3002783/01

Date: June 2002.

© Valor Heating

Safety Upgrade Instructions

These instructions are for the

Valor Legend Ultra

(Model 837 AN and 837 AP)

Important: Switch the appliance off, isolate the gas supply to the appliance and

ensure that the appliance is completely cool before continuing any further.

1. Removal of Fascia

Cast Iron Fascia

1. Unscrew and remove the ignition bar knob

(See figure 1).

2. Remove the lower front casting by lifting and

pulling forward (See figure 2).

3. Remove two screws located behind the upper

decorative casting (See figure 3).

4. Remove the Fascia by gentle pulling the top of

the fascia forward. Two retaining clips hold the

top of the fascia. Once clear of these the fascia

can be lifted clear of the lower bottom fascia

brackets (See figure 4)

Figure 1. Removal of ignition bar

knob.

Figure 2. Removal of lower front

casting.

Safety Upgrade Instructions

Standard fascia – three or four sided.

1. Unscrew and remove

the ignition bar knob

(See figure 1).

2. Remove the Fascia by

gentle pulling the top

of the fascia forward.

Two retaining clips

hold the top of the fascia. Once

clear of these the fascia can be

lifted clear of the lower bottom

fascia brackets (See figure 4).

Figure 3. Removal of Screws on cast Iron fascia.

Figure 4. Fascia Removal on Cast Iron and

Standard fascia.

Page 2

Safety Upgrade Instructions

b

2. Removal of bushing from ignition bar

For models fitted with a locating bracket (See figure 5)

1. Remove the self-tapping screw from the

ignition bar locating bracket (See figure 5).

2. Place a suitable flat instrument on the

underside of the bushing and lift the bushing

clear of the mounting bracket (see figure 6).

3. Pull the ignition bar forward and clear of the

mounting bracket.

4. Remove bushing from ignition bar by sliding

up around bend and off bar. If bushing is too

tight to slide off, cut off bushing with a utility

knife.

5. With the bushing removed, push the ignition

bar back into the mounting bracket.

6. Replace the locating bracket and secure using

the self-tapping screw removed previously.

For models NOT fitted with a locating bracket

(See figure 5)

7. Place a suitable flat instrument on the

underside of the bushing and lift the bushing

clear of the mounting bracket (see figure 6).

8. Pull the ignition bar forward and clear of the

mounting bracket.

9. Remove bushing from ignition bar by sliding

up around bend and off bar. If bushing is too

tight to slide off, cut off bushing with a

utility knife.

10. With the bushing removed, push the ignition

bar back into the mounting bracket.

Figure 5. Removal of Screw from

locating bracket.

Figure 6. Removal of Bushing.

11. Position the locating bracket with its sides in

line with those of the mounting bracket (See

figure 7). Mark the position of the hole.

12. Remove the bracket and drill a 3.5mm (1/8

in) hole

13. Reposition the location bracket

and secure using a self-tapping screw.

Figure 7. Fitting the locating

racket.

Page 3

Safety Upgrade Instructions

3. Replacing the Gas Valve

Refer to figure 8.

1. Loosen the screw attaching the ignition bar to the top of the gas valve.

2. Lift the ignition bar clear of the gas valve spindle.

3. Supporting the elbow with a wrench, unscrew the nut to the inlet elbow on the gas

valve.

4. Unscrew the pilot line nut from the gas valve. Pull the pilot line clear of the valve.

5. Unscrew and remove the thermocouple

nut connecting the thermocouple to the

interrupter block at the base of the gas

valve.

6. Remove the microswitch leads from

the interrupter block. Do not pull on

the leads. Grip the terminals close to

the interrupter block and gently pull

the leads clear of the interrupter block.

This will avoid damage to the leads.

7. Unscrew and remove the interrupter

block.

8. Supporting the connector with a

wrench, unscrew the pipe nut below

the thermostat valve.

9. Unscrew and remove the brass nut at

the top of the gas valve.

10. The gas valve can now be removed.

11. Supporting the elbow, unscrew and

remove the nut holding the thermostat

pipe to the elbow.

12. Place the old valve away from the

work area.

13. Obtain the replacement gas valve and

fit to the appliance in reverse to

above.

When fitting the new valve it may be easier if the screws at the top of the

regulator support bracket are loosened. These screws must be tightened after

fitting the new gas valve.

Figure 8. Gas Valve

Page 4

Safety Upgrade Instructions

Important Note:

When connecting the ignition bar to

the top of the gas valve it is important

that the arm of the microswitch is

behind the ignition arm (See figure 9).

Ensure that when the ignition bar is

depressed the microswitch arm does

not pass over the top of the ignition

arm. If it does, or appears likely to

during future use, then the angle of the

ignition arm must be adjusted. Only

make the adjustment if absolutely

necessary. Do not overbend the

ignition arm.

Figure 9. Microswitch arm location

The screw at the base of the ignition

bar must be against the ‘D’ flat on the gas valve spindle.

4. Replacing the electronic spark generator battery

Refer to figure 10.

1. Remove the battery from the electronic spark generator. To do this simply grip the

battery at the left hand side, lift and pull to the left.

2. Remove the old battery from the work area.

3. Obtain a new battery

and fit this into the

electronic spark

generator. To do this

hold the battery so

that the positive

terminal is towards

the rear of the

appliance. Slide the

battery in from the

left side. When the

battery stops sliding

push it down so that

it locates against the

left-hand retainer.

Figure 10.Battery Replacement

Page 5

Safety Upgrade Instructions

5. Relief Panel operation

The relief panels on the underside of the firebox should be held in place by their spring

retainers, but should be capable of opening when the pressure within the firebox becomes

too great.

• To check the operation of the

relief panels push them down

from inside the firebox. They

can be accessed behind the

lower ceramic support by first

removing the two cross logs

and front log. (See figure 11).

Push down by 40-50mm and

ensure that they open easily

and freely. There should be

no restriction.

• If there is any restriction or

metallic scrapping sound then

the relief panels may be

coming into contact with the

stop plates. These are located

on the underside of the

firebox behind the relief

panels and are to ensure that

the springs are not over bent

during operation. If the relief

plate is coming into contact

with the stop plate then push

the bottom of the stop plate

towards the rear of the appliance by about 1/8th inch. Try the operation of the relief

plate and ensure that it closes against the base of the firebox. It is Important that

Figure 11. Relief panels

the relief doors operate easily and freely before leaving the

appliance.

Page 6

Safety Upgrade Instructions

6. Adjusting the height of the ignition bar

When refitting the Fascia it is important that the height of the ignition bar is

adjusted to ensure smooth operation.

The height of the ignition bar can be adjusted to suit the slot in the fire front. The

adjustment must be made before the window is refitted as follows:

1. Locate slots in the fascia over the claws at the sides of the main appliance (figure.

12).

Figure 12. Fascia locating

2. Angle the fascia up and turn the ignition bar to test if it will project through the slot

in the fascia.

Page 7

Safety Upgrade Instructions

3. If the ignition bar does not

locate satisfactorily

through the fascia, loosen

the screw securing the

ignition bar sleeve (figure.

13).

4. Adjust the height of the

ignition bar so that it can

rotate freely through the

slot. Retighten the sleeve

screw.

5. The thermostat wheel

height can be adjusted by

simply sliding it up or

down the spindle and the

tightening the bushing

below so that it is flush

against the wheel (figure

13)

6. Remove the fascia.

Figure 13 Ignition bar adjustment screw

Page 8

Safety Upgrade Instructions

7. Final Review

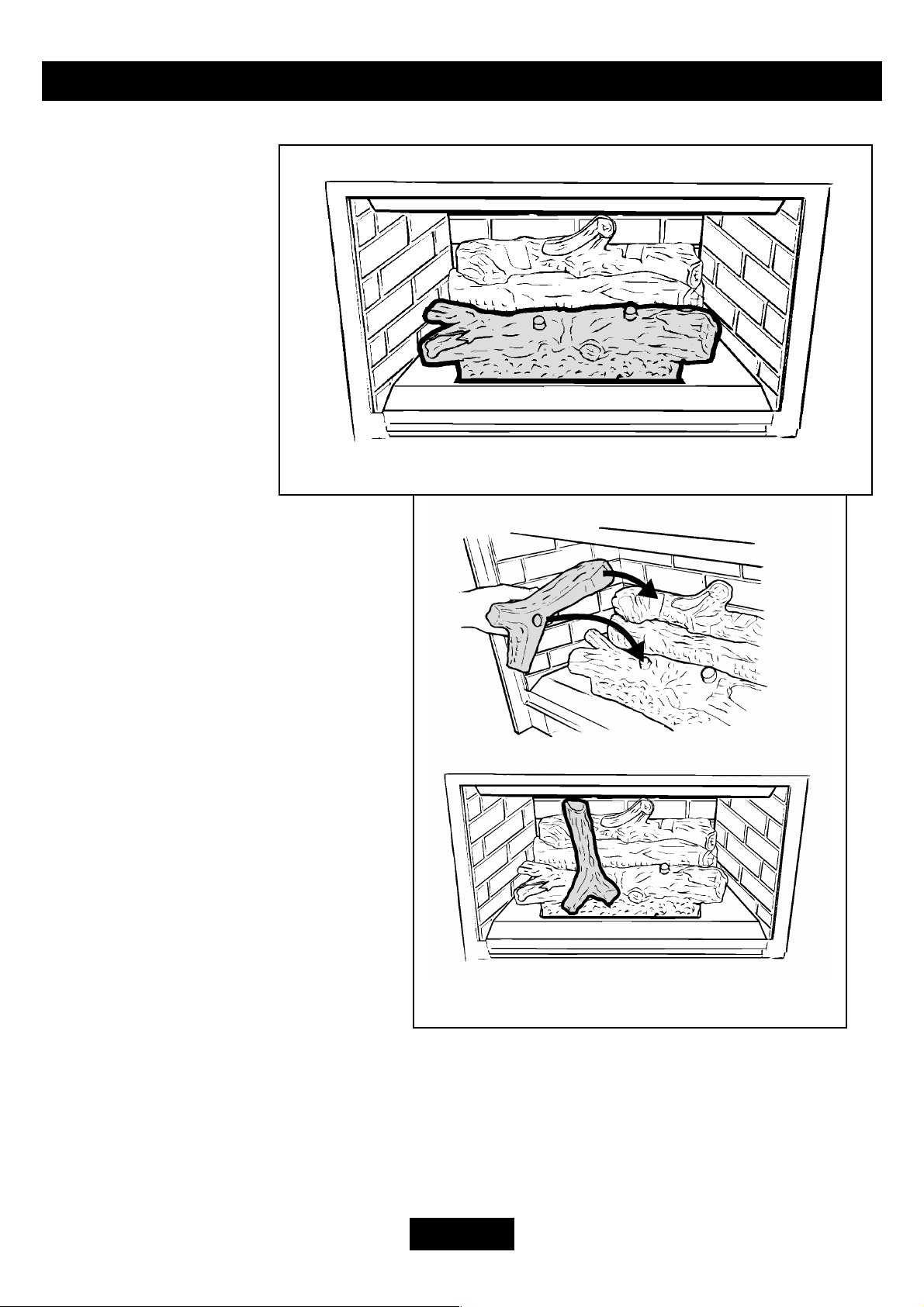

Replace the ceramic fuel effect bed as below

1. Place the lower rear

log in the support cradles at

the back of the firebox (See

figure 14).

Figure 14. Lower rear log

2. Place the upper rear log on top of

the lower rear log. The pegs in the lower

log locate in the holes in the upper log

(figure 15).

Figure 15. Upper rear log

Page 9

Safety Upgrade Instructions

3. Place the front

log in the opening of

the firebox base cover.

Slide the log forward

as far as it will go (See

figure 16).

Figure 16. Front log

4. Place the left cross log

(stamped “L” underneath) over the

front and rear logs. Locate the cross

log over the peg in the front log and

into the channel in the rear log (See

figure 17).

Figure 17. Left cross log

Page 10

Safety Upgrade Instructions

5. Place the right front log

(stamped “R” underneath) over the

other logs. Locate it over the peg in

the front log and into the channel

in the rear log (See figure 18).

Figure 18. Right cross log

• Without replacing the glass window, fit the fascia. Check for smooth operation of the

ignitor lever. If the ignitor lever contacts the fascia at its lowest depressed position,

adjustment is required. Insert a screwdriver between the firebox and fascia (through

the void space where the glass window would be) and loosen the set screw halfway up

on the ignitor bar. Adjust the ignitor lever up to almost the top of the opening in the

fascia and tighten set screw. Re-check operation of ignitor lever to ensure no contact

with fascia in the upper released or lower depressed position. Remove fascia again.

• With the glass window still removed, re-connect the gas supply to the heater and carry

out a leak test on all of the gas connections up to the control valve. Next light the

fireplace and leak test between the control valve and the burners. Shut off the

fireplace.

• Replace the glass window as in the Installation and Owner’s manual. Ensure window

is completely down in lower support track and all three upper buckles secured.

• Fit the Fascia and ignition bar knob.

• Conduct full operational checks as in the Installation and Owner’s manual.

Page 11

Safety Upgrade Instructions

Advise the customer that: -

1. The battery should be replaced each season.

2. If for any reason the fascia has been removed the smooth operation of the ignition

lever must be checked. If it is not smooth then the appliance must not be used until

rectified by a qualified person.

Page 12

Loading...

Loading...