Page 1

© 2017 Vanderbilt 1 / 4 021_AGB800-AM_I-200259_EN

Acoustic Glass Break Detector

with Antimasking

Instruction and installation manual AGB800-AM

EC DECLARATION OF CONFORMITY

Hereby, Vanderbilt International (IRL) Ltd declares that this

equipment is in compliance with all relevant EU Directives for

CE marking. From 20/04/2016 it is in compliance with Directive

2014/30/EU (Electromagnetic Compatibility Directive).

The full text of the EU declaration of conformity is available at:

http://pcd.vanderbiltindustries.com/doc/intrusionaccessories

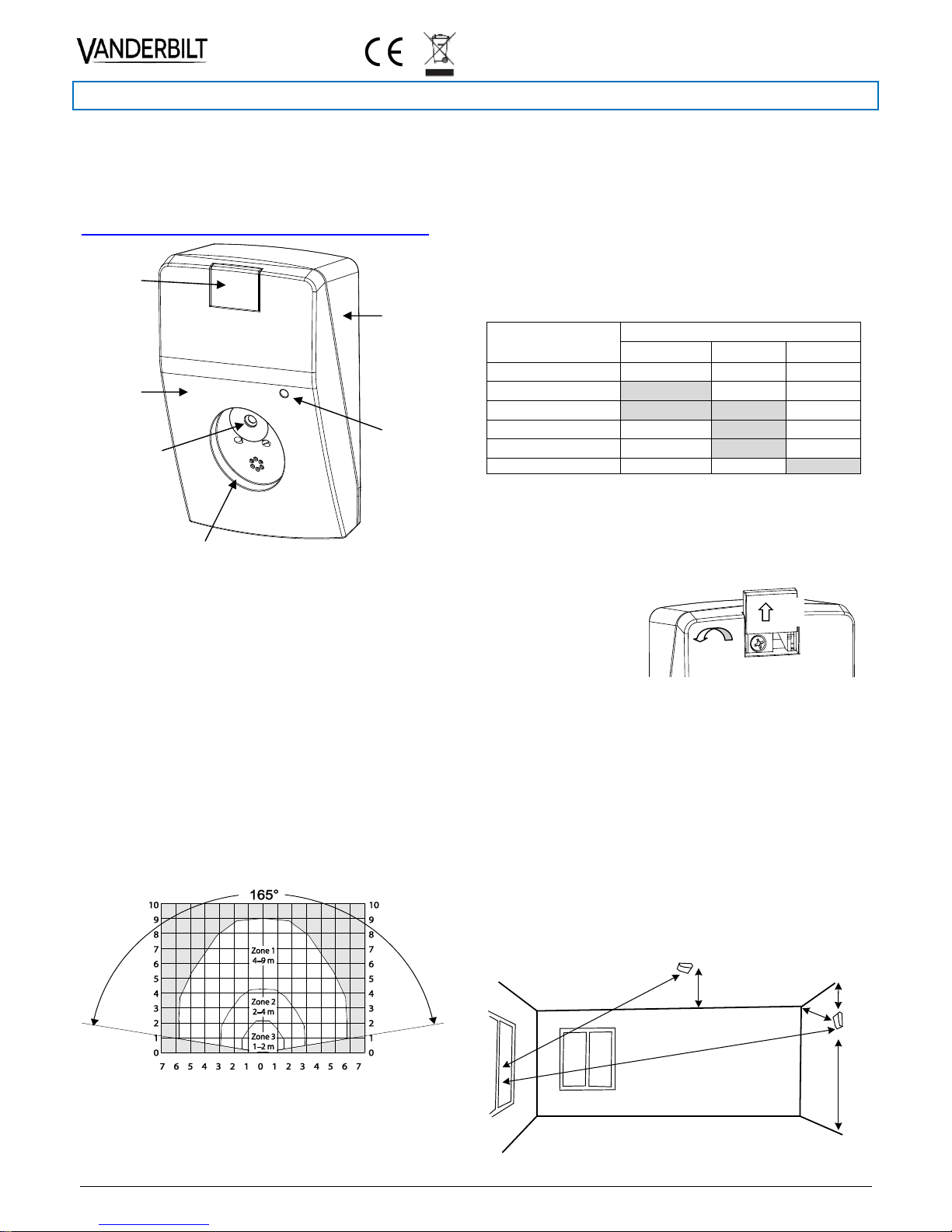

DESCRIPTION

AGB800-AM is an acoustic glass break detector giving an

alarm when glass is smashed at intruder attempts through windows, doors and glazed walls.

The detector is based on advanced microcontroller technology

and programmed to take a lot of relevant acoustic factors into

account: The Digital Room Compensation (DRC). This makes

the detector able to distinguish between a true glass break and

other irrelevant sounds.

The detector is for indoor use. The coverage distance is 1–9 m.

The coverage angle is 165º, which means that one detector can

protect several windows in the same room. The detector can

be mounted in the ceiling or on a wall with a free “line-of-sight”

to the window being protected.

AGB800-AM is equipped with an AM function, a separate relay,

which gives an alarm at sabotage of microphone.

AGB800-AM is certified according to EN 50131-2-7-1:2012,

security grade 3.

Coverage area in the acoustic room Zone 1–3

CONNECTION TO A 24-HOUR LOOP

The detector is constructed for continuous supervision and is

extra resistant to different acoustic disturbances. It will function

well in most environments. However in rooms with very high

rates of disturbances as in industrial workshops and gyms, it is

recommended to test the detector for 3–4 weeks before deciding to use it continuously. In rare cases a combination of random sounds can trigger an alarm.

SIGNALLED EVENTS

Detector has two relays and one micro-switch to signal detected and processed events to control panel in prioritised order

as following signals:

Glass break – signalled by INTRUSION relay

Low power supply voltage or self-test fail – signalled by

FAULT relay

Masking – signalled by INTRUSION and FAULT relay

Sabotage is signaled independently by TAMPER micro-switch.

Event

Signal sent by relay or micro-switch

INTRUSION

FAULT

TAMPER

No stimulus

Closed

Closed

Closed

Intrusion

OPEN

Closed

Closed

Masking

OPEN

OPEN

Closed

Low Supply Voltage

Closed

OPEN

Closed

Local Self-Test Fail

Closed

OPEN

Closed

Tamper

Closed

Closed

OPEN

SPECIAL TOOLS

In most rooms (e.g. offices) no special tools are required during

the installation. In rooms with complicated acoustics it is recommended to use the ADT700 tester. ADT700 can also be

used for function test and annual service.

OPENING THE DETECTOR

MOUNTING INSTRUCTIONS

Detector should be installed on a ceiling or on a wall oppo-

site to the glass to be protected

Clear “line-of- sight” between the “microphone” of the de-

tector and the glass is required

Distance between the glass and the detector should be 1–9m

Detector should be installed min. 50cm from a corner

Detector should be installed min. 1m over the floor

Detector should be installed min. 30cm from the ceiling (at

wall mounting)

Detector should be installed on a flat surface, which is free

from objects in a radius of 50cm from the detector

Detector should not be installed close to air vents or big

sound reflecting obstacles

Never mount the detector in the corners

Base

Cover

Cover

lock

LED

Microphone

Masking detection device

Slide the lock cover up

Loosen the screw

Pull cover to open

min. 0.5 m

max

.

8

.

5

m

max

. 9

m

min. 0.3 m

min. 0.5 m

min.

1 m

Location for wall or ceiling mount

Page 2

© 2017 Vanderbilt 2 / 4 021_AGB800-AM_I-200259_EN

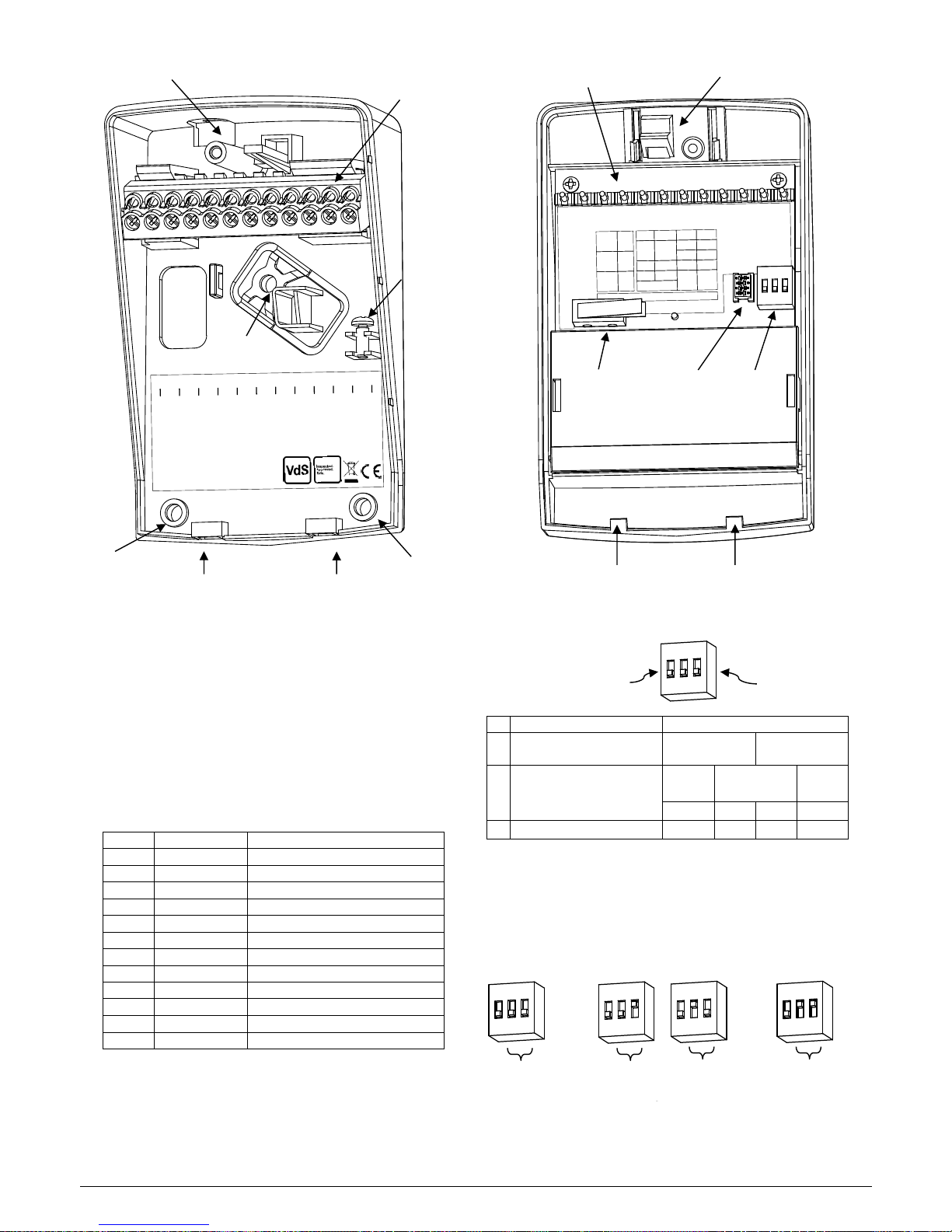

DETECTOR BASE AFTER REMOVAL OF THE COVER

INSTALLATION

1. Choose the best mounting position on the wall or ceiling.

2. Loosen the cover screw and remove the upper part

3. Use the bottom part as a template and mark the place of

the holes of with a pen

4. Use a 2.5mm drill for the self-tapping screws provided. If

necessary, use wall anchors

5. If necessary, cut out the marked “knockout hole” on the

back of the base with a pair of pliers

6. Pull the wiring cable through the “knockout hole” in the bot-

tom plate

7. Connect the wires to the screw terminals

Pin

Marking

Function

1

(-)

Ground

2

(+)

Plus 7 to 30 V DC

3

D/N

Day and Night control of LED

4

INTRUSION

INTRUSION relay output C

5

INTRUSION

INTRUSION relay output NC

6

Spare

Spare contact (unconnected)

7

FAULT

FAULT relay output C

8

FAULT

FAULT relay output NC

9

Spare

Spare contact (unconnected)

10

TAMPER

Tamper switch output C

11

TAMPER

Tamper switch output NC

12

Spare

Spare contact (unconnected)

8. Use the cable strap provided to fix the wiring cable to the

detector.

9. Fix the detector firmly to the base with the enclosed

screws.

COVER SEEN FROM BELOW

UNDERSTANDING THE DIP SWITCH

#

Function

Setting

1

INTRUSION relay

mode

ON – Latch

OFF – Auto

2

Range setting

4–9m

Zone1

2–4m

Zone 2

1–2m

Zone 3

OFF

OFF

ON

ON

3

Range setting

OFF

ON

OFF

ON

DIP1=ON: INTRUSION relay mode ON means the INTRUSION relay will Latch and be open in alarm.

DIP1=OFF: INTRUSION relay mode OFF means the INTRUSION relay will be auto reset after 2 seconds in alarm.

10. Set the desired range, i.e. the detector sensitivity setting

by using the DIP switch no 2 and 3.

11. Check the window constructions and note what kind of

glass is used and especially in the pane closest to the

room.

Mounting

hole #2

Slots for assembling

the cover hooks

Mounting

hole #3

Mounting

hole #1

Terminal

block

Cable jacket

“knock-out”

Cover

screw

4

5

INTRUSION

7

8

FAULT

10

11

TAMPER

1

(

-

)

2

(+)

3

D/N

6

Spare

9

Spare

12

Sp.

Acoustic Glass Break Detector

with Antimasking

EN 50131

-

2

-

7

-

1 Security Grade 3

EN 50130

-

5 Environmental Class I

VdS 117504

AGB 800

-

AM

Vanderbilt Intl (IRL) Ltd.

Clonshaugh Business Park

Clonshaugh, Dublin, D17 KV84

Ireland, V54535

-

Z130

-

A100

Terminal block pins

Tamper

switch

DIP

switch

PC

interface

Hooks holding the cover to the base

Cover lock

AGB 800

-AM

PC interface

USB

-

link

12

Sp.

11

9

Sp.

7

6

Sp.

1

(

-

)

2

(+)

3

D/N

8

10

FAULT

TAMPER

4

5

INTRUSION

DIP Switch Settings

Acoustic Glass Break

Detector w. Antimasking

4

-

9 m

OFF

OFF

OFF

2

Range

3

ON

2

-

4 m

ON

OFF

ON

ON

1

-

2 m

Relay

mode

Latch

Auto

Reset

1

OFF

ON

DIP

Switch

1

2

3

Zone

Setting

ON

1

2

3

ON

1

2

3

INTRUSION relay

mode (DIP1)

Range setting

(DIP2, DIP3)

4–9m, Zone 1

OFF, OFF

2–4m, Zone 2

OFF, ON or ON,

1–2m, Zone 3

ON, ON

ON

1

2

3

ON

1

2

3

ON

1

2

3

ON

1

2

3

Page 3

© 2017 Vanderbilt 3 / 4 021_AGB800-AM_I-200259_EN

SUGGESTED SETTINGS OF THE DETECTOR DEPENDING ON WINDOW DESIGN AND TYPE OF GLASS:

Check the window constructions and note what kind of glass is

used and especially in the pane closest to the room.

Single glazed (float & tempered) – Set the detector at the

measured distance from the glass to the detector.

Double glazed (float & tempered). If there are high disturb-

ances in the surroundings – set the detector at the measured distance from the glass to the detector. At normal or

low disturbances – the detector shall be set at Zone 1.

Double glazed where the inner pane is covered with secu-

rity film – Set the detector at Zone 1 apart from the meas-

ured distance.

Triple glazed (float & tempered) – Set the detector at Zone

1 apart from measured distance.

Laminated glass – Set the detector at Zone 1 apart from

the measured distance.

Window design

Glass type of pane inside room

Range

1–2m

2–4m

4–9m

1

Single glazed

Float & tampered

Zone 3

Zone 2

Zone 1

2

Double glazed

Float & tampered

High disturbances

Zone 3

Zone 2

Zone 1

Low disturbances

Zone 1

3

Triple glazed

Float & tampered

Zone 1

4

Double glazed with security film

Float with security film

Zone 1

5

Single & multi-glazed

Laminated

Zone 1

CHECK THE SETTINGS WITH ADT700 TESTER

If the detector is placed too far or too close from the glass, it

will not respond. At DRC testing the LED of the detector will

flash 1, 2 or 3 times to show it is in a certain Zone. If it does not

flash a better place must be selected.

1. Put the cover on and make sure it hooks properly into the

base of the detector.

2. Apply power – LED will now indicate your range setting by

blinking 1–3 times.

3. Use ADT700 to test and calibrate the detector for optimal

position.

TESTING AND CALIBRATING

ADT700 tester is a specially developed tool for calibrating and

adjusting the detector AGB800-AM for optimal function in the

acoustic room – the DRC Digital Room Compensation procedure. When testing the detector settings you do not need to

open it again as the tester will communicate with the detector

acoustically. Never test the AGB800-AM with a cover disassembled from a base. Make sure the cover is fastened properly.

Caution: Do not use the ADT700 tester in proximity to your

ears as the tester produces loud noises.

DIGITAL ROOM COMPENSATION PROCEDURE

Prepare the acoustic detector for DRC by setting the D/N line

(if used) in DAY mode – D/N line should be left open or Low.

1. Press the START button of the ADT700 tester to put the

power on. Green LED will light.

2. Hold the tester 1 to 3m from the detector and aim the

speaker at it.

3. Press the START button once more to initiate the DRC

mode. The LED on the detector will start to flicker.

4. Go to the furthest distance (max. 9m) of the glass to be

protected and aim the speaker at the detector.

5. The DRC range calculated by the detector will be displayed as a number of pulses from 1 to 3.

Press the DRC button to send a DRC signal out. Make this 2–

10 times from different angles of the protection area for optimal

capability. The LED will flash confirming it has received the signal. The LED will then start to blink and flicker. The DRC range

calculated by the detector will be displayed as a number of

pulses from 1 to 3. In case of too weak or too strong signals

outside the compensation range (means that the detector is

placed too close or too far from the object to be protected), the

detector will then not show DRC range.

6. Press the STOP button from a distance of 1 to 3m from the

detector to terminate the DRC procedure.

If DRC range measured by the detector is different from actual

DIP-switch settings, the LED will continue to blink 1–3 times

showing the correct range number to be set in the detector.

The LED blinks 1 time: set to Zone 1 (4–9 m)

The LED blinks 2 times: set to Zone 2 (2–4 m)

The LED blinks 3 times: set to Zone 3 (1–2 m)

Insert cover hooks

into slots in the base

Close the cover

Tighten the locking screw

Slide down the lock cover

CLOSING THE DETECTOR

Page 4

© 2017 Vanderbilt 4 / 4 021_AGB800-AM_I-200259_EN

PROTECTING SEVERAL WINDOWS BY ONE DETECTOR

Detector can protect several windows in one room if the windows are within the coverage area. Make independent DRC

test for each window to be protected. Follow the procedure

above for each window. The detector shall be set to the lowest

Zone number that is the longest range from the detector.

TIMEOUT

Both the AGB800-AM detector and ADT700 tester are

equipped with a timeout feature. The AGB800-AM will stop the

DRC mode and the ADT700 will switch off power if no activity

has happened within 3–4 minutes.

D/N CONTROL (Day/Night)

The D/N makes it possible to remote control the alarm indications of the detectors and remote reset during DAY->NIGHT

transition. The D/N increases the security of the detector, as it

enables the alarm indications to be concealed in NIGHT mode

without any influence on the relay function.

SELF-TEST

Detector is continuously checking all vital parts responsible for

proper detection of glass break signal using internal self-test

procedure.

ANTI-MASKING

Test of antimasking system:

1. Put the power on. Seal microphone completely with elastic

material like chewing gum or isolation tape.

2. INTRUSION and FAULT relays will open after max. of 180

s signaling masking of microphone.

3. Remove sealing material from microphone. Relays will

close in less than minute.

Issued by Vanderbilt

Clonshaugh Business and Technology Park

Clonshaugh, Dublin 17

D17 KV84, Ireland

www.vanderbiltindustries.com

Doc ID: I-200259 Edition Date: 01.05.2017

UNDERSTANDING THE LED WHEN THE DETECTOR IS IN OPERATION

LED

Detector status

Flashes 1–3 times

when powered ON

Indication of range setting after power-on

Off

Normal state, no alarms

Permanently on

Intrusion detected – if detector in Latch

mode

Permanently on

with 1 blink per 3s

Masking detected

Permanently on

with 2 blinks per 3s

Low supply voltage or self-test failure

Short blink

Antimasking warning – foreign object in

close proximity of microphone

UNDERSTANDING THE LED WHEN TESTING THE

DETECTOR WITH ADT700 TESTER

LED

Detector status

Flickers

In test mode

Flickers and blinks

In calibration mode

Flashes 1.5s

Confirms received signal

Blinks slowly 1 time each

2.5s after calibration

Set range setting to Zone 1 (4–9m)

Blinks slowly 2 times each

2.5s after calibration

Set range setting to Zone 2 (2–4m)

Blinks slowly 3 times each

2.5s after calibration

Set range setting to Zone 3 (1–2m)

TROUBLESHOOTING

Detector does not respond

Check the supply voltage and polarity

LED permanently on

Switch off the detector for a short period

Check if LED is in latching mode (DIP1=ON)

LED permanently on with 1 dip per 3 s

Check if microphone not masked with foreign material

LED permanently on with 2 dips per 3 s

Check supply voltage – should be higher than 7 V

No alarm

Check the INTRUSION and FAULT relay wiring

Check the alarm loop wiring

TECHNICAL DATA

Type (thickness) of protected glass

float (4mm), laminated P2, P4 (4mm + 4mm)

Size of protected glass

min 40 × 40 cm

Max range

9m radius/165°

Range setting

Zone 1 = 4–9m

Zone 2 = 2–4m

Zone 3 = 1–2m

Supply voltage

7–30V DC

Max. voltage ripple

2 Vpp at 12V, 4 Vpp at 24V

Voltage monitoring

Fault signaled at < 7V

Current consumption quiescent state

12mA @ 12V, 7mA @ 24V

D/N signal levels

DAY = D/N open or < 2.5V, NIGHT = D/N > 2.5V

INTRUSION output, FAULT output

relay

INTRUSION and FAULT relay contact rating

50mA, 50V DC/peak AC, Rs ≤ 30Ω

TAMPER contact rating

50mA/50V DC/peak AC

Intrusion/fault indication

LED

Environmental class

EN50130-5:2011, VdS 2110 Class I

Operating temp. range

-25°C to +40°C

Operating humidity range

max. 93% RH

Housing material

plastic ABS, white

Dimensions [WxHxD]

68 x 109 x 40 mm

Security grade

EN 50131-2-7-1:2012/A1:2013, Grade 3, VdS class B

Approvals

ORDERING INFORMATION

Type

Art No.

Description

Weight

AGB800-AM

V54535-Z129-A100

Acoustic glass break detector G3

0.126Kg

Accessory

ADT700

N54535-Z100-A100

Acoustic glass break tester

0.743Kg

Loading...

Loading...