Vanderbilt SPC6, SPC5, SPC6350.320, SPC4000, SPC6330.320 Installation & Configuration Manual

...Page 1

SPC4xxx/5xxx/6xxx

Installation & Configuration Manual

Document ID: A6V10276959-d

Edition date: 12.09.2018

Page 2

Data and design subject to change without notice. /Supply subject to availability.

© 2018 Copyright by Vanderbilt InternationalLtd.

We r eserve allrights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights and

undertakes not to publish the document nor the subject ther eof in full or in part, nor to make them available to any third party without our pr ior

express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Page 3

Table of Contents

Table of Contents 3

1 Meaning of symbols 10

2 Security 11

2.1 Target group 11

2.2 General safety instructions 11

2.2.1 General information 11

2.2.2 Transport 11

2.2.3 Setup 12

2.2.4 Operation 12

2.2.5 Service and maintenance 12

2.3 Meaning of written warning notices and hazard symbols 12

2.3.1 Warning notices 12

2.3.2 Hazard symbols 13

3 Directives and standards 14

3.1 EU directives 14

3.2 Overview of Conformity to EN50131 Standard 14

3.2.1 Compliance with EN50131 Approvals 20

3.3 Compliance with EN 50136-1:2012 and EN 50136-2:2014 22

3.4 Compliance with INCERT Approvals 22

3.5 PD 6662:2010 Conformance Guidelines 23

3.5.1 Product scope 23

3.5.2 Standards overview 24

3.5.3 Methods for the completion of setting and unsetting 24

3.5.4 Configuration requirements for PD 6662:2010 conformance 26

3.5.5 Additional commissioning requirements for PD 6662:2010 conformance 27

3.5.6 Additional information 27

3.6 Compliance with VdS approvals 28

3.7 Compliance with NF and A2P approvals 29

4 Technical Data 31

4.1 SPC4000 31

4.2 SPC5000 33

4.3 SPC6000 37

4.4 SPCP355.300 40

5 Introduction 42

6 Mounting system equipment 43

6.1 Mounting a G2 housing 43

6.2 Mounting a G3 housing 44

© Vanderbilt 2018 3 A6V10276959-d

12.09.2018

Page 4

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Table of Contents

6.2.1 Mounting a Back Tamper Kit 46

6.2.2 Battery installation for EN50131 compliance 50

6.3 Mounting a G5 housing 51

6.3.1 Tamper protection 52

6.3.2 Mounting the housing with tamper protection 53

6.3.3 Installing the batteries 55

6.4 Mounting a keypad 56

6.5 Mounting an expander 56

7 Smart PSU 57

7.1 SPCP355.300 Smart PSU 57

7.1.1 Supervised Outputs 59

7.1.2 Batteries 60

7.1.3 Wiring the X-BUS Interface 62

7.1.4 Compliance with NF and A2P approvals 65

7.1.5 PSU LED Status 66

7.1.6 System Recovery 67

8 Controller hardware 68

8.1 Controller Hardware 42xx/43xx/53xx/63xx 68

8.2 Controller Hardware SPC5350 and 6350 70

9 Door Expander 74

10 Wiring the system 75

10.1 Wiring the X-BUS interface 75

10.1.1 Loop configuration 76

10.1.2 Spur configuration 77

10.1.3 Star and multi-drop configuration 78

10.1.4 Shielding 83

10.1.5 Cable Map 83

10.2 Wiring of branch expander 83

10.3 Wiring the system ground 84

10.4 Wiring the relay output 84

10.5 Wiring the zone inputs 85

10.6 Wiring an external SAB bell 88

10.7 Wiring an internal sounder 89

10.8 Wiring Glassbreak 89

10.9 Installing plug-in modules 90

11 Powering up the SPC controller 92

11.1 Powering from battery only 92

12 Keypad user interface 93

12.1 SPCK420/421 93

© Vanderbilt 2018 4 A6V10276959-d

12.09.2018

Page 5

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Table of Contents

12.1.1 About the LCDkeypad 93

12.1.2 Using the LCD keypad interface 95

12.1.3 Data entry on the LCD keypad 98

12.2 SPCK620/623 99

12.2.1 About the Comfort keypad 99

12.2.2 LED description 103

12.2.3 Viewing mode description 103

12.2.4 Function keys in idle state 104

13 Software support tools 105

14 Starting the system 106

14.1 Engineer modes 106

14.1.1 Engineer PINs 106

14.2 Programming with the keypad 106

14.3 Configuring start-up settings 107

14.4 Creating system users 108

14.5 Programming the portable ACE 109

14.6 Configuring wireless fob devices 110

14.6.1 Clearing alerts using the fob 110

15 Soft Engineer programming via the keypad 111

16 Engineer programming via the keypad 112

16.1 System Status 112

16.2 Options 113

16.3 Timers 117

16.4 Areas 121

16.5 Area Groups 123

16.6 X-BUS 123

16.6.1 X-BUS Addressing 123

16.6.2 XBUS Refresh 124

16.6.3 Reconfigure 124

16.6.4 Keypads/Expanders/Door Controllers 125

16.6.5 Addressing Mode 133

16.6.6 XBUS Type 134

16.6.7 Bus Retries 134

16.6.8 Comms Timer 135

16.7 Users 135

16.7.1 Add 135

16.7.2 Edit 135

16.7.3 Delete 138

16.8 User Profiles 138

© Vanderbilt 2018 5 A6V10276959-d

12.09.2018

Page 6

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Table of Contents

16.8.1 Add 138

16.8.2 Edit 138

16.8.3 Delete 139

16.9 Wireless 140

16.9.1 Select a wireless programming option 141

16.9.2 One-way wireless 142

16.9.3 Two-way wireless 146

16.10 Zones 149

16.11 Doors 149

16.12 Outputs 153

16.12.1 Outputs types and output ports 154

16.13 Communication 158

16.13.1 Serial Ports 158

16.13.2 Ethernet Ports 158

16.13.3 Modems 159

16.13.4 Central Station 161

16.13.5 SPCConnect PRO 163

16.14 Test 163

16.14.1 Bell Test 163

16.14.2 Walk Test 163

16.14.3 Zone Monitor 164

16.14.4 Output Test 165

16.14.5 Soak Test 165

16.14.6 Audible Options 165

16.14.7 Visual Indicators 166

16.14.8 Seismic Test 166

16.15 Utilities 166

16.16 Isolate 167

16.17 Event Log 167

16.18 Access Log 167

16.19 Alarm Log 167

16.20 Change Engineer Pin 168

16.21 SMS 168

16.21.1 Add 169

16.21.2 Edit 169

16.21.3 Delete 170

16.22 X-10 170

16.23 Set Date/Time 170

16.24 Installer Text 171

© Vanderbilt 2018 6 A6V10276959-d

12.09.2018

Page 7

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Table of Contents

16.25 Door Control 171

16.26 SPC Connect 171

17 Engineer programming via the browser 173

17.1 System Information 173

17.2 Ethernet interface 173

17.3 Connecting to the panel via USB 175

17.4 Logging into the browser 177

17.5 SPC Home 178

17.5.1 System Summary 178

17.5.2 Alarms Overview 179

17.5.3 Viewing Video 179

17.6 Panel status 180

17.6.1 Status 180

17.6.2 X-Bus Status 181

17.6.3 Wireless 188

17.6.4 Zones 191

17.6.5 Doors 192

17.6.6 FlexC Status 193

17.6.7 System alerts 195

17.7 Logs 195

17.7.1 System Log 195

17.7.2 Access Log 196

17.7.3 ALARM LOG 196

17.8 Users 197

17.8.1 Adding/Editing a User 197

17.8.2 Adding/Editing User Profiles 200

17.8.3 Configuring SMS 204

17.8.4 SMS Commands 205

17.8.5 Deleting Web Passwords 208

17.8.6 Configuring Engineer Settings 208

17.9 Wireless 211

17.9.1 One-way wireless 212

17.9.2 Two-way wireless 222

17.10 Configuration 231

17.10.1 Configuring controller inputs and outputs 231

17.10.2 X-BUS 241

17.10.3 Changing system settings 255

17.10.4 Configuring zones, doors and areas 272

17.10.5 Calendars 287

© Vanderbilt 2018 7 A6V10276959-d

12.09.2018

Page 8

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Table of Contents

17.10.6 Change own PIN 290

17.10.7 Configuring advanced settings 290

17.11 Configuring Communications 298

17.11.1 Communications Settings 298

17.11.2 FlexC® 308

17.11.3 Reporting 328

17.11.4 PC Tools 341

17.12 File Operations 343

17.12.1 File Upgrade Operations 343

17.12.2 File Manager Operations 347

18 Accessing web server remotely 349

18.1 PSTN connection 349

18.2 GSM connection 351

19 Intruder alarm functionality 354

19.1 Financial mode operation 354

19.2 Commercial mode operation 354

19.3 Domestic mode operation 355

19.4 Full and local alarms 355

20 System examples and scenarios 357

20.1 When to use a common area 357

21 Seismic Sensors 359

21.1 Seismic Sensor Testing 360

21.1.1 Manual and Automatic Test Process 360

21.1.2 Automatically Testing Sensors 360

21.1.3 Manually Testing Sensors 361

22 Blocking Lock Operation 363

22.1 Blocking Lock 363

22.2 Authorized Setting of the Blocking Lock 364

22.3 Locking Element 365

23 Appendix 367

23.1 Network cable connections 367

23.2 Controller status LEDs 368

23.3 Powering expanders from the auxiliary power terminals 369

23.4 Calculating the battery power requirements 370

23.5 Domestic, Commercial and Financial mode default settings 372

23.6 Wiring of the X10 interface 373

23.7 SIA Codes 374

23.8 CID Codes 379

23.9 Overview of keypad types 381

© Vanderbilt 2018 8 A6V10276959-d

12.09.2018

Page 9

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Table of Contents

23.10 User PIN combinations 382

23.11 Duress PINs 382

23.12 Automatic inhibits 382

23.12.1 Zones 382

23.12.2 Access PINs 383

23.12.3 Engineer Access 383

23.12.4 Keypad User Logoff 383

23.13 Wiring of mains cable to the controller 383

23.14 Maintenance controller 383

23.15 Maintenance Smart PSU 384

23.16 Zone types 385

23.17 Zone attributes 390

23.18 Applicable attributes to zone types 393

23.19 ATS levels and attenuation specifications 394

23.20 Supported card readers and card formats 394

23.21 SPC Support for E-Bus Devices 396

23.21.1 Configuring and Addressing E-Bus Devices 397

23.22 FlexC Glossary 399

23.23 FlexC Commands 400

23.24 ATS Category Timings 403

23.25 ATP Category Timings 404

24 Notes 406

© Vanderbilt 2018 9 A6V10276959-d

12.09.2018

Page 10

1 Meaning of symbols

There are several symbols in the document:

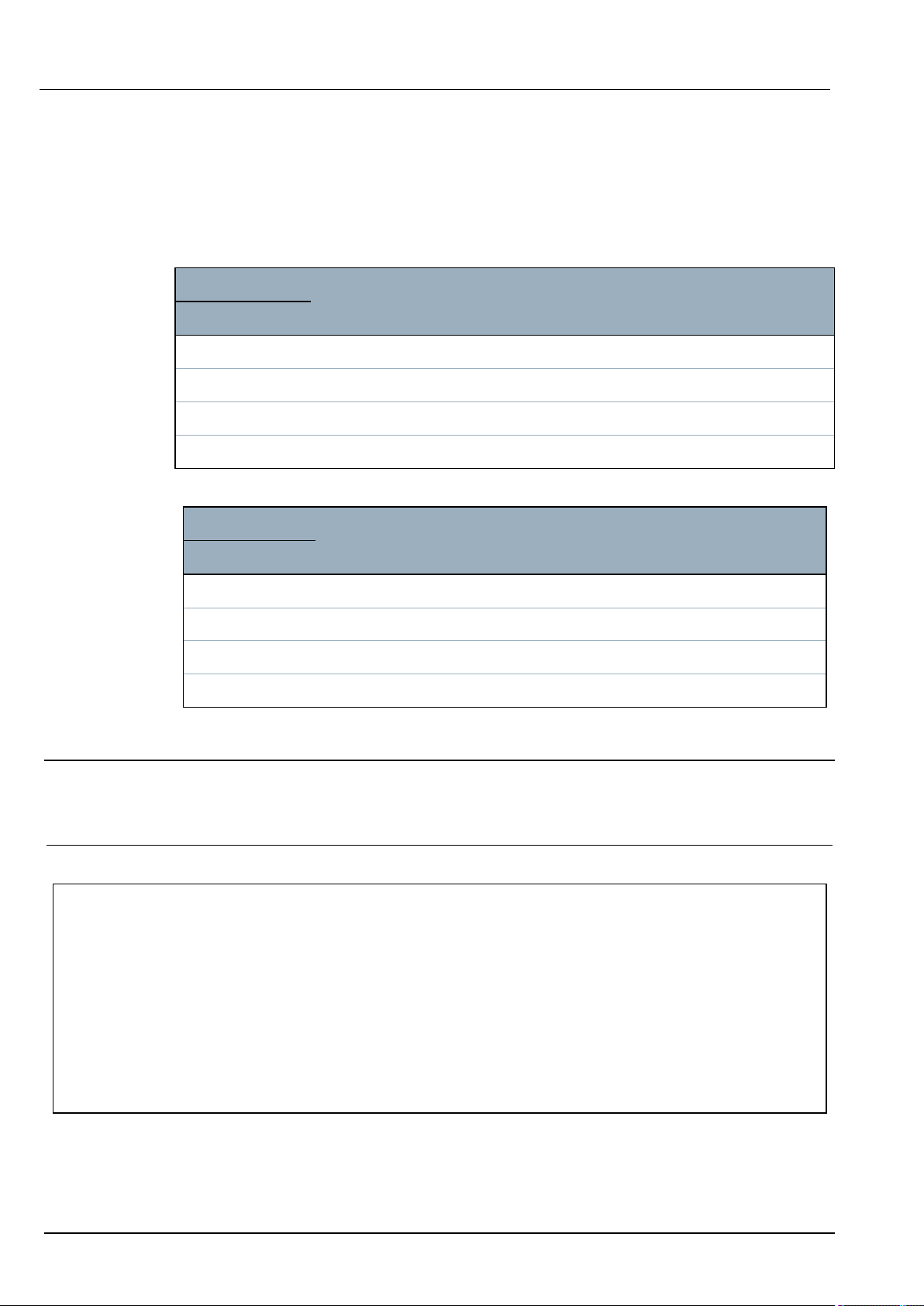

Symbol Description

Not available for SPC42xx, SPC43xx.

Only available for SPC controller with IP interface

(SPC43xx/SPC53xx/SPC63xx).

Not available for installation type Domestic.

Only available in unrestricted mode.

Find further information about Security Grade, Region or Mode in text.

See Appendix for further information.

© Vanderbilt 2018 10 A6V10276959-d

12.09.2018

Page 11

2 Security

This chapter covers:

2.1 Target group 11

2.2 General safety instructions 11

2.3 Meaning of written warning notices and hazard symbols 12

2.1 Target group

The instructions in this documentation are directed at the following target group:

Target

readers

Installation

personnel

Operational

startup

personnel

Qualification Activity

Technical training for building or electrical

installations.

Has appropriate technical training with

regard to the tasks and the products,

devices or systems to be put in service.

2.2 General safety instructions

WARNING: Before starting to install and work with this device, read the Safety Instructions. This

device shall only be connected to power supplies compliant to EN60950-1, chapter 2.5 ("limited power

source").

2.2.1 General information

l Keep this document for later reference.

Assembles and installs the

hardware components on site.

Puts the device or system

which is readily assembled and

installed on site into service.

Condition of the

equipment

Individual components

that need to be

assembled and

installed.

New, readily

assembled and

installed device or

modified device.

l Always pass this document on together with the product.

l Also take into account any additional country-specific, local safety standards or regulations

concerning project planning, operation and disposal of the product.

Liability claim

l Do not connect the device to the 230V supply network if it is damaged or any parts are missing.

l Do not make any changes or modifications to the device unless they are expressly mentioned in this

manual and have been approved by the manufacturer.

l Use only spare parts and accessories that have been approved by the manufacturer.

2.2.2 Transport

Unit damage during transport

l Keep the packaging material for future transportation.

l Do not expose the device to mechanical vibrations or shocks.

© Vanderbilt 2018 11 A6V10276959-d

12.09.2018

Page 12

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Security

2.2.3 Setup

Radio interference with other devices in the environment/EMS

l When handling modules that are susceptible to electrostatic discharge, observe the ESD

guidelines.

Damage due to unsuitable mounting location

l The environmental conditions recommended by the manufacturer must be observed.

See Technical Data on page31.

l Do not operate the device close to sources of powerful electromagnetic radiation.

Danger of electrical shock due to incorrect connection

l Connect the device only to power sources with the specified voltage. Voltage supply requirements

can be found on the rating label of the device.

l Ensure that the device is permanently connected to the electricity supply; a readily accessible

disconnect device must be provided.

l Ensure that the circuit that the device is connected to is protected with a 16A (max.) fuse. Do not

connect any devices from other systems to this fuse.

l This device is designed to work with TN power systems. Do not connect the device to any other

power systems.

l Electrical grounding must meet the customary local safety standards and regulations.

l Primary supply cables and secondary cables should be routed such that they do not run in parallel or

cross over or touch one anther inside the housing.

l Telephone cables should be fed into the unit separately from other cables.

Risk of cable damage due to stress

l Ensure that all outgoing cables and wires are sufficiently strain-relieved.

2.2.4 Operation

Dangerous situation due to false alarm

l Make sure to notify all relevant parties and authorities providing assistance before testing the

system.

l To avoid panic, always inform all those present before testing any alarm devices.

2.2.5 Service and maintenance

Danger of electrical shock during maintenance

l Maintenance work must only be carried out by trained specialists.

l Always disconnect the power cable and other cables from the main power supply before performing

maintenance.

Danger of electrical shock while cleaning the device

l Do not use liquid cleaners or sprays that contain alcohol, spirit or ammonia.

2.3 Meaning of written warning notices and hazard symbols

2.3.1 Warning notices

Signal Word Type of Risk

DANGER Danger of death or severe bodily harm.

© Vanderbilt 2018 12 A6V10276959-d

12.09.2018

Page 13

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Security

Signal Word Type of Risk

WARNING Possible danger of death or severe bodily harm.

CAUTION Danger of minor bodily injury or property damage

IMPORTANT Danger of malfunctions

2.3.2 Hazard symbols

WARNING: Warning of hazard area

WARNING: Warning of dangerous electrical voltage

© Vanderbilt 2018 13 A6V10276959-d

12.09.2018

Page 14

3 Directives and standards

This chapter covers:

3.1 EU directives 14

3.2 Overview of Conformity to EN50131 Standard 14

3.3 Compliance with EN 50136-1:2012 and EN 50136-2:2014 22

3.4 Compliance with INCERT Approvals 22

3.5 PD 6662:2010 Conformance Guidelines 23

3.6 Compliance with VdS approvals 28

3.7 Compliance with NF and A2P approvals 29

3.1 EU directives

This product complies with the requirements of the European Directives 2004/108/EC “Directive of

Electromagnetic Compatibility”, 2006/95/EC “Low Voltage Directive”, and1999/5/EC on Radio and

Telecommunications Terminal Equipment (R&TTE). The EU declaration of conformity is available to the

responsible agencies at http://pcd.vanderbiltindustries.com/doc/SPC

European Directive 2004/108/EC “Electromagnetic Compatibility”

Compliance with the European Directive 2004/108/EC has been proven by testing according to the

following standards:

emc emission EN 55022 Class B

emc immunity EN 50130-4

European Directive 2006/95/EC “Low-Voltage Directive”

Compliance with the European Directive 2006/95/EC has been proven by testing according to the

following standard:

Safety EN 60950-1

3.2 Overview of Conformity to EN50131 Standard

This section gives an overview of the SPC compliance to the EN50131 standard.

Address of Certifying Body

VdS (VdS A/C/EN/SES Approval)

AG Köln HRB 28788

Sitz der Gesellschaft:

Amsterdamer Str. 174, 50735 Köln

Geschäftsführer:

Robert Reinermann

JörgWilms-Vahrenhorst (Stv.)

SPC products listed have been tested according to EN50131-3:2009 and all relevant RTC specifications.

© Vanderbilt 2018 14 A6V10276959-d

12.09.2018

Page 15

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

Product Type Standard

l SPC6350.320

l SPC6330.320

l SPC5350.320

l SPC5330.320

l SPCP355.300

l SPCP333.300

l SPCE652.100

l SPCK420.100

l SPCK421.100

l SPCE452.100

l SPCE110.100

l SPCE120.100

l SPCA210.100

l SPCK620.100

l SPCK623.100

l SPCN110.000

l SPCN320.000

EN50131 Grade 3

l SPC5320.320

l SPC4320.320

l SPCP332.300

l SPCW110.000

l SPCW112.000

l SPCW114.000

l SPCW130.100

EN50131 Grade 2

Specific information in relation to EN50131 requirements can be found in the following sections in this

document.

EN50131 Requirement (and relevant section) Relevant Vanderbilt documentation

Operating temperature and humidity range Technical data:

l SPC4000 on page31

l SPC5000 on page33

l SPC6000 on page37

Weights and dimensions Technical data:

l SPC4000 on page31

l SPC5000 on page33

l SPC6000 on page37

Fixing details Mounting system equipment on page43

© Vanderbilt 2018 15 A6V10276959-d

12.09.2018

Page 16

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

EN50131 Requirement (and relevant section) Relevant Vanderbilt documentation

Installation, commissioning and maintenance instructions,

including terminal identifications

Mounting system equipment on page43

Controller hardware on page68

Type of interconnections (see 8.8) Technical data:

l SPC4000 on page31

l SPC5000 on page33

l SPC6000 on page37

Wiring the X-BUS interface on page75

Details of methods of setting and unsetting possible (see 11.7.1

to 11.7.3 and Tables 23 to 26)

User programming via the keypad:

l Setting/Unsetting on page279

l Configuring a Keyswitch Expander on

page245

l Configuring wireless fob devices on

page110

l Triggers on page292

Serviceable parts Technical data:

l SPC4000 on page31

l SPC5000 on page33

l SPC6000 on page37

Power supply requirement if no integrated PS See installation instructions for SPCP33x and

SPCP43x Expander PSUs.

Where PS is integrated, the information required by EN 501316:2008, Clause 6

Technical data:

l SPC4000 on page31

l SPC5000 on page33

l SPC6000 on page37

Maximum number of each type of ACE and expansion device. Wiring the X-BUS interface on page75

Technical data:

l SPC4000 on page31

l SPC5000 on page33

l SPC6000 on page37

Current consumption of the CIE and each type of ACE and

See relevant installation instructions.

expansion device, with and without an alarm condition.

Maximum current rating of each electrical output Technical data:

l SPC4000 on page31

l SPC5000 on page33

l SPC6000 on page37

© Vanderbilt 2018 16 A6V10276959-d

12.09.2018

Page 17

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

EN50131 Requirement (and relevant section) Relevant Vanderbilt documentation

Programmable functions provided Engineer programming via the keypad on

page112

Engineer programming via the browser on

page173

How indications are made inaccessible to level 1 users when

level 2, 3 or 4 user is no longer accessing the information (see

8.5.1)

Masking/reduction of range signals/messages processed as

“fault” or “masking” events (see 8.4.1, 8.5.1 and Table 11)

Keypad user interface on page93

LCD Keypad Settings on page126

Comfort Keypad Settings on page127

Configuring an Indicator Expander on page243

System Options on page255

Wiring the zone inputs on page85

SIA Codes on page374

PIR masking is always reported as a zone

masked event (SIA - ZM). Additionally, antimask can cause an alarm, tamper, trouble or no

additional action depending on configuration

Current defaults of PIR addition effect:

Ireland

Unset - None

Set - Alarm

UK, Europe, Sweden, Swiss, Belgium

Unset - Tamper

Set - Alarm

Prioritization of signal and message processing and indications

(see 8.4.1.2, 8.5.3)

Using the LCD keypad interface on page95

Using the Comfort keypad interface - see About

the Comfort keypad on page99

Minimum number of variations of PIN codes, logical keys,

User PIN combinations on page382

biometric keys and/or mechanical keys for each user (see 8.3)

Method of time-limiting internal WD for level 3 access without

level 2 authorization (see 8.3.1)

Not supported - Engineer cannot access system

without permission.

Number and details of disallowed PIN codes (see 8.3.2.2.1) Automatic inhibits on page382

Details of any biometric authorization methods used (see

Not applicable

8.3.2.2.3)

Method used to determine the number of combinations of PIN

User PIN combinations on page382

codes, logical keys, biometric keys and/or mechanical keys

(see 11.6)

Number of invalid code entries before user interface is disabled

Access PINs on page383

(see 8.3.2.4)

Details of means for temporary authorization for user access

User Menus – Grant Access

(see 8.3.2)

© Vanderbilt 2018 17 A6V10276959-d

12.09.2018

Page 18

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

EN50131 Requirement (and relevant section) Relevant Vanderbilt documentation

If automatic setting at pre-determined times provided, details of

Setting/Unsetting on page279

pre-setting indication and any automatic over-ride of prevention

of set (see 8.3.3, 8.3.3.1)

Details of conditions provided for the set state (see 8.3.3.4) Setting/Unsetting on page279

LCD Keypad Settings on page126

Comfort Keypad Settings on page127

Editing an output on page233

Zone types on page385

Notification of output signals or messages provided (see 8.6) Editing an output on page233

Setting/Unsetting on page279

User rights on page201

Other output configurations to interface with I&HAS

components (see 8.2)

Editing an output on page233

Zone types on page385

Test on page163

Keypad user interface on page93

Criteria for automatic removal of “soak test” attribute (see 8.3.9) Timers on page264

Number of events resulting in automatic inhibit Automatic inhibits on page382

If ACE is Type A or Type B (see 8.7) and whether portable or

moveable (see 11.14)

All devices are hardwired and powered by

system PSUs. See the relevant technical data

on PSUs (separate documents).

Component data for non-volatile memory components (see

Table 30, step 6)

See user documentation for SPCK420/421 and

SPCK620/623 keypads.

Life of memory support battery (see 8.10.1) N/A. Stored in non-volatile memory.

Optional functions provided (see 4.1) Engineer programming via the keypad on

page112

Engineer programming via the browser on

page173

Additional functions provided (see 4.2, 8.1.8) Unrestricted Grade on page271

Options on page255

Access levels required to access such additional functions

provided

Edit on page135

User configuration (browser) - see

Adding/Editing a User on page197

Details of any programmable facility that would render an

I&HAS non-compliant with EN 50131-1:2006, 8.3.13 or

compliant at a lower security grade, with instruction on

consequent removal of compliance labeling (see 4.2 and

8.3.10).

Unrestricted Grade on page271

Options on page255

Compliance with EN50131 Approvals on

page20

SPC products listed have been tested according to EN50131-6, and all relevant RTC specifications.

© Vanderbilt 2018 18 A6V10276959-d

12.09.2018

Page 19

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

Product Type Standard

l SPC6350.320

l SPC6330.320

l SPC5350.320

l SPC5330.320

l SPCP355.300

l SPCP333.300

l SPCP355.300

l SPCE652.100

l SPCK420.100

l SPCK421.100

l SPCE452.100

l SPCE110.100

l SPCE120.100

l SPCA210.100

l SPCK620.100

l SPCK623.100

l SPCN110.000

EN50131-6

l SPCN310.000

l SPC5320.320

l SPC4320.320

l SPCP332.300

EN50131-6

© Vanderbilt 2018 19 A6V10276959-d

12.09.2018

Page 20

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

3.2.1 Compliance with EN50131 Approvals

Software Requirements

l In the Standards settings page, select Europe under Region to implement EN50131

requirements.

l Select Grade 2 or Grade 3 to implement the grade of EN50131 compliance.

l The Wireless setting Prevent Setting Time must be set to a value greater than 0 and less than

20.

l The Wireless setting Device Lost Time must be set to a value less than 120.

l The X-BUS Settings, Retries, must be set to a value of 10.

l The X-BUS Settings, Comms timer, must be set to a value of 5.

l Select Synchronization Time with Mains under Clock settings to use mains as clock master.

© Vanderbilt 2018 20 A6V10276959-d

12.09.2018

Page 21

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

l DO NOT select the attribute Setting State in the Keypad configuration settings for Visual

indications.

Hardware Requirements

l The back tamper kit (SPCY130) must be installed for panels and power supplies for compliance with

EN50131 Grade 3.

l EN50131 Grade 3 compliant components must be installed for EN50131 Grade 3 compliant

systems.

l Either EN50131Grade 2 or 3 compliant components must be installed for EN50131 Grade 2

compliant systems.

l It is not possible to enrol a wireless device with a signal strength lower than 3.

l The recommended ratio of wireless receivers to transmistters is no more than 20 transmitters for

every one receiver.

l Glassbreak must be used with an EN-compliant glassbreak interface.

l To comply with EN50131-3:2009, do not set or unset the system using the SPCE120 (Indicator

Expander) or the SPCE110 (Keyswitch Expander).

© Vanderbilt 2018 21 A6V10276959-d

12.09.2018

Page 22

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

The SPCN110 PSTN module and SPCN320 GSM/GPRS module are tested with EN50131

approved Grade 2 and Grade 3 panels and can be used with these approved panels.

3.3 Compliance with EN 50136-1:2012 and EN 50136-2:2014

SPC products listed have been tested according to EN 50136-1:2012 and EN 50136-2:2014.

3.4 Compliance with INCERT Approvals

Software Requirements

Selecting Belgium (*) under Region implements local or national requirements which supercede

EN50131 requirements.

Selecting Grade 2 or Grade 3 selects EN50131 compliance plus any additional INCERT requirements:

l Only an engineer can restore a tamper. For INCERT, this applies across all grades.

This is normally only a requirement for Grade III En50131.

l A tamper on an Inhibited/Isolated zone must be sent to an ARC and displayed to the user.

For INCERT, tampers are processed for isolated zones. On all other standard variations,

tampers are ignored on isolated zones.

l User PIN codes must be defined with more than 4 digits.

© Vanderbilt 2018 22 A6V10276959-d

12.09.2018

Page 23

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

Hardware Requirements

l The minimum battery capacity for SPC42xx/43xx/52xx/53xx/63xx is 10Ah/12V. If a 10Ah battery is

used, then the battery is biased to the left of the housing and the bottom flap is bent to meet the

battery.

l Fit jumper (J12) on the battery selector for 17/10Ah battery use and remove for 7Ah battery.

l The amount of current from Aux output using a 10Ah battery for SPC42xx/SPC52xx is:

COMMS

NONE (mA) PSTN (mA) GSM (mA) PSTN+GSM (mA)

Standby time

12 h 568 543 438 413

24h 214 189 84 59

30 h 143 118 13 N/A

60h 2 N/A N/A N/A

l The amount of current from Aux output using a 10Ah battery for SPC43xx/SPC53xx/ SPC63xx is:

COMMS

NONE (mA) PSTN (mA) GSM (mA) PSTN+GSM (mA)

Standby time

12 h 538 513 408 383

24 h 184 159 54 29

30 h 113 88 N/A N/A

60 h N/A N/A N/A N/A

3.5 PD 6662:2010 Conformance Guidelines

This document contains all the criteria for the installation, and commissioning and maintenance of the SPC

System to enable it to conform to the PD 6662:2010 Standard.

3.5.1 Product scope

The scope of this document is aimed at the following components of the SPC system:

SPC4320.320-L1 Grade2 Controller

SPC5320.320-L1 Grade2 Controller

SPC5330.320-L1 Grade3 Controller

SPCE652.100Expander, 8Inputs/2Outputs

SPCP332.300 Smart PSU with I/O Expander

SPCP355.300Smart PSU with 8Inputs/2Outputs Expander

SPC5350.320-L1 Grade3 Controller

SPC6330.320-L1 Grade3 Controller

SPC6350.320-L1 Grade3 Controller

SPCP333.300 Smart PSU with I/O Expander

SPCN110.000 PSTN Module

SPCN320.000 GSM Module

SPCK420/421.100 LCD Keypad

SPCE452.100Expander, 8Relay Outputs

© Vanderbilt 2018 23 A6V10276959-d

12.09.2018

Page 24

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

3.5.2 Standards overview

Guidelines are provided for the implementation of PD 6662:2010 conformance for an SPC system to

the following relevant standards:

PD 6662:2010

BS 4737-3.1:1977

BS 8243:2010

BS 8473:2006+A1:2008

BS EN 50131-1:2006+A1:2009

BS EN 50136-1-1:1998+A2:2008

BS EN 50136-1-2:1998

BS EN 50136-1-3:1998

BS EN 50136-1-5:2008

BS EN 50136-2-1:1998 +A1:1998

BS EN 50136-2-2:1998

BS EN 50136-2-3:1998

BS EN 50131-3:2009

BS EN 50131-6:2008

DD 263:2010

DD CLC/TS 50131-7:2008

3.5.3 Methods for the completion of setting and unsetting

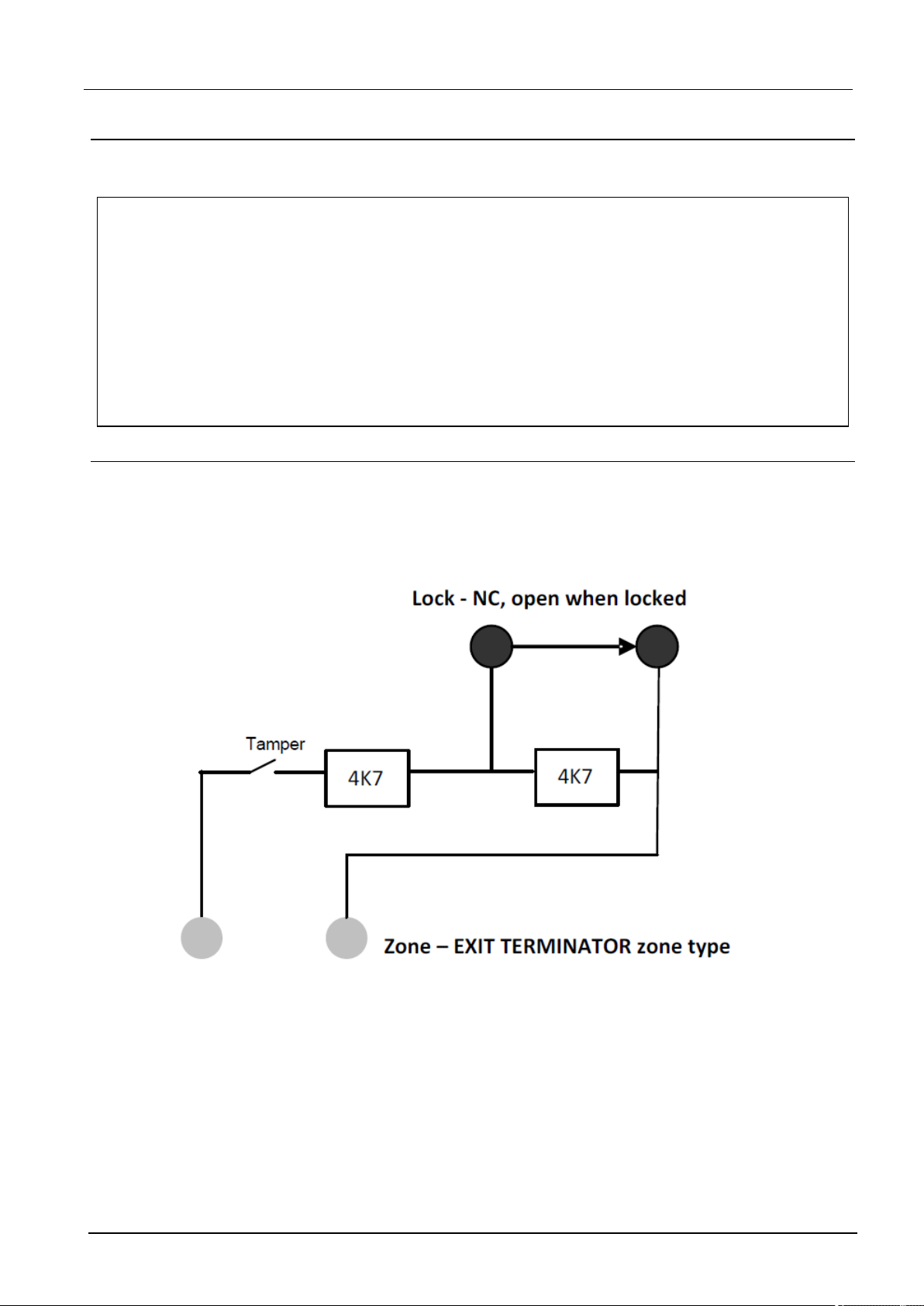

3.5.3.1 Methods of completion of setting (BS 8243:2010 - Clause 6.3)

Completion/Termination of the full setting procedure is achieved by any of the following methods:

a) Shunt lock fitted to the final exit door

A shunt lock must be installed by the installer as follows:

An EXIT TERMINATOR zone type must be configured for SPC.

See Zone types on page385.

b) Push button switch mounted outside the supervised premises

Connect the push button into an SPC zone input as follows:

An EXIT TERMINATOR zone type must be configured for SPC.

See Zone types on page385.

© Vanderbilt 2018 24 A6V10276959-d

12.09.2018

Page 25

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

c) Protective switch (that is, door contact) fitted to the final exit door of the alarmed premises or

area

Connect the switch to the SPC System as follows:

The contact is fitted to the final exit door and is connected to an ENTRY/EXIT zone with a ‘Final Exit‘

attribute.

See Zone types on page385 and Zone attributes on page390.

A misoperation signal is possible using the alarm abort feature. This is enabled by default.

See Options on page113 (Keypad) and Options on page255 (Browser).

d) Digital key

Not supported by SPC.

e) In conjunction with an ARC

This method of setting is supported by using SPC COM XT or other third party ARC software using EDP

commands.

3.5.3.2 Methods of completion of unsetting (BS 8243:2010 - Clause 6.4)

Unsetting methods are complied with as follows:

6.4.1 For all the unsetting methods in the SPC system there is an audible indication to the user that the

system has been unset successfully. This is in the form of a beep sequence from the CIE.

6.4.2 Prevention of entry to the supervised premises before the intruder alarm system (IAS) is

unset:

a) Unlocking the initial entry door causes the IAS to be unset;

Compliance by SPC if KEYARM zone type is used with the UNSET attribute only. This zone type must

not be used for setting.

b) Unsetting the IAS by the user before entering the supervised premises causes or permits the initial entry

door to be unlocked.

Compliance by SPC by unsetting using an access card reader on an entry reader with the UNSET option,

or an input from a third party access system to a KEYARM zone with an UNSET attribute.

6.4.3 Prevention of entry to the supervised premises before all means of intruder alarm

confirmation have been disabled:

a) Unlocking the initial entry door causes all means of confirmation to be disabled

Operation not permitted by SPC.

b) Disabling all means of confirmation by the user before entering the supervised premises causes or

permits the initial entry door to be unlocked

Operation not permitted by SPC.

6.4.4 Opening the initial entry door disables all means of intruder alarm confirmation

Operation not permitted by SPC.

6.4.5 Completion of unsetting using a digital key

a) Operation of a digital key before entering the supervised premises (for example, via radio)

SPC satisfies this clause when the installer installs a PACE reader (for example, SPCK421) outside the

premises.

b) Operation of a digital key after entering the supervised premises from a location as near as practicable

to the initial entry door.

This functionality is provided by use of a PACE reader (for example, SPCK421) near the entry door of a

premises.

© Vanderbilt 2018 25 A6V10276959-d

12.09.2018

Page 26

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

See Zone types on page385 and Zone attributes on page390.

WARNING: Your attention is drawn to the fact that by allowing this method of unsetting, if an

intruder succeeds in forcing the initial entry door, the police will not be called, regardless of the

intruder’s further progress through the premises.

This method of unsetting the intruder alarm system might be unacceptable to your insurers.

6.4.6 Unsetting in conjunction with an alarm receiving centre (ARC)

Compliance by SPC using third party ARC software. Indication external to the building must be

provided by means of a timed buzzer/strobe, etc., that will operate on a system unset for a timed

period, for example, 30 seconds.

See Timers on page117.

3.5.4 Configuration requirements for PD 6662:2010 conformance

Recommendations for the recording of remotely notified alarm conditions (BS 8243:2010 Annex G.1 and G.2)

Alarm conditions can be categorised for analysis in accordance with Annex G if the SPC system is

configured so that the entry timer is less than 30 seconds, and the dialer delay is set to 30 seconds.

See the following sections:

l Areas on page121

l Adding/Editing an area on page273

l Timers on page117

Requirements for systems using dedicated alarm paths (BS EN 50136-1-2, 1998)

The SPC system should be configured to do an automated test call to the ARC.

The SPC system should be configured with a 'Fail to Communicate‘output.

See the following section:

l Adding/Editing an ARC using SIA or CID on page329

Requirements for equipment used in systems with digital communicators using PSTN (BS EN

50136-2-2, 1998)

Fault Output

The SPC system should be configured with a 'Fail to Communicate‘output.

See the following sections:

l Outputs on page153 (Keypad)

l Configuring controller inputs and outputs on page231 (Browser)

l Adding/Editing an ARC using SIA or CID on page329

Retransmission Attempts

Retransmission attempts (Dial Attempts) are configured in this manual:

l Adding/Editing an ARC using SIA or CID on page329

l Editing EDP settings on page339

A minimum of 1 and a maximum of 12 retransmissions are allowed.

Intrusion and hold-up - System design (DD CLC TS 50131-7, 2008)

Setting and unsetting

SPC system is configurable in such a way that the setting is completed by 'Final Exit'.

It is possible to configure the SPC so that a WD (Warning Device) is activated momentarily on setting.

© Vanderbilt 2018 26 A6V10276959-d

12.09.2018

Page 27

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

See the following sections:

l Timers on page117

l Zone attributes on page390

l Outputs on page153 (Keypad)

l Editing an output on page233 (Browser)

Intrusion and confirmed hold-up alarm (BS8243:2010 Designation of hold-up alarm (HUA) signals

for sequential confirmation)

SPC system is configurable in such a way that the following scenarios, when triggered more than two

minutes apart from any hold-up zone or hold-up device (HD), will report a confirmed hold-up alarm event

(HV for SIA and 129 for CID) to the CIE:

l two hold-up zone activations

l a hold-up zone and a panic zone activation

If a hold-up zone and a tamper zone or a panic zone and a tamper zone activation occurs within the two

minute period, this will also send a confirmed hold-up alarm event.

A confirmed hold-up will not require an engineer restore even if engineer restore is enabled. A confirmed

hold-up event is logged in the system log.

3.5.5 Additional commissioning requirements for PD 6662:2010 conformance

Information to be included in the system design proposal and as-fitted document (BS 8243:2010 Annex F)

l During the installation, configuration and commissioning of an SPC system, the installer must

adhere to the following guidelines as required in the above annex:

l It is recommended that dual paths are used for signalling which are supported in the SPC system

using GSM, PSTN and Ethernet options.

l The SPC system must be installed and configured to provide an effective confirmation facility. Any

exceptions to this should be outlined in the ‘As Fitted’ document.

l Combinations and sequences which contribute to a confirmed alarm should be clearly notified to the

end user.

l The intrusion confirmation time should be clearly notified to the end user.

l Methods of completion of setting and unsetting methods should be clearly described to the end user

as detailed in this document.

l Ensure written arrangements are supplied to the end user in the event of a lock failure.

It is recommended that the enclosed PD 6662:2010 label is affixed in an appropriate position on the

inside of the SPC housing beside the product type label.

3.5.6 Additional information

Transmission Network Requirements – Performance, Availability and Security Levels (BS EN

50136-1-2, 1998 and BS EN 50136-1-5, 2008)

The SPC System has been tested and approved to EN50136-1-1.

SPC levels are classified as follows:

Transmission time D2 as max.

© Vanderbilt 2018 27 A6V10276959-d

12.09.2018

Page 28

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

Transmission time, max. values M0 – M4

Reporting time T3 as max.

Availability See ATS levels and attenuation specifications on page394.

Signalling security level Tested to EN50136-1-1 and classified as ‘S0’.

3.6 Compliance with VdS approvals

This installation document encompasses the required product installation information for VdS

approvals.

Vanderbilt

SPC42xx/43xx/53xx/63xx : VdS Approval Nr. G 112104, G112124, and G112128. VdS EN Certificates

EN-ST000142, EN-ST000143, EN-ST000055, EN-ST000056, EN-ST000057, EN-ST000058, ENST000061, EN-ST000062.

Siemens

SPC42xx/43xx/53xx/: VdS Approval Nr. G116035. VdS EN Certificates EN-ST000225, ENST000226, EN-ST000227, EN-ST000228, EN-ST000229, EN-ST000230, EN-ST000231, ENST000232.

This section describes the compliance of this system with VdS approvals.

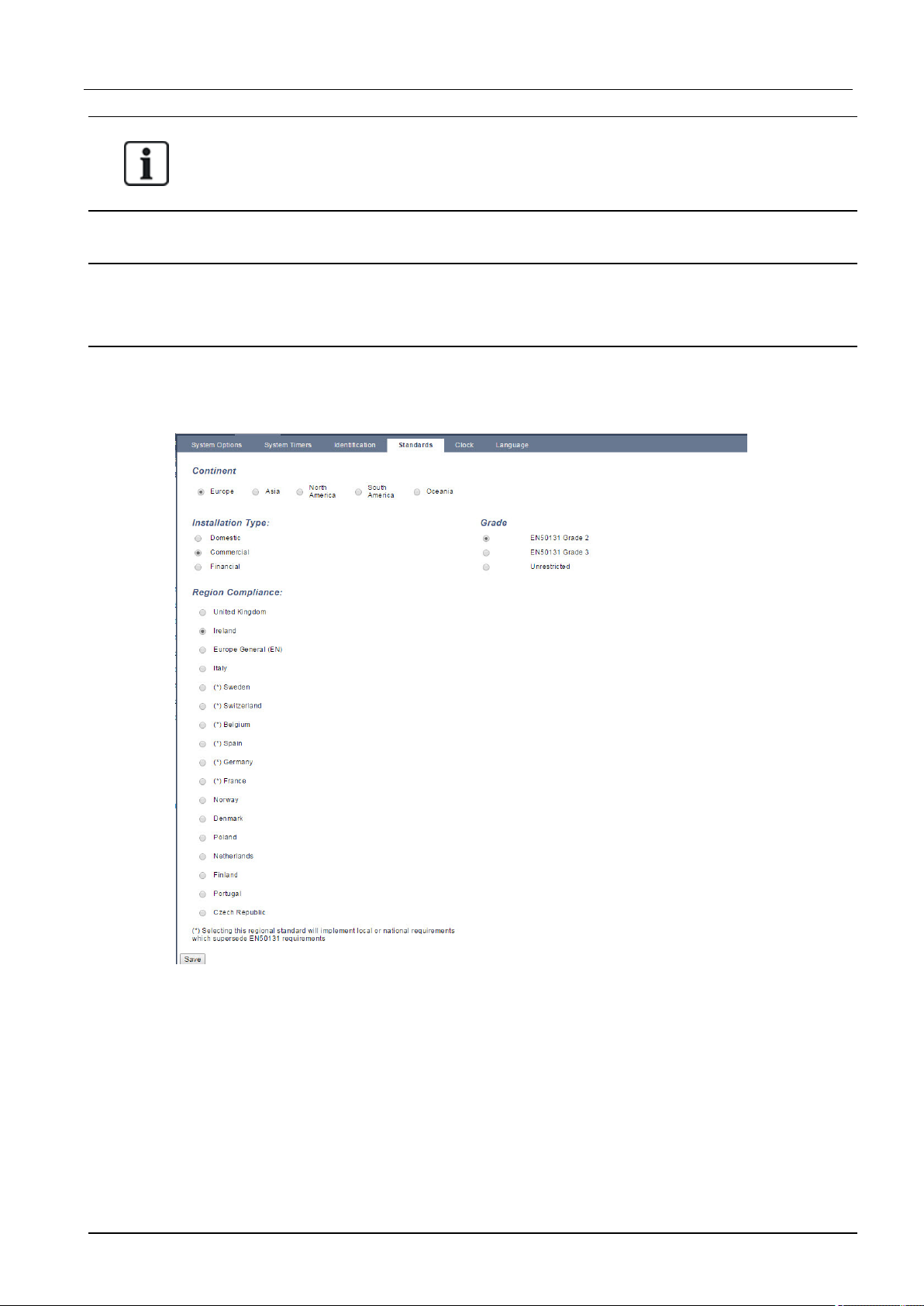

Configuring software for VdS compliance

To set the system for VdS compliance, do the following:

1. Log on to the panel with the browser.

2. Click Full Engineer.

3. Click Configuration > System > Standards.

4. Select Europe in the Continent section of the page.

5. Select Germany in the Region Compliance section of the page.

6. Select the VDS grade required by your installation type.

Hardware Fault reporting — in Configuration > System > System Options, you must select the

Enabled + Reporting (10s) option from the Watchdog Output Mode drop-down list.

Hardware faults are not reported if the Engineer is logged in to the system.

Hardware

VdS compliance requires the following:

l A G5 housing with Front tamper implemented as a minimum requirement.

l Keypads do not show status information if the system is armed.

l The number of supported zones is as follows:

– 512 zones in ring configuration

– 128 zones per X-Bus in multi-drop (spur) configuration

l The following end of line resistance combinations do not comply with VdS standards:

– 1k, 470 ohm

– 1k, 1k, 6k6 ohm

© Vanderbilt 2018 28 A6V10276959-d

12.09.2018

Page 29

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directives and standards

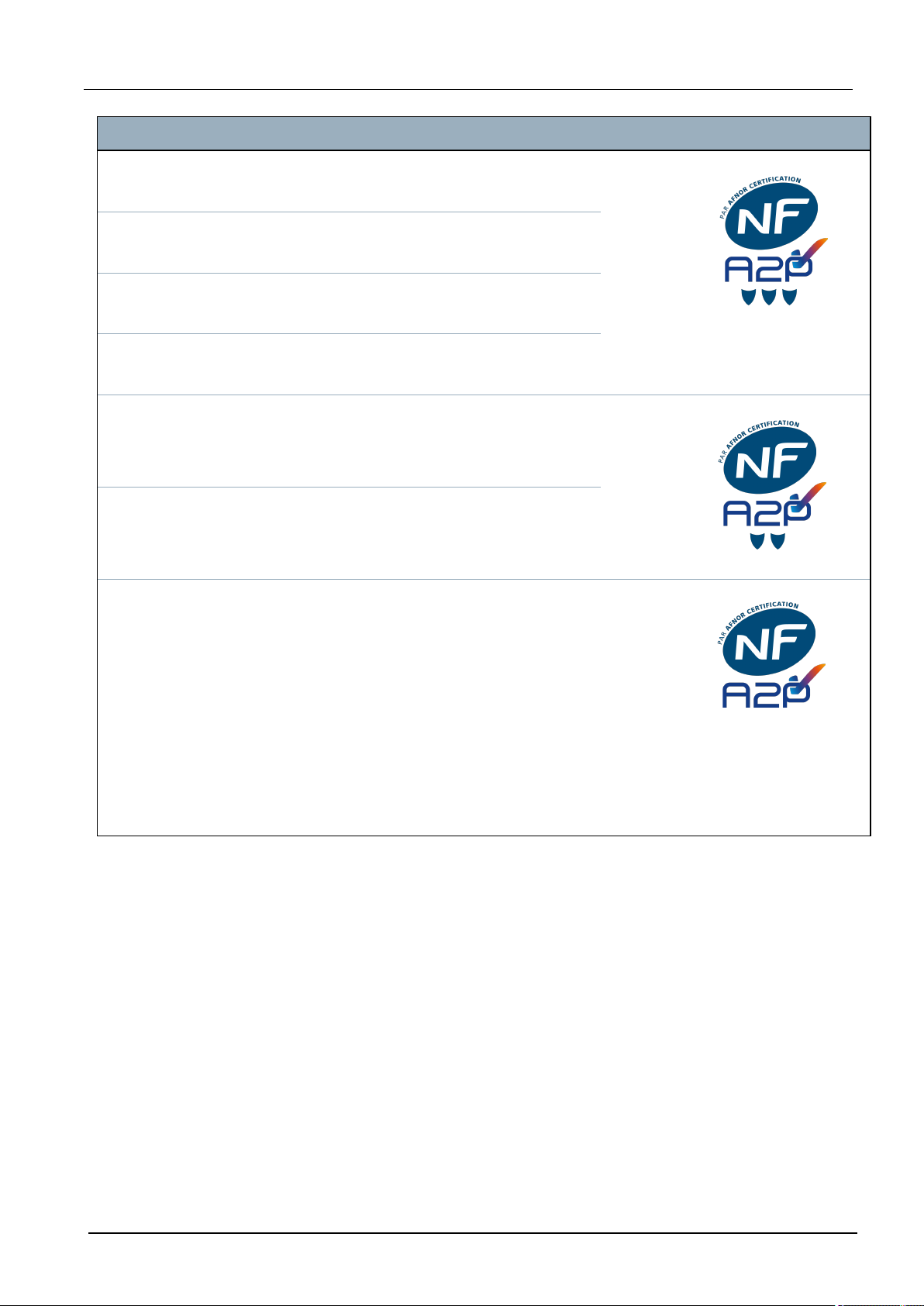

3.7 Compliance with NF and A2P approvals

Address of Certifying Body

CNPP Cert

Pôle Européen de Sécurité - Vernon

Route de la Chapelle Réanville

CD 64 - CS 22265

F-27950 SAINT MARCEL

www.cnpp.com

AFNOR Certification

11 rue François de Pressensé

93571 Saint Denis La Plaine Cedex

www.marque-nf.com

To comply with NF and A2P installation regulations, this housing must be sealed by affixing the

accompanying Tamper Label after installation.

SPC products listed have been tested according to NF324 - H58, with reference to RTC50131-6 and

RTC50131-3 and current EN certifications. See Compliance with EN50131 Approvals on page20.

Product Type Configuration Standard Logo

SPC6350.320 + SPCP355.300

(Cert. 1233700001 + Cert.8033700002)

60h, unmonitored NF Grade

3,

Class 1

SPC5350.320 + SPCP355.300

60h, unmonitored

(Cert. 1233700001 + Cert.8033700002)

SPC6350.320

60h, unmonitored

(Cert. 1233700001)

SPC5350.320

60h, unmonitored

(Cert. 1233700001)

© Vanderbilt 2018 29 A6V10276959-d

12.09.2018

Page 30

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Directivesand standards

Product Type Configuration Standard Logo

SPC6330.320 + SPCP333.300

(Cert. 1233700001)

SPC5330.320 + SPCP333.300

(Cert. 1232200003)

SPC6330.320

(Cert. 1233700001)

SPC5330.320

(Cert. 1232200003)

SPC5320.320

(Cert. 1232200003)

SPC4320.320

(Cert. 1232200003)

SPCN110.000

SPCN320.000

SPCK420.100

60h, unmonitored NF Grade

3,

Class 1

60h, unmonitored

30h, monitored

30h, monitored

36h, unmonitored NF Grade

2,

Class 1

36h, unmonitored

NF Grade 2

and 3,

Class 1

SPCK620.100

SPCK623.100

SPCE652.100

SPCE452.100

SPCE110.100

SPCE120.100

© Vanderbilt 2018 30 A6V10276959-d

12.09.2018

Page 31

4 Technical Data

This chapter covers:

4.1 SPC4000 31

4.2 SPC5000 33

4.3 SPC6000 37

4.4 SPCP355.300 40

4.1 SPC4000

Programmable areas 4

Max. number of user PINs 100

Remote controls Up to 32

PACE Devices 32

Wireless Panic Alarm Up to 128

Event memory 1000 intrusion events, 1000 access events

Number of on-board zones 8

Max. number of hardwired zones 32

Max. number of wireless zones 32 (take away wired zones)

Max. number of Intrunet wireless

20

detectors per wireless receiver

(recommended)

EOL resistor Dual 4k7 (default), other resistor combinations configurable

Number of on-board relays 1 strobe (30V DC/1A resistive switching current)

Number of on-board open coll. 2 internal/external bell, 3 freely programmable (each max. 400mA resistive

switching current, supplied via auxiliary output)

Firmware V3.x

Door capacity Max. 4 entry doors or 2 entry/exit doors

Number of card reader Max. 4

Radio module l SPC4221: integrated SiWay RF receiver (868MHz)

l SPC4320.220: Optional (SPCW111)

l SPC4320.320: Optional (SPCW110)

Verification 4 verification zones with max. 4 IP-cameras and 4 audio devices.

Video Up to 16 pre/16 post event images (by JPEG resolution 320 x 240, max. 1

frame/sec.)

© Vanderbilt 2018 31 A6V10276959-d

12.09.2018

Page 32

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Audio Up to 60sec. pre/60sec. post audio recording

Field bus 1) X-BUS on RS-485 (307kb/s)

Number of field devices 2) Max. 11 (4 keypads, 2 door-expanders, 5 input/output expanders)

Connectable field devices l Keypads: SPCK42x, SPCK62x

l Door expanders: SPCA210, SPCP43x

l Expanders with I/O: SPCE65x, SPCE45x, SPCP33x, SPCE110,

SPCE120, SPCV32x

Interfaces l 1 X-BUS (1 spur)

l 1 RS232

l USB (PC connection)

l SPC43xx: Additionally 1 Ethernet (RJ45)

Tamper contact Front spring tamper, 2 auxiliary tamper contact inputs

Power supply Type A (per EN50131-1)

Mains voltage 230V AC, + 10%/ -15%, 50Hz

Mains fuse 250mA T (replaceable part on mains terminal block)

Power consumption SPC42xx: Max. 160mA at 230V AC

SPC43xx: Max. 200mA at 230V AC

Operating current SPC42xx Controller: Max. 160mA at 12V DC

SPC43xx Controller: Max. 200mA at 12V DC

Quiescent current SPC42xx Controller:

Max. 140mA at 12V DC (165mA with PSTN, 270mA with GSM, 295mA with

PSTN and GSM)

SPC43xx Controller:

Max. 170mA at 12V DC (195mA with PSTN, 300mA with GSM, 325mA with

PSTN and GSM)

Output voltage 13–14V DC in normal conditions (mains powered and fully charged battery),

min. 10.5V DC when powered by secondary device (before system shut down

to battery deep discharge protection)

Low voltage trigger 7.5V DC

Overvoltage protection 15.7V DC

Peak to Peak ripple Max. 5% of output voltage

Auxiliary power (nominal) Max. 750mA at 12V DC

Battery type

(Battery not supplied)

SPC422x/4320:

l YUASA NP7-12FR (12V/7Ah) - NF

l PowerSonic PS1270 (12V/7Ah)

l YUASA Yucel Y7-12FR (12V/7Ah)

Battery charger SPC422x/4320: Max. 72h to 80% of battery capacity

© Vanderbilt 2018 32 A6V10276959-d

12.09.2018

Page 33

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Battery protection Current limited to 1A (fuse protected), deep discharge protection at 10.5V DC

+/- 3%

Software update Local and remote upgrade for controller, peripherals and GSM/PTSN modems.

Calibration No calibration checks required (calibrated at manufacturing)

Serviceable parts No serviceable parts

Operating temperature -10 to +50°C

Relative humidity Max. 90% (non condensing)

Colour RAL 9003 (signal white)

Weight SPC422x/4320: 4.500kg

Dimensions (W x H x D) SPC422x/4320: 264 x 357 x 81mm

Housing SPC4320.320: Small metal housing (1.2mm mild steel)

SPC422x.220: Small housing with metal base (1.2mm mild steel) and plastic lid

Housing can contain up to SPC422x/4320: 1 additional expander (size 150 x 82mm)

IP rating 30

ATS 3

ATP 8

Event Profiles 5

Event Exceptions 10

Command Profiles 5

1) Max. 400m between devices/cable types IYSTY 2 x 2 x Ø 0.6mm (min.), UTP cat5 (solid core) or

Belden 9829.

2) More I/O expanders can be addressed instead of a keypad or door expander, but number of

programmable inputs/outputs cannot exceed specified system limits.

4.2 SPC5000

Programmable areas 16

Max. number of user PINs 500

Remote controls Up to 100

PACE Devices 250

Wireless Panic Alarm Up to 128

Event memory 10,000 intrusion events, 10,000 access events

Number of on-board zones l SPC5320/5330 — 8

l SPC5350 — 16

© Vanderbilt 2018 33 A6V10276959-d

12.09.2018

Page 34

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Max. number of hardwired

128

zones

Max. number of wireless zones 120 (take away wired zones)

Max. number of Intrunet

20

wireless detectors per wireless

receiver (recommended)

EOL resistor Dual 4k7 (default), other resistor combinations configurable

Relay Outputs l SPC5320/5330 — 1 strobe (30V DC/1A resistive switching current)

l SPC5350 — 4 (single-pole changeover, 30V DC/ maximum 1A resistive

switching current)

Electronic Outputs l SPC5320/5330 — 5 outputs:

– 2 internal/external bells

– 3 programmable. Maximum 400mA resistive switching current per

output, supplied by auxiliary output.

l SPC5350 — 8 outputs. Maximum 400mA resistive switching current per

output

– 5 standard power outputs

– 3 supervised outputs

Firmware V3.x

Door capacity Max. 16 entry doors or 8 entry/exit doors

Number of card reader Max. 16

Radio module Optional (SPCW110)

Verification 16 verification zones with max. 4 IP-cameras and 16 audio devices.

Video Up to 16 pre/16 post event images (by JPEG resolution 320 x 240, max. 1

frame/sec.)

Audio Up to 60sec. pre/60sec. post audio recording

Field bus 1) X-BUS on RS-485 (307kb/s)

Number of field devices 2) Max. 48 (16 keypads, 8 door-expanders, 16 input/output expanders)

Connectable field devices l Keypads: SPCK42x, SPCK62x

l Door expanders: SPCA210, SPCP43x

l Expanders with I/O: SPCE65x, SPCE45x, SPCP33x, SPCP35x,

SPCE110, SPCE120, SPCV32x

Interfaces l 2 X-BUS (2 spurs or 1 loop)

l 2 RS232

l 1 USB (PC connection)

l SPC53xx: Additionally 1 Ethernet (RJ45)

© Vanderbilt 2018 34 A6V10276959-d

12.09.2018

Page 35

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Tamper contact l SPC5320/5330: Front spring tamper, 2 auxiliary tamper contact inputs

l SPC5350: Front/back tamper switch

Power supply Type A (per EN50131-1)

Mains voltage 230V AC, + 10%/-15%, 50Hz

Mains fuse l SPC5320/5330: 250mA T (replaceable part on mains terminal block)

l SPC5350: 800mA T (replaceable part on mains terminal block)

Power consumption l SPC5320/5330: Max. 200mA at 230V AC

l SPC5350: Max. 500mA at 230V AC

Operating current l SPC5320/5330: Controller: Max. 200mA at 12V DC

l SPC5350: Max. 210mA at 12V DC

Quiescent current SPC53xx Controller: Max. 170mA at 12V DC (195mA with PSTN, 300mA

with GSM, 325mA with PSTN and GSM)

Output voltage 13–14V DC in normal conditions (mains powered and fully charged battery),

min. 10.5V DC when powered by secondary device (before system shut

down to battery deep discharge protection)

Low voltage trigger 11V DC

Overvoltage protection l SPC5320/5330: 15.7V DC

l SPC5350: 15V DC nominal

Peak to Peak ripple Max. 5% of output voltage

Auxiliary power (nominal) l SPC5320/5330: Max. 750mA at 12V DC

l SPC5350: Max. 2200mA at 12V DC (8 separately fused outputs, 300mA

per output)

© Vanderbilt 2018 35 A6V10276959-d

12.09.2018

Page 36

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Battery type

(Battery not supplied)

SPC5320:

l YUASA NP7-12FR (12V/7Ah) - NF

l PowerSonic PS1270 (12V/7Ah)

l YUASA Yucel Y7-12FR (12V/7Ah)

SPC5330:

l YUASA NP17-12IFR (12V/17Ah) - NF

l YUASA Yucel Y17-12FR (12V/17Ah)

l PowerSonic PS12170 (12V/7Ah)

SPC5350:

l FIAMM FGV22703 (12V/27Ah) - NF

l PowerSonic PS12260FR (12V/26Ah)

l PowerSonic PS12170 (12V/17Ah)

l Alarmcom AB1227-0 (12V/27Ah)

l YUASA NPL24-12IFR (12V/24Ah)

l YUASA Yucel Y17-12IFR (12V/17Ah)

l YUASA Yucel Y24-12FR (12V/24Ah)

Battery charger l SPC5320: Max. 72h,

l SPC5330/5350: Max. 24h to 80% of battery capacity

Battery protection l SPC5320/5330: Current limited to 1A (fuse protected), deep discharge

protection at 10.5V DC +/- 3%

l SPC5350: Current limited to 2A (protected by PTC resettable fuse),

deep discharge protection at 10.5V DC

Software update Local and remote upgrade for controller, peripherals and GSM/PTSN

modems.

Calibration No calibration checks required (calibrated at manufacturing)

Serviceable parts l SPC5320/5330: No serviceable parts

l SPC5350: 8 glass fuses (400mA AT) for 12V DC outputs

Operating temperature -10 to +50°C

Relative humidity Max. 90% (non condensing)

Colour RAL 9003 (signal white)

Weight l SPC5320: 4.500kg

l SPC5330: 6.400kg

l SPC5350: 18.600kg

Dimensions (W x H x D) l SPC5320: 264 x 357 x 81mm

l SPC5330: 326 x 415 x 114mm

l SPC5350: 498 x 664 x 157mm

© Vanderbilt 2018 36 A6V10276959-d

12.09.2018

Page 37

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Housing l SPC5320: Small metal housing (1.2mm mild steel)

l SPC5330: Hinged metal housing (1.2mm mild steel)

l SPC5350: Metal housing (1.5mm mild steel)

Housing can contain up to l SPC5320: 1 additional expander

l SPC5330: 4 additional expanders (size 150 x 82mm)

l SPC5350: 4 additional expanders (150 x 82mm)

IP/IK Rating 30/06

ATS 5

ATP 15

Event Profiles 10

Event Exceptions 50

Command Profiles 8

1) Max. 400m between devices/cable types IYSTY 2 x 2 x Ø 0.6mm (min.), UTP cat5 (solid core) or

Belden 9829.

2) More I/O expanders can be addressed instead of a keypad or door expander, but number of

programmable inputs/outputs cannot exceed specified system limits.

4.3 SPC6000

Programmable areas 60

Max. number of user PINs 2500

Remote controls Up to 100

PACE Devices 250

Wireless Panic Alarm Up to 128

Event memory 10,000 intrusion events, 10,000 access events

Number of on-board zones l SPC6320/6330 — 8

l SPC6350 — 16

Max. number of hardwired

zones

Max. number of wireless

zones

512

120 (take away wired zones)

Max. number of Intrunet

20

wireless detectors per

wireless receiver

(recommended)

EOL resistor Dual 4k7 (default), other resistor combinations configurable

© Vanderbilt 2018 37 A6V10276959-d

12.09.2018

Page 38

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Relay Outputs l SPC6320/6330 — 1 strobe (30V DC/1A resistive switching current)

l SPC6350 — 4 (single-pole changeover, 30V DC/ maximum 1A resistive

switching current)

Electronic Outputs l SP6320/6330 — 5 outputs:

– 2 internal/external bells

– 3 programmable. Maximum 400mA resistive switching current per

output, supplied by auxiliary output.

l SPC6350 — 8 outputs. Maximum 400mA resistive switching current per

output

– 5 standard power outputs

– 3 supervised outputs

Firmware V3.x

Door capacity Max. 64 entry doors or 32 entry/exit doors

Number of card reader Max. 64

Radio module Optional (SPCW110)

Verification 32 verification zones with max. 4 IP-cameras and 32 audio devices.

Video Up to 16 pre/16 post event images (by JPEG resolution 320 x 240, max. 1

frame/sec.)

Audio Up to 60sec. pre/60sec. post audio recording

Field bus 1) X-BUS on RS-485 (307kb/s)

Number of field devices 2) Max. 128 (32 keypads, 32 door-expanders, 64 input/output expanders)

Connectable field devices l Keypads: SPCK42x, SPCK62x

l Door expanders: SPCA210, SPCP43x

l Expanders with I/O: SPCE65x, SPCE45x, SPCP33x, SPCP35x,

SPCE110, SPCE120, SPCV32x

Interfaces l 2 X-BUS (2 spurs or 1 loop)

l 2 RS232

l 1 USB (PC connection)

l SPC63xx: Additionally 1 Ethernet (RJ45)

Tamper contact l SPC6330: Front spring tamper, 2 auxiliary tamper contact inputs

l SPC6350: Front/back tamper switch

Power supply Type A (per EN50131-1)

Mains voltage 230V AC, +10%/-15%, 50Hz

Mains fuse l SPC6330: 250mA T (replaceable part on mains terminal block)

l SPC6350: 800mA T (replaceable part on mains terminal block)

© Vanderbilt 2018 38 A6V10276959-d

12.09.2018

Page 39

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Power consumption l SPC6330: Max. 200mA at 230V AC

l SPC6350: Max. 500mA at 230V AC

Operating current l SPC6330: Max. 200mA at 12V DC

l SPC6350: Max. 210mA at 12V DC

Quiescent current SPC63xx Controller: Max. 170mA at 12V DC (195mA with PSTN, 300mA

with GSM, 325mA with PSTN and GSM)

Output voltage l SPC6330: 13–14V DC in normal conditions (mains powered and fully

charged battery), min. 10.5V DC when powered by secondary device

(before system shut down to battery deep discharge protection)

l SPC6350: 13–14V DC in normal conditions (mains powered and fully

charged battery), min. 10.5V DC when powered by secondary device

(before system shut down to battery deep discharge protection)

Low voltage trigger 11V DC

Overvoltage protection l SPC6330: 15.7V DC

l SPC6350: 15V DC nominal

Peak to Peak ripple Max. 5% of output voltage

Auxiliary power (nominal) l SPC6330: Max. 750mA at 12V DC

l SPC6350: Max. 2200mA at 12V DC (8 separately fused outputs, 300mA

per output)

Battery type

(Battery not supplied)

SPC6330:

l YUASA NP17-12FR (12V/17Ah) - NF

l YUASA Yucel Y17-12IFR (12V/17Ah)

l YUASA Yucel Y24-12FR (12V/24Ah)

l PowerSonic PS12170 (12V/7Ah)

l PowerSonic PS12260 (12V/26Ah)

SPC6350:

l YUASA NP17-12FR(12V/17Ah) - NF

l FIAMM FGV22703 (12V/27Ah) - NF

l YUASA NPL24-12IFR (12V/24Ah)

l Alarmcom AB1227-0 (12V/27Ah)

l PowerSonic PS12260 (12V/26Ah)

Battery charger SPC63xx: Max. 24h to 80% of battery capacity

Battery protection l SPC6330: Current limited to 1A (fuse protected), deep discharge

protection at 10.5V DC +/- 3%

l SPC6350: Current limited to 2A (protected by PTC resettable fuse), deep

discharge protection at 10.5V DC, low voltage indicator at 11V DC

Software update Local and remote upgrade for controller, peripherals and GSM/PTSN modems.

Calibration No calibration checks required (calibrated at manufacturing)

© Vanderbilt 2018 39 A6V10276959-d

12.09.2018

Page 40

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Serviceable parts l SPC6330: No serviceable parts

l SPC6350: 8 glass fuses (400mA AT) for 12V DC outputs

Operating temperature -10 to +50°C

Relative humidity Max. 90% (non condensing)

Colour RAL 9003 (signal white)

Weight l SPC6330: 6.400kg

l SPC6350: 18.600kg

Dimensions (W x H x D) l SPC6330: 326 x 415 x 114mm

l SPC6350: 498 x 664 x 157mm

Housing l SPC6330: Hinged metal housing (1.2mm mild steel)

l SPC6350: Metal housing (1.5mm mild steel)

Housing can contain up to l SPC6330: 4 additional expanders (size 150 x 82mm)

l SPC6350: 6 additional expanders (150 x 82mm) or 1 additional controller +

4 expanders

IP/IK Rating 30/06

ATS 10

ATP 30

Event Profiles 20

Event Exceptions 100

Command Profiles 10

1) Max. 400 m between devices/cable types IYSTY 2 x 2 x Ø 0.6mm (min.), UTP cat5 (solid core) or

Belden 9829.

2) More I/O expanders can be addressed instead of a keypad or door expander, but number of

programmable inputs/outputs cannot exceed specified system limits.

4.4 SPCP355.300

Number of on-board zones 8

EOL resistor Dual 4k7 (default), other resistor combinations selectable

Relay Outputs 3 (single-pole changeover, 30V DC/max. 1A resistive switching current)

Electronic Outputs 3 supervised (each max. 400mA resistive switching current),

Interfaces X-BUS (in, out, branch)

Mains Voltage 230V AC, +10 to -15%, 50Hz

Operating Current Max. 245mA at 12V DC (all relays activated)

Quiescent Current Max. 195mA at 12V DC

Output voltage 13–14V DC in normal conditions (mains powered and fully charged battery),

© Vanderbilt 2018 40 A6V10276959-d

12.09.2018

Page 41

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Technical Data

Auxiliary power (nominal) Max. 2360mA at 12V DC (8 separately fused outputs, max. 300mA per output)

Battery type

(Battery not supplied)

l FIAMM FGV22703 (12V/27Ah) - NF

l YUASA NP17-12FR (12V/17Ah)

l YUASA NPL24-12IFR (12V/24Ah)

l Alarmcom AB1227-0 (12V/27Ah)

l PowerSonic PS12170 (12V/17Ah)

l PowerSonic PS12260 (12V/26Ah)

l YUASA Yucel Y17-12IFR (12V/17Ah)

l YUASA Yucel Y24-12FR (12V/24Ah)

Tamper contact Front/back tamper switch

Operating temperature 0 to +40°C

Housing Metal housing (1.5mm mild steel)

Colour RAL 9003 (signal white)

Dimensions 498 x 664 x 157mm

Weight (without batteries) 18.400kg (housing incl. cover), 11.300kg (housing without cover)

IP/IK Rating 30/06

© Vanderbilt 2018 41 A6V10276959-d

12.09.2018

Page 42

5 Introduction

The SPC series controller is a true hybrid controller with 8 on-board wired zones that communicate with

intruder devices.

The flexible design of the controller allows the functional components (PSTN/GSM/RF) to be mixed and

matched, improving the capability of the system. Using this approach, an installer can ensure that an

efficient installation with minimal wiring is achieved.

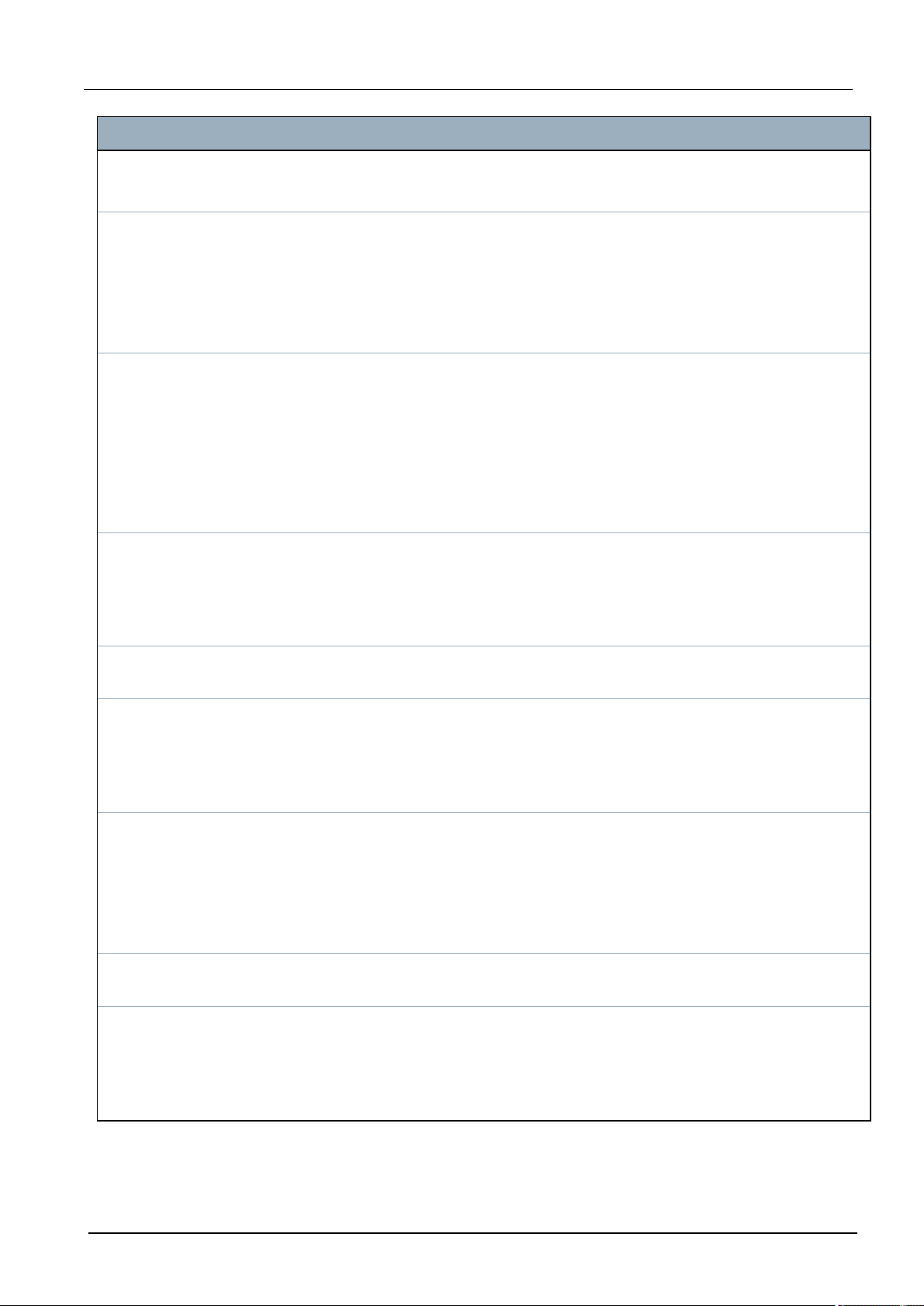

Overview

Number Description Number Description

1 PSTN 13 Wireless expander

2 GSM 14 PSU

3 Ethernet 15 Loop configuration

4 Wireless Receiver 16 PSTN network

5 AC mains 17 GSM network

6 Battery 12V 18 Broadband router

7 RF 19 Network

8 Wired outputs (6) 20 Central

9 Wired inputs (8) 21 LAN/WLAN

10 Keypads 22 Service desk

11 IO expander 23 Remote user

12 Output Expander 24 Mobile interfaces

© Vanderbilt 2018 42 A6V10276959-d

12.09.2018

Page 43

6 Mounting system equipment

This chapter covers:

6.1 Mounting a G2 housing 43

6.2 Mounting a G3 housing 44

6.3 Mounting a G5 housing 51

6.4 Mounting a keypad 56

6.5 Mounting an expander 56

6.1 Mounting a G2 housing

The SPC G2 housing is supplied with a metallic or plastic cover. The cover is attached to the base of the

housing by 2 securing screws located on the top and bottom of the front cover.

To open the housing, remove both screws with the appropriate screwdriver and lift the cover directly from

the base.

The G2 housing contains the controller PCB (Printed Circuit Board) mounted on 4 support pillars. An

optional input/output module can be mounted directly beneath the controller PCB. A battery with capacity

of 7Ah max. can be accommodated below the controller.

An optional external antenna must be fitted to housings with metallic lid if the wireless functionality is

required. If an antenna is fitted to the unit, it must be enabled in the firmware.

The SPC G2 housing provides 3 screw holes for wall mounting the unit.

To wall mount the housing, remove the cover and locate the initial fixing screw hole at the top of the

housing. Mark the position of this screw hole on the desired location on the wall and drill the initial screw

hole. Screw the unit to the wall and mark the position of the bottom 2 screw hole positions with the unit

vertically aligned.

Screws with a 4–5mm shank, a minimum head diameter of 8mm and a minimum length of 40mm are

recommended for mounting the housing. Additional expansion plugs or fixings may be required depending

on the construction of the wall.

© Vanderbilt 2018 43 A6V10276959-d

12.09.2018

Page 44

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

Standard housing

Number Description

1 Wireless antenna

2 SPC controller

3 Wall mounting screw holes

6.2 Mounting a G3 housing

The SPC G3 housing is supplied with a metallic front cover. The cover is attached to the base of the

housing by hinges and secured with one screw on the right hand side of the front cover.

To open the housing, remove the screws with the appropriate screwdriver and open the front cover.

The G3 housing contains the controller PCB (Printed Circuit Board) mounted on a hinged mounting

bracket. Expanders and PSUs can be mounted on the underside of the hinged mounting bracket and also

on the back wall of the housing underneath the mounting bracket.

© Vanderbilt 2018 44 A6V10276959-d

12.09.2018

Page 45

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

Number Description

1 Expanders/PSU

2 Controller

3 Expanders/PSU

4 Battery

An optional external antenna must be fitted to housings with metallic lid if the wireless functionality is

required. If an antenna is fitted to the unit, it must be enabled in the firmware.

The SPC G3 housing provides 3 screw holes for wall mounting the unit (see item 1 below).

Screws with a 4–5mm shank, a minimum head diameter of 8mm and a minimum length of 40mm are

recommended for mounting the housing. Additional expansion plugs or fixings may be required

depending on the construction of the wall.

© Vanderbilt 2018 45 A6V10276959-d

12.09.2018

Page 46

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

To wall mount the housing:

Open the cover and locate the initial fixing screw hole at the top of the housing.

1.

Mark the position of this screw hole on the desired location on the wall and drill the initial screw hole.

2.

3. Screw the unit to the wall and mark the position of the bottom 2 screw hole positions with the unit

vertically aligned.

Back Tamper Requirements

A back tamper switch may be required by your local approval.

The back tamper switch is delivered with SPC panels in G3 housings or is available as an optional extra

with a mounting kit (SPCY130). EN50131 G3 panels (SPCxx3x.x20) are supplied with a back tamper kit

as standard.

6.2.1 Mounting a Back Tamper Kit

The SPC back tamper kit provides SPC control panels and power supplies with the option of having back

tamper as well as front tamper.

The back tamper kit comprises the following parts:

l Tamper switch

l Leads for connecting the back tamper switch to the controller

l Wall fixing plate

© Vanderbilt 2018 46 A6V10276959-d

12.09.2018

Page 47

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

Mounting the Wall Fixing Plate

1. Mount the SPC in the appropriate position on the wall using all three fixings (see item 1 below).

2. Draw a line around the inside of the back tamper cut out (see item 2 above) to provide a guide for

the wall plate on the fixing wall. Remove the housing from the wall.

3. Place the wall plate (see item 1 below) on the wall centering it precisely around the rectangle

previously drawn (see item 2 below).

4. Ensure all four flanges on the wall plate are flush with the wall.

5. Mark the four fixings on the wall plate.

6. Drill and use suitable screws (max. 4mm) for the wall substrate.

7. Fit the wall plate to the wall.

Fitting the Back Tamper Switch

1. Insert the tamper switch (see item 2 below) into the back of the housing so that the plunger faces

outwards (see item 1 below).

© Vanderbilt 2018 47 A6V10276959-d

12.09.2018

Page 48

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

2. Fit the housing back onto the wall using the three fixings previously removed (see item 2 below).

Visually check to ensure there is a flush finish between the wall plate and the housing metalwork.

© Vanderbilt 2018 48 A6V10276959-d

12.09.2018

Page 49

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

Number Description

1 Housing

2 Wall

3 Wall Fixing Plate

4 Tamper Switch

WARNING: If the wall fixing plate is not accurately aligned then the housing will not sit properly on

its fixings.

Wiring the Back Tamper Switch to the Control Panel

All control panels have spare inputs configured as tamper inputs that are designed for wiring the tamper

switch and do not require any programming.

This tamper switch will be referred to as ‘Aux Tamper 1’ by the system.

© Vanderbilt 2018 49 A6V10276959-d

12.09.2018

Page 50

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

1. Connect NO on the tamper switch to T1 on the controller.

2. Connect COM on the tamper switch to C on the controller. Ensure the T2 jumper is not removed.

3. When the tamper switch is wired, the controller can be commissioned in the normal manner.

6.2.2 Battery installation for EN50131 compliance

For EN50131 compliance the battery needs to be retained within the housing to stop movement. This is

achieved by bending out the flaps in the rear of the Hinged Housing so that the battery is retained.

If a 7Ah battery is used then the battery is biased to the left of the housing and bottom flap is bent to meet

the battery.

If a 17Ah battery is used then the battery is biased to the right of the housing and middle flap is bent to

meet the battery.

The battery flaps should be bent carefully as not to damage the battery. If any signs of a damaged

battery exist or any leakage of the electrolyte then the battery should be discarded as per the current

regulations and a new battery fitted.

© Vanderbilt 2018 50 A6V10276959-d

12.09.2018

Page 51

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

6.3 Mounting a G5 housing

The SPC G5 housing comprises of a metallic base and front cover. The cover is attached to the base of

the housing by 4 securing screws located on the top and bottom of the front cover.

To open the housing, remove all the screws with the appropriate screwdriver and lift the cover directly

from the base.

The G5 housing contains the controller PCB (Printed Circuit Board) and the SPCP355.300 Smart PSU,

both mounted on 4 support pillars. An 8 In/2 Output Expander is mounted on top of the PSU. Four extra

pillars are included to give you the option to mount the 8 In/2 Output Expander below the PSU board in

the G5 housing. Additional expanders can be installed in the housing as shown.

Number Description Number Description

1 Battery 6 Battery temperature leads

2 Battery strap 7 PSU

© Vanderbilt 2018 51 A6V10276959-d

12.09.2018

Page 52

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

Number Description Number Description

3 Fixing tabs 8 Optional expander positions

4 Strap holes 9 Controller

5 Battery leads 10 Antenna

Two batteries, with a maximum capacity of 27Ah, can be accommodated in the battery compartment at

the bottom of the housing.

An optional external antenna must be fitted to a metallic housing if wireless functionality is required.

Knockout holes are available in three positions on the top of the housing where the antenna can be

installed. If an antenna is fitted to the unit, it must be enabled in the firmware.

The SPC G5 housing provides 4 screw holes for wall mounting the unit.

Number Description

1 Corner fixings

2 Tamper cutout

3 Shelf separating battery compartment

4 Telecom socket cutout

6.3.1 Tamper protection

The tamper switch and back tamper bracket are fitted to the housing. The switch is used on its own for

front tamper purposes only or used with the back tamper bracket for both front and back tamper protection.

Either back or front tamper protection is required depending on local approval.

The tamper bracket is held firmly in place with a securing screw. Remember to remove this screw if

commissioning the system for back tamper protection. Do not remove this screw if using front tamper

only.

© Vanderbilt 2018 52 A6V10276959-d

12.09.2018

Page 53

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

6.3.2 Mounting the housing with tamper protection

To mount the housing:

1. Using the supplied mounting template, mark the 4 drill positions for fixing the housing to the wall.

2. Drill and install suitable screws (see enclosed template) into the wall. Leave the screws

protruding 1.5cm from the wall.

3. The G5 housing is pre-configured for front tamper only. To configure the housing for both front

and back tamper, remove the front tamper securing screw (item 1).

The tamper bracket swings to the far right of the orientation slot (item 6).

4. Mount the G5 housing in the appropriate position on the wall and tighten the 4 mounting screws.

Ensure that the housing is flush with the wall surface.

5. Move the tamper bracket to the far left of the orientation slot and tighten the back tamper screw

(item 5) to the wall. The tamper bracket should be perpendicular to the back wall of the housing.

6. Install the lid on the housing to test the tamper switch connection. Lift the lid by approximately

1mm to activate the tamper switch.

Number Description Number Description

1 Front tamper securing screw 5 Back tamper screw

2 Tamper bracket 6 Orientation slot

3 Tamper switch 7 Shelf separating battery compartment

4 Back tamper cutout

WARNING: If the back tamper screw is not secure against the wall, then tamper protection is

compromised. If the housing is removed from the wall or displaced, the back tamper contact needs

to be tested again for proper functionality and re-adjusted if required.

© Vanderbilt 2018 53 A6V10276959-d

12.09.2018

Page 54

SPC4xxx/5xxx/6xxx – Installation & Configuration Manual Mounting system equipment

6.3.2.1 Tamper operation

Tamper switch - normal

Number Description

1 Wall

2 Back tamper screw

3 Back wall of housing