INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

1

CONTENTS

WELCOME . . . . . . . 2

STATEMENT OF COMPLIANCE . . . . . 3

WARRANTY . . . . . . . 4

1. EQUIPMENT DESCRIPTION . . . . . 5

2. TRANSPORT, HANDLING AND STORAGE . . . 9

3. OPERATION . . . . . . . 9

3.1. Safety rules . . . . . . 9

3.2. Starting-up the equipment. . . . . 10

3.3. Calibration . . . . . . 12

4. MAINTENANCE AND CLEANING . . . . 15

5. SAFETY RULES . . . . . . 16

6. DISASSEMBLY CONDITIONS . . . . . 16

MANUAL EXTERNAL MIX SET-UP CHART . . . 17

VISCOSITY EVOLUTION IN ACCORDANCE

WITH SOLVENT-BASED PAINTS TERMPERATURE . . 20

APPLICATION GUN EXPLODED . . . . . 21

MAINTENANCE OPERATIONS . . . . . 25

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

2

Dear costumer:

Our work at VALVER AIR SPEED involves manufacturing different painting equipment and

application systems for users and companies consuming varnishes and paints.

Specifically, the AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT guarantees absolute

compliance with product manufacturers’ instructions. It also guarantees a correct, uniform mix.

The mixture is prepared outside the equipment - no internal process – offering advantages in

cleaning and time, product and diluent savings. It is only used the solvent required to dilute the

mixture to be applied. The mixtures are accurate and the mixing ratio control is carried out by hand.

We offer automatic modules for mixture calibration depending upon the mixture percentages and the

nature of each product. If you are interested, do not hesitate to contact us.

The system and the TRIMIX® external mix heads have been developed by VALVER AIR

SPEED S.L. after a long term of investigation, development and tests carried out by our design and

R+D team. We have improved the existing heads in the market obtaining the catalyst or component B

mixture and integration together with the resin or component A. Thanks to a careful and studied

design with compressed air sprayer at both ends of the principal product´s output we have achieved a

perfect spray area for the colour application free from any imperfection.

The external mix has been tested with numerous products obtaining a perfect application

and full compliance with the characteristics of the product as indicated by the manufacturer. Due to

lack of knowledge concerning the whole range of two-component-chemicals available in the market,

unfortunately we cannot ensure all possible applications. Before purchasing external mix equipment

from VALVER AIR SPEED S.L. we recommend to carry out the necessary product tests prior to

production.

VALVER AIR SPEED thanks you for your trust in having chosen one of our products and

would like to inform you that if any problem should arise or simply a need for enquiries or

personalised advice, you should please get in touch with our company’s official technical and

maintenance service, as stated below:

TECHNICALSERVICE/ MAINTENANCE

VALVER AIR SPEED, S.L.

Pol. Industrial La Pascualeta

Camino viejo de Picasent s/n

46200 PAIPORTA (VALENCIA) SPAIN

Tel. 96 397 58 16 / Fax. 96 397 58 15

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

3

STATEMENT OF COMPLIANCE

Mr. Ricardo Verdú, as Manager of the company VALVER AIR SPEED, S.L. manufacturer of the

equipment for paint application, whose registered office is at Polígono Industrial La Pascualeta, Cno.

Viejo de Picasent, s/n 46200 PAIPORTA (VALENCIA) Spain. Declares at his own sole responsability that

the machine:

MAKE: VALVER

DESCRIPTION: AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

MODEL: SERIAL Nº:

DATE OF MANUFACTURE:

As described in the enclosed documents, complies with the essential requisites of the following

Community Directives:

x

2006/42/CE Machinery Safety Directive.

That all the aspects covered in the following harmonised standards were taken into account in

its the design and manufacture:

x

UNE-EN ISO 12100:2012. Safety of machinery. General principles for design. Risk assessment and

risk reduction.

x

UNE-EN ISO 4414:2011. Pneumodrives. General rules and safety requirements for systems and their

components.

x

UNE-EN 626-1:1995+A1:2008. Safety of machinery. Reduction of risks to health from hazardous

substances emitted by machinery.

x

UNE-EN 12621:2006+A1:2010. Machinery for the supply and circulation of coating materials under

pressure. Safety requirements.

x

UNE-EN 12162:2001+A1:2009. Pumps for liquids. Safety requirements. Hydrostatic Test Procedure.

x

UNE-EN 809:1999+A1:2010. Pumps and pump units for liquids group. Common safety

requirements.

That has been constituted the corresponding technical process of construction; and in order

that it consists to the opportune effects it issues the present statement of compliance.

In Valencia,

VALVER AIR SPEED, S.L.

Fdo. Ricardo Verdú

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

4

NAME: _________________________________________________________________________________________

COMPANY NAME: ____________________________________________________________________________

ADDRESS: _________________________________________________________________________________

MODEL OF MACHINE: _______________________________________________________________________

SERIAL NO.: ______________________________________________________________________________

DATE: _________________________________________________________________________________

STAMP AND SIGNATURE:

___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Description: AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

Model:

Serial nº:

All equipment has 2 years warranty from the date of the invoice: The warranty covers the replacement

or repair of the machine’s components and Valver Air Speed S.L.’s acknowledgement that they are faulty due to

manufacturing errors, in addition to the labour involved in the replacement and/or repair of parts. Service during

the warranty will only be valid if it is carried out by Valver Air Speed S.L. in its own workshops.

The materials will be sent with the postage paid and once the machinery has been repaired it will be

returned to the client, who must pay for the postage. The warranty does not include our engineers working in the

place where the machine is installed or the dismantling of the machinery. If it is absolutely necessary to send

Valver Air Speed S.L. staff out, it will always be done at their own discretion and an invoice will be issued for the

job plus the travelling expenses.

This warranty will only be valid if it is signed, stamped and dated by Valver Air Speed S.L. and it must

also be accompanied by the receipt of purchase for the machine under warranty.

The warranty does not include:

-Compensation for either direct or indirect damage caused by our machines to objects or people. Likewise, it

does not include repairs carried out by the client or by third parties.

-Breakdowns caused by inappropriate use or assembly.

-Breakdowns caused by outside agents.

-Breakdowns due to negligence or insufficient maintenance.

-Damage caused by neglect, incompetence, running wear, not having used the appropriate cleaning solvent

or poor maintenance or use of the machine.

The warranty will lose validity in the event of default on payments or other forms of non-compliance

with the contract. Repairs carried out during the warranty period do not reduce or increase its duration. The

warranty will also lose validity if the machine is handled without our authorisation, or if the machine is

dismantled in another workshop. The guaranty will be void if the serial no. is erased or tampered with, or when

the damage arises from inappropriate operation or use, from negligence, knocks, falls and other reasons that are

not a result of its normal operation.

Both parties agree to submit any legal dispute or conflict to the Courts of the city of Valencia, expressly

renouncing any corresponding rights with regard to other jurisdiction.

Valencia,

VALVER AIR SPEED, S.L.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

5

Before using for the first time the machine will read the instructions carefully. The improper

uses eliminate any responsibility to VALVER AIR SPEED.

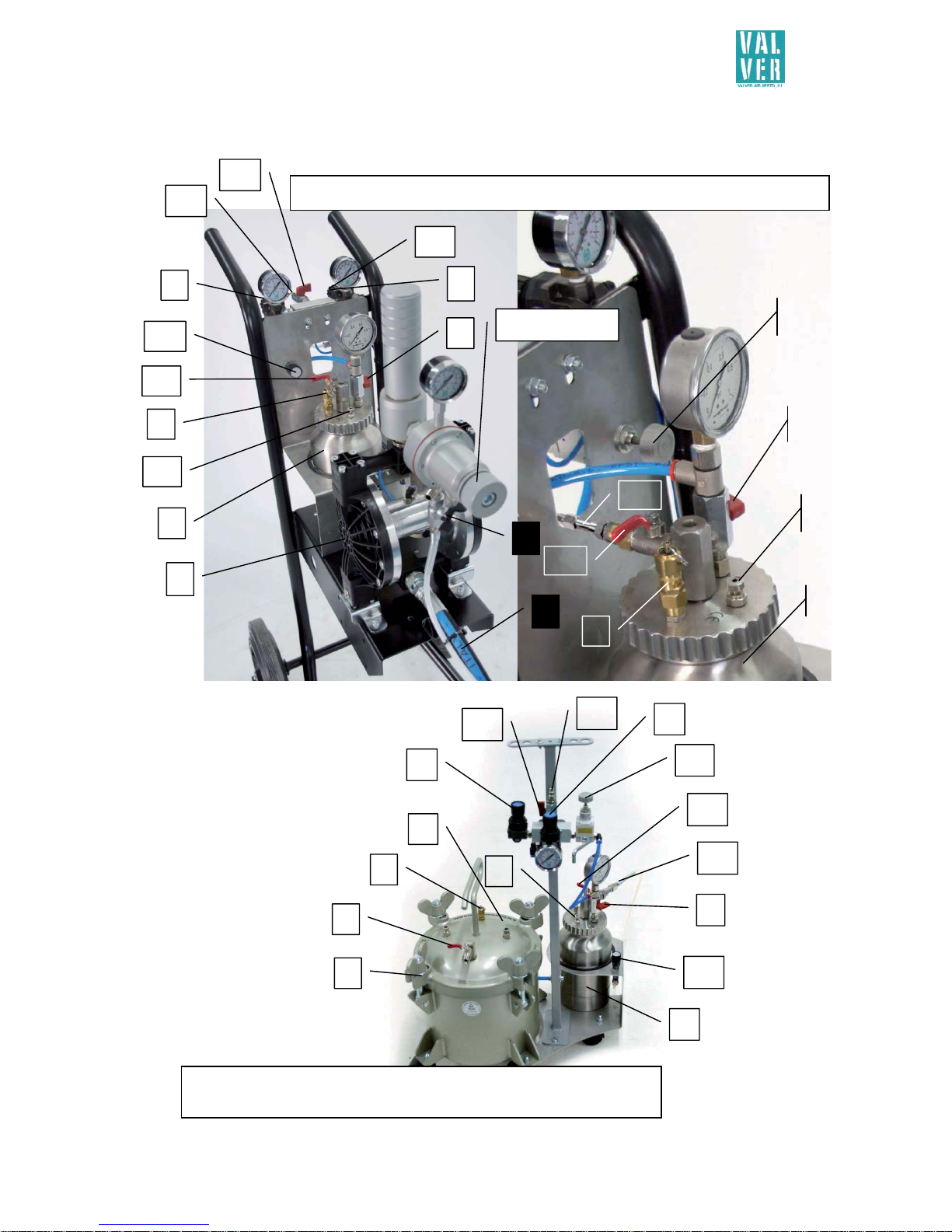

1. EQUIPMENT DESCRIPTION

The AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT is composed of two pumps.

The first pump is for resin and the type employed can be selected. The second pump for the

catalyser is a pressure tank.

A specially-prepared spray gun for combining and applying the two products. The

two products are always separated prior to their reaching the gun tip, where they are then

mixed by the air fan. This facilitates cleaning, as the equipment need not be cleaned at the

end of each task, and reduces solvent consumption considerably.

EQUIPMENTS for GLUES

Pressure tank or double diaphragm for resin, pressure tank for catalyst

10

11

12

9

2

Catalyst pump (pressure tank) (8)

1

7

5

4

2

8

3

13

resin

catalyst

2

12

10

9

15

10 L PRESSURE TANK option

1

5

7

8

resin catalyst

10

11

14

13

12

3

9

11

4

8 or 18 L PRESSURE TANK option

2

2

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

6

6

7

8

4

1

resin

catalyst

7

14

13

13

6

14

Catalyst regulator

Resin regulator

10

DOUBLE DIAPHRAGM option

for 2 or 4 spray guns

Option for 2 guns

Can incorporate sets of 2-8-18 L

pressure tanks and combined with a

double diaphragm pump

4

1

12

7

8

resin

catalyst

10

14

13

Resin REGULATOR

9

7

13

14

4

5

10

7

2 L PRESSURE TANK option

3

9

12

2

2

8

1

resin

catalyst

2

11

6

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

7

EQUIPMENT FOR POLYESTER, GEL COAT…

Pressure tank or double diaphragm for resin, pressure tank 2 L for catalyst

4

1

5

6

7

8

resin

10

DOUBLE DIAPHRAGM for RESIN – PRESSURE TANK for CATALYST option

2

14

13

12

11

9

8

9

1

4

Resin regulator

21

2

resin

catalyst

3

5

10 L RESIN PRESSURE TANK - 2 L RESIN PRESSURE TANK option

With micrometer valve (21)

21

12

11

2

10

8

9

25

catalyst

25

12

2

14

13

7

10

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

8

Application gun (15)

Exploded in page 21

1. Resin pump

2. Safety valve

3. Resin pump air stopcock

4.

Resin pump air control

5. Resin valve

6. Absorption

7. Air gun control

8. Catalyser pump

9. Catalyser pump air stopcock

10. Catalyser pump air control

11. Catalyser pump bleed

12. Catalyser valve

13. Intake air mixer adaptor

14. Mixer air stopcock

15. Gun

16. Catalyser head tube

17.

TRIMIX® mixer head

18. Gun trigger

19. Gun tip

20. Gun hook

21.

Micrometric valve

22. Air inlet spray pressure regulator

23. Material needle Regulator

24. Catalyser regulator

25. Catalyser outlet filter

17

16

18

20

19

15

24

23

22

Catalyser outlet filter (25)

Disassembled filter and filter holder

with mesh 100 (ref.FI00000000005)

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

9

1.1. Technical features:

You can choose different pumps depending on the mix and their percentage. The

characteristics depend on the models chosen.

For further information about the characteristics and features of the equipment to be

chosen, consult the Valver Air Speed pressure tank or dual-membrane pump general

catalogue and manuals. The manuals are supplied with the complete equipment.

2. TRANSPORT, HANDLING AND STORAGE.

The installation and set-up of the VALVER AIR SPEED, S.L., AIRBRUSH MANUAL

EXTERNAL MIX EQUIPMENT is carried out either by the manufacture’s staff or by

authorized distributors.

3. OPERATION

3.1. Safety rules

Before using the equipment it is important to know all the rules of use, operating conditions

and instructions for use.

SPEED AIR VALVER is not responsible if the operator fails to comply with the following

conditions and is not responsible for any negligence in using the equipment.

To avoid breaking pressure hoses or items to check before the equipment implementation:

x

All components are not worn or damaged.

x

Fittings and joints of the filters are very tight.

x

Use the machine with gloves, masks and eye protection and appropriate protective

clothing.

x

The products used in the machine may be highly inflammable. The equipment has not

been designed or manufactured for use in potentially explosive atmospheres, always use

the equipment in well-ventilated places; avoid any kind of activity which could cause

fire such as smoking, producing sparks, or shavings, or any electrical hazards. In

order to avoid the risk of sparks from electrostatic charges, the machine should be

adequately earthed.

x

Before starting, any cleaning or maintenance check electrical disconnection of the

equipment and the discharge pressure of the pneumatic elements.

x

Always use the solvent recommended by the product’s manufacturer for cleaning

the equipment.

x

Using the machine may cause intoxication from possible toxic fumes. The air extraction

system should function properly to ensure it is not used in a place where you can create

explosive atmospheres.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

10

To avoid any risk of fire or explosion:

x

NO SMOKING, next to the machine.

x

NON-sparking.

In the case of fire or explosion, use extinguishers - do not use water.

Extinguishers:

Class ABC: Dry powder, for LIQUIDS AND GASES

Class E: CO

2

for ELECTRICAL PARTS

3.2. Starting-up equipment.

1. Make sure that the Mixer air stopcock (14), the Resin pump air stopcock (3)

(pressure tank only) and the Catalyser pump air stopcock (9) (pressure tank) are

closed.

2. Connect the air supply to the AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT’S

intake mixer air adaptor (13), which supplies the pumps and the gun (15).

3. Place the absorption (6) in the resin, in the case of dual-membrane units, or load the

tank, in the case of pressure tanks (closing correctly the Mixer air stopcock (14).

4. Open the Resin pump air stopcock (3) in the pressure tank and adjust the pressure

of the resin pump (1) using the resin pump air control (4).

5. Open the Catalyser pump air stopcock (9) in the pressure tank and adjust the

pressure of the catalyser pump (8) using the catalyser pump air control (10).

6. The gun (15) pressure can be adjusted using the air gun control (7).

7. Set the air gun control (7) to 0 bar to avoid splashing.

8. Open the resin valve (5) and adjust the resin pump air control (4).

9. Place the gun tip (19) in the nozzle of the resin test tube

(used for cleaning,

bleeding, recycling and calibration of mix percentage).

10. Squeeze the gun trigger (18) until resin begins to flow from the gun and the circuit

is loaded without air bubbles.

11. Close the resin valve (5) (dual membrane or pressure tank) before loading the

catalyser pump (8).

12. Make sure that there is no pressure in the catalyser pump (8) (pressure tank), keep

the catalyser air pump bleed cock (9) and open the Catalyser pump bleed (11)

(pressure tank).

13. Remove the top from the catalyser pump (8) (pressure tank) and fill the catalyser.

14. Replace the pressure tank top, making sure that it is properly closed.

15. Close the Catalyser pump bleed (11) and open the Catalyser pump air stopcock

(9) (pressure tank).

16. Adjust the catalyser pump air control (10) (pressure tank).

17. Open the catalyser valve (12).

18. Remove the TRIMIX® mixer head (17) from the gun (15). Once the TRIMIX® mixer

head (17) has been removed from gun (15), the equipment is ready for priming.

19. Place the TRIMIX® mixer head (17) in the nozzle of the catalyser test tube

(used for

cleaning, bleeding, recycling and calibration of mix percentage) in order to recycle

and prime the catalyser circuit.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

11

20. Squeeze the gun trigger (18) until resin begins to flow from the TRIMIX® mixer

head (17) and there are no air bubbles in the circuit. The residual pressure in the

resin pump (1) will force resin to flow for a few seconds.

21. Replace the TRIMIX® mixer head (17) in the gun (15).

The AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT is pressurised with material and

ready for calibration.

Recommendations.

Clean the AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT thoroughly after use. Proper

maintenance will extend the equipment’s useful life.

Always use the solvent recommended by the product’s manufacturer for cleaning the

equipment.

The gun should be left immersed in cleaning solvent when not in use. The solvent must not

touch the air valve, in order that the nozzle remains clean.

Clean the outside of the TRIMIX® mixture head (17) frequently when working and leave the

gun (15) hanging vertically from the gun hook (20) when not in use. Avoid leaving the gun

(15) in a horizontal position, as this will lead to paint remains obstructing the catalyser

outlets.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

12

3.3. Calibration.

1. Start-up the equipment.

2. Close the Mixer air stopcock (14), close the Resin pump air stopcock (3) and

close the Catalyser pump air stopcock (9).

3. Prepare 2 calibrated test tubes

. For maximum accuracy, place each test tube on

scales and weigh. If no scales are available, use the test tubes to calibrate by

volume.

4. Remove the TRIMIX® mixer head (17) with the catalyser head tube (16).

5. Open the Mixer air stopcock (14), open the Resin pump air stopcock (3) and

open the Catalyser pump air stopcock (9).

6. Open the resin valve (5).

7. Regulate the resin pressure to 1 bar with the resin pump air control (4) and the

user adjusts the resin or component A output for the application on a bad

coating surface and counting the lack of catalyst output to be considered

depending on the mix percentage (If f. e. the product mix percentage is two parts

A for one part B and it is only applied resin in this set-up, the user has to consider

that 33% less product is outputted. Afterwards it will be incorporated while

adding the catalyst when the calibration process has been completed. The

regulation is done by opening the material needle regulator (23) until

adjusting the desired product output. This can also be adjusted by changing the

flow of the available needles 0.8 – 1.0 – 1.3 – 1.5 – 1.8 – 2.0 and as well by

increasing or decreasing the pressure with the resin pump air control (4). Our

recommendation is to start with 1 bar and adjust by opening the material

needle regulator (23) up to a maximum of three rotations. Having reached

three opening rotations at 1 bar without having obtained the required flow, the

material pressure has to be increased in steps of 0.2 bar. Once you have reached

2 bar and go further on without getting the required flow, the needle valve has

to be replaced immediately by the superior one and the calibration process has

to be repeated starting again at 1 bar. When the final user has achieved the

desired quantity of the component A it has to be started the final calibration of

the catalyst or component B.

8.

For that open the catalyser valve (12) and adjust the catalyst output pressure

with the catalyser pump air control (10) starting for the first calibration like in

the beginning with the resin at 1 bar.

9. Position the gun tip (19) in the resin measuring cylinder and position the

dismantled TRIMIX® mixer head (17) in the catalyst measuring cylinder. Close

the spray pressure inlet with the air inlet spray pressure regulator (22).

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

13

10. After that press the gun trigger (18) and fill the measuring cylinders up to the

desired quantity.

11. Check the volume proportion or the material weight with a balance and adjust

the proportion with the catalyser pump air control (10) at the pressure tank or

with the catalyser regulator (24) of the pistol. In case of two-componentproducts application with a small mix ratio the machine is equipped with a

micrometric valve (21). To adjust the mixture proportions directly with the

micrometric valve, please follow the guidance table and the advices:

PRESSUREINLETPRESSURETANK

VALVEROTATIONS

0,5 0,6 0,7 0,8 0,9 1

1 0 0 0 0 0 0

2 2,1 2,6 3,4 3,7 4,7 5,2

3 5,4 6,2 7,3 8,1 9,1 10

4 8,2 9,9 11,3 12,9 14,3 15,6

5 12,1 13,5 15,4 15,9 17,1 17,8

6 16,4 18,6 21,9 23,1 25,4 26,7

7 20,8 24,8 28,7 30,4 32 33,2

8 25,7 30,2 34 36,6 39,2 42,4

9 33,6 40,2 44,7 46,9 50,1 53,8

10 48,7 54,4 59,7 64,2 69,6 72,6

This table facilitates and orientates only for the start-up procedure. Attention! It is neither an

orientation nor an exact formula, because these flows always may vary depending on viscosities, hose

length and material losses.

Advices

: After finishing step 6 and achieving the required quantity of component A it will be

proceeded to the final calibration of the catalyst or component B.

Therefore the flow per minute of the component A has to be controlled by a balance removing the

spray air from the pistol.

When we know the resin flow per minute selected by the user, for example 150g/min, we

have to multiply this with the catalyst or component B mix percentage expressed by the application

product manufacturer, for example 5% means 150 x 0.05 = 8g/min. Looking to the table we have two

consistent adjustment options.

Option 1. Feeding the pressure tank with the catalyser air pump control (10) with 0.5 bar and

turning the knob of the micrometric valve (21) 4 times starting at 0

Opción 2. . Feeding the pressure tank with the catalyser air pump control (10) with 0.8 bar and

turning the knob of the micrometric valve (21) 3 times starting at 0

If we aim for option 2 we get the more balanced valve regulation option, where the catalyst

pressure is closer to the resin pressure.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

14

12. For the calibration adjustments follow the application product manufacturer

instructions. Repeat the calibration until getting the proportion as indicated by

the manufacturer.

Register the regulation parameters shown on the pages 14-15-

16 of this manual, paragraph SETTING UP EXTERNAL MANUAL MIX.

13. Close the mixer air stopcock (14), close the resin pump air stopcock (3) and

close the catalyser pump air stopcock (9) and recharge the deposits if

necessary.

14. Place the TRIMIX® mixer head (17) .

15. Open the mixer air stopcock (14), open the resin pump air stopcock (3) and

open the catalyser pump air stopcock (9) and the spray pressure with the air

inlet spray pressure regulator (22). Adjust the spray pressure according to the

nature of the product and user requirements with the air gun control (7).

16. Adjust the pressure with the air gun control (7) or with the spread regulator.

The AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT is calibrated and ready for use.

Recommendations.

Clean the AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT thoroughly after use. Proper

maintenance will extend the equipment’s useful life.

Always use the solvent recommended by the product’s manufacturer for cleaning the

equipment.

The gun should be left immersed in cleaning solvent when not in use. The solvent must not

touch the air valve, in order that the nozzle remain clean.

Clean the outside of the TRIMIX® mixture head (17) frequently when working and leave the

gun (15) hanging vertically from the gun hook (20) when not in use. Avoid leaving the gun

(15) in a horizontal position, as this will lead to paint remains obstructing the catalyser

outlets.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

15

4. CLEANING AND MAINTENANCE

Cleaning.

1. Close the Mixer air stopcock (14), close the Resin pump air stopcock (3) and close

the Catalyser pump air stopcock (9).

2. Keep the resin valve (5) and the resin pump air control (12) closed.

3. Remove the absorption (6) and place in cleaning solvent.

4. Open the Catalyser pump bleed (11) (pressure tank), release the air an open the

cover of the catalyser pump (8) (pressure tank).

5. Fill the catalyser pump (8) (pressure tank) with cleaning solvent.

6. Follow steps 4 and 5 for pressure tank resin pumps (1).

7. Replace the catalyser pump (8) cover, making sure that it is properly closed.

8. Open the Mixer air stopcock (14), open the Resin pump air stopcock (3) and open

the Catalyser pump air stopcock (9).

9. Open the resin valve (5) and the resin pump air control (12).

10. Squeeze the gun trigger (18) until clean solvent –free of resin and catalyser residueis expelled.

11. Close the Mixer air stopcock (14), close the Resin pump air stopcock (3) and close

the Catalyser pump air stopcock (9).

12. Always leave the equipment PRESSURISED. Loaded with pressurized cleaning

solvent.

Maintenance.

1. Clean the TRIMIX® mixer head (17) frequently when in use.

2. Always leave the TRIMIX® mixer head (17) immersed in cleaning solvent. When left

unused for long periods, place in a tightly sealed recipient with solvent. This will

impede the evaporation of the solvent and the catalyser outlets becoming blocked

by any remaining residue.

3. Clean the equipment each day with the cleaning solvent recommended by the

manufacturer and which we applied to the resin pump (1) (dual membrane or

pressure tank) to avoid blockage from resin residue.

4. Clean the equipment each day with the cleaning solvent recommended by the

manufacturer and which we applied to the catalyser pump (8) (pressure tank) to

avoid blockage from the catalyser.

5. Check the gun, anti-pulsation chamber or absorption filters between the 1st and the

2nd cleaning.

6. Grease the exchange valves in dual membrane units ONCE PER WEEK when the

equipment is in use.

The equipment is to be subjected to an initial revision some 3 months after installation. This

check is to cover all the AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT’S spray

equipment, as well as the correct operation of all the equipment’s safety systems. If

everything is as it should be after the service check, further service checks are to be carried

out every six months until the end of the guarantee period. After the guarantee expires, the

frequency of service checks will be agreed with the client.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

16

Periodic revisions undertaken during the guarantee period will be charged to the customer.

Periodic maintenance:

For EXTERNAL MIX EQUIPMENT spray equipment, change only used, dirty or old filters.

The equipment contains no other consumable components requiring periodic replacement.

The revisions to be carried out by the maintenance staff of the company responsible for

acquiring the AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT spray equipment are

aimed at verifying the correct operation of the equipment and the early detection of possible

problems. We recommend that such revisions be carried out at least once a week:

Preventive maintenance every 7 days:

Check air suplly unit.

Check air leakage of pneumatic circuit.

Check filters.

Preventive maintenance every 30 days:

Check purges and safety pneumatic valves.

If an abnormality is found during this preventive maintenance, take appropriate measures to

correct them.

5. SAFETY RULES

In the design and manufacture of equipment have been taken into account the essential

safety requirements for machine safety directive 98/37/EEC.

6. DISASSEMBLY CONDITIONS

When you stop using the machine, contact to VALVER AIR SPEED service.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

17

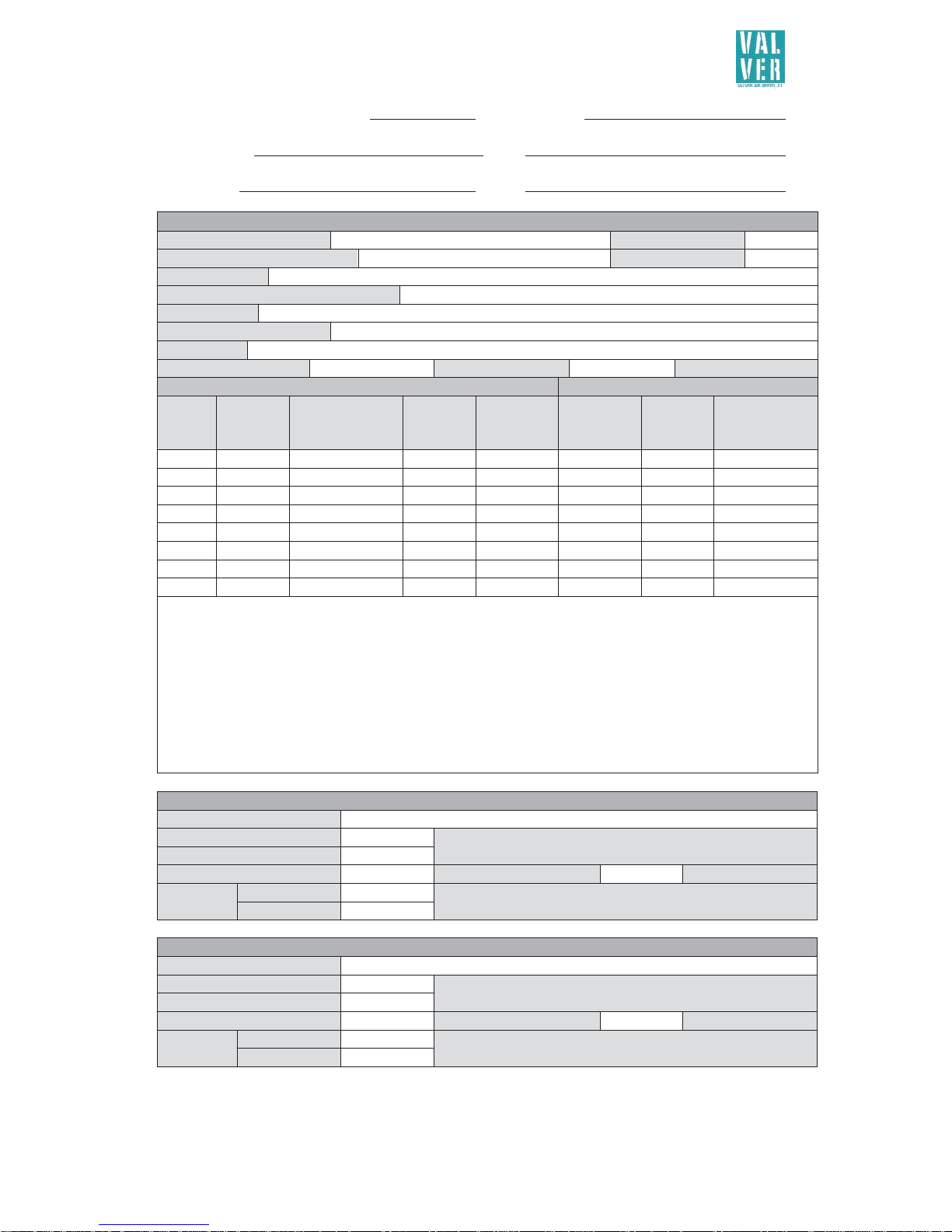

MANUAL EXTERNAL MIX SET-UP CHART

EQUIPMENT IDENTIFICATION Nº:

PURCHASE DATE:

DISTRIBUTOR: C

ontact:

CUSTOMER:

Contact:

Customer phone:

Fax/e-mail:

Factory Testing:

Technical:

date:

Checking in customer:

Technical:

date:

Delivery Note No

MIX CHARACTERISTICS

Manufacturer: Fund Finishing

Product to: Solvent-based Water-based

Resin Type: (polyurethane, acrylic, polyester, gel coat, etc.)

A Component

Reference Viscosit

y

% Formula for TOTAL % Formula for RESIN

Resin

A

ccelerator

Diluent

Other

B Component

Reference Viscosit

y

% Formula for TOTAL % Formula for RESIN

Diluent

Catalyst

Other

Mix formula Comments:

Resin temperature

A

bsortion Viscosit

y

A

pplication Viscosity

ºC ºC

Catalyst temperature

A

bsortion Viscosit

y

A

pplication Viscosity

ºC ºC

Heater

Material

Set Tº Reached T

ª

Bel

t

ºC ºC

line ºC ºC

Heated hose ºC ºC

A

ir Heated hose ºC ºC

MANUAL EXTERNAL MIX SET-UP CHART

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

18

EQUIPMENT IDENTIFICATION Nº:

PURCHASE DATE:

DISTRIBUTOR: C

ontact:

CUSTOMER:

Contact:

MIX SETTING CHART

Resin model equipmen

t

Manometer scale

Catalyst model equipment Manometer scale

Gun model

External mix head mode

l

Nozzle type

Gun spray air pressure

Material

A

mbient temperature: ºC

A

mbient humidity: %

BEFORE CALIBRATING AFTER CALIBRATING

TEXT nº

Threads

nozlle

Regulator gun

needle laps

Resin

pump

pressure

Catalyst

pump

pressure

Dose

catalyst

(g./ml.)

Dose

resin

(g./ml.)

%

catalyst/resin

1

2

3

4

5

6

7

8

Comments:

TEXT 1

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

TEXT 2

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

19

MANUAL EXTERNAL MIX SET-UP CHART

TEXT 3

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

TEXT 4

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

TEXT 5

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

TEXT 6

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

TEXT 7

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

TEXT 8

Piece dimensions

Weight part without appling g.

Weight part freshly applied g.

Weight part at 30 min g. Weight partat60 min g.

Drying

To contac

t

min.

In package min.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

20

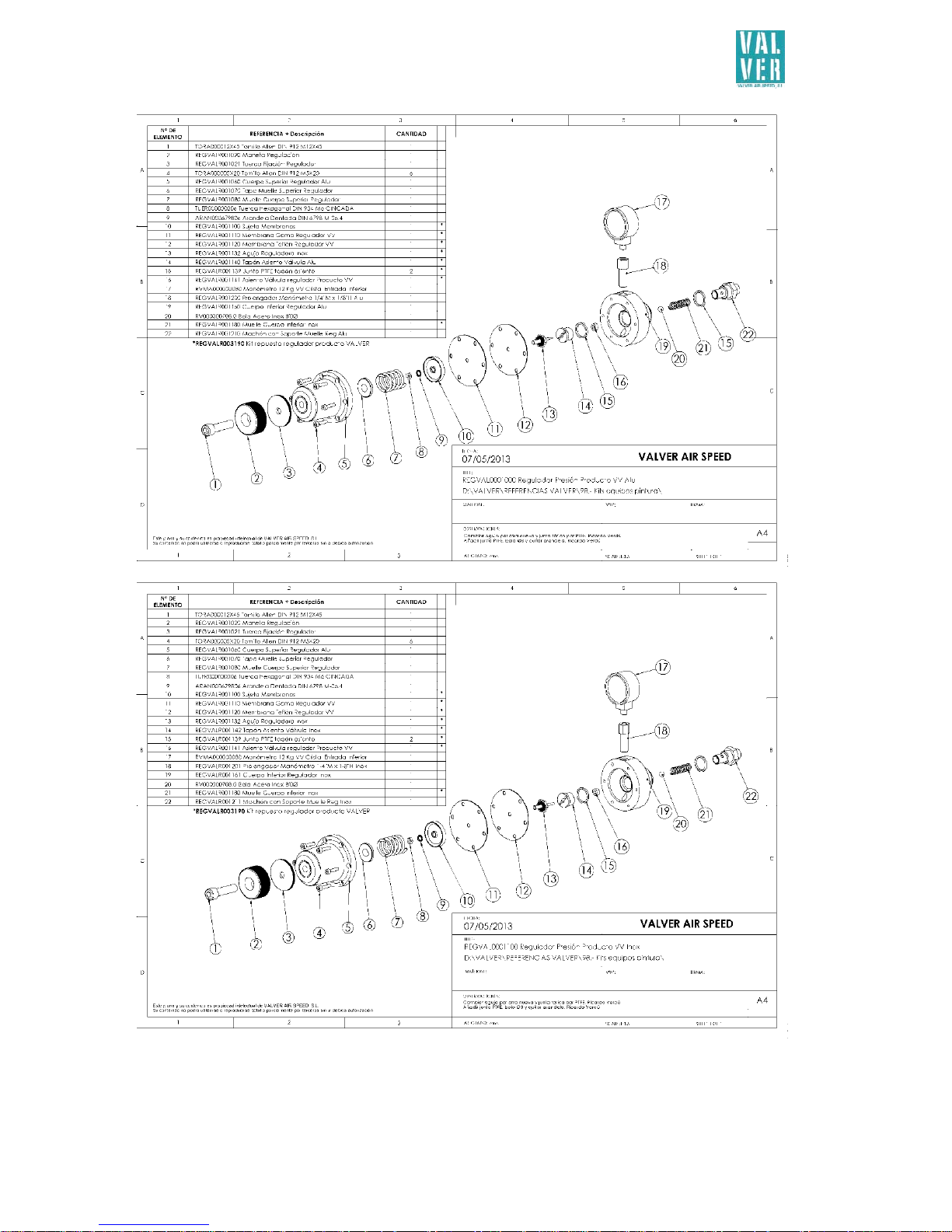

VISCOSITY EVOLUTION IN ACCORDANCE WITH SOLVENT-BASED PAINTS TERMPERATURE

We recommend reducing resin viscosity in order to obtain optimum curing of both the

mixture and the final finish. The viscosity and the temperature can be reduced without

adding emission-increasing solvents to the mixture, thus ensuring compliance with the

applicable legislation.

Temperature (ºC)

CF4 VISCOSITY en seconds

2º 4º 6º 8º 10º 12º 14º 16º 18º 20º 22º 24º 26º 28º 30º 32º 34º 36º 38º 40º

27 26 24 23 22 21 21 20 19 18 18 17 17 16 15 15 14 14 14 14

33 31 29 27 26 25 23 22 21 20 19 18 18 17 16 16 15 15 14 14

39 36 34 32 30 28 26 24 23 22 21 20 19 18 17 17 16 15 15 14

46 42 39 36 34 31 29 27 26 24 23 22 21 19 18 17 17 16 15 15

54 49 45 41 38 35 32 30 28 26 24 23 21 20 19 18 17 17 16 15

58 51 47 43 40 36 33 31 29 27 25 23 21 20 20 19 18 17 16 16

61 55 50 46 42 38 35 32 30 28 26 24 22 21 20 19 18 17 16 16

69 63 56 52 46 42 39 35 32 30 28 25 24 23 21 20 19 18 17 16

77 69 62 55 50 46 41 38 35 32 29 27 25 24 22 21 19 18 17 16

84 74 67 61 54 50 44 40 36 34 30 28 26 25 23 22 20 18 17 16

95 84 75 66 60 54 48 44 40 36 33 30 28 26 24 22 20 19 18 17

104 92 81 73 65 58 52 46 42 38 35 31 29 27 24 23 21 20 19 18

112 100 88 76 69 62 54 49 44 40 36 32 30 27 25 23 21 20 19 18

122 108 90 85 75 66 59 53 47 42 38 35 31 28 26 24 22 21 19 18

132 120 102 90 80 70 63 55 50 44 40 36 33 30 27 25 23 22 20 18

142 124 108 95 84 74 65 58 52 46 41 37 34 31 27 25 23 22 20 18

152 132 119 101 90 80 69 61 54 48 43 38 35 31 28 26 24 23 21 18

164 140 123 106 94 83 73 64 56 50 45 40 36 32 29 27 24 23 21 19

If viscosity is 26 s at 18ºC, a drop of 10ºC will produce a viscosity of 34 s, while a rise to 40ºC will produce a

viscosity of 15 s.

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

21

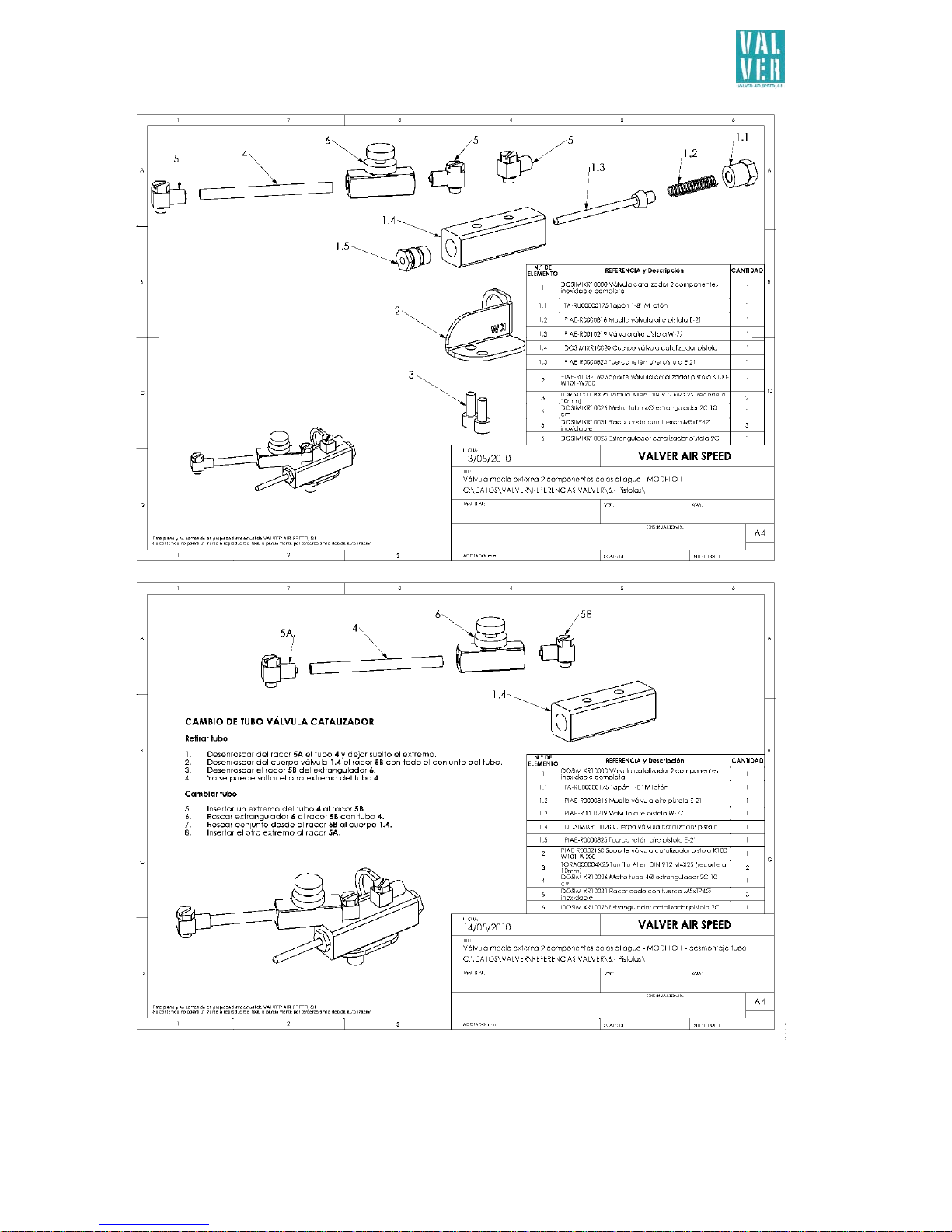

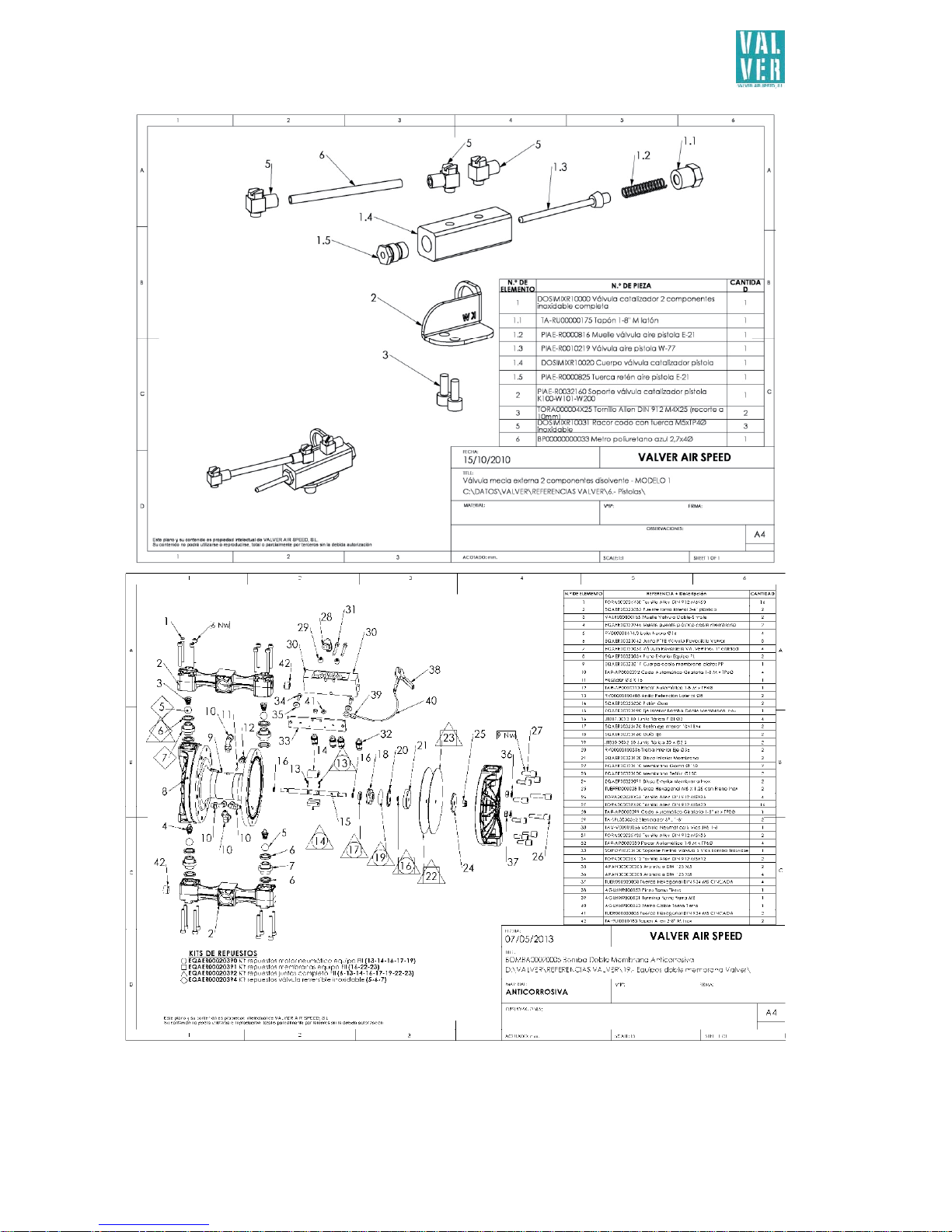

APPLICATION GUN EXPLODED

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

22

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

23

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

24

INSTRUCTIONS MANUAL

AIRBRUSH MANUAL EXTERNAL MIX EQUIPMENT

25

MAINTENANCE OPERATIONS

OPERATION

PERIODICITY

maintenance personal

DAILY WEEKLY MONTHLY* SEMIANNUAL*

*

INDICATE THE DATE.

Loading...

Loading...