VAMP 50 / VAMP 51

Overcurrent & earthfault protection relay

VAMP 52

Feeder and motor protection relay

Operation and configuration

instructions

Technical description

Operation and configuration Table of Contents

1. General...................................................................................3

1.1. Relay features.....................................................................3

1.2. User interface......................................................................4

1.3. Operating Safety................................................................4

2. Local panel user interface ....................................................5

2.1. Relay front panel................................................................5

2.1.1. Display .........................................................................6

2.1.2. Menu navigation and pointers................................7

2.1.3. Keypad........................................................................8

2.1.4. Operation indicators.................................................9

2.1.5. Adjusting display contrast ........................................9

2.2. Local panel operations.................................................. 10

2.2.1. Navigating in menus .............................................. 10

2.2.2. Menu structure of protection functions .............. 13

2.2.3. Setting groups ......................................................... 17

2.2.4. Fault logs.................................................................. 18

2.2.5. Operating levels...................................................... 19

2.3. Operating measures....................................................... 21

2.3.1. Control functions .................................................... 21

2.3.2. Measured data....................................................... 22

2.3.3. Reading event register .......................................... 23

2.3.4. Forced control (Force)........................................... 24

2.4. Configuration and parameter setting......................... 25

2.4.1. Parameter setting................................................... 26

2.4.2. Setting range limits ................................................. 27

2.4.3. Disturbance recorder menu DR ........................... 27

2.4.4. Configuring digital inputs DI.................................. 28

2.4.5. Configuring digital outputs DO ............................ 28

2.4.6. Configuring analogue outputs AO (Option)...... 29

2.4.7. Protection menu Prot............................................. 29

2.4.8. Configuration menu CONF................................... 30

2.4.9. Protocol menu Bus.................................................. 31

2.4.10. Single line diagram editing ................................... 35

2.4.11. Blocking and interlocking configuration............. 35

3. VAMPSET PC software ..........................................................36

2

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 1 General 1.1 Relay features

1. General

This first part (Operation and configuration) of the publication

contains general descriptions of the functions, of the protection

relay as well as operation instructions. It also includes

instructions for parameterization and configuration of the relay

and instructions for changing settings.

The second part (Technical description) of the publication

includes detailed protection function descriptions as well as

application examples and technical data sheets.

The Mounting and Commissioning Instructions are published

in a separate publication with the code VMMC.EN0xx.

1.1. Relay features

The comprehensive protection functions of the relay make it

ideal for utility, industrial, marine and off-shore power

distribution applications. The relay features the following

protection functions.

List of protection functions

IEEE/ANSI

code

50/51

46R

46 I2> Current unbalance protection Only VAMP 51/52

47 I2>>

48 Ist> Stall protection

66

49 T> Thermal overload protection

37 I< Undercurrent protection Only VAMP52

50N/51N

67NT

67N

59N

59

27

51F2 If2> Second harmonic stage

50BF

99 Prg1…8 Programmable stages Only VAMP51/52

IEC symbol Function name Note

3I>, 3I>>, 3I>>> Overcurrent protection

> Broken conductor protection

I

2/I1

Phase reversal / incorrect

phase sequence protection

N> Frequent start protection

>, I0>>, I0>>>,

I

0

I

>>>>

0

> Intermittent transient earth

I

0t

>, U0>> zero sequence voltage

U

0

U>, U>>, U>>> Single-phase overvoltage

U<, U<<, U<<< Single-phase undervoltage

CBFP Circuit-breaker failure

Earth fault protection

fault protection

Directional earth fault

protection

protection

protection

protection

protection

application option is

in motor protection

measurement option

measurement option

is 1LL (line-to-line

(phase-to-neutral

Only VAMP52

available when

mode.

Only VAMP52

available when

is Uo

Only VAMP 52

available when

voltage) or 1LN

voltage).

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

3

1.2 User interface 1 General Operati o n and configuration

50ARC/

50NARC

ArcI>, ArcI01> Optional arc fault protection

Further the relay includes a disturbance recorder. Arc

protection is optionally available.

The relay communicates with other systems using common

protocols, such as the Modbus RTU, ModbusTCP, Profibus DP,

IEC 60870-5-103, IEC 60870-5-101, IEC 61850, SPA bus, and

DNP 3.0. An optional communication option is required for

this (see ordering code in technical description).

1.2. User interface

The relay can be controlled in three ways:

Locally with the push-buttons on the relay front panel

Locally using a PC connected to the USB port on the front

Via remote control over the optional remote control port on

the relay rear panel.

(with an external module)

1.3. Operating Safety

The terminals on the rear panel of the relay may

carry dangerous voltages, even if the auxiliary

voltage is switched off. A live current transformer

secondary circuit must not be opened.

Disconnecting a live circuit may cause dangerous

voltages! Any operational measures must be carried out

according to national and local handling directives and

instructions.

Carefully read through all operation instructions before any

operational measures are carried out.

4

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.1 Relay front panel

2. Local panel user interface

2.1. Relay front panel

The figure below shows, as an example, the front panel of the

overcurrent and earthfault protection relay VAMP 50 and the

location of the user interface elements used for local control.

1

2

3

VAMP50Front

Figure 2.1-1. Relay front panel

1. LCD dot matrix display

2. Keypad

3. LED indicators

4. USB communication port for PC

4

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

5

2.1 Relay front panel 2 Local panel user interface Operation and configuration

2.1.1. Display

The relay is provided with a backlighted 128x64 LCD dot

matrix display. The display enables showing 21 characters is

one row and eight rows at the same time. The display has two

different purposes: one is to show the single line diagram of the

relay with the object status, measurement values, identification

etc. (Figure 2.1.1-1). The other purpose is to show the

configuration and parameterization values of the relay (Figure

2.1.1-2).

Figure 2.1.1-1 Sections of the LCD dot matrix display

1. Freely configurable single-line diagram

2. Controllable objects (max six objects)

3. Object statuses (max eight objects)

4. Bay identification

5. Local/Remote selection

6. Auto-reclose on/off selection (if applicable)

7. Freely selectable measurement values (max. six values)

Figure 2.1.1-2 Sections of the LCD dot matrix display

6

1. Main menu column

2. The heading of the active menu

3. The cursor of the main menu

4. Possible navigating directions (push buttons)

5. Measured/setting parameter

6. Measured/set value

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.1 Relay front panel

Backlight control

Display backlight can be switched on with a digital input,

virtual input or virtual output. LOCALPANEL CONF/Display

backlight ctrl setting is used for selecting trigger input for

backlight control. When the selected input activates (rising

edge), display backlight is set on for 60 minutes.

2.1.2. Menu navigation and pointers

1. Use the arrow keys UP and DOWN to move up and down in

the main menu, that is, on the left-hand side of the display.

The active main menu option is indicated with a cursor. The

options in the main menu items are abbreviations, e.g. Evnt

= events.

2. After any selection, the arrow symbols in the upper left

corner of the display show the possible navigating directions

(applicable navigation keys) in the menu.

3. The name of the active submenu and a possible ANSI code

of the selected function are shown in the upper part of the

display, e.g. CURRENTS

4. Further, each display holds the measured values and units

of one or more quantities or parameters, e.g. Ilmax 300A.

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

7

2.1 Relay front panel 2 Local panel user interface Operation and configuration

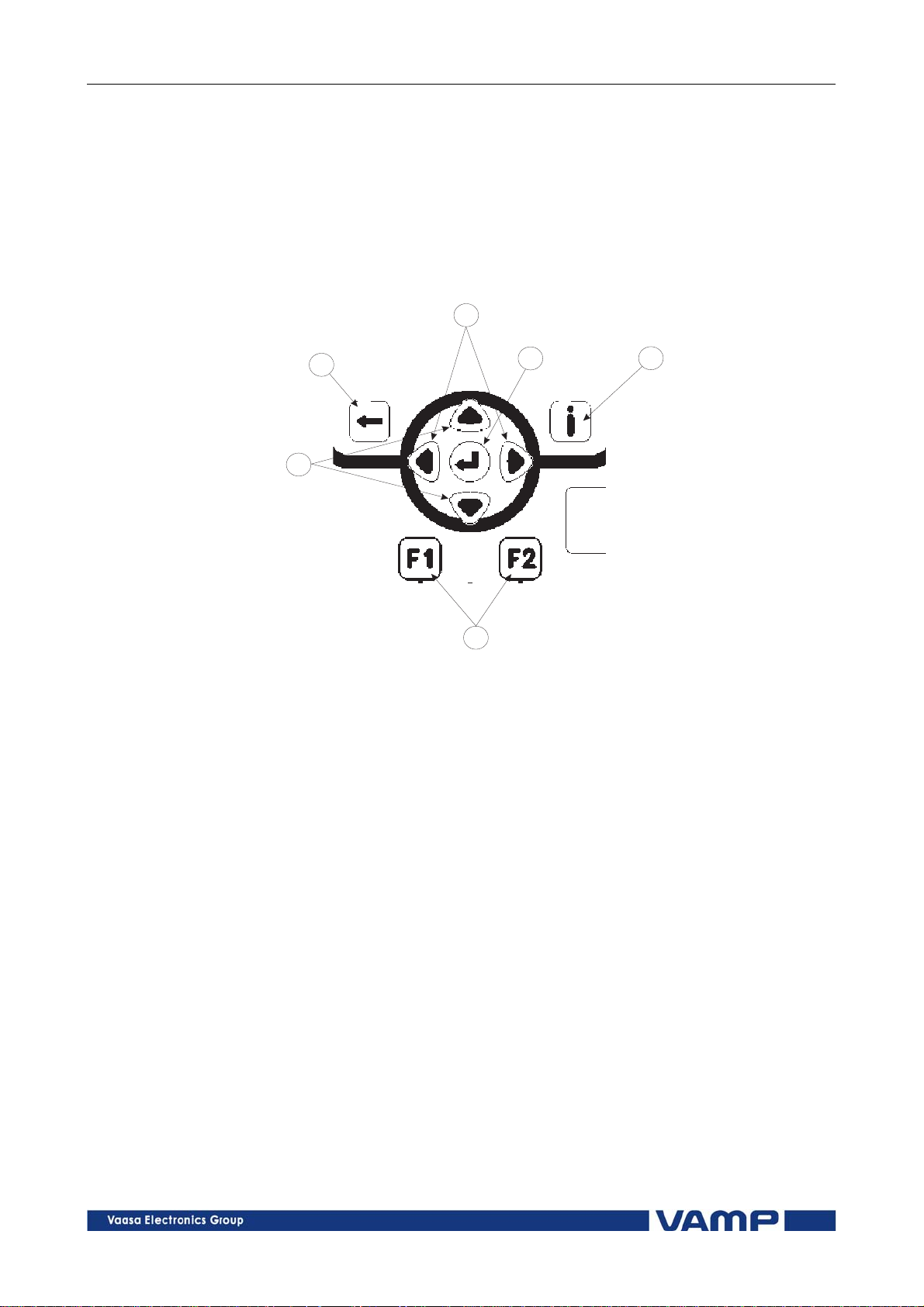

2.1.3. Keypad

You can navigate in the menu and set the required parameter

values using the keypad and the guidance given in the display.

Furthermore, the keypad is used to control objects and switches

on the single line diagram display. The keypad is composed of

four arrow keys, one cancel key, one enter key, one info key and

two configurable function keys.

4

2

3

6

Figure 2.1.3-1 Keys on the keypad

1

nappain

5

1. Enter and confirmation key (ENTER)

2. Cancel key (CANCEL)

3. Up/Down [Increase/Decrease] arrow keys (UP/DOWN)

4. Keys for selecting submenus [selecting a digit in a

numerical value] (LEFT/RIGHT)

5. Additional information key (INFO)

6. Function keys 1 and 2 (F1 / F2)

F1 toggles Virtual Input 1 (VI1) On/Off

F2 toggles Virtual Input 2 (VI2) On/Off

NOTE! The term, which is used for the buttons in this manual, is inside the

brackets.

8

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.1 Relay front panel

2.1.4. Operation indicators

The relay is provided with twelve LED indicators:

Figure 2.1.4-1. Operation indicators of the relay

LED indicator Meaning Measure/ Remarks

Power LED lit

Error LED lit

A- H LED lit

F1 / F2 LED lit

The auxiliary power has

been switched on

Internal fault, operates in

parallel with the self

supervision output relay

Application-related status

indicators.

Corresponding function

key pressed / activated

Normal operation state

The relay attempts to

reboot [REBOOT]. If the

error LED remains lit,

call for maintenance.

Configurable

Depending of function

programmed to F1 / F2

Resetting latched indicators and output relays

All the indicators and output relays can be given a latching

function in the configuration.

There are several ways to reset latched indicators and relays:

From the alarm list, move back to the initial display by

pushing the CANCEL key for approx. 3s. Then reset the

latched indicators and output relays by pushing the ENTER

key.

Acknowledge each event in the alarm list one by one by

pushing the ENTER key equivalent times. Then, in the

initial display, reset the latched indicators and output

relays by pushing the ENTER key.

The latched indicators and relays can also be reset via a remote

communication bus or via a digital input configured for that

purpose.

2.1.5. Adjusting display contrast

The readability of the LCD varies with the brightness and the

temperature of the environment. The contrast of the display

can be adjusted via the PC user interface, see chapter 3.

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

9

2.2 Local panel operations 2 Local panel user interface Operation and configuration

2.2. Local panel operations

The front panel can be used to control objects, change the local/

remote status, read the measured values, set parameters, and

to configure relay functions. Some parameters, however, can

only be set by means of a PC connected to the local

communication port. Some parameters are factory-set.

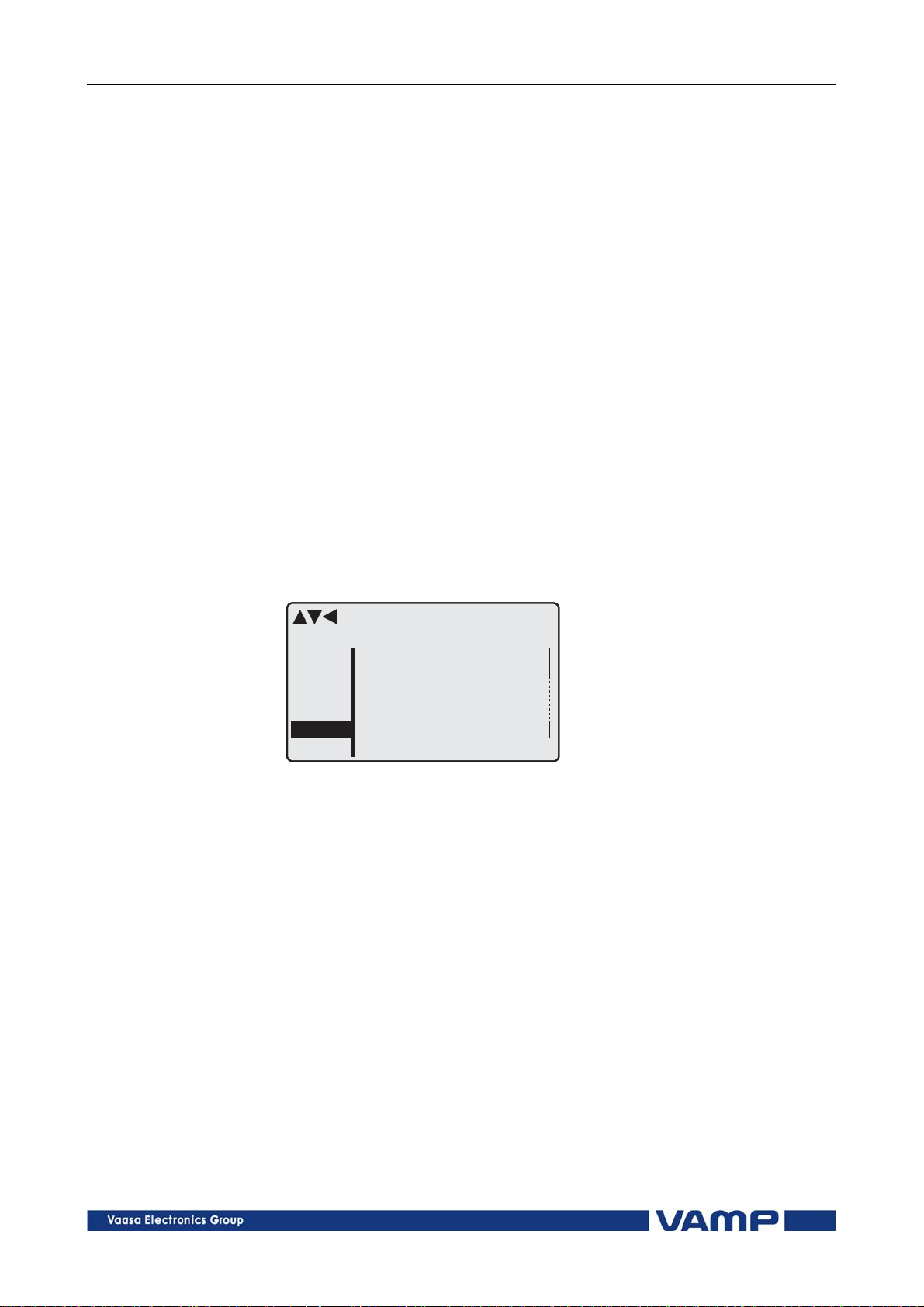

2.2.1. Navigating in menus

All the menu functions are based on the main menu/submenu

structure:

1. Use the arrow keys UP and DOWN to move up and down in

the main menu.

2. To move to a submenu, repeatedly push the RIGHT key

until the required submenu is shown. Correspondingly,

push the LEFT key to return to the main menu.

3. Push the ENTER key to confirm the selected submenu. If

there are more than six items in the selected submenu, a

black line appears to the right side of the display (Figure

2.2.1-1). It is then possible to scroll down in the submenu.

scroll

ENABLED STAGES 3

Evnt

DR

DI

DO

Prot

I>

Figure 2.2.1-1 Example of scroll indication

I>

I>>

I>>>

I2>

Io>

Io>>

On

On

On

Off

Off

Off

4. Push the CANCEL key to cancel a selection.

5. Hold the CANCEL key pushed for appr. 4 sec. to display the

title screen.

6. Pushing the UP or DOWN key in any position of a

submenu, when it is not selected, brings you directly one

step up or down in the main menu.

The active main menu selection is indicated with black

background color. The possible navigating directions in the

menu are shown in the upper-left corner by means of black

triangular symbols.

10

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.2 Local panel operations

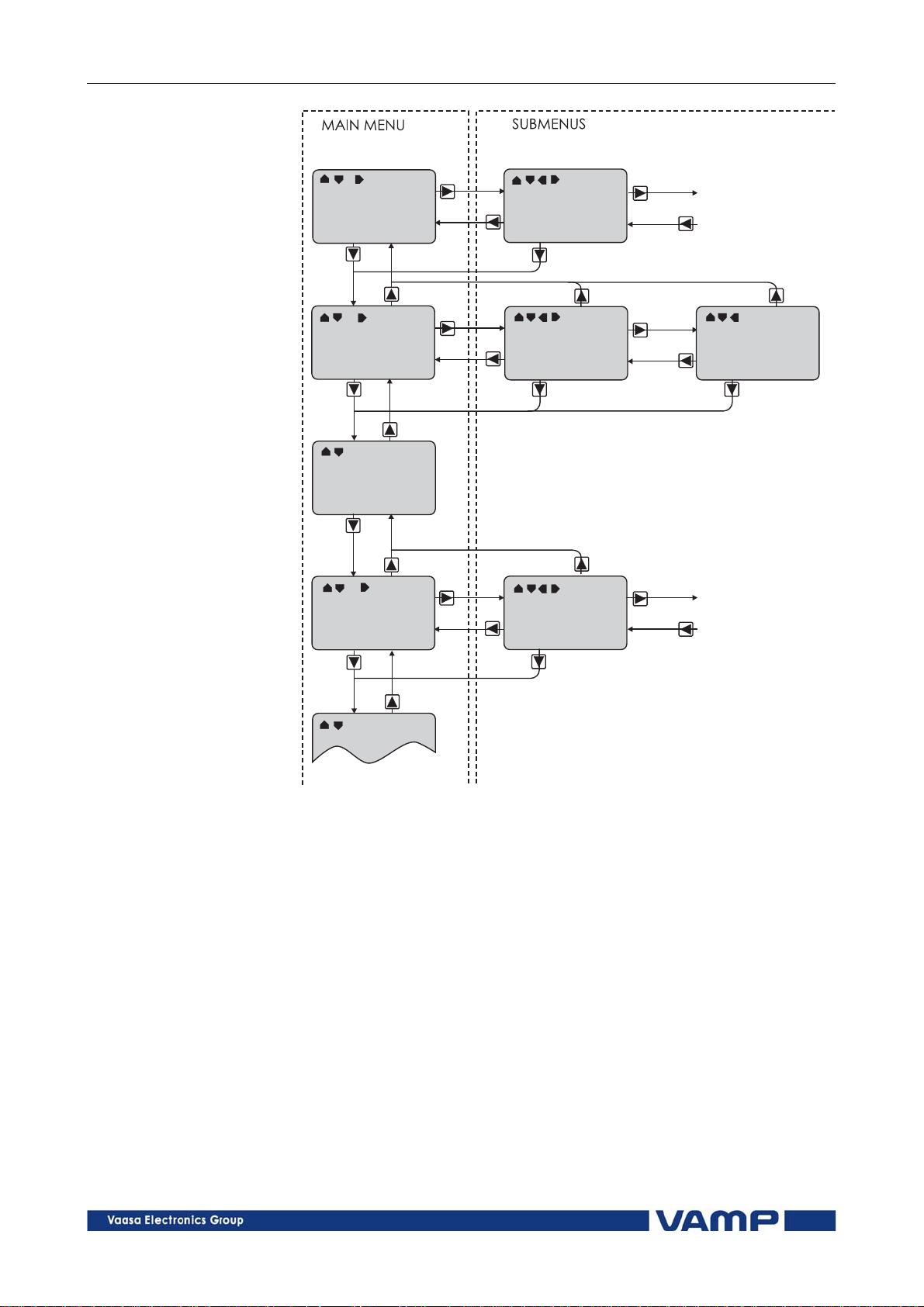

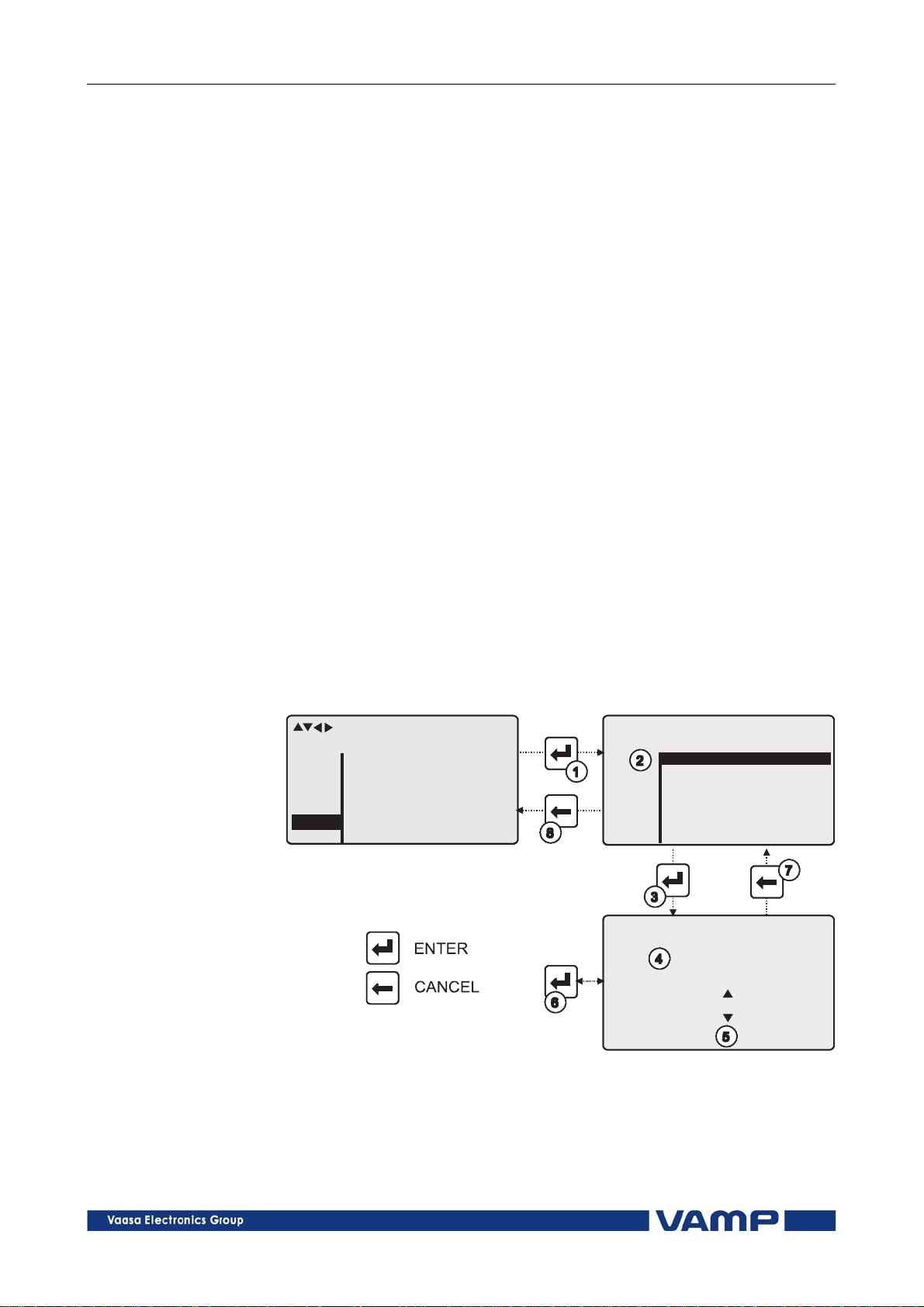

Figure 2.2.1-2 Principles of the menu structure and navigation in the menus

7. Push the INFO key and then the ENTER key to give the

password.

8. Push the INFO key to obtain additional information about

any menu item.

9. Push the CANCEL key to revert to the normal display.

Main menu

The general menu structure is shown in Figure 2.2.1-2. The

menu is dependent on the user’s configuration and the options

according the order code. For example only the enabled

protection stages will appear in the menu.

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

11

2.2 Local panel operations 2 Local panel user interface Operation and configuration

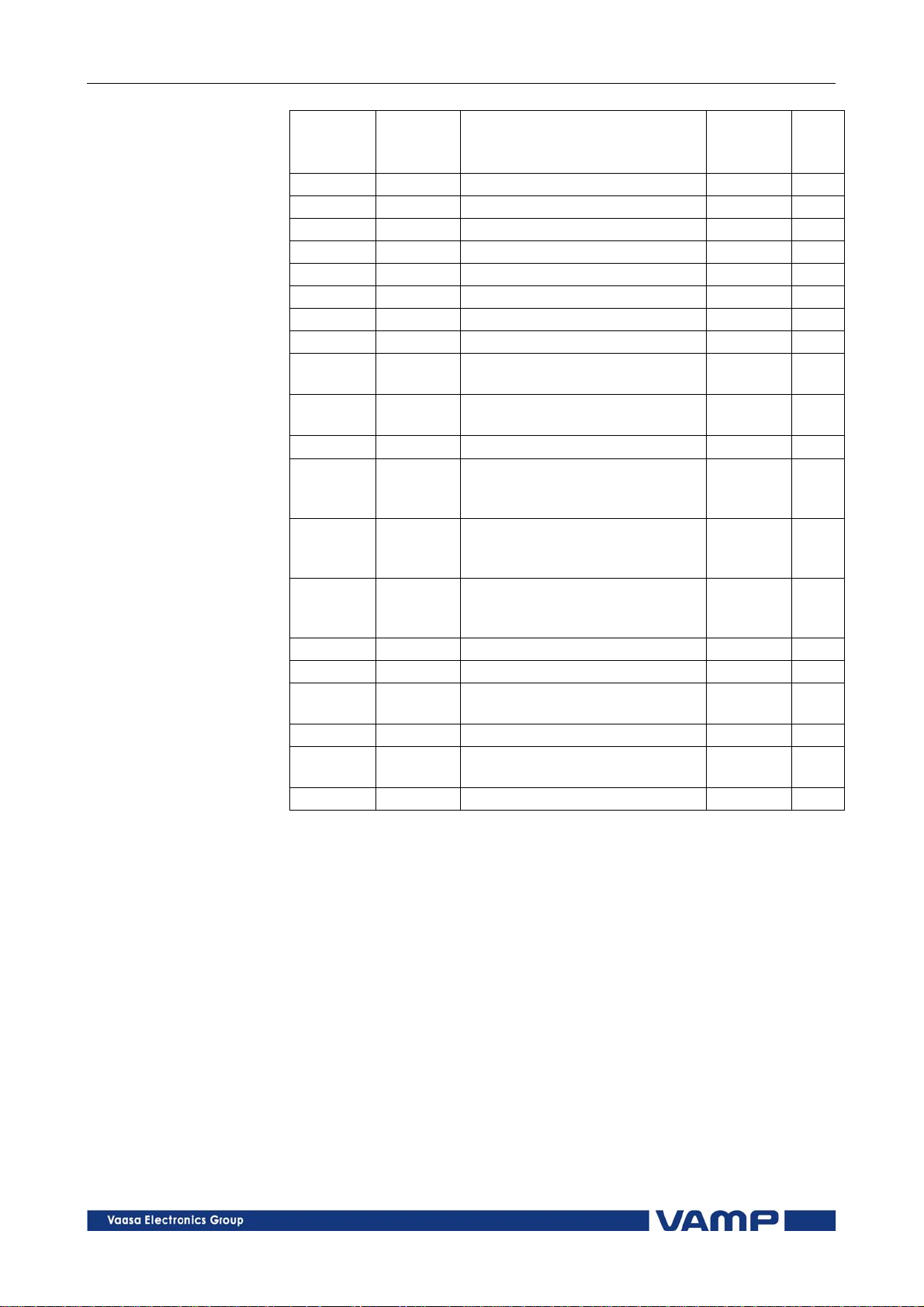

A list of the local main menu

Main

menu

Number

of

Description

ANSI

code

menus

1 Interactive mimic display 1

5

Double size measurements

1

defined by the user

1

Title screen with device name,

time and firmware version.

Meas 7 Measurements

Imax 8

Time stamped min & max of

currents

Mont 17

Maximum values of the last 31

days and the last twelve

months

Evnt 2 Events

DR 3 Disturbance recorder 2

Runh 1

Running hour counter. Active

time of a selected digital input

and time stamps of the latest

start and stop.

TIMR 6 Day and week timers

DI 4

Digital inputs including virtual

inputs

DO 3

Digital outputs (relays) and

output matrix

ExtAI External analogue inputs 3

ExDI External digital inputs 3

ExDO External digital outputs 3

Prot 18

Protection counters, combined

overcurrent status, protection

status, protection enabling, cold

load and inrush detectionIf2>

and block matrix

I> 12 1st overcurrent stage 50/51 4

I>> 11 2nd overcurrent stage 50/51 4

I>>> 11 3rd overcurrent stage 50/51 4

I< 11 Undercurrent stage 37 4

I2/I1> 11 Broken conductor prot. Stage 46R 4

I2> 10 Unbalance stage 46 4

I2>> 10

Phase reversal / incorrect phase

47 4

sequence stage

Ist> 10 Stall protection stage 48 4

N> 11 Frequent start 66 4

T> 3 Thermal overload stage 49 4

Io> 12 1st earth fault stage 50N/51N 4

Io>> 11 2nd earth fault stage 50N/51N 4

Io>>> 11 3rd earth fault stage 50N/51N 4

Io>>>> 11 4th earth fault stage 50N/51N 4

Prg1 11 1st programmable stage 4

Note

12

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.2 Local panel operations

Main

menu

Prg2 11 2nd programmable stage 4

Prg3 11 3rd programmable stage 4

Prg4 11 4th programmable stage 4

Prg5 11 5th programmable stage 4

Prg6 11 6th programmable stage 4

Prg7 11 7th programmable stage 4

Prg8 11 8th programmable stage 4

If2> 3 Second harmonic O/C stage 51F2 4

CBFP 10

CBWE 5

CTSV 1 CT supervisor 4

ArcI> 11

ArcIo> 10

ArcIo2> 10

AR 4 Auto-reclose 79 8

OBJ 10 Object definitions 5

Lgic 2

CONF 9 Device setup, scaling etc. 6

Bus 11

Diag 9 Device selfdiagnosis

Notes

1 Configuration is done with VAMPSET

2 Recording files are read with VAMPSET

3

The menu is visible only if protocol "ExternalIO" is selected for one of

the serial ports. Serial ports are configured in menu "Bus".

4 The menu is visible only if the stage is enabled.

5 Objects are circuit breakers, disconnectors etc.

6

There are two extra menus, which are visible only if the access level

"operator" or "configurator" has been opened with the corresponding

password.

7 Detailed protocol configuration is done with VAMPSET.

8 VAMP51 and VAMP52

Number

of

menus

Circuit breaker failure

protection

Circuit breaker wearing

supervision

Optional arc protection stage

for phase-to-phase faults and

delayed light signal.

Optional arc protection stage

for earth faults. Current input

= I01

Optional arc protection stage

for earth faults. Current input

= I02

Status and counters of user's

logic

Serial port and protocol

configuration

Description

ANSI

code

50BF 4

4

50ARC 4

50NARC 4

50NARC 4

1

7

Note

2.2.2. Menu structure of protection functions

The general structure of all protection function menus is

similar although the details do differ from stage to stage. As an

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

13

2.2 Local panel operations 2 Local panel user interface Operatio n and configuration

example the details of the second overcurrent stage I>> menus

are shown below.

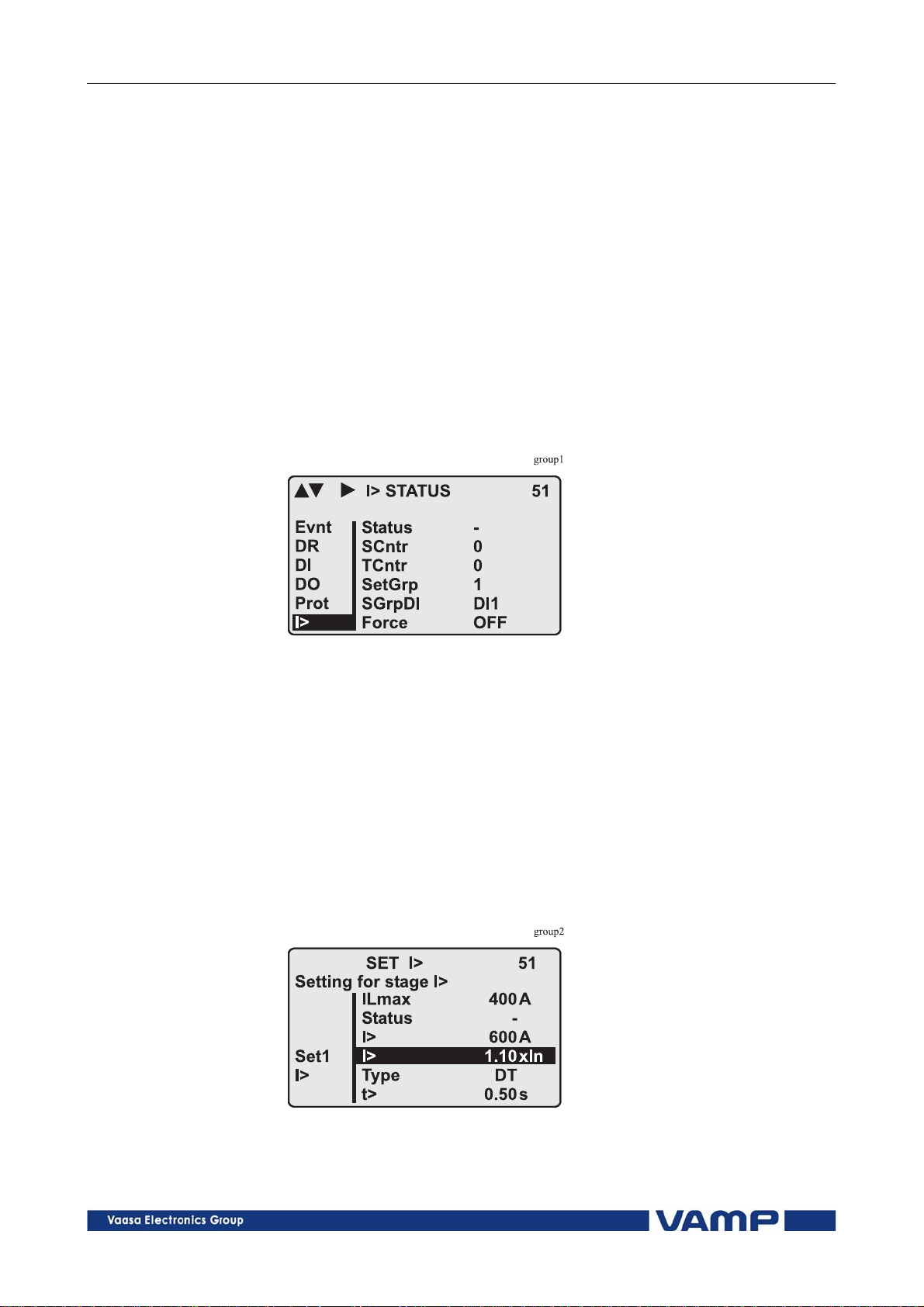

First menu of I>> 50/51 stage

first menu

I>> STATUS 50 / 51

ExDO

Prot

I>

I>>

Iv>

I>

Figure 2.2.2-1 First menu of I>> 50/51 stage

Status

SCntr

TCntr

SetGrp

SGrpDI

Force

OFF

5

2

1

-

This is the status, start and trip counter and setting group

menu. The content is:

Status –

The stage is not detecting any fault at the moment. The

stage can also be forced to pick-up or trip is the operating

level is “Configurator” and the force flag below is on.

Operating levels are explained in chapter 2.2.5

SCntr 5

The stage has picked-up a fault five times since the last

reset or restart. This value can be cleared if the operating

level is at least “Operator”.

TCntr 2

The stage has tripped two times since the last reset or

restart. This value can be cleared if the operating level is at

least “Operator”.

SetGrp 1

The active setting group is one. This value can be edited if

the operating level is at least “Operator”. Setting groups are

explained in chapter 2.2.3.

SGrpDI –

The setting group is not controlled by any digital input. This

value can be edited if the operating level is at least

“Configurator”.

Force Off

The status forcing and output relay forcing is disabled. This

force flag status can be set to “On” or back to “Off” if the

operating level is at least “Configurator”. If no front panel

button is pressed within five minutes and there is no

VAMPSET communication, the force flag will be set to “Off”

position. The forcing is explained in Chapter 2.3.4.

14

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.2 Local panel operations

Second menu of I>> 50/51 stage

second menu

I>> SET 50 / 51

Stage setting group 1

ExDI

ExDO

Prot

I>>

CBWE

OBJ

Figure 2.2.2-2 Second menu(next on the right) of I>> 50/51 stage

ILmax

Status

I>>

I>>

t>>

403A

-

1013A

2.50xIn

0.60s

This is the main setting menu. The content is:

Stage setting group 1

These are the group 1 setting values. The other setting

group can be seen by pressing push buttons ENTER and

then RIGHT or LEFT. Setting groups are explained in

chapter 2.2.3.

ILmax 403A

The maximum of three measured phase currents is at the

moment 403 A. This is the value the stage is supervising.

Status –

Status of the stage. This is just a copy of the status value in

the first menu.

I>> 1013 A

The pick-up limit is 1013 A in primary value.

I>> 2.50xIn

The pick-up limit is 2.50 times the rated current of the

generator. This value can be edited if the operating level is

at least “Operator”. Operating levels are explained in

chapter 2.2.5.

t>> 0.60s

The total operation delay is set to 600 ms. This value can be

edited if the operating level is at least “Operator”.

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

15

2.2 Local panel operations 2 Local panel user interface Operatio n and configuration

Third menu of I>> 50/51 stage

third menu

I>> LOG 50/51

FAULT LOG 1

ExDI

ExDO

Prot

I>>

CBWE

OBJ

2006-09-14

12:25:10.288

Type

Flt

Load

EDly

1-2

2.86xIn

0.99xIn

81%

SetGrp 1

Figure 2.2.2-3 Third and last menu (next on the right) of I>> 50/51 stage

This is the menu for registered values by the I>> stage. Fault

logs are explained in chapter 2.2.4.

FAULT LOG 1

This is the latest of the eight available logs. You may move

between the logs by pressing push buttons ENTER and then

RIGHT or LEFT.

2006-09-14

Date of the log.

12:25:10.288

Time of the log.

Type 1-2

The overcurrent fault has been detected in phases L1 and

L2 (A & B, red & yellow, R/S, u&v).

Flt 2.86xIn

The fault current has been 2.86 per unit.

Load 0.99xIn

The average load current before the fault has been 0.99 pu.

EDly 81%

The elapsed operation delay has been 81% of the setting

0.60 s = 0.49 s. Any registered elapsed delay less than 100 %

means that the stage has not tripped, because the fault

duration has been shorter that the delay setting.

SetGrp 1

The setting group has been 1. This line can be reached by

pressing ENTER and several times the DOWN button.

16

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.2 Local panel operations

2.2.3. Setting groups

Most of the protection functions of the relay have two setting

groups. These groups are useful for example when the network

topology is changed frequently. The active group can be

changed by a digital input, through remote communication or

locally by using the local panel.

The active setting group of each protection function can be

selected separately. Figure 2.2.3-1 shows an example where the

changing of the I> setting group is handled with digital input

one (SGrpDI). If the digital input is TRUE, the active setting

group is group two and correspondingly, the active group is

group one, if the digital input is FALSE. If no digital input is

selected (SGrpDI = -), the active group can be selected by

changing the value of the parameter SetGrp.

Figure 2.2.3-1 Example of protection submenu with setting group

parameters

The changing of the setting parameters can be done easily.

When the desired submenu has been found (with the arrow

keys), press the ENTER key to select the submenu. Now the

selected setting group is indicated in the down-left corner of the

display (See Figure 2.2.3.-2). Set1 is setting group one and Set2

is setting group two. When the needed changes, to the selected

setting group, have been done, press the LEFT or the RIGHT

key to select another group (the LEFT key is used when the

active setting group is 2 and the RIGHT key is used when the

active setting group is 1).

Figure 2.2.3-2 Example of I> setting submenu

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

17

2.2 Local panel operations 2 Local panel user interface Operatio n and configuration

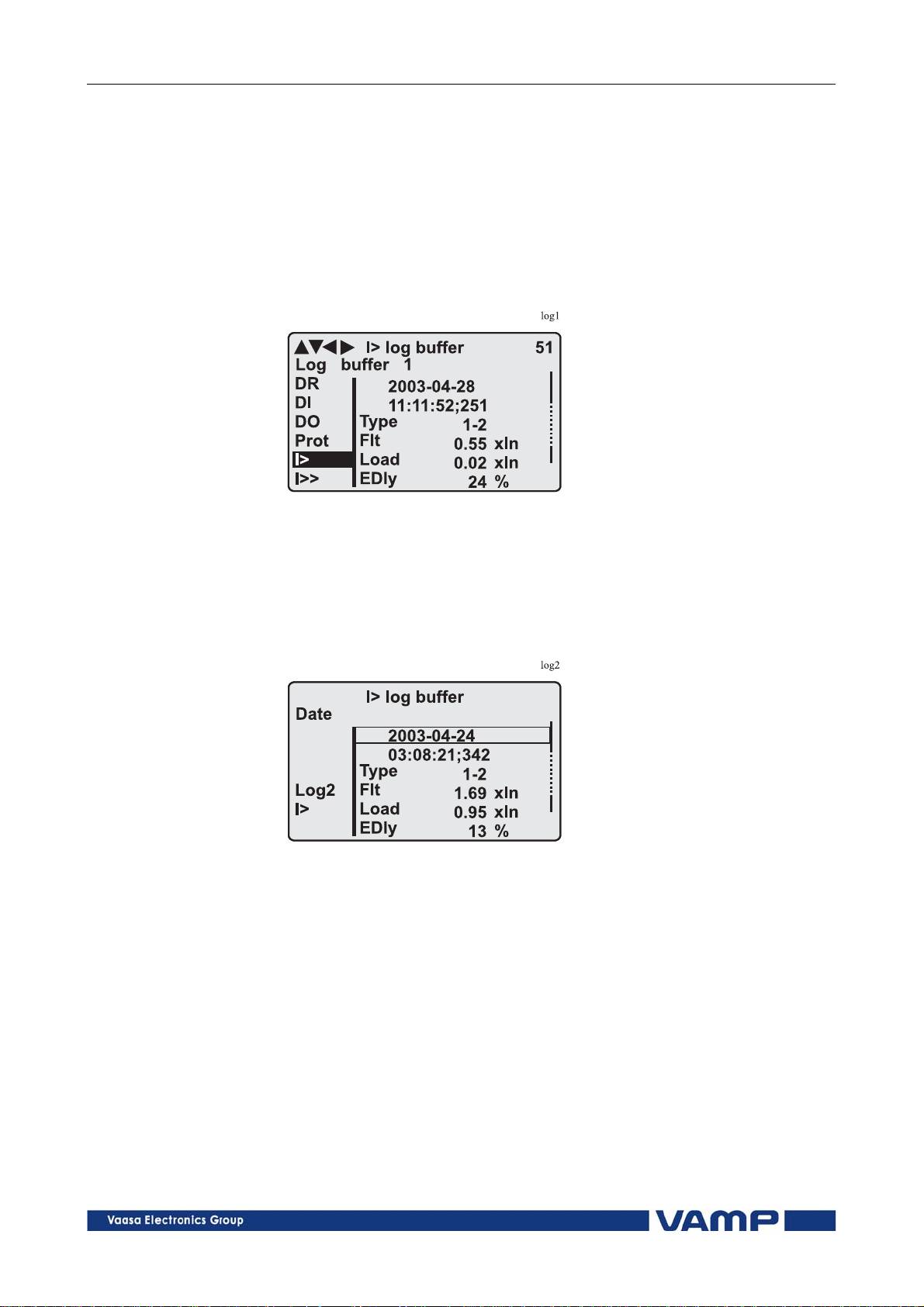

2.2.4. Fault logs

All the protection functions include fault logs. The fault log of a

function can register up to eight different faults with time

stamp information, fault values etc. The fault logs are stored in

non-volatile memory. Each function has its own logs. The fault

logs are not cleared when power is switched off. The user is

able to clear all logs using VAMPSET. Each function has its

own logs (See Figure 2.2.4-1).

Figure 2.2.4-1 Example of fault log

To see the values of, for example, log two, press then ENTER

key to select the current log (log one). The current log number

is then indicated in the down-left corner of the display (See

Figure 2.2.4-2, Log2 = log two). The log two is selected by

pressing the RIGHT key once.

Figure 2.2.4-2 Example of selected fault log

18

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.2 Local panel operations

2.2.5. Operating levels

The relay has three operating levels: User level, Operator level

and Configurator level. The purpose of the access levels is to

prevent accidental change of relay configurations, parameters

or settings.

USER level

Use: Possible to read e.g. parameter values,

measurements and events

Opening: Level permanently open

Closing: Closing not possible

OPERATOR level

Use: Possible to control objects and to change e.g.

the settings of the protection stages

Opening: Default password is 1

Setting state: Push ENTER

Closing: The level is automatically closed after 10

minutes idle time. Giving the password 9999

can also close the level.

CONFIGURATOR level

Use: The configurator level is needed during the

commissioning of the relay. E.g. the scaling of

the voltage and current transformers can be

set.

Opening: Default password is 2

Setting state: Push ENTER

Closing: The level is automatically closed after 10

minutes idle time. Giving the password 9999

can also close the level.

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

19

2.2 Local panel operations 2 Local panel user interface Operatio n and configuration

Opening access

1. Push the INFO key and the ENTER key on the front panel

ENTER PASSWORD

0

***

Figure 2.2.5-1 Opening the access level

2. Enter the password needed for the desired level: the

password can contain four digits. The digits are supplied

one by one by first moving to the position of the digit using

the RIGHT key and then setting the desired digit value

using the UP key.

3. Push the ENTER key.

Password handling

The passwords can only be changed using VAMPSET software

connected to the USB -port in front of the relay.

It is possible to restore the password(s) in case the password is

lost or forgotten. In order to restore the password(s), a relay

program is needed. The virtual serial port settings are 38400

bps, 8 data bits, no parity and one stop bit. The bit rate is

configurable via the front panel.

Command Description

get pwd_break

get serno

Send both the numbers to vampsupport@vamp.fi and ask for a

password break. A device specific break code is sent back to

you. That code will be valid for the next two weeks.

Command Description

set pwd_break=4435876

Now the passwords are restored to the default values (See

chapter 2.2.5).

Get the break code (Example:

6569403)

Get the serial number of the relay

(Example: 12345)

Restore the factory default

passwords (“4435876” is just an

example. The actual code should be

asked from VAMP Ltd.)

20

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.3 Operating measures

2.3. Operating measures

2.3.1. Control functions

The default display of the local panel is a single-line diagram

including relay identification, Local/Remote indication, Autoreclose on/off selection and selected analogue measurement

values.

Please note that the operator password must be active in order

to be able to control the objects. Please refer to page 20 opening

access.

Toggling Local/Remote control

1. Push the ENTER key. The previously activated object

starts to blink.

2. Select the Local/Remote object (“L” or “R” squared) by

using the arrow keys.

3. Push the ENTER key. The L/R dialog opens. Select

“REMOTE” to enable remote control and disable local

control. Select “LOCAL” to enable local control and

disable remote control.

4. Confirm the setting by pushing the ENTER key. The

Local/Remote state will change.

Object control

1. Push the ENTER key. The previously activated object

starts to blink.

2. Select the object to control by using the arrow keys.

Please note that only controllable objects can be selected.

3. Push the ENTER key. A control dialog opens.

4. Select the “Open” or “Close” command by using the UP

and DOWN arrow keys.

5. Confirm the operation by pushing the ENTER key. The

state of the object changes.

Toggling virtual inputs

1. Push the ENTER key. The previously activated object

starts to blink.

2. Select the virtual input object (empty or black square)

3. The dialog opens

4. Select “VIon” to activate the virtual input or select

“VIoff” to deactivate the virtual input

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

21

2.3 Operating measures 2 Local panel user interface Operation and configuration

2.3.2. Measured data

The measured values can be read from the Meas menu and its

submenus. Furthermore, any measurement value in the

following table can be displayed on the main view next to the

single line diagram. Up to six measurements can be shown.

Value Menu/Submenu Description

IL1 MEAS/PHASE CURRENTS Phase current IL1 [A]

IL2 MEAS/PHASE CURRENTS Phase current IL2 [A]

IL3 MEAS/PHASE CURRENTS Phase current IL3 [A]

IL1da

IL2da

IL3da

Io

IoC

I1

I2

I2/I1

Uo MEAS/MISCELLANEOUS

f MEAS/MISCELLANEOUS Frequency [Hz]

THDIL

THDIL1

THDIL2

THDIL3

IL1har HARMONICS of IL1 Harmonics of phase current IL1 [%]

IL2har HARMONICS of IL2 Harmonics of phase current IL2 [%]

IL3har HARMONICS of IL3 Harmonics of phase current IL3 [%]

MEAS /PHASE

CURRENTS

MEAS /PHASE

CURRENTS

MEAS /PHASE

CURRENTS

MEAS /SYMMETRIC

CURRENTS

MEAS /SYMMETRIC

CURRENTS

MEAS /SYMMETRIC

CURRENTS

MEAS /SYMMETRIC

CURRENTS

MEAS /SYMMETRIC

CURRENTS

MEAS /HARM.

DISTORTION

MEAS /HARM.

DISTORTION

MEAS /HARM.

DISTORTION

MEAS /HARM.

DISTORTION

15 min average for IL1 [A]

15 min average for IL2 [A]

15 min average for IL3 [A]

Primary value of zerosequence/

residual current Io [A]

Calculated Io [A]

Positive sequence current [A]

Negative sequence current [A]

Negative sequence current related

to positive sequence current (for

unbalance protection) [%]

Residual voltage Uo [%] (Only in

VAMP52)

Total harmonic distortion of the

mean value of phase currents [%]

Total harmonic distortion of phase

current IL1 [%]

Total harmonic distortion of phase

current IL2 [%]

Total harmonic distortion of phase

current IL3 [%]

22

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.3 Operating measures

Figure 2.3.2-1. Example of harmonics bar display

2.3.3. Reading event register

The event register can be read from the Evnt submenu:

1. Push the RIGHT key once.

2. The EVENT LIST appears. The display contains a list of all

the events that have been configured to be included in the

event register.

Figure 2.3.3-1. Example of an event register

3. Scroll through the event list with the UP and DOWN keys.

4. Exit the event list by pushing the LEFT key.

It is possible to set the order in which the events are sorted. If

the “Order” -parameter is set to “New-Old”, then the first event

in the EVENT LIST is the most recent event.

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

23

2.3 Operating measures 2 Local panel user interface Operation and configuration

2.3.4. Forced control (Force)

In some menus it is possible to switch a function on and off by

using a force function. This feature can be used, for instance,

for testing a certain function. The force function can be

activated as follows:

1. Move to the setting state of the desired function, for

example DO (see chapter 2.4, on page 25).

2. Select the Force function (the background color of the force

text is black).

Figure 2.3.4-1 Selecting Force function

3. Push the ENTER key.

4. Push the UP or DOWN key to change the "OFF" text to

"ON", that is, to activate the Force function.

5. Push the ENTER key to return to the selection list. Choose

the signal to be controlled by force with the UP and DOWN

keys, for instance the T1 signal.

6. Push the ENTER key to confirm the selection. Signal T1

can now be controlled by force.

7. Push the UP or DOWN key to change the selection from "0"

(not alert) to "1" (alert) or vice versa.

8. Push the ENTER key to execute the forced control operation

of the selected function, e.g., making the output relay of T1

to pick up.

9. Repeat the steps 7 and 8 to alternate between the on and off

state of the function.

10. Repeat the steps 1...4 to exit the Force function.

11. Push the CANCEL key to return to the main menu.

24

NOTE! All the interlockings and blockings are bypassed when the force control

is used.

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.4 Configuration and paramete

r

setting

2.4. Configuration and parameter setting

The minimum procedure to configure a relay is

1. Open the access level "Configurator". The default password

for configurator access level is 2.

2. Set the rated values in menu [CONF] including at least

current transformers, voltage transformers and generator

ratings. Also the date and time settings are in this same

main menu.

3. Enable the needed protection functions and disable the rest

of the protection functions in main menu [Prot].

4. Set the setting parameter of the enable protection stages

according the application.

5. Connect the output relays to the start and trip signals of the

enabled protection stages using the output matrix. This can

be done in main menu [DO], although the VAMPSET

program is recommended for output matrix editing.

6. Configure the needed digital inputs in main menu [DI].

7. Configure blocking and interlockings for protection stages

using the block matrix. This can be done in main menu

[Prot], although VAMPSET is recommended for block

matrix editing.

Some of the parameters can only be changed via the USB-port

using the VAMPSET software. Such parameters, (for example

passwords, blockings and mimic configuration) are normally set

only during commissioning.

Some of the parameters require the restarting of the relay. This

restarting is done automatically when necessary. If a

parameter change requires restarting, the display will show as

Figure 2.4-1.

Figure 2.4-1 Example of auto-reset display

Press CANCEL to return to the setting view. If a parameter

must be changed, press the ENTER key again. The parameter

can now be set. When the parameter change is confirmed with

the ENTER key, a [RESTART]- text appears to the top-right

corner of the display. This means that auto-resetting is

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

25

2.4 Configuration and parameter

setting

2 Local panel user interface Operation and configuration

pending. If no key is pressed, the auto-reset will be executed

within few seconds.

2.4.1. Parameter setting

1. Move to the setting state of the desired menu (for example

CONF/CURRENT SCALING) by pushing the ENTER key.

The Pick text appears in the upper-left part of the display.

2. Enter the password associated with the configuration level

by pushing the INFO key and then using the arrow keys

and the ENTER key (default value is 0002). For more

information about the access levels, please refer to Chapter

2.2.5.

3. Scroll through the parameters using the UP and DOWN

keys. A parameter can be set if the background color of the

line is black. If the parameter cannot be set the parameter

is framed.

4. Select the desired parameter (for example Inom) with the

ENTER key.

5. Use the UP and DOWN keys to change a parameter value.

If the value contains more than one digit, use the LEFT and

RIGHT keys to shift from digit to digit, and the UP and

DOWN keys to change the digits.

6. Push the ENTER key to accept a new value. If you want to

leave the parameter value unchanged, exit the edit state by

pushing the CANCEL key.

paramm

CURRENT SCALING

I>

Io>

Io>

>

CBFP

CONF

Inom

Isec

Ionom

Iosec

Ioinp

200A

5A

100A

1.0A

1.0A

Figure 2.4.1-1.Changing parameters

PICK CURRENT SCALING

CT primary

CONF

Edit VALUE CHANGE

CT primary

Inom

Isec

Ionom

Iosec

Ioinp

200

200A

5A

100A

1.0A

1.0A

26

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.4 Configuration and parameter

setting

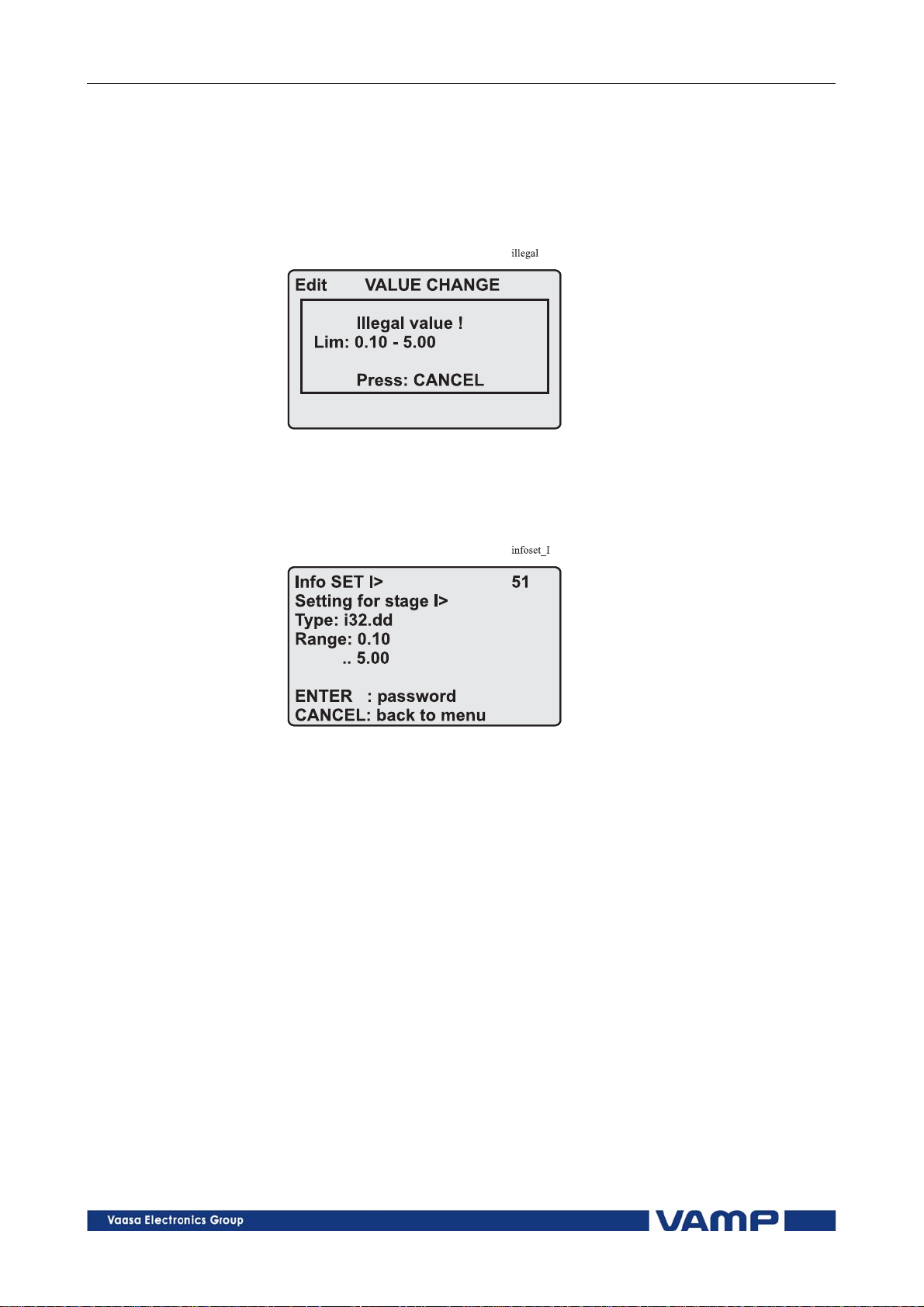

2.4.2. Setting range limits

If the given parameter setting values are out-of-range values, a

fault message will be shown when the setting is confirmed with

the ENTER key. Adjust the setting to be within the allowed

range.

Figure 2.4.2-1 Example of a fault message

The allowed setting range is shown in the display in the setting

mode. To view the range, push the INFO key. Push the

CANCEL key to return to the setting mode.

Figure 2.4.2-2 Allowed setting ranges show in the display

2.4.3. Disturbance recorder menu DR

Via the submenus of the disturbance recorder menu the

following functions and features can be read and set:

DISTURBANCE RECORDER

Recording mode (Mo

Sample rate (SR)

Recording time (Time)

Pre trig time (PreTrig)

Manual trigger (ManTrig)

Count of ready records (ReadyRec)

REC. CHANNELS

Add a link to the recorder (AddCh)

Clear all links (ClrCh)

de)

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

27

2.4 Configuration and parameter

setting

2 Local panel user interface Operation and configuration

Available links:

DO, DI

IL

I2/In, I2/I1, I2, I1, IoCalc

f

Io

IL3, IL2, IL1

THDIL1, THDIL2, THDIL3

IL1RMS, IL2RMS, IL3RMS

ILmin

ILmax

T

Uo, U12 or UL1 depending on the voltage measurement

mode. (VAMP 52 only)

2.4.4. Configuring digital inputs DI

The following functions can be read and set via the submenus

of the digital inputs menu:

The status of digital inputs (DIGITAL INPUTS 1,2)

Operation counters (DI COUNTERS)

Operation delay (DELAYs for DigIn)

The polarity of the input signal (INPUT POLARITY). Either

normally open (NO) or normally closed (NC) circuit.

Event enabling EVENT MASK1

2.4.5. Configuring digital outputs DO

The following functions can be read and set via the submenus

of the digital outputs menu:

The status of the output relays (RELAY OUTPUTS1 and 2)

The forcing of the output relays (RELAY OUTPUTS1 and 2)

(only if Force = ON):

o Forced control (0 or 1) of the Trip relays

o Forced control (0 or 1) of the Alarm relays

o Forced control (0 or 1) of the IF relay

The configuration of the output signals to the output relays.

The configuration of the operation indicators (LED) Alarm

and Trip and application specific alarm leds A, B, C, D, E, F,

G and H (that is, the output relay matrix).

NOTE! The amount of Trip and Alarm relays depends on the relay type and

optional hardware.

28

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Operation and configuration 2 Local panel user interface 2.4 Configuration and parameter

setting

2.4.6. Configuring analogue outputs AO (Option)

Via the submenus of the analogue output menu the following

functions can be read and set:

ANALOG OUTPUT

Value of AO1 (AO1)

Forced control of analogue output (Force)

ANALOG OUTPUT

Value linked to the analogue output (Lnk1)

(See list available links)

Scaled minimum of linked value (Min)

Scaled maximum of linked value (Max)

Scaled minimum of analogue output (AOmin)

Scaled maximum of analogue output (AOmax)

Value of analogue output (AO1)

Available links:

IL1, IL2, IL2

F

IL

Io, IoCalc

U12

UL1

2.4.7. Protection menu Prot

The following functions can be read and set via the submenus

of the Prot menu:

Reset all the counters (PROTECTION SET/ClAll)

Read the status of all the protection functions (PROTECT

STATUS 1-x)

Enable and disable protection functions (ENABLED

STAGES 1-x)

Define the interlockings using block matrix (only with

VAMPSET).

Each stage of the protection functions can be disabled or

enabled individually in the Prot menu. When a stage is

enabled, it will be in operation immediately without a need to

reset the relay.

The relay includes several protection functions. However, the

processor capacity limits the number of protection functions

that can be active at the same time.

VM50.EN004 VAMP 24h support phone +358 (0)20 753 3264

29

2.4 Configuration and parameter

setting

2 Local panel user interface Operation and configuration

2.4.8. Configuration menu CONF

The following functions and features can be read and set via

the submenus of the configuration menu:

DEVICE SETUP

Bit rate for the command line interface in communication

ports and the USB-port in the front panel. The front panel

is always using this setting. If SPABUS is selected for the

rear panel port, the bit rate is according SPABUS settings.

Access level [Acc]

LANGUAGE

List of available languages in the relay

CURRENT SCALING

Rated phase CT primary current (Inom)

Rated phase CT secondary current (Isec)

Rated input of the relay [Iinput]is 5 A

Rated value of I

Rated value of I

Rated I

input of the relay [Ioinp] is 5 A / 1 A or 1 A / 0.2 A.

01

This is specified in the order code of the device.

The rated input values are usually equal to the rated secondary

value of the CT.

CT primary current (Ionom)

01

CT secondary current (Iosec)

01

The rated CT secondary may be greater than the rated input

but the continuous current must be less than four times the

rated input. In compensated, high impedance earthed and

isolated networks using cable transformer to measure residual

current I0, it is quite usual to use a relay with 1 A or 0.2 A

input although the CT is 5 A or 1A. This increases the

measurement accuracy.

The rated CT secondary may also be less than the rated input

but the measurement accuracy near zero current will decrease.

MOTOR SETTING

Rated current of the motor (Imot).

VOLTAGE SCALING (only VAMP52)

Rated Uo VT secondary voltage (Uosec)

Voltage measuring mode (Umode)

DEVICE INFO

Relay type

(Type VAMP 5X)

Serial number (SerN)

Software version (PrgVer)

Bootcode version (BootVer)

30

VAMP 24h support phone +358 (0)20 753 3264 VM50.EN004

Loading...

Loading...