Page 1

CHSM2210/2211

Medium Camera Housing

Installation Guide

Page 2

© Vanderbilt 2016

2

Data and design subject to change without notice. / Supply subject to availability.

© 2016 Copyright by Vanderbilt

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Page 3

© Vanderbilt 2016

3

Contents

1 Safety ....................................................................................................... 5

1.1 Target group .............................................................................................. 5

1.2 General safety precautions ....................................................................... 5

1.3 Meaning of the signal words ..................................................................... 6

1.4 Meaning of the hazard symbols ................................................................ 6

2 EU Directives ........................................................................................... 7

3 Technical data ......................................................................................... 8

3.1 Specifications ............................................................................................ 8

3.2 Mechanical dimensions ............................................................................. 9

3.3 Key to parts ............................................................................................... 9

4 Scope of delivery .................................................................................. 10

5 Installation ............................................................................................. 11

5.1 Accessing the inside of the housing enclosure ....................................... 11

5.2 Fitting the power supply modules ........................................................... 12

5.3 Cable entry into the camera housing ...................................................... 14

5.4 Fitting the camera and lens ..................................................................... 14

5.5 Mounting the camera housing assembly ................................................ 15

5.6 Connecting to the power supply .............................................................. 16

5.7 Adjusting the sunshield ........................................................................... 17

6 Maintenance and service ..................................................................... 18

7 Disposal ................................................................................................. 18

Page 4

Page 5

© Vanderbilt 2016

5

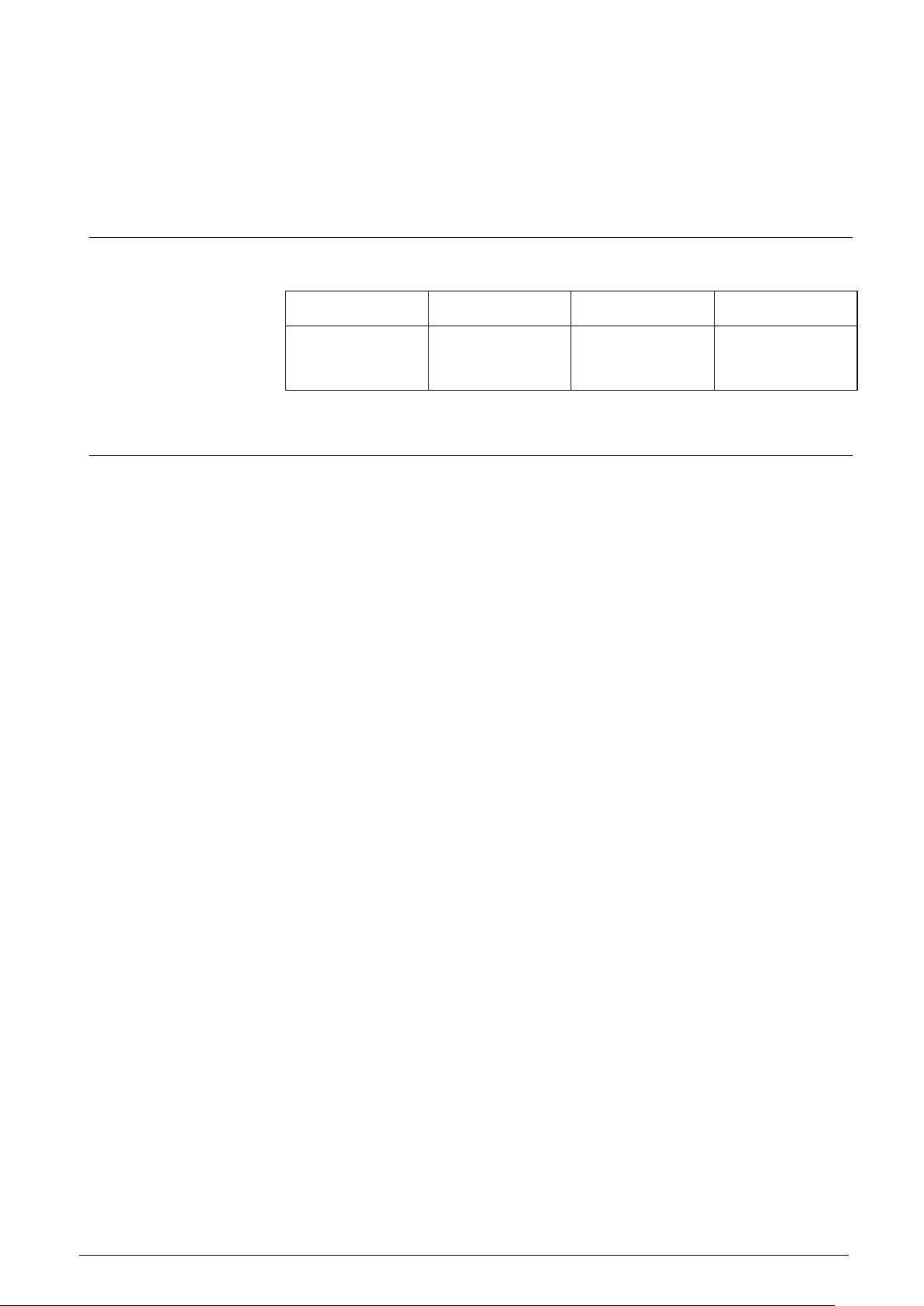

1 Safety

Target readers

Qualification

Activity

Condition of the

product

Installer

Technical training for

building or electrical

installations.

Installs the product,

individual components

of the product or

replacement parts.

Components of the

product are not yet

installed or need to be

replaced or modified.

1.1 Target group

The instructions in this document are designed only for the following target group.

1.2 General safety precautions

Read the general safety precautions before operating the device.

Follow all warnings and instructions marked on the device.

Keep this document for reference.

Always pass this document on together with the product.

Please also take into account any additional country-specific, local safety

standards or regulations concerning project planning, operation and disposal of

the product.

It is recommended that all possible work be carried out in a workshop prior to

final installation.

Safety

Liability claim

Do not connect the device if it is damaged or any parts are missing.

Do not make any changes or modifications to the device unless they are

expressly mentioned in this manual and have been approved by the

manufacturer.

Use only spare parts and accessories that have been approved by the

manufacturer.

Risk of failure due to incorrect installation

The fuse for the device and the fuse for the electrical system of the building must

be installed separately.

Risk of cable damage due to stress

Use only cable types that are approved for the environmental requirements.

The cable glands used must be appropriate for the cable diameter.

Page 6

Safety

© Vanderbilt 2016

6

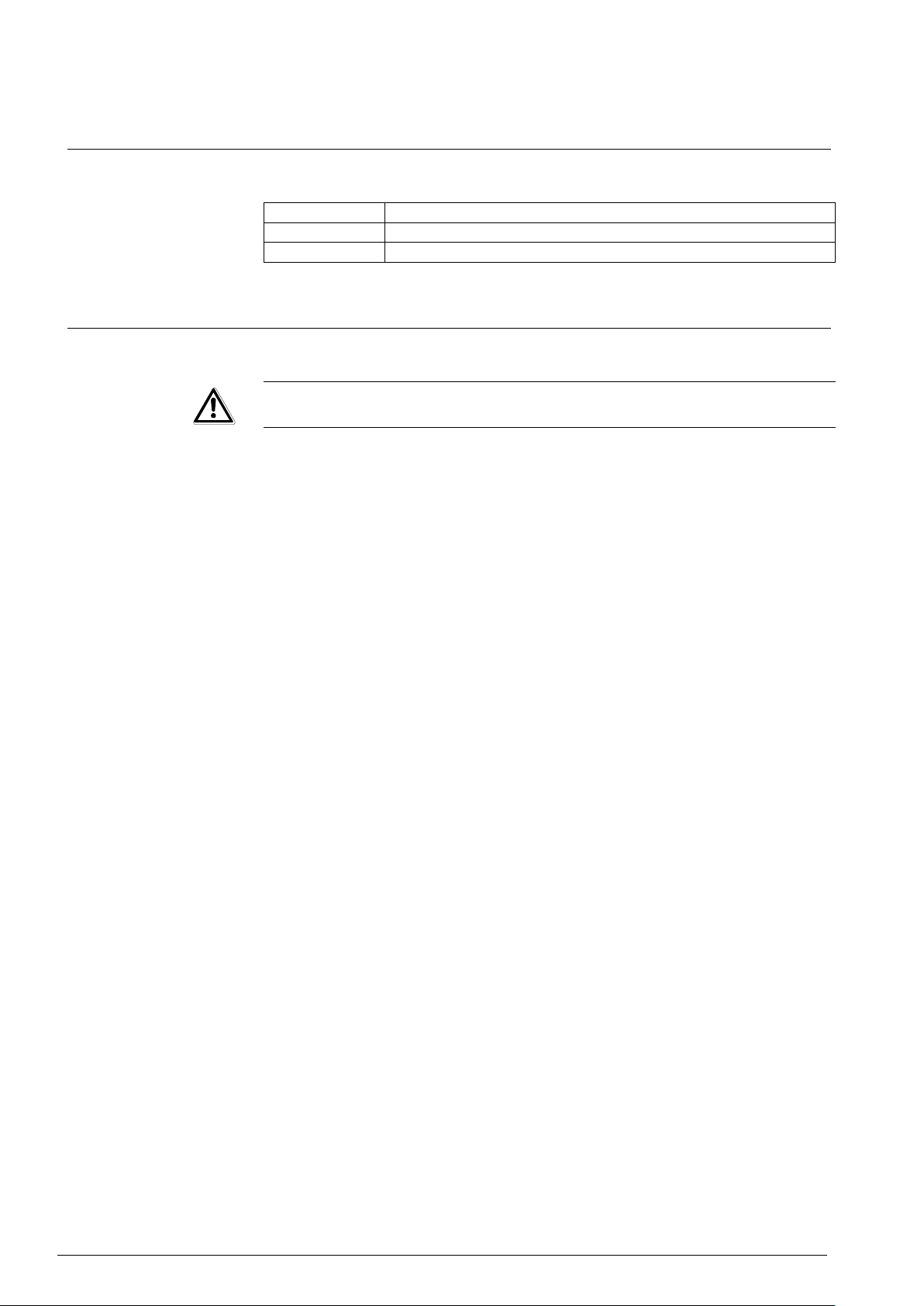

Signal word

Type of hazard

CAUTION

There is a risk of minor to medium injuries or damage to property

IMPORTANT

Malfunctioning may result

Warning of a hazard

1.3 Meaning of the signal words

The severity of a hazard is indicated by the following written warning notices.

1.4 Meaning of the hazard symbols

The nature of the hazard is indicated by icons.

Page 7

© Vanderbilt 2016

7

2 EU Directives

Emitted interference:

EN 61000-3-2

EN 61000-3-3

EN 55022 Class B

Resistance to interference:

EN 50130-4

Safety:

EN 60950-1

The product complies with the requirements of the following EU directives. The EU

declaration of conformity is available from:

Vanderbilt

Clonshaugh Business and Technology Park

Clonshaugh

Dublin 17

Ireland

www.vanderbiltindustries.com

EU Directive 2004/108/EC on electromagnetic compatibility

Conformity with the European Directive 2004/108/EC is demonstrated by

compliance with the following standards:

EU Directives

EU Directive 2006/95/EC “Low-Voltage Directive”

Compliance with the European Directive 2006/95/EC has been proven by testing

according to the following standard:

Page 8

Technical data

© Vanderbilt 2016

8

Nominal Voltage

CHSM2210: 110 – 230 V AC, 50/60 Hz

CHSM2211: 12 – 24 V AC, 50/60 Hz

Fuse Rating (Fuse F1)

CHSM2210: 2 A, 250 V AC, 5 x 20 Type (T), HBC

CHSM2211: 5 A, 250 V AC, 5 x 20 Type (T), HBC

Electrical Connections

Main supply connections via fused PCB mounted terminal blocks.

Use crimped ferrules when terminating cables.

6 way pillar terminal block available for user connections.

Cable Entry

1 x 20 mm Cable Gland (6 – 12 mm diameter cable range)

2 x 16 mm Cable Glands (5 – 10 mm diameter cable range)

Heater

Nominal: 7 W

max.: 25 W

PTC resistor heating element, thermostatically controlled.

Environmental

Operating Temperature

-20 to +60 °C

Ensure fitted equipment has suitable temperature range for the

application (e.g. maximum typical ambient operating temperature of

camera and lens. Ta = 40 °C).

Maximum internal dissipated power

30 W

Relative humidity

Up to 95 % non-condensing

Ingress Protection

IP66, BS EN 60529

Material

Toughened Glass Window

Housing body/Sunshield/Mounting rails: Aluminium extrusions

End caps: Die cast aluminium

Finish

Housing body: Polyester powder coat, RAL9006 White Aluminium

Sunshield: Polyester powder coat, RAL9006 White Aluminium

End caps: Polyester powder coat, RAL7016 Grey

Internal Dimensions (L x W x H)

300 x 85 x 85 mm

Weight

2.5 kg

Suitable Pan and Tilt Units

CDD2425, CDD2416-T, CDAP2316-T, CDAP2416-T

Suitable Brackets

CHBS2815, CDBS4540 + CAHA1040

3 Technical data

3.1 Specifications

Page 9

© Vanderbilt 2016

9

3.2 Mechanical dimensions

1

246 mm

2

208 mm

3

3 mm

4

66 mm

5

133 mm

6

76 mm

7

125 mm

1

Front End Cap

6

Cable Anchors

2

Housing Body

7

Terminal Board

3

Sunshield

8

Camera Mounting Slot

4

Rear End Cap

9

Demister Assembly

5

Cable Glands

10

Window

Fig. 1 Mechanical dimensions

Technical data

3.3 Key to parts

Fig. 2 Key to parts

Page 10

Scope of delivery

© Vanderbilt 2016

10

NOTE

The complete assembly should be mounted and tested in the workshop prior to use on-site.

Type

Designation

CAPD1210-C230

12 V DC 500 mA PSU 230 V AC input

4 Scope of delivery

Camera housing assembly

Installation Guide

Camera fixing screw (¼” BSW x ½” hex hd.)

Camera fixing screw (¼” BSW x ¾” hex hd.)

Spacer block (1.6 mm thick)

Spacer block (3 mm thick)

2.5 mm (across flats) ALLEN Key, long reach

Camera plate insulator

Shoulder washer (to insulate screw from camera mounting plate)

Accessories

Page 11

© Vanderbilt 2016

11

5 Installation

NOTE

To re-assemble carry out steps 1 to 4 in reverse, making sure the earth wire is reconnected. The two

M4 screws which secure the housing to the rear cap should be retightened to a torque of 2 Nm.

1

Sun Shield

2

Demister

3

Termination Board

4

Cable Anchor

5

Rear Cap

6

Camera Mounting Plate

7

Housing Cover

5.1 Accessing the inside of the housing enclosure

1. Undo the two M4 captive screws that secure the housing cover to the rear cap

assembly and slide the housing cover forward slightly.

2. Disconnect the earth wire from the termination board.

3. Slide the housing cover all the way forward towards the front of the camera

mounting plate, until it hinges downward (see Fig. 3).

4. If required, you can remove the housing cover from the camera mounting

plate by twisting it slightly and withdrawing it from the hinge pins.

Installation

Fig. 3 Inside the housing enclosure

Page 12

Installation

© Vanderbilt 2016

12

1

M3 Screw

2

12 V DC Power Supply Module

5.2 Fitting the power supply modules

In some installations the camera requires a 12 V DC power supply; Vanderbilt

power supply module CAPD1210-C230 is available and mounts inside the rear end

cap (see Fig. 4). It is fused by connecting it through the terminal board. To fit the

module:

1. Secure the module in the rear end cap using two M3 screws and lock washers

(see Fig. 4), taking care not to trap any cables.

Fig. 4 Power supply module

2. Cut the module’s input cables (brown/blue) to a suitable length and connect

them to the termination board’s “Fused Output” terminals (brown – live; blue –

neutral). See section 5.6 for terminal board details.

3. Connect the module’s output cable to the camera supply terminals after fitting

the camera (White stripe or ribbed stripe – positive, +12 V DC; black –

negative, 0 V.). Use suitable cable clips (not supplied, see Fig. 5).

Page 13

© Vanderbilt 2016

13

Fig. 5 Power supply module cable routing

1

12 V DC power supply module

2

Suitable cable clip (not supplied)

3

PSU module output cable to camera

supply terminals

4

PSU module input cable

5

‘Fused output’ terminals

IMPORTANT

Ensure all SELV and signal wiring is kept away from live parts and is suitably

protected from live parts by double insulation.

Installation

Page 14

Installation

© Vanderbilt 2016

14

1

Camera

4

Adjustment location slot

2

Spacer block

5

Shoulder washer

3

Camera plate insulator

6

Mounting screw (1/4 BSW) 1/2” or 3/4”

5.3 Cable entry into the camera housing

The camera housing is supplied fitted with two M16 (5 – 10 mm diameter cable

range) compression glands and one M20 (6 – 12 mm diameter cable range)

compression gland. These glands should be suitable for most power and video

signal cables and are positioned on the rear cap of the housing. To feed a cable

through a gland:

1. Select the appropriate cable gland for the cable being used and remove the

blanking plug from the gland by unscrewing the compression nut.

2. Pass the selected cable through the seal, gland and nut.

3. Pull through sufficient cable to allow termination in the housing.

4. Clamp the cable securely using one of the cable anchors. The central anchor

point is for larger cables, the two outer ones are for smaller cables. Do not

overtighten the screws as this may damage the cable.

5. Tighten the compression nut to ensure a weatherproof seal.

5.4 Fitting the camera and lens

The camera should be mounted so that the lens is aligned with the centre of the

housing window and as close to the window as possible.

1. With the slots aligned, fit the self-adhesive camera plate insulator to the

camera plate (see Fig. 6).

Fig. 6 Mounting the camera and lens assembly

2. Position the camera at the required height by placing the appropriate spacer

blocks between the mounting plate and the camera. Note that two thicknesses

of spacer are supplied.

3. Place the supplied shoulder washer through the slot in the camera mounting

plate from the bottom up, then feed the mounting screw through the washer

and spacer blocks and screw into the camera mounting.

4. Adjust the camera position before you fully tighten the mounting screw.

5. Connect power to the camera as described in Section 5.6.

Page 15

© Vanderbilt 2016

15

6. Terminate and connect the necessary video signal cable to the camera (e.g.

1

Rear end cap

2

Compression glands

3

4 M6 tapped holes on 101.6 mm (4”) PCD

4

Compression glands

coax cable).

5.5 Mounting the camera housing assembly

The housing has a set of 4 x M6 (10 mm deep) tapped holes on a 101.6mm (4”)

PCD for mounting the camera housing to a bracket. Ensure that the screws used to

mount the housing to a bracket are not too long, so there is no risk that they will

bottom out in the mounting holes.

1. Secure the chosen bracket to the mounting surface, following the installation

guide supplied with the bracket.

2. Screw the mounting bracket to the base of the unit (see Fig. 7) using suitable

screws.

3. Position the assembly as required to obtain the desired video image.

4. Ensure all fasteners are tightened correctly, use anti-vibration fixings where

necessary.

Installation

Fig. 7 Mounting the camera housing assembly

Page 16

Installation

© Vanderbilt 2016

16

IMPORTANT

Read section 1: Safety before connecting to the Power Supply.

IMPORTANT

All wiring must be installed to local and national standards. Ensure all SELV and

signal wiring is kept away from live parts and is suitably protected from live parts

by double insulation.

CAUTION

A readily accessible all-pole disconnect device with at least 3 mm contact

separation shall be incorporated in the building installation wiring. As part of the

building installation, protect the unit via a fuse or circuit breaker rated at 2 A for

CHSM2210 110 – 230 V AC units and 5 A for CHSM2211 12 – 24 V AC units.

NOTE

Use only cable suitable for the application and that meets the standards required by the installation.

The conductor size for power cable(s) must be at least 0.75 mm2. The maximum recommended

conductor size is 1.5 mm2.

Indicator

Description

L

Live (Brown)

N

Neutral (Blue)

E

Earth (Green/Yellow)

1

Ancillary Connections Block

2

Fused Output

3

Earth (Gnd)

4

Input Supply Terminal

5

Fuse F1

2 A 250 V AC 5 x 20 Type (T), HBC for T462 (230 V AC)

5 A 250 V AC 5 x 20 Type (T), HBC for T463 (24 V AC)

6

Heater Output (pre-wired and connected through fuse F1)

5.6 Connecting to the power supply

1. Bring the power supply cable into the housing through the correct size gland,

as described in section 5.3.

2. Connect the power cable to the terminal board at the “Input supply terminal”

(see Fig. 8), it is recommended to use crimp ferrules on the cores.

3. It is possible to move the terminal board assembly along the camera mount

rail. Loosen the M3 screw and move the assembly, then retighten the screw.

Fig. 8 Terminal board connection details

Page 17

© Vanderbilt 2016

17

5.7 Adjusting the sunshield

1. Firmly squeeze (A) the sides of the sunshield (See Fig. 9).

2. Slide (B) the sunshield to the required position.

3. Release the sunshield and it will remain in position.

Fig. 9 Sunshield adjustment

Installation

Page 18

Maintenance and service

© Vanderbilt 2016

18

Cleaning

Use only soap and water to clean the housing and window – no abrasive solvents. Additional

protection can be applied to the window to reduce contamination and droplet formation from moisture

or rain. Products from the automotive or cleaning industry which use nanotechnology to reduce

surface energies and thus contamination and moisture build-up can be used for this purpose.

6 monthly checks

1. All fastenings and cables should be checked for tightness and wear.

2. Regular checks should be performed to ensure that the outer sheaths of the cables are not

damaged and that the cables are not fouling on any obstruction.

NOTE

This installation guide cannot cover all conceivable cases of installation, operation or maintenance.

Should you require further information or should special problems occur which are not discussed in

adequate detail in the installation guide, please request the required information from your local

Vanderbilt office.

We must also point out that the contents of this installation guide do not constitute a part of an earlier

or existing agreement. Neither do they constitute or amend any earlier or existing commitment or legal

relationship. All obligations on the part of Vanderbilt result from the relevant purchase agreement

which also contains the complete and solely valid warranty regulations. This installation guide neither

extends nor restricts these contractual warranty regulations.

All electrical and electronic products should be disposed of separately from the

municipal waste stream via designated collection facilities appointed by the

government or the local authorities.

This crossed-out wheeled bin symbol on the product means the product is covered

by the European Directive 2002/96/EC.

The correct disposal and separate collection of your old appliance will help prevent

potential negative consequences for the environment and human health. It is a

precondition for reuse and recycling of used electrical and electronic equipment. For

more detailed information about disposal of your old appliance, please contact your

city office, waste disposal service or the shop where you purchased the product.

6 Maintenance and service

The following maintenance guidelines should be observed.

7 Disposal

Page 19

Page 20

Issued by Vanderbilt

Clonshaugh Business and Technology Park

Clonshaugh

Dublin 17

Ireland

www.vanderbiltindustries.com

© Vanderbilt 2016

Data and design subject to change without notice

Supply subject to availability

Document no.: C-301053

Document version: 2.0

Edition:23/05/2016

Loading...

Loading...