Page 1

ACTpro-100 / ACTpro-1002A

Installation and Operating Instructions

Document ID: A-100542

Edition date: 05.11.2018

Page 2

Data and design subject to change without notice. / Supply subject to availability.

© 2018 Copyright by Vanderbilt International Ltd.

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights and

undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our prior

express written authorization, nor to use it for any purpose other than for which it was delivered to him.

ACTpro-100

Hereby, Vanderbilt International (IRL) Ltd declares that this equipment type is in compliance with the following EU Directives for CE marking:

• Directive 2014/30/EU (Electromagnetic Compatibility Directive)

• Directive 2011/65/EU (Restriction of the use of certain hazardous substances Directive)

The full text of the EU declaration of conformity is available at: http://van.fyi?Link=DoC

ACTpro-1002A

Hereby, Vanderbilt International (IRL) Ltd declares that this equipment type is in compliance with the following EU Directives for CE marking:

• Directive 2014/30/EU (Electromagnetic Compatibility Directive)

• Directive 2014/35/EU (Low Voltage Directive)

• Directive 2011/65/EU (Restriction of the use of certain hazardous substances Directive)

The full text of the EU declaration of conformity is available at: http://van.fyi?Link=DoC

&

http://van.fyi?Link=ACTpro100

Page 3

Table of Contents

1 Overview 4

1.1 Technical specification 4

1.1.1 ACTpro-1002A electrical specification 4

1.2 Ordering details 5

1.3 Monitoring 5

2 Installation 6

2.1 Wiring 6

2.1.1 DIP switch addressing 7

2.1.2 Wiring for Vanderbilt EM1030e Clock & Data or Wiegand Reader 8

2.1.3 Wiring exit readers 9

2.2 ACTpro-100 9

2.2.1 Mounting 9

2.2.2 Power supply 9

2.3 ACTpro-1002A 9

2.3.1 Mounting 10

2.3.2 Mains power up 10

2.3.3 Load Output 10

2.3.4 Standby Battery 11

2.3.5 Tamper 11

© Vanderbilt 2018 3 A-100542

05.11.2018

Page 4

1 Overview

This guide describes the installation of the ACTpro-100 door stations, which are compatible with all

ACTpro controllers.

The ACTpro-100 is a single door station.

The ACTpro-1002A is a single door station with a 12V DC 2A PSU.

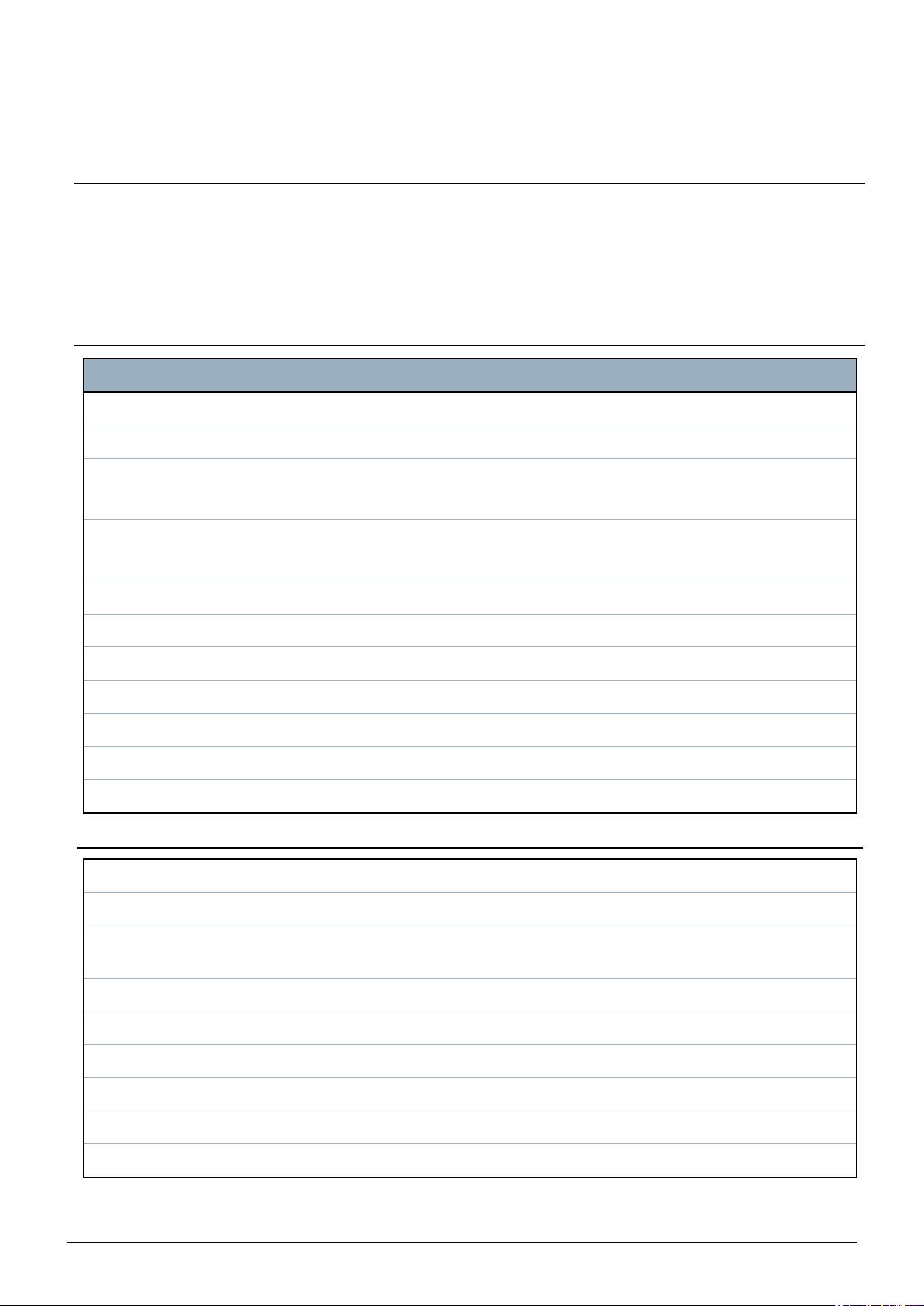

1.1 Technical specification

ACTpro-100 ACTpro-1002A

Input Voltage Range 12V DC 12V DC

Current Consumption 40–120 mA 40–120 mA

Operating Environment Surface mounting

Internal use only

Operating Temperature -10 to +50° C -10 to +40° C

Dimensions (H x W x D mm) 165 x 235 x 55 275 x 330 x 80

Weight (kg) 0.4 2.2

Enclosure Material ABS 1.2mm steel grey powder coated

LED Status Indicators Yes Yes

PSU Fault Output n/a Yes

Lid Opening Tamper Detection (Front) Yes Yes

Rear Tamper Detection No Yes

Surface mounting

Internal use only

75% RH non-condensing

1.1.1 ACTpro-1002A electrical specification

Battery charging Yes

Standby Battery 12V 7Ah Battery

Battery Deep Discharge

Protection

Input: Voltage Rated 100–240V AC

Input: Voltage Operating 90–264V AC

Input: Frequency 50–60Hz

Input: Max Current 1.0A (@ 90V AC)

Input: Mains input fuse T2.0A

Input: Max standby power 0.5W (no load and no battery connected)

© Vanderbilt 2018 4 A-100542

No

05.11.2018

Page 5

ACTpro-100 / ACTpro-1002A – Installation and Operating Instructions Overview

Output: Voltage 13.4–14.2V DC (13.8V DC Nominal) on mains power

Output: Max load current 2.0A

Output: Ripple 150mA pk–pk max

Output: Load output fuse F2.0A

Output: Overload Electronic shutdown until overload or short circuit removed (Under mains

power only)

1.2 Ordering details

ACTpro-100 V54502-C120-A100 Single door station

ACTpro-1002A V54502-C121-A100 Single door station with 12V DC 2A PSU

1.3 Monitoring

All faults including Mains Present and Tamper are reported on the ACT Enterprise software.

Mains present The PSU MAINS PRESENT output, when available, is pre-wired to the MAINS PRESENT

input.

Output Voltage The PSU output voltage level is reported to the ACT Enterprise software.

Tamper The enclosure lid is tamper monitored.

© Vanderbilt 2018 5 A-100542

05.11.2018

Page 6

2 Installation

The ACTpro-100 door stations are for indoor installation only and must be installed as permanently

connected equipment.

Reset the ACTpro-100 door station to its factory default condition before installation. To do this, power the

unit up with ALL switches in the OFF position. The unit will beep after 3 seconds. The unit is now

defaulted. Set the DIP switches to the appropriate address.

If using the ACTpro-1002A, Vanderbilt recommend that an external mains disconnect device is fitted

before installation, and you should ensure that the mains supply to the controller is disconnected during

installation.

Mains power should be connected by a licensed electrician in accordance with local/national codes.

2.1 Wiring

A Door contact F Vanderbilt reader wire colour coding

B Door push button G Important: Always place varistor across lock terminals.

C From previous door or controller H Double pole Break Glass / Emergency Door Release

When the Break Glass is not activated the B/GL input pin is

held low at 0 volts. When the Break Glass device is

activated the B/GL input pin will lose the 0 volts (goes high)

and report a Break Glass event.

D To next door J DIP switches for door station addressing. See DIP switch

addressing on the next page.

E Break glass monitoring, normally closed

© Vanderbilt 2018 6 A-100542

05.11.2018

Page 7

ACTpro-100 / ACTpro-1002A – Installation and Operating Instructions Installation

Notes:

l This illustration shows wiring for a normally energised lock. If a normally deenergised lock is

required, use the N/O relay contacts.

l RS485 Network cable is single shielded twisted pair, Belden 9501 or equivalent. Total Length max

1.4km.

l If the Mains Present, Door Contact or BreakGlass inputs are not used, they should be linked to 0V,

or the feature should be disabled in ACT Enterprise software.

l The Blue Comms OK LED is on while ACTpro-100 is communicating with the controller.

l Red Fault LED illuminates on:

l Tamper

l Comms Offline

l BreakGlass

l Voltage Low

l Current Limiting Fuse (500mA)

2.1.1 DIP switch addressing

Door 1 is on the ACTpro-1500 controller (max. 31 doors).

Door 1 and 2 is on the ACTpro-4000 controller (max. 16 doors).

© Vanderbilt 2018 7 A-100542

05.11.2018

Page 8

ACTpro-100 / ACTpro-1002A – Installation and Operating Instructions Installation

The following table shows how to set the door station DIP switch for each address (01–32).

2.1.2 Wiring for Vanderbilt EM1030e Clock & Data or Wiegand Reader

Wire Colour Terminal

White SENSE

Green CLOCK / DATA 1

Blue DATA / DATA 0

Red +12V

Black 0V

Brown RED

Yellow GREEN

© Vanderbilt 2018 8 A-100542

05.11.2018

Page 9

ACTpro-100 / ACTpro-1002A – Installation and Operating Instructions Installation

Wire Colour Terminal

Orange (Buzzer Control)

2.1.3 Wiring exit readers

For Clock & Data readers, wire exit reader in parallel but leave the sense line unconnected.

For Wiegand readers, wire the DATA 0 of the exit reader to SENSE on the ACTpro-100.

Max length 30m with 5V DC

Max length 100m with 12V DC

Cable: 8 Core Screened Belden 9504 or equivalent

2.2 ACTpro-100

2.2.1 Mounting

Mount the ACTpro door station directly on to the wall with the supplied screws.

The keyed mounting hole should be screwed first to the wall to aid the mounting.

The unit should be installed in a ventilated area that allows for accessibility after installation.

2.2.2 Power supply

The ACTpro-100 requires an external 12V DC power supply. The supply should be connected to the +12V

DC and 0V/GND connections.

2.3 ACTpro-1002A

This unit is only suitable for installation as permanently connected equipment.

l The PSU is not suitable for external installation.

l Equipment must be earthed.

Before installation, ensure that external disconnect device is OFF. The PSU should be installed via a 3A

fused spur according to all relevant safety regulations applicable to the application.

© Vanderbilt 2018 9 A-100542

05.11.2018

Page 10

ACTpro-100 / ACTpro-1002A – Installation and Operating Instructions Installation

2.3.1 Mounting

1. Mount securely in correct orientation allowing minimum clearance – see diagram.

N Neutral M Green Mains LED

E Earth F Red Fault LED

L Live

2. Route mains and low voltage output cables via different knockouts and/or cable entry holes.

3. Use bushes and cable glands rated to UL94 HB minimum.

2.3.2 Mains power up

1. Attach correctly rated mains cable (minimum 0.5mm2 [3A], 300/500V AC) and fasten using

cable ties.

Note: After you install the ACTpro-1002A, Vanderbilt recommend that you place the provided

ferrite bead (a noise-suppression device) around the power supply cable to attain a desired level

of electromagnetic compatibility (EMC). The ferrite bead is provided along with a screw kit in a

clear ziplock bag inside the unit enclosure.

2. Apply mains power and:

l Check for 13.8V DC on load outputs.

l Check the green Mains LED is on.

3. Disconnect mains power.

2.3.3 Load Output

1. Attach correctly rated load cable and fasten using cable ties. Note polarity.

2. Apply mains power and check the green Mains LED is on.

© Vanderbilt 2018 10 A-100542

05.11.2018

Page 11

ACTpro-100 / ACTpro-1002A – Installation and Operating Instructions Installation

Note: The red Fault LED may be illuminated (dependent upon model) to indicate that no battery has

been connected. This is normal.

3. Verify load is operating correctly.

4. Disconnect mains power.

2.3.4 Standby Battery

Note: Ensure batteries being fitted to this unit are in good condition

1. Connect battery leads to battery, ensuring correct polarity of battery connections. Vanderbilt

recommend using a 7Ah battery.

2. Apply mains power and check that the green Mains LED is on.

3. Disconnect mains power.

4. Check that the batteries continue to supply voltage and current to the load.

The green Mains LED should be off.

Note: Batteries must have sufficient charge to supply the load.

5. Reconnect mains power.

The green Mains LED should be on.

6. Remove Load fuse and check that the red Fault LED is on (dependent on model).

2.3.5 Tamper

A tamper condition is reported in software.

1. Check that the tamper switch is reported in the software as:

2. Close cover and secure using fastening screw(s) provided.

l Closed when the enclosure is mounted on the wall, lid is closed, and the lid screw is fitted.

l Open when the lid is open.

© Vanderbilt 2018 11 A-100542

05.11.2018

Page 12

vanderbiltindustries.com

© Vanderbilt 2018

Data and design subject to change without notice.

Supply subject to availability.

Document ID: A-100542

Edition date: 05.11.2018

Issued by Vanderbilt International Ltd.

Clonshaugh Business and Technology Park

Clonshaugh, Dublin D17 KV 84, Ireland

@VanderbiltInd Vanderbilt Industries

vanderbiltindustries.com/contact

Loading...

Loading...