ROTARY SCREW AIR COMPRESSOR

OPERATOR’S MANUAL & PARTS LIST

NOTE

This publication contains the

latest information available at

the time of preparation. Every

effort has been made to ensure

accuracy. However, Vanair

Manufacturing, Inc. takes no

responsibility for errors or

consequential damages

caused by reliance on the

information contained herein.

Vanair Manufacturing, Inc.

reserves the right to make

design change modifications

or improvements without prior

notification.

NOTE

Use only Vanai r Vanguard™

Premium Synthetic Oil and

Genuine Vana ir P ar ts. Inspect

and replace damaged

components before operation.

Substituting non-Vanguard™

Oil or non-genuine Vanair filter

components WILL VOID THE

COMPRESSOR WARRANTY!

Vanair Manufacturing, Inc.

10896 West 300 North

Michigan City, IN 46360

Phone: (219) 879-5100

(800) 526-8817

Service Fax: (219) 879-5335

Parts Fax: (219) 879-5340

Sales Fax: (219) 879-5800

www.vanair.com

Read this manual before

installing, operating or

servicing this equipment.

Failure to comply with the

operation and maintenance

instructions in this manual

WILL VOID THE EQUIPMENT

WARRANTY.

NOTE

Making unauthorized

modifications to the system

components WILL VOID THE

WARRANTY!

Always inform Vanair

Manufacturing, Inc., befo re

beginning any changes to the

Viper Diesel system.

KEEP THE MANUAL

WITH THE VEHICLE

©2014 Vanair Manufacturing, Inc.

All rights reserved.

P/N: 090058-OP_r0

Effective Date:

August-2014

WARRANTY: VIPER SERIES AIR COMPRESSORS

The rotary screw compressor unit is warranted for life when adhering to the prescribed maintenance schedule.

The hydraulic motor on the hydraulic Viper is warranted for two (2) years. This warranty does not cover damage

caused by accident, misuse or negligence. If a compressor unit is disassembled the warranty is void. Any

disassembly of major components must be approved by Vanair to avoid voiding of warranty. All other parts

including the compressor unit shaft seal are warranted for twelve (12) months subject to the same conditions

mentioned previously. Any and all such claims for warranty consideration must be coordinated prior to work being

performed through the Warranty-Service Department at the address below. Do not return parts without prior

authorization.

Warranty is limited to the supply of replacement part s failing within the warranty period. Credit for labor required to

refit replacement parts is NOT included. All warranted pa rts ar e to be shipped PREPAID to V ANAIR. Replacement

parts will be shipped back to the customer by VANAIR via ground shipment. Cost to expedite delivery of

replacement parts will be incurred by customer.

Warranty will commence upon receipt of the Warranty Registration Card. If the Warranty Registration Card is not

received within six (6) months, the warranty commencement date shall be thirty (30) days from the date of

shipment from VANAIR. Records of warranty adherence are the responsibility of end user.

This statement of warranty is expressly in lieu of and disclaims all other express warranties, implied warranties of

merchantability and fitness for a particular purpose and all other implied warranties which extend beyond the

description on the face hereof. In no event shall Vanair be responsible for special, indirect, incidental,

consequential or punitive damages of any kind, including without limitation, lost profits or other monetary loss,

whether or not any such matters or causes are within Vanair's control or due to negligence or other fault of Vanair,

its agents, affiliates, employees or representatives.

This warranty shall be void and VANAIR shall have no resp onsibili ty to repair, replace or repay the purchase price

of defective or damaged parts resulting from the use of or repair of replacement parts or fluids not of VANAIR'S

manufacture or from buyer's failure to store, install, maintain and operate the compressor according to the

recommendations contained in the Manual.

All claims under the Warranty shall be made by con tacting VANAIR Warranty-Service Department.

Please note that engines are warranted separately by the engine manufacturer. Consult engine manual.

Register Your Warranty Online at www.vanair.com under the Support Tab!

Or Call: (800) 526-8817 • Fax: (219) 879-5800

Mail to: 10896 W 300 North • Michigan City, IN 46360

Effective February 11, 2013

DIESEL VIPER TABLE OF CONTENTS

TABLE OF

CONTENTS

WARRANTY ............................................... BEHIND COVER

TABLE OF CONTENTS...................................................... I

WARRANTY CLAIMS PROCEDURE ................................V

CLAIMS PROCESS FOR WARRANTED PARTS..................................................................................... V

PROCEDURE........................................................................................................................................... V

SECTION 1: SAFETY .....................................................1

1.1 GENERAL INFORMATION......................................................................................................1

1.2

1.3

1.4

DANGERS, WARNINGS, CAUTIONS AND NOTES...............................................................1

SUMMARY OF DANGERS, WARNINGS CAUTIONS AND NOTES.......................................1

1.3.1

1.3.2

1.3.3

1.3.4

DANGERS .......................................................................................................................................................1

WARNINGS......................................................................................................................................................1

CAUTIONS.......................................................................................................................................................2

SAFETY DECALS............................................................................................................................................3

DISPOSING OF MACHINE FLUIDS .......................................................................................3

SECTION 2: SPECIFICATIONS..........................................5

TABLE 2A: SPECIFICATIONS FOR VIPER DIESEL ROTARY SCREW COMPRESSOR........................5

SECTION 3: INSTALLATION..............................................7

3.1 MACHINE PACKAGE RECEIPT/INSPECTION............................................................................7

3.2 INSTALLATION INSTRUCTIONS.... ... ... .... .......................................... ... ......................................7

3.3 INSTRUMENT PANEL RELOCATION .........................................................................................8

FIGURE 3-1: DIMENSION DIAGRAM - PART 1 OF 2..............................................................................8

FIGURE 3-1: DIMENSION DIAGRAM - PART 2 OF 2..............................................................................9

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - I

TABLE OF CONTENTS DIESEL VIPER

SECTION 4: OPERATION................................................ 11

FIGURE 4-1: MAIN MACHINE COMPONENT LOCATIONS................................................................. 10

4.1 GENERAL INFORMATION..........................................................................................................11

4.2 INSTRUMENTATION..................................................................................................................11

4.2.1 DIGITAL DISPLAY SCREEN ................................................................................................................................11

4.2.2 SCROLL SELECTOR ROCKER SWITCH...........................................................................................................11

4.2.3 ON AND STOP SELECTION KEY SWITCH........................................................................................................11

4.3 INITIAL START-UP PROCEDURE..............................................................................................11

4.4 SHUTDOWN PROCEDURE ...................................................................................................... 12

4.5 SUBSEQUENT START-UP PROCEDURE ................................................................................ 12

4.6 CONTROLLER GUIDE............................................................................................................... 12

4.6.1 HOME SCREEN..................................................................................................................................................13

4.6.2 SPLASH SCREEN ..............................................................................................................................................13

4.6.3 ADJUSTING USER SETTINGS.......................................................................................................................... 13

4.6.3.1 PARAMETERS.............................................................................................................13

4.6.3.2 AUTO SHUTDOWN............................. ... ... .... ... ... ....................................... ... ... ... .... .. 13

4.6.3.3 AUTO CRANK............... .... ... ... ... ....................................... ... ... .... ... ............................. 13

4.6.3.4 SLEEP STATE TIMER ................................................................................................13

4.6.4 SETTING PRESSURE.........................................................................................................................................13

4.6.5 SAFETY...............................................................................................................................................................13

4.6.6 SERVICE INTERVALS ........................................................................................................................................14

4.7 OPERATING CONDITIONS....................................................................................................... 14

4.8 EXTREME CONDITIONS...........................................................................................................14

SECTION 5: MAINTENANCE...........................................15

5.1 GENERAL INFORMATION ........................................................................................................ 15

5.2 ROUTINE MAINTENANCE SCHEDULE............................. ... .... ... .......................................... ... 15

5.3A MAINTENANCE SCHEDULE TABLE - COMPRESSOR INTERVALS....................................... 17

5.3B MAINTENANCE SCHEDULE TABLE - ENGINE INTERVALS................................................... 18

5.4 REPLACEMENT PARTS . .... ... ... ... .... ..........................................................................................21

5.5 PARTS REPLACEMENT AND ADJUSTMENT PROCEDURES............ .... ... ... ... .... ... ... ... ... .... ... 21

5.5.1 ADJUSTING THE ENGINE SPEED.....................................................................................................................21

5.6 SERVICING THE SYSTEM FUSES AND CIRCUIT BREAKER ................................................ 21

5.7 STORAGE AND INTERMITTENT USE .. ... .......................................... ... .... ... ... ... .... ... ................ 21

5.7.1 INTERMITTENT USE................................................................................................................................................22

5.7.2 LONG TERM STORAGE ..........................................................................................................................................22

PAGE - II 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

DIESEL VIPER TABLE OF CONTENTS

SECTION 6: TROUBLESHOOTING .................................23

6.1 GENERAL INFORMATION.........................................................................................................23

6.2 TROUBLESHOOTING GUIDE....................................................................................................24

6.3 EXTREME CONDITION OPERATION........................................................................................28

6.3.1 HIGH MOISTURE CONDITION: EMULSIFICATION OF OIL IN

ROTARY SCREW COMPRESSOR SYSTEMS....................................................................................................28

TABLE 6.3A HIGH MOISTURE CONDITION OPERATION....................................................... 29

6.3.2 COLD WEATHER OPERATION...........................................................................................................................29

TABLE 6.3B COLD WEATHER OPERATION............................................................................30

6.3.3 HIGH TEMPERATURE OPERATION...................................................................................................................30

TABLE 6.3C HIGH TEMPERATURE OPERATION.................................................................... 31

6.3.4 HIGH DUST CONTENT OPERATION..................................................................................................................31

TABLE 6.3D HIGH DUST CONTENT OPERATION................................................................... 31

6.3.5 HIGH ALTITUDE OPERATION.............................................................................................................................32

SECTION 7: ILLUSTRATED PARTS LIST.......................33

7.1 PARTS ORDERING PROCEDURE............................................................................................33

TABLE 7A: RECOMMENDED SPARE PARTS LIST.................... .... ......................................... .... ... ... ... .34

TABLE 7B: MACHINE OPTIONS LIST ....................................................................................................34

TABLE 7C: MAINTENANCE TRACKING LOG.................... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... .................35

7.2 COMPRESSOR REPLACEMENT PARTS ................................................................................36

7.3 AIREND AND ATT ......................................................................................................................38

7.4 ENGINE AND DRIVE PARTS (1 OF 2).......................................................................................40

7.4 ENGINE AND DRIVE PARTS (2 OF 2).......................................................................................42

7.5 COOLING SYSTEM (PART 1 OF 2)...........................................................................................44

7.5 COOLING SYSTEM (PART 2 OF 2)...........................................................................................46

7.6 CANOPY AND FRAME PARTS....... ... ... .... ... ... ... .... ... ... ..............................................................48

7.7 COMPRESSOR THERMAL CONTROL .....................................................................................50

7.8 INSTRUMENT PANEL................................................................................................................50

7.9 ELECTRICAL SYSTEM..............................................................................................................52

7.10 FUEL TANK ASSEMBLY............................................................................................................54

7.11A DECALS (LOCATION)........................... .... ...................................... .... ... ... ... .... ... .......................56

7.11B DECALS (IDENTIFICATION)........... ... ... .... ...................................... .... ... ... ... .... ... .......................57

7.11C DECALS (PART NUMBERS).............. ... .... ... ... ... .... ... ... ... .... ... .......................................... ... ... ....58

7.12 WIRING DIAGRAM.....................................................................................................................59

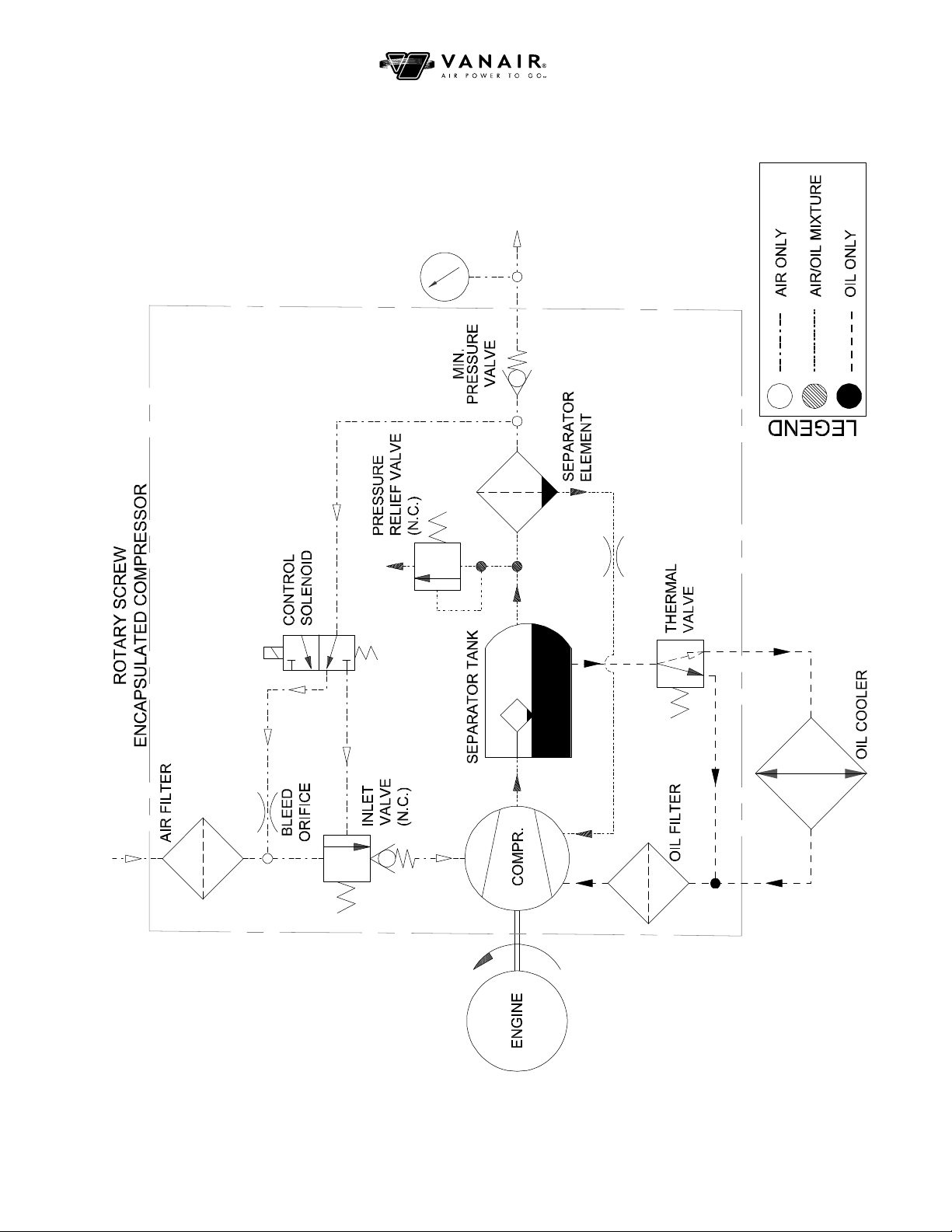

7.13 SCHEMATIC FLOW DIAGRAM..................................................................................................60

7.14 HOSE INSTALLATION GUIDE....................................................................................................61

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - III

TABLE OF CONTENTS DIESEL VIPER

BLANK PAGE

PAGE - IV 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL WARRANTY PROCEDURE

WARRANTY CLAIMS

PROCEDURE

CLAIMS PROCESS FOR

WARRANTED VANAIR PARTS

This process must be used by owners of

®

Vanair

warranted item needs repair or replacement

under the terms of the purchase warranty.

Do not return items to Vanair without prior

authorization from the Vanair Warranty

Administrator.

PROCEDURE:

When a customer needs assistance in

troubleshooting a system and/or returning

parts, follow the steps below.

1. Locate the machine’s serial number:

The machine package serial number plate is

located inside the machine com partment on

the floor near to the engine air filter mounting

location (see Figure W-1).

The engine and the compressor also have

individual serial numbers respectively (see

Figure W-1). For engine warranty issues,

consult the Engine Operator’s Manual for

the engine’s limited warranty details. For

particular compressor unit issues, the

compressor serial number may be needed.

In any case, engine and/or compressor

issues can be confirmed using the machin e

serial number as found in Figure W-1.

2. Have a list of the symptoms/condition/

malfunctions along with any applicable

temperature and pressure readings, and

also the number of operational hours

available:

Note that the above information will also

need to be included on the Return Material

equipment in situations where a

Authorization Form (per Step #6); this form

is necessary for warranty processing if the

warranty claim is deemed valid by the

service case review.

3. Contact the Vanair

by phone (1-219-879-5100) to speak with

a Service Technician.

4. Vanair Service will troubleshoot the

problem based on the information

provided by the customer, and attempt to

return the unit to service as quickly as

possible.

5. If the unit cannot be returned to service,

and Vanair determines this matter is a

warranty issue, the Service Technician

will assign an RMA (Return Material

Authorization) number that will provide

for the return of the item to Vanair for

analysis and a final determination as to

the item’s warranty status.

®

Service Department

NOTE

The RMA number must be placed on the

outside of the package being returned.

6. Warranty Claims are solicited via a

Return Material Authorization (RMA)

Form. This form can be obtained via

download from the web site, or requested

directly from the Vanair Service

Department:

Once a current form has been obtained,

follow the instructions given on the form to fill

in the information needed. This form is used

for the purpose of soliciting a warranty case.

All of the field information except for the

bottom section block fields, which includes

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - V

WARRANTY PROCEDURE VIPER DIESEL

800-526-881 7

260940

MODEL NUMBER

SERIAL NU MBER

MAXIMUM PR ESSURE

COMPRESSOR INPUT R PM

www.v ana ir.c om

Machine Serial Number

Engine Serial Number

Compressor Unit

Serial Number

Disposition of Goods, Notifications and

Additional Notes, will be required.

Customers have 30 days after the RMA

number is issued to return the item. If the

part is not returned within this period, the

RMA is void and any claims will be denied.

Before sending a warranty part to a

customer, Vanair

card number to cover the cost of the part and

shipping. After the part is analyzed and

deemed to be covered under warranty,

Figure W-1: Machine Serial Number Location

NOTE

All labor claims or invoices must be

approved by the Vanair Warranty

Administrator prior to starting repair work

along with the cost of the repair . All p aper

work associated with the returned item

and warranty repair cost must reference

the RMA number issued against the part,

and be forwarded to Vanair within 30 days

of the completion of work.

®

will need a P.O. or credit

Vanair will issue credit to the customer. All

parts eligible for warranty must have the

RMA number on the invoice at the time of

purchase.

No items can be returned “freight collect”.

Freight costs will be addressed at the time

the claim is closed. The customer pays any

additional costs for warranty parts delivered

through expedited services (i.e., Next Day,

Second Day).

VANAIR WILL NEVER ACCEPT ANY

INVOICES FOR PARTS RETURNED: ANY

P ARTS RETURNED VIA INVOICE WILL BE

RETURNED FREIGHT COLLECT: NO

PARTS ARE TO BE RETURNED FREIGHT

COLLECT!

Vanair Mfg., Inc. strives to continuously

improve its customer service. Please forward

any questions, comments, or suggestions to

Vanair Service:

Phone: 219-879-5100, ext. 400 or toll free

Email: warranty@vanair.com

844-VANSERV (826-7378)

PAGE - VI 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 1: SAFETY

SECTION 1:

SAFETY

1.1 GENERAL INFORMATION

IMPORTANT

Read this manual before operating or

servicing the Viper Diesel compressor

system. Failure to do could result in

damage equipment, bodily injury, or

death

The products provided by Vanair

Manufacturing, Inc., are designed and

manufactured for safe operation and

maintenance. But it is ultimately the

responsibility of the users and maintainers

for safe use of this equipment. Part of this

responsibility is to read and be familiar with

the contents of this manual before operation

or performing maintenance action s.

harm. When you see the international

warning symbol, pay extremely careful

attention, and follow the given instructions

or indications to avoid any possible hazard.

1.3 SUMMARY OF WARNINGS, CAUTIONS AND NOTES

These boxed inserts are placed throughout

this manual in the sections where they apply.

This subsection is a general summary of

their contents.

®

1.3.1 DANGERS

• Keep tools or other conductive objects away

from live electrical parts.

• Never touch electrical wires or components

while the machine is operating. They can be

sources of electrical shock.

1.3.2 WARNINGS

1.2 DANGERS, WARNINGS, CAUTIONS AND NOTES

These boxes are labeled clearly with the title

block listing either Danger, Warning,

Caution, or other non-safety issue. They

draw attention to specific issues that are

pertinent to the safe and correct operation of

the machine.

The symbols shown and defined in Section

1: Safety are used throughout this manual

and on the machine to call attention to, and

identify, possible hazards.

The international warning symbol (shown

below) is used on all decals, labels and signs

that concern information pertaining to bodily

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - 1

• DO NOT EVER use this compressor as a

breathing air source. Vanair Manufacturing

Inc., disclaims any and all liabilities for

damage or loss due to fatalities, personal

injuries resulting from the use of a Vanair

compressor to supply breathing air.

• DO NOT perform any modifications to this

equipment without prior factory approval.

• DO NOT install this compressor in a

confined space that lacks proper

ventilation and airflow; breathing and

cooling air circulation must not be

compromised.

• DO NOT operate the compressor or any of

its systems if there is a known unsafe

condition. Disable the equipment by

disconnecting it from its power source.

Install a lock-out tag to identify the

SECTION1: SAFETY VIPER DIESEL

equipment as inoperable to other

personnel.

• DO NOT operate the compressor with

any by-pass or other safety systems

disconnected or rendered inoperative.

• DO NOT operate the equipment while

you are under the influence of alcohol or

drugs.

• DO NOT operate the equipment while

you are feeling ill.

• DO NOT attempt to service the

equipment while it is operating.

• Before performing maintenance or

replacing parts, relieve the entire system

pressure by opening a service valve

which will vent all pressure to the

atmosphere: remove all electrical power.

• DO NOT use the compressor for

purposes other than for which it is

intended. High pressure air can cause

serious and even fatal injuries.

• DO NOT operate the compressor

outside of its specified pressure and

speed ratings. (See Section 2:

Specifications or refer to the equipment

data plate.)

•DO NOT use flammable solvents or

cleaners for cleaning the compressor or

it parts.

• DO NOT operate the compressor in

areas where flammable, toxic, or

corrosive fumes, or other damaging

substance can be ingested by the

compressor intakes.

• Keep arms, hands, hair and other body

parts, and clothing away from fans, drive

shafts, and other moving parts.

• DO NOT wear jewelry, unbuttoned cuffs,

ties, or loose-fitting clothing when you are

working near moving/rotating parts.

• ALWAYS confine long hair when working

near moving/rotating parts.

• NEVER operate the equipment while

wearing a headset to listen to music or the

radio.

• Wear personal protective equipment

such as gloves, work shoes, and eye

and hearing protection as required for

the task at hand.

• DO NOT operate the compressor with

any guards removed or damaged, or

other safety devices inoperative.

• DO NOT operate the compressor in

enclosed or confined spaces where

ventilation is restricted or closed-off.

• Ensure that hoses connected to se rvice

valves are fitted with correctly sized and

rated flow limiting devices which comply

with applicable codes. Pressurized

broken or disconnected hoses c an whip

causing injuries or damage.

• Over speed is hazardous! NEVER

tamper with the governor components or

settings to increase the maximum

speed. Severe personal injury and

equipment damage can result if

operated at speeds above the maximum.

• DO NOT use tools, hoses, or equipment

that have maximum ratings below that of

this compressor .

• Keep metal tools, and other conductive

objects away from live electrical

components.

• Before performing maintenance or repair

operations on the compressor, ensure

that all power has been removed and

been locked out to prevent accidental

application.

• DO NOT assume that because the

compressor is in a STOPPED condition

that power has been removed.

• Use this compressor only to compress

atmospheric air. Use of this equipment

as a booster pump and/or to compress

any other gaseous or aerosol substance

constitutes improper use. It can also

cause damage or injuries. Such misuse

will also void the warranty.

• Install, operate, and maintain this

equipment in full compliance with all

applicable OSHA, other Federal, state,

local codes, standards, and regulations.

• When lifting objects, be aware of proper

lifting techniques to avoid injury.

• ALWAYS read and follow safety related

precautions found on containers of

hazardous substances.

• DO NOT play with compressed air. It can

cause serious injury.

1.3.3 CAUTIONS

• Check all safety devices for proper

operation on a routine basis.

• Ensure that no tools, rags, or other

objects are left on compressor drive

systems or near intakes.

PAGE - 2 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 1: SAFETY

• Keep the equipment clean when

performing maintenance or service

actions. Cover openings to prevent

contamination.

• DO NOT operate the compressor if

cooling air is not available (fan/cooler not

operating) or if lubricant levels are below

their specified minimum levels.

• Ensure all plugs, hoses, connectors,

covers, and other parts removed for

maintenance actions are replaced

before applying power to the

compressor.

• Avoid touching hot surfaces and

components.

• Ensure that electrical wiring, terminals;

hoses and fittings are kept in serviceable

condition through routine inspections

and maintenance. Replace any

damaged or worn components.

• DO NOT install safety devices and/or

replacement parts other than authorized

®

Vanair

• Keep personnel out of line with, and

away from discharge opening of valves,

hoses and tools.

• Immediately clean up any lubricant or

spills.

replacement parts.

hazard to operators or service personne l. All

pertinent decals listed in Section 7.11A,

Decal Locations are located near a

component, which is subject to respect in

terms of safety precautions. Always heed the

information noted on the safety decals.

WARNING

DO NOT REMOVE OR COVER ANY

SAFETY DECAL. Replace any safety

decal that becomes damaged or illegible.

1.4 DISPOSING OF MACHINE FLUIDS

Always dispose of machine fluids under the

guidance of all applicable local, regional and/

or federal law.

®

Vanair

For additional information, consult the

container label of the fluid in question.

encourages recycling when allowed.

1.3.4 SAFETY DECALS

Safety decals are placed onto, or located

near, system components that can present a

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - 3

SECTION 1: SAFETY VIPER DIESEL

BLANK PAGE

PAGE - 4 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 2: SPECIFICATIONS

SECTION 2:

SPECIFICATIONS

TABLE 2A: SPECIFICATIONS FOR VIPER DIESEL ROTARY SCREW COMPRESSOR

GENERAL SYSTEM

INFORMATION

ENGINE

Engine Speed

Engine Oil Capacity Four (4) Quarts 15W40 (Refer to Engi ne Operator’s Manual fo r Extreme

Fuel Consumption 1.25 GPH at Full Engine Speed / Load Nine (9) Hour Runtime (one

Fuel Tank Capacity Nine (9) Gallons

Fuel Type

Operating Temperature Limits

COMPRESSOR Single Stage, Oil Injected Rotary Screw

Model 80 CFM / 100 PSIG

Inlet Control Electric

Diesel 25HP

Idle Speed: 2200 RPM

Conditions)

gallon/hour @ 60% Duty Cycle)

Diesel Fuel

+10 °F (-7°C) to 120 °F (49 °C)

70 CFM / 125 PSIG

60 CFM / 150 PSIG

High Altitude: 70 CFM / 100 PSIG

I

II

SPECIFICATION

// Full Speed: 3600 RPM

III

Air Filter Pleated Paper, Dry Typ e

Table continued on next page

I

For specification and requirements regarding the Kubota® 25 HP Diesel Engine, refer to the Engine Operator’s

Manual. IMPORTANT: Do not adj ust the engine speed without first consulting the Vanair

(refer to Section 5.5.1).

II

Vanair recommends: Diesel Fuel Speci fica tion Type and Sulfur Content % (ppm) used must be compliant with all

applicable emission regulations for the area in which the engine is operated.

Engine manufacturer recommends a fuel sulfur content of less than 0.10% (1000 ppm). For fuels with a high sulfur

content 0.50% (5000 ppm) to 1.0% (10000 ppm) a more frequent engine oil and oil filter change schedule is needed

(approximately half). DO NOT USE fuels with a sulfur content greater than 1.0% (10000 ppm). For additional

information on fuel for this engine, consult Section 6.3 (Extreme Condition Operation), and the Engine Operator’s

Manual.

III

With cold weather option kit temperature range expands to: -40 °F (-40 °C). Refer to Section 7, Table 7B for options

list.

NOTE: Specifications are subject to change without notice.

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - 5

®

Service Department

SECTION 2: SPECIFICATIONS VIPER DIESEL

TABLE 2A: SPECIFICATIONS FOR VIPER DIESEL ROTARY SCREW COMPRESSOR (cont.)

GENERAL SYSTEM

SPECIFICATION

INFORMATION

COMPRESSOR (specifications continued from previous page)

Oil Filter Spin-on Style

Oil Capacity / Type Air End - 3 Quarts // Machine - 4 Quarts (1 gallon) (Vanguard™

Premium Synthetic Oil)

Safety Relief Valve Setting 200 PSIG

Operating Pressure Range 75-100 (Maximum) PSI; Pressure setting is set at factory to 100 PSI, but

may be adjusted downward accordingly.

Electrical System 12 VDC

Cooling System Air to Oil Heat Exchanger

Instrumentation Display Run Hours, Fuel Level, Compressor Temperature, Pressure, RPM

I

For specification and requirements regarding the Kubota® 25 HP Diesel Engine, refer to the Engine Operator ’s

Manual. IMPORTANT: Do not adjust the engine speed without first consulting the Vanair

(refer to Section 5.5.1).

II

Vanair recommends: Diesel Fuel Specification Type and Sulfur Content % (ppm) used must be compliant with all

applicable emission regulations for the area in which the engine is operated.

Engine manufacturer recommends a fuel sulfur content of less than 0.10% (1000 ppm). For fuels with a high sulfur

content 0.50% (5000 ppm) to 1.0% (10000 ppm) a more frequent engine oil and oil filter change schedule is needed

(approximately half). DO NOT USE fuels with a sulfur content greater than 1.0% (10000 ppm). For additional

information on fuel for this engine, consult Section 6.3 (Extreme Condition Operation), and the Engine Operator’s

Manual.

®

Service Department

III

With cold weather option kit temperature range expands to: -40 °F (-40 °C). Refer to Section 7, Table 7B for options

list.

NOTE: Specifications are subject to change without notice.

PAGE - 6 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 3: INSTALLATION

SECTION 3:

INSTALLATION

3.1 MACHINE PACKAGE RECEIPT/INSPECTION

Upon receipt of the machine package,

inspect the exterior of the shipping crate for

signs of shipping/transit damage. Any

damage should be reported immediately to

the shipping company. Open the lid and

inspect the component parts and supports to

ensure that there has been no internal

movements of assemblies or components

which may have caused damage. To install

the Viper Diesel Compressor System, refer

to the following sections.

NOTE

Contact Vanair® at

(219) 879-5100 / (800) 526-8817

Service Fax: (219) 879-5335

www.vanair.com

to report missing items, incorrect part

numbers, or other discrepancies.

3.2 INSTALLATION INSTRUCTIONS

DANGER

DO NOT install in enclosed spaces.

WARNING

ELECTRICAL HAZARD! Be sure the

battery is disconnected before starting

the installation.

NOTE

In order to prevent accidental damage to

vehicle components (fuel tanks, lines,

brake lines, wiring harnesses), note their

location before drilling any holes.

Refer to Figure 3-1 (parts 1 and 2), and the

following procedure:

1. Position the machine so that there is no

restriction of cooling air through the

enclosure (minimum of 12 inches from

front access side; minimum of six

inches from rear side. Cooling air

enters the enclosure through the front

and rear panels, passes through the

cooler, and exits through vents in the

end shroud.

2. Ensure that adequate height and

clearance exists to allow for the hood to

open (minimum of 49.9 inches from

mounting surface), and a clear passage

for service allowance to the

maintenance access panel located at

the back.

3. Mounting surface or support should be

adequate for the weight of the machine

and should be level for normal operation.

Mounting holes for four (4) 1/2” hold

down bolts are provided. Refer to

Section 7, Illustrations and Parts Lists

for additional installation and system

schematic drawings.

4. Service connections are conveniently

grouped at the end of the unit in the

base frame.

5. Electrical connections (system

designed for 12VDC negative ground).

Ensure all supply hoses and electrical wiring

are correctly specified, adequately supported

and do not touch or rest on any sharp edges.

Wiring should be protected with split loom to

prevent corrosion and consequently, loose

due to down time.

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - 7

SECTION 3: INSTALLATION VIPER DIESEL

NOTE

The dimensions listed in this diagram are

the minimum required clearance

distances needed for properly cooling the

machine. Additional clearance room may

be desired for easier access for control

and/or maintenance functions.

050848_r1_1of2

DISCLAIMER

If machine package is to be mounted

within a confined space such as beneath a

canopy, the unit must have a minimum of

eight (8) inch clearances on the front and

back sides for ventilation.

3.3 INSTRUMENT PANEL RELOCATION

The Viper Diesel compressor allows for the

instrument panel to be remote mounted if it

better-suits the vehicle’s mounting allowance

space or the compressor’s functions. The

optional extension harness must be used for

remote panel installation (see Table 7B).

Please note that if relocating the panel, you

should re-apply any zip ties that were cut to

re-establish the cable wire to the new

location. Tying the wire at intervals may be

needed to secure the panel cable away from

moving objects or sharp edges during

operation.

PAGE - 8 090058-OP_r0 (AUGUST-2014)

Figure 3-1: Dimension Diagram - Part 1 of 2

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 3: INSTALLATION

050848_r1_2of2

NOTE

The dimensions listed in this

diagram are the minimum

required clearance distances

needed for properly cooling the

machine. Additional clearance

room may be desired for easier

access for control and/or

maintenance functions.

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

Figure 3-1: Dimension Diagram - Part 2 of 2

090058-OP_r0 (AUGUST-2014) PAGE - 9

SECTION 4: OPERATION VIPER DIESEL

B

C

F

E

D

G

H

A

T

S

Q

P

Y

Z

X

K

L

M

N

J

V

W

U

AA

R

KEY DESCRIPTION KEY DESCRIPTION KEY DESCRIPTION

A BATTERY K LIFTING BAIL U ENGINE OIL DRAIN OUTLET/TUBE

B DIESEL FUEL PORT CAP L ENGINE OIL FILL PORT CAP V ENGINE AIR FILTER (HOUSING)

C COMPRESSOR UNIT M COOLER ASSEMBLY - ENGINE

D COMPRESSOR AIR INLET N COOLER ASSEMBLY / COM-

E PRESSURE RELIEF VALVE P ENGINE OIL FILTER Y COMPRESSOR OIL LEVEL SIGHT

W INLET VALVE SOLENOID

RADIATOR

X COMPRESSOR OIL DRAIN OUTLET/

PRESSOR OIL COOLER

TUBE

GLASS

F COMPRESSOR OIL FILTER Q RADIATOR FILL PORT Z COMPRESSOR OIL FILL PORT

G COMPRESSOR AIR FILTER

R COOLING FAN ASSEMBLY AA ENGINE OIL LEVEL/ DIPSTICK

(HOUSING)

H COMPRESSOR AIR/OIL

S COOLANT RECOVERY TANK

SEPARATOR

J ENGINE EXHAUST MUFFLER T RADIATOR DRAIN VALVE

I

There is an oil dipstick indicator locat ed on either side of the engine.

INDICATOR

I

Figure 4-1: Main Machine Component Locations

PAGE - 10 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 4: OPERATION

SECTION 4:

OPERATION

4.1 GENERAL INFORMATION

Refer to Figure 4-1. The Vanair® Viper

Diesel compressor has a comprehensive

array of controls and indicators for optimum

machine performance. Understanding the

correct operation of the system will help to

distinguish between a properly functioning

system and a system that may be indicating

the beginning of a malfunction. The

information in the Operation Section will help

the operator to recognize and interpret the

readings to assure that the system is

performing optimally.

NOTE

Before starting the Vanair Viper Diesel

compressor, read this section

thoroughly and familiarize yourself with

the controls and indicators - their

purpose, location and use.

NOTE

If start-up and shut-do wn procedures are

not followed, damage to the system and

its components may occur.

4.2 INSTRUMENTATION

Refer to Figure 4-2. The standard

instrument panel for the Viper Diesel

compressor features a digital display sc reen

with scrolling and operational rocker

switches.

4.2.1 DIGITAL DISPLAY SCREEN

The air pressure readout monitors service air

pressure and incorporates an over-pressure

shutdown function.

4.2.2 SCROLL SELECTOR ROCKER SWITCH

The scroll selector rocker switch allows the

operator to navigate through the settings and

displays related to the machine’s functions

during operation.

4.2.3 ON AND STOP SELECTION KEY

SWITCH

The ON AND STOP selection key switch is

used to turn the machine on and off.

4.3 INITIAL START-UP

PROCEDURE

The following procedure should be used to

make the initial start-up of the compressor.

1. Position the compressor on a level

surface so that proper amounts of

liquid can be added, if required.

2. Check engine and compressor oil levels

and add oil, if necessary.

3. Fill fuel tank.

4. Connect air hose/piping to discharge.

5. Press and hold Start button for one (1)

second to turn on display.

6. Press and hold Start button a second

time for one (1) second to start Engine

cranking sequence.

7. Allow the machine to sufficiently warm-up

before operating.

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - 11

SECTION 4: OPERATION VIPER DIESEL

A B C

KEY DESCRIPTION

A INS TRU MENT PANEL MODULAR DIS-

PLAY SCREEN: Di splay con ta ins fou r lines,

20 characters/line.

B SCROLL SELECTOR ROCKER SWITCH

C ON/START AND STOP SELECTION

ROCKER SWITCH

8. After the initial run, shut down machine

allow it to depressurize and top off

compressor oil sump, as required.

Inspect for any leaks, and tighten any

loose fittings.

4.4 SHUTDOWN PROCEDURE

1. Allow engine to run at idle for

approximately sixty (60) seconds.

2. Press the STOP button; NOTE: Allow the

compressor to blow down prior to re-

starting.

IMPORTANT

In case of emergency where immediate

shutdown is required, this procedure is

not necessary.

Press the STOP button immediately.

4.5 SUBSEQUENT START-UP PROCEDURE

On subsequent starts, follow the procedure

PAGE - 12 090058-OP_r0 (AUGUST-2014)

explained below:

Figure 4-2: Controller Panel

1. Check engine and compressor oils

and add oil, if necessary.

2. Fill the fuel tank.

3. Press and hold Start button for one (1)

second to turn on display.

4. Press and hold Start button a second

time for one (1) second to start Engine

cranking sequence.

5. Allow the machine to warm up

sufficiently before operating.

WARNING

Engage stop button prior to opening

panel or servicing machine. Engine can

start at any time in Auto mode.

4.6 CONTROLLER GUIDE

Refer to Figure 4-2 for controller panel

display features. The electronic controller

supplied in the Diesel Viper package has

been designed to work in conjunction with

the linear actuator that operates the speed

control. When used properly, they will reduce

fuel consumption, remind the user when

periodic service is due, extend the useful life

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 4: OPERATION

of the package, and help diagnose any

problems that may arise during the life of the

compressor system.

4.6.1 HOME SCREEN

The home screen displays the basic

information required during each state the

package can exist in. Before startup, it

displays fuel level and a message that helps

instruct the user how to start the engine.

While the engine is in its cranking sequence,

it displays a message describing what it is

doing (glow plugs, warm-up period, etc.).

During regular operation, it displays engine

RPM, compressor pressure and

temperature, fuel level, and hours of

operation. After shutdown, it displays the

blowdown timer required to elapse before

engine can be restarted.

4.6.2 SPLASH SCREEN

When the display first turns on, it displays the

manufacturer information, software version,

current hours, and serial number of the

machine. To access this screen after the

display goes to the home screen, press the

Up or Down button while at the home screen

and it can be accessed like the adjustable

parameters.

2. Press ON/START to select a parameter

to adjust.

3. Use the Up and Down buttons to cycle

between available settings.

4. Press ON/START to confirm the

parameter setting. This will return view

access to the home screen.

4.6.3.2 AUTO SHUTDOWN

When enabled, auto shutdown will turn off

the compressor package until air demand is

needed again.

4.6.3.3 AUTO CRANK

When enabled (ON/OFF , default to ON), auto

crank will apply the appropriate length of

glow plugs, crank the engine until it starts,

and allow for a brief warm-up period before

making air. When off, manual crank by

depressing ON/OFF switch.

4.6.3.4 SLEEP STATE TIMER

The sleep state timer is the length of time

that the package can be “asleep” before it

will turn off completely to reduce battery draw

and reduce the possibility of accidental

restart when no one is around.

4.6.4 SETTING PRESSURE

4.6.3 ADJUSTING USER SETTINGS

The Diesel Viper controller has several

settings that can be adjusted to suit each

user's specific requirements. The following

parameters can be adjusted as follows:

4.6.3.1 PARAMETERS

Parameter Name

Auto Shutdown (min.) 0-30 (1) 5

Auto Crank On/Off On

Sleep State Timer (min.) 0-15 (5) 10

1. After the display is turned on, from the

home screen press the Up or Down

buttons on the control panel to toggle

between each parameter.

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

Setting Limits

(Increment)

Default

090058-OP_r0 (AUGUST-2014) PAGE - 13

Refer to Section 2, Specifications for

pressure range. When the machine is

running, the Up and Down buttons adjust the

pressure set point.

4.6.5 SAFETY

The controller is designed with the user's

safety in mind. There are several safety

conditions that must be met to run the

compressor package. The pressure

transducer and temperature thermistor on

the compressor must be plugged in and

functional for the package to run. The

alternator connector must be plugged in for

the package to run. The hood must remain

closed until after the engine has started. If

any unsafe condition is present before the

package is started or during it s opera tion, the

controller will alert the user with a message

SECTION 4: OPERATION VIPER DIESEL

on the display. Once the problem is

corrected, the message can be cleared by

holding the Up button.

4.6.6 SERVICE INTERVALS

The controller will remind the user of periodic

service intervals. Once the package has

been serviced, the message can be cleared

by holding the Up button.

4.7 OPERATING CONDITIONS

1. Operate only in well-ventilated areas.

Exhaust fumes can be lethal.

2. Ensure there are no obstructions on

cooling air intakes at both ends of the

machine.

3. Do not leave anything resting on top of

the machine. Hot engine exhaust and

cooling air will generate high heat.

4. Be sure to leave sufficient room around

the machine for cooling air. See Figure

3-1.

5. Operate machine with top cover closed to

avoid engine exhaust fumes and heat

from being deflected.

6. Refer to specifications for operating

parameters, speeds, etc.

4.8 EXTREME CONDITIONS

When operating in extreme cold or hot

conditions, in the presence of high humidity,

or at a high altitude, extra attention should be

given to any indication that could lead to a

serious problem. Preventative safeguards

exist that can minimize the possibility of

malfunctions that are prone to occur under

certain ambient conditions. Refer to Section

6.3, Extreme Condition Operation, for

additional information on variable ambient

operating conditions, and adjustment

adaptations that can be made accordingly.

PAGE - 14 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 5: MAINTENANCE

KEY DESCRIPTION

A COMPRESSOR FILL CAP

B FILL CAP BLEED VENT GROOVE: Open/crack

cap slightly to allow bleed vent to relieve air

pressure before removing cap.

C OIL FILL LEVEL: Full indication is the center of

the sight glass.

Figure 5-1: Compressor Pressure Relief Check

A

B

C

WARNING

DO NOT remove caps, plugs and/or other

components when compressor is running or

pressurized. Stop compressor and de-

pressurize system prior to maintenance of

system. Relieve the entire system pressure

by opening the air tank drain/vent valve, if

equipped, which will vent all pressure to the

atmosphere.

Wear personal protective equipment such as

gloves, work boots, and eye and hearing

protection as required for the task at hand.

Refer to Figure 5-1. Open fill cap SLOWLY

(contents under pressure ) to mak e s ure all

pressure has been relieved.

MAINTENANCE

5.1 GENERAL INFORMATION

A strict maintenance program is the key to

long life for the Viper Series Compressor

System package. Below is a program that,

when adhered to, should keep the package

in top operating condition. Refer to Table

5.3A, Table 5.3B, and Section 5.5, Parts

Replacement and Adjustment Procedures

for detailed descriptions of specific

compressor system components. Refer to

Table 7A in Section 7 for part order

information.

WARNING

To avoid accidental system start-ups

during periods of maintenance,

disconnect the positive (+) cable to the

battery terminal, and place the wire

aside, or tape the contact end so that it

cannot accidentally contact the battery

post.

SECTION 5:

Operating the machine package in a

severe environment requires more

frequent service interval s.

5.2 ROUTINE MAINTENANCE SCHEDULE

Vanair® Manufacturing, Inc. considers the

maintenance schedule given in Section 5.3,

Maintenance Schedule Table (5.3A for

compressor; 5.3B for engine), to be part of

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

the warranty agreement with the customer.

This maintenance regimen must be followed

in order to protect the warranty of the

machine package.

NOTE

090058-OP_r0 (AUGUST-2014) PAGE - 15

SECTION 5: MAINTENANCE VIPER DIESEL

NOTE

Follow the prescribed periodic

maintenance (PM) schedule as

recommended. Perform the required PM

schedule at recommended intervals.

Failure to follow this prescribed periodic

maintenance at the recommended

intervals will impair the package safety,

performance characteristics, shorten the

package’s life, and will negatively affect

the warranty coverage

of the package.

Vanair® Manufacturing, Inc. especially

requires that a consistent service regimen be

established for engine oil changes, and

engine and compressor air filter servicing.

The following schedule is designed so that

many of the other maintenance tasks are

completed when the engine and compressor

air filters are serviced, and the engine oil is

changed.

WARNING

Follow all applicable safety

recommendations as outlined in Section

1: Safety of this manual.

Please take a moment to acquaint yourself

with the service schedule presented in

Section 5.3 (5.3A for compressor; 5.3B for

engine) to assist the customer in

establishing a maintenance routine log.

For assistance in obtaining routine

maintenance or replacement parts, consult

Section 7.1, Parts Ordering Procedure,

and Table 7A: Recommended Spare Parts

List.

PAGE - 16 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 5: MAINTENANCE

NOTE

ACTION TO TAKE

If working in dusty or dirty conditions, reduce the

recommended time intervals between servicing by

half for engine and compressor oil change, and

engine and compressor filter servicing.

SCHEDULE

Hours

MAINTENANCE

DAILY

Hours

PERIOD

BREAK-IN

(2) years

Hours or Two

Every 1000

(1) year

Hours or One

Every 500

Every 100

First 50

Refer to Figure 5-1 to determine proper oil level, which is

equal to the center of the sight glass. Add as necessary.

• •

Ensure that all connections and fittings, including tubing and

electrical connections, are snugly fastened without being

twisted or compromised by extreme bending or contact with

sharp corners or surfaces. Zip-tie any loose length of fitting if

it appears to have a tendency to shift or cause wear while

machine is in operation.

Visually review the entire machine being mindful of any

evidence of abnormal wear, including pooled oil, frayed or

rubbed connection piping, loose fasteners or hardware, l eaks,

etc.

Order oil and oil filter element replacement kits. Refer to

Table 7A: Recommended Spare Parts for reorder number.

Order air filter replacement element.Refer to Table 7A:

Recommended Spare Parts for reorder number.

Use low pressure wash down on exterior.

Order separator/coalescer replacement element. Refer to

Table 7A: Recommended Spare Parts for reorder number.

•

•

•

•

• •

• •

WARNING

Before performing maintenance:

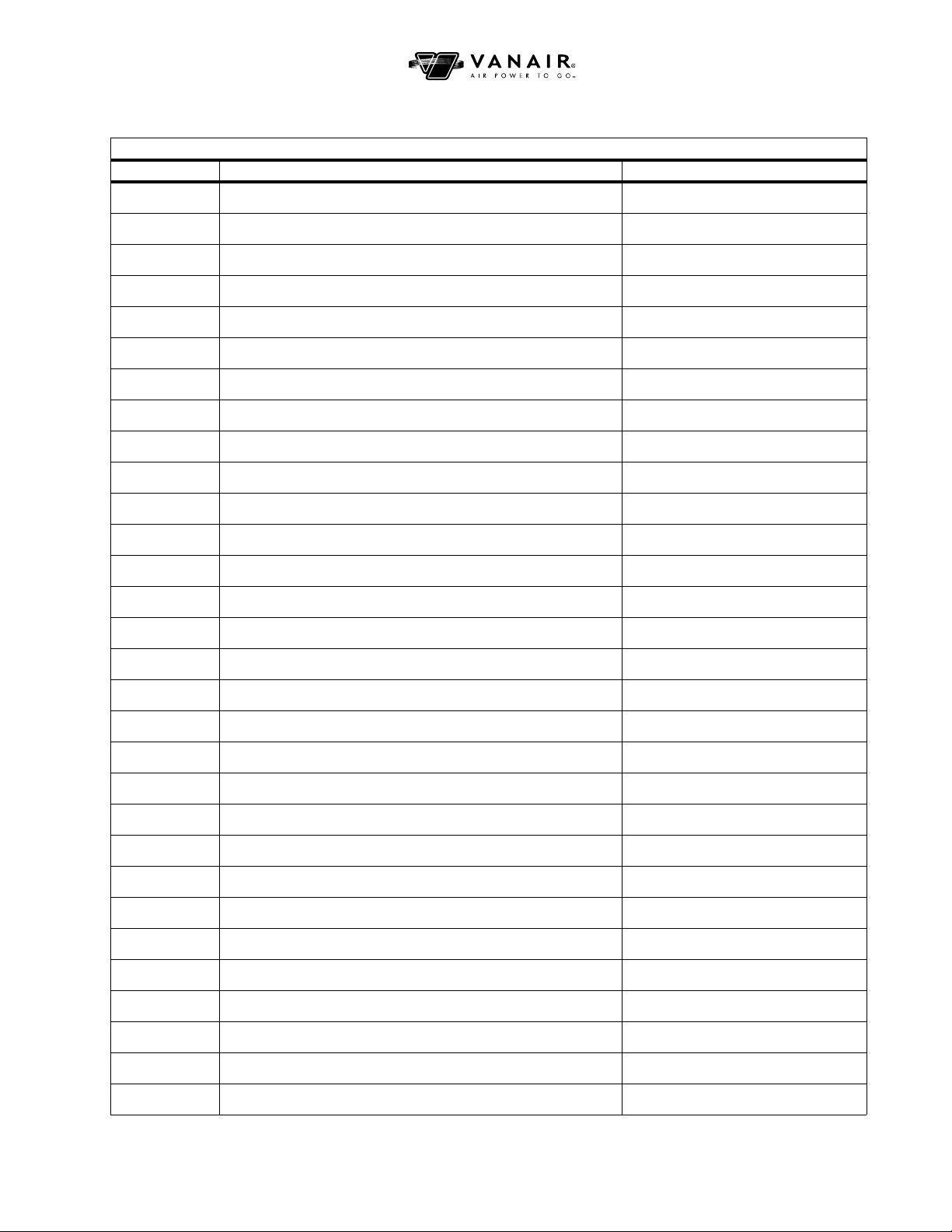

5.3A MAINTENANCE SCHEDULE TABLE - COMPRESSOR INTERVALS

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

Shut down machine, relieve all system pres-

ing maintenance.

Section of this manual.

Always clearly tag the start-up instrumenta-

sure and lock out all power , as per the Safety

tion against accidental system start-up s dur-

Check oil level

KEY TASK DESCRIPTION

090058-OP_r0 (AUGUST-2014) PAGE - 17

Check line fittings and electrical

connections

1

2

System inspection

Change compressor oil and filter

3

Change air filter element

(check every 100 hours)

Clean cooler

(check every 100 hours)

Change separator element

4

5

6

7

SECTION 5: MAINTENANCE VIPER DIESEL

NOTE

and engine and compressor filter servicing.

by half for engine and compressor oil change,

recommended time intervals between servicing

If working in dusty or dirty conditions, reduce the

years

Every two (2)

Every 500 Hours

Consult the Engine Operator’s Manual for engine oil

specification. Consult Table 7A: Recommended Spare

Parts List for replacement kit or part order number.

Ensure that all fuel hose connections and fittings are

free of any telltale signs of leaking and well connected.

Zip-tie any loose length of hose fitting if it appears to

have a tendency to shift or contact an abrasive surface

while machine is in operation.

Consult the Engine Operator’s Manual for procedure on

changing the engine air filter element. Should the

element need to be replaced, refer to Table 7A:

Recommended Spare Parts List for replacement kit or

part order number. Consult the Engine Operator’s

Manual for procedure on cleaning the engine fuel filter.

Tighten if necessary. Consult the Engine Operator’s

Manual for fan belt information.

Consult the Engine Operator’s Manual for procedure on

changing the engine oil filter, and manufacturer’s

recommended oil usage.

Ensure that the intake hose is properly fastened and

free from any compromises such as tears or holes.

or One (1) Year

Every 50 Hours

MAINTENANCE SCHEDULE

PERIOD

BREAK-IN

Daily

First 50 Hours

Every 400 Hours

Every 200 Hours

Every 100 Hours

•

••

• •

•• •

•

•

WARNING

5.3B MAINTENANCE SCHEDULE TABLE - ENGINE INTERVALS

negative (-) battery cable.

Shut down machine, relieve all

Before performing maintenance:

system pressure and lock out all power,

For lock-out/tag-out disconnect the

as per the Safety Section of this manual.

KEY TASK DESCRIPTION ACTION TO TAKE

Change engine oil.

1

PAGE - 18 090058-OP_r0 (AUGUST-2014)

Check fuel lines and clamps

2

Check engine air filter element

(replace if necessary), and fuel filter

3

bowl (clean if necessary).

Check alternator belt tightness

Change oil filter

4

5

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

Check air intake hose

6

VIPER DIESEL SECTION 5: MAINTENANCE

Continued on next page

NOTE

and engine and compressor filter servicing.

by half for engine and compressor oil change,

recommended time intervals between servicing

If working in dusty or dirty conditions, reduce the

years

Every two (2)

Ensure that the radiator hoses and clamp bands are

intact, in good working order and fastened correctly. If

hoses are showing signs of wear (cracking, stretching,

etc.), replace hoses (refer to Section 7.14, Hose

Installation Guide for assistance when replacing

damaged hoses).

Consult the Engine Operator’s Manual for procedure on

replacing the engine fuel filter element. Refer to Table

7A: Recommended Spare Parts List for replacement

kit or part order number.

Consult the Engine Operator’s Manual for procedure on

cleaning the radiator water jacket.

Consult the Engine Operator’s Manual for procedure on

replacing the engine fan belt. Refer to Table 7A:

Recommended Spare Parts List for replacement kit or

part order number.

Consult the Engine Operator’s Manual for procedure on

changing the engine air filter. Refer to Table 7A:

Recommended Spare Parts List for replacement kit or

part order number.

or One (1) Year

Every 50 Hours

MAINTENANCE SCHEDULE

PERIOD

BREAK-IN

Daily

First 50 Hours

Every 500 Hours

Every 400 Hours

Every 200 Hours

Every 100 Hours

I

•

•

•

•

WARNING

Shut down machine, relieve all

Before performing maintenance:

5.3B MAINTENANCE SCHEDULE TABLE - ENGINE INTERVALS

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

system pressure and lock out all power,

negative (-) battery cable.

For lock-out/tag-out disconnect the

as per the Safety Section of this manual.

KEY TASK DESCRIPTION ACTION TO TAKE

Check radiator hoses and clamp

bands

7

Replace fuel filter element

8

Flush cooling system

Replace fan belt

9

10

Replace air filter element

11

Every 200 hours or six (6) months.

I

090058-OP_r0 (AUGUST-2014) PAGE - 19

SECTION 5: MAINTENANCE VIPER DIESEL

Continued on next page

NOTE

and engine and compressor filter servicing.

by half for engine and compressor oil change,

recommended time intervals between servicing

If working in dusty or dirty conditions, reduce the

years

Every two (2)

Every 500 Hours

Replace the radiator hoses and clamp bands. Refer to

Section 7.14, Hose Installation Guide for assistance

when replacing worn or damaged hoses. Refer t o Table

7A: Recommended Spare Parts List for replacement

kit or part order number.

Due to shipping regulations pertaining to lead acid bat-

teries, Vanair recommends procuring a replacement bat-

tery from a localized source. Two possible replacement

•

•

Replace the fuel hose and clamp bands. Refer to

Section 7.14, Hose Installation Guide for assistance

when replacing worn or damaged tubing. Refer to Table

7A: Recommended Spare Parts List for replacement

kit or part order number.

Consult the Engine Operator’s Manual for procedure on

changing the radiator coolant. Follow Engine Operator’s

models include: BatteriesPlus® no. SLi96R, and NAPA

battery no. BAT 7590.

II

Manual recommendations for coolant type to use.

•

or One (1) Year

Every 50 Hours

MAINTENANCE SCHEDULE

PERIOD

BREAK-IN

Daily

First 50 Hours

Every 400 Hours

Every 200 Hours

Every 100 Hours

•

Service Department.

®

WARNING

negative (-) battery cable.

Shut down machine, relieve all

5.3B MAINTENANCE SCHEDULE TABLE - ENGINE INTERVALS

Before performing maintenance:

system pressure and lock out all power,

as per the Safety Section of this manual.

For lock-out/tag-out disconnect the

KEY TASK DESCRIPTION ACTION TO TAKE

PAGE - 20 090058-OP_r0 (AUGUST-2014)

Replace radiator hoses and clamp

bands

12

Replace battery

13

Inspect fuel lines and clamps

14

Change radiator coolant

15

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

Consult the Vanair

II

VIPER DIESEL SECTION 5: MAINTENANCE

KEY DESCRIPTION

A 50 AMP CIRCUIT BREAKER - AUTO RESET

B ENGINE STARTER (Location reference)

C ENGINE OIL FILTER (Location reference)

Figure 5-2: 50A Circuit Breaker Location

AC B

5.4 REPLACEMENT PARTS

Replacement parts should be purchased

®

through your local Vanair

where the Viper Diesel Air Compressor

System was purchased. If, for any reason,

parts are not available in this manner, they

can be purchased through Vanair directly.

NOTE

For assistance when ordering new

replacement parts, consult Section 7.1,

Parts Ordering Procedure, and Table 7A:

Recommended Spare Parts List.

NOTE

If additional spare parts are being stored

for future use, make certain that they are

stored in proper cont ainers that a llow for

protection against contamination, and

kept in a clean area of moderate

temperature reading. For information on

storing the machine package for periods

of non-use, consult Section 5.7.2, Long

Term Storage.

representative or

NOTE

Do not tamper with the RPM setting to

increase the maximum engine speed.

Overspeed is hazardous and will void the

engine warranty.

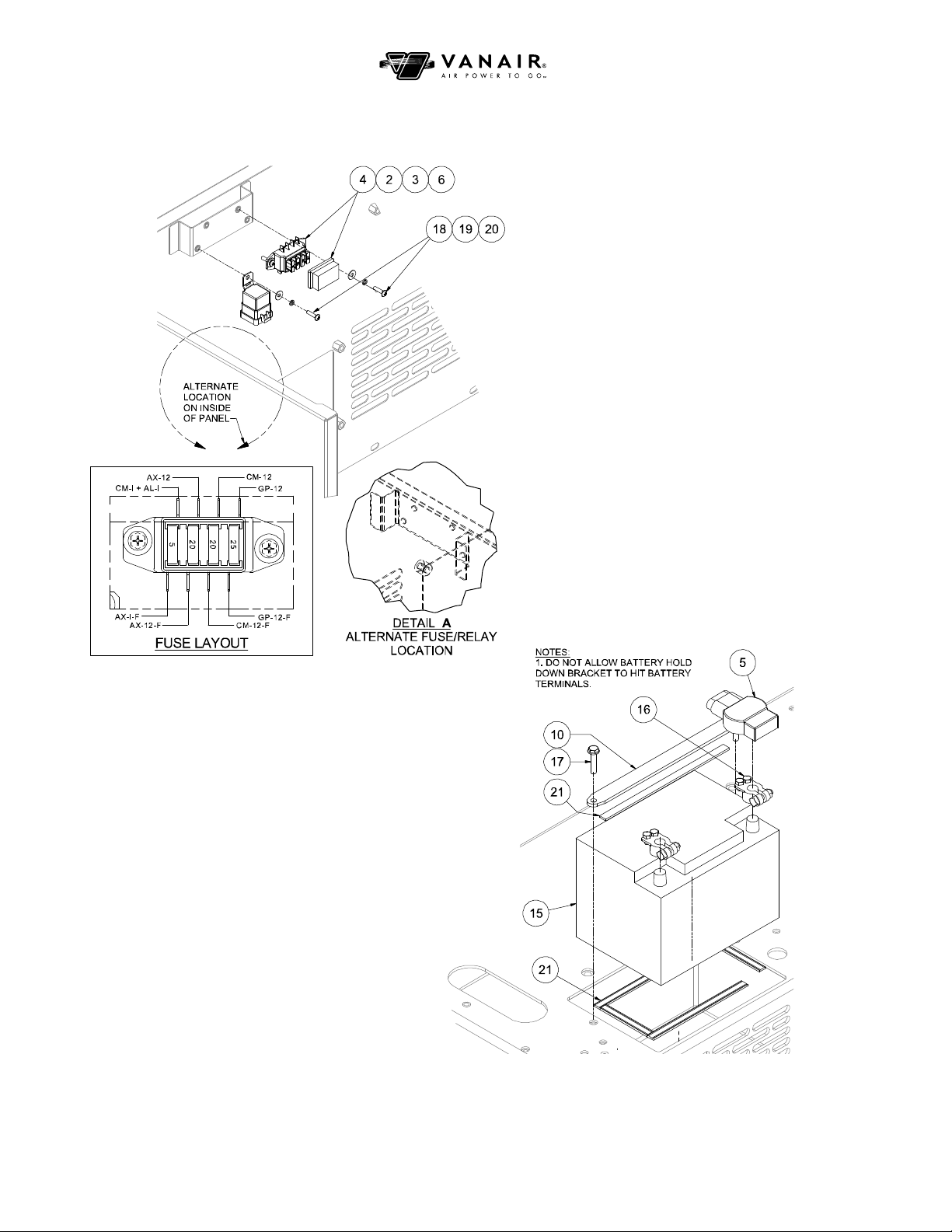

5.6 SERVICING THE SYSTEM FUSES AND CIRCUIT BREAKER

Consult Section 7.9, Electrical System,

(FUSE LAYOUT diagram insert) to

determine the location of the specific fuses.

Refer to Figure 5-2 for reference location of

the 50A circuit breaker.

NOTE

Refer to the Engine Operator’s Manual for

detailed maintenance and replacement

procedures for the engine.

5.7 STORAGE AND

INTERMITTENT USE

VANAIR MANUFACTURING, INC.

10896 West 300 North

Michigan City, IN 46360

Telephone: (800) 526-8817

(219) 879-5100

Service Fax: (219) 879-5335

Parts Fax: (219) 879-5340

Sales Fax: (219) 879-5800

www.vanair.com

5.5 PARTS REPLACEMENT AND ADJUSTMENT PROCEDURES

5.5.1 ADJUSTING THE ENGINE SPEED

The Viper Diesel was designed in such a

way that the governor speeds should not

need to be adjusted. Should the unit operate

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

outside of specified speeds, consult the

090058-OP_r0 (AUGUST-2014) PAGE - 21

SECTION 5: MAINTENANCE VIPER DIESEL

5.7.1 INTERMITTENT USE

If the unit is not used very regularly always

treat the fuel with a fuel stabilizer.

Check all belts and hoses for signs of

deterioration such as visible surface cracks,

stiffness or discoloration.

5.7.2 LONG TERM STORAGE

Disconnect the battery cable that is

connected to the negative (-) side of the

battery.

Cover the unit with a tarp or plastic to

prevent the accumulation of dust, but le ave

the bottom open for air circulation.

Fill the fuel tank with fuel and fuel stabilizer

to prevent moisture build-up in the tank.

PAGE - 22 090058-OP_r0 (AUGUST-2014)

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 6: TROUBLESHOOTING

Figure 6-1: Machine Serial Plate Location

NOTE

When contacting the Vanair Service

Department, please have machine serial

number on hand to quickly expedite

service. See below for machine serial plate

location.

NOTE

Machine serial number also displays on

instrument panel at start-up, on the hours

screen.

TROUBLESHOOTING

6.1 GENERAL INFORMATION

The information contained in this section has

been compiled from years’ worth of inform ation gathered from the field. It contains symptoms and usual causes for the most common

types of problems that may occur. All available data concerning the trouble should be

systematically analyzed before undertaking

any repairs or component replacement.

A visual inspection is worth performing for

almost all problems and may avoid unnecessary additional damage to the machine. The

procedures which can be performed in the

least amount of time and with the least

amount of removal or disassembly of parts

should be performed first.

SECTION 6:

WARNING

Before starting, performing maintenance,

or replacing parts, relieve the entire

system pressure by opening a service

valve, which will vent all pressure to the

atmosphere.

Although Vanair

tions that may occur during the operation life

of the machine package, the Troubleshooting

Guide may not cover all possible situations.

Be aware that additional troubleshooting

information may be found in other sources,

such as the Engine Operator’s Manual.

Should the situation remain unresolved after

exhausting available sources, contact the

Vanair Service Department at:

Phone: 800-526-8817 (toll free)

Phone: 219-879-5100

Fax: 219-879-5335

®

strives to anticipate situa-

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - 23

SECTION 6: TROUBLESHOOTING VIPER DIESEL

6.2 TROUBLESHOOTING GUIDE

Fault/Malfunction Possible Cause Corrective Action

Machine does not start

Fault:

Freq Sensor Error, Machine Will

Not Run

Engine will not crank Faulty battery connection. Check for proper battery connections and

Engine will not start Low fuel and/or oil supply Check fuel gauge. Replenish as necessary.

Controller is not receiving input from

alternator connector

ENGINE

Battery out of power Recharge or replace battery.

Control module fuse blown Check fuse; refer to Section 7.9.

Machine hood shutdown safety switch

prevents start-up of engine

Faulty starter or starter solenoid Replace.

Faulty 50A circuit breaker Replace.

Check connection/continuity.

During extremely cold weather, use of

heater pads is required to get engine to spin

fast enough to generate a usable signal. If

no heater pads are installed, change crank

sequence to Manual Crank (refer to Section

4.6.3.1, Parameters).

battery charge.

Close hood panel or check if roof switch is

faulty.

Consult the Engine Operator’s Manual for

additional information on engine

maintenance.

Pinched fuel line Replace or reroute if necessary.

Plugged fuel filter(s) Replace if necessary. Refer to the Engine

Low battery voltage Recharge or replace if necessary.

Plugged engine air filter Replace engine air filter. Refer to Engine

Defective oil pressure switch Check continuity, and replace if necessary.

Defective engine temperature switch Check continuity, and replace if necessary.

Poor ground connection Check and clean/renew connection.

Improper Control Operation:

Engine does not speed up

Speed control actuator stuck Lubricate; replace speed control actuator if

Engine speed control lever stuck Free lever and lubricate if necessary.

PAGE - 24 090058-OP_r0 (AUGUST-2014)

Operator’s Manual for additional information

on engine maintenance.

Loose connections; tighten connections.

Dirty connections; clean connections.

Operator’s Manual.

necessary.

Continued on next page

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

VIPER DIESEL SECTION 6: TROUBLESHOOTING

6.2 TROUBLESHOOTING GUIDE

Fault/Malfunction Possible Cause Corrective Action

ENGINE (CONTINUED)

Improper Control Operation:

Engine does not speed up

(continued)

Improper Control Operation:

Engine does not slow down

Engine stops during operation

Fault:

Engine High Temp Shutdown

Engine stops during operation

Fault:

Low Engine Oil Pressure

Fuel filter partly plugged Replace fuel filter. Refer the Engine

Operator’s Manual.

Auxiliary fuel pump may be needed for

remote fuel tank.

Speed control actuator stuck Lubricate; replace speed control actuator if

necessary.

Engine speed control lever stuck Free lever and lubricate if necessary. Refer

to Engine Operator’s Manual.

Faulty pressure tranducers Check and replace, if necessary.

Located too close to obstruction Move further from obstruction.

Engine radiator plugged Clear debris/dirt from engine radiator.

Fault with engine cooling system Consult Engine Operator’s Manual.

Ambient temperature too high Consult Section 6.3.3, High Temperature

Operation.

Faulty temperature switch Replace.

Low oil level Check engine oil level; replenish as

necessary. Consult the Engine Operator’s

Manual for additional information on engine

maintenance.

Engine shutdown switch activated Confirm that access door is properly in

place. Replace faulty engine shutdown

switch.

Faulty oil pressure switch Replace.

Engine oil filter plugged Replace engine oil filter. Refer to the Engine

Operator’s Manual.

Gradual loss of engine power Contaminated fuel Drain and replace fuel supply.

Engine air filter contaminated Check air filter. Replace if necessary (refer

to the Engine Operator’s Manual).

Fuel filter(s) contaminated Check fuel filters. Refer to the Engine

Operator’s Manual for additional information

on engine maintenance.

Low fuel level Add fuel.

Overload Reduce load; check load use, and reduce

Continued on next page

VANAIR MANUFACTURING, INC.

(800) 526-8817 • www.vanair.com

090058-OP_r0 (AUGUST-2014) PAGE - 25

SECTION 6: TROUBLESHOOTING VIPER DIESEL

6.2 TROUBLESHOOTING GUIDE

Fault/Malfunction Possible Cause Corrective Action

ENGINE (CONTINUED)

Gradual loss of engine power

(continued)

For additional information concerning an engine problem, consult the Engine Operator’s Manual.

Compressor overheats

Fault:

Compressor High Temp

Shutdown

Compressor will not build up

pressure

Engine not warmed up Allow engine to warm up.

COMPRESSOR

Low compressor oil level Check oil level and refill to proper level if

necessary (ensure machine is parked on a

level surface).

Obstructed cooler fins Clear/clean if required.

Insufficient air flow over cooler Check for obstructions (frame, body, etc.) to

cooling air flow.

Defective temperature thermistor Check sensor; replace if necessary.

Compressor oil filter plugged Replace compressor oil filter.

Defective compressor thermal valve Replace valve.

Low compressor oil level Check oil level and refill to proper level if

necessary (ensure machine is parked on a

level surface).

Unload solenoid valve defective Replace solenoid valve.

Air demand too high Check for leaks and take corrective action.

Check air tools for wear, damage, or

malfunctions. Replace or repair.

Compressor capacity too low to

accommodate demand

Compressor air filter plugged Check air filter. Replace if necessary.

Engine does not speed up: input RPM

too slow

Engine speed control lever stuck Free lever and lubricate if necessary.

Service valve is open Close service valve.

Pressure transducer is malfunctioning Replace as necessary.

Inlet valve fails to open

Inlet valve frozen shut

Leak in air control line Check for leaks and take corrective action.

PAGE - 26 090058-OP_r0 (AUGUST-2014)

Substitute larger capacity compressor

system.

Check engine speed control actuator.

Consult the Engine Operator’s Manual.