P25201 HydroMax Automatic Fresh Water Pump

RV/MARINE

INST ALLA TION AND OPERA TION MANUAL

HYDROMAX design delivers smooth,consistent flow at all ranges of operation, while drawing

low current. The balanced motor design incorporates precision ball bearings for long life, and is

equipped with an integrated thermal breaker. All RV/marine duty pumps have sealed switche s and

are finished with a Electro Coating to inhibit corrosion. HYDROMAX water pumps have been

strictly inspected and can run smoothly. RV/Marine duty fresh water pumps are enclosed to

prevent incidental moisture from entering and when installed correctly, RV/Marine Duty Fresh

Water Pumps provide years of quiet operation. A HYDROMAX pump in combination with a low

backpressure water system can exceed all expectations. All HYDROMAX pumps are CE certifie d.

GENERAL INFORMATION

HYDROMAX realizes that in many instances our pump is being insta lled as a replacement pump

within an existing system. The following guides should be considered to achieve optimum pump

operation. Always follow all local or national installation codes & standards.

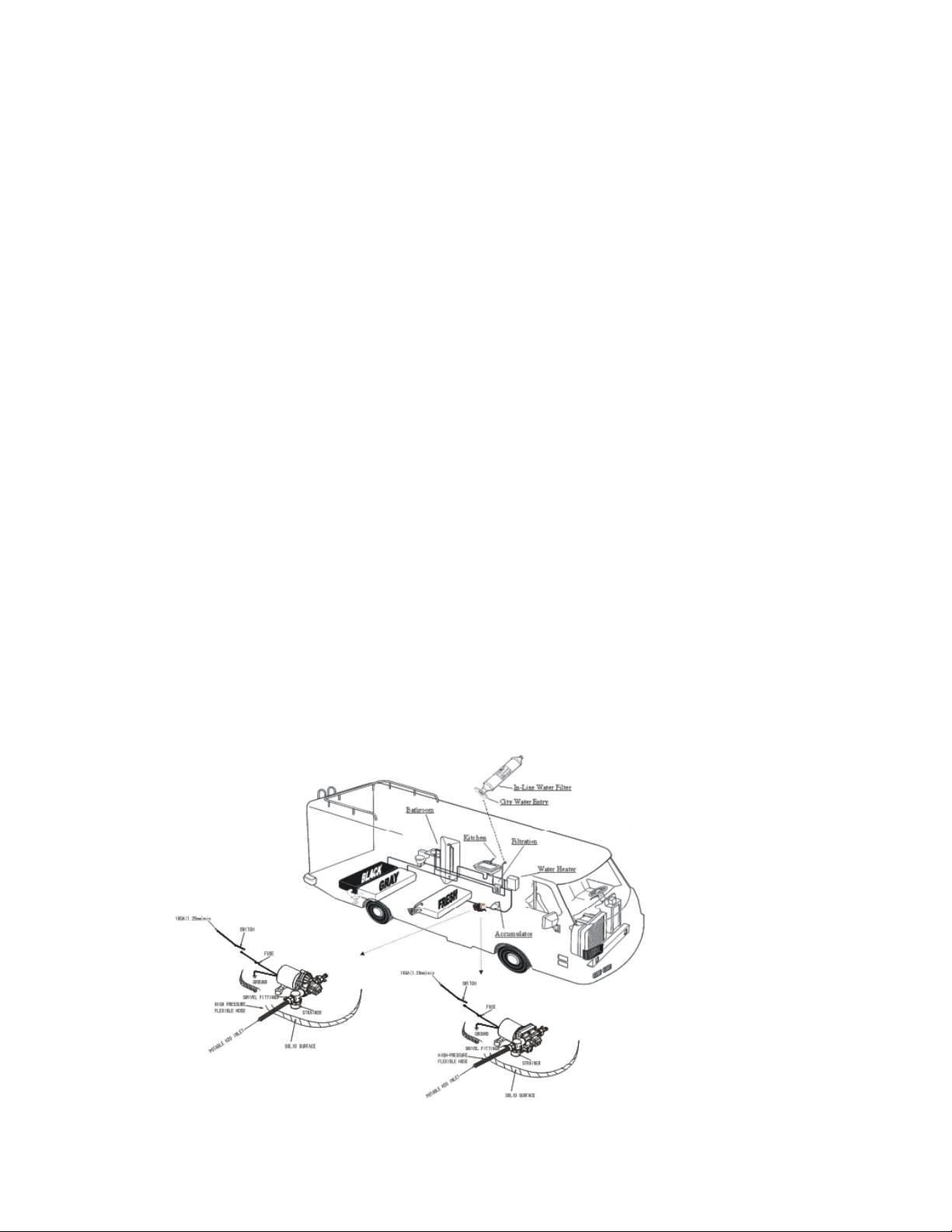

Installation instructions: ( RV )

·Solid surface.

·Accessible location away from living quarters.

·Properly sized wiring.

·Proper electrical protection.

·Flexible hose on inlet and outlet.

·Strainer on plumb ing elbows and valves near the pump.

·Minimize flow restrictions in the system.

Valterra Products, LLC Mission Hills, CA 91346 1-800-806-6159 www.valterra.com

MARINE

MOUNTING

·The pump can be at the same level or below the water tank. It may be positioned

above the water tank if needed, as it is capable of a 6 ft.(1.8m) vertical prime.

Horizontal inlet tubing will allow priming to 30ft(9m)

·Consider a dry location that allows easy access if maintenance is required. The

pumps should not be located in an area of less than one cubic foot unless adequate

ventilation is provided. Excessive heat may trigger the integrated thermal breaker and

interrupt operation. When the temperature drops the breaker will automatically reset

and re-start operation.

·The pump can be mounted in any position. If mounting the pump vertically. The

pump head should be in the down position.

·The mounting feet are intended to isolate the pump from the mounting surface;

over-tightening, flattening, or use of oversized screws will reduce the ability to isolate

vibration and noise through the lines.

ELECTRICAL

·The pump should be on a de dicated (individua l) circuit protected by the specified fuse indicated

on the motor label.

·A U/L, CE, etc approved marine duty (ignition protected) switch rated at above 20 amps is

recommended and must interrupt current flow on the positive (+ red) lead.

·The pump must be grounded to a known ground (battery). The ground wire must be the same

size (gauge/mm2) as the positive wire.

·Wire Sizing: Proper wire sizing is required for good pump operation. If the wire is too small, low

voltage will affect the pump performance and can create a fire hazard.

Valterra Products, LLC Mission Hills, CA 91346 1-800-806-6159 www.valterra.com

Minimum Wire Size for a 10% voltage drop on a 12VDC, 10Amp Circuit. Length is the distance

from the power source to pump and back to ground.

·The total current draw on the circuit must not exceed 15 amp s. If the pump is used in conjunction

with other components, overload current protection (fuse or circuit breaker) and wire size must be

for the total amp requirements of all devices on the circuit.

Feet [Meters] AWG [mm 2 ]

0-25 [0-7.6] 14 [2.1]

25-50 [7.6-15.2] 12 [3.3]

50-70 [15.2-21.3] 10 [5.3]

70-110 [21.3-33.5] 8 [8.4]

PLUMBING

HYDROMAX recommends at least 1ft[.3m]of 1/2"[13mm]I.D. flexible high pressure tubing to

both ports. Ideally the pump's ports/strainer should not be connected to plastic or rigid pipe. The

pump's normal oscillation may transmit through rigid plumbing causing noise, and possibly loosen

or crack components.

Installation of a 50 mesh strainer such as the HYDROMAX P25206VP is recommended to

prevent foreign debris from entering the pump. HYDROMAX P25205VP is a hex/swivel barb

fittings that provides easy removal if maintenance or access is required. The fittings are designed

with a "taper-seal", creating a water tight connection when hand-tightened. Always secure barb

tubing connections with properly sized stainless steel clamps to prevent leaks. Never use Teflon

tape or sealing compounds on threads. Sealer may enter the pumps causing a failure. Failure due

to foreign debris is not covered under warranty.

Rapid cycling may be caused by excessive back pressure created by one or more of the foll owing

within a plumbing system: Water filters and purifiers not on separate feed lines, Flow restrictors in

faucets and shower heads, Small ID lines Pipe/tubing should be at least 1/2”(13mm) for main lines,

Restrictive fittings and connections (elbows, “T” s, feeder lines to faucets, etc). The pump with

by-pass do not need to use pressure t ank.

If the pump is cycling rapidly increase the setting by turning the screw clockwise (1 1/2 turn

MAX.) until the pump operates for 1 sec. with at least 2 sec.” OFF time”.

The pump's duty cycle is: intermittently. Do not use the pump under anti-osmosis filtering system.

Continuous running under higher pressure may reduce pump life and it is not under the warranty.

Operation(only for HYDROMAX Automatic Fresh Water Pumps-42series)

This pump is designed for intermittent duty only.

The pump operates normally up to about 40-psi, where a spring-loaded by-pass valve opens,

allowing flow back from the output side to the input side, providing smooth, steady flow with

virtually no cycling, all the way down to a trickle. As a faucet is opened back up, the pressure will

drop, the by-pass will close and full flow is again obtained. This allows good flow, even with

today's restrictive showers and pullout sprayer faucets. Performance will vary, of course,

depending on the voltage to the pump; lower voltage=lower flow, higher voltage=higher flow.

Remember your electrical safety: It is always best to shut off power to the pump OFF when

Valterra Products, LLC Mission Hills, CA 91346 1-800-806-6159 www.valterra.com

Loading...

Loading...