Page 1

INSTALLATION & OPERATION MANUAL

DO NOT DISCARD THIS MANUAL!

POWERMAX

GAS INFRA-RED WATER BOOSTER HEATERS

Model PM200 and PM400

IMPORTANT FOR YOUR SAFETY

WARNING: IF THESE INSTRUCTIONS ARE NOT FOLLOWED EXACTLY, FIRE OR

EXPLOSION MAY RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

-Do not store or use gasoline or any other flammable liquids or vapors in the vicinity of

this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electrical switch

• Do not use any phone in the area

• Immediately call your gas supplier from another location.

• Follow gas suppliers instructions

• If you cannot reach the gas supplier, call the local fire dept. or 911

-If overheating should occur or the automatic gas valve fails to operate properly, turn off

the manual gas valve on the gas supply piping to the appliance.

-Installation and service of this equipment must be performed by a qualified installer,

service agency or the gas supplier.

tm

Tested to: ANSI Z21.10.3 1998

NSF Std. 5, 1992

800-624-4809 CAN/CGA 1-4.3 M98

Page 2

TABLE OF CONTENTS

Page

General Information 1

Installation Codes 2

Unpacking 2

Locating 2

Combustion Air/Ventilation 3

Exhaust Venting 3

Gas Piping 5

Water Requirements 6

Water Piping 7

Electrical 9

Wiring Diagrams 10

Operating Sequence 12

Start-up Procedure 13

Operating Instructions 14

To Turn Off Gas Appliance 15

Maintenance 16

Troubleshooting 17

Replacement Parts List 18

Limited Warranty 19

Appendix A 20

Sample Start Up Checklist 24

Interior View/Parts Breakdown 26

ii

Page 3

GENERAL INFORMATION

tm

The POWERMAX

gas fired, infra-red water booster heater provides 180 degree

sanitizing rinse water for commercial dishwashing machines. Dishware and utensils used

in the preparation and serving of food are required by Health Codes and the National

Sanitation Foundation (NSF) to be sanitized by hot (min. 180 degrees Fahrenheit) water or

a chemical sanitizing solution to destroy bacteria and parasitical organisms. The

POWERMAXtm booster heater operates as a semi-instantaneous water heater. As 180

degree rinse water is drawn from the unit, incoming supply water flow activates the burner

and pump to circulate the water through a high efficiency finned copper coil heat

exchanger. Heat is provided by an advanced infra-red ceramic fabric power burner which

heats and maintains a constant supply of 180 degree rinse water. When the dishwasher is

not in use, the POWERMAXtm continues operating for a few minutes before going into a

stand-by mode, operating only as needed to maintain a small (approx. 4.5 gallon) reservoir

of 180 degree water for the next dishwashing rinse demand.

1

Page 4

INSTALLATION CODES

Installation must be performed in accordance with state and local codes, or, in the

absence of local codes, with the following: National Fuel Code, ANSI Z223.1 (latest

edition) the National Electric Code (NEC) ANSI/NFPA 70 (latest edition). Canada:

CAN/CGA B149.1, CAN/CGA B149.2 and CSA C22.2 No. 1 (latest edition).

UNPACKING

Immediately after unpacking, check thoroughly for any possible shipping damage. If the

POWERMAXtm is found to be damaged, contact the carrier immediately (15 days

maximum). Be sure to save all the packaging materials for shipper’s inspection.

LOCATING THE POWERMAXtm BOOSTER HEATER

Locate the POWERMAXtm so that all required clearances are maintained. The appliance

must be located in an area that is clear and free from combustible materials, including

gasoline and other flammable or corrosive liquids and vapors. The booster heater should

not be located in an area where water leakage could cause damage to adjacent areas or

areas below the unit. If this is not possible, the booster heater should be installed in an

adequate catch pan (preferably stainless steel) that is properly drained. If appliance is

installed on carpeting, it must be installed on a wood or metal panel extending beyond the

full width and depth of the appliance by at least 3 inches (76.2mm) in each direction. The

booster heater should be installed with no more than five feet of pipe between the 180degree outlet and the dishwasher rinse valve (as specified by NSF-5). If the piping

exceeds five feet, the optional circulation return kit must be installed to maintain proper

temperature at the dishwasher rinse valve. The POWERMAXtm may be installed up to 150

feet from the dishwasher when using the circulation kit. Call factory for details.

INSTALLATION CLEARANCES

Minimum clearances from combustible or non-combustible construction -

8” (fire 2”, service 8”) Left side, 2” Right side, 6” Back, 0” Top, 24” Front (minimum for

service). The four 6” adjustable legs allow the unit to be leveled on uneven floors by

screwing the feet up or down as needed.

2

Page 5

COMBUSTION AIR / VENTILATION

tm

The POWERMAX

must be provided with an adequate supply of air for proper

combustion and ventilation as required by the National Fuel Gas Code, ANSI Z 223.1 or

any local codes that supercede the National Code. Do not obstruct the combustion and/or

ventilation air supply openings.

CAUTION: Combustion air must not be contaminated by corrosive vapors or fumes, i.e.

salt, chlorine, refrigerant gases, detergents, paints, cleaners, etc.. Any damage caused by

insufficient or contaminated combustion air or improper venting will not be covered under

the warranty.

EXHAUST VENTING

The POWERMAX

tm

Booster Heater is classified as a category IV appliance (positive flue

pressure, flue gas temperature of approximately 190 degrees Fahrenheit, possible

condensate). Vent piping must be one of the types detailed in this manual or a factory

approved (in writing) alternate and must be installed according to the vent pipe

manufacturers instructions. All joints must be properly sealed and secured to maintain

joint integrity. All vent piping must slope toward the appliance a minimum of 1/4 inch per

foot of length. The National Fuel Gas Code, ANSI Z223.1 requires that the booster heater

be vented in one of the following three ways:

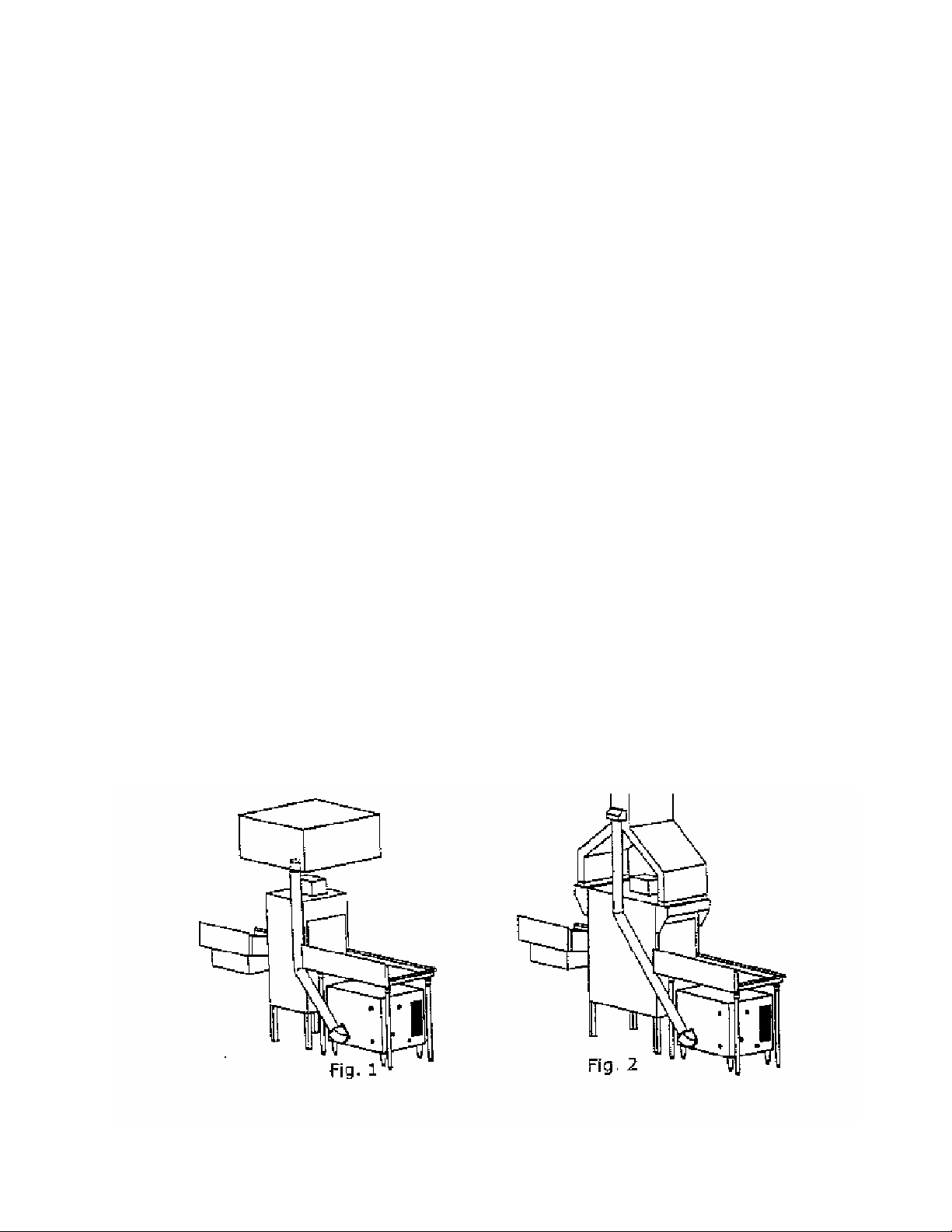

1. Into the dishwasher exhaust system. (See fig.1). The vent pipe must not penetrate

any grease filter, but should terminate within the hood “capture zone”. In cases of a

“pantleg” type of vent (see fig. 2), the vent pipe may terminate below an approved

‘eyebrow’ penetration of the duct. When vented into the dishwasher exhaust system,

an electrical interlock must be provided (by others) to prevent the appliance from

firing if the exhaust system is not providing sufficient draft for any reason.

3

Page 6

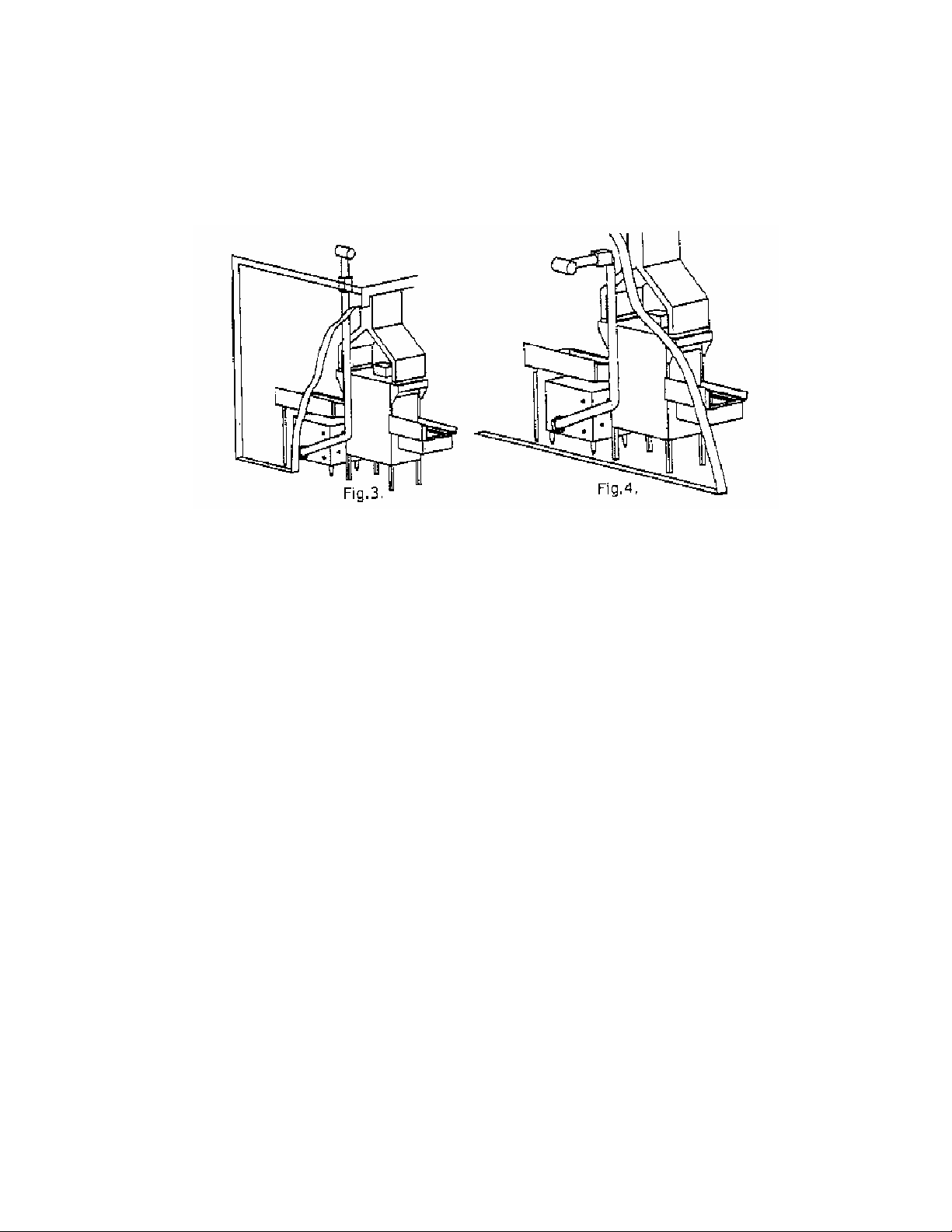

2. Through the ceiling/roof (see fig.3) or through a sidewall (see fig. 4). Type B-1 vent

pipe (inch min. diameter) may be used when venting vertically through the roof,

provided a one inch minimum clearance to combustible material is maintained

throughout and the vent terminates into a listed wind cap above the roof.

3. Vented freely into the room or space where it is installed, provided that:

a) A Mechanical exhaust system is present in the space where the

booster heater is installed.

b) An electrical interlock is provided (by others) so that the booster will not fire if the

exhaust system is not providing adequate ventilation to the area.

c) The total BTU input rating of all the unvented gas appliances installed divided by

the total cubic foot volume of the room area (including any adjacent areas that

cannot be physically closed off from the installation area) does not exceed 20

BTU’s per hour per cubic foot of space.

For sidewall venting, the booster heater should be located as close as possible to the wall

being used. The minimum and maximum wall thickness is determined by the wall thimble

available from the vent manufacturer. Refer to the vent manufacturer’s installation

instructions.

All horizontal runs of vent pipe must have a minimum rise of 1/4 inch per foot of length and

must be supported every 5 feet or less (3 feet in Canada) and at every elbow.

For horizontal venting: The total length of approved 4 inch diameter vent pipe can be a

maximum of 40 feet, including two 90 degree elbows and one termination vent. For each

elbow above two, reduce the total allowable vent length by ten feet. Minimum horizontal

vent length is 2 feet.

For vertical venting: The maximum length of approved 4 inch diameter vent pipe is the

same as above; the same requirements for elbows and termination vent apply; the

minimum length for vertical venting is 5 feet. An auxiliary power vent kit is available for

installations where the vent length must exceed these lengths. Call the factory for

assistance. Additional requirements when venting through a sidewall:

-The vent terminal shall be located at least three feet above any forced air inlet located

within ten feet; at least four feet below and four feet horizontally from, or one foot above

4

Page 7

any door, opening window or gravity air inlet into any building. It shall also have a

minimum horizontal clearance of four feet from any electric meter, gas meter, regulator,

relief valve or other equipment.

-The vent terminal shall be located not less than seven feet above grade when it is

adjacent to public walkways.

-The bottom of the vent terminal shall be located at least twelve inches above grade or

ground or the normally expected snow accumulation level.

The snow level may be higher on walls exposed to prevailing winds.

-Avoid areas where local experience indicates that condensate drippage may cause

problems, such as above planters, patios, public walkways or areas where condensate or

vapor could cause a nuisance or hazard, or where its discharge could be detrimental to the

operation of regulators, relief valves or other equipment.

Examples of ACCEPTABLE VENT PIPING/ See Appendix A

MANUFACTURER MODEL MATERIAL

SPECIFICATION

Heat-Fab Inc.

38 Haywood St.

Greenfield, MA 01301

Z-Flex US, Inc.

20 Commerce Park North

Bedford, NH 03110

Flex-L International, Inc.

6385 Kennedy Rd

Mississauga, ON

L5T2W4

Saf-T-Vent AL 29-4C

Stainless Steel

Z-Vent AL 29-4C

Stainless Steel

StaR-34 AL 29-4C

Stainless Steel

Termination Box

Termination Tee

Part Name

Tee

Rain Cap

Mitre I Straight

Tee

Rain Cap

Wall Thimble

3”

Part Number

7390TEE

5300C1

7390GC

#02SVSTTX-3

#02VRSRCX03

#02SVSRTX-3

SRTT03

SRWT153

4”

Part Number

7490TEE

5400C1

-

#02SVSTTX-4

#02VRSRCX04

#02SVSRTX-4

SRTT04

SRWT154

GAS PIPING

The gas inlet pipe size is 3/4 inch NPT, male thread, located at the lower right front corner

of the appliance. The gas supply piping must be sized to adequately provide the input

BTU/hr rate for the appliance at the specified flowing pressure (see table 1). The

maximum inlet gas pressure must not exceed the maximum value shown in table 1. The

minimum gas pressure shown in Table 1 is for purposes of input adjustment.

FLOWING Gas Pressure Requirement (not static)

Inches W.C. (Water Column)

Incoming Line Pressure Natural Gas/LP

Minimum Maximum

Manifold

Pressure

PM200 4.5”NG/10”LP 10.5”NG/14”LP 3.5”NG/7.5”LP

PM400 4.5”NG/10”LP 10.5”NG/14”LP 3.5”NG/7.5”LP

TABLE 1

5

Page 8

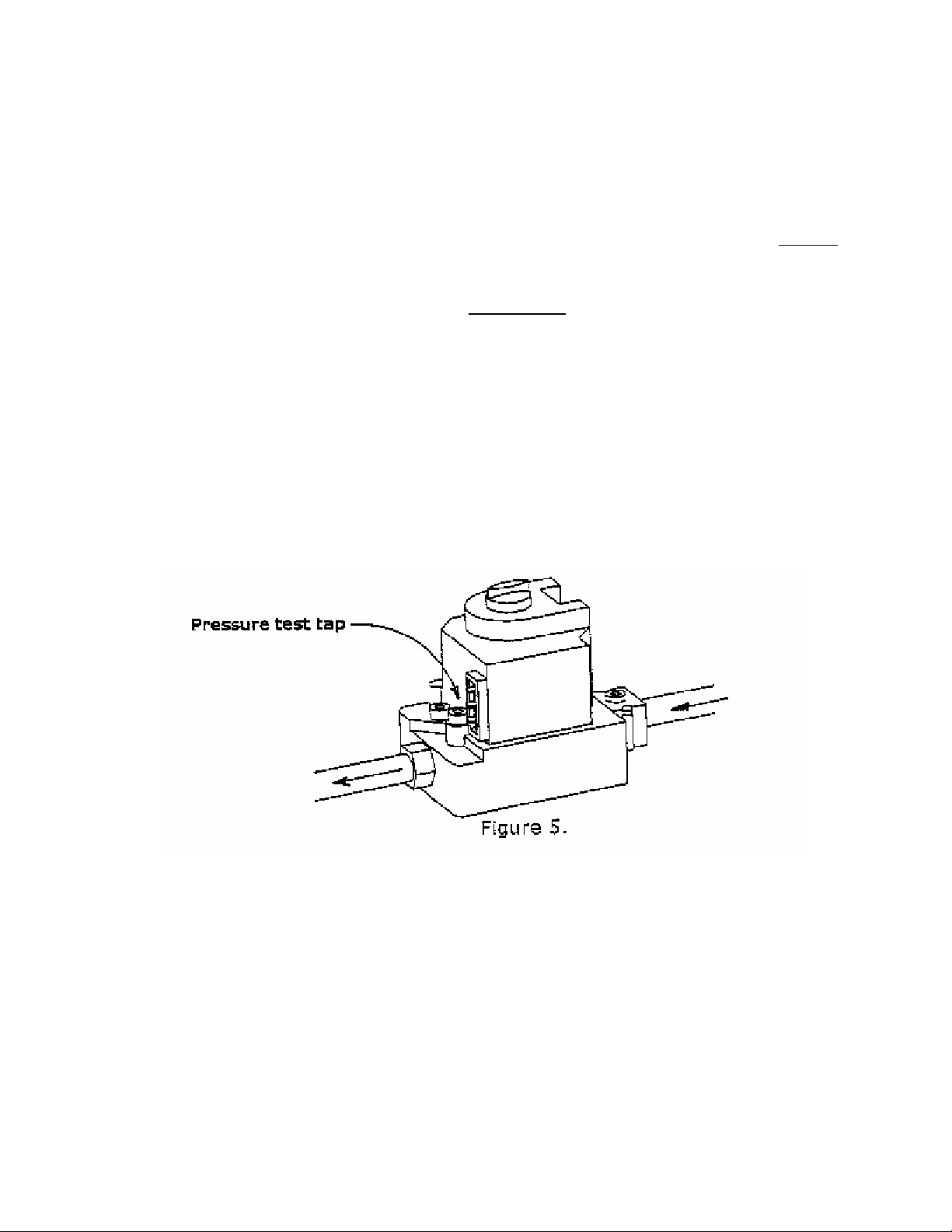

The gas valve is provided with a pressure tap to measure gas pressure downstream, which is also

the manifold pressure (fig. 5.). The gas piping must have a sediment trap ahead of the heater gas

controls and an approved manual shut-off valve (provided by others) located outside the jacket and

easily accessible. The heater and its gas connections must be leak tested before placing the

appliance in operation. DO NOT use an open flame for leak testing. The heater must be isolated

from the gas supply piping by closing its individual manual shut-off valve during any pressure

testing of the gas supply piping at test pressures equal to or less than 1/2 p.s.i.g. (3.5 kPa). The

heater and its individual shut-off valve must be disconnected from the gas supply during any

pressure testing of that system at test pressures in excess of 1/2 p.s.i.g. (3.5 kPa). Dissipate test

pressure from the gas supply line before re-connecting the heater and its manual shut-off valve to

the gas supply line.

CAUTION: Failure to follow this procedure may damage the gas valve and cause a

dangerous condition. Over pressured gas valve damage is not covered under

warranty.

NOTE: Do not use Teflontm tape on gas line threads. Use only a flexible thread sealant

approved for use with fuel gases.

WATER REQUIREMENTS

Local water conditions vary greatly between even near-by locations and can greatly affect

the performance and maintenance requirements of warewashing equipment, including

your booster heater. Proper water conditions will provide lower chemical costs, improved

cleaning performance, reduced spotting and longer equipment life as well as more efficient

labor use and reduced damage to dishware and utensils. Proper water treatment for

effective and efficient performance of this equipment will vary depending upon the makeup of the local water supply.

6

Page 9

Recommended water hardness is 4-6 grains of hardness per gallon. Chlorides must NOT

exceed 50 parts per million. Water hardness above 6 grains per gallon should be treated

with a proper water conditioner (water softener or in-line treatment). Water hardness

below 4 grains per gallon also requires water treatment to reduce its corrosive effects.

Sediment, silica, chlorides or other dissolved solids may require particulate filtration or

reverse osmosis treatment. Proper water treatment has been shown to reduce machine

cleaning, mineral build-up, detergent usage and corrosion of metal surfaces in booster

heaters and dishwashers.

Damage caused by water conditions is not covered under warranty.

WATER PIPING

WARNING: All piping and plumbing connections must comply with applicable

sanitary, safety and plumbing codes.

CAUTION: All piping and any components connected to this appliance for the

purpose of space heating shall be suitable for use with potable water. Toxic

chemicals, such as used for boiler treatment, shall not be introduced into the

potable water used for space heating. This appliance, when used to supply

potable water, shall not be connected to any heating system or component(s)

previously used with a non-potable water heating appliance or system.

The inlet and outlet water connections are 1 inch NPT (inlet is 1” female pipe, outlet is 1”

male pipe). An inlet and outlet union adaptor is provided with your POWERMAXtm Booster

Heater.

The inlet water supplied to the booster heater should be a minimum of 110-degrees

Fahrenheit, except in the case of single rack, door type dishwashers and some “watersaver” conveyor machines, in which case incoming water can be as low as 45 degrees

tm

Fahrenheit. DO NOT connect the POWERMAX

Booster Heater to a cold water supply

pipe if it is to be used with a full flow conveyor dishwasher.

Recommended flowing water pressure to the booster heater is 45 p.s.i. Flowing water

pressure at the dishwasher rinse valve should be 20 p.s.i. An optional pressure regulating

valve and pressure gauge for the booster heater outlet is available from Vanguard

Technology if the dishwasher is not equipped with these items. The supply water inlet to

the booster heater does not require a pressure-regulating valve unless the supply water

pressure exceeds 50 p.s.i. A full-flow shut off valve must be provided in the water supply

piping to the booster heater. Installation of a suitable water hammer arrester is

recommended between the booster heater and the dishwasher rinse valve.

A drain valve assembly is provided for installation on the lower outlet at the back of the

booster heater.

The Temperature and Pressure Relief valve is installed at the left side of the booster

heater. Install a suitable 3/4” i.d. drainpipe from the discharge of the Temperature and

Pressure Relief valve to a suitable drain or catch pan with drain. The Temperature and

Pressure Relief valve should be manually test-operated at least once annually to ensure

that it is functioning properly. Be careful when operating the relief valve.

7

Page 10

Follow instructions on the tag located on the Temperature and Pressure Relief valve to

avoid contact with hot water discharge and to prevent water damage from operation of the

valve.

Repair or alteration of the Temperature and Pressure Relief valve in any way is prohibited

by National Safety Standards and local codes. DO NOT PLUG THE RELIEF VALVE OR

INSTALL A SHUT OFF VALVE OR ANY OTHER RESTRICTION IN THE DISCHARGE

DRAIN LINE! The booster heater should be located as close to the dishwasher rinse valve

as possible. If the booster heater is installed more than 5 feet from the dishwasher rinse

valve, an optional rinse water re-circulation kit is available from Vanguard Technology and

must be used to insure a consistent water temperature of 180-degrees at the rinse valve

(Fig.6.).

NOTE: All water supply piping to the booster heater must be completely flushed of

all debris and flux residue before connection to the booster heater. Damage caused

by debris or aggressive flux residue will not be covered under warranty

If booster heater is installed in a closed water supply system, such as one having a

backflow preventer in the water supply line, means shall be provided to control thermal

expansion. Contact the water supplier or local plumbing inspector on how to control this

situation or call the factory.

8

Page 11

ELECTRICAL

The electrical power supply requirement for the booster heater is 120 volts, AC, 60Hz, 6.0

amps or less. Field wiring connections and electrical grounding must comply with local

codes, or, in the absence of local codes, with the latest edition of the National Electric

Code (NEC), ANSI/NFPA 70. NOTE: Polarity must be observed for the booster heater to

operate properly. Consult wiring diagram. Provide a separate fused circuit from the main

electrical panel to the booster heater and a means of disconnecting within sight of the

heater. Electrical connection is made from the bottom left front of the unit and into the

2”X4” field wiring connection box. All internal electrical components are factory wired and

operate with the heater control system. NOTE: If it is necessary to replace any of the

original wiring, it must be replaced with 105 degree centigrade rated wire or its equivalent.

CAUTION: DO NOT TURN THE POWER SWITCH ON UNTIL THE BOOSTER

HEATER HAS BEEN FILLED WITH WATER AND ALL AIR HAS BEEN PURGED

FROM HEAT EXCHANGER AND THE ACCUMULATOR TANK.

If an auxiliary power vent is installed, or in certain cases, if the booster heater is vented

through the dishwasher exhaust system, an airflow-proving switch must be installed in the

duct system to interrupt power to the booster heater and prevent its operation without

sufficient draft. The airflow-proving switch is provided by others.

If the optional circulation kit (for remote booster installation) is used, it is wired separately

from the booster heater through the provided lighted switch box.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors

can cause improper and dangerous operation. Verify proper operation after servicing.

9

Page 12

10

Page 13

11

Page 14

The booster heater is designed to produce 180-190 degree sanitizing rinse water for

commercial dishwashing machines. Specific performance depends upon the exact water

flow and supply water temperature. (See table)

Temperature rise Gallons per Minute Gallons per Hour

40o F 8.7 520

50o F 7.0 420

60o F 5.8 348

70o F 5.0 300

140o F 2.5 (7.5 for 15 sec. Per minute) 150

After the necessary power, water, gas and vent connections are completed correctly and

all air is purged from gas and water piping, the unit is started by turning on the power

switch located on the top, front of the left side panel. The combustion air fan will start and

run continuously and the digital temperature display will light, showing the water

temperature in the accumulator tank. If the tank temperature sensor detects water

temperature below the set point, it will turn on the internal circulating pump, prove water

flow, combustion air flow and hi-limit compliance and activate the hot surface igniter.

Following a 3 second warm up for the igniter, the gas valve opens and the burner ignites.

If the burner flame is not proved within a few seconds, the gas valve automatically closes.

This cycle will repeat 3 times. If ignition/flame is not proved the control will go into

automatic lock-out, requiring a re-set. Re-set is accomplished by turning power switch to

‘off’ for 10 seconds and then turning back on. When the tank water temperature exceeds

the thermostat set point, the burner will shut off until the next call for heat.

The internal circulating pump will operate whenever the thermostat is calling for heat. The

combustion air blower operates continuously whenever the ‘on-off’ switch is on.

The operating temperature control is factory-set and is not to be user-adjusted. If

temperature rise is not satisfactory, call your service agency and/or call the factory.

OPERATING SEQUENCE

PowerMax200tm Performance Data

12

Page 15

POWERMAX

For your safety, read completely before operating.

CAUTION: DO NOT turn Power Switch ‘on’ until the booster has been filled with

water and all air has been purged from the water lines and accumulator

tank.

FILL THE BOOSTER HEATER

Open the water supply valve at the Booster Heater water supply inlet and fill Booster

Heater. Manually open the temperature/pressure relief valve on the left side of the

cabinet to vent air from water piping. Cycle dishwasher to ensure that all air is

purged from the system and to flush out any contaminants left from piping process.

CHECK ELECTRIC CONTROLS

Do this procedure with the manual gas valve CLOSED (gas supply off). With water supply

valve open (water side under pressure) and with manual gas supply valve in CLOSED

position (no gas flow to unit), push power supply rocker switch on left, top side of cabinet

to ON position. Combustion air fan should start, digital temperature readout should

illuminate and indicate water temperature in accumulator tank and LED indicators in

readout panel should illuminate. If water temperature is below control set point, circulating

pump will start, air flow, water flow and hi-limit E.C.O.’s will prove and ignition system will

be powered. Red LED on ignition control will illuminate briefly, confirming internal selfcheck. Following 2-3 seconds igniter warm-up (observe igniter through viewing window to

verify), an audible ‘click’ will be heard from the gas valve opening. With gas supply off,

ignition will not occur and flame-proving sensor will shut off gas valve. This process will

repeat for, 3 cycles, after which the ignition system will automatically lock-out, requiring a

manual re-set. The combustion fan will remain on low speed, providing a continuous

purge of the combustion chamber. Manual re-set is accomplished by turning off power

switch on booster left side panel for 10 seconds, then turning back on.

tm

START-UP PROCEDURE

13

Page 16

FOR YOUR SAFETY, READ BEFORE OPERATING

WARNING! - IF YOU DON’T FOLLOW THESE INSTRUCTIONS EXACTLY,

A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

A. This appliance DOES NOT have a standing pilot ignition system. It is equipped with a

hot surface ignition device that automatically lights the burner. DO NOT attempt to

light the burner by hand.

B. Before starting the appliance, smell all around the appliance area for gas odor. Be

sure to smell next to the floor because some gases are heavier than air and will

collect on the floor.

WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch.

• DO NOT use any phone in your building.

• IMMEDIATELY call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions. If you cannot reach your gas supplier, call

the fire department and/or ‘911’.

C. Use only your hand to push in and turn the gas control knob. NEVER use tools. If the

knob will not turn by hand, do not try to repair it. Call a qualified service

technician. Using force or attempting to repair may result in a fire or explosion.

D. Do not operate this heater if any part has been under water. Immediately call a

qualified service technician to inspect the heater and replace any part of the control

system and any gas control that has been under water.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Turn off electrical power to appliance at switch on upper left side panel.

3. Remove front access panel by lifting on handle until bottom of panel is released, tilt

bottom of panel away from unit and remove.

4. This appliance is equipped with an ignition device which automatically lights the

burner(s). DO NOT try to light the burner(s) by hand.

5. Turn the gas control knob clockwise to the ‘OFF’ position. (Fig. 7)

6. Wait 5 minutes to clear out any gas. If you smell gas, stop and follow the

instructions under “WHAT TO DO IF YOU SMELL GAS” (ABOVE). If you do not

smell gas, proceed to the next step.

7. Turn gas control knob counterclockwise to the ‘ON’ position.

8. Turn on electrical power to the appliance. Be careful not to contact any live

electrical connections when access panel is open.

9. If appliance does not ignite, there may be air in the gas supply system. Repeat the

cycle several times to remove air.

10. If the appliance will not operate, follow the instructions under “TURN OFF GAS TO

APPLIANCE” (following) and call your service technician or gas supplier.

11. Replace front access panel.

14

Page 17

TO TURN OFF GAS TO APPLIANCE

1. Turn off all electric power to the booster heater if service is to be performed.

2. Turn off manual gas valve in gas supply piping.

3. Remove front access panel by lifting panel to release bottom, tilting panel away from

unit and removing panel.

4. Push in and turn gas control knob clockwise to the ‘OFF’ position.

5. Replace front access panel.

WARNING!

IF OVERHEATING OCCURS OR THE GAS SUPPLY FAILS TO SHUT OFF

CORRECTLY, DO NOT TURN OFF OR DISCONNECT ELECTRIC SUPPLY TO THE

PUMP. SHUT OFF GAS SUPPLY AT THE MANUAL GAS VALVE IN GAS SUPPLY

PIPING. IF WATER IS LEAKING FROM UNIT, AFTER TURNING OFF GAS, LET

BURNER COOL, THEN TURN OFF POWER AND SHUT OFF WATER SUPPLY VALVE.

15

Page 18

MAINTENANCE

Lubrication

The water pump motor and the combustion air blower are permanently lubricated and

require no periodic maintenance. Auxiliary power vent motor (depending upon model)

may or may not need periodic adjustment or lubrication. Consult power vent manual.

Vent System

Check the vent system annually for damage and/or obstruction. Any deformation of the

vent system should be examined carefully to determine the cause of the deformation. The

problem MUST be rectified and any damage to the vent system MUST be repaired.

Check Burner Flame Condition

When the burner is operating properly, the flame will appear to have a light orange base

with a blue tint as you look through the burner observation window and across the burner

surface (fig.8 ). Inspect the burner periodically through the observation window. If areas

of the burner appear different or if the observation window is obscured, contact your

authorized service agency to have the burner inspected for proper operation. If the burner

is burning bright orange, red or white; it is too hot and will burn up igniters at an excessive

rate. Call factory and/or authorized service company to adjust air shutter.

Piping and General Condition

Periodically inspect the booster heater for any signs of water leakage, combustion byproduct leakage (soot, etc.), or wiring damage (electrical arcing, insulation damage).

Contact your authorized service agency to correct any damage or improper operation that

is discovered.

Check Air Filter

Regularly remove and inspect externally mounted air filter on the left side of booster. Filter

is easily cleaned with soap and water. A clogged filter will restrict flow of combustion air

which can lead to malfunction and internal damage. Damage caused by a blocked or

clogged filter is not covered under the warranty.

16

Page 19

CAUTION: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

PROBLEM

3. On-Off switch

powered, Unit does

not operate.

TROUBLE SHOOTING

CAUSE

a. No power to heater.

b. Manual reset Hi-limit

tripped.

c. Vent fan interlock not

proving (if auxiliary

power vent or E-Z

Vent system) is

being used.

REMEDY

a. Check circuit breaker

b. Manually reset hi-

limit. Determine

cause. If hi-limit trips

again, call service.

c. Turn on fan, check

switch.

2. Unit energized,

blower not operating,

pump not operating,

burner(s) not on.

3. Unit energized,

blower and pump

operating, burner(s)

are NOT on, ignition

control LED flashing.

4. Unit energized,

blower on, pump not

operating, burner(s)

NOT on.

Note: For service and/or parts call your authorized service agency or the

factory @ 1-800-624-4809

17

a. Fan defective.

b. Fan relay defective

or wiring

disconnected.

a. Igniter Defective

b. Water flow switch

not proving.

c. Air flow/flue

blockage switch not

proving.

d. Control relay(s)

defective.

e. Control sensor(s)

defective.

f. Control board

defective

g. Ignition control

defective.

h. Burner flame not

proving

a. Pump defective

b. Relay defective

a. Check, replace fan.

b. Check, correct.

c. Check, clean air filter

a. Replace igniter or

call Service

b. Check, replace flow

switch.

c. Clear flue. Repair or

replace switch,

d. Call Service

e. Call Service

f. Call Service

g. Call Service

h. Check, replace flame

sensor

a. Call Service

b. Call Service

Page 20

REPLACEMENT PARTS LIST

When ordering parts, always refer to the Model number and Serial Number.

The data plate is mounted on the electrical panel face behind the front cover

panel. NOTE- Part numbers may change without notification. To obtain the

most recent part numbers contact the Factory or your authorized Vanguard

service agency.

Model PM200, 199,900 BTU/Hr. & Model PM400, 399,800 BTU/Hr.

PART# DESCRIPTION PART#

19052-01612 Blower 20000-00303 Orifice, LP, PM

10050-00039 Board, Temp. Control 20000-00302 Orifice, NG, PM

10592-20000 Control Panel, Complete 20000-00031 Orifice, Pilot, PM LP

10050-00043 Display, Digital Temp. 20000-00030 Orifice, Pilot, PM NG

32200-34209 ECO, Hi-Limit, PM 20021-20001 Pilot Hood Assm w/Ign.Plate, gasket

10051-02383 ECO, Hi-Limit, Manual Reset 75220-90011 Pump, Grundfos W/O Housing 26-99F

19052-20075 Filter, Air FF-5 75220-26099/ Pump, Grundfos, 26-99BF complete

19020-70200 Flex Tube, Gas, 1" x 18" 10080-00025 Relay, Power

19020-70201 Flex Tube, Gas, 7/8x 12" 10050-00042 Sensor, Flame, 18" Lead Wire.

19020-70202 Flex Tube, Gas,1/4ODX18" 10550-00141 Sensor, Temp PM 41"

10080-02466 Gas Control Valve, Honeywell 19010-70001.159 Solonoid, Hi-Lo Gas, LP

10080-02602 Gasket, Igniter Plate 19010-70001.250 Solonoid, Hi-Lo Gas, NG

75220-90051 Gasket, Pump Flange 10080-19101 Switch, Air

10080-02465 Ignition Control, Fenwal 10070-00110 Switch, Water Flow, 1".

40000-40004 Legs, Black 10080-00071 Switch, Sq. Rocker.

50304-20001 Manifold, Cold-Lower, 200 10570-00103 Transformer, 120V/ 24V

50303-20001 Manifold, Cold-Upper, 200 10070-00104 Transformer, 120V/12v, 596

50603-20001 Manifold, Hot, 200 19025-70015 Tube, Vent Pipe Drain

10080-02601 Mini-Igniter, 120V, 250 C 19025-70012 Tube, Air Switch

20000-00304 Orifice, Hi-altitude NG/LP, PM 13053-07501 Valve, T & P. 3/4"

DESCRIPTION

18

Page 21

LIMITED WARRANTY:

Products manufactured by Vanguard Technology. Inc.

are warranted to be free from defects in material and

workmanship, when installed and maintained in

accordance with Vanguard’s instructions and in normal

use and service for the time periods, terms and

conditions as set forth below:

1) For a period of One Year

installation, but no longer than 18 months from

factory shipment, Vanguard will, at its sole

discretion, repair or replace defective parts,

assemblies or entire units, including labor costs

of its authorized service agency. Travel expense

of Vanguard’s authorized service agent will be

paid for the first ninety (90) days of this period,

not to exceed sixty (60) miles or two (2) hours.

2) For an addition al Four Years

warrants the fin tube heat exchanger in the

PowerMax Gas Booster to be free from defects

in material or workmanship. At Vanguard

Technology’s sole discretion and in accordance

with this warranty, defective heat exchangers will

be replaced on a pro-rated and parts only basis.

i.e. Owner will pay a percentage of the current

list price of a replacement heat exchanger as

follows: Failure within first year, no charge: within

second year, 20%; within third year, within fourth

year, 60%; within fifth year 80%.

3) The stainless steel accumulator is covered by a

limited lifetime warranty and is warranted to be

free from leaks for this time. Any attached

gauges; controls or other parts are subject to the

standard one-year parts and labor warranty.

This warranty is limited to the foregoing and does not

apply to defect or malfunction resulting from or caused

by installation, operation or maintenance not in

accordance with manufacturer’s instructions, damage

related to shipping, accident, abuse, fire, flood, or other

acts of God; units operated in corrosive or other

damaging atmospheres or at temperatures outside

specified operating range. Damage caused by

freezing, improper water conditions (excessively

from date of

, Vanguard

acidic or alkaline water, excessive pressure, chemical

contamination, sediment build-up, etc.), incorrect

electrical supply or connection, insufficient combustion

air or negative draft, insufficient water supply, stray

current or voltage conducted through water piping, or

unauthorized alteration shall in no way be covered

under this warranty. Cleaning of filters, pumps, valves,

burners, fans or electrical connections, tightening of

threaded connections and/or adjustment or calibration

of controls is considered a part of normal installation

and/or maintenance and is not covered under this

warranty. Hot surface igniters are considered a

consumable item, similar to a spark plug, and are not

generally considered a warranty item. Accessory

components sold but not installed by Vanguard are

covered by a one-year parts-only warranty. Warranty

on replaced parts or assemblies shall be the lesser of

90 days or the unexpired portion of the original

warranty. Factory reconditioned and tested parts may

be used to satisfy claims under this warranty. Warranty

work shall be done only by Vanguard Technology’s

authorized service agency during normal working

hours. Overtime labor will not be paid under this

warranty.

There are no other expressed or implied warranties of

any kind, including but not limited to any implied

warranty of merchantability or fitness for any particular

purpose or usage. The remedies under this warranty

as set forth here-in are at the exclusion of all others and

Vanguard Technology, Inc., neither assumes nor

authorizes anyone to assume for it any other

obligations. In no event shall Vanguard Technology,

Inc. be liable for any remote or consequential damage

of any nature, no matter how arising or from any cause

whatsoever, or any amounts in excess of the selling

price of the product. Vanguard Technology’s policy of

constant Quality Improvement means that prices,

specifications, and policies are subject to change at any

time and without notice.

VANGUARD TECHNOLOGY, INC.

29495 Airport Road, Eugene, OR 97402

541-461-6020 • FAX 541-461-6023

800-624-4809

R12/03

19

Page 22

TYPICAL SPECIAL STAINLESS STEEL VENTING

For use with Category II, III, IV appliances

Contact Local Building or Fire Officials About Restrictions and Installation Inspections in your area as well as National codes:

USA -National fuel gas code ANS1-Z223.l

CANADA -CAN\CGA-B 149.1 or .2 Fuel Burning Installation Code

Please refer to appliance manufacturers’ instructions to determine proper sizing and connection of venting system to appliance, including

maximum horizontal length, maximum height, and installation clearances (air spaces). The proper operation of the vent system and

appliance requires parts specified by Z-FLEX with no deletions or substitutions. NOTE: Co-venting with other appliances is

PARTS LIST

COMPONENT

10 FOOT PIPE SVEPWC0310 SVEPWC04I0

8 FOOT PIPE SVEPWC0308 SVEPWC0408

5 FOOT PIPE SVEPWC0305 SVEPWC0405

4 FOOT PIPE SVEPWC0304 SVEPWC0404

3 FOOT PIPE SVEPWC0303 SVEPWC0403 FIRESTOP SUPPORT SVSFSS03 SVSFSS04

2 FOOT PIPE SVEPWC0302 SVEPWC0402 FTRESTOP SPACER SVSFSX03 SVSFSX04

1 FOOT PIPE SVEPWC0301 SVEPWC0401

6 INCH PIPE SVEPWC03.5 SVEPWCO4.5

90 0ELBOW SVEEWC0390 SVEEWC0490

45 ELBOW SVEEWC0345 SVEEWC0345 TOP SUPPORT SVSLSX03 SVSLSX04

HORJZ. DRAIN TEE SVEDWC03 SVEDWC04 STORM COLLAR SVSSCX03 SVSSCX04

VERTICAL DRAIN TEE SVEVWC03 SVEVWC04

WALL THIMBLE

WM GV STARTER SVEWMG03

DRAIN TUBE KIT

Z-FLEX recommends that the installation be performed by an experienced professional who works with venting systems on a-regular

basis. These instructions are intended as a guide to assist a professional installer.

When the Z-VENT system is installed, the following should be observed:

1. A venting system that exits the structure through a sidewall or the like, shall terminate not less than 12 inches (254 mm) above the ground

(see illustration # 2, page 4).

2. The termination of a system shall be located above the snow line in geographical areas where snow accumulates. The termination area

should be kept clear of snow and ice at all times.

3. The vent shall not terminate less than 7 ft. (2.13 m) above a paved sidewalk or driveway.

4. The termination shall be 6 ft. (1.8 m) or more from the combustion air intake of any appliance.

5. The system shall terminate more than 3 ft. (.91 m ) from any other building opening, gas utility meter, service regulator or the like.

6. Exterior mounted venting systems should be enclosed below the roof line with a chase to limit condensation and protect against

mechanical failure.

NOTES:

A. The Z-FLEX SPECIAL STAINLESS VENT SYSTEM is for use only with appliances having a positive vent pressure of 3” of water column

or less.

B. Except for installation in one and two family dwellings, a venting system that extends through any zone above that on which the connected

appliance is located shall be provided with an enclosure having a fire resistance rating equal to or greater than that of the floor or roof

assemblies through which it passes

C. Do not place any type of insulation in any required air spaces surrounding the venting system.

D. A termination must be used on all installations to assure proper operation and to prevent debris from entering the venting system.

3” SYSTEM CAT. # 4” SYSTEM CAT. # COMPONENT 3” SYSTEM CAT. # 4” SYSTEM CA1~#

SVSWTX03 SVSWTX04 WM TERM COUPLING SVSTPX03

SVEDTK WM CGI STARTER SVEWMFA03

ADJUST. FLASHING

REDUCER 4” TO 3”

FLAT FLASHING

LOCKING BAND

TERMINATION TEE

TERMINATION BOX

RAIN CAP

Z-VENT SEALANT

AMETEK FAN CONN.

SVSADJ03 SYSADJ04

SVSERWC0403 SVSR0404

SVSSCS03 SVSSCS04

SVSLBX03 SVSLBX04

SVSTTX03 SVSTTX04

SVSRTX03 SVSRTX04

SVSRCX03 SVSRCX04

GE106X

SVSACA03

APPENDIX A

prohibited

20

Page 23

Appendix A

JOINT PROCEDURE

(see illustration #1 below)

1. The outside of male end and inside of female end of pipe must be cleaned before applying silicone

bead. Remove dirt, grease, and moisture from surface to be sealed. Dry surface or allow to dry

thoroughly.

2. Apply high temperature silicone approxi mately one half inch from end around male end of pipe and

along both sides of seam for one inch in an even 1/4” bead as per illustration #1.

3. Pipes can now be pushed together as far as they will go. The seams on pipes should be aligned and

oriented upwards in all horizontal applications. Apply another bead of silicone around this joint and

smooth out.

4. Tighten gear clamps (15 [N/LB. MAX.).

5. Check all joints and seams for tightness prior to using vent system.

6. Allow the sealant to cure for one hour b efore operating the appliance. Length of time required for full

cure depends upon thickness of application and other factors such as weather, ambient temperature,

humidity, etc. All sealants must be used within the time limitations marked.

CLEARANCE TO COMBUSTIBLES

SYSTEM

OPERATING

HORIZONTAL VERTICAL HORIZONTAL VERTICAL

300OF (149OC) 8” (200 mm) 4” (100 mm) 1” (25 mm) 1” (25 mm)

480OF (249OC) 8” (200 mm) 4” (100 mm) 1” (25 mm) N/A

CLEARANCE

ENCLOSED

CLEARANCE

UNENCLOSED

SEALANT

REQUIRED

G.E 108

DOW CORNING 732

Z-FLEX Z-VENT

SEALANT

G.E 106

Z-FLEX Z-VENT

SEALANT

*Note: Flexible elbows parts # SVEFEX03 AND SVEFEX04 must not be enclosed

21

Page 24

Appendix A

SIDE WALL VENTING INSTALLATION

SIDE WALL VENTING INSTALLATION

(see illustration #2)

1. Install wall thimble into wall, observing the aforementioned rules and/or local building codes. Select the

point of wall penetration where the minimum 114” per foot of slope (6.4 mm per 305 mm) can be

maintained. The pipe can be located between joists spaced 16” (400 mm) on centre. The pipe may be

mortared in directly without using a wall thimble, if the wall is non-combustible. Penetrating a combustible

wall requires the use of a wall thimble. A framed opening is required to insert the thimble halves. The

thimble is adjustable for different wall thicknesses. Caulk around outside edge of plates as necessary

and fasten to wall using suitable screws or nails. The vent pipe must be sealed at wall thimble as per

code regarding continuous vapor barrier.

2. The system can now be assembled through the thimble (attach the termination first - note “UP” arrow)

and then back to the appliance as per illustration using JOINT PROCEDURE as described on page #3. A

gear clamp (or locking band) must be installed around the pipe in position so th at the system cannot be

removed in or out of wall. This applies to both combustible and non-combustible walls.

22

Page 25

Appendix A

3. The system must be supported along its horizontal length at all elbow locations and joints (every forty-

eight inches or less) using straps around pipes maintaining clearance to combustibles as per table.

Any horizontally installed portion of a venting system shall have a slope (upwards for Category II, III, or

IV appliances or (upwards for Category Ill or IV appliances) not less than 1/4” (6.4 mm) every 12 inches

(305 mm) to prevent collection of condensate at any location in the assembly. The components of the

system must not be penetrated by fasteners either when joining pipes and fittings or using support

straps. The lengths of pipe may be cut on non-expanded end using aviation snips or a hacksaw (24 tpi).

The cut end must be filed or sanded smooth before joining. When installing the condensate tube, be sure

to form a trap by means of a 3” (76.2 mm) loop filled with water. This tube must be 3/8” ID high

temperature silicone for at least the first 6 inches (152 mm) and attached with a gear clamp or hose

clamp. The effluent must be disposed of according to local regulations.

NOTE: Z-FLEX recommends using a neutralizer kit when using a conden sate trap. A condensate pump

may be required.

VERTICAL VENTING

NOTE: The vent termination must be at least 3 ft. (1 m) above the roof line and 2 ft. (.61 m) higher than

any part of a structure within 10 ft. (3.1 m). The total vertical distance of the vent system from appliance

flue collar to the rain cap termination and the maximum length of offsets shall not exceed that specified in

the appliance manufacturer’s installation instructions. No continuous vertical run shall be lon ger than

sixty feet (18.3 m). All horizontal sections must observe the rules for HORIZONTAL VENTING. The

clearance to combustibles inside a chase shall be no less than 4” (100 mm).

1. Prior to beginning the installation loosely assemble all parts required to make sure all parts are

present.

2. Locate position for venting system and proceed to cut holes for firestop support and firestop spacers.

All vertical installations require the use of a support. Frame the opening of the floor using lumber which is

dimensionally consistent with the structural members. Insert the support from beneath the framed

opening and secure with nails or screws as required.

Refer to JOINT PROCEDURE before assembling system.

23

Page 26

29495 A irport Road, Eu gene, O R 97402

Tel:(541) 461-6020 Fax:(541) 461-6023

Toll Free: 1-800-624-4809

Factory Authorized PowerMax Start-Up

Verification Worksheet

Job Name:______________________________________________________________

Job Location:____________________________________________________________

Dealer Name: ___________ Serial # ___________________

! Verify incoming water temperature to booster heater is 110Ε to 140Ε.

! Verify size of vent piping. ____” dia.

! Is there any horizontal vent piping? YES / NO (Circle one) How much? _____ ft.

! Is vent pipe correct pipe for application? ‘Z’-vent Mfg. By Z-Flex U.S., Saf-T-Vent Mfg.

By Heat Fab., Inc., or StaR-34 By Flex-L International. All are constructed of AL294Ctm Stainless Steel.

! If an auxiliary power vent is being used, is it installed with an indirect connection, per

drawing?

Exhaust

! If used, is power vent installed and operating correctly? YES / NO (Circle One)

! Must come on with burner and continue for 4 minutes after burner shutdown.

! Verify electrical connection to unit is correct and to NEC code.

! Verify size, volume, pressure and type of gas supply & that they are in accordance with

manufacturers specification: 3.25"w.c. NG or 8"w.c. LP; Check at test port on gas

valve.

! Verify gas supply pipe size. _____” dia.

! Verify pipe size, flow pressure and volume of water supply to unit according to

manufacturers specifications. Water supply pipe size. _____” dia.

! Does dishwasher have pressure-regulating valve and gauge? Flow rinse pressure must be

18-20 p.s.i. YES / NO (Circle one)

! Verify that pipe length from booster accumulator outlet or circulating loop to rinse valve

does not exceed 5 feet. (NSF maximum) and is correct diameter (both supply and return)

_____” dia.

! Verify that unit has been flushed properly; both water & gas piping.

! Check all gas connections for leaks.

! Check all water connections for leaks.

24

Page 27

Page 2 Vanguard Technology Inc.

Factory Authorized Start-Up - Verification Worksheet - continued

! Bleed air from accumulator and heat exchanger through temperature/pressure relief

valve.

! Turn power switch ‘on’.

! Burner(s) will activate until accumulator temperature setting is reached. Output

temperature sensor should reduce burner to low flame shortly before burner shuts off.

! When unit is at temperature, flush approx. 25 gal. of hot water through the unit before

shutting off.

! Check flame color and condition through view window. Burner should have a light

orange base with a blue tint. Air shutter may be adjusted to achieve this flame.

FOR CIRCULATOR OPTION: In addition to above........

! Verify circulator pump is operating & pumping in right direction. Pump should be

located in return side of circulator loop and pumping toward booster.

! Verify pipe is sized properly, (complete loop should be 3/4" I.D. minimum for 1

dishwasher and 1" I.D. for 2 dishwashers or dishwashers with both rinse and fill valves

filling through booster), and insulated to minimum R-4 throughout the loop.

! Call factory if booster is being used to heat Dishwasher wash tanks.

Comments and Recommendations:

Service Agency: ____________________________________________________

Address: _________________________________________________________

Please make 2 copies and send to Facility Manager & Vanguard Technology Inc.

For any assistance, please call factory at: 1-800-624-4809

______________________________________

Technician Signature

_______________________________________

Technician Name (please print)

_______________________

Date

25

Page 28

26

Loading...

Loading...