VAMP 120

Arc protection unit

User manual

VAMP 120

Arc protection unit

User manual

VAMP Ltd

2

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

3

Table of content

1. General ...................................................................................4

1.1. Arc protection unit VAMP 120...........................................4

1.2. Unit features .........................................................................4

2. Unit configuration...................................................................5

3. Sensors ....................................................................................6

3.1. Arc sensor VA 1 DA .............................................................6

4. Functions .................................................................................8

5. Applications............................................................................9

6. Connections .........................................................................10

7. Technical data .....................................................................12

Auxiliary voltage..................................................................12

Tripping contacts ................................................................12

BIO Input ...............................................................................12

Disturbance tests .................................................................12

Voltage tests ........................................................................13

Mechanical tests .................................................................13

Environmental conditions ..................................................13

8. Dimensions............................................................................14

8.1. VAMP 120 ...........................................................................14

8.2. VA 1 DA arc sensor ...........................................................15

8.3. Mounting plates for VA 1 DA...........................................15

9. Order information.................................................................16

10. Reference information.........................................................17

VAMP 120

Arc protection unit

User manual

VAMP Ltd

4

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

1. General

This manual describes the general functions of the arc

protection unit, it also includes mounting and configuration

instructions.

1.1. Arc protection unit VAMP 120

Figure 1.1-1. Arc protection unit VAMP 120

1.2. Unit features

VAMP 120 is a state of the art arc protection unit for electrical

power distribution systems.

By using VAMP 120 in switchgears considerable safety

improvements are obtained in the form of minimized injury and

damage in case of an arc fault.

VAMP 120 is a “stand alone” system, which gives a compact

solution when the application doesn’t require overcurrent

measurement or when the overcurrent information is available

from the incomer protection relay or any other arc protection

unit (VAMP 221 / VAM 4C). It is possible to connect 4 arc

sensors, of the type VA 1 DA or VA 1 EH, to the VAMP 120

unit.

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

5

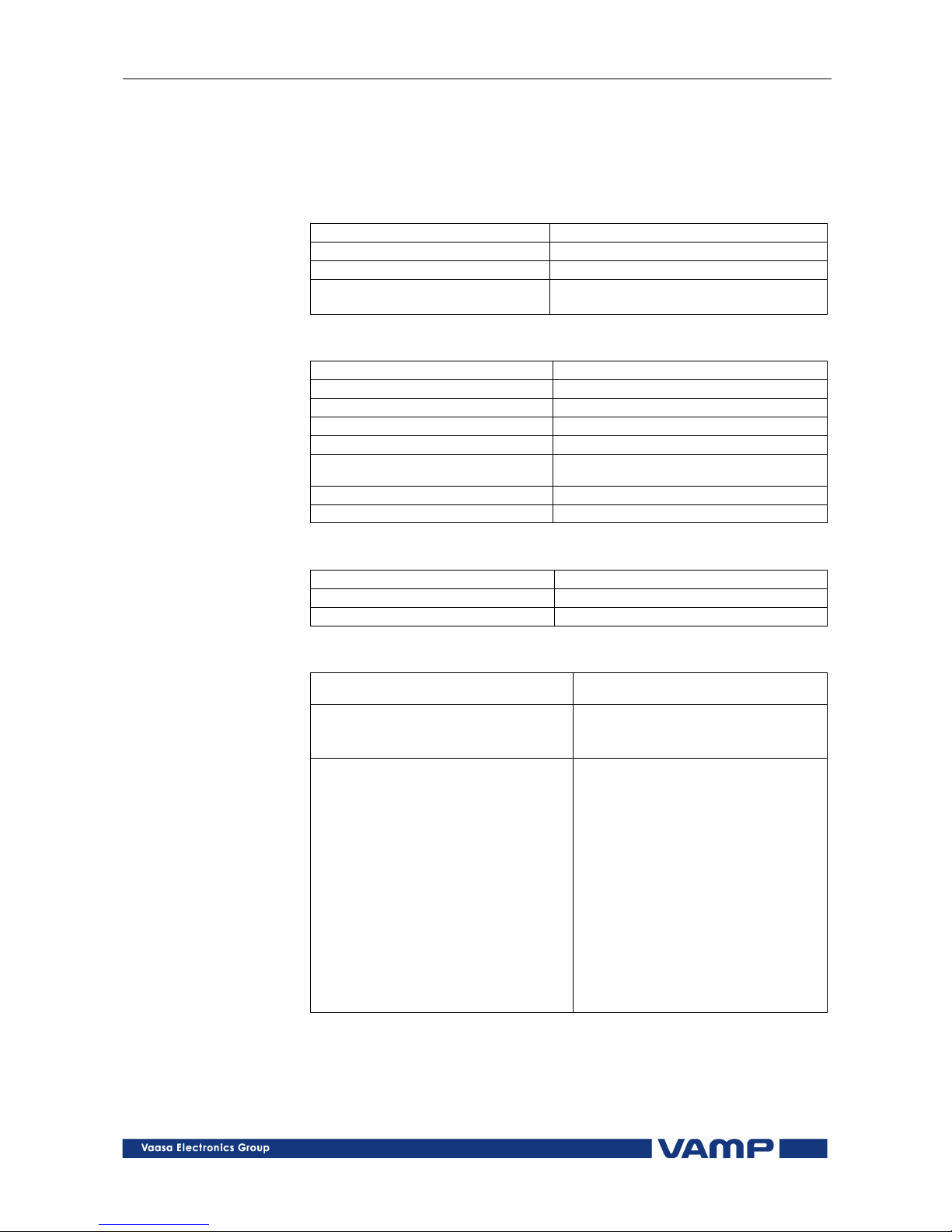

2. Unit configuration

Figure 2-1. VAMP 120 dipswitch operations and sensor connection

The unit is configured using the dipswitches:

Dipswitches 1-5 (see Figure 2-1):

If only one arc sensor in use, SENSOR 1 input should be used.

•

SW nr. 1 : if sensor input 2 is also required, SEN 1

should be set to the left position.

•

SW nr. 2 and 3 : if sensor input 3 and 4 are used, SW nr. 2

and 3 should respectively be set to left

position.

•

SW nr. 4 : is setting the system selectivity. If set to

the left position, sensor nr. 1 and 2 will

trip relay T1. Accordingly sensor nr. 3 and

4 will trip relay T2. The NC trip signal

out put will always work in parallel with

T1. If SW nr. 4 is to the right, all four

sensor channels will activate both trip

groups.

•

SW nr. 5 : is the selection of tripping criteria. If set

to the right, the unit will trip for light

only. If set to the left, the unit needs both

light and current information for tripping.

•

SW nr. 6 and 7 : the Latch switches enables latching of the

trip relays. When it is in ON position the

latching function is activated.

•

SW nr. 8 : is the configuration switch for sensor

inputs 2 and 3. If it is in “ON” position,

sensor 2 or 3 activation will make a

common trip of both T1 and T2. If it is in

“OFF” position, sensor 2 is linked to T1

and sensor 3 to T2.

VAMP 120

Arc protection unit

User manual

VAMP Ltd

6

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

3. Sensors

3.1. Arc sensor VA 1 DA

The arc sensor is a light sensitive element, which is activated

by strong light. Arc sensors should be mounted in the switchgear cubicles, in such a way that the light sensitive part (see

Figure 3.1-2) covers the protected area as completely as

possible.

Figure 3.1-1. Arc sensor VA 1 DA

403020100

50

60

70

80

90

100

120

130

140

100%

80

60

40

20

Figure 3.1-2. The sensitivity of the VA1DA arc sensor to light from different

directions.

In open spaces, such as the bus bar section, arc sensors should

be mounted max. four meters apart.

The light sensitivity of the arc sensor is 8000 LUX

The arc sensor can be mounted from the outside on partition

wall of the switchgear. The active part of the sensor is mounted

in a 10 mm hole, to the area in the switchgear that should be

protected, and fastened with a 4 mm self-tapping screw (see

Figure 3.1-3).

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

7

The arc sensor can alternatively be mounted completely in the

protected area with the help of a mounting plate VYX 01 (Zshaped) or VYX 02 (L-shaped). (See Figure 8.3-1)

10mm

Fastening screw4 x 15

Active part of the sensor

Anchoring

Sensor cable

Figure 3.1-3. Arc sensor mounting picture.

VAMP 120

Arc protection unit

User manual

VAMP Ltd

8

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

4. Functions

VAMP 120 includes an extensive self-supervision. The selfsupervision includes internal functions as well as all arc

sensors.

Figure 4-1. Self-supervision block diagram

If an internal fault occurs the self-supervision relay is activated

and the ERROR-led is lit.

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

9

5. Applications

Every compartment is equipped with an arc sensor. Up to four

sensors can be connected to the VAMP 120 unit. The trip relays

are electromechanical and can be connected directly to control

the circuit-breakers (see chapter Technical data).

The VAMP 120 is suitable for small power generation plants

where light is the only criteria for tripping and full selectivity

is required.

Figure 5-1 Wind power application

Figure 5-2 Diesel power plant application

VAMP 120

Arc protection unit

User manual

VAMP Ltd

10

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

6. Connections

*Connection for shield if shield sensor cable used (VA1DA-20s)

Figure 6-1. VAMP 120 connection

The VAMP 120 unit comprises two independent arc protection

zones. Both zones have their own trip relay, trip 1 and trip 2.

Trip 1 is controlled by sensor inputs 1 and 2. Trip is controlled

by sensors 3 and 4.

Trip alarm is activated if either or both are tripping. If “T1=T2”

dip switch is at “on” position, both trip outputs will work in

parallel for any sensor activation.

If “S1=S2” dip switch is at “on” position, sensors 2 and 3

activation will cause both T1 and T2 to trip. This is e.g. used for

CB compartment supervision where two zones are overlapping

each other.

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

11

If overcurrent criteria is required simultaneously with light

activation, a binary current signal has to be connected to X215/16. This I> signal can e.g. be taken from a VAM 4C or

VAMP 221 unit. The external reset is possible by correcting an

auxiliary voltage to X2-17/18.

The auxiliary boltage is connected to X2-1 and X2-2. VAMP has

a wide range power supply from 19 to 265 Vdc or 40 to 265 Vac

in the same hardware.

VAMP 120

Arc protection unit

User manual

VAMP Ltd

12

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

7. Technical data

Auxiliary voltage

Us 19 … 265 V dc / 40 … 265 V ac

In (stby) 30mA

IsensAct 20mA

Iarc 120mA + (IsensAct x n);

n = number of active sensors

Tripping contacts

Number 1

Rated voltage

≤250V ac/dc

Continuous carry 5A

Make and carry for 0.5s 30A

Make and carry for 3s 15A

Breaking capacity DC, when time

constant L/R=40ms

50W

Contact material AgCdO2

Operating time 7ms

BIO Input

Rated voltage 18 - 265 Vac/dc

Rated current / input 5 mA

Number of inputs 2

Disturbance tests

EMC test CE approved and tested according to EN

50081-2, EN 50082-2

Emission

- Conducted (EN 55011 class A) 0.15 - 30 MHz

- Emitted (EN 55011 class A) 30 - 1 000 MHz

Immunity

- Static discharge (ESD) (According to

IEC244-22-2 and EN61000-4-2, class III)

Air discharge 8 kV

Contact discharge 6 kV

- Fast transients (EFT) (According to

EN61000-4-4, class III and IEC801-4, level 4)

Power supply input 2kV, 5/50ns

other inputs 2 kV, 5/50ns

- Surge (According to EN61000-4-5 [09/96],

level 4)

Between wires 2 kV / 1.2/50µs

Between wire and earth 4 kV / 1.2/50µs

- RF electromagnetic field test (According. to

EN 61000-4-3, class III)

f = 80….1000 MHz 10V /m

- Conducted RF field (According. to EN 61000-

4-6, class III)

f = 150 kHz….80 MHz 10V

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

13

Voltage tests

Insulation test voltage acc- to IEC 60255-5 2 kV, 50Hz, 1min

Impulse test voltage acc- to IEC 60255-5 5 kV, 1.2/50us, 0.5J

Mechanical tests

Vibration test 2 ... 13.2 Hz ±3.5mm

13.2 ... 100Hz, ±1.0g

Shock/Bump test acc. to IEC 60255-21-2 20g, 1000 bumps/dir.

Environmental conditions

Specified ambient service temp. range -35…+70°C

Transport and storage temp. range -40…+70°C

VAMP 120

Arc protection unit

User manual

VAMP Ltd

14

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

8. Dimensions

8.1. VAMP 120

Figure 8.1-1. Arc protection unit VAMP 120 dimensions

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

15

8.2. VA 1 DA arc sensor

25

14

22

4

10

Figure 8.2-1. VA 1 DA arc sensor dimensions

8.3. Mounting plates for VA 1 DA

50

10 mm

3mm

44

59

25

15

15

26

50

50

30

10 mm

3mm

44

59

15

15

26

30

VYX 001 VYX002

Figure 8.3-1. Mounting plate dimensions.

VAMP 120

Arc protection unit

User manual

VAMP Ltd

16

VAMP 24h support phone : +358 (0)20 753 3264

VM120.EN001

9. Order information

Unit

UnitUnit

Unit Ordering code

Ordering codeOrdering code

Ordering code

VAMP 120 unit VAMP 120

Installation kit for flush mounting VB 263

Arc sensor, 6 m cable VA 1 DA-6

Arc sensor, 6 m cable VA 1 EH-6 (1P65)

Arc sensor, 20 m cable VA 1 DA-20

VAMP Ltd

Arc protection unit

User manual

VAMP 12

0

VM120.EN001 VAMP 24h support phone : +358 (0)20 753 3264

17

10. Reference information

Manufacturer data:

VAMP Ltd

P.O.Box 810

FIN-65101 Vaasa, Finland

Visiting address: Yrittäjänkatu 15

Phone: +358 (0)20 753 3200

Fax: +358 (0)20 753 3205

Service:

VAMP Ltd

P.O.Box 810

FIN-65101 Vaasa, Finland

Visiting address: Yrittäjänkatu 15

Phone: +358 (0)20 753 3200

Fax: +358 (0)20 753 3205

24h support phone:

Tel . +358 (0)20 753 3264

Email: vampsupport@vamp.fi

VM120.EN001

VAMP Ltd Street address: Yrittäjänkatu 15 Phone: +358 20 753 3200

Post address: Fax: +358 20 753 3205

Box 810, FIN 65101 Vaasa, Internet: www.vamp.fi

Finland Email: vamp@vamp.fi

We reserve the rights to changes without prior notice

Loading...

Loading...