Operator’s Manual

2018

VM-5500

The Daugherty Companies, Inc.

P.O. Box 306

Warren, IN 46792

Ph. 260-375-2415 - Fax 260-375-3800

www.ag-electronics.com

Rev 0418.1

VM-5500 Operator’s Manual

2018

2

Introduction | Rev 0418.1

NOTES:

VM-5500 Operator’s Manual

2018

Rev 0418.1 | Introduction

3

Table of Contents

1 Introduction.................................................................................................................................................................................................... 6

1.1 System Overview ................................................................................................................................................................................. 6

1.2 Specifications ....................................................................................................................................................................................... 7

1.3 Installation ........................................................................................................................................................................................... 8

1.4 Monitor and Power Connections (Harness 647103) ............................................................................................................................ 8

1.5 VM-5500 Console Main Harness (Harness 647117) ............................................................................................................................. 9

1.6 Internal GPS ......................................................................................................................................................................................... 9

2 Quick Start .................................................................................................................................................................................................... 10

2.1 Entering Setup Assistant .................................................................................................................................................................... 10

2.2 Setup Assistant Features ................................................................................................................................................................... 10

2.3 Quick Start Screens ............................................................................................................................................................................ 11

2.3.1 Implement Sensor Select ........................................................................................................................................................ 11

2.3.2 Implement Type Select ........................................................................................................................................................... 12

2.3.3 Implement Row, Spacing and Width settings ......................................................................................................................... 12

2.3.4 Display Assignments ............................................................................................................................................................... 14

2.3.5 Section Assignments ............................................................................................................................................................... 14

2.3.6 Product Sensor “Seeds” .......................................................................................................................................................... 15

2.3.7 Product Sensor “Flow” ............................................................................................................................................................ 16

2.4 Exiting Quick Setup (Setup Assistant) ................................................................................................................................................ 17

2.4.1 Exit Finish ................................................................................................................................................................................ 17

2.4.2 Exit Early ................................................................................................................................................................................. 17

2.4.3 Not Finished ??? ..................................................................................................................................................................... 17

3 Optional Setup .............................................................................................................................................................................................. 18

3.1 Extra Product Sensor Configurations ................................................................................................................................................. 18

3.1.1 Implement Page Options ........................................................................................................................................................ 18

3.1.2 Area Monitor Setup ................................................................................................................................................................ 19

3.1.3 Manual Harness Assignment ................................................................................................................................................... 19

3.1.4 Section Control ....................................................................................................................................................................... 20

3.2 Accessory Sensors .............................................................................................................................................................................. 21

3.2.1 RPM Shaft ............................................................................................................................................................................... 22

3.2.2 VAC/Pressure Sensor Setup .................................................................................................................................................... 22

3.2.3 Lift Switch Configuration ......................................................................................................................................................... 25

3.2.4 Hopper Type Sensor Setup ...................................................................................................................................................... 25

3.3 User Interface Setup .......................................................................................................................................................................... 26

3.3.1 Alarm Setup ............................................................................................................................................................................ 26

3.3.2 Display Settings ....................................................................................................................................................................... 26

3.3.3 Misc. Settings .......................................................................................................................................................................... 27

3.3.4 Speed Setup ............................................................................................................................................................................ 27

3.3.5 Speed Calibration .................................................................................................................................................................... 28

VM-5500 Operator’s Manual

2018

4

Introduction | Rev 0418.1

3.4 Setup Screen ...................................................................................................................................................................................... 29

4 Monitor Operation Screens .......................................................................................................................................................................... 30

4.1 Menu Bar ........................................................................................................................................................................................... 31

4.1.1 Screen Navigation ................................................................................................................................................................... 31

4.1.2 Alarm Message Area ............................................................................................................................................................... 31

4.1.3 Speed Icon .............................................................................................................................................................................. 31

4.1.4 Manual Speed ......................................................................................................................................................................... 32

4.2 Home Screen ..................................................................................................................................................................................... 32

4.2.1 Console Area ........................................................................................................................................................................... 32

4.2.2 Bar Graph Area ....................................................................................................................................................................... 34

4.3 Seed Dash Board ................................................................................................................................................................................ 35

4.3.1 Population and Spacing ........................................................................................................................................................... 35

4.3.2 Acre Counters ......................................................................................................................................................................... 35

4.3.3 Acre/Hr and Singulation .......................................................................................................................................................... 35

4.3.4 Accessory Sensor Tiles ............................................................................................................................................................ 36

4.4 Flow Dash Board ................................................................................................................................................................................ 36

4.5 Singulation Screen ............................................................................................................................................................................. 37

4.6 Area Monitor ..................................................................................................................................................................................... 38

Internal GPS Status ................................................................................................................................................................. 39 Appendix A

Flow Meters ............................................................................................................................................................................ 40 Appendix B

Flow Meter Installation ...................................................................................................................................................................... 40 B.1

Master Flow ....................................................................................................................................................................................... 43 B.2

Post Season Storage for the Vanguard Visu-FloTM Flow Meters ......................................................................................................... 44 B.3

VM5500 Console Pinouts ........................................................................................................................................................ 45 Appendix C

30 Pin Console Pinout ........................................................................................................................................................................ 45 C.1

18 Pin Console Pinout ........................................................................................................................................................................ 45 C.2

4 Pin Power In/ Alarm Out Pinout ...................................................................................................................................................... 45 C.3

4 Pin Bottom Speed In Pinout (Radar/Speed) .................................................................................................................................... 45 C.4

VM-5500 Implement Pinouts .................................................................................................................................................. 46 Appendix D

37 Pin Harness Pinout ........................................................................................................................................................................ 46 D.1

Part Numbers .......................................................................................................................................................................... 47 Appendix E

Monitor.............................................................................................................................................................................................. 47

E.1

Implement Harnesses and Cables

Console Harnesses

Visu-FloTM Parts and Accessories ....................................................................................................................................................... 48 E.4

E.4.1 Flowmeters ............................................................................................................................................................................. 48

E.4.2 Flowmeter Bracket .................................................................................................................................................................. 48

E.4.3 Visu-FloTM Harness .................................................................................................................................................................. 48

E.4.4 Y Cables ................................................................................................................................................................................... 48

. ........................................................................................................................................................................... 47 E.3

.................................................................................................................................................... 47 E.2

VM-5500 Operator’s Manual

2018

Rev 0418.1 | Introduction

5

Table of Figures

Figure 1 Monitor Mounting .............................................................................................................................................................. 8

Figure 2 Setup Assistant Region explanation .................................................................................................................................. 10

Figure 3 Setup Assistant Start Page ................................................................................................................................................ 11

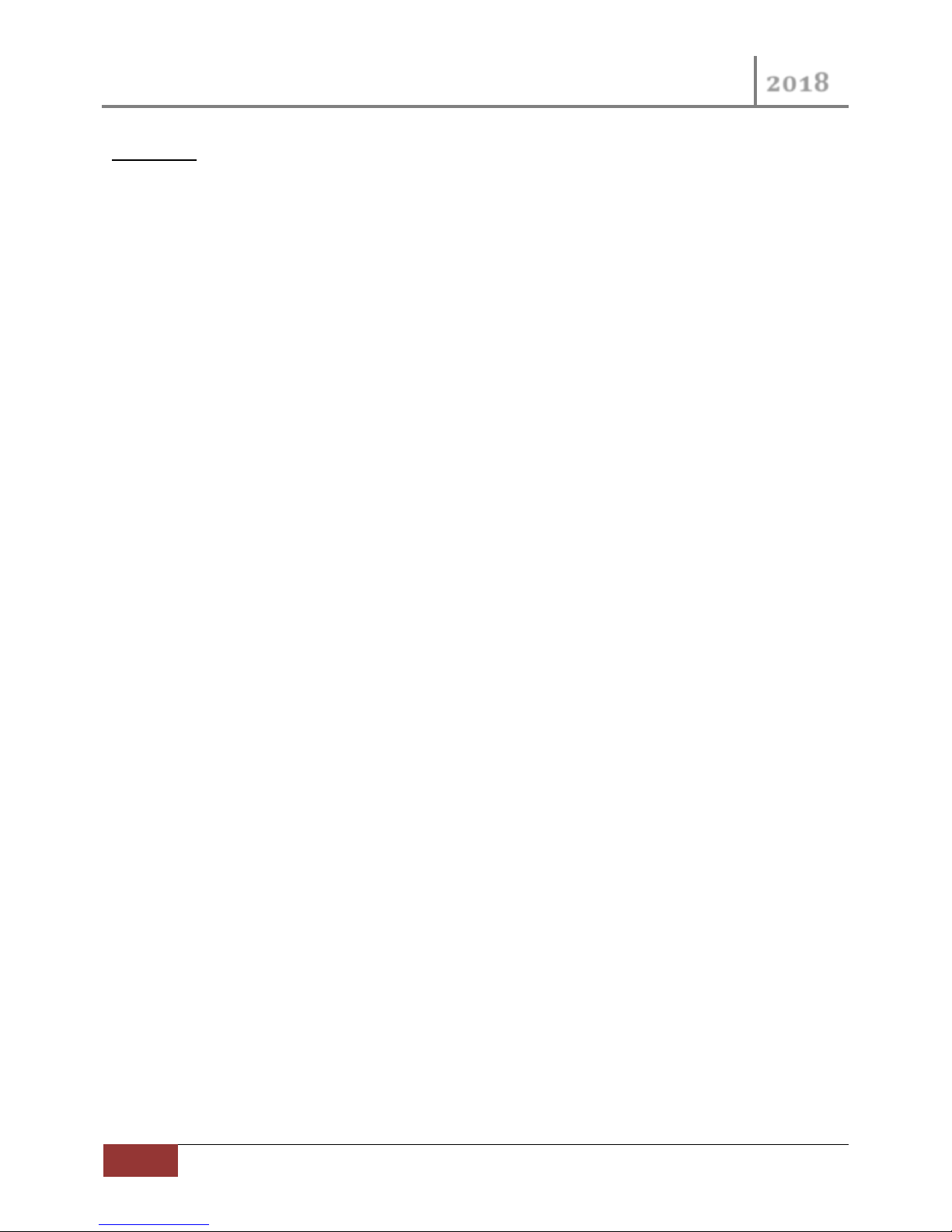

Figure 4 Implement Configuration Dialog ....................................................................................................................................... 11

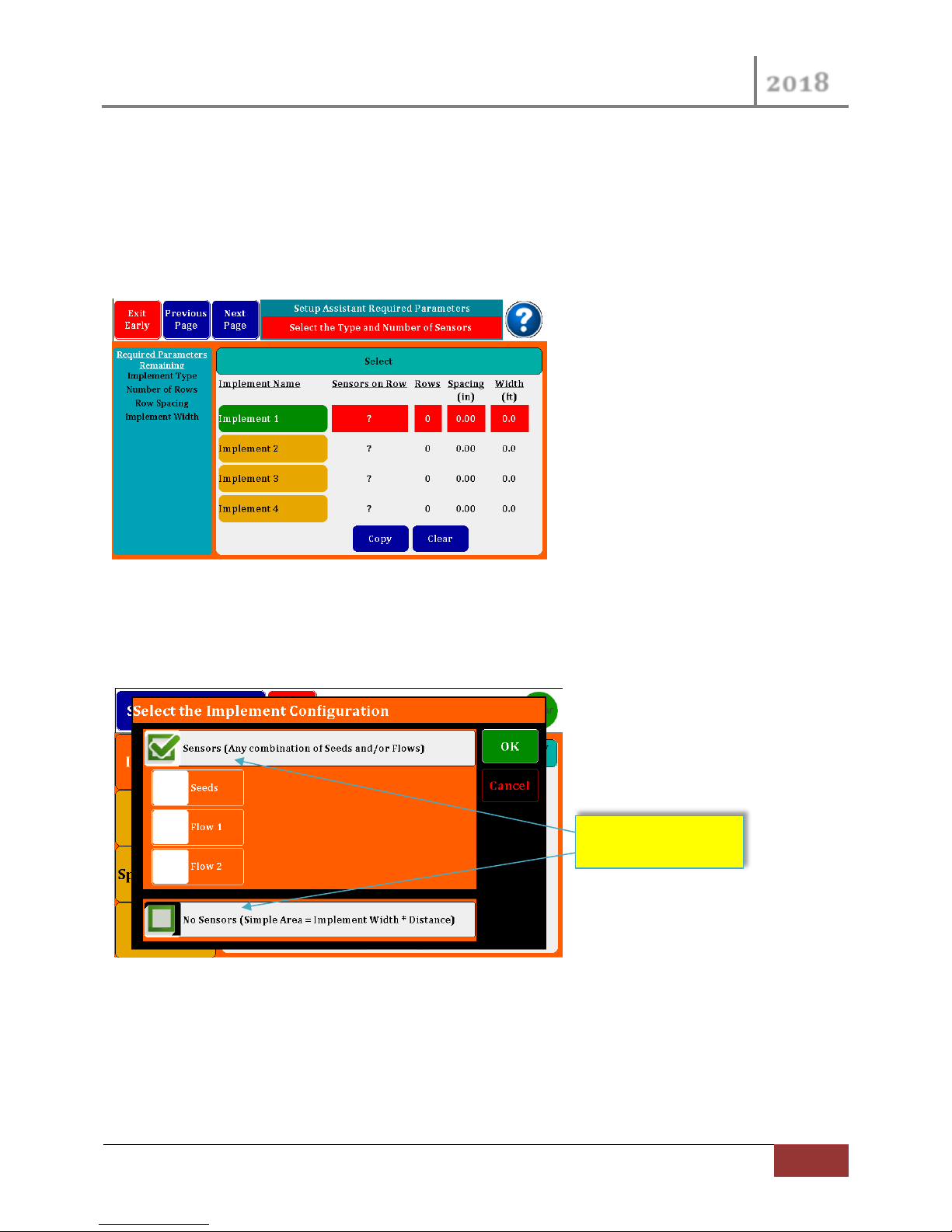

Figure 5 Implement Configuration with All Sensors ....................................................................................................................... 12

Figure 6 Row, Spacing and Width Setup ......................................................................................................................................... 13

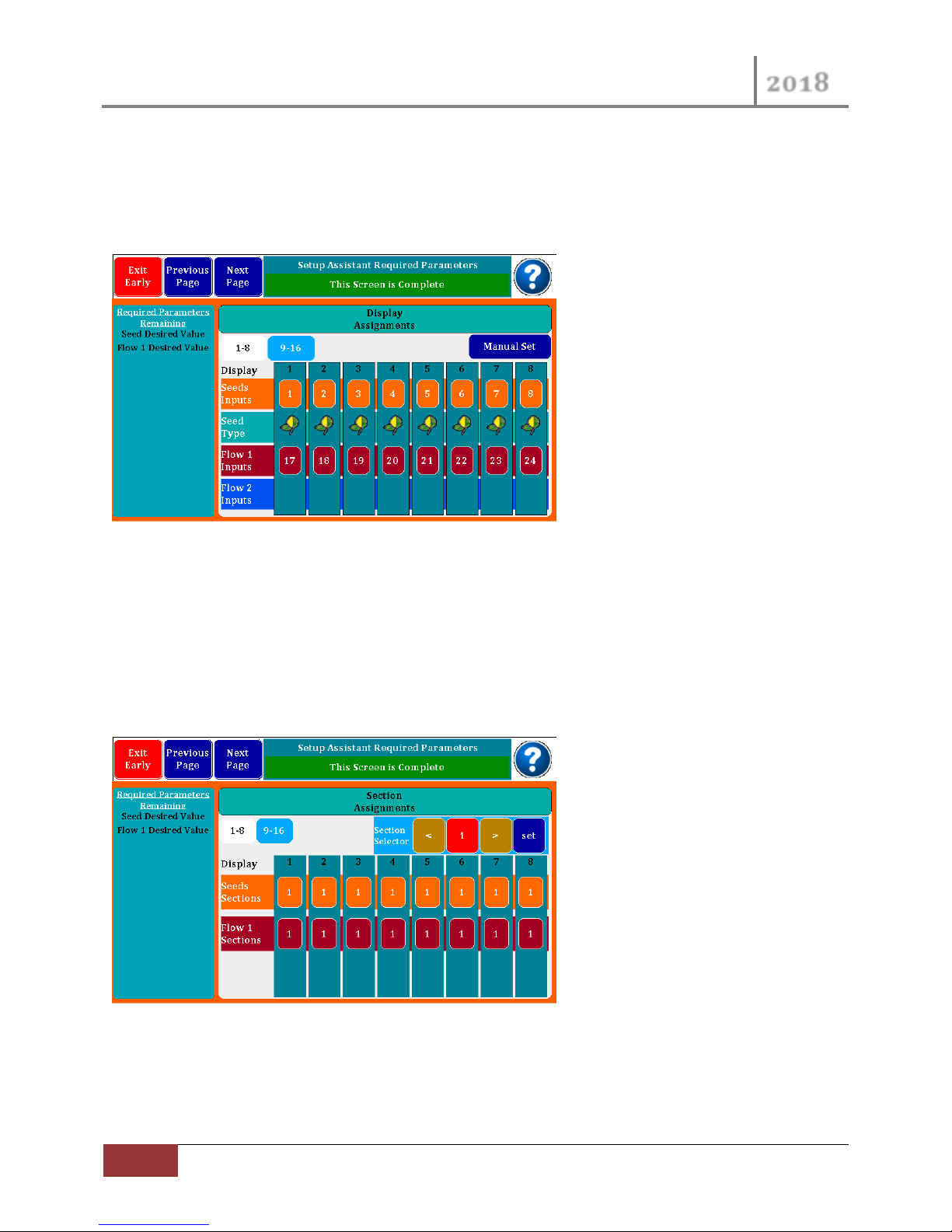

Figure 7 Display Assignments Viewer ............................................................................................................................................. 14

Figure 8 Section Control ................................................................................................................................................................. 14

Figure 9 Product Sensor Setup for Seeds ........................................................................................................................................ 15

Figure 10 Product Sensor Setup for Flow ½ .................................................................................................................................... 16

Figure 11 Area Monitor (No Sensors) Setup ................................................................................................................................... 19

Figure 12 Manual Harness Assignment Dialog ................................................................................................................................ 20

Figure 13 Resulting Display Assignments ........................................................................................................................................ 20

Figure 14 Section Control ............................................................................................................................................................... 21

Figure 15 Accessory Sensors ........................................................................................................................................................... 21

Figure 16 RPM Sensor Setup ........................................................................................................................................................... 22

Figure 17 VAC / Pressure Setup Screen .......................................................................................................................................... 22

Figure 18 VAC / Pressure Sensor Select .......................................................................................................................................... 23

Figure 19 Zero Pressure Calibration Start ....................................................................................................................................... 24

Figure 20 Zero Press Calibration Processing ................................................................................................................................... 24

Figure 21 Lift Switch Setup Screen .................................................................................................................................................. 25

Figure 22 Hopper Setup Screen ...................................................................................................................................................... 25

Figure 23 Alarm Setup .................................................................................................................................................................... 26

Figure 24 Display Settings ............................................................................................................................................................... 26

Figure 25 Misc. Settings .................................................................................................................................................................. 27

Figure 26 Speed Setup .................................................................................................................................................................... 27

Figure 27 Speed Calibration ............................................................................................................................................................ 28

Figure 28 Speed Calibration "End" .................................................................................................................................................. 28

Figure 29 Setup Screen ................................................................................................................................................................... 29

Figure 30 Home Screen Layout ....................................................................................................................................................... 32

Figure 31 Home Console Area ........................................................................................................................................................ 32

Figure 32 Home Console Sensor Select ........................................................................................................................................... 32

Figure 33 Individual Parameter Selection ....................................................................................................................................... 33

Figure 34 Home Bar Graph Area ..................................................................................................................................................... 34

Figure 35 Bar Graph Examples ........................................................................................................................................................ 34

Figure 36 Seed Dash Board ............................................................................................................................................................. 35

Figure 37 Seed Dash Optional Tiles ................................................................................................................................................. 36

Figure 38 Flow Dash Board ............................................................................................................................................................. 36

Figure 39 Flow Dash Optional Tiles ................................................................................................................................................. 37

Figure 40 Singulation Screen........................................................................................................................................................... 38

Figure 41 Speed/Area Monitor Screen ........................................................................................................................................... 38

Figure 42 Satellite Signal Strength .................................................................................................................................................. 39

Figure 43 GPS Lock Status ............................................................................................................................................................... 39

Figure 44 Pluming Diagram ............................................................................................................................................................. 41

Figure 45 Flow Manifold ................................................................................................................................................................. 43

Figure 46 Monitor Implement Type Selection ................................................................................................................................ 43

Figure 47 Monitor Implement Configuration .................................................................................................................................. 44

VM-5500 Operator’s Manual

2018

6

Introduction | Rev 0418.1

1 Introduction

1.1 System Overview

The VM-5500 Planter Monitor is designed for maximum performance in the field and is easy to install

and use. The system is capable of monitoring up to 16 rows and provides not only seed population, but

also will display area, hopper level, RPM and vacuum information when sensors are connected, and has

capabilities of monitoring liquid flow with Vanguard “Visu-FloTM Technology”.

7” Color Touch Screen

VM-5500 1-16 Row Monitoring

Built in GPS Speed option

Bar graphs

Setup assist for easy programming

Adjustable accumulating time

RAM 1 1/2” Ball Mount

Adjustable Back light

Day/Night Mode

Adjustable Audible Alarm

Optional Visual Alarm Light

View Home or Dashboard

View Seed population or GPM

View 20 sec. Row History

Visu-Flo

Optional Lift Switch

2 Hopper Level, 2 RPM, 2 Vac. Opt.

Section grouping

TM

Option

Scan for Additional Online Assistance

VM-5500 Operator’s Manual

2018

Rev 0418.1 | Introduction

7

Power

10–16 VDC, 3.5 A maximum

Operating temperature

-20°C to 70°C (-4°F to 158°F)

Storage temperature

-40°C to 85°C (-40°F to 185°F)

Size

27.30 cm W x 16.50 cm H x 5.08 cm

D (10.75" W x 6.5" H x 2" D)

Weight

3.08 kg (6.8 lbs.) for 16-row

VM-5500

system

Wire Harnesses

The

VM-5500

includes detachable

harnesses to supply the unit's power

(fused) and sensor inputs (to hitch).

Connectors on the back for GPS

Antenna, USB on Front, Radar on

Bottom

Sensors

Compatible with Vanguard and other

major brands of seed sensors.

Standard mounting

RAM Mount 1

½

” Ball Mounting

Alarm adjustment

Four levels audible alarm with mute

onscreen selection. Optional external

light available.

Backlight adjustment

Five increments plus Day/Night

mode

1.2 Specifications

SAFETY NOTICES

VM-5500 Operator’s Manual

2018

8

Introduction | Rev 0418.1

Figure 1 Monitor Mounting

1.3 Installation

Your VM-5500 comes with a RAM 1 ½” Mounting Ball. Any RAM Mount 1 ½” fixtures will adapt to your

monitor.

Install the RAM-238-U 1 ½” Ball supplied with your console by removing the two screws from the rear of

the unit and use them to attach the ball.

Any RAM configuration may be used to attach your console to a convenient location in your cab. If you

need a base mount, see the above for more options. See your local dealer for brackets and arms that

are available, or visit www.agdirectusa.com to purchase online.

1.4 Monitor and Power Connections (Harness 647103)

Route the power leads of the main harness to the battery. Allow some slack to tie the harness off to a

secure location in the cab to provide strain relief and for the protection of the harness.

The monitor operates on 12 VDC only. The red (Fused)

lead should be connected to the positive battery terminal

and the black lead should be connected to the negative

battery terminal.

There is a short two pin Deutsch connector at the monitor

end of the power cord. This is for connecting the

optional Visual Alarm Light (Part No. 647105)

VM-5500 Operator’s Manual

2018

Rev 0418.1 | Introduction

9

1.5 VM-5500 Console Main Harness (Harness 647117)

Route the main harness to the rear of the tractor. Attach the connector to the bottom of the monitor

with a ¼” nut driver. Tie the harness securely in the cab as a strain relief.

The 647117 harness will attach to your planter or implement with a 37 pin AMP CPC style connector.

This connector is pinned to match standards used by Dickey-john, Agco, Kinze and many other

manufacturers. Be aware that Deere uses the same connector but uses a different wiring pattern. If

you are connecting to a Deere harness, you will need a 37D37J adapter for each harness available

online from www.agdirectusa.com.

If you are using an external speed source such as a radar or external GPS, connect it to the 4 pin AMP

connector on the bottom of the monitor. (Adapters are available for most common radar and GPS

connectors)

If you are using the internal GPS, attach the antenna to the coax connector on the back of the monitor.

Once your implement is connected, you are ready to operate your monitor.

1.6 Internal GPS

The VM-5500 can be purchased with the optional onboard GPS enabled, or it may be enabled by the

customer upon the purchase of a valid license.

The License may be obtained from your Vanguard dealer or by contacting our customer service

department. Once the transaction is complete, you will be provided with a license code to install on a

USB flash drive. Upon insertion into the USB port of the monitor, the license will install and enable the

onboard GPS.

VM-5500 Operator’s Manual

2018

10

Quick Start | Rev 0418.1

Control Buttons

Still Required

Launch Help

Attributes Still

Required

Implement

Selection

Instruction Area

2 Quick Start

The Quick Start feature of the Monitor is a method that will step you through a complete setup of your

monitor. This feature will insure proper configuration while providing you with a good working

knowledge of the parameters that need to be set for your implement.

This Quick Start section will discuss typical implement configurations, for more in depth configurations

or implements with Accessory Sensors please reference the Optional Step Up section that immediately

follows the Quick Start.

This Quick Start section uses your monitors Setup Assistant feature to walk you through configuring your

monitor. In the Setup Assistant you will be provided a list of parameters that need to be entered. Once

you have entered the required information a GREEN “Exit Finish” Button will appear, you are then ready

to Exit the Quick Start.

2.1 Entering Setup Assistant

The Setup Assistant feature is automatically entered when you power up your monitor for the first time.

If you have to leave the Setup Assistant early, don’t worry when you return you will come back into the

Setup Assistant to finish configuring you implement. At any time there after, you can re-enter this mode

using the Navigation Buttons at the top of the monitor. By pressing the “Setup” navigation button, the

“Setup” button will change to the “Setup Assist”, by pressing this button again you will re-enter the

Setup Assistant feature.

2.2 Setup Assistant Features

When in the Setup Assistant the Normal Navigation Buttons will change to 3 Control Buttons (Exit,

Previous and Next Buttons). An Instruction Area to the right of the Control Buttons will instruct you on

the next required parameters that are required prior to you advancing to the next Page. On the left side

of the screen you will see a list of the “Required Parameters Remaining”, if this area is empty you will be

allowed to proceed. The items in the list are also highlighted in RED on the main area of each screen.

Figure 2 Setup Assistant Region explanation

VM-5500 Operator’s Manual

2018

Rev 0418.1 | Quick Start

11

Sensor / No Sensor

Select

2.3 Quick Start Screens

Your Monitor is very configurable, however it is very easy to setup. We will walk you through a typical

Seed and Liquid Flow implement configuration. Don’t worry if this configuration is not exactly what you

have we will discuss more details in a later section.

The following screen is our starting page for the Setup Assistant.

Figure 3 Setup Assistant Start Page

2.3.1 Implement Sensor Select

By pressing the Red ? Button in the “Sensors on Row” column, the following dialog box will appear.

Figure 4 Implement Configuration Dialog

You have two options by selecting the “Sensors” check box at the top of the screen you may select your

implement Sensors. The “No Sensor” selection is discussed in the Optional Setup Section.

VM-5500 Operator’s Manual

2018

12

Quick Start | Rev 0418.1

Image indicates you

selected Seeds and Flow

2.3.2 Implement Type Select

Use the Check Boxes to select if your monitor is connected to seed sensors, flow meters or both. If you

select Flow 1, you may select Flow 2 as well if you are using two different flow rates on your

system. Keep in mind that you are limited to 16 total sensors on this monitor. Depending on your

selections the monitor will configure itself to ask for only the required parameters.

Figure 5 Implement Configuration with All Sensors

For each Flow you have set, you may selection if there is a Sensor per Row, or only Sensor at the pump

or Master Flow. This Flow selection is independent for each Flow (1/2). In the page above you would

have an Implement with Seeds and Flow 1 with sensors at each row.

Press Ok will return you to the Starter page which will now look like this.

2.3.3 Implement Row, Spacing and Width settings

For the Row, Spacing and Width settings press the appropriate button and a Numeric keypad will pop-

up. Enter your number of Rows first, if you then enter the Spacing your Width will be calculated for you.

If after the Row entry, you enter the Width the Spacing will be calculated for you. You can override the

calculated values if you desire.

VM-5500 Operator’s Manual

2018

Rev 0418.1 | Quick Start

13

Green Background indicates that

you are done with this page.

List Changes as you Enter

Parameters.

Figure 6 Row, Spacing and Width Setup

By pressing the Red 0 Button under the Rows column a “Enter Row Spacing” Dialog Box will appear.

Press the Spacing and Width Buttons to open up the Numeric Keypad and enter each parameter.

As you enter each Parameter you will see the List of Require Parameters on the Left change.

Press “Next Page” to go to the Display Assignments Page.

VM-5500 Operator’s Manual

2018

14

Quick Start | Rev 0418.1

2.3.4 Display Assignments

The Display Assignments page is a visual cross reference between the Display Rows and the cable

harness Row wires. Only 8 Display Rows can be seen at 1 time, navigation buttons are available to

navigate to the next set of 8 Rows.

Figure 7 Display Assignments Viewer

The assignments are automatically chosen for you, you can change them to match your implement. If

you need to Change the assignments see Manual Row Assignments in section 3.1.3 below.

2.3.5 Section Assignments

If you have a planter or liquid system that is setup with section shutoff’s, you can configure the rows to

match so the monitor will recognize the shutoffs and not report continuous row failures.

Figure 8 Section Control

By default All Sensors are setup as 1 Section.

If you are not going to use Section Control with your implement, just Press the BLUE “Next Page” button

to navigate to Product Sensor page.

VM-5500 Operator’s Manual

2018

Rev 0418.1 | Quick Start

15

2.3.6 Product Sensor “Seeds”

If you had selected Seeds at the start of this Quick Start the following Screen will appear. The Product

Sensors Seed screen is where you can set your Desired target rate for your Seeds/Acre. After you enter

this rate the default Maximum and Minimum Limits will be calculated with +/- 20%. You may change

percentages or enter absolute numbers.

Press and hold Blue entry fields for a pop-up Numeric Keypad.

Figure 9 Product Sensor Setup for Seeds

Press the Desired Rate Button

After you enter the Desired Value you can likewise change the calculated Limits. Notice the Require List

for our example is now down to only one parameter.

At this point you may also adjust the Sensor Gain parameter. The Sensor Gain is a method to adjust the

actual number of seeds being planted to what is being detected by the seed sensor. You can move

Loading...

Loading...