Selection

Duct width

B mm

700-950

950-1450

1450+

In-duct Length

L mm

(Kg)

650 (1.8)

900 (2.2)

1400 (3.2)

8

1.3 Plumbing Considerations.

1.3.1 Cold water supply.

General

The Resistance Heater range of units is capable o f

operating with a range of water quality ra w mains or

de-mineralised/de-ionised. The water supply should

be within the following limits:-

Conductivity 0 – 1000µS

PH 7.3 – 8.0

Silica 0

Pressure of between 1 - 8 bar.

Maximum chloride level 170 ppm

Water Supply rates

1.70 l/min

1.70 l/min

2.00 l/min

2.50 l/min

4.00 l/min

4.50 l/min

5.00 l/min

LR05

LR10

LR20

LR30

LR40

LR50

LR60

LR05P

LR10P

LR20P

LR30P

LR40P

LR50P

LR60P

Do’s

Do install a stop-valve/Shut-off valve and a strainer

close to the unit.

Do provide a water supply with sufficient pressure

and pipe size to ensure an adequate flow rate to

all units connected to the system.

Do use the water connection with nylon nut

provided.

ALL Dimensions in mm

A

B

C

D

F

K

L

M

N

Single Cylinder Units 5-30kg/h

Twin Cylinder units 40-60kg/h

H

G S V

Fig 7

Water type Selected

De-mineralised < 50

De-ionised 50 – 100 < 80

Softened 100 – 200 80 – 100

Potable (Low conductivity) 200 – 300 100 – 150

Potable (Med. conductivity) 300 – 500 > 150

Potable High conductivity > 500

Conductivity

range µS

Max. Chlorine

level ppm

Generally the water type will be selected by the

conductivity levels, however they should be

modified as shown, e.g. conductivity of 75µS and

chlorine level of 85 ppm the correct setting is

Softened”.

Don'ts

Don’t use a wrench or other tool to tighten the water

supply connection - the nylon nut and rubber

washer provided, should only require tightening

by hand to effect a seal. If water seepage occurs,

undo the nut to wipe the washer clean and reseat it.

1.3.2 Drain connection

General

Do's

Do ensure metal drain and supply water pipe work is

grounded electrically close to the unit (a

ground/earth stud is positioned on the under side

of the cabinet.

Drain capacity per cylinder

= pump discharge rate of max 16.8 l/min at 50 Hz.

Power supply 17.2 l/min at 60 Hz.

Do’s

Do use copper or plastic pipe rated for 100

Do arrange to discharge drain water from the unit

into a trapped and vented drain at a position

where flash steam rising from the drain line vent

will not pose a problem for the Vapac or other

equipment.

Do provide adequate fall for the drain pipework to

allow free flow of water drained from each unit.

Do ensure drain line pipe size will accommodate

water being drained at the same time from all the

Vapac units which are connected to it.

KEY: A Tundish Fill-cup

B Steam Cylinder

C Feed Drain Manifold

D Drain Pump

F Feed Solenoid Valve

G Water Connection ¾” BSP.

H Flexible hose ¾” BSP.

K 35∅ Steam Hose coupling and Hose

Clips.

L 35∅ copper or plastic Drain for 110°C

Water with supports.

M Tundish

N U-trap side exit.

S Optional Strainer

V Isolation stop cock

.

o

C.

9

1.4 Electrical Connections

Important Power Connection Information

Vapac 24V and 9 V secondary Transformer Primary supply connections:

Vapac units are wired to allow connection to alternative site Voltages.

Make the following simple checks before connecting the power supply:Move the RED connection on the VAPANET transformer primary winding circuit to the

position marked with the supply Voltage t hat is to be connected between VAPANET

power terminals A1 and A2.

The transformer primary circuit terminal positions are clearly marked:- 200V, 230V,

380, 415 & 440V. If the actual (measured) site voltage is 400v the preferred

tapping is 380V. The transformer is fitted below the Drain tray, and is accessible by

Note:

24 V a.c. Control circuit -

9 V a.c. PCB Circuit -

Transformer Primary Circuit And RDU.

230V ac Pump Supply. -

removing two screws and the cover, which should be slid it towards you.

6.3 A 20 mm (T – Time Lag) fuse (Pt.No. 1080093)

Echelon PCB (Pt.No.1150630).

2 A 20 mm (F - Quick blow) fuse (Pt No. 1080099) mounted on the VAPANET

Echelon PCB (Pt, No. 1150630).

Two fuses protect the control circuit on Single cylinder units F1 2.0A (slow blow)

(Pt. No. 1080095) mounted in fuse-terminal holder protects Primary transformer

and RDU unit if fitted. F2 500 mA 20 mm (F - Quick blo w) fuse (Pt No. 1080054)

mounted in fuse-terminal holder protects Transformer Primary a nd Pump or both

pumps if two pumps are fitted.

The pump or pumps on twin cylinder units are fed from the main transformer via a

230 volt auto winding. The pumps are protected by fuse F1 and F2 above feeding

the transformer primary.

1.4.1 Important E.M.C. Considerations

Use a dedicated, earthed metal conduit for both the

control signal cable and the security circuit cables

along their entire length - they may share the same

conduit where practicable. The earth must be made

by "metal-to-metal" contact and should be a good

RF (Radio Frequency) earth.

The control and security circuit connections should

be run in screened cable with the screen g rounded

at the VAPANET end (onto the electrical section

back panel). The screen should be maintained as

close as possible to the cable ends and any tail

between the screen and the earth point must be

kept short (50 mm maximum).

Control Cable / Security Circuit

Conduit Entry Arrangement

Electrical section metalwork

All metal surfaces which come

into contact with each other,

must be free of paint, grease,

dirt, etc., thereby ensuring a

good low impedance R.F.

(Radio Frequency) path to

ground.

Control Cable / Security Circuit

Cables to control terminals

Outer insulation

mounted on VAPANET

Screening Arrangement

Tail to be kept short

(less than 50mm)

Screen left intact

Earthed back panel

Metal conduit

1.4.2 Power Supply Connection

The unit requires the following connections as shown in

the diagram below

10

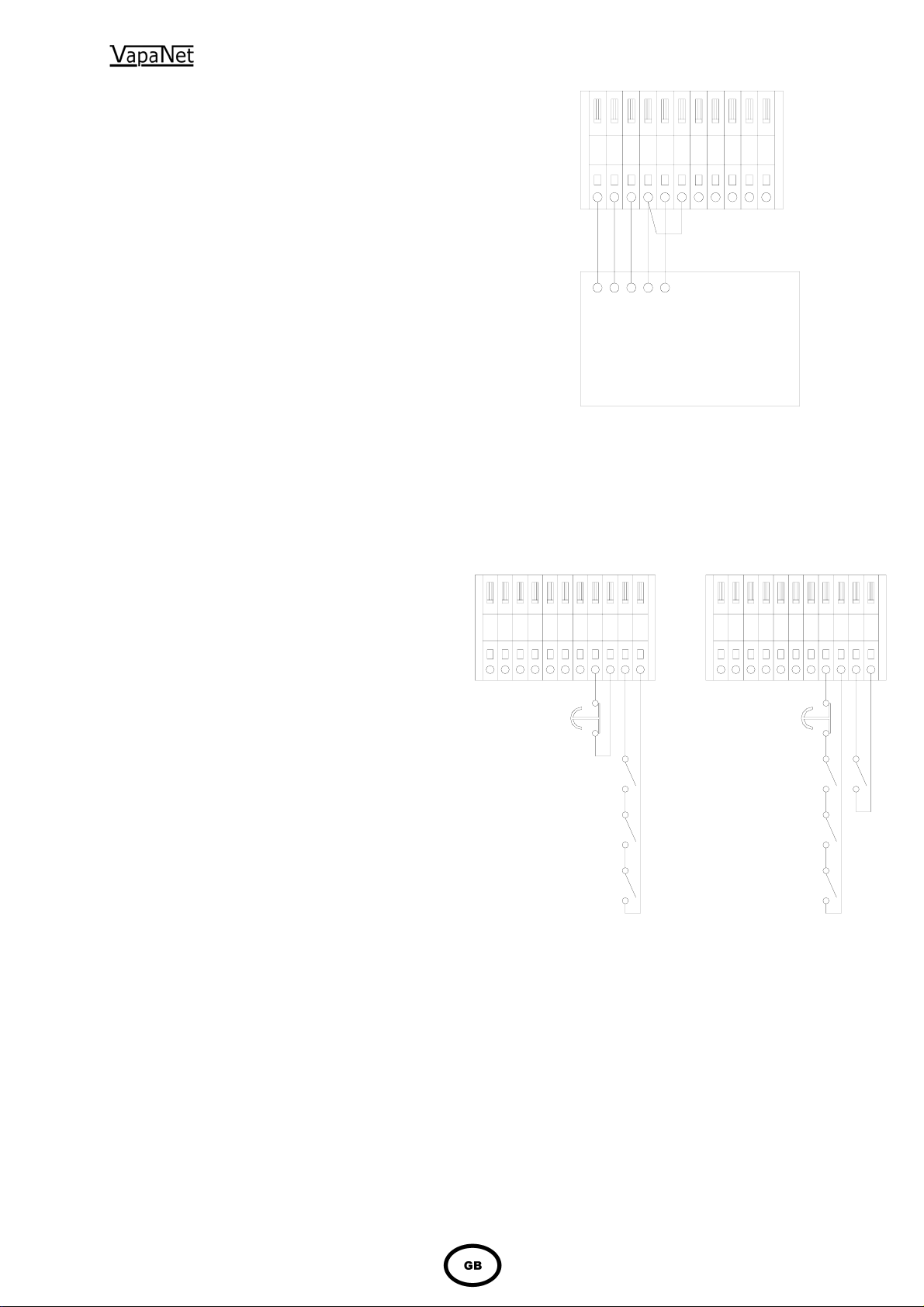

1.4.2.1 Volt free alarm outputs

The unit has connections for volt free alarm outputs these

are on the three double terminals next to the main power

input terminals.

The top terminals are for unit volt free fault alarm as

follows:

The bottom terminals are for unit volt free run signal as

follows:

542 common for fault alarm

543 Normally closed when no fault

544 Normally open when no fault

545 Common for run signal

546 Normally closed when unit is in

standby or fault (not running)

547 Normally open when unit is in standby

or fault (not running)

If the unit is part of a master slave system or

network, the run & fault outputs can be selected (via

keypad & display) as either network (system) or unit

only. This is selectable at Service Engineers Level,

in the Engineering Menu, in the window “Fault/Run

Scope”. The default is “network”. It is possible to

get both alarm & Run indication in all units: Single

cylinder units will give this indication if the service

interval has expired; Twin Cylinder & Networked

units will give this indication if the service interval

has expired or if the master cylinder is operating and

any slave cylinder (or cylinders) are in fault.

1.4.2.2 Unit control terminals

For unit control and network termination see

section 1.5 the terminal layout is shown.

11

1.4.3 Electrical Connections

The wiring to the Vapac should be done by a

qualified electrician. The external overcurrent

protection and wiring should comply with the

appropriate Regulations and Codes of Practice

Important: Make sure the connection to the primary

Voltage winding of the Vapac transformer matches

the supply Voltage which is to be connected

between Vapac terminals A1 & A2.If the actual

(measured) site voltage is 400v the preferred

tapping is 380V

.

A fused disconnect/isolator or MCB should be used

to disconnect the supply from all electrodes

simultaneously.

This must be sized to suit the total maximum

phase/line current of the unit and should be located

adjacent to the Vapac cabinet or within easy reac h

and readily accessible.

In Vapac VAPANET units terminals 1, 2 and 3 are

for the power supply connections as indicated in the

diagrams below.

Twin cylinder units’ have terminals for the

connection of two power supply input circuits. On

twin cylinder units’ this allows individual external

protection of each steam cylinder. Fused

disconnect/isolator or MCB provision must be linked

to ensure both 3 phase supply inputs are

disconnected simultaneously.

Notes:-

1. All units must have a PE earth connection connected to the units terminal.

2. Unit with N.A. in the following tables means NOT AVAILABLE there is not a unit available to run at the voltage

and phases shown. Please check that the correct model reference is ordered and installed, for the low or high

voltage required, and at the desired steam output.

3. Standard design is for 50 Hz. Supplies. Design for 60 Hz. Also available - 60 Hz. Supply must be specified with

order as the standard pump is only 50Hz.

FOR FULL ELECTRO-MAGNETIC COMPATIBILITY A NEUTRAL CONNECTION IS REQUIRED FOR ALL

PROPORTIONAL UNITS AS INDICATED IN THE CONNECTION DIAGRAMS ON THE FOLLOWING PAGES.

RDU Connection

The three type’s of RDU are for various voltages and phase without neutrals connections that can be made to the Microvap unit. Please refer

to the Microvap connection diagram on the following three pages as to which type of unit is required. On twin cylinder units two fan circuits as

shown below one for each cylinder will be in the RDU unit.

RDU electrical load

Model RDU05LR RDU09LR RDU20LR RDU30L

Number of fans 2 3 3 5

Fan voltage 230 v 230 v 230 v 230v

Each fan current 50Hz (60 Hz) 115 mA (105 mA) 115 mA (105 mA) 115 mA (105 mA) 115 mA (105 mA)

RDU total load current 50Hz (60 Hz) 225 mA (210 mA) 345 mA (315 mA) 345 mA (315 mA) 575 mA (525 mA)

200 – 250 V 1Ph. N + earth

200 – 250 V 2Ph. + earth

.

1.4.4 Cable Entry Provision

Cable glands must be used to ensure cables are

held securely at the entry position. All Vapac

cabinets are equipped with a removable gland-p late.

The installing electrician should remove this and

take it to a work-bench to drill for the required cable

gland size.

1.4.5 Vapac Control Circuit Transformer

The internal control circuit of the Vapac unit

operates at 24Vac - the transformer secondary is

set at 24V.

As standard the Vapac VAPANET includes a

transformer with alternative primary winding options

200V, 230, 380, 415, and 440V and requires on site

adjustment to match it to the Voltage connected to

Vapac terminals A1 and A2.

The transformer also has a 9V secondary tapping

which provides power to the VAPANET 1150630

PCB.

Important: The Vapac transformer must NOT be

used to power other equipment or the warranty will

be invalidated.

1.4.6 RDU Connection

Vapac terminals 25 & 26 are included to provide a

230Vac electrical supply for the fan motor in the

RDU (Room Distribution Unit) .

Note: The 230Vac at terminals is derived from the

incoming electrical supply to the Vapac. If the local

supply cannot provide 230Vac (example 400V No

Neutral supply) it will be necessary for a transformer

to be fitted in the RDU as indicated below.

380 – 440 V 2Ph + earth

TRANSFORMER

PRIMARY

380 – 440 V

SECONDARY

210 – 250

V

pply

g

r

r

12

1.4.7 Cylinder Electrical demand loads

5 K

/hr Cylinder 10 Kg/hr Cylinde

Voltage V 200 230 250 200 230 200 230 380 415 440

Nominal cylinder size Kg/hr 5 5 5 10 10 10 10 10 10 10

Electrical Supply Ph+N Ph+N Ph+N Ph+N Ph+N 3Ph 3Ph 3Ph 3Ph 3Ph

No. of elements 1113333333

Element Resistance ohms 13.7 13.7 13.7 20.9 20.9 20.9 20.9 20.9 20.9 20.9

Element connection direct direct direct Par/star Par/star DELTA DELTA STAR STAR STAR

Element Matrial

Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800

Full load Current A 14.6 16.8 18.2 28.7 33.0 16.6 19.1 10.5 11.5 12.2

Power rating Kw 2.92 3.861 4.562 5.742 7.593 5.742 7.593 6.909 8.240 9.263

Max. Output Kg/hr 3.96 5.24 6.19 7.79 10.3 7.79 10.3 9.37 11.17 12.56

Fuse Rating/phase A20202032402025202020

Supply cable terminals mm

2

4 4 4 16161616101010

20 Kg/hr Cylinder 30 Kg/hr Cylinde

Voltage V 200 230 380 415 440 200 230 380 415 440

Nominal cylinder size Kg/hr 20 20 20 20 20 30 30 30 30 30

Electrical Supply 3Ph 3Ph 3Ph 3Ph 3Ph 3Ph 3Ph 3Ph 3Ph 3Ph

No. of elements 6666666666

Element Resistance ohms 20.9 20.9 20.9 20.9 20.9 13.7 13.7 13.7 13.7 13.7

Element connection DELTA DELTA STAR STAR STAR DELTA DELTA STAR STAR STAR

Element Matrial

Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800 Incoloy 800

Full load Current A 33.1 38.1 21.0 22.9 24.3 50.6 58.2 32.0 35.0 37.1

Power rating Kw 11.483 15.187 13.818 16.481 18.526 17.518 23.168 21.080 25.142 28.263

Max. Output Kg/hr 15.57 20.59 18.74 22.35 25.12 23.75 31.41 28.58 34.09 38.32

Fuse Rating/phase A40403232326363404040

Su

cable terminals mm

2

16 16 10 10 10 16 16 10 10 10

Resistive unit model reference LR5 and LR5P LR10 & LR10P LR20 & LR2 0P LR30 & LR30P LR40 & LR40P LR50 & LR50P LR60 & LR60P

Cylinder 1 Size Left hand power feed 5 10 20 30 20 30 30

Cylinder 2 Size Right hand power feed None None None Non e 20 20 30

Number of Power supplies to unit 1 1 1 1 2 2 2

Note :- Cylinder 1 power supply equals Cylinder load from table above plus 1amp for control (feed valves and drain pumps ) plus RDU load from 1.4.5 on page 8 if fitted.

13

1.5 Control Circuit Connections

1.5.1 Control Circuit Wiring

Use a dedicated, earthed metal conduit for both the

control signal cable and the security circuit cables,

sharing the same conduit if practicable.

Use screened cable for all control and security circuit

connections to minimise risk of electrical interference.

The screen should be grounded at the VAPANET end

only. See detail on page 7. NB. The control signal

should be connected to ground at the PCB by

connecting either terminal 5 or 6 to terminal 7 –

I

mportant note if the controller output is

referenced to ground, then the “leg” which is

ground must be the one linked to terminal 7.

1.5.2 Proportional Control

The VAPANET Electrode Boiler (LExxP) models can

all be operated by either a potentiometric signal, a

lonworks network signal or by one of 6 standard

proprietary DC analogue signals.

Input signal:

Potentiometric control

0-5V

0-10V

0-20V

(Actually 0-18V – not phase cut)

2-10V

1-18V

4-20mA

Network

Master)

(Ensure jumper J1 is in place)

(Slave unit – demand generated by

Response:

8-100%

1.5.3 Control Signal Selection

Selection of the control signals is done a part of the

initial set-up procedure using the keypad display. For

confirmation that the signal has been selected, view

the information window. If the unit has not got a

keypad then this is done on the configuration board

1150634 mounted on the main control board 115063 0

using the jumpers provided. The appropriate right

hand link should be made to select the site feed water

type and the appropriate left hand link representing

the actual site control signal should be linked using

the jumper plugs provided.

1.5.4 On/Off Control

Vapanet models can be operated by a single

step humidistat which has Volt-free contacts –

select control option Pot.

1

CR1

F2

CR2

UCP

configuration

resistor

NetCR7

J6

CR6

1

16

Vapac PART No. 1150630

J5

CR5

6

1

16

F1

CR2

1

18

CR4

1

Jumper J1

should be

fitted if

control

signal is

4 – 20 mA

J4

16

J3

CR3

J2

J1

10

6

DC 0 - 20 4 – 20 Ma POTENTIOMETRIC

VOLTAGE CURRENT CONTROL

CONTROL CONTROL min. 135 Ohms

Max. 10,000 Ohms

NOTE :- FOR CURRENT INPUT ONLY JUMPER J1 ON THE

1150630 CONTROL BOARD MUST BE LINKED.

Network

or slave

Full o/p

pot

4-20mA

0-20v

1-18v

2-10v

0-10v

0-5v

J1

CR2

1245678

Vapac part no. 1150634

UCP1

9

J2

101112

Electro

boiler

Pot high

Pot medium

Pot low

Softened

De-iron

De-min

HYGROSTAT WITH VOLT FREE CONTACTS (max.

RESISTANCE OF EXTERNAL CONNECTION 100

Ohms.

1.5.5 Sensing Head

The units are designed to operate using a sensing

head, supplied by Vapac Humidity Control Ltd. which

should be connected as shown below. Other

propriety sensing heads which give a DC signal

may also be used, providing the control signal is

connected to control terminals 5 & 6, and the

sensing head is powered externally from the unit.

If “Frost Protection” is required do not connect

the thermistor input from the sensing head to

control terminals 1 & 2, which should be used to

connect the “frost protection thermistor” (part

number 1220275) instead. Frost protection is

selected via the display – Set the frost demand

above the minimum cylinder demand (LE units

>20%; LE(P) & LE(C) units >8%)

Note:

Use of the 24V supply of the VAPANET unit

to power other items of equipment will

invalidate the Vapac warranty.

1.5.6 Security Circuit / E.P.O. Shutdown

As standard units are shipped such that terminals 9 &

10 are provided for connection of an E.P.O.

(Emergency Power Off) switch or fire shutdown

facility. Other control interlocks, such as high limit

humidistat, airflow switch and/or fan interlock and time

switches etc. should be connected to terminals 11 &

12. Please note that if a display is connected to

the unit “DI1 Control Option” must be set to

“Shutdown”.

NB breaking terminals 9 & 10 will prevent any unit

operation including frost protection.

1.5.7 Load Shed Option

This can only be evoked via a display, either “hard

wired” or hand held. When this option is selected,

making the connection between terminals 11 & 12 will

activate the “load shed” software routine, which will

inhibit the operation of either the unit or in the case of

twin cylinder units unit or just the 2

limit the power used during peak supply periods. If

this option is selected, the fan interlock, airflow switch

and/or high limit hygrostat should be wired into

terminals 9 & 10 with the EPO switch if fitted (as per

the drawing on the far right). It should be noted that

selection of this option will mean that frost protection

cannot be utilized.

Please note that if a display is connected to the

unit “DI1 Control Option” must be set to the

following:

Single cylinder units: “Load shed”.

Twin cylinder units: either “Load Shed Cyl 2” or

“Load Shed Both”.

nd

cylinder. This will

14

1245678

Thermistor

Thermistor

+9 Volt

0 Volt Ref.

RH Output

Vapac’s accessory kit part numbers for sensors are

Remote Room mounted sensing head FVKIT-107

And

Remote Duct mounted sensing head FVKIT-108

Standard Operation Load Shed Operation

678

9

121011

5

4

2

1

E.P.O.

Fire Stop

Fan

Interlock

Air Flow

Switch

High Limit

Hygrostat

9

101112

Vapac

HUMIDITY

SENSOR

9 VOLT

POWER SUPPLY

TEMPERATURE

AND

HUMIDITY

SENSOR

124

5

E.P.O.

Fire Stop

Fan

Interlock

Air Flow

Switch

High Limit

Hygrostat

8

7

6

9

111012

Load Shed

NB. The total cable length of the network (using the cable recommended by V.H.C.L. – Our part number 8040251) is 500 m and it should

be assumed that there is 1 m of cable in each unit of the “system” (including the “master”).

Loading...

Loading...