VAMP 259

Line manager

Operation and configuration

instructions

Technical description

VM259EN007

Operation and configuration

Table of Contents

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

3

Table of Contents

1. General ................................................................................... 4

1.1. Relay features ..................................................................... 4

1.2. User interface ...................................................................... 5

1.3. Operating Safety ................................................................ 5

2. Local panel user interface .................................................... 6

2.1. Front panel .......................................................................... 6

2.1.1. Display ......................................................................... 6

2.1.2. Menu navigation and pointers ................................ 8

2.1.3. Keypad ........................................................................ 8

2.1.4. Operation Indicators ................................................. 9

2.1.5. Adjusting display contrast ..................................... 10

2.2. Local panel operations .................................................. 11

2.2.1. Navigating in menus .............................................. 11

2.2.2. Menu structure of protection functions .............. 16

2.2.3. Setting groups ......................................................... 19

2.2.4. Fault logs .................................................................. 20

2.2.5. Operating levels ...................................................... 21

2.3. Operating measures ....................................................... 23

2.3.1. Control functions .................................................... 23

2.3.2. Measured data ....................................................... 24

2.3.3. Reading event register .......................................... 27

2.3.4. Forced control (Force) ........................................... 28

2.4. Configuration and parameter setting ......................... 29

2.4.1. Parameter setting ................................................... 30

2.4.2. Setting range limits ................................................. 31

2.4.3. Disturbance recorder menu DR ........................... 32

2.4.4. Configuring digital inputs DI .................................. 32

2.4.5. Configuring digital outputs DO ............................ 33

2.4.6. Protection menu Prot ............................................. 33

2.4.7. Configuration menu CONF ................................... 34

2.4.8. Protocol menu Bus .................................................. 36

2.4.9. Single line diagram editing ................................... 39

2.4.10. Blocking and interlocking configuration ............. 39

3. VAMPSET PC software .......................................................... 40

1.1 Relay features

1 General

Operation and configuration

4

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

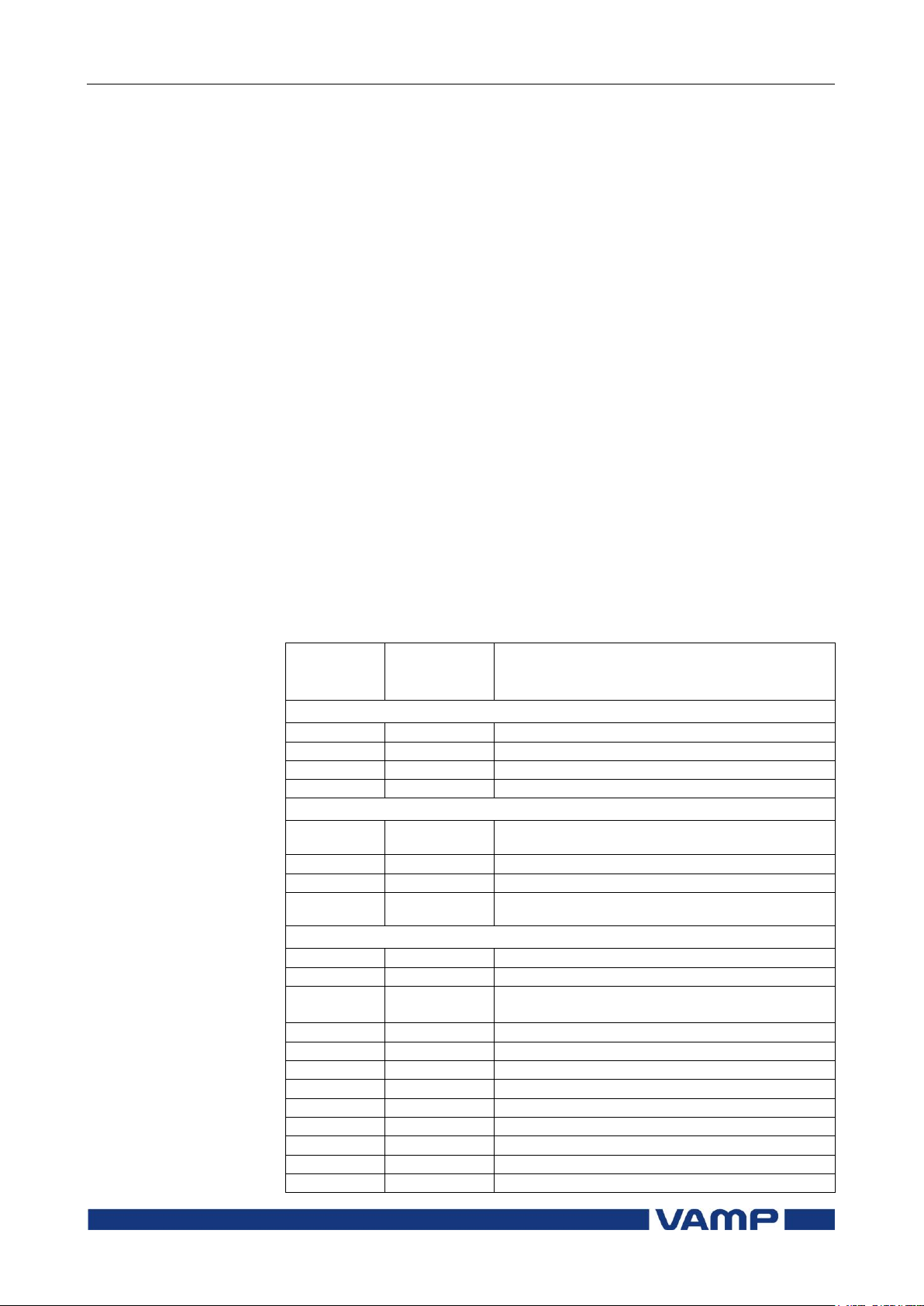

IEEE/

ANSI code

IEC symbol

Function name

Main protection functions

21

Z<

Short circuit distance protection

21N

Ze<

Earth-Fault distance protection

87

dI>

Line differential protection

85

Pilot signalling

Back-up protection functions

67

I

dir

>, I

dir

>>,

I

dir

>>>, I

dir

>>>>

Directional overcurrent protection

67N

Directional earth fault protection

50/51

3I>, 3I>>, 3I>>>

Non directional overcurrent protection

50N/51N

I0>, I0>>, I0>>>,

I0>>>>

Non directional earth fault protection

Supporting functions

79

0 1

Autoreclosing

25

∆f, ∆U, ∆φ

Synchrocheck

50ARC/

50NARC

ArcI>, ArcIO>

Optional arc fault protection

50BF

CBFP

Circuit-breaker failure protection

81R

df/dt

Rate of change of frequency (ROCOF) protection

46R

I2/I1>

Broken line protection

37

I<

Undercurrent protection

59N

U0>, U0>>

Zero sequence voltage protection

49

T>

Thermal overload protection

59

U>, U>>, U>>>

Overvoltage protection

27

U<, U<<, U<<<

Undervoltage protection

32

P<, P<<

Reverse and underpower protection

1. General

This first part (Operation and configuration) of the publication

contains general descriptions of the functions as well as

operation instructions. It also includes instructions for

parameterization and configuration of the relay and

instructions for changing settings.

The second part (Technical description) of the publication

includes detailed protection function descriptions as well as

application examples and technical data sheets.

The Mounting and Commissioning Instructions are published

in a separate publication with the code VMMC.EN0xx.

1.1. Relay features

The comprehensive protection functions of the relay make it

ideal for utility, industrial, marine and off-shore power

distribution applications. The relay features the following

protection functions.

List of protection functions

Operation and configuration

1 General

1.2 User interface

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

5

IEEE/

ANSI code

IEC symbol

Function name

Supporting functions

81H/81L

f><, f>><<

Overfrequency and underfrequency protection

81L

f<, f<<

Underfrequency protection

99

Prg1...8

Programmable stages

Further the relay includes a disturbance recorder. Arc

protection is optionally available.

The relay communicates with other systems using common

protocols, such as the Modbus RTU, ModbusTCP, Profibus DP,

IEC 60870-5-103, IEC 60870-5-101, IEC 61850, SPA bus and

DNP 3.0.

1.2. User interface

The relay can be controlled in three ways:

Locally with the push-buttons on the relay front panel

Locally using a PC connected to the serial port on the front

panel or on the rear panel of the relay (both cannot be used

simultaneously)

Via remote control over the remote control port on the relay

rear panel.

1.3. Operating Safety

The terminals on the rear panel of the relay may

carry dangerous voltages, even if the auxiliary

voltage is switched off. A live current transformer

secondary circuit must not be opened.

Disconnecting a live circuit may cause dangerous

voltages! Any operational measures must be carried out

according to national and local handling directives and

instructions.

Carefully read through all operation instructions before any

operational measures are carried out.

2.1 Front panel

2 Local panel user interface

Operation and configuration

6

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

2. Local panel user interface

2.1. Front panel

The figure below shows, as an example, the front panel of

VAMP 259 and the location of the user interface elements used

for local control.

Figure 2.1-1. The front panel of VAMP 259

1. LCD dot matrix display

2. Keypad

3. LED indicators

4. RS 232 serial communication port for PC

2.1.1. Display

The relay is provided with a backlightedt 128x64 LCD dot

matrix display. The display enables showing 21 characters in

one row and eight rows at the same time. The display has two

different purposes: one is to show the single line diagram of the

relay with the object status, measurement values, identification

etc. (Figure 2.1.1-1). The other purpose is to show the

configuration and parameterization values of the relay (Figure

2.1.1-2).

Operation and configuration

2 Local panel user interface

2.1 Front panel

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

7

Figure 2.1.1-1 Sections of the LCD dot matrix display

1. Freely configurable single-line diagram

2. Five controllable objects

3. Six object statuses

4. Bay identification

5. Local/Remote selection

6. Auto-reclose on/off selection (if applicable)

7. Freely selectable measurement values (max. six values)

Figure 2.1.1-2 Sections of the LCD dot matrix display

1. Main menu column

2. The heading of the active menu

3. The cursor of the main menu

4. Possible navigating directions (push buttons)

5. Measured/setting parameter

6. Measured/set value

Backlight control

Display backlight can be switched on with a digital input,

virtual input or virtual output. LOCALPANEL CONF/Display

backlight ctrl setting is used for selecting trigger input for

backlight control. When the selected input activates (rising

edge), display backlight is set on for 60 minutes.

2.1 Front panel

2 Local panel user interface

Operation and configuration

8

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

2.1.2. Menu navigation and pointers

1. Use the arrow keys UP and DOWN to move up and down in

the main menu, that is, on the left-hand side of the display.

The active main menu option is indicated with a cursor. The

options in the main menu items are abbreviations, e.g. Evnt

= events.

2. After any selection, the arrow symbols in the upper left

corner of the display show the possible navigating directions

(applicable navigation keys) in the menu.

3. The name of the active submenu and a possible ANSI code

of the selected function are shown in the upper part of the

display, e.g. CURRENTS.

4. Further, each display holds the measured values and units

of one or more quantities or parameters, e.g. Ilmax 300A.

2.1.3. Keypad

You can navigate in the menu and set the required parameter

values using the keypad and the guidance given in the display.

Furthermore, the keypad is used to control objects and switches

on the single line diagram display. The keypad is composed of

four arrow keys, one cancel key, one enter key and one info key.

Figure 2.1.3-1 Keys on the keypad

1. Enter and confirmation key (ENTER)

2. Cancel key (CANCEL)

3. Up/Down [Increase/Decrease] arrow keys (UP/DOWN)

4. Keys for selecting submenus [selecting a digit in a

numerical value] (LEFT/RIGHT)

5. Additional information key (INFO)

NOTE! The term, which is used for the buttons in this manual, is inside the

brackets.

Operation and configuration

2 Local panel user interface

2.1 Front panel

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

9

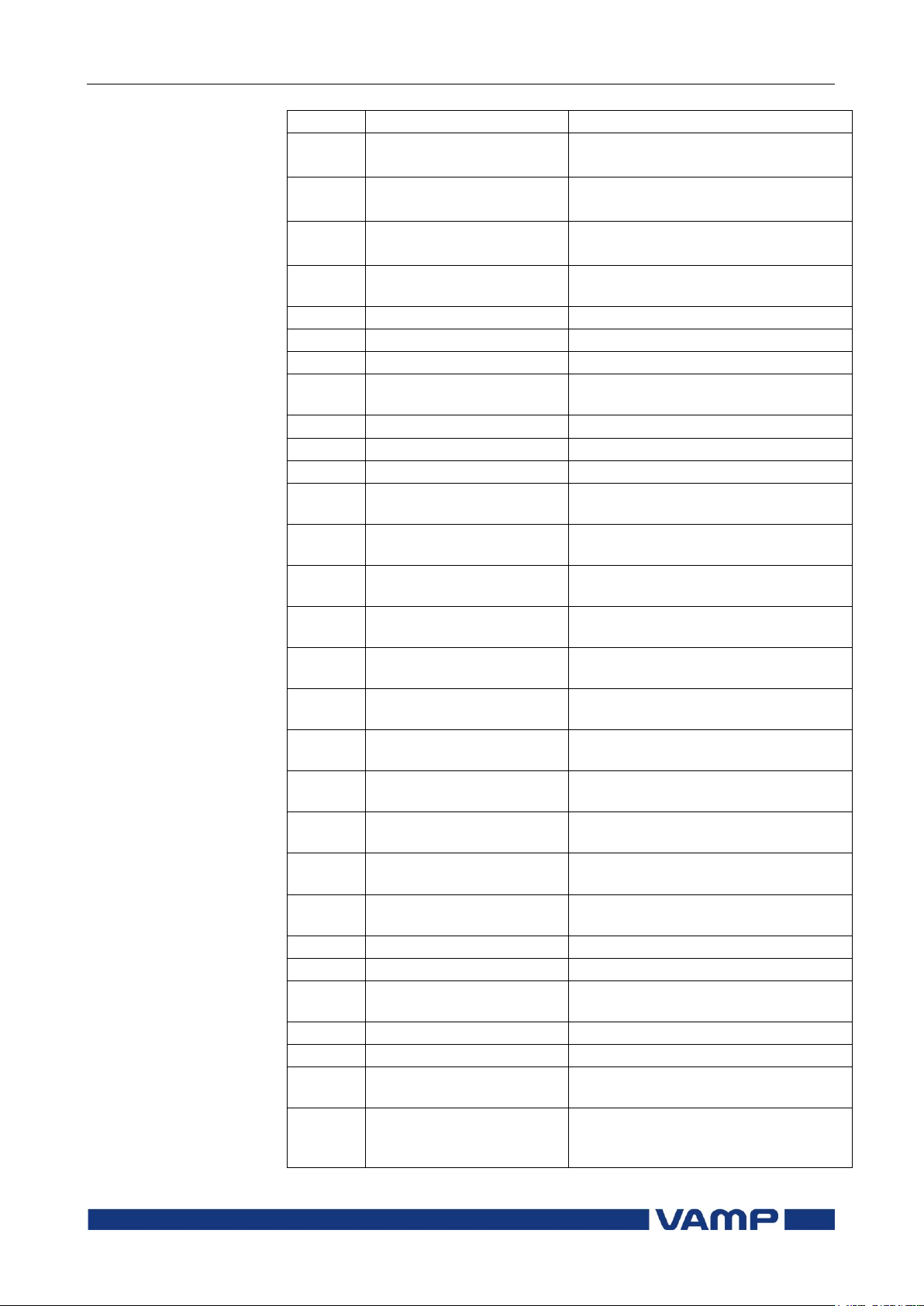

LED indicator

Meaning

Measure/ Remarks

Power LED lit

The auxiliary power has

been switched on

Normal operation state

Error LED lit

Internal fault, operates in

parallel with the self

supervision output relay

The relay attempts to

reboot [REBOOT]. If the

error LED remains lit,

call for maintenance.

Com LED lit or

flashing

The serial bus is in use

and transferring

information

Normal operation state

Alarm LED lit

One or several signals of

the output relay matrix

have been assigned to

output LA and the output

has been activated by one

of the signals. (For more

information about output

matrix, please see chapter

2.4.5).

The LED is switched off

when the signal that

caused output Al to

activate, e.g. the START

signal, is reset. The

resetting depends on the

type of configuration,

connected or latched.

Trip LED lit

One or several signals of

the output relay matrix

have been assigned to

output Tr, and the output

has been activated by one

of the signals. (For more

information about output

relay configuration, please

see chapter 2.4.5).

The LED is switched off

when the signal that

caused output Tr to

activate, e.g. the TRIP

signal, is reset. The

resetting depends on the

type of configuration,

connected or latched.

A- C LED lit

Application-related status

indicators.

Configurable

2.1.4. Operation Indicators

The relay is provided with eight LED indicators:

Figure 2.1.4-1. Operation indicators of the relay

2.1 Front panel

2 Local panel user interface

Operation and configuration

10

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

Resetting latched indicators and output relays

All the indicators and output relays can be given a latching

function in the configuration.

There are several ways to reset latched indicators and relays:

From the alarm list, move back to the initial display by

pushing the CANCEL key for approx. 3 s. Then reset the

latched indicators and output relays by pushing the ENTER

key.

Acknowledge each event in the alarm list one by one by

pushing the ENTER key equivalent times. Then, in the

initial display, reset the latched indicators and output

relays by pushing the ENTER key.

The latched indicators and relays can also be reset via a remote

communication bus or via a digital input configured for that

purpose.

2.1.5. Adjusting display contrast

The readability of the LCD varies with the brightness and the

temperature of the environment. The contrast of the display

can be adjusted via the PC user interface, see chapter 3.

Operation and configuration

2 Local panel user interface

2.2 Local panel operations

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

11

2.2. Local panel operations

The front panel can be used to control objects, change the local/

remote status, read the measured values, set parameters, and

to configure relay functions. Some parameters, however, can

only be set by means of a PC connected to one of the local

communication ports. Some parameters are factory-set.

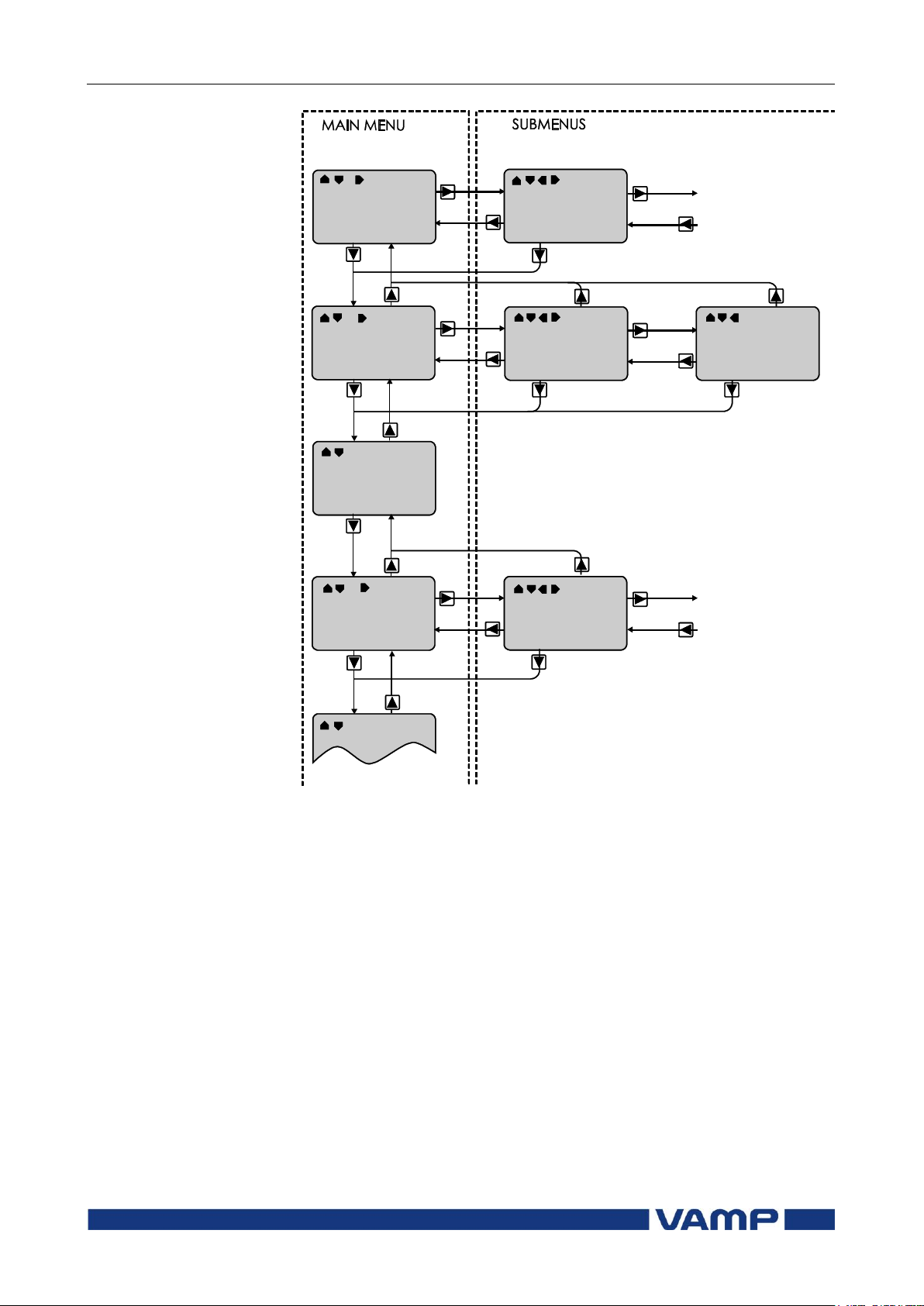

2.2.1. Navigating in menus

All the menu functions are based on the main menu/submenu

structure:

1. Use the arrow keys UP and DOWN to move up and down in

the main menu.

2. To move to a submenu, repeatedly push the RIGHT key

until the required submenu is shown. Correspondingly,

push the LEFT key to return to the main menu.

3. Push the ENTER key to confirm the selected submenu. If

there are more than six items in the selected submenu, a

black line appears to the right side of the display (Figure

2.2.1-1). It is then possible to scroll down in the submenu.

Figure 2.2.1-1. Example of scroll indication

4. Push the CANCEL key to cancel a selection.

5. Pushing the UP or DOWN key in any position of a sub-

menu, when it is not selected, brings you directly one step

up or down in the main menu.

The active main menu selection is indicated with black background color. The possible navigating directions in the menu

are shown in the upper-left corner by means of black triangular

symbols.

2.2 Local panel operations

2 Local panel user interface

Operation and configuration

12

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

Figure 2.2.1-2. Principles of the menu structure and navigation in the

menus

6. Push the INFO key to obtain additional information about

any menu item.

7. Push the CANCEL key to revert to the normal display.

Operation and configuration

2 Local panel user interface

2.2 Local panel operations

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

13

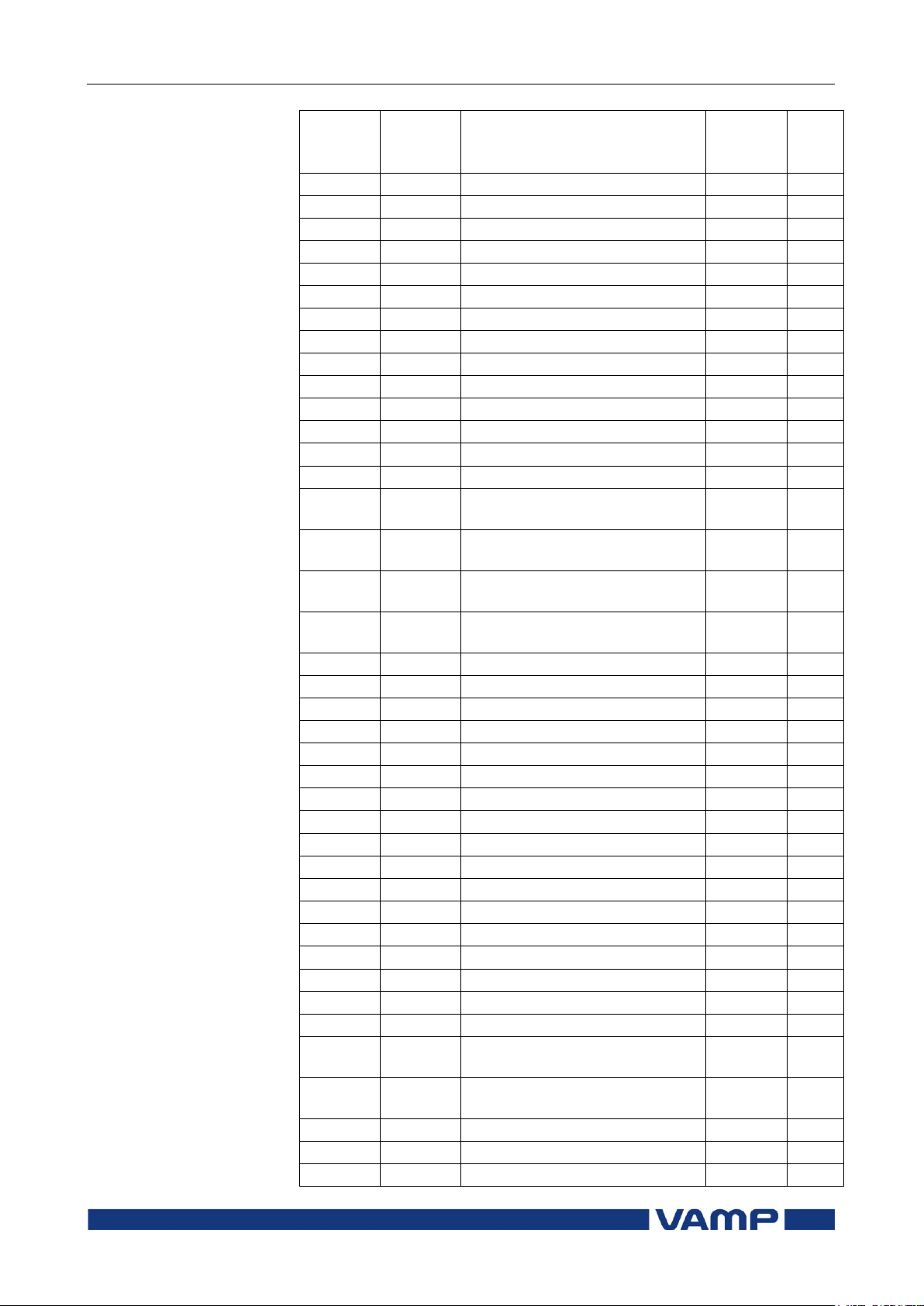

Main menu

Number

of

menus

Description

ANSI

code

Note

1 Interactive mimic display

1

5

Double size measurements

defined by the user

1

1

Title screen with device name,

time and firmware version.

P

14

Power measurements

E 4 Energy measurements

I

13

Current measurements

U

15

Voltage measurements

Dema

15

Demand values

Umax

5

Time stamped min & max of

voltages

Imax

9

Time stamped min & max of

currents

Pmax

5

Time stamped min & max of

power and frequency

Mont

21

Maximum values of the last 31

days and the last twelve

months

Evnt

2

Events

DR 2 Disturbance recorder

2

Runh

2

Running hour counter. Active

time of a selected digital input

and time stamps of the latest

start and stop.

TIMR

6

Day and week timers

DI

5

Digital inputs including virtual

inputs

DO

4

Digital outputs (relays) and

output matrix

ExtAI

3

External analogue inputs

3 ExDI

3

External digital inputs

3 ExDO

3

External digital outputs

3

Prot

27

Protection counters, combined

overcurrent status, protection

status, protection enabling,

cold load and inrush

detectionIf2> and block matrix

DIST

1

Common settings for distance

zones (Z1 … Z5)

Main menu

The general menu structure is shown in Figure 2.2.1-2. The

menu is dependent on the user’s configuration and the options

according the order code. For example only the enabled

protection stages will appear in the menu.

A list of the local main menu

2.2 Local panel operations

2 Local panel user interface

Operation and configuration

14

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

Main

menu

Number

of

menus

Description

ANSI

code

Note

Z1<

6

Short circuit distance zone 1

21

4

Z2<

6

Short circuit distance zone 2

21

4

Z3<

6

Short circuit distance zone 3

21 4 Z4<

6

Short circuit distance zone 4

21 4 Z5<

6

Short circuit distance zone 5

21 4 Ze1<

6

Earth fault distance zone

21N

4

Ze2<

6

Earth fault distance zone

21N

4

Ze3<

6

Earth fault distance zone

21N

4

Ze4<

6

Earth fault distance zone

21N

4

Ze5<

6

Earth fault distance zone

21N

4

LdI>

4

Line differential stage

87 4 I> 5 1st overcurrent stage

50/51

4

I>> 3 2nd overcurrent stage

50/51

4

I>>>

3

3rd overcurrent stage

50/51

4

I>

6

1st directional overcurrent

stage

67

4

I>>

6

2nd directional overcurrent

stage

67

4

I>>>

4

3rd directional overcurrent

stage

67

4

I>>>>

4

4th directional overcurrent

stage

67

4

I< 3 Undercurrent stage

37 4 I2> 3 Current unbalance stage

46 4 T> 3 Thermal overload stage

49 4 Io> 5 1st earth fault stage

50N/51N

4

Io>>

3

2nd earth fault stage

50N/51N

4

Io>>>

3

3rd earth fault stage

50N/51N

4

Io>>>>

3

4th earth fault stage

50N/51N

4

Io>

6

1st directional earth fault stage

67N

4

Io>>

6

2nd directional earth fault stage

67N

4

U> 4 1st overvoltage stage

59 4 U>>

3

2nd overvoltage stage

59 4 U>>>

3

3rd overvoltage stage

59 4 U< 4 1st undervoltage stage

27 4 U<<

3

2nd undervoltage stage

27 4 U<<<

3

3rd undervoltage stage

27 4 Uo>

3

1st residual overvoltage stage

59N

4

Uo>>

3

2nd residual overvoltage stage

59N

4

P<

3

1st reverse and underpower

stage

32 4 P<<

3

2nd reverse and underpower

stage

32

4

f>< 4 1st over/under-frequency stage

81

4

f>><<

4

2nd over/under-frequency stage

81 4 f< 4 1st underfrequency stage

81L

4

Operation and configuration

2 Local panel user interface

2.2 Local panel operations

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

15

Main

menu

Number

of

menus

Description

ANSI

code

Note

f<< 4 2nd underfrequency stage

81L

4

dfdt

3

Rate of change of frequency

(ROCOF) stage

81R

4

Prg1

3

1st programmable stage

4

Prg2

3

2nd programmable stage

4 Prg3

3

3rd programmable stage

4 Prg4

3

4th programmable stage

4 Prg5

3

5th programmable stage

4 Prg6

3

6th programmable stage

4 Prg7

3

7th programmable stage

4 Prg8

3

8th programmable stage

4 If2>

3

Second harmonic O/C stage

51F2

4

CBFP

3

Circuit breaker failure

protection

50BF

4

CBWE

4

Circuit breaker wearing

supervision

4

AR

15

Auto-reclose

79 CTSV

1

CT supervisor

4

VTSV

1

VT supervisor

4

ArcI>

4

Optional arc protection stage

for phase-to-phase faults and

delayed light signal.

50ARC

4

ArcIo>

3

Optional arc protection stage

for earth faults. Current input

= I01

50NARC

4

OBJ

11

Object definitions

5

Lgic

2

Status and counters of user's

logic

1

CONF

10+2

Device setup, scaling etc.

6

Bus

13

Serial port and protocol

configuration

7

Diag

6

Device selfdiagnosis

1

Configuration is done with VAMPSET

2

Recording files are read with VAMPSET

3

The menu is visible only if protocol "ExternalIO" is selected for one

of the serial ports. Serial ports are configured in menu "Bus".

4

The menu is visible only if the stage is enabled.

5

Objects are circuit breakers, disconnectors etc.. Their position or

status can be displayed and controlled in the interactive mimic

display.

6

There are two extra menus, which are visible only if the access level

"operator" or "configurator" has been opened with the corresponding

password.

7

Detailed protocol configuration is done with VAMPSET.

Notes

2.2 Local panel operations

2 Local panel user interface

Operation and configuration

16

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

Status –

The stage is not detecting any fault at the moment. The stage can also

be forced to pick-up or trip if the operating level is "Configurator" and

the force flag below is on. Operating levels are explained in chapter

2.2.5.

SCntr 5

The stage has picked-up a fault five times since the last reset of restart.

This value can be cleared if the operating level is at least "Operator".

TCntr 1

The stage has tripped two times since the last reset of restart. This

value can be cleared if the operating level is at least "Operator".

SetGrp 1

The active setting group is one. This value can be edited if the

operating level is at least "Operator". Setting groups are explained in

chapter 2.2.3.

SGrpDI -

The setting group is not controlled by any digital input. This value can

be edited if the operating level is at least "Configurator".

Force Off

The status forcing and output relay forcing is disabled. This force flag

status can be set to "On" or back to "Off" if the operating level is at least

"Configurator". If no front panel button is pressed within five minutes

and there is no VAMPSET communication, the force flag will be set to

"Off" position. The forcing is explained in chapter 2.3.4.

2.2.2. Menu structure of protection functions

The general structure of all protection function menus is

similar although the details do differ from stage to stage. As an

example the details of the second overcurrent stage I>> menus

are shown below.

First menu of I>> 50/51 stage

Figure 2.2.2-1 First menu of I>> 50/51 stage

This is the status, start and trip counter and setting group

menu. The content is:

Operation and configuration

2 Local panel user interface

2.2 Local panel operations

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

17

Stage setting group 1

These are the group 1 setting values. The other setting group can be

seen by pressing push buttons ENTER and then RIGHT or LEFT.

Setting groups are explained in chapter 2.2.3.

ILmax 403A

The maximum of the three measured phase currents is at the moment

403 A. This is the value the stage is supervising.

Status –

Status of the stage. This is just a copy of the status value in the first

menu.

I>> 1013 A

The pick-up limit is 1013 A in primary value.

I>> 2.50xIn

The pick-up limit is 2.50 times the rated current of the CT or motor

depending on the application mode in use. This value can be edited if

the operating level is at least "Operator". Operating levels are

explained in chapter 2.2.5.

t>> 0.60s

The total operation delay is set to 600 ms. This value can be edited if

the operating level is at least "Operator".

Second menu of I>> 50/51 stage

Figure 2.2.2-2. Second menu (next on the right) of I>> 50/51 stage

This is the main setting menu. The content is:

2.2 Local panel operations

2 Local panel user interface

Operation and configuration

18

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

FAULT LOG 1

This is the latest of the eight available logs. You may move between the

logs by pressing push buttons ENTER and then RIGHT or LEFT.

2006-09-14

Date of the log.

12:25:10.288

Time of the log.

Type 1-2

The overcurrent fault has been detected in phases L1 and L2 (A & B,

red & yellow, R&S, u&v).

Flt 2.86xIn

The fault current has been 2.86 per unit.

Load 0.99xIn

The average load current before the fault has been 0.99 pu.

EDly 81%

The elapsed operation delay has been 81% of the setting 0.60 s = 0.49 s.

Any registered elapsed delay less than 100 % means that the stage has

not tripped, because the fault duration has been shorter than the delay

setting.

SetGrp 1

The setting group has been 1. This line can be reached by pressing

ENTER and several times the DOWN button.

Third menu of I>> 50/51 stage

Figure 2.2.2-3. Third and last menu (next on the right) of I>> 50/51 stage

This is the menu for registered values by the I>> stage. Fault

logs are explained in chapter 2.2.4.

Operation and configuration

2 Local panel user interface

2.2 Local panel operations

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

19

2.2.3. Setting groups

Most of the protection functions of the relay have two setting

groups. These groups are useful for example when the network

topology is changed frequently. The active group can be

changed by a digital input, through remote communication or

locally by using the local panel.

The active setting group of each protection function can be

selected separately. Figure 2.2.3-1 shows an example where the

changing of the I> setting group is handled with digital input

one (SGrpDI). If the digital input is TRUE, the active setting

group is group two and correspondingly, the active group is

group one, if the digital input is FALSE. If no digital input is

selected (SGrpDI = -), the active group can be selected by

changing the value of the parameter SetGrp.

Figure 2.2.3-1. Example of protection submenu with setting group

parameters

The changing of the setting parameters can be done easily.

When the desired submenu has been found (with the arrow

keys), press the ENTER key to select the submenu. Now the

selected setting group is indicated in the down-left corner of the

display (See Figure 2.2.3-2). Set1 is setting group one and Set2

is setting group two. When the needed changes, to the selected

setting group, have been done, press the LEFT or the RIGHT

key to select another group (the LEFT key is used when the

active setting group is 2 and the RIGHT key is used when the

active setting group is 1).

Figure 2.2.3-2. Example of I> setting submenu

2.2 Local panel operations

2 Local panel user interface

Operation and configuration

20

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

2.2.4. Fault logs

All the protection functions include fault logs. The fault log of a

function can register up to eight different faults with time

stamp information, fault values etc. The fault logs are stored in

non-volatile memory. The fault logs are not cleared when power

is switched off. The user is able to clear all logs using

VAMPSET. Each function has its own logs (See Figure 2.2.4-1).

Figure 2.2.4-1. Example of fault log

To see the values of, for example, log two, press the ENTER key

to select the current log (log one). The current log number is

then indicated in the down-left corner of the display (See

Figure 2.2.4-2, Log2 = log two). The log two is selected by

pressing the RIGHT key once.

Figure 2.2.4-2. Example of selected fault log

Operation and configuration

2 Local panel user interface

2.2 Local panel operations

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

21

Use:

Possible to read e.g. parameter values,

measurements and events

Opening:

Level permanently open

Closing:

Closing not possible

Use:

Possible to control objects and to change e.g.

the settings of the protection stages

Opening:

Default password is 1

Setting state:

Push ENTER

Closing:

The level is automatically closed after 10

minutes idle time. Giving the password 9999

can also close the level.

Use:

The configurator level is needed during the

commissioning of the relay. E.g. the scaling of

the voltage and current transformers can be

set.

Opening:

Default password is 2

Setting state:

Push ENTER

Closing:

The level is automatically closed after 10

minutes idle time. Giving the password 9999

can also close the level.

2.2.5. Operating levels

The relay has three operating levels: User level, Operator level

and Configurator level. The purpose of the access levels is to

prevent accidental change of relay configurations, parameters

or settings.

USER level

OPERATOR level

CONFIGURATOR level

2.2 Local panel operations

2 Local panel user interface

Operation and configuration

22

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

Command

Description

get pwd_break

Get the break code (Example:

6569403)

get serno

Get the serial number of the relay

(Example: 12345)

Command

Description

set pwd_break=4435876

Restore the factory default

passwords (“4435876” is just an

example. The actual code should be

asked from VAMP Ltd.)

Opening access

1. Push the INFO key and the ENTER key on the front panel.

Figure 2.2.5-1. Opening the access level

2. Enter the password needed for the desired level: the

password can contain four digits. The digits are supplied

one by one by first moving to the position of the digit using

the RIGHT key and then setting the desired digit value

using the UP key.

3. Push the ENTER key.

Password handling

The passwords can only be changed using VAMPSET software

connected to the local RS-232 port on the relay.

It is possible to restore the password(s) in case the password is

lost or forgotten. In order to restore the password(s), a relay

program is needed. The serial port settings are 38400 bps, 8

data bits, no parity and one stop bit. The bit rate is

configurable via the front panel.

Send both the numbers to vampsupport@vamp.fi and ask for a

password break. A device specific break code is sent back to

you. That code will be valid for the next two weeks.

Now the passwords are restored to the default values (See

chapter 2.2.5).

Operation and configuration

2 Local panel user interface

2.3 Operating measures

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

23

2.3. Operating measures

2.3.1. Control functions

The default display of the local panel is a single-line diagram

including relay identification, Local/Remote indication, Autoreclose on/off selection and selected analogue measurement

values.

Please note that the operator password must be active in order

to be able to control the objects. Please refer to page 22

Opening access.

Toggling Local/Remote control

1. Push the ENTER key. The previously activated object starts

to blink.

2. Select the Local/Remote object (“L” or “R” squared) by using

the arrow keys.

3. Push the ENTER key. The L/R dialog opens. Select

“REMOTE” to enable remote control and disable local

control. Select “LOCAL” to enable local control and disable

remote control.

4. Confirm the setting by pushing the ENTER key. The

Local/Remote state will change.

Object control

1. Push the ENTER key. The previously activated object starts

to blink.

2. Select the object to control by using the arrow keys. Please

note that only controllable objects can be selected.

3. Push the ENTER key. A control dialog opens.

4. Select the “Open” or “Close” command by using the UP and

DOWN arrow keys.

5. Confirm the operation by pushing the ENTER key. The

state of the object changes.

Toggling virtual inputs

1. Push the ENTER key. The previously activated object starts

to blink.

2. Select the virtual input object (empty or black square)

3. The dialog opens

4. Select “VIon” to activate the virtual input or select “VIoff” to

deactivate the virtual input

2.3 Operating measures

2 Local panel user interface

Operation and configuration

24

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

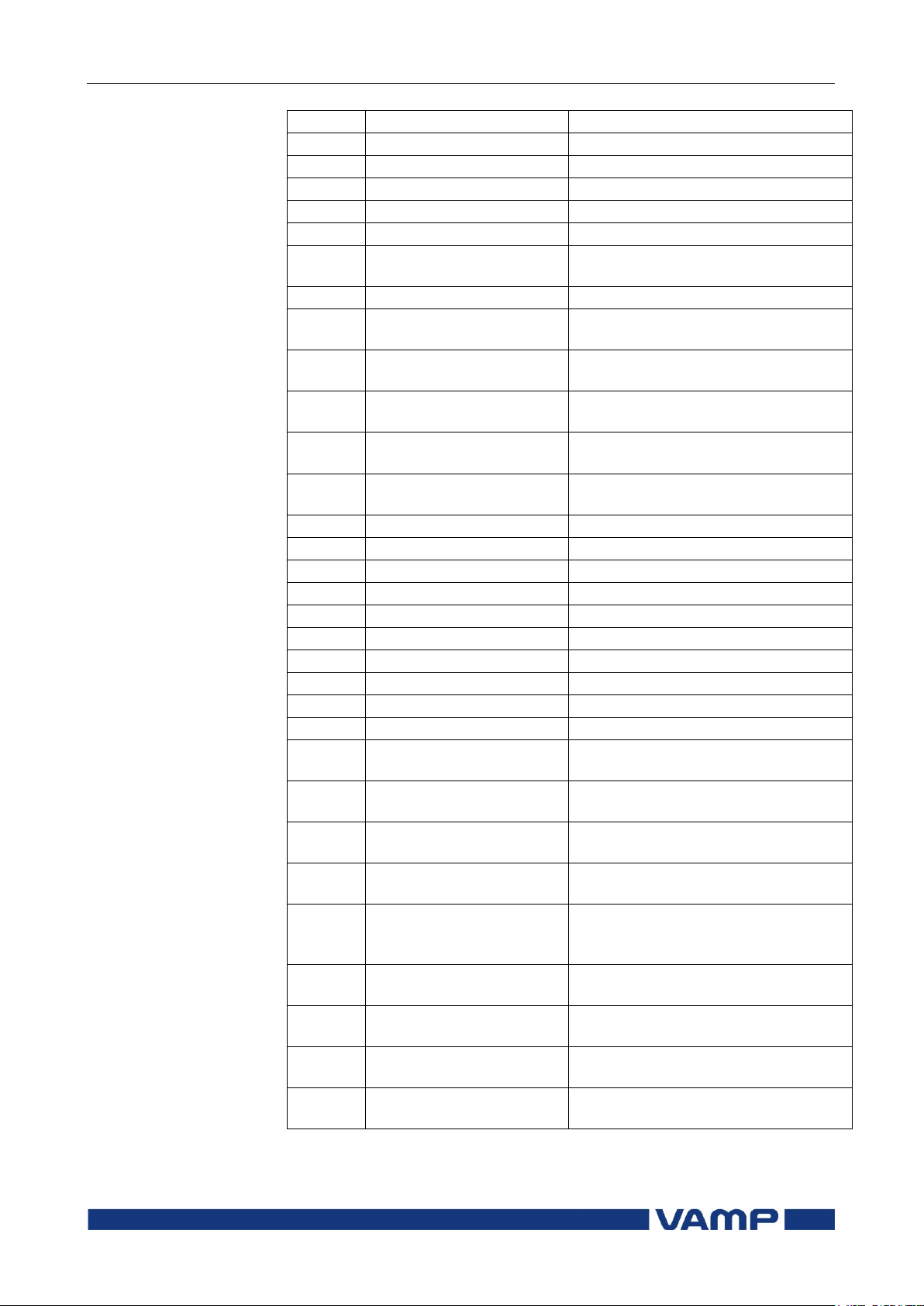

Value

Menu/Submenu

Description

P

P/POWER

Active power [kW]

Q

P/POWER

Reactive power [kvar]

S

P/POWER

Apparent power [kVA]

P/POWER

Active power angle []

P.F.

P/POWER

Power factor [ ]

f

P/POWER

Frequency [Hz]

Pda

P/15 MIN POWER

Active power [kW]

Qda

P/15 MIN POWER

Reactive power [kvar]

Sda

P/15 MIN POWER

Apparent power [kVA]

Pfda

P/15 MIN POWER

Power factor [ ]

fda

P/15 MIN POWER

Frequency [Hz]

PL1

P/POWER/PHASE 1

Active power of phase 1 [kW]

PL2

P/POWER/PHASE 1

Active power of phase 2 [kW]

PL3

P/POWER/PHASE 1

Active power of phase 3 [kW]

QL1

P/POWER/PHASE 1

Reactive power of phase 1 [kvar]

QL2

P/POWER/PHASE 1

Reactive power of phase 2 [kvar]

QL3

P/POWER/PHASE 1

Reactive power of phase 3 [kvar]

SL1

P/POWER/PHASE 2

Apparent power of phase 1 [kVA]

SL2

P/POWER/PHASE 2

Apparent power of phase 2 [kVA]

SL3

P/POWER/PHASE 2

Apparent power of phase 3 [kVA]

PF_L1

P/POWER/PHASE 2

Power factor of phase 1 [ ]

PF_L2

P/POWER/PHASE 2

Power factor of phase 2 [ ]

PF_L3

P/POWER/PHASE 2

Power factor of phase 3 [ ]

cos

P/COS & TAN

Cosine phi [ ]

tan

P/COS & TAN

Tangent phi [ ]

cosL1

P/COS & TAN

Cosine phi of phase L1 [ ]

cosL2

P/COS & TAN

Cosine phi of phase L2 [ ]

cosL3

P/COS & TAN

Cosine phi of phase L3 [ ]

Iseq

P/PHASE SEQUENCIES

Actual current phase sequency [OK;

Reverse; ??]

Useq

P/PHASE SEQUENCIES

Actual voltage phase sequency [OK;

Reverse; ??]

Io

P/PHASE SEQUENCIES

Io/Uo angle []

fAdop

P/PHASE SEQUENCIES

Adopted frequency [Hz]

E+

E/ENERGY

Exported energy [MWh]

Eq+

E/ENERGY

Exported reactive energy [Mvar]

E-

E/ENERGY

Imported energy [MWh]

Eq-

E/ENERGY

Imported reactive energy [Mvar]

2.3.2. Measured data

The measured values can be read from the P, E, I and U menus

and their submenus. Furthermore, any measurement value in

the following table can be displayed on the main view next to

the single line diagram. Up to six measurements can be shown.

Impedance measurements (Z12, Z23, Z31) are located in

distance stage displays.

Operation and configuration

2 Local panel user interface

2.3 Operating measures

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

25

Value

Menu/Submenu

Description

E+.nn

E/DECIMAL COUNT

Decimals of exported energy [ ]

Eq.nn

E/DECIMAL COUNT

Decimals of reactive energy [ ]

E-.nn

E/DECIMAL COUNT

Decimals of imported energy [ ]

Ewrap

E/DECIMAL COUNT

Energy control

E+

E/E-PULSE SIZES

Pulse size of exported energy [kWh]

Eq+

E/E-PULSE SIZES

Pulse size of exported reactive energy

[kvar]

E-

E/E-PULSE SIZES

Pulse size of imported energy [kWh]

Eq-

E/E-PULSE SIZES

Pulse duration of imported reactive

energy [ms]

E+

E/E-PULSE DURATION

Pulse duration of exported energy

[ms]

Eq+

E/E-PULSE DURATION

Pulse duration of exported reactive

energy [ms]

E-

E/E-PULSE DURATION

Pulse duration of imported energy

[ms]

Eq-

E/E-PULSE DURATION

Pulse duration of imported reactive

energy [ms]

E+

E/E-pulse TEST

Test the exported energy pulse [ ]

Eq+

E/E-pulse TEST

Test the exported reactive energy [ ]

E-

E/E-pulse TEST

Test the imported energy [ ]

Eq-

E/E-pulse TEST

Test the imported reactive energy [ ]

IL1

I/PHASE CURRENTS

Phase current IL1 [A]

IL2

I/PHASE CURRENTS

Phase current IL2 [A]

IL3

I/PHASE CURRENTS

Phase current IL3 [A]

IL1da

I/PHASE CURRENTS

15 min average for IL1 [A]

IL2da

I/PHASE CURRENTS

15 min average for IL2 [A]

IL3da

I/PHASE CURRENTS

15 min average for IL3 [A]

Io

I/SYMMETRIC

CURRENTS

Primary value of zerosequence/

residual current Io [A]

IoC

I/SYMMETRIC

CURRENTS

Calculated Io [A]

I1

I/SYMMETRIC

CURRENTS

Positive sequence current [A]

I2

I/SYMMETRIC

CURRENTS

Negative sequence current [A]

I2/I1

I/SYMMETRIC

CURRENTS

Negative sequence current related to

positive sequence current (for

unbalance protection) [%]

THDIL

I/HARM. DISTORTION

Total harmonic distortion of the mean

value of phase currents [%]

THDIL1

I/HARM. DISTORTION

Total harmonic distortion of phase

current IL1 [%]

THDIL2

I/HARM. DISTORTION

Total harmonic distortion of phase

current IL2 [%]

THDIL3

I/HARM. DISTORTION

Total harmonic distortion of phase

current IL3 [%]

2.3 Operating measures

2 Local panel user interface

Operation and configuration

26

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

Value

Menu/Submenu

Description

Diagram

I/HARMONICS of IL1

Harmonics of phase current IL1 [%]

(See Figure 2.3.2-1)

Diagram

I/HARMONICS of IL2

Harmonics of phase current IL2 [%]

(See Figure 2.3.2-1)

Diagram

I/HARMONICS of IL3

Harmonics of phase current IL3 [%]

(See Figure 2.3.2-1)

Uline

U/LINE VOLTAGES

Average value for the three line

voltages [V]

U12

U/LINE VOLTAGES

Phase-to-phase voltage U12 [V]

U23

U/LINE VOLTAGES

Phase-to-phase voltage U23 [V]

U31

U/LINE VOLTAGES

Phase-to-phase voltage U31 [V]

UL

U(PHASE VOLTAGES

Average for the three phase voltages

[V]

UL1

U/PHASE VOLTAGES

Phase-to-earth voltage UL1 [V]

UL2

U/PHASE VOLTAGES

Phase-to-earth voltage UL2 [V]

UL3

U/PHASE VOLTAGES

Phase-to-earth voltage UL3 [V]

Uo

U/SYMMETRIC

VOLTAGES

Residual voltage Uo [%]

U1

U/SYMMETRIC

VOLTAGES

Positive sequence voltage [%]

U2

U/SYMMETRIC

VOLTAGES

Negative sequence voltage [%]

U2/U1

U/SYMMETRIC

VOLTAGES

Negative sequence voltage related to

positive sequence voltage [%]

THDU

U/HARM. DISTORTION

Total harmonic distortion of the mean

value of voltages [%]

THDUa

U/HARM. DISTORTION

Total harmonic distortion of the

voltage input a [%]

THDUb

U/HARM. DISTORTION

Total harmonic distortion of the

voltage input b [%]

THDUc

U/HARM. DISTORTION

Total harmonic distortion of the

voltage input c [%]

Diagram

U/HARMONICS of Ua

Harmonics of voltage input Ua [%]

(See Figure 2.3.2-1)

Diagram

U/HARMONICS of Ub

Harmonics of voltage input Ub [%]

(See Figure 2.3.2-1)

Diagram

U/HARMONICS of Uc

Harmonics of voltage input Uc [%]

(See Figure 2.3.2-1)

Count

U/VOLT. INTERRUPTS

Voltage interrupts counter [ ]

Prev

U/VOLT. INTERRUPTS

Previous interruption [ ]

Total

U/VOLT. INTERRUPTS

Total duration of voltage

interruptions [days, hours]

Prev

U/VOLT. INTERRUPTS

Duration of previous interruption [s]

Status

U/VOLT. INTERRUPTS

Voltage status [LOW; NORMAL]

Z12, Z23,

Z31

Z1<, Z2<, Z3<, Z4<, Z5<

Line to line impedance (primary/sec)

Z12angle

Z23angle

Z31angle

Z1<, Z2<, Z3<, Z4<, Z5<

Impedance angle

Operation and configuration

2 Local panel user interface

2.3 Operating measures

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

27

Figure 2.3.2-1. Example of harmonics bar display

2.3.3. Reading event register

The event register can be read from the Evnt submenu:

1. Push the RIGHT key once.

2. The EVENT LIST appears. The display contains a list of all

the events that have been configured to be included in the

event register.

Figure 2.3.3-1. Example of an event register

3. Scroll through the event list with the UP and DOWN keys.

4. Exit the event list by pushing the LEFT key.

It is possible to set the order in which the events are sorted. If

the “Order” -parameter is set to “New-Old”, then the first event

in the EVENT LIST is the most recent event.

2.3 Operating measures

2 Local panel user interface

Operation and configuration

28

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

2.3.4. Forced control (Force)

In some menus it is possible to switch a signal on and off by

using a force function. This feature can be used, for instance,

for testing a certain function. The force function can be

activated as follows:

1. Move to the setting state of the desired function, for

example DO (see Chapter 2.4, on page 29).

2. Select the Force function (the background color of the force

text is black).

Figure 2.3.4-1. Selecting Force function

3. Push the ENTER key.

4. Push the UP or DOWN key to change the "OFF" text to

"ON", that is, to activate the Force function.

5. Push the ENTER key to return to the selection list. Choose

the signal to be controlled by force with the UP and DOWN

keys, for instance the T1 signal.

6. Push the ENTER key to confirm the selection. Signal T1

can now be controlled by force.

7. Push the UP or DOWN key to change the selection from "0"

(not alert) to "1" (alert) or vice versa.

8. Push the ENTER key to execute the forced control operation

of the selected function, e.g., making the output relay of T1

to pick up.

9. Repeat the steps 7 and 8 to alternate between the on and off

state of the function.

10. Repeat the steps 1...4 to exit the Force function.

11. Push the CANCEL key to return to the main menu.

NOTE! All the interlockings and blockings are bypassed when the force control

is used.

Operation and configuration

2 Local panel user interface

2.4 Configuration and parameter

setting

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

29

2.4. Configuration and parameter setting

The minimum procedure to configure a relay is

1. Open the access level "Configurator". The default password

for configurator access level is 2.

2. Set the rated values in menu [CONF] including at least

current transformers, voltage transformers and motor

ratings if applicable. Also the date and time settings are in

this same main menu.

3. Enable the needed protection functions and disable the rest

of the protection functions in main menu [Prot].

4. Set the setting parameter of the enable protection stages

according the application.

5. Connect the output relays to the start and trip signals of the

enabled protection stages using the output matrix. This can

be done in main menu [DO], although the VAMPSET

program is recommended for output matrix editing.

6. Configure the needed digital inputs in main menu [DI].

7. Configure blocking and interlockings for protection stages

using the block matrix. This can be done in main menu

[Prot], although VAMPSET is recommended for block

matrix editing.

Some of the parameters can only be changed via the RS-232

serial port using the VAMPSET software. Such parameters,

(for example passwords, blockings and mimic configuration) are

normally set only during commissioning.

Some of the parameters require the restarting of the relay. This

restarting is done automatically when necessary. If a

parameter change requires restarting, the display will show as

Figure 2.4-1.

Figure 2.4-1 Example of auto-reset display

Press CANCEL to return to the setting view. If a parameter

must be changed, press the ENTER key again. The parameter

can now be set. When the parameter change is confirmed with

the ENTER key, a [RESTART]- text appears to the top-right

corner of the display. This means that auto-resetting is

2.4 Configuration and parameter

setting

2 Local panel user interface

Operation and configuration

30

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

pending. If no key is pressed, the auto-reset will be executed

within few seconds.

2.4.1. Parameter setting

1. Move to the setting state of the desired menu (for example

CONF/CURRENT SCALING) by pushing the ENTER key.

The Pick text appears in the upper-left part of the display.

2. Enter the password associated with the configuration level

by pushing the INFO key and then using the arrow keys

and the ENTER key (default value is 0002). For more

information about the access levels, please refer to Chapter

2.2.5.

3. Scroll through the parameters using the UP and DOWN

keys. A parameter can be set if the background color of the

line is black. If the parameter cannot be set the parameter

is framed.

4. Select the desired parameter (for example Inom) with the

ENTER key.

5. Use the UP and DOWN keys to change a parameter value.

If the value contains more than one digit, use the LEFT and

RIGHT keys to shift from digit to digit, and the UP and

DOWN keys to change the digits.

6. Push the ENTER key to accept a new value. If you want to

leave the parameter value unchanged, exit the edit state by

pushing the CANCEL key.

Figure 2.4.1-1.Changing parameters

Operation and configuration

2 Local panel user interface

2.4 Configuration and parameter

setting

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

31

2.4.2. Setting range limits

If the given parameter setting values are out-of-range values, a

fault message will be shown when the setting is confirmed with

the ENTER key. Adjust the setting to be within the allowed

range.

Figure 2.4.2-1 Example of a fault message

The allowed setting range is shown in the display in the setting

mode. To view the range, push the INFO key. Push the

CANCEL key to return to the setting mode.

Figure 2.4.2-2. Allowed setting ranges show in the display

2.4 Configuration and parameter

setting

2 Local panel user interface

Operation and configuration

32

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

2.4.3. Disturbance recorder menu DR

Via the submenus of the disturbance recorder menu the

following functions and features can be read and set:

DISTURBANCE RECORDER

Recording mode (Mode)

Sample rate (Rate)

Recording time (Time)

Pre trig time (PreTrig)

Manual trigger (MnlTrig)

Count of ready records (ReadyRe)

REC. COUPLING

Add a link to the recorder (AddLink)

Clear all links (ClrLnks)

Available links:

DO, DI

Uline, Uphase

IL

U2/U1, U2, U1

I2/In, I2/I1, I2, I1, IoCalc

CosFii

PF, S, Q, P

f

Uo

UL3, UL2, UL1

U31, U23, U12

Io

IL3, IL2, IL1

Prms, Qrms, Srms

Tanfii

THDIL1, THDIL2, THDIL3

THDUa, THDUb, THDUc

IL1RMS, IL2RMS, IL3RMS

ILmin, ILmax, ULLmin, ULLmax, ULNmin, ULNmax

fy, fz, U12y, U12z

2.4.4. Configuring digital inputs DI

The following functions can be read and set via the submenus

of the digital inputs menu:

The status of digital inputs (DIGITAL INPUTS 1-20/24/32)

Operation counters (DI COUNTERS)

Operation delay (DELAYs for DigIn)

The polarity of the input signal (INPUT POLARITY). Either

normally open (NO) or normally closed (NC) circuit.

Event enabling EVENT MASK1

Operation and configuration

2 Local panel user interface

2.4 Configuration and parameter

setting

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

33

2.4.5. Configuring digital outputs DO

The following functions can be read and set via the submenus

of the digital outputs menu:

The status of the output relays (RELAY OUTPUTS 1, 2, 3

and 4)

The forcing of the output relays (RELAY OUTPUTS 1, 2, 3

and 4) (only if Force = ON):

o Forced control (0 or 1) of the Trip relays

o Forced control (0 or 1) of the Alarm relays

o Forced control (0 or 1) of the IF relay

The configuration of the output signals to the output relays.

The configuration of the operation indicators (LED) Alarm

and Trip and application specific alarm leds A, B and C

(that is, the output relay matrix).

NOTE! The amount of Trip and Alarm relays depends on the relay type and

optional hardware.

2.4.6. Protection menu Prot

The following functions can be read and set via the submenus

of the Prot menu:

Reset all the counters (PROTECTION SET/ClAll)

Read the status of all the protection functions (PROTECT

STATUS 1-x)

Enable and disable protection functions (ENABLED

STAGES 1-x)

Define the interlockings using block matrix (only with

VAMPSET).

Each stage of the protection functions can be disabled or

enabled individually in the Prot menu. When a stage is

enabled, it will be in operation immediately without a need to

reset the relay.

The relay includes several protection functions. However, the

processor capacity limits the number of protection functions

that can be active at the same time.

2.4 Configuration and parameter

setting

2 Local panel user interface

Operation and configuration

34

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

2.4.7. Configuration menu CONF

The following functions and features can be read and set via

the submenus of the configuration menu:

DEVICE SETUP

Bit rate for the command line interface in ports X4 and the

front panel. The front panel is always using this setting. If

SPABUS is selected for the rear panel local port X4, the bit

rate is according SPABUS settings.

Access level [Acc]

LANGUAGE

List of available languages in the relay

CURRENT SCALING

Rated phase CT primary current (Inom)

Rated phase CT secondary current (Isec)

Rated input of the relay [Iinput]. 5 A or 1 A. This is specified

in the order code of the device.

Rated value of I

Rated value of I

Rated I

input of the relay [Ioinp]. 5 A, 1 A or 0.2 A. This is

0

specified in the order code of the device.

The rated input values are usually equal to the rated secondary

value of the CT.

CT primary current (Ionom)

0

CT secondary current (Iosec)

0

The rated CT secondary may be greater than the rated input

but the continuous current must be less than four times the

rated input. In compensated, high impedance earthed and

isolated networks using cable transformer to measure residual

current I0, it is quite usual to use a relay with 1 A or 0.2 A

input although the CT is 5 A or 1A. This increases the

measurement accuracy.

The rated CT secondary may also be less than the rated input

but the measurement accuracy near zero current will decrease.

MOTOR CURRENTS

Rated current of the motor

VOLTAGE SCALING

Rated VT primary voltage (Uprim)

Rated VT secondary voltage (Usec)

Rated U

VT secondary voltage (Uosec)

0

Voltage measuring mode (Umode)

Operation and configuration

2 Local panel user interface

2.4 Configuration and parameter

setting

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

35

UNITS FOR MIMIC DISPLAY

Unit for voltages (V). The choices are V (volt) or kV

(kilovolt).

Scaling for active, reactive and apparent power [Power].

The choices are k for kW, kvar and kVA or M for MW, Mvar

and MVA.

DEVICE INFO

Device type (Type VAMP 2XX)

Serial number (SerN)

Software version (PrgVer)

Bootcode version (BootVer)

DATE/TIME SETUP

Day, month and year (Date)

Time of day (Time)

Date format (Style). The choices are "yyyy-mm-dd",

"dd.nn.yyyy" and "mm/dd/yyyy".

CLOCK SYNCHRONISATION

Digital input for minute sync pulse (SyncDI). If any digital

input is not used for synchronization, select "".

Daylight saving time for NTP synchronization (DST).

Detected source of synchronization (SyScr).

Synchronization message counter (MsgCnt).

Latest synchronization deviation (Dev).

The following parameters are visible only when the access level

is higher than "User".

Offset, i.e. constant error, of the synchronization source

(SyOS).

Auto adjust interval (AAIntv).

Average drift direction (AvDrft): "Lead" or "lag".

Average synchronization deviation (FilDev).

2.4 Configuration and parameter

setting

2 Local panel user interface

Operation and configuration

36

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

2.4.8. Protocol menu Bus

There are three communication ports in the rear panel. The

availability depends on the communication options (see chapter

Ordering code in the technical description). In addition there is

a connector in the front panel overruling the local port in the

rear panel.

REMOTE PORT

Communication protocol for remote port X5 [Protocol].

Message counter [Msg#]. This can be used to verify that the

device is receiving messages.

Communication error counter [Errors].

Communication time-out error counter [Tout].

Information of bit rate/data bits/parity/stop bits.

This value is not directly editable. Editing is done in the

appropriate protocol setting menus.

The counters are useful when testing the communication.

LOCAL PORT

This port is disabled, if a cable is connected to the front panel

connector.

Communication protocol for the local port X4 [Protocol]. For

VAMPSET use "None" or "SPABUS".

Message counter [Msg#]. This can be used to verify that the

device is receiving messages.

Communication error counter [Errors].

Communication time-out error counter [Tout].

Information of bit rate/data bits/parity/stop bits.

This value is not directly editable. Editing is done in the

appropriate protocol setting menus. For VAMPSET and

protocol "None" the setting is done in menu CONF/DEVICE

SETUP.

PC (LOCAL/SPA BUS)

This is a second menu for local port X4. The VAMPSET

communication status is showed.

Bytes/size of the transmitter buffer [Tx].

Message counter [Msg#]. This can be used to verify that the

device is receiving messages.

Communication error counter [Errors]

Communication time-out error counter [Tout].

Same information as in the previous menu.

Operation and configuration

2 Local panel user interface

2.4 Configuration and parameter

setting

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

37

EXTENSION PORT

Communication protocol for extension port X4 [Protocol].

Message counter [Msg#]. This can be used to verify that the

device is receiving messages.

Communication error counter [Errors].

Communication time-out error counter [Tout].

Information of bit rate/data bits/parity/stop bits.

This value is not directly editable. Editing is done in the

appropriate protocol setting menus.

Ethernet port

These parameters are used by the ethernet interface. For

changing the nnn.nnn.nnn.nnn style parameter values,

VAMPSET is recommended.

Ethernet port protocol [Protoc].

IP Port for protocol [Port]

IP address [IpAddr].

Net mask [NetMsk].

Gateway [Gatew].

Name server [NameSw].

Network time protocol (NTP) server [NTPSvr].

TCP Keep alive interval [KeepAlive]

MAC address [MAC]

IP Port for Vampset [VS Port]

Message counter [Msg#]

Error counter [Errors]

Timeout counter [Tout]

MODBUS

Modbus addres for this slave device [Addr]. This address

has to be unique within the system.

Modbus bit rate [bit/s]. Default is "9600".

Parity [Parity]. Default is "Even".

For details see the technical description part of the manual.

EXTERNAL I/O protocol

This is a Modbus master protocol to communicate with the

extension I/O modules connected to the extension port. Only

one instance of this protocol is possible.

Bit rate [bit/s]. Default is "9600".

Parity [Parity]. Default is "Even".

For details see the technical description part of the manual.

2.4 Configuration and parameter

setting

2 Local panel user interface

Operation and configuration

38

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

SPA BUS

Several instances of this protocol are possible.

SPABUS addres for this device [Addr]. This address has to

be unique within the system.

Bit rate [bit/s]. Default is "9600".

Event numbering style [Emode]. Default is "Channel".

For details see the technical description part of the manual.

IEC 60870-5-103

Only one instance of this protocol is possible.

Address for this device [Addr]. This address has to be

unique within the system.

Bit rate [bit/s]. Default is "9600".

Minimum measurement response interval [MeasInt].

ASDU6 response time mode [SyncRe].

For details see the technical description part of the manual.

IEC 103 DISTURBANCE RECORDINGS

For details see the technical description part of the manual.

PROFIBUS

Only one instance of this protocol is possible.

[Mode]

Bit rate [bit/s]. Use 2400 bps. This parameter is the bit rate

between the main CPU and the Profibus ASIC. The actual

Profibus bit rate is automatically set by the Profibus master

and can be up to 12 Mbit/s.

Event numbering style [Emode].

Size of the Profibus Tx buffer [InBuf].

Size of the Profibus Rx buffer [OutBuf].

When configuring the Profibus master system, the length of

these buffers are needed. The size of the both buffers is set

indirectly when configuring the data items for Profibus.

Address for this slave device [Addr]. This address has to be

unique within the system.

Profibus converter type [Conv]. If the shown type is a dash

“-“, either Profibus protocol has not been selected or the

device has not restarted after protocol change or there is a

communication problem between the main CPU and the

Profibus ASIC.

For details see the technical description part of the manual.

Operation and configuration

2 Local panel user interface

2.4 Configuration and parameter

setting

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

39

DNP3

Only one instance of this protocol is possible.

Bit rate [bit/s]. Default is "9600".

[Parity].

Addres for this device [SlvAddr]. This address has to be

unique within the system.

Master's addres [MstrAddr].

For further details see the technical description part of the

manual.

IEC 60870-5-101

Bit rate [bit/s]. Default is “9600”.

[Parity].

Link layer address for this device [LLAddr].

ASDU address [ALAddr].

For further details see the technical description part of the

manual.

2.4.9. Single line diagram editing

The single-line diagram is drawn with the VAMPSET software.

For more information, please refer to the VAMPSET manual

(VMV.EN0xx).

Figure 2.4.9-1. Single line diagram.

2.4.10. Blocking and interlocking configuration

The configuration of the blockings and interlockings is done

with the VAMPSET software. Any start or trip signal can be

used for blocking the operation of any protection stage.

Furthermore, the interlocking between objects can be

configured in the same blocking matrix of the VAMPSET

software. For more information, please refer to the VAMPSET

manual (VMV.EN0xx).

3 VAMPSET PC software

Operation and configuration

40

VAMP 24h support phone +358 (0)20 753 3264

VM259EN007

3. VAMPSET PC software

The PC user interface can be used for:

On-site parameterization of the relay

Loading relay software from a computer

Reading measured values, registered values and events to a

computer.

Continuous monitoring of all values and events.

Two RS 232 serial ports are available for connecting a local PC

with VAMPSET to the relay; one on the front panel and one on

the rear panel of the relay. These two serial ports are connected

in parallel. However, if the connection cables are connected to

both ports, only the port on the front panel will be active. To

connect a PC to a serial port, use a connection cable of type VX

003-3.

The VAMPSET program can also use TCP/IP LAN connection.

Optional hardware is required.

There is a free of charge PC program called VAMPSET

available for configuration and setting of VAMP relays. Please

download the latest VAMPSET.exe from our web page

www.vamp.fi. For more information about the VAMPSET

software, please refer to the user’s manual with the code

VMV.EN0xx. Also the VAMPSET user’s manual is available at

our web site.

Technical description Table of Contents

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

41

Table of Contents

1. Introduction .......................................................................... 45

1.1. Main features ................................................................... 46

1.2. Principles of numerical protection techniques .......... 47

2. Protection functions ............................................................. 49

2.1. Maximum number of protection stages in one

application ................................................................................ 49

2.2. List of protection functions ............................................. 49

2.3. General features of protection stages ........................ 50

2.4. Distance protection Z< ................................................... 54

2.4.1. Short circuit distance protection Z< (21) ............. 54

2.4.2. Earth-fault distance protection Ze< (21N) .......... 57

2.4.3. Distance protection applications ........................ 66

2.5. Line differential protection LdI> (87) ............................ 71

2.6. Overcurrent stage I> (50/51) ......................................... 73

2.7. Directional overcurrent protection I

> (67) ............... 77

dir

2.8. Current unbalance stage I2> (46) ................................. 83

2.9. Undercurrent protection I< (37) .................................... 84

2.10. Directional earth fault protection I0φ> (67N) ............... 85

2.11. Earth fault protection I0> (50N/51N) ............................. 91

2.12. Zero sequence voltage protection U0> (59N) ............ 96

2.13. Thermal overload protection T> (49) ........................... 99

2.14. Overvoltage protection U> (59) ................................. 103

2.15. Undervoltage protection U< (27) ............................... 105

2.16. Reverse power and underpower protection P< (32)

108

2.17. Overfrequency and underfrequency Protection f>, f<

(81H/81L).................................................................................. 110

2.18. Rate of change of frequency (ROCOF) protection

df/dt (81R) ............................................................................... 112

2.19. Synchrocheck (25) ........................................................ 117

2.20. Second harmonic O/C stage If2>(51F2) .................... 121

2.21. Circuit breaker failure protection CBFP (50BF) ......... 122

2.22. Programmable stages (99) .......................................... 124

2.23. Arc fault protection (50ARC/50NARC)- optional ..... 127

2.24. Inverse time operation ................................................. 131

2.24.1. Standard inverse delays IEC, IEEE, IEEE2, RI ...... 133

2.24.2. Free parametrisation using IEC, IEEE and IEEE2

equations ........................................................................... 143

2.24.3. Programmable inverse time curves ................... 144

3. Supporting functions .......................................................... 145

3.1. Event log ......................................................................... 145

3.2. Disturbance recorder ................................................... 147

3.3. Cold load pick-up and inrush current detection ..... 152

3.4. Voltage sags and swells ............................................... 154

3.5. Voltage interruptions .................................................... 156

Table of Contents

Technical description

42

VAMP 24h support phone +358 (0)20 753 3264

VM259.EN007

3.6. Current transformer supervision .................................. 158

3.7. Voltage transformer supervision ................................. 159

3.8. Circuit breaker condition monitoring ......................... 160

3.9. Energy pulse outputs .................................................... 165

3.10. System clock and synchronization ............................. 168

3.11. Running hour counter ................................................... 172

3.12. Timers ............................................................................... 173

3.13. Combined overcurrent status ..................................... 175

3.14. Self supervision ............................................................... 177

3.14.1. Diagnostics ............................................................ 177

3.15. Short circuit fault location ............................................ 179

3.16. Earth-fault location ....................................................... 183

4. Measurement functions ..................................................... 185

4.1. Measurement accuracy .............................................. 186

4.2. RMS values ..................................................................... 187

4.3. Harmonics and Total Harmonic Distortion (THD) ...... 188

4.4. Demand values ............................................................. 189

4.5. Minimum and maximum values ................................. 190

4.6. Maximum values of the last 31 days and twelve

months ..................................................................................... 191

4.7. Voltage measurement mode ..................................... 191

4.8. Power calculation ......................................................... 192

4.9. Direction of power and current .................................. 193

4.10. Symmetric components ............................................... 194

4.11. Primary, secondary and per unit scaling................... 197

4.11.1. Current scaling ...................................................... 197

4.11.2. Voltage scaling ..................................................... 199

5. Control functions ................................................................ 201

5.1. Output relays ................................................................. 201

5.2. Digital inputs ................................................................... 202

5.3. Virtual inputs and outputs ............................................ 205

5.4. Output matrix ................................................................. 206

5.5. Blocking matrix .............................................................. 207

5.6. Controllable objects ..................................................... 207

5.6.1. Local/Remote selection ...................................... 209

5.7. Auto-reclose function (79) ........................................... 210

5.8. Logic functions .............................................................. 217

6. Communication ................................................................. 218

6.1. Communication ports .................................................. 218

6.1.1. Local port ............................................................... 219

6.1.2. Remote port X9 ..................................................... 221

6.1.3. Extension port ........................................................ 223

6.1.4. Ethernet port .......................................................... 224

6.2. Communication protocols .......................................... 225

6.2.1. PC communication .............................................. 225

6.2.2. Modbus TCP and Modbus RTU ........................... 225

6.2.3. Profibus DP ............................................................. 226

Technical description

Table of Contents

VM259.EN007

VAMP 24h support phone +358 (0)20 753 3264

43

6.2.4. SPA-bus ................................................................... 228

6.2.5. IEC 60870-5-103 ..................................................... 229

6.2.6. DNP 3.0 ................................................................... 231

6.2.7. IEC 60870-5-101 ..................................................... 232

6.2.8. External I/O (Modbus RTU master) ..................... 233

6.2.9. IEC 61850 ................................................................ 233

6.2.10. EtherNet/IP ............................................................. 235

7. Applications ........................................................................ 236

7.1. Subtransmission line protection ................................... 236

7.2. Distributed generation application ............................ 237

7.3. Medium voltage ring network protection ................. 238

7.4. Trip circuit supervision ................................................... 239

7.4.1. Internal parallel digital inputs .............................. 239

7.4.2. Trip circuit supervision with one digital input .... 239

7.4.3. Trip circuit supervision with two digital inputs ... 246

8. Connections ....................................................................... 249

8.1. Rear panel view ............................................................ 249

8.2. Auxiliary voltage ............................................................ 256

8.3. Serial communication connection ............................ 256

8.3.1. Pin assignments of communication options ..... 259

8.3.2. Front panel connector ......................................... 262

8.4. Optional two channel arc protection card .............. 263

8.5. Optional digital I/O card (DI19/DI20) ......................... 264

8.6. External I/O extension modules .................................. 265

8.6.1. External LED module VAM 16D ........................... 265

8.6.2. External input / output module .......................... 265

8.7. Block diagrams .............................................................. 271

8.7.1. VAMP 259-4C6 ...................................................... 271

8.7.2. VAMP 259-4C7 ...................................................... 272

8.7.3. VAMP 259-4C8 ...................................................... 273

8.8. Block diagrams of option modules ............................ 274

8.8.1. Optional arc protection ...................................... 274

8.8.2. Optional DI19/DI20 ............................................... 274

8.9. Connection examples .................................................. 275

9. Technical data ................................................................... 278

9.1. Connections .................................................................. 278

9.1.1. Measuring circuitry ............................................... 278

9.1.2. Auxiliary voltage ................................................... 279

9.1.3. Digital inputs .......................................................... 279