Page 1

For Briggs & Stratton Discount Parts Call 606-678-9623 or 606-561-4983

TABLE OF CONTENTS

SAFETY, MAINTENANCE AND ADJUSTMENTS Section 1. . . . . . . . . . . . . . . . . .

TROUBLESHOOTING Section 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE DISASSEMBLY Section 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL SYSTEMS AND CARBURETION Section 4. . . . . . . . . . . . . . . . . . . . . . . . . .

GOVERNOR Section 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER HEADS AND VALVES Section 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTERS Section 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION SYSTEMS Section 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDERS AND CRANKCASE COVERS/SUMPS Section 9. . . . . . . . . . . . . . .

CRANKSHAFTS AND CAMSHAFTS Section 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

PISTONS, RINGS AND CONNECTING RODS Section 11. . . . . . . . . . . . . . . . . . .

ENGINE ASSEMBLY Section 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SPECIFICATIONS Section 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

www.mymowerparts.com

Page 2

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Section 1

Safety, Maintenance and Adjustments

Page

AIR CLEANER SERVICE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Round Air Cleaner 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Square Air Cleaner 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cyclonic Air Cleaner 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARMATURE AIR GAP ADJUSTMENT 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRIGGS & STRATTON NUMERICAL IDENTIFICATION SYSTEM 6. . . . . . . . . . . . . . . . . . . . . . . . .

CARBURETOR ADJUSTMENTS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 290000 – 350000 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance ControlE Engines 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 351400, 380400, 351700, 380700 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHOKE CONTROL ADJUSTMENT 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMBUSTION CHAMBER DEPOSITS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COOLING SYSTEM CLEANING 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRANKCASE OIL 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL AND OIL RECOMMENDATIONS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Recommendations 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Recommendations 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GOVERNOR ADJUSTMENTS 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static Governor Adjustment 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamic Governor Adjustment 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IN THE INTEREST OF SAFETY 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND ADJUSTMENTS SCHEDULE 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL COOLER 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVERHAUL PROCEDURE 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassemble 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repairs 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassemble 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPARK PLUGS 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPEED CONTROL WIRE ADJUSTMENT 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TUNE UP PROCEDURE 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VALVE CLEARANCE ADJUSTMENT 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 3

1

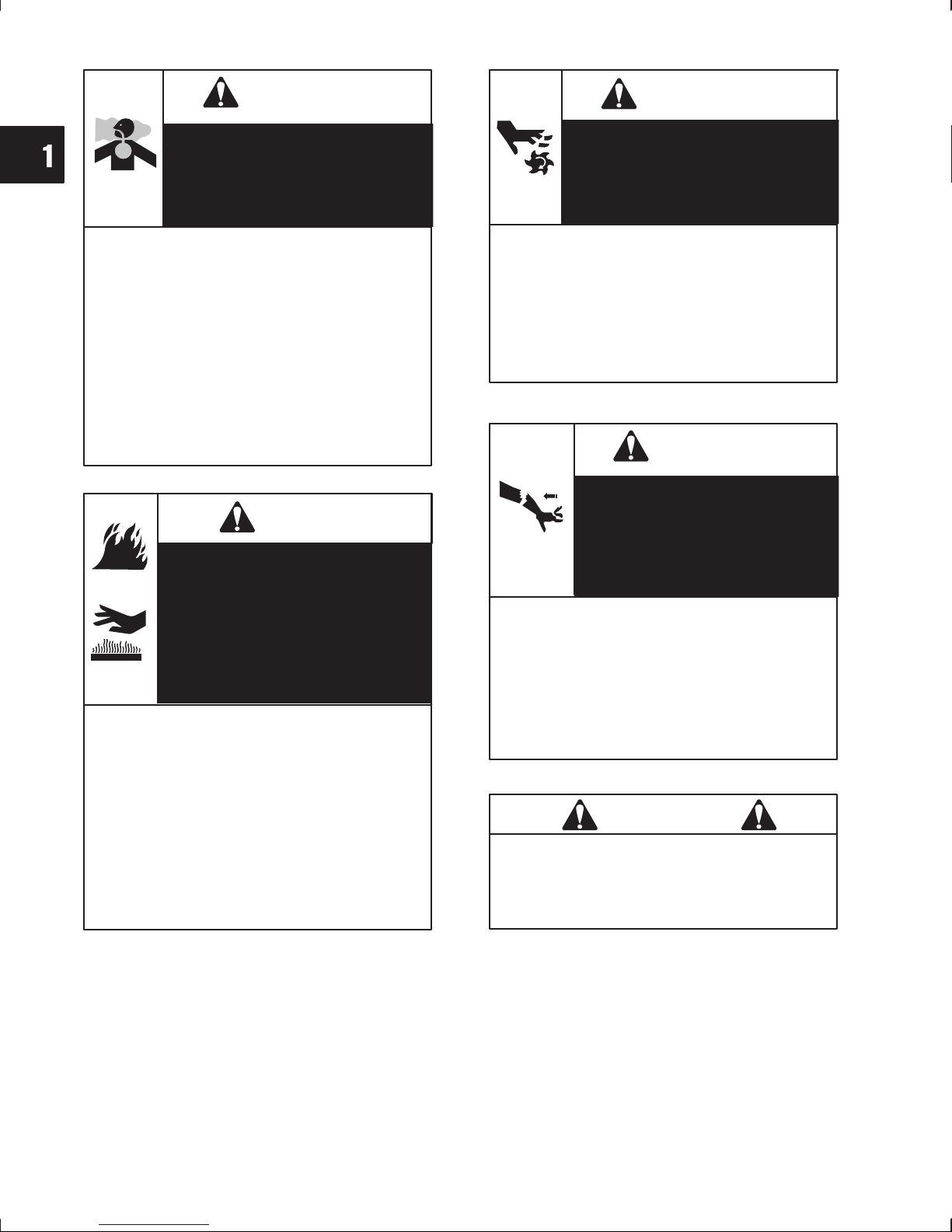

IN THE INTEREST OF SAFETY

DANGER

FOLLOW INSTRUCTIONS

CAREFULLY !

• Before attempting to service this equipment,

read and understand this manual and the

operating instructions.

• Failure to follow instructions could result in

DEATH, SERIOUS INJURY (including paralysis) or property damage.

* Briggs & Stratton does not necessarily know what

equipment this engine will power. For that reason,

carefully read and understand the operating instructions for the equipment your engine is powering.

CAUTION indicates a hazard that, if not

avoided, might result in minor or moderate injury.

CAUTION, when used without the alert symbol, in-

dicates a situation that could result in damage to

the engine.

NOTE: A NOTE is used to inform you of a method,

reference or procedure that could assist

with specific operations or procedures.

HAZARD SYMBOLS AND MEANINGS

Fire

Explosion

Hot Surface

THE OPERATING, MAINTENANCE &

REPAIR INSTRUCTIONS CONTAIN

SAFETY INFORMATION TO:

• Make you aware of hazards associated with

engines

• Inform you of the risk of injury associated with

those hazards, and

• Tell you how to avoid or reduce the risk of injury.

SAFETY ALERT SYMBOL

The safety alert symbol ( ) is used to identify

safety information about hazards that can result in

personal injury.

A signal word (DANGER, WARNING, or CAUTION)

is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to represent

the type of hazard.

DANGER indicates a hazard that, if not

avoided, will result in death or serious injury.

Shock

Eye Protection

Required

INTERNATIONAL SYMBOLS AND MEANINGS

Safety Alert

Choke Start Position

Toxic Fumes

Flying Objects

Oil

Moving Parts

Kickback

Read Operator’s

Manual

Stop

WARNING indicates a hazard that, if not

avoided, could result in death or serious injury.

2

Fuel

Fuel Shutoff

Page 4

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

WARNING

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe

burns or death.

WHEN ADDING FUEL

• Turn engine OFF and let engine cool at least 2

minutes before removing gas cap.

• Fill fuel tank outdoors or in a well-ventilated

area. Keep gasoline and its vapors away from

sparks, open flames, pilot lights, heat, and

other ignition sources.

• Do not overfill fuel tank. Fill tank to

approximately 1-1/2 inches below top of neck

to allow for fuel expansion.

• Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace if

necessary.

WHEN STARTING ENGINE

• Make sure spark plug, muffler, fuel cap and

air cleaner are in place.

• Do not crank engine with spark plug removed.

• If fuel spills, wait until it evaporates and the

vapors dissipate before starting engine.

• If engine floods, set choke to OPEN/RUN

position, place throttle in FAST position.

Crank until engine starts.

WHEN OPERATING EQUIPMENT

• Do not tip engine or equipment at an angle

that causes gasoline to spill.

• Do not choke carburetor to stop engine.

WHEN TRANSPORTING EQUIPMENT

• Transport with fuel tank EMPTY or with fuel

shut-off valve OFF.

WHEN STORING GASOLINE OR EQUIPMENT

WITH FUEL IN TANK

• Store away from furnaces, stoves, water

heaters or other appliances that have pilot

light or other ignition source. These can ignite

gasoline vapors.

WARNING

Kerosene and its vapors are

extremely flammable, and should

be handled with the same

precautions as gasoline.

WARNING

Unintentional sparking can result

in fire or electric shock.

Unintentional start-up can result in

entanglement, traumatic amputation, or laceration.

BEFORE PERFORMING ADJUSTMENTS

OR REPAIRS

• Disconnect spark plug wire and keep it away

from spark plug.

• Disconnect battery at negative terminal (only

engines with electric start).

WHEN TESTING FOR SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug

removed.

WARNING

All fuel components should be

in good condition and properly

maintained.

• Repairs should only be made with

factory approved parts.

• Repair work should be done by a

qualified technician.

• Flexible supply lines should be

checked regularly to make sure

they are in good condition.

Replace damaged or leaking

components.

3

Page 5

1

WARNING

Engines give off carbon

monoxide, an odorless, colorless,

poison gas.

Breathing carbon monoxide can

cause nausea, fainting or death.

• Start and run engine outdoors.

• DO NOT start or run engine in enclosed area,

even if doors or windows are open.

• Inhalation of high concentrations of vapor,

even for short periods can cause unconsciousness or might prove fatal.

• Inhalation may cause irritation to the nose and

throat, headache, nausea vomiting, dizziness,

and drowsiness.

• Unconsciousness or asphyxiation may result

in poorly ventilated areas or confined spaces.

WARNING

Running engines produce heat.

Engine parts, especially muffler,

become extremely hot.

Severe thermal burns can occur

on contact.

Combustible debris, such as

leaves, grass, brush, etc. can

catch fire.

• Allow muffler, engine cylinder and fins to cool

before touching.

• Remove accumulated combustibles from

muffler area and cylinder area.

• Install and maintain in working order a spark

arrester before using equipment on forestcovered, grass-covered, brush-covered

unimproved land. The state of California

requires this (Section 4442 of the California

Public Resources Code). Other states may

have similar laws. Federal laws apply on

federal land.

WARNING

Rotating parts can contact or

entangle hands, feet, hair, clothing,

or accessories.

Traumatic amputation or severe

laceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating

parts.

• Tie up long hair and remove jewelry.

• DO NOT wear loose-fitting clothing,

dangling drawstrings or items that could

become caught.

WARNING

Rapid retraction of starter cord

(kickback) will pull hand and arm

toward engine faster than you can

let go.

Broken bones, fractures, bruises

or sprains could result.

• When starting engine, pull cord slowly until

resistance is felt, then pull rapidly.

• Remove all external equipment/engine loads

before starting engine.

• Direct coupled equipment components such

as, but not limited to, blades, impellors,

pulleys, sprockets, etc., must be securely

attached.

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

4

Page 6

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Additional Precautions

Before working on the engine, read and understand

the applicable sections of this manual. Follow all

safety warnings. Death, personal injury and/or property damage may occur unless service instructions

are followed carefully.

DO NOT store, spill, or use gasoline near an open

flame, or near an appliance like a stove, furnace, or

water heater that uses a pilot light or creates a spark.

DO NOT refuel indoors or in an unventilated area.

DO NOT operate or tip engine/equipment at an

angle that causes gasoline spillage.

DO NOT operate engine if gasoline is spilled, when

smell of gasoline is present, or when other explosive

conditions exist. (Move equipment away from spill.

Avoid ignition until gasoline has evaporated.)

DO NOT transport engine with fuel in tank or fuel

shut-off valve open.

DO NOT choke carburetor to stop engine, especially

in an enclosed vehicle. (Gradually reduce engine

speed before stopping.)

DO NOT tamper with governor springs, links or other

parts to increase engine speed. (Run engine at speed

set for equipment manufacturer.)

DO NOT check for spark with spark plug removed.

(Use an approved tester.)

DO NOT run engine with blower housing or other

safety shields removed.

DO NOT crank engine with spark plug removed. (If

engine is flooded, place throttle in FAST position and

crank until engine starts.)

DO NOT strike flywheel with a hammer or hard object.

This could cause the flywheel to shatter in operation.

(Use only Briggs & Stratton approved tools and procedures to remove the flywheel.)

DO NOT operate engine without a muffler. (Inspect

periodically and replace if worn or leaking. If engine

is equipped with muffler deflector, inspect periodically

and replace if necessary. Replacement parts must be

same as on original equipment.)

DO NOT operate engine with grass, leaves or other

combustible material accumulated in the muffler

area.

DO NOT touch hot muffler, cylinder, or fins which can

cause burns.

DO NOT start engine with air cleaner or air cleaner

cover removed.

DO NOT attempt to start engine with cutting blade

loose or removed. (Blade must be tight, otherwise

kickback may occur.)

DO NOT remove fuel tank cap or fill the fuel tank

while the engine is hot or running. DO NOT refuel indoors or in an unventilated area. Allow the engine to

cool at least 2 minutes before refueling.

WEAR suitable eye protection (safety glasses,

goggles or face shield) when performing repair procedures.

PREVENT ACCIDENTAL STARTING by disconnecting spark plug wire from spark plug when servicing engine or equipment. Disconnect negative wire

from battery terminal if equipped with electric starting system.

USE ONLY genuine Briggs & Stratton parts or their

equivalent. The use of non-equivalent replacement

parts may damage the engine.

GASEOUS FUEL ENGINES – Check fuel lines and

fittings frequently for cracks or leaks. Replace as

necessary.

5

Page 7

BRIGGS & STRATTON NUMERICAL IDENTIFICATION SYSTEM

YOUR KEY TO THE WORLD'S FINEST ENGINES

This chart explains the unique Briggs & Stratton numerical model designation system. It is possible to determine most of the

important mechanical features of the engine by merely knowing the model number. Here is how it works:

A. The first one or two digits indicate the approximate CUBIC INCH DISPLACEMENT.

B. The first digit after the displacement indicates the BASIC DESIGN SERIES, relating to cylinder

construction, ignition, general configuration, etc.

C. The second digit after the displacement indicates ORIENTATION OF CRANKSHAFT.

D. The third digit after the displacement indicates TYPE OF BEARINGS, and whether or not the

engine is equipped with REDUCTION GEAR or AUXILIARY DRIVE.

E. The last digit indicates the TYPE OF STARTER.

BRIGGS & STRATTON MODEL NUMBERING SYSTEM

FIRST DIGIT

AFTER DISPLACEMENT

A B C D E

CUBIC INCH

DISPLACEMENT

ă6

ă8

ă9

10

11

12

13

16

18

19

20

21

22

23

24

25

28

29

30

31

32

35

38

40

42

43

44

46

47

52

54

58

EXAMPLE - To identify Model 303447:

30 3 4 4 7

30 Cubic Inch Design Series 3 Horizontal Shaft Ball Bearing

BASIC

DESIGN SERIES

0

1

2

3

4

5

6

7

8

9

A to Z

A to G - Horizontal Shaft

H to Z - Vertical Shaft

TYPE 1234Ć01, The type number identifies the engines mechanical parts, color of paint, decals, governed speed, and Original

Equipment Manufacturer.

CODE

01061201, The code is the manufacturing date and is read as follows:

YEAR MONTH DAY ASSEMBLY LINE AND MANUFACTURING PLANT

01 06 12 01

Revised 4/04

SECOND DIGIT

AFTER DISPLACEMENT

CRANKSHAFT

ORIENTATION

0 to 4 - Horizontal Shaft

5 to 9 - Vertical Shaft

THIRD DIGIT

AFTER DISPLACEMENT

PTO BEARING,

REDUCTION GEAR,

AUXILIARY DRIVE,

LUBRICATIONă TYPE OF STARTER

0 - Plain Bearing/DU

NonĆFlange Mount

1 - Plain Bearing

Flange Mounting

2 - Sleeve Bearing

Flange Mounting

Splash Lube

3 - Ball Bearing

Flange Mounting

Splash Lube

4 - Ball Bearing

Flange Mounting

Pressure Lubrication

5 - Plain Bearing

Gear Reduction

(6 to 1) CCW Rotation

Flange Mounting

6 - Ball Bearing

Gear Reduction

(2 to 1) CCW Rotation

7 - Plain Bearing

Pressure Lubrication

8 - Plain Bearing

Auxiliary Drive (PTO)

Perpendicular to

Crankshaft

9 - Plain Bearing

Auxiliary Drive

Parallel to Crankshaft

A - Plain Bearing

Pressure Lubrication

Without Oil Filter

Flange Mounting

Pressure Lubrication

FOURTH DIGIT

AFTER DISPLACEMENT

0 - Without Starter

1 - Rope Starter

2 - Rewind Starter

3 - Electric Starter Only

110 or 230 Volt Gear

Drive

4 - Electric Starter/110 or

230 Volt Gear Drive

with Alternator

5 - Electric Starter Only

12 or 24 Volt Gear

Drive

6 - Alternator Only

7 - Electric Starter

12 or 24 Volt Gear

Drive with Alternator

8 - Vertical Pull Starter or

Side Pull Starter

9 - Mechanical Starter

A - Electric Starter

12 or 24 Volt Gear

Drive with Alternator

and Inverter

Electric Starter

12 or 24 Volt Gear Drive

with Alternator

6

Page 8

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

FUEL & OIL RECOMMENDATIONS

Fuel Recommendations

Gasoline Engines

• Use clean, fresh regular unleaded gasoline with a

minimum of 85 octane. Fresh fuel prevents gum

from forming in the fuel system or on essential

carburetor parts. Purchase fuel in a quantity that

can be used within 30 days.

• Do not use gasoline containing Methanol.

• Do not mix oil with gasoline.

• For engine protection use Briggs & Stratton Fuel

Stabilizer #5041 or single use pouch #5058

available from your Authorized Briggs & Stratton

Dealer.

CAUTION: Some fuel, called “oxygenated” or

“reformulated” gasoline, is gasoline blended

with alcohol or ether. Excessive amounts of

these blends can damage the fuel system or

cause performance problems. If any undesirable operating symptoms occur, use gasoline

with a lower percentage of alcohol or ether.

Gaseous Fuel Engines

DANGER

AVOID INJURY! Gaseous fuel

systems should only be worked

on in a very well ventilated area.

• Many state, county and city governments

require that service be performed ONLY

outdoors.

• Have a fan blowing across the engine BEFORE

loosening fuel line connections!

NOTE: Gaseous fueled engines require special

equipment to remain emissions certified.

See a certified gaseous fuel dealer or a

certified OEM dealer for service.

Use clean fuel free of moisture or particulate

material, within the following values:

For propane (LPG) fueled engines, use commercial

grade HD% propane. Recommended fuel has a

minimum fuel energy of 2500 BTU/ft3, maximum

propylene content 5%, butane, heavier gas content

2.5%, minimum propane content 90%.

WARNING

Inline Fuel Filter Service

Replace inline fuel filter yearly or every 100 hours,

whichever occurs first. Replace filter if dirt or water

are present. See illustrated parts list for correct

fuel filter.

AVOID INJURY! Gaseous fueled

equipment is equipped with an automatic safety gas fuel lock-off valve.

• Do not operate gaseous fueled equipment if the

fuel lock-off valve is missing or inoperative.

7

Page 9

1

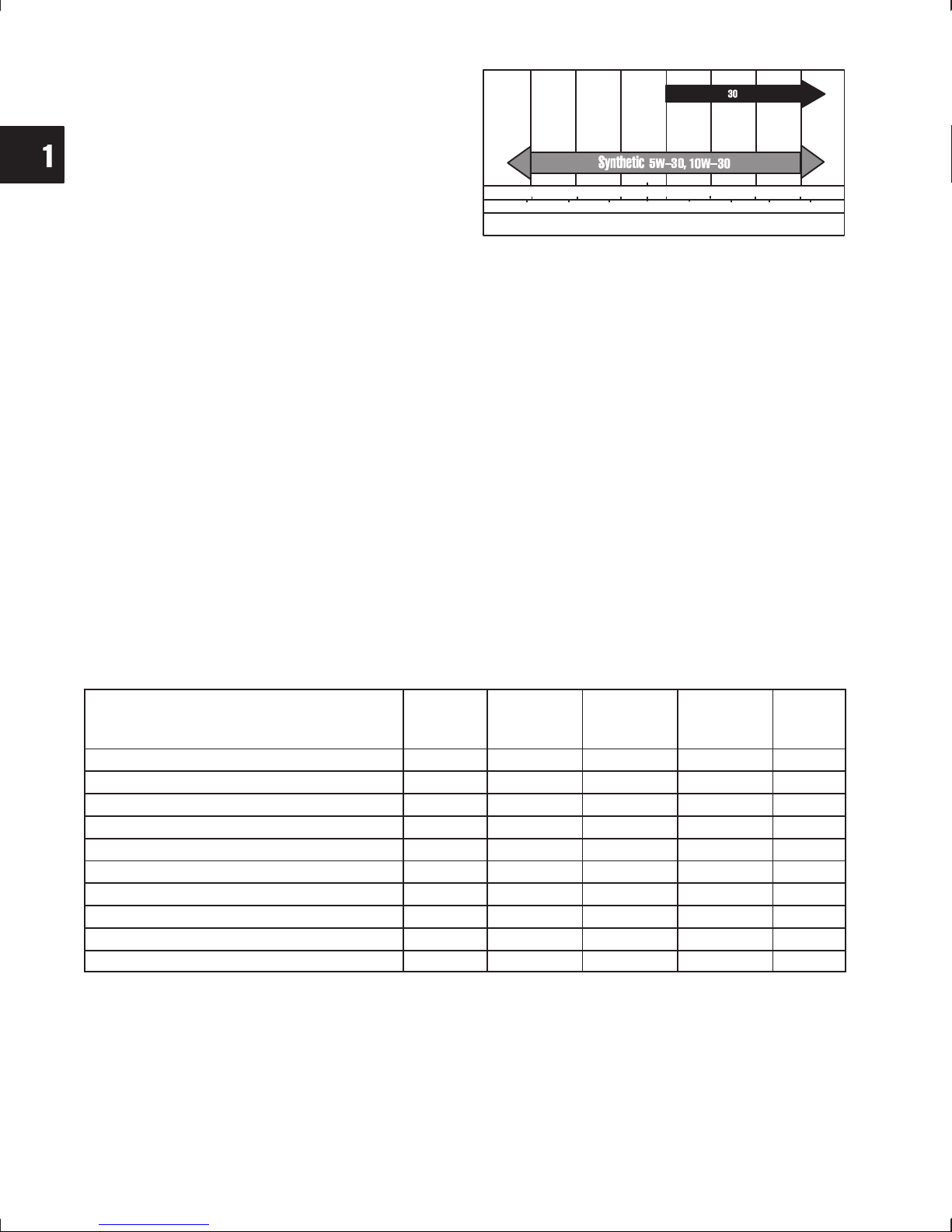

Oil Recommendations

Oil has four purposes. It cools, cleans, seals and lubricates. During normal operation, small particles of

metal from the cylinder walls, pistons, bearings and

combustion deposits contaminate the oil. Dust particles from the air also contaminate the oil, forming

an abrasive mixture that can wear internal engine

parts if the oil is not changed regularly. Fresh oil assists in cooling. Old oil gradually thickens and loses

its cooling ability and its lubricating qualities.

Briggs & Stratton OHV V-Twin engines are lubricated with a gear-driven oil pump.

Use a high quality detergent oil classified “For Service SJ or HIGHER” such as Briggs & Stratton 30

weight oil part #100005 or #100028. Detergent oils

keep the engine cleaner and retard the formation of

gum and varnish deposits. Do not use additives with

recommended oils.

**

-20 0

°F

-30

°C

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

-20 -10 0 10 20 30 40

20 40 60 80 100

32

Air cooled engines run hotter than automotive

engines. Use of multi-viscosity oils (10W-30,

etc.) in ambient temperatures above 40 F

(4C) will result in high oil consumption. If

multi-viscosity oil is used, check oil level more

frequently to prevent any possible engine

damage due to lack of lubrication.

** SAE 30 oil, if used in ambient temperatures

below 40 F (4 C) will result in hard starting

and possible engine damage due to inadequate lubrication.

Synthetic oil meeting ILSAC GF-2, API certification mark and API service symbol with “SJ/

CF ENERGY CONSERVING” rating or higher,

is an acceptable oil at all temperatures.

NOTE: Use of synthetic oil does not alter

the required oil change intervals.

MAINTENANCE & ADJUSTMENTS SCHEDULE

The following maintenance schedule is a general guide. See the Engine Operating & Maintenance Instructions

for details on specific engine models.

25 Hours

or Every

Season

Note #2

Maintenance Schedule

Check oil level *

Change oil

Change oil filter

Clean/Replace air filter pre-cleaner

Clean/Replace air filter cartridge

Clean cooling system

Inspect/clean spark arrester (if used)

Replace or clean spark plugs

Replace in-line fuel filter

Remove combustion chamber deposits

8 Hours

or Daily

* Change oil after the first 5 to 8 hours of operation (break-in period), then after every 50 hours or every season.

NOTE: #1 – Change oil every 25 hours when operating under heavy load or in high temperatures.

50 Hours

or Every

Season

Note #1

100 Hours

or Every

Season

Note #2

Note #2

500

Hours

NOTE: #2 – Clean more often under dusty conditions or when airborne debris is present. Replace air cleaner

parts when dirty.

8

Page 10

AIR CLEANER SERVICE

AVOID FIRES!

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

WARNING

• Never operate an engine with the air cleaner

assembly or air cleaner cartridge removed!

A properly serviced air cleaner protects internal engine parts from airborne dirt and dust particles. If air

cleaner instructions are not followed, particles that

should be collected in the air cleaner will pass into

the engine. These particles are abrasive and will

cause the piston rings and cylinder bore to wear

quickly. As the rings and bore wear, the abrasive particles enter the crankcase and contaminate the oil,

forming an abrasive mixture that will wear internal

parts.

Examine the air cleaner on every engine brought in

for a check up or repair. If the air cleaner shows signs

of neglect, show it to the customer before cleaning.

Instruct the customer on proper care to assure long

engine life.

NOTE: Replace worn or damaged air cleaner gas-

kets and mounting gaskets to prevent dirt

and dust from entering engine through improper sealing. Replace air cleaner mounting bracket if bent.

Fig. 1

Remove and service foam pre-cleaner, if equipped,

every 25 hours or every season, whichever occurs

first. Service cartridge every 100 hours or every season, whichever occurs first.

NOTE: Service air cleaner more often under dusty

conditions.

Round Air Cleaner

1. Remove cover (1), knob (2), plate (3), and air

cleaner cartridge (4) with pre-cleaner (5), Fig. 1

or Fig. 2.

Fig. 2

2. Remove foam pre-cleaner from cartridge.

3. Wash pre-cleaner in liquid detergent and water.

4. Squeeze dry in a clean cloth. Set aside.

5. Inspect cartridge. Replace if damaged or dirty.

9

Page 11

1

CAUTION: DO NOT use petroleum solvents to

clean paper cartridge.

DO NOT oil paper cartridge.

DO NOT use pressurized air to clean or dry paper

cartridge.

6. Reinstall pre-cleaner over cartridge.

7. Install cartridge to air cleaner.

8. Install plate, knob and air cleaner cover.

Square Air Cleaner

1. Remove knob(s) (2) and cover assembly (1),

Fig. 3.

Cyclonic Air Cleaner

NOTE: The debris valve automatically discharges

dust and debris. There should be minimal

debris for removal.

1. Remove debris from the air cleaner by

squeezing the ends of the debris valve (5),

Fig. 4.

Fig. 3

2. Remove cartridge (4) and pre-cleaner (5) from

cover.

3. Wash pre-cleaner in liquid detergent and water.

4. Squeeze dry in a clean cloth. Set aside.

5. Inspect cartridge. Replace if damaged or dirty.

CAUTION: DO NOT use petroleum solvents to

clean paper cartridge.

DO NOT oil paper cartridge.

DO NOT use pressurized air to clean or dry paper

cartridge.

6. Install pre-cleaner in cover with foam toward

cover. (Nylon screen toward paper element.)

Fig. 4

2. Remove the cover (4) from the air cleaner

housing (1).

3. Remove the primary filter (3) and inspect.

Replace the filter if damaged, or dirty.

CAUTION: DO NOT clean or oil these filters.

DO NOT use pressurized air to clean or dry filters.

REPLACE filters if damaged or dirty

4. Inspect the safety filter (2).

NOTE: DO NOT remove the safety filter (2) as part

of the inspection.

If it is necessary to remove the safety filter,

Fig. 5, be sure all debris is removed from the

air cleaner housing before removal.

Replace the safety filter with every third

replacement of the primary filter, or if

damaged or dirty.

7. Install paper cartridge in cover with tabs on

cartridge (3) in slots of cover, Fig. 3.

8. Reinstall cover assembly on air cleaner body.

10

5. Reinstall filter(s).

6. Reinstall air cleaner cover.

Page 12

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

CARBURETOR ADJUSTMENTS

Models 290000 – 350000

The Vanguard OHV twin cylinder engine carbure-

tor fuel mixture adjustment procedure is unique. Perform adjustments exactly in the sequence shown.

NOTE: If engine is equipped with Performance

Control electronic governor see separate

adjustment procedure.

Initial Adjustment

Fig. 5

ARMATURE AIR GAP ADJUSTMENT

1. Loosen screws holding armature in place. Slide

armature away from flywheel and tighten one of

the screws.

2. Rotate flywheel until magnet is under armature

laminations.

3. Place thickness gauge (1) between magnet and

armature laminations, Fig. 6.

• All EXCEPT Models 540000, 610000 – Use

0.008” – 0.012” (0.20 – 0.30 mm) gauge.

• Models 540000, 610000 – Use 0.005 – 0.007”

(0.13 – 0.18 mm) gauge.

1. Turn idle mixture screw (1), Fig. 7, CLOCKWISE

until it just seats. DO NOT FORCE.

2. Turn valve COUNTERCLOCKWISE 1-1/4

turns.

This setting will permit engine to start. Final adjustment will be made with engine running.

NOTE: Parts removed for clarity.

Fig. 6

4. Loosen screw on the armature. Allow armature

to be pulled against the gauge by the flywheel

magnet. Tighten both armature screws to 25 in.

lbs. (3 Nm).

5. Rotate flywheel to remove gauge.

6. Repeat procedure for the other armature.

Fig. 7

If engine is equipped with a secondary governor

spring, Fig. 8, check governor lever adjustment

procedure before starting engine.

(1) Primary Governor Spring

(2) Loop (faces UP)

(3) Secondary Governor Spring

(4) Loop Over Tab

(5) #2 Hole (Generators)

(6) #1 Hole (Remote Control)

11

Page 13

1

Ì

Fig. 8

Final Adjustment

All carburetor adjustments performed with the engine running must be made with the air cleaner

installed.

• Tools Required, Fig. 9:

Tachometer #19200 or #19389

Fig. 10

4. Turn idle mixture screw slowly CLOCKWISE (1)

until engine speed just starts to slow (LEAN

mixture), Fig. 11.

Tang Bender #19352

1. Start engine. Run for approximately 5 minutes to

allow engine to warm up.

2. Move control lever on equipment to SLOW

position.

1938919200

19352

Fig. 9

3. Hold throttle lever (2) against idle speed screw

(1), Fig. 10. Temporarily adjust idle to RPM

shown below.

Fig. 11

5. Then turn idle mixture screw COUNTERCLOCKWISE (3) until engine speed just starts to

slow (RICH mixture).

6. Turn screw to mid point (2) between RICH and

LEAN.

7. Hold throttle lever against idle speed adjustment

screw and re-adjust idle to RPM shown below:

a. 1200 RPM – Governed Idle Spring #805453

(RED).

b. 900 RPM – Governed Idle Spring #805454

(WHITE).

8. Release throttle lever. Note RPM.

9. If necessary bend governed idle tang (5) with

Tang Bender #19352 (4), Fig. 12, to obtain RPM

shown:

a. 1400 RPM – Governed Idle Spring #805453

(RED).

b. 1100 RPM – Governed Idle Spring #805454

(WHITE).

12

a. 1750 RPM – Governed Idle Spring #805453

(RED).

b. 1100 RPM – Governed Idle Spring #805454

(WHITE).

Page 14

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

10. If the carburetor is equipped with an idle mixture

limiter cap install it at this time.

a. Position limiter cap (7) so that stop(s) on

limiter cap are at mid point between stop(s)

on carburetor body, Fig. 13.

Fig. 12

Fig. 14

Performance Control Engines

NOTE: All carburetor adjustments with engine

running must be made with the air cleaner

correctly installed.

1. Start engine and run it for approximately 5

minutes to allow engine to reach operating

temperature.

2. Activate idle down device, or ground BLUE wire

(1) from control module using a jumper wire (2),

Fig. 15.

3. Temporarily adjust idle speed to 1400 RPM.

Fig. 13

b. Press limiter into position using Knock Out

Pin, #19135 (6) as shown.

11. With equipment control lever in SLOW position

and engine running at governed idle, use Tang

Bender, #19352 (9), to bend throttle restrictor

tang (8) so that tang just contacts governor lever

(10), Fig. 14.

12. Move equipment control to FAST position.

Engine should accelerate smoothly.

Re-adjust idle mixture valve 1/8 turn richer if

necessary.

Fig. 15

4. Turn idle mixture screw slowly CLOCKWISE (3)

until engine speed just starts to slow (LEAN

mixture), Fig. 16.

5. Then turn idle mixture valve COUNTERCLOCKWISE (5) until engine speed just starts to slow

(RICH mixture).

6. Turn valve to mid point (4) between RICH and

LEAN.

7. Re-adjust idle speed to 1750 RPM.

13

Page 15

1

NOTE: Idle speed may vary according to OEM

specifications.

Fig. 16

8. Deactivate idle-down device, or remove jumper

wire. Engine should accelerate smoothly to top

governed speed. Re-adjust idle mixture screw

1/8 turn richer if necessary.

9. If the carburetor is equipped with an idle mixture

limiter cap, install it at this time.

a. Position limiter cap (7) so that stop on limiter

cap is at mid point between stops on

carburetor body, Fig. 17.

Fig. 18

2. Then turn screw COUNTERCLOCKWISE 3/4

turn.

Fig. 17

b. Press limiter into position using Knock Out

Pin #19135 (6).

Models 351400, 380400, 351700 and 380700

The OHV twin cylinder engine carburetor fuel

mixture adjustment procedure is unique. Perform

adjustments exactly in the sequence shown.

Horizontal crankshaft engines (1) and vertical

crankshaft engines (2) are shown in Fig. 18.

Initial Adjustment

3. Repeat for #2 cylinder.

This setting will permit engine to start. Final adjustment will be made with engine running.

Final Adjustment

Carburetor adjustments performed with engine running must be made with the air cleaner correctly

installed.

NOTE: Idle mixture adjustment MUST be per-

formed with the engine running at 1200

RPM.

Tools Required:

• Tachometer #19200 or #19389

• Tang Bender #19352

1. Start engine and run it for approximately 5

minutes to allow engine to reach operating

temperature.

2. Move equipment control lever to SLOW

position.

1. Turn idle mixture screw for #1 cylinder CLOCKWISE until it just seats. DO NOT FORCE,

Fig. 18.

14

3. Hold throttle lever (1) against idle speed screw

(2), Fig. 19. Temporarily adjust idle to 1200

RPM.

Page 16

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

4. While holding throttle lever, SLOWLY turn idle

mixture screw for #1 cylinder CLOCKWISE until

engine speed just starts to slow (LEAN mixture).

Fig. 19

5. Then turn idle mixture screw (3) COUNTER-

CLOCKWISE 3/8 turn, Fig. 20.

NOTE: It may be necessary to re-adjust idle speed

to 1200 RPM before proceeding.

a. 1750 RPM – Governed Idle Spring #805453

(RED).

b. 1100 RPM – Governed Idle Spring #805454

(WHITE).

NOTE: Parts removed for clarity.

Fig. 21

10. If carburetor is equipped with idle mixture limiter

caps, install at this time.

6. Adjust idle mixture screw for #2 cylinder as

described in steps 4 and 5.

7. If necessary, re-adjust idle speed screw to RPM

shown below.

a. 1200 RPM – Governed Idle Spring #805453

(RED).

b. 900 RPM – Governed Idle Spring #805454

(WHITE).

8. Release throttle lever. Note RPM.

Fig. 20

9. If necessary, use Tang Bender #19352 (6),

Fig. 21. Bend governed idle tang LEFT to

INCREASE (4), right to DECREASE (5) engine

speed to obtain RPM shown:

a. Position limiter cap (8) so that stop on limiter

cap is at mid point between stops on carburetor body. Press limiter into position using

Knock Out Pin #19135 (7) as shown in,

Fig. 22.

b. Repeat for other idle mixture valve.

11. With equipment control lever in SLOW position

and engine running at governed idle, use Tang

Bender #19352 (10), to bend throttle restrictor

tang (9) so that it just contacts governor lever

(11), Fig. 23.

12. Move equipment control to FAST position.

Engine should accelerate smoothly. Re-adjust

idle mixture valve 1/8 turn richer if necessary.

Fig. 22

15

Page 17

1

Remove deposits from combustion chamber and

around valves using a wire brush or scraper. With

piston at Top Dead Center (TDC), remove

combustion chamber deposits from top of piston.

Use care to prevent combustion chamber deposits

from entering push rod or oil return cavity in cylinder.

Take care not to damage cylinder, top of piston,

cylinder head and cylinder head gasket surfaces.

11

Fig. 23

Choke Control Adjustment

NOTE: Be sure choke control wire is installed in #2

hole (2) in choke lever, Fig. 24.

Fig. 24

1. Place choke control lever on equipment in

CHOKE position.

NOTE: Remove only the combustion chamber de-

posits. It is not necessary to remove the discoloration marks on the piston, valves and

cylinder head. These marks are normal and

will not affect engine operation.

Remove the loose deposits from around the top ring

land area using compressed air or a soft bristle

brush.

Cooling System Cleaning

Grass particles, chaff or dirt can clog the air cooling

system, especially after prolonged service in cutting

dry grass or very dirty air. Operating with a clogged

cooling system can cause overheating and engine

damage. Cleaning the cooling system should be a

regular maintenance operation, performed yearly or

every 100 hours, whichever comes first.

All Except Models 540000, 610000

Fig. 25 shows the blower housing removed and

areas to be cleaned (1) on the Vanguard engine.

2. Loosen control casing clamp screw (4).

3. Move control casing and wire (3) until choke is

completely closed (1).

4. Tighten casing clamp screw.

Combustion Chamber Deposits

Combustion chamber deposits should be removed

every 500 hours or whenever cylinder heads are

removed.

WARNING

AVOID EYE INJURY!

• Wear eye protection whenever using

compressed air to clean parts.

16

Fig. 25

Page 18

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Ì

Models 540000, 610000

1. Use a coin or screwdriver to twist the Easy Clean

Access panel fasteners (1), Fig. 26

COUNTERCLOCKWISE until a CLICK is heard

(approx. 3/4 turn).

2. Remove the panel (2).

Fig. 26

3. Blow compressed air from the PTO side to clean

the cooling fins (3), Fig. 27 around each cylinder

and to back flush the cooling system.

Fig. 28

Fig. 29

Fig. 27

4. Insert the access panel tab into the blower housing slot. Be certain the access panel is correctly

engaged to the blower housing. Push the panel

completely into the housing. Twist each fastener

CLOCKWISE until it “CLICKS”, approx. 3/4 turn.

CAUTION: DO NOT run the engine unless the

Easy Clean Access panel is correctly installed.

Crankcase Oil

Change Oil and Filter

Drain oil while the engine is still warm. See Fig. 28

for approximate drain plug locations on vertical

crankshaft engines; Fig. 29 for horizontal crankshaft

engines.

1. Remove oil drain plug (1). Drain oil into

approved container.

2. Remove dipstick.

3. Replace oil filter (2) every 100 hours. Before

installing new filter, lightly oil filter gasket with

new engine oil.

4. Screw filter on CLOCKWISE (arrow) by hand

until gasket contacts filter adapter. Hand tighten

an additional 1/2 - 3/4 turn.

5. Replace drain plug.

6. Refill crankcase slowly with new oil of proper

service classification and viscosity grade. Refill

to FULL mark on dipstick.

CAUTION: DO NOT OVERFILL THE ENGINE

WITH OIL!

17

Page 19

1

The crankcase capacity of Vanguard V-Twin

engines is approximately:

• All (except Model 540000) – 48 oz. (1.4

liters) with filter

• Models 540000, 610000 – 79 oz. (2.3

liters) with filter

• Models 540000, 610000 – 71 oz. (2.1

liters) without filter

NOTE: When checking oil level, screw the dipstick

all the way in for accurate readings.

7. Start engine. Run at IDLE for 30 seconds and

stop engine. Recheck oil level and add if

required. Restart engine and check for oil leaks.

Governor Adjustments

CAUTION

AVOID INJURY! Complete the

governor static adjustment BEFORE

starting or running engine.

CAUTION:

2. Use a screwdriver (2) to rotate governor shaft

COUNTERCLOCKWISE as far it will go. Torque

governor nut to 70 in. lbs. (8 Nm).

3. Install throttle and choke control cables and

check for proper operation.

Dynamic Governor Adjustment

NOTE: Carburetor mixture adjustments must be

• Tools Required, Fig. 31:

Tachometer #19200 (1) or #19389 (3)

Tang bender #19352 (2)

Do not bend governor link or distort

governor lever.

made before adjusting governed idle,

throttle restrictor and top no-load RPM.

• Incorrect adjustment could result in engine

overspeeding, causing engine damage,

property damage or personal injury.

Static Governor Adjustment

(Before Running Engine)

1. Loosen governor lever nut. Push on governor

lever (1) until throttle is wide open, Fig. 30.

Fig. 31

Manual Friction and Remote Speed Controls

Governor spring is installed in #1 hole (3) in governor

lever, Fig. 32.

Start and run engine for approximately 5 minutes to

allow engine to warm up.

1. Move control lever to SLOW position.

2. Use tool #19352 (1) to bend governed idle tang

(2) to obtain RPM shown:

Fig. 30

18

a. 1750 RPM – Governed Idle Spring #805453

(RED).

b. 1100 RPM – Governed Idle Spring #805454

(WHITE).

Page 20

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Fixed Speed Adjustable – Except Generators

Governor spring is installed in #1 hole in governor

lever (3), Fig. 35.

Start and run engine for approximately 5 minutes to

allow engine to warm up.

1. Turn fixed speed adjustable control nut counterclockwise until control swivel contacts slow

speed stop.

3. With equipment control lever in SLOW position

and engine running at governed idle RPM, use

Tang Bender #19352 (1), to bend throttle

restrictor tang (4) so that it just contacts

governor lever (5), Fig. 33.

Fig. 32

Fig. 33

4. Refer to Service Engine Sales Microfiche,

MS-6225 or the Service Engine Sales Manual,

MS-4052, for Top No-Load RPM by engine

Model and Type Number.

5. Move control throttle lever to FAST position and

check engine RPM.

6. Use Tool #19352 (1) to bend tang (6) UP (7) to

increase and DOWN (8) to decrease engine

speed, to obtain desired Top No-Load RPM,

Fig. 34.

NOTE: Air cleaner removed for clarity.

2. Use Tool #19352 (1) to bend governed idle tang

(2) to obtain RPM shown:

a. 1750 RPM – Governed Idle Spring #805453

(RED).

b. 1100 RPM – Governed Idle Spring #805454

(WHITE).

Fig. 35

3. Use Tool #19352 (1) to bend throttle restrictor

tang (4) so that it just contacts governor lever (5),

Fig. 36.

Fig. 34

Fig. 36

NOTE: Be sure the governor spring is installed in #1

hole in governor lever (9), Fig. 37.

4. Refer to Service Engine Sales Microfiche,

MS-6225 or the Service Engine Sales Manual,

MS-4052, for Top No-Load RPM by engine

Model and Type Number.

19

Page 21

1

5. Turn fixed speed adjustable control nut (6)

clockwise (8) to increase or counter-clockwise

(7) to decrease engine speed until desired Top

No-Load RPM is obtained, Fig. 37.

Fig. 37

Fixed Speed Adjustable – Generators

No governed idle spring is used with this system. No

throttle restrictor adjustment is necessary. The

primary governor spring (1) is installed in #2 hole on

governor lever (5). A secondary governor spring (3)

is installed with loop (4) over the governor lever tab

(4), and the rear loop facing (2) UP as shown in

Fig. 38.

Adjust Secondary Governor Spring

1. Disengage the adjustable fixed speed control

nut (Inset, Fig. 40).

2. Loosen and remove fixed speed adjustable

control nut, spring and retainer.

3. Rotate governor control swivel (1) counterclockwise to end of travel, Fig. 39.

4. Install Adjustment Gauge #19385 (3), with notch

over end of governor lever and flat end of tool

against governor control bracket as shown in

Fig. 39.

5. Hold gauge in position and bend tab (5) with Tang

Bender #19352 (4) so that all slack is removed

from secondary governor spring (2) between its

two anchor points, Fig. 39. DO NOT STRETCH

SPRING.

6. Remove adjustment gauge.

NOTE: Secondary governor spring must be

adjusted BEFORE the engine is started.

Perform adjustment in the sequence

shown.

Fig. 38

Fig. 39

Start engine. Run for approximately 5 minutes to

allow engine to warm up.

7. With engine running, pull control rod (7) out until

swivel is against stop. Hold in this position,

Fig. 40.

8. Use tang bender (4) to bend tang (6). Adjust to

Top No-Load RPM for the type of generator

listed in Table 1.

9. Re-install control nut, spring and retainer. Turn

nut clockwise until threads on control rod are

visible from end of nut, inset Fig. 40.

20

Page 22

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

TABLE NO. 1

Generator

Type

3600 RPM

60 Cycle

3000 RPM

50 Cycle

Top No-Load

RPM

4250 RPM 3750 RPM

3600 RPM 3150 RPM

Regulated

No-Load RPM

Fig. 40

10. Engage fixed speed adjustable control nut (8)

and adjust to Regulated No-Load RPM for the

type of generator listed in Table 1, Fig. 41.

a. Turn nut CLOCKWISE (10) to increase

speed.

b. Turn nut COUNTERCLOCKWISE (9) to

decrease speed.

NOTE: Final adjustment should be made with

generator loaded to rated capacity or to

manufacturer’s specifications.

Adjust Secondary Governor Spring

1. Move equipment control to SLOW position.

2. Install Adjustment Gauge #19385 (4), with notch

over end of governor lever and flat end of tool

against governor control bracket as shown in

Fig. 42.

3. Hold gauge in position and bend tab (2) with Tang

Bender #19532 (1), so that all slack is removed

from secondary governor spring (5) between its

two anchor points, Fig. 42. DO NOT STRETCH

SPRING.

4. Remove adjustment gauge.

Fig. 41

Remote Speed Control Engines Equipped With

Secondary Governor Spring

Some Vanguard OHV V-Twin engines with remote

speed control are equipped with a secondary governor spring (5). The primary governor spring is

installed in #1 hole (3) on governor lever, Fig. 42.

NOTE: The secondary governor spring must be

adjusted BEFORE the engine is started.

Perform the adjustment in the sequence

shown.

Start engine. Run for approximately 5 minutes to

allow engine to warm up.

5. Move control lever to SLOW position.

6. Use tang bender (1) to bend governed idle tang

(6) to obtain RPM shown, Fig. 43:

a. 1750 RPM – Governed Idle Spring #805453

(RED).

b. 1100 RPM – Governed Idle Spring #805454

(WHITE).

NOTE: Engine Model 303447 Type 0411-01 – Set

governed idle to 1350 RPM 50 RPM.

Fig. 42

21

Page 23

1

7. With equipment control lever in SLOW position

and engine running at governed idle RPM, use

Tang Bender #19352 (1), and bend throttle

restrictor tang (7) so that tang just contacts

governor lever (8), Fig. 44.

Fig. 43

Fig. 45

Oil Cooler

Some engines are equipped with an oil cooler,

Fig. 46. The oil cooler is mounted on the blower

housing. Filtered oil is routed through the oil cooler

through two oil lines from a special oil filter adapter.

Forced air from the flywheel fan flows through the oil

cooler fins dissipating heat from the engine oil.

The oil cooler fins should be cleaned every 100

hours, checked periodically for debris, and cleaned

with compressed air or a soft bristle brush.

Fig. 44

8. Refer to Service Engine Sales Microfiche,

MS-6225 or the Service Engine Sales Manual,

MS-4052, for Top No-Load RPM by engine

Model and Type Number.

9. Move control throttle lever to FAST position and

check engine RPM.

10. Bend tang (8) with Tool #19352 (1) to obtain desired top no-load RPM, Fig. 45.

NOTE: Engine Model 303447 Type 0411-01 – Set

Top No-Load Speed to 2900 RPM 50

RPM.

22

Fig. 46

Spark Plugs

Replace spark plugs every 100 hours of operation or

every season, whichever occurs first. Replace spark

plugs if electrodes are burned away, or if the

porcelain is cracked.

NOTE: Do not blast-clean spark plugs. Spark plugs

should be cleaned by scraping or hand wire

brushing and washing in a commercial

solvent.

Use a wire gauge (1) to set spark plug gap, Fig. 47.

Torque spark plugs to 180 in. lbs. (20 Nm).

Page 24

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Fig. 47

All Except Models 540000, 610000

Resistor spark plugs recommended by Briggs &

Stratton:

• B&S #491055 (Champion RC12YC) or

• B&S #496018 (Champion RC14YC)

Gap to 0.030” (0.76 mm).

FAST

SLOW

Fig. 48

Valve Clearance Adjustment

1. Set No. 1 cylinder at 1/4” (6 mm) past TDC,

compression stroke.

Models 540000, 610000

Resistor spark plug recommended by Briggs &

Stratton:

• B&S #692051

Gap to 0.020” (0.51 mm).

Speed Control Wire Adjustment

NOTE: Manual friction and remote control

adjustment procedure is identical.

1. Loosen control casing clamp screw (1) at

governor control bracket, Fig. 48.

2. Move speed control lever to FAST position (in-

set, Fig. 48).

3. Move control casing and wire until governor

control swivel is at end of travel.

2. Use a feeler gauge (1) to measure the valve

clearance. Valve clearance should be 0.005”

(0.13 mm) for the intake and exhaust valve.

NOTE: Measure valve clearance with the engine

COLD.

3. If the valve clearance requires adjustment,

loosen the lock nut (2) with a wrench (4). Use a

hex wrench (5) to turn the adjusting screw (3) to

adjust the valves, Fig. 49.

4. With the valve clearance correctly adjusted,

hold the adjusting screw. Torque the lock nut to

70 in. lbs. (8 Nm).

5. Repeat for No. 2 cylinder.

4. Tighten casing clamp screw.

Fig. 49

23

Page 25

1

TUNE-UP PROCEDURE

A “Tune-Up,” see the steps listed below, would normally be performed on relatively new engines brought in for

minor difficulties. By performing these steps you will either be sure that the engine is functioning properly or will

know what major repairs should be made. The steps are also covered in the Overhaul Procedure and will normally

be performed as a part of the complete overhaul.

1. Disconnect and ground spark plug wires.

2. Remove air cleaner cartridge, check for proper

servicing. Check gaskets, pre-cleaner and

cartridge for damage.

3. Check oil level. Drain oil. Remove oil filter.

4. Remove blower housing, inspect rewind

assembly when equipped.

touch flywheel. Check ground wire and stop

switch connections.

10. Remove cylinder heads. Remove carbon.

Check head gaskets. Inspect valves for seating.

11. Install cylinder heads and new gaskets. Tighten

to specified torque. Adjust valve clearance. Set

spark plug gaps.

5. Clean cooling fins and entire engine.

6. Check governor, linkage and springs for

damage and wear. Check governor adjustment.

7. Remove intake manifold and carburetor.

Disassemble carburetor. Wash in solvent and

inspect for wear or damage. Replace gaskets

and parts as necessary. Reinstall carburetor on

manifold. Set initial adjustment.

8. Replace spark plugs. Remove flywheel. Check

flywheel key. Check for oil seal leakage on both

flywheel and PTO sides.

9. Check coils. Inspect all wires for breaks and/or

damaged insulation. Be sure ground wires do not

12. Reinstall intake manifold using new gaskets.

13. Reinstall blower housing.

14. Install new oil filter. Replace oil and fuel.

15. Adjust equipment control and cables, if used, for

correct operation.

16. Service air cleaner pre-cleaner and cartridge, or

replace.

17. Check muffler for restrictions or damage.

18. Start engine and bring up to operating

temperature. Then, adjust carburetor mixture

and engine top speed.

OVERHAUL PROCEDURE

The following Overhaul Procedure is intended to help you to establish a systematic method of repairing Briggs

& Stratton OHV engines. These steps may be performed in a different order but best efficiency is obtained when

the repairs are performed in the same sequence every time. The exact procedure will vary according to the engine

model being repaired. Be careful to locate the instructions covering the specific model being repaired.

Disassemble

1. Drain oil. Remove oil filter.

2. Remove spark plugs.

3. Air cleaner assembly (if equipped).

Fuel tank and bracket assembly (if equipped).

Fuel pump and bracket (if equipped).

4. Rotating screen (if equipped). Blower housing.

5. Rewind starter (if equipped).

6. Exhaust manifold, muffler(s).

7. Intake manifold and carburetor.

8. Check throttle shaft and bushings for wear.

9. Disassemble carburetor.

10. Check armature air gap. Remove armatures.

11. Flywheel.

12. Electric starter.

13. Breather. Valve covers and valley cover.

14. Governor control bracket.

15. Check valve clearances.

16. Cylinder shields, rocker arms, push rods,

cylinder heads.

17. Valves, springs and seals. Inspect valve guides

and seats.

18. Check crankshaft end play. Remove burrs from

crankshaft extension.

19. Crankcase cover. Inspect bearings. Remove oil

seal.

20. Cam gear and tappets. Inspect governor.

21. Connecting rods and pistons.

22. Inspect crankshaft.

24

Page 26

1LOCKED FOR PRINTING – SELECT SECT. NEEDED >

23. Cylinder – check cylinder bores and bearings.

Remove oil seal.

24. Disassemble and check connecting rods,

pistons, piston pins and rings.

25. Disassemble and inspect oil pump.

Inspection and Repairs

1. Clean parts.

2. Resize cylinder bore as required.

3. Replace main bearing.

4. Replace all oil seals.

5. Replace valve guides.

6. Reface and lap valves and seats.

7. Replace armatures.

8. Repair carburetor.

9. Replace rewind starter spring and rope (if

equipped)

Reassemble

1. Crankshaft.

2. Pistons, piston pins, rings and connecting rods.

3. Tappets, cam gear.

4. Mechanical governor.

5. Oil pump.

6. Crankcase cover – check end play. Replace oil

seal.

7. Electric starter.

8. Flywheel and starter pulley (if equipped).

9. Armatures – adjust air gap.

10. Check spark.

11. Valves, seals, springs and retainers.

12. Cylinder heads, push rods, rocker arms and

cylinder shields.

13. Adjust valve clearance.

14. Valve covers, breather and valley cover.

15. Linkage and governor controls.

16. Carburetor and intake manifold.

17. Check and adjust mechanical governor.

18. Blower housing.

19. Fuel pump and bracket (if equipped).

Fuel tank and bracket (if equipped).

20. Clean and assemble air cleaner.

21. Exhaust manifold, mufflers.

22. Install new spark plugs.

23. Replace oil filter. Fill crankcase with oil. Fill with

gas. Start engine.

24. Adjust carburetor.

25. Adjust governor controls to obtain correct

engine speed (remote controls).

26. Re-torque cylinder head screws.

27. Spray paint engine and apply decals.

25

Page 27

1

26

Page 28

2LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Section 2

Troubleshooting

Page

ELECTRICAL SYSTEMS 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternators 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternator System Diagnosis 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging System Identification 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel Magnet Identification 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Used to Test Alternators 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Alternator Output 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Alternator 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Alternator 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dual Circuit Alternator 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tri-Circuit Alternator 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 & 9 Amp Regulated Alternator 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 & 16 Amp Alternator 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 Amp Regulated Alternator 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powerlink System 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anti-Afterfire Solenoid 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Battery 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Engine Wiring Harness 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel Kit with Key Switch and Solenoid 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Motor 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditions Affecting Starter Motor Performance 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid Test 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance ControlE Electronic Governor 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor Test 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Actuator 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EQUIPMENT PROBLEMS AFFECTING ENGINE OPERATION 64. . . . . . . . . . . . . . . . . . . . . . . . . . .

GASEOUS-FUELED ENGINES 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Guide 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carburetor Adjustment 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPG-Only Operation 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEMATIC CHECK 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carburetion 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Page 29

2

Most complaints concerning engine operation can be

classified as one or more of the following:

1. Will not start

2. Hard starting

3. Lack of power

4. Runs rough

5. Vibration

6. Overheating

7. High oil consumption

NOTE: What appears to be an engine problem may

actually be the fault of the powered

equipment. If equipment is suspect, see

Equipment Affecting Engine Operation.

SYSTEMATIC CHECK

A systematic check of the engine can be performed

in minutes, and is an accurate method of

determining the source of the problem. The basic

procedure is the same for all engine models.

Variations, by model, will be shown under the subject

heading. If the engine will not start and the cause is

not apparent, perform a systematic check in the

following order:

1. Ignition

2. Carburetion

Fig. 1

If there is NO SPARK look for –

1. Improperly operating equipment interlock

system

2. Shorted equipment stop switch wire

3. Two closed diodes in ground wire harness

(current style) or ground terminal (early style)

4. Incorrect armature air gap

5. Armature failure

3. Compression

Ignition

Test Using Electric Starter

NOTE: MagnetronR ignition systems require a

minimum of 350 RPM to produce spark.

WARNING

AVOID ELECTRICAL SHOCK!

• A partially sheared flywheel key will affect

ignition timing and engine performance.

• Spark can still occur with a sheared flywheel

key. A severe shock or kickback hazard may

exist.

With spark plugs installed, attach Ignition Tester

#19368 (1) to each spark plug lead (2). Ground the

other end of the tester as shown, Fig. 1. Spin the flywheel rapidly with engine starter. If spark jumps the

tester gap the ignition system is working correctly.

Test With Engine Running

If the engine runs, but misses under load, test the

ignition by installing an Ignition Tester #19368 (2)

between the spark plug lead (1) and each spark plug

(3), Fig. 2. A spark miss will be readily apparent

when the engine is running. If the spark appears

good in the tester but the engine misses, check for

a fouled spark plug.

Fig. 2

28

Page 30

2LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Fouled Plug or Dead Cylinder

To test for a fouled spark plug or a non-functioning

cylinder, attach Ignition Tester #19368 (2) between

the spark plug lead (1) and each spark plug (4). With

engine running at top no-load speed, use a

screwdriver (3) with an insulated handle to ground

one spark plug by contacting the alligator clip on the

ignition tester to a good ground on the engine, Fig.

3. The engine should continue to run on the other

cylinder. Repeat this test with the other cylinder. If

the engine dies when performing this test, the

cylinder that is NOT grounded is not functioning

and/or the spark plug is fouled. Install a new spark

plug and re-check. If miss continues see the

following procedures.

If plugs are dry, look for –

1. Leaking carburetor mounting gaskets

2. Gummy or dirty carburetor, fuel line or tank

3. Float needle valve stuck shut

4. Inoperative fuel pump

5. Inoperative anti-afterfire solenoid

To determine if fuel is getting to the combustion

chamber through the carburetor, remove either

spark plug and pour a small quantity of gasoline

through the spark plug hole. Replace the spark plug.

If the engine fires a few times and then stops, look for

the same conditions as for a dry plug.

Compression

Compression Test

Briggs & Stratton does not publish compression

pressures, as it is difficult to obtain an accurate

reading without special equipment. An assessment

of the engine’s compression can be made as follows:

Fig. 3

Carburetion

NOTE: Gaseous fuel engines use carburetors that

must be serviced by a certified gaseous fuel

installer or by a certified dealer for the equipment powered.

Before performing a carburetion check, be sure the

fuel tank has an ample supply of fresh, clean gasoline. Be sure that the shutoff valve, if equipped, is

open and fuel flows freely through the fuel line before starting engine. Inspect and adjust the idle

needle valve. Make sure the choke closes completely. If engine will not start, remove and inspect

the spark plugs.

If plugs are wet, look for –

1. Overchoking

Remove both spark plugs and insert a compression

gauge into either cylinder (one cylinder at a time).

Turn engine over with engine starter until there is no

further increase in gauge pressure reading. Record

this reading. Repeat procedure on other cylinder and

record that reading. Divide the difference between the

cylinders by the compression pressure of the higher

of the two cylinders. A difference over 25% between

the cylinders indicates a loss of compression in the

cylinder with lower pressure. See example below.

Engine #1 Engine #2

Cylinder #1 65 PSI 75 PSI

Cylinder #2 60 PSI 55 PSI

Difference 5 PSI 20 PSI

% Difference 7.7% 26.7%

If compression is poor, look for –

1. Loose cylinder head bolts

2. Blown head gasket

3. Burned valves, burned and/or loose valve seats

4. Insufficient valve clearance

2. Excessively rich fuel mixture

3. Water in fuel

4. Float needle valve stuck open

5. Plugged air cleaner

5. Warped cylinder head

6. Warped valve stems

7. Worn bore and/or rings

8. Broken connecting rods

29

Page 31

2

Cylinder Leakdown Test

Use a leakdown tester to test the sealing capability

of each cylinder. Follow the instructions for the leakdown tester you are using to determine the likely

problem area(s).

1. Run engine for 5 minutes allowing engine to

reach operating temperature.

NOTE: If the engine is cold or cannot be started, air

flow may be higher (gauge readings lower)

because compression components are not

at normal operating temperatures.

2. Remove spark plug from engine. Disconnect

crankcase breather tube.

3. Rotate crankshaft in direction of operation until

piston is at Top Dead Center (TDC) of the compression stroke.

4. Hold flywheel nut with socket and breaker bar.

NOTE: Hold the crankshaft with the piston at TDC

to minimize the chance of rotation.

CAUTION

AVOID INJURY!

• Injury could occur if the crankshaft is

allowed to rotate or if the engine is not

securely fastened to a stand or to the

application.

Fig. 4

Cylinder Balance Test

If the engine starts hard, runs rough, misses or lacks

power, perform a cylinder balance test to determine

whether both cylinders are operating correctly.

A cylinder balance test will also detect a cylinder that

is not functioning. When grounding one cylinder

there will be no RPM loss. When the other cylinder

is grounded the engine will stop.

• Tools Required:

Tachometer #19200

Two @ Ignition Tester #19368

Screwdriver with insulated handle.

1. Attach Ignition Tester #19368 (2) between each

spark plug lead (1) and spark plug (3), Fig. 5.

5. Connect tester to a shop air source with

minimum air pressure of 70 psi (480 kPa).

6. Install outlet hose into spark plug hole of cylinder

being tested. Insure O-ring is seated to prevent

air leak at spark plug hole. Connect other end to

tester.

7. While securely holding the flywheel nut with the

breaker bar and socket, pull the adjustment

knob OUT (arrow), Fig. 4. Slowly turn the regulator adjustment knob (1) CLOCKWISE until tester

needle (2) is on the set point. Push in regulator

adjustment knob.

NOTE: Any air leaks at connections or fittings of

tester will affect the accuracy of test.

8. Slowly open the valve and note the reading on

the gauge.

30

Fig. 5

2. Start engine. Run at top no-load speed and note

spark at ignition testers. If the spark is equal at

both ignition testers, the problem is not ignition

related. A spark miss should be readily

apparent.

3. Note RPM of engine. Ground one cylinder with

screwdriver (4) by contacting alligator clip on

ignition tester to a good ground on engine,

Fig. 6. Note RPM loss.

Page 32

2LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Conclusion: Cylinder #1 is weaker cylinder.

NOTE: A partially sheared flywheel key will affect

ignition timing and engine performance.

Fig. 6

4. Ground the other spark plug and again note the

RPM loss.

If the difference between the two cylinders does not

exceed 75 RPM, the amount of work the two

cylinders are doing is considered equal.

An RPM loss greater than 75 RPM indicates that the

cylinder with the lower RPM loss is the weaker of the

two cylinders. Look to that cylinder for a problem.

See example below.

Engine RPM – Both Cylinders = 3400 RPM

Engine RPM – Cylinder #1 Grounded = 3300 RPM

Problems Affecting One Cylinder

NOTE: A two cylinder engine will run on one

cylinder as long as the power required for

the application does not exceed the power

produced by one cylinder.

1. Spark plug – A fouled spark plug may also

indicate that carburetor is out of adjustment.

2. Spark plug wire

3. Head gasket

4. Intake manifold – A leak at either end of the

intake manifold will affect only one cylinder.

5. Valves

6. Rings

7. Piston

8. Cylinder

Problems Affecting Two Cylinders

1. Carburetion

2. Crankcase vacuum

Engine RPM – Cylinder #2 Grounded = 3100 RPM

3. Ignition timing

31

Page 33

2

ELECTRICAL SYSTEMS

Alternators

Alternator System Diagnosis

The following list is provided to help diagnose alternator system problems.

COMPLAINT POSSIBLE CAUSES

• Engine RPM too low.

• Inline fuse “blown” (if equipped).

• Defective battery.

• Loose, pinched, or corroded battery ground leads.

• Loose, pinched, or corroded battery charge leads.

Battery not charging

Battery overcharged

Headlamps not working

Electric clutch not working

(Tri-Circuit Alternator)

• Open, shorted, or grounded wires between output connector and battery.

• Defective diode (open or shorted).

• Defective or improperly grounded regulator-rectifier.

• Diode installed incorrectly (reversed).

• Damaged battery (shorted battery cells).

• Excessive current draw from accessories.

• Low magnetic flux or damaged alternator magnets.

• Severe battery vibration (missing or broken tie-down straps).

• Battery rate of charge not matched to alternator output.

• Damaged battery (shorted battery cells).

• Defective regulator.

• One OHM resistor shorted or grounded (Tri-Circuit system only).

• Inline fuse “blown” (if equipped).

• Defective headlamps.

• Loose or corroded wires.

• Open, shorted or grounded wires between output connector and headlamps.

• Light switch defective.

• Defective diode Tri-Circuit system (open or shorted – white output lead side).

• Low magnetic flux or damaged alternator magnets.

• Inline fuse “blown” (if equipped).

• Loose or corroded wires.

• Open, shorted or grounded wires between output connector and electric clutch.

• Defective diode (open or shorted - red output lead side).

NOTE: Battery will also not charge.

• Defective electric clutch switch.

• Open, shorted or grounded clutch circuit.

• Low magnetic flux or damaged alternator magnets.

32

Page 34

2LOCKED FOR PRINTING – SELECT SECT. NEEDED >

Charging System Identification

Table No. 1 provides a means of identifying the various alternator systems.

The alternator systems installed on Briggs & Stratton OHV V-Twin Cylinder Engines can be identified by the color

of the stator output wires and the connector.

TABLE 1

Alternator

Type

AC Only Black White

DC Only Red Red

Dual

Circuit

Tri-Circuit Black Green

Regulated

5 Amp

Regulated

9 Amp

Regulated

10 Amp

Stator Output

Wire(s) Color

Red

Black