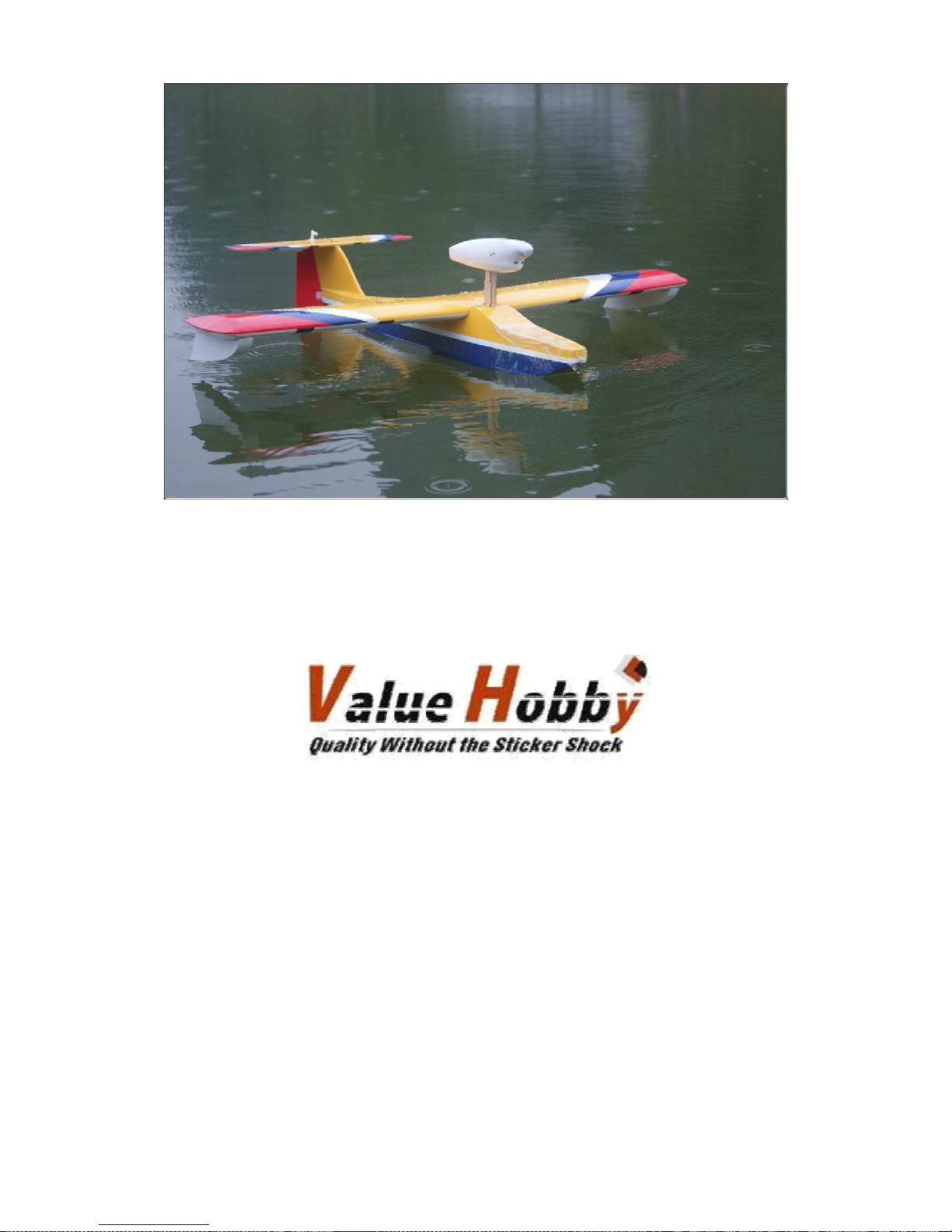

Neptune Seaplane25 ARF

Instruction Manual

Specifications

Wingspan: 1270mm (50in)

Length: 1155mm (45.5in)

Wing Area: 34.8 sq dm (539.4 sq in)

Weight: 1950g (4.30lbs)

Product Highlights

Removable hatch on the fuselage for easy battery

access. Includes high quality hardware.

Classic Neptune trim scheme.

www.valuehobby.com/neptune25.html

Dear Customer,

Congratulations on your purchase of Neptune Seaplane 25 ARF from Value Hobby. We thank you for

your generous support, and hope you enjoy your new airplane.

At Value Hobby, we hope to offer competitive prices, good performance, and products that you can setup

and use with ease. That’s why we extensively researched and tested this airplane, and suggested all the

products necessary for you to setup properly. We understand that you have many choices when purchasing,

and we are grateful you choose to buy from us.

As vendors, one of the most gratifying things for us is to hear from our customers. We would welcome any

suggestion to help us improve. Please make us aware of any errors and imperfections in the airplane or the

instructions, or about the setup that we suggested. We hope you’ll find our setup suggestions to be helpful,

and enjoy flying your new airplane. Please feel free to contact us at (630) 948-0947 or email us at

support@valuehobby.com

Disclaimer

By purchasing and/or building this model, user assumes ALL liability and risk involved with this product.

This model should be built and flown by an experienced pilot and only flown at AMA sanctioned sites.

Value Hobby guarantees this model to be free of defects in materials and workmanship at the date of purchase.

This warranty does not cover any parts damaged by use or modifications. In no way shall Value Hobby’s liability

exceed the original cost of the purchased model. Further, Value Hobby reserves the right to modify this

warranty without notice. Value Hobby has no control over the final stages of assembly or the material used for

the final assembly. No liability shall be assumed nor materials used for the final user-assembled product. By the

act of using the final product the user accepts all resulting liability. Value Hobby, as a R/C product vendor,

provides a top quality airplane and instructions to complete the model. The quality and flight characteristics of

the finished model depend greatly on how it is built; we cannot guarantee the performance for the completed

model and representations are expressed or implied as to the performance of the completed model. If the

buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to

return this kit immediately, in new and unused condition.

Safety in Assembly

During assembly of this aircraft, you will be asked to use sharp knives and hobby adhesives. Please follow

all safety procedures recommended by the manufacturers of the products you use, and always follow

these important guidelines:

ALWAYS protect your eyes when working with adhesives, knives, or tools, especially power tools. Safety

glasses are the best way to protect your eyes.

ALWAYS protect your body, especially your hands and fingers when using adhesives, knives, or tools, especially

power tools. Do not cut toward exposed skin with hobby knives. Do not place hobby knives on tables or

benches where they can roll off or be knocked off.

ALWAYS have a first-aid kit handy when working with adhesives, knives, or tools, especially power tools.

ALWAYS keep hobby equipment and supplies out of the reach of children.

2

www.valuehobby.com/neptune25.html

Safety in Flying

This is NOT a toy! It is a very high-performance RC airplane capable of high speeds and extreme maneuvers.

It should only be operated by a competent pilot in a safe area with proper supervision.

ONLY fly your aircraft in a safe, open area, away from spectators and vehicles–and where it is legal to fly.

NEVER fly over an unsafe area, such as a road or street.

Never fly too close to yourself or spectators.

Never run your motor inside a house or building with the propeller attached – Remove the prop for safety.

Required Items

CA Glue – Thin and Thick

Epoxy glue

Hobby Knife

Small Phillips Screwdriver

Set Metric Allen Wrenches

Scissors

Small Pliers

Wire Cutters

Masking tape

Optional – Heat gun

Before Starting Assembly

Examination

Unpack your airplane and examine the components. Check for damage of any kind. If you see any

damage, please contact Value Hobby immediately.

Covering

Your airplane was packed in plastic at the factory without any wrinkles in the covering. You may notice some

wrinkles now; more likely, you will notice a few in a day or two or the first time you take the plane out to the

flying field. These wrinkles are the result of wood shrinkage and/or expansion. Balsa wood changes size and

shape slightly as it is exposed to varying humidity in the air. This is a natural property of balsa wood. As your

airplane adjusts to the weather in your part of the world, wrinkles may appear and disappear. Wrinkles may be

removed with the gentle application of heat to the covering material on your airplane. The best tool to use is a

hobby heat gun. Apply the heat gently: the covering material will shrink as you apply the heat, and this will

remove the wrinkles. BE CAREFUL! Too much heat applied too quickly can damage the covering, either by

causing it to pull away from the wood at seams and corners or even by melting it. The covering will shrink at

low temperature with patient application of heat.

Wrinkles in the covering DO NOT affect flight performance.

Remove the canopy before attempting to use heat on your covering! The canopy is made of thermoactivated plastic and WILL deform with the application of heat. Do not apply heat to the canopy.

If you need to clean your airplane, we recommend using a damp towel. The paint used on the canopy and cowl

is not safe for all cleaners. In particular, DO NOT use alcohol on these parts, it will remove the paint.

3

www.valuehobby.com/neptune25.html

RECOMMENDED RADIO EQUIPMENT

Product

SKU

Quantity

Radio

4 channel

FLY-RC-1310

1

Servo

Emax ES3104 Metal Gear Mini Servo

EMX-SV-2472

4

Y-Harness

Universal Servo Y-Harness 12-Inch (Futaba "J" and JR Compatible) AMS-AC-0869

1

Extension

Universal Servo Extension 12-Inch (Futaba "J" and JR Compatible) AMS-AC-0560

1

RECOMMENDED POWER SETUP

Light Power Setup

Product

SKU

Motor

Gforce G15 (35-42) 1100KV

SAT-MT-1741

ESC

Hobbywing Flyfun 60A ESC

HWG-SC-0241

Battery

GForce Elite Series 40C 2200mAh 3S 11.1V

FLM-LP-1804

Prop

12 x 6E

EMX-MP-1769

High Power Setup

Product

SKU

Motor

Gforce G25 (35-48) 850KV

SAT-MT-1882

ESC

Hobbywing Flyfun 60A ESC

HWG-SC-0241

Battery

GForce Elite Series 40C 2200mAh 4S 14.8V

FLM-LP-1810

Prop

13 x 6.5E

EMX-MP-1765

OPTIONAL ACCESSORIES:

Product

SKU

Quantity

GT Power C6 6S LiPO Charger

GTP-CH-1427

1

Quickie Thin CA

VHB-AC-2097

1

Quickie Medium CA

VHB-AC-2098

1

Foam Field Stand

VHB-AC-1997

1

GT Power 130A Watt Meter

GTP-AC-0591

1

T Discharge Connector Female

AMS-AC-1914

1

T Discharge Connector Male

AMS-AC-1913

1

LiPO Battery Charging Bag

VHB-LP-0330

1

Tarot Socket Head Drivers Set

FYM-AC-2100

1

4

www.valuehobby.com/neptune25.html

Main Parts and Accessories:

5

www.valuehobby.com/neptune25.html

Part Lists:

Fuselage x 1

Wing panel x 2

Aileron x 2

Horizontal stabilizer x 1

Elevator x 1

Fin x 1

Rudder x 1

Cowling x 1

M3*12mm (0.5-inch) round head self-tapping screw x 6 for mounting cowling

Motor mount x 1

M3*12mm (0.5-inch) screw x 1 for mounting motor mount

M3*20mm (0.8-inch) screw x 4 for mounting motor

M3 washer x 4 for mounting motor

M3 nut x 4 for mounting motor

Battery hatch x 1

M3*12mm (0.5-inch) screw x 2 for mounting battery hatch

Tie cable 300mm (11.8-inch) x 2 for binding battery

Rear hatch x 1

M3*12mm (0.5-inch) screw x 4 for mounting battery hatch

Tail skid x 1

Wing joiner x 1

M3*40mm (1.6-inch) wing bolt x 2 for mounting wing

M3 washer x 2

Wing bolt plate x 1

Float x 2

Aileron pushrod wire Φ1.8x145mm (5.7-inch) x 2

Rudder pushrod wire Φ1.8x655mm (25.8-inch) x 1

Elevator pushrod wire Φ1.8x750mm (29.5-inch) x 1

Elevator pushrod wire Φ1.8x50mm (2.0-inch) x 1

Pushrod connector x

5 Control horn x 4

Back plate x 4

Clevis x 4

M2*16mm (0.6-inch) screw x 4 for mounting rudder and elevator control

horn M2*20mm (0.8-inch) screw x 4 for mounting aileron control horn

M2*10mm (0.4-inch) clevis bolt x 4

Hinge x 20

6

www.valuehobby.com/neptune25.html

Section1: Install the ailerons and floats

Step1. Drill a 3/32-inch hole into the center of each

hinge slot in the aileron and wing panel. Trim the

covering away from each hinge slot to ensure that

the hinges will be properly glued in place.

Step2. Insert four hinges into the wing

panel, and drop some thin CA into the hole

in the hinge slot to glue the hinge to the

wing panel. Make sure to glue both the top

and bottom.

Step2. Attach the aileron to the wing panel

through the hinges, and use a hobby knife to set a

small gap between the wing and aileron. Also

check the aileron can move freely without rubbing

at the wing foot.

Step3. Apply some thin CA to glue the aileron to

the wing panel. Make sure to glue both the top

and bottom. Once the CA has cured, gently pull on

the aileron to make sure the hinges are secure. If

not, apply more CA to loose hinges.

Step4. Use the epoxy to glue the float to the

wing. Make sure the float is aligning with the

leading edge of the wing.

Step5. Repeat step1 to step4 for the

remaining aileron and float.

7

www.valuehobby.com/neptune25.html

Section2: Install the ailerons servo

& linkages

Step1. Use a hobby knife to remove the covering

for inboard servo in the bottom of the wing.

Step2. Electronically center the servo, and

install the servo arm with pushrod connector to

the servo.

Step3. Install the servo onto the wing using two selftapping screws provided with servo. Use three

M2*8mm (0.3in) self-tapping screws to install the

servo cover to the wing. Trim the cover as shown.

(Note: you need use the glue to seal the gap.)

Step4. Connect the aileron servo pushrod

Φ1.8x145mm (5.7-inch) to control horn using

clevis and M2x10mm (0.4-inch) clevis bolt.

Step5. With the pushrod wire aligned 90 degrees

to hinge line and the holes in the control horn

aligned with the hinge line, use two M2x20mm

(0.8-inch) screws and back plate to install the

control horn to the aileron.

Step6. With control surface centered, tighten

the grub screw to secure the pushrod to

pushrod connector.

Step7. Repeat step2 to step6 for the

remaining servo.

8

www.valuehobby.com/neptune25.html

Section3: Install fin and rudder

Step1. Position the fin on the fuselage, and use

a felt-tipped pen to trace the outline of the fin.

Step2. Use a hobby knife to remove the coverings

along the line drawn in the previous step. Apply

some epoxy to the bare wood on the fuselage

and the fin to secure the fin to the fuselage.

Step3. Use thin CA to glue two hinges to

the rudder.

Step4. Use thin CA to secure the rudder to the

fin. Position the tail skid on the fuselage, and use

a felt-tipped pen to trace the outline of the fin.

Step5. Use a hobby knife to remove the coverings

along the line drawn in the previous step. Apply

some epoxy to the bare wood on the fuselage and

the tail skid to secure the tail skid to the fuselage.

9

www.valuehobby.com/neptune25.html

Section4: Install horizontal

stabilizer and elevator

Step1. Attach the elevator to horizontal stabilizer

in the same procedure as installing the aileron in

section1.

Step2. Use epoxy to glue the horizontal stabilizer

and elevator assembly to the fuselage. (Note: the

stabilizer should be parallel with work surface

and centered in the fuselage.)

Step3. Use a hobby knife to remover the coverings

for the rear hatch. (for sliding the pushrod wire

through the fuselage in following steps)

Section5: Install elevator and

rudder servo & linkages

Step1. Connect the

Elevator pushrod wire

Φ1.8x750mm (29.5-inch) to control horn through

clevis and M2*10mm (0.4-inch) clevis bolt.

Slide the pushrod wire through the fuselage

as shown.

Step2. Use four

M3*12mm (0.5-inch) screws

to install the rear hatch to the fuselage.

Step3. With pushrod wire aligned 90 degrees to

the hinge line and the holes in the control horn

aligned with the hinge line, use two

M2*16mm

(0.6-inch) screws and back plate to install the control

horn to the elevator.

10

www.valuehobby.com/neptune25.html

Step4. In the same procedure install the

control horn onto the rudder.

Step5. Install the servo arm with pushrod

connector to the servo, and install two servos into

the fuselage. (Electronically center the servo

before mounting).

Step6. With control surface centered, tighten

the grub screws.

Section6: Install elevator servo

and linkage (optional)

We offer another installing method for

elevator servo.

Step1. Use a hobby knife to remove the

coverings for inboard servo.

Step2. Install the servo onto the

horizontal stabilizer.

Step3. Connect

pushrod wire Φ1.8x50mm (2.0-

inch) to control horn.

With pushrod wire aligned

90

degrees to the hinge line and the holes in the

control horn aligned with the hinge line, use two

M2*16mm (0.6-inch) screws and back plate to

install the control horn to the elevator.

11

www.valuehobby.com/neptune25.html

Step4. With control surface centered, tighten

the grub screw.

Section7: Install motor and prop

Step1. Prepare a extension cable for connecting

the battery and ESC.

Step2. As shown thread a 12-inch servo extension

and battery-to-ESC cable though the motor

mount as shown.

12

www.valuehobby.com/neptune25.html

Step3. Remove the coverings for motor mount.

Step4. Insert the motor mount into the fuselage.

Step5. Use one

M3*12mm (0.5-inch) socket

head

self-tapping screw

to secure the motor

mount to

the fuselage.

Step6. Use four

M3*20mm (0.8-inch) screws, four

M3 washer and four M3 nut to install the motor

to the motor mount.

Step7. Position the cowling in the motor mount.

13

www.valuehobby.com/neptune25.html

Step8. Drill the mounting holes.

Step9. Use six

M3*12mm (0.5-inch) self-tapping

screws to secure the cowling to the motor mount.

Step10. Install the prop and spinner.

Step11. You can use two

M3*12mm (0.5-inch)

screws to install the battery hatch to the fuselage.

Section8: Install wing

Step1. Use wing joiner and epoxy to join two

wing panels together.

Step2. Install the wing by aligning the dowels

from the wing into the holes in the fuselage.

Step3. Secure the wing using two wing bolts and

one bolt plate.

14

www.valuehobby.com/neptune25.html

Section9: Set up CG and control throws

Measure the CG from the leading edge of wing

panel. Adjust the battery pack; the CG should be

at 25-30% MAC (Mean Airfoil Chord).

The CG is 79mm (3.1-inch) from the leading edge

of the wing.

Set up the control throws:

15

www.valuehobby.com

2013-1-24

Loading...

Loading...