Valor Portrait 530ILN, Portrait 530ILP, Portrait 530ICN, Portrait 530ICP, Portrait 530IRN Installation & Operating Instructions Manual

...

PORTRAIT

Models 530ILN/ILP (logs),

530ICN/ICP (coals), 530IRN/IRP (rocks)

Direct Vent Gas Fireplace Heater

Installation & Operating Instructions

This manual contains

instructions to install the

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

ENGINE ONLY. A front trim kit is

REQUIRED to install the engine

as it affects the framing cavity

and position of the engine.

Refer to the manual supplied

with the front for framing and

fi nishing.

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury or loss of life.

Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light the appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fi re department.

Installation and service must be performed

by a qualifi ed installer, service agency or the

gas supplier.

This appliance is suitable for installation in a

bedroom or bed sitting room.

INSTALLER: Leave this manual with the

appliance.

CONSUMER: Retain this manual for future

reference.

Please read this manual BEFORE installing

and operating this appliance.

This appliance may be installed in an aftermarket permanently located, manufactured

(mobile) home where not prohibited by local

codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This appliance is not convertible for use with other

gases, unless a certifi ed kit is used.

Massachusetts: The piping and fi nal gas

connection must be performed by a licensed

plumber or gas fi tter in the State of Massa-

chusetts. Also, see Carbon Monoxide Detector requirements under “Safety and Warning

Information” on page 5.

MILES INDUSTRIES LTD., British Columbia, Canada

4001754-12

©2011, Miles Industries Ltd. All rights reserved.

Manufactured by

www.valorfi replaces.com

Thank You ...

For purchasing a Valor by Miles Industries. Your new radiant gas heater is a technical

appliance that must be installed by a qualifi ed dealer. Each Valor is fully tested during

the production process for your safety and comfort.

Your unit has been professionally installed by:

Dealer Name _______________________________________

Phone Number ______________________________________

Should you encounter an operational problem, call your dealer immediately.

Do not try to repair the unit as you may cause an injury or damage the fi replace.

The information contained in this installation manual is believed to be correct at

the time of printing. Miles Industries Ltd. reserves the right to change or modify any

information or specifi cations without notice. Miles Industries Ltd. grants no warranty,

implied or stated, for the installation or maintenance of your heater, and assumes no

responsibility for any consequential damage(s).

Fireplace

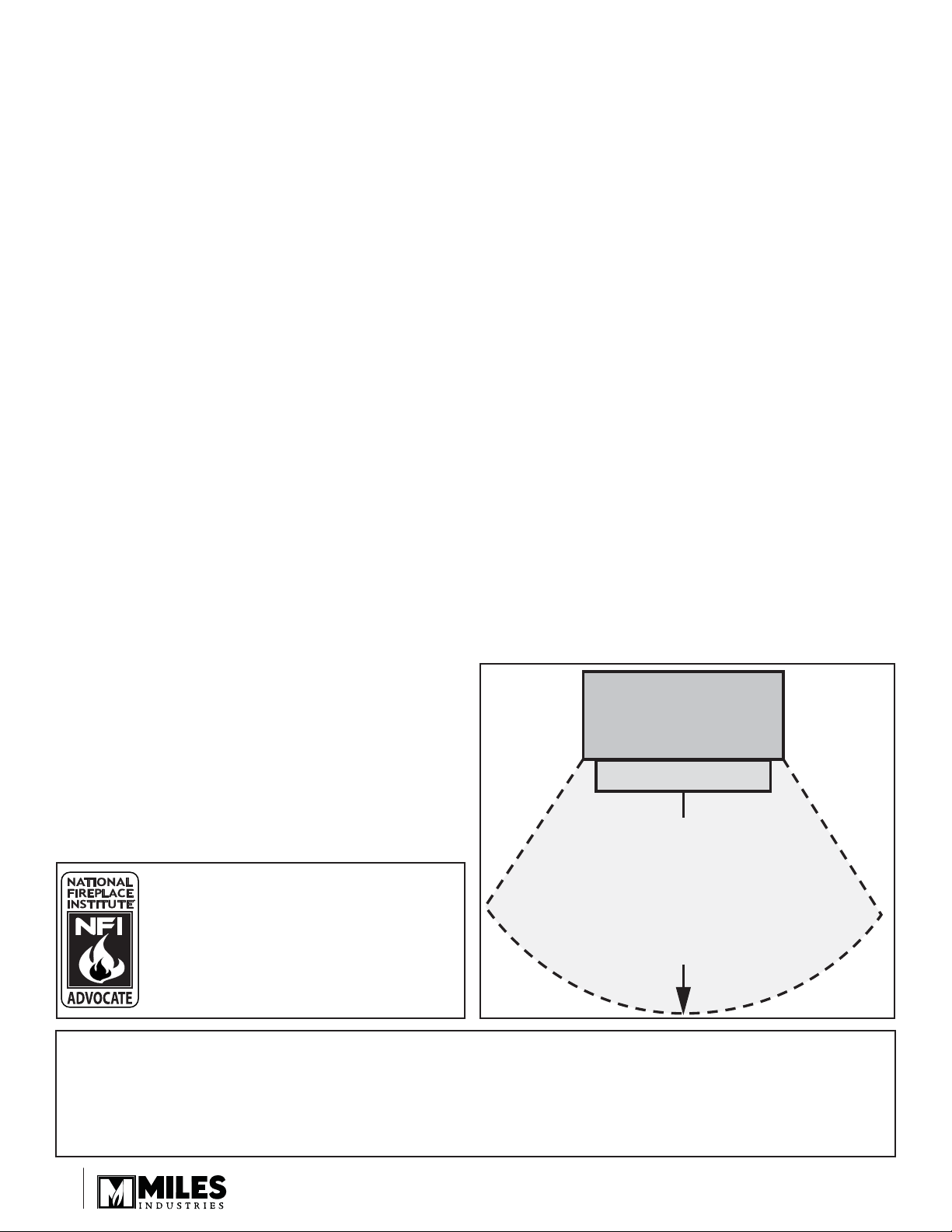

Hearth

Do not put

furniture or other objects

We recommend that our gas

hearth products be installed

and serviced by professionals

who are certifi ed in the United

States by NFI (National Fireplace

Institute®).

Designed and Manufactured by

Miles Industries Ltd.

190 – 2255 Dollarton Highway, North Vancouver, BC, CANADA V7H 3B1

Tel. 604-984-3496 Fax 604-984-0246

www.valorfi replaces.com

© Copyright Miles Industries Ltd., 2011

in this space in front of

the replace:

36” (0.9 m)

2

2

Table of Contents

Safety and Warning Information ..............................................................4

Specifi cations ............................................................................................7

Dimensions, Clearance and Framing ......................................................8

Horizontal Termination Locations ............................................................9

Horizontal Termination Venting Confi gurations ...................................10

Horizontal Termination Installations ......................................................12

Vertical Termination Venting Confi gurations ........................................ 13

Vertical Termination Installations ..........................................................15

Appliance Preparation ............................................................................16

Air Restrictors Installation......................................................................19

◊

Gas Supply Installation ...........................................................................20

Aeration Setting Check ...........................................................................21

Ceramic Walls Installation (logs and coals only) ................................21

Ceramic Logs Installation .......................................................................22

Ceramic Coals Installation......................................................................23

Ceramic Rocks Installation.....................................................................24

Window Refi tting and Checking .............................................................26

Remote Control Initial Set-up .................................................................26

Operation Checks ....................................................................................27

Remote Control Handset Wall Holder Installation ...............................27

Owner’s Information ................................................................................28

Remote Control Operation ......................................................................30

Options .....................................................................................................33

Lighting Instructions ...............................................................................34

Wiring Diagram ........................................................................................35

Approved Venting Components .............................................................36

Warranty ...................................................................................................38

Replacement Parts ..................................................................................39

◊

= Updated content

◊

33

Safety and Warning Information

READ and UNDERSTAND all instructions carefully

before starting the installation. FAILURE TO

FOLLOW these installation instructions may result in

possible fi re hazard and will void the warranty.

Prior to the fi rst fi ring of the fi replace, READ the

Owner’s Information section of this manual.

DO NOT USE this appliance if any part has been

under water. Immediately, CALL a qualifi ed service

technician to inspect the unit and to replace any part

of the control system and any gas control that has

been under water.

THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

Installation and repair should be PERFORMED

by a qualifi ed service person. The appliance and

venting system should be INSPECTED before initial

use and at least annually by a professional service

person. More frequent cleaning may be required due

to excessive lint from carpeting, bedding, etc. It is

IMPERATIVE that the unit’s control compartment,

burner, and circulating air passageways BE KEPT

CLEAN to provide for adequate combustion and

ventilation air.

Always KEEP the appliance clear and free from

combustible materials, gasoline, and other fl ammable

vapors and liquids.

NEVER OBSTRUCT the fl ow of combustion and

ventilation air. Keep the front of the appliance CLEAR

of all obstacles and materials for servicing and proper

operation.

Due to the high temperature, the appliance should be

LOCATED out of traffi c areas and away from furniture

and draperies. Clothing or fl ammable material

SHOULD NOT BE PLACED on or near the appliance.

Children and adults should be ALERTED to the

hazards of high surface temperature and should STAY

AWAY to avoid burns or clothing ignition.

This unit MUST be used with a vent system as

described in this installation manual. NO OTHER vent

system or components MAY BE USED.

This gas fi replace and vent assembly MUST be

vented directly to the outside and MUST NEVER be

attached to a chimney serving a separate solid fuel

burning appliance. Each gas appliance MUST USE

a separate vent system. Common vent systems are

PROHIBITED.

INSPECT the external vent cap on a regular basis to

make sure that no debris, plants, trees, shrubs are

interfering with the air fl ow.

The glass door assembly MUST be in place and

sealed before the unit can be placed into safe

operation.

DO NOT OPERATE this appliance with the glass

door removed, cracked, or broken. Replacement of

the glass door should be performed by a licensed or

qualifi ed service person. DO NOT strike or slam the

glass door.

The glass door assembly SHALL ONLY be replaced

as a complete unit, as supplied by the fi replace

manufacturer. NO SUBSTITUTE material may be

used.

DO NOT USE abrasive cleaners on the glass door

assembly. DO NOT ATTEMPT to clean the glass door

when it is hot.

TURN OFF the gas before servicing this appliance.

It is recommended that a qualifi ed service technician

perform an appliance check-up at the beginning of

each heating season.

Any safety screen or guard removed for servicing

MUST BE REPLACED before operating this

appliance.

DO NOT place furniture or any other combustible

household objects within 36” of the fi replace front.

YOUNG CHILDREN should be CAREFULLY

SUPERVISED when they are in the same room as

the appliance. Toddlers, young children and others

may be susceptible to ACCIDENTAL CONTACT

BURNS. A physical barrier is recommended if there

are at risk individuals in the house. To restrict access

to a fi replace or stove, INSTALL AN ADJUSTABLE

SAFETY GATE to keep toddlers, young children and

other at risk individuals out of the room and away

from hot surfaces.

44

BE CAREFUL not to put any decorating objects

sensitive to heat to close above or around the

fi replace as it gets very hot when operating.

DO NOT use this heater as a temporary source of

heat during construction.

This appliance is a DOMESTIC ROOM-HEATING AP-

PLIANCE. It must not be used for any other purposes

such as drying clothes, etc.

Safety and Warning Information

Operating Your Fireplace for the First Time.

When operating your new fi replace for the fi rst time,

some vapors may be released due to the burning of

curing compounds used in the manufacture of the

appliance. They may cause a slight odor and could

cause the fl ames to be the full height of the fi rebox, or

even slightly higher, for the fi rst few hours of operation.

It is also possible that these vapors could set off any

smoke detection alarms in the immediate vicinity.

These vapors are quite normal on new appliances. We

recommend opening a window to vent the room. After

a few hours use, the vapors will have disappeared and

the fl ames will be at their normal height.

State of California. Proposition 65 Warning.

Fuels used in gas, wood-burning or oil fi red appliances,

and the products of combustion of such fuels, contain

chemicals known to the State of California to cause

cancer, birth defects and other reproductive harm.

California Health & Safety Code Sec. 25249.6.

State of Massachusetts Carbon Monoxide

Detector/Vent Terminal Signage

Requirements

For all side wall horizontally vented gas fueled

equipment installed in every dwelling, building or

structure used in whole or in part for residential

purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust

vent termination is less than seven (7) feet above

fi nished grade in the area of the venting, including

but not limited to decks and porches, the following

requirements shall be satisfi ed:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing

plumber or gas fi tter shall observe that a hard wired

carbon monoxide detector with an alarm and battery

back-up is installed on the fl oor level where the gas

equipment is to be installed. In addition, the installing

plumber or gas fi tter shall observe that a battery

operated or hard wired carbon monoxide detector

with an alarm is installed on each additional level of

the dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment. It shall

be the responsibility of the property owner to secure

the services of qualifi ed licensed professionals for the

installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space or

an attic, the hard wired carbon monoxide detector with

alarm and battery back-up may be installed on the next

adjacent fl oor level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of installation,

the owner shall have a period of thirty (30) days

to comply with the above requirements; provided,

however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an

alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in

accordance with the above provisions shall comply

with NFPA 720 and be ANSI/UL 2034 listed and IAS

certifi ed.

3. SIGNAGE. A metal or plastic identifi cation plate

shall be permanently mounted to the exterior of the

building at a minimum height of eight (8) feet above

grade directly in line with the exhaust vent terminal for

the horizontally vented gas fueled heating appliance

or equipment. The sign shall read, in print size no less

than one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of

the side wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon

inspection, the inspector observes carbon monoxide

detectors and signage installed in accordance with the

provisions of 248 CMR 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt

from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the most

current edition of NFPA 54 as adopted by the Board;

and

2. Product Approved side wall horizontally vented

gas fueled equipment installed in a room or structure

separate from the dwelling, building or structure used in

whole or in part for residential purposes.

55

Safety and Warning Information

(c) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM PROVIDED.

When the manufacturer of Product Approved side

wall horizontally vented gas equipment provides a

venting system design or venting system components

with the equipment, the instructions provided by the

manufacturer for installation of the equipment and the

venting system shall include:

1. Detailed instructions for the installation of the venting

system design or the venting system components; and

2. A complete parts list for the venting system design or

venting system.

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does

not provide the parts for venting the fl ue gases, but

identifi es “special venting systems”, the following

requirements shall be satisfi ed by the manufacturer:

1. The referenced “special venting system” instructions

shall be included with the appliance or equipment

installation instructions; and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for that

system shall include a parts list and detailed installation

instructions.

(e) A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists

for venting instructions, and/or all venting design

instructions shall remain with the appliance or

equipment at the completion of the installation.

66

Specifi cations

Approvals and Codes

This appliance is certifi ed to ANSI Z21.88–2009/CSA

2.33–2009 American National Standard/CSA Standard

for Vented Gas Fireplace Heaters for use in Canada

and USA.

The appliance complies with CSA P4.1-09, Testing

method for measuring annual fi replace effi ciencies.

The installation must conform with local codes or, in

the absence of local codes with the National Fuel Gas

Code, ANSI Z223.1or the Natural Gas and Propane

Installation Code CAN/CGA-B149. Only qualifi ed

licensed or trained personnel should install the

appliance.

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 or the Canadian Electrical Code,

CSA C22.1.

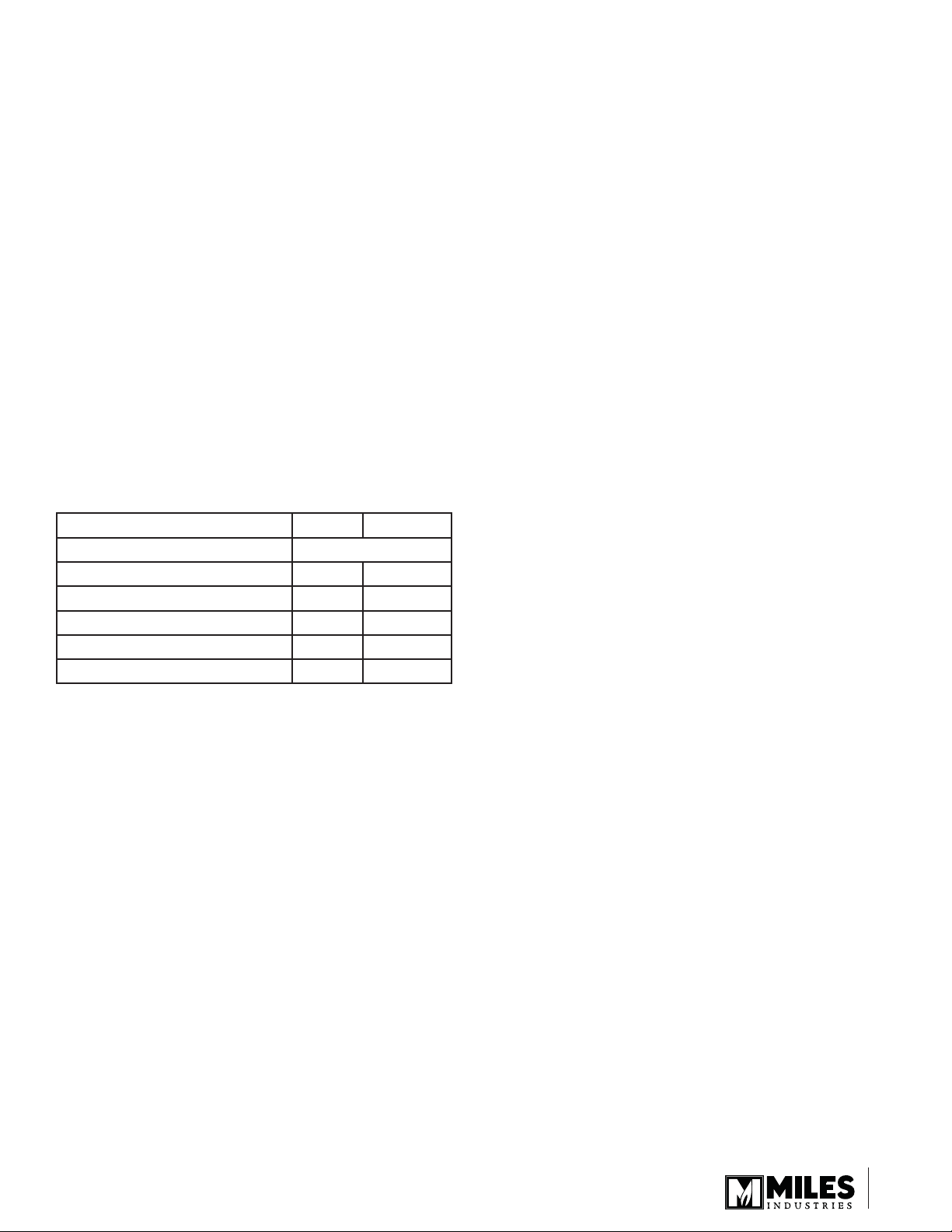

Ratings

NG LPG

Altitude (Ft) 0-4500 *

Input Max. (Btu/h) 20,500 19,000

Input Min (Btu/h) 6,500 12,500

Manifold pressure (in.w.c.) 3.5–3.9 10.3–10.7

Min. Supply pressure (in. w.c.) 5 11

Max. Supply pressure (in. w.c.) 10.5 14

*Tested to CGA - 2.17-91 Gas fi red appliances for use

at high altitudes. In USA, installations may require

deration over 2000’ —Check local codes.

*High Altitude Installations

Input ratings are shown in BTU per hour and are

certifi ed without deration for elevations up to 4,500 feet

(1,370 m) above sea level.

For elevations above 4,500 feet (1,370 m) in USA,

installations must be in accordance with the current

ANSI Z223.1 and/or local codes having jurisdiction.

Heating value of gas in some areas is reduced to

compensate for elevation—consult your local gas utility

to confi rm.

For installations at elevations above 4,500 feet

(1,370 m) in Canada, please consult provincial and/or

local authorities having jurisdiction.

Front Trims

Various fronts are available for the 530I engine. This

engine may be installed as a free standing, zero

clearance or insert application depending on which

style front trim is selected. The front trim style

affects the framing cavity, clearances and position

of the engine. A front trim kit is required for all

applications and should be on site when the engine

is installed as the parts to make the engine suitable

for zero clearance are supplied with the front trim kits

(except 549 front).

Fuel Beds

The 530I engine is available in either natural gas

or propane gas and comes equipped with either a

simulated logs, coals, or rocks fuel bed in either fuel.

Venting options

The 530I engine unit is supplied standard with a

rear direct vent outlet and may be converted to a top

direct vent outlet with no extra parts required—see

Conversion to Top Outlet for Solid Direct Vent Co-axial

Piping in the Appliance Preparation section further on

in this manual.

Direct Vent Installations (solid piping)

A list of all approved venting accessories is shown on

pages 36–37 of this manual.

Direct Vent Co-Linear Installations for Free

Standing or Recessed Installations (fl exible piping)

Converts the appliance outlet collars to accept two

3-inch diameter fl exible liners for installation into

existing solid-fuel burning fi replaces and chimneys.

Requires a co-linear adapter at the appliance and

either a co-linear terminal or co-linear-to-co-axial

terminal at the top of the chimney. A list of approved

venting accessories is shown on pages 36–37 of this

manual.

77

Specifi cations

Wall Thickness

The appliance vent is suitable for penetrating a

combustible wall up to 14 inches (36 cm) thick.

A non-combustible wall can be any thickness up to

the maximum horizontal run of vent pipe allowed for

the particular installation—see Horizontal Termination

Venting Confi gurations section.

Supply Gas

Heater engine 530ILN/ICN/IRN is used for natural gas

installations.

Heater engine 530ILP/ICP/IRP is used for propane gas

installations.

The supply pressure must be between the limits shown

in the Ratings table on the previous page.

The supply connection is 3/8 inch NPT female located

at the left side of the control valve.

The opening for the gas supply line is at the rear left

corner of the appliance.

Controls

The unit is supplied standard with a battery operated,

hand-held remote control and receiver which has the

ability to light the pilot and adjust the gas input of the

unit between the pilot setting and the maximum input.

The pilot light may be left on or turned off with each

use to save energy. The remote control provides full

thermostatic or manual operation with the option of

programming thermostat function between certain

times of the day. Manual operation of the valve is also

possible should the batteries or remote control fail.

Electrical

The unit does not require an electrical power source

unless fi tted with an optional circulating fan.

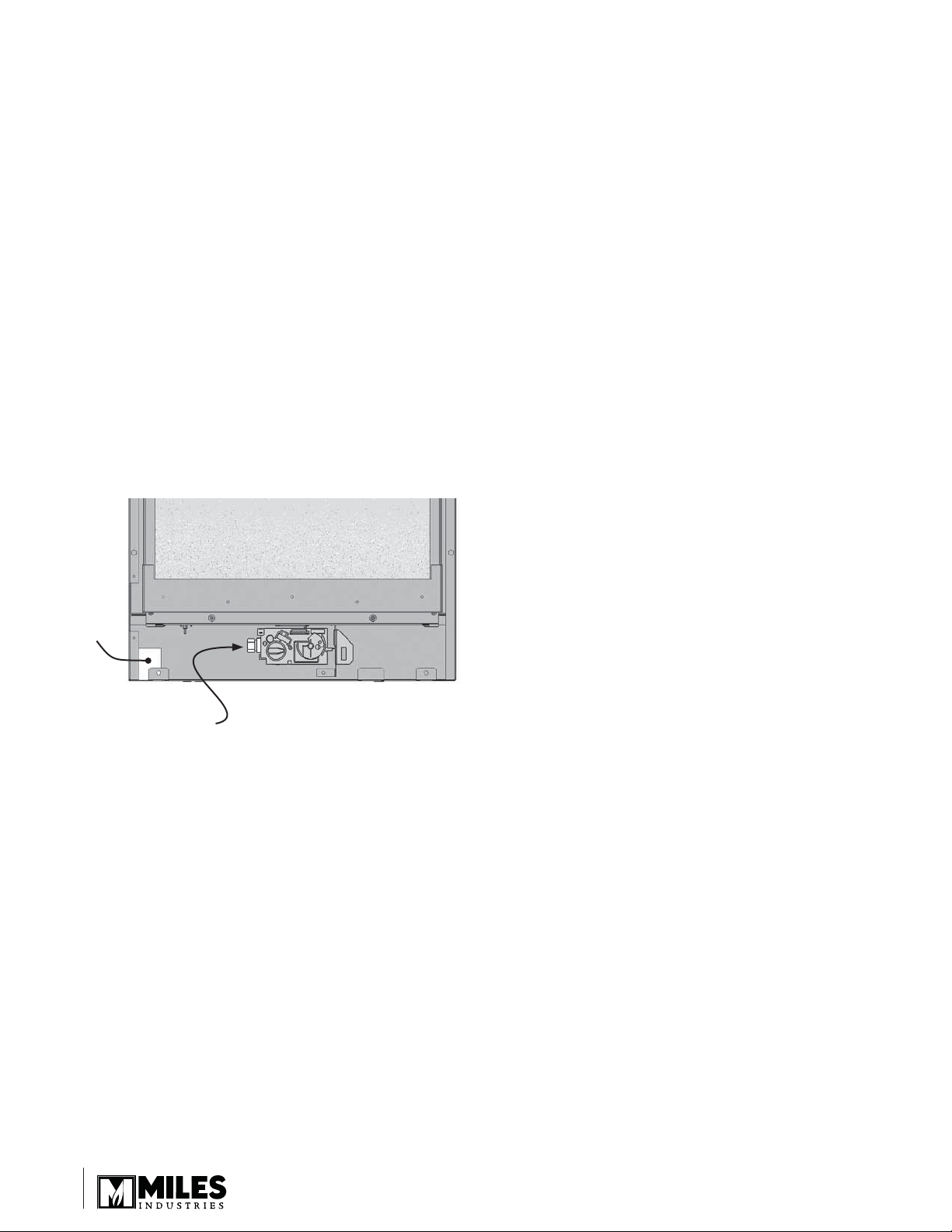

Gas line access at rear

left corner

Gas supply connection

3/8” NPT female at valve

Dimensions, Clearance and Framing

The dimensions, clearances and framing vary with

each applications and with the front trim installed. Refer

to the installation instructions of the front trim chosen

for more information.

88

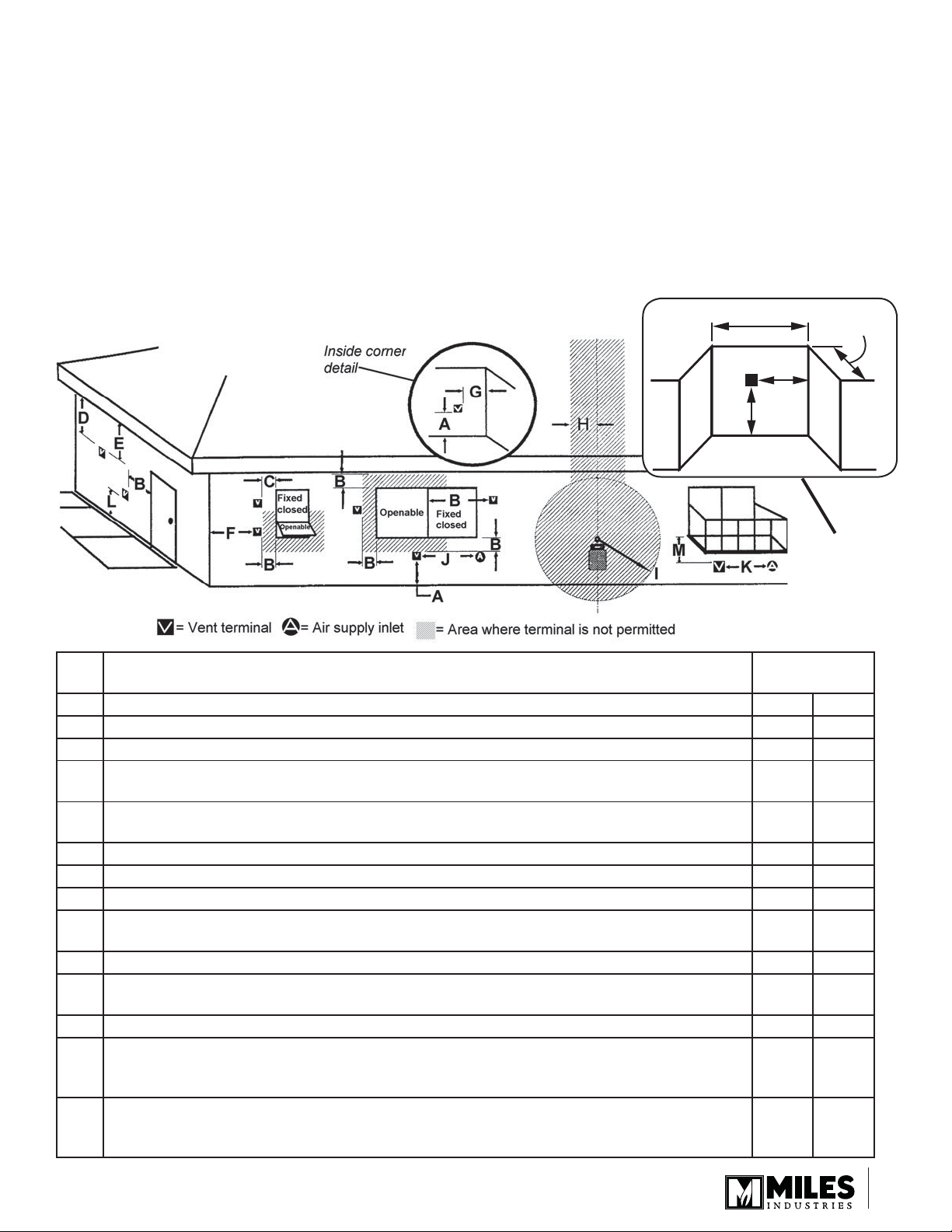

Horizontal Termination Locations

V

G

A

Min. 72”

Max. 72”

• The vent terminal must be located on an outside

wall or through the roof.

• This direct vent appliance is designed to operate

when an undisturbed airfl ow hits the outside vent

terminal from any direction.

• The minimum clearances from this terminal that

must be maintained when located on an outside wall

are shown in fi gure below. Any reduction in these

clearances could result in a disruption of the airfl ow

or a safety hazard. Local codes or regulations may

require greater clearances.

• The vent terminal must not be recessed into a wall

or siding.

• The vent terminal should be positioned where any

snowdrifts will not cover it.

• 551DVK sidewall vent termination requires the

terminal guard 835TG when accessible—within 7’ of

ground.

Alcove detail

(open on one

side) Normal

ceiling/soffi t

clearances

apply.

KEY VENT TERMINAL LOCATIONS - MINIMUM DISTANCES MINIMUM

CLEARANCE

Inches Cm

A Clearance above grade, verandah, porch, deck or balcony 12 30

B Clearance to window or door that may be opened 12 30

C Clearance to permanently closed window (recommended to prevent condensation on

window)

D Vertical clearance to ventilated soffi t located above the terminal within a horizontal distance

of 2 feet (60 cm) from the center-line of the terminal

E Clearance to unventilated soffi t1230

F Clearance to outside corner 12 30

G Clearance to inside corner 12 30

H Horizontal clearance to center-line of meter/regulator assembly located within 15 feet

(4.6 m) below the terminal

I Clearance to service regulator vent outlet 36 90

J Clearance to non-mechanical air supply inlet to the building or the combustion air inlet to

any other appliance

K Clearance to a mechanical air supply inlet 72 180

L Clearance above paved sidewalk or a paved driveway located on public property

Note: A vent must not terminate directly above a sidewalk or paved driveway, which is

located between two single-family dwellings and serves both dwellings

M Clearance under a verandah, porch, deck or balcony

Only permitted if veranda, porch, deck or balcony is fully open on a minimum of 2 sides

beneath the fl oor

Note: Local codes and regulations may require different clearances.

12 30

18 46

36 90

12 30

84 210

12 30

99

Horizontal Termination Venting Confi gurations

See venting accessories list on pages 36–37 for allowable components.

Rear Outlet—No Vertical Rise

Flat on the Wall

• Maximum 26” horizontal pipe length;

• 817VAK Vent Collar Adapter required if using other

than Valor’s 551DVK pipe with termination;

• 835TG Terminal Guard is required with 551DVK if

terminating within 7’0” of grade or where accessible.

530

engine

14” (36 cm) max.

within

combustible wall.

26” (66 cm) max.

vent length

Approved

trough wall

shield/thimble

Use 835TG vent

guard with the

551DVK

termination

located at less

than 7’ (2.13 m)

above grade

Approved

side wall

termination

In Corner—No Vertical Rise

• Maximum 1 x 45° elbow allowed;

• Maximum 18” horizontal pipe length;

• 835TG Terminal Guard is required with 551DVK if

terminating within 7’0” of grade or where accessible.

530

engine

Max. 26” (66 cm)

18” (46 cm)

max vent pipe

Approved

side wall

termination

Approved

through wall

shield/thimble

1010

Horizontal Termination Venting Confi gurations

See venting accessories list on pages 36–37 for allowable components.

Rear Outlet w/Vertical Rise —Horizontal

Termination

• 817VAK Vent Collar Adapter required;

• Maximum 2 x 90° elbows allowed (or equivalent: 2 x 45°

elbows = 1 x 90° elbow);

• 835TG Terminal guard is required with the 551DVK if

terminating within 7’0” of grade or where accessible.

Minimum Maximum

D: Vertical pipe run 12”

(30 cm)8’(244 cm)

E: Horizontal pipe run (Total

before and after elbows) E

2

+ E

F: Clearance to combustible

materials above horizontal

pipe run

G: Clearance to combustible

materials below horizontal

pipe run

H: Clearance to combustible

materials all round vertical

pipe run and at sides of horizontal pipe run

1

-

2-5/8”

(6.7 cm)

1-5/16”

(3.3 cm)

1-5/16”

(3.3 cm)

4’-6”

(137 cm)

-

-

530

engine

-

Use 835TG vent

guard with the

551DVK

termination

located at less

than 7’ (2.13 m)

above grade

14” (36 cm) max

combustible wall

Top Outlet w/Vertical Rise—Horizontal

Termination

See Conversion to Top Outlet for Solid Direct Vent Co-axial

Piping in Appliance Preparation section for conversion to

top outlet;

• 817VAK Vent Collar Adapter required;

• Maximum 2 x 90° elbows allowed (or equivalent: 2 x 45°

elbows = 1 x 90° elbow);

• 835TG Terminal guard is required with 551DVK if

terminating within 7’0” of grade or where accessible.

Minimum Maximum

D: Vertical pipe run (total) 9”

(23 cm)8’(244 cm)

E: Horizontal pipe run (Total)

F: Clearance to combustible

materials above horizontal

pipe run

G: Clearance to combustible

materials below horizontal

pipe run

H: Clearance to combustible

materials all round vertical

pipe run and at sides of horizontal pipe run

-

2-5/8”

(6.7 cm)

1-5/16”

(3.3 cm)

1-5/16”

(3.3 cm)

4’-6”

(137 cm)

-

-

-

530

engine

Approved

side wall

termination

Use 835TG vent

guard with the

551DVK

termination

located at less

than 7’ (2.13 m)

above grade

Approved

through wall

shield/thimble

14” (36 cm)

max.

combustible

wall

1111

Horizontal Termination Installations

• The 530 heater may be installed using components from a variety of

manufacturers listed on pages 36–37.

• Allowable vent confi gurations and clearances for the 530 heater are listed in this

manual and apply for all vent components listed on pages 36–37. For details of

component installation, follow instructions packaged with each component.

• The 530 heater is supplied with a smooth 4-by-6-5/8-inch co-axial collar

intended to accept the Valor 551DVK Vent Termination with pipe attached. All

other applications will require an 817VAK Vent Adapter to convert the collar to a

twist-lock type collar. All other manufacturers’ components listed (including Valor

551DVK) have designed their components to fi t this twist-lock type collar.

• Do not mix components from different manufacturers.

• Do not cut pipe lengths, except the 551DVK which may be cut to desired length.

Use adjustable lengths otherwise.

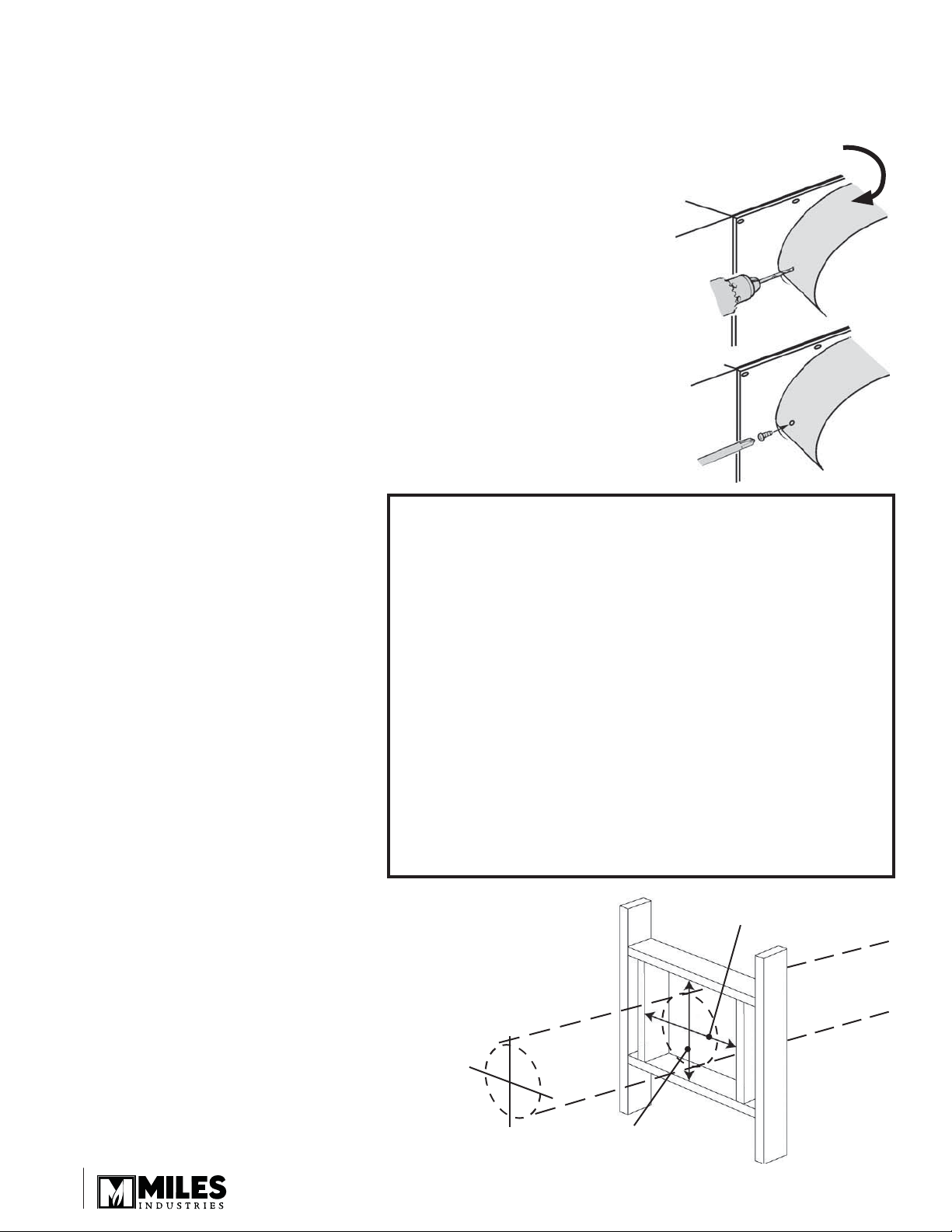

Fix the Vent Unit or 817VAK to

Appliance

• Fit the vent unit or 817VAK over the

inlet and outlet collars of the appliance,

pushing on fi rmly. If using the 551DVK,

ensure that the end of the pipe is cut

cleanly and square. Rotate the pipe to

ensure that the seam will pass through

notch in the wall plates and that the drain

hole is at the bottom.

• Drill through the outer tube and the

appliance collar with no. 6 screws. Make

sure the drill does not penetrate the inner

pipe.

• Secure the vent unit or 817VAK to the

outer collar with two no. 6 thread-cutting

screws supplied.

Through the wall details

• If the wall has combustible material,

appropriate insulation shielding or wall

thimble must be used specifi c to the

manufacturer of the venting. In any case,

a minimum of 10 x 10 inches square

or 10-inch diameter hole is required. If

the wall is totally non-combustible (e.g.

masonry block or concrete) mark for a

7-inch circular hole. In both cases, the

center of the hole should line up with the

center line of the horizontal vent.

• See Horizontal Termination Locations

section for allowable vent terminal

locations.

• Avoid structural elements when locating

the hole through the wall.

Important Installer Notice – Weather Sealing

& Vapor Barriers

It is the installer’s responsibility to ensure that vent installations

through exterior walls are caulked and weatherproofed in such a

manner as to:

• Prevent rain water from entering the wall from the weather side

by adequately caulking the outer vent plate to the exterior wall

surface.

• Prevent moisture inside the home from penetrating into the wall

structure by ensuring the inside wall plate is adequately sealed to

the inside vapor barrier.

• Prevent rain water and moisture from entering the walls by

sealing the joints between the outer vent tube and the inner and

outer wall plates.

We recommend the use of a high quality polyurethane sealant.

Align the

vent center

to the center

of the frame

10” (254 mm)

551DVK Pipe or

817VAK Vent Adapter

10” (254 mm)

1212

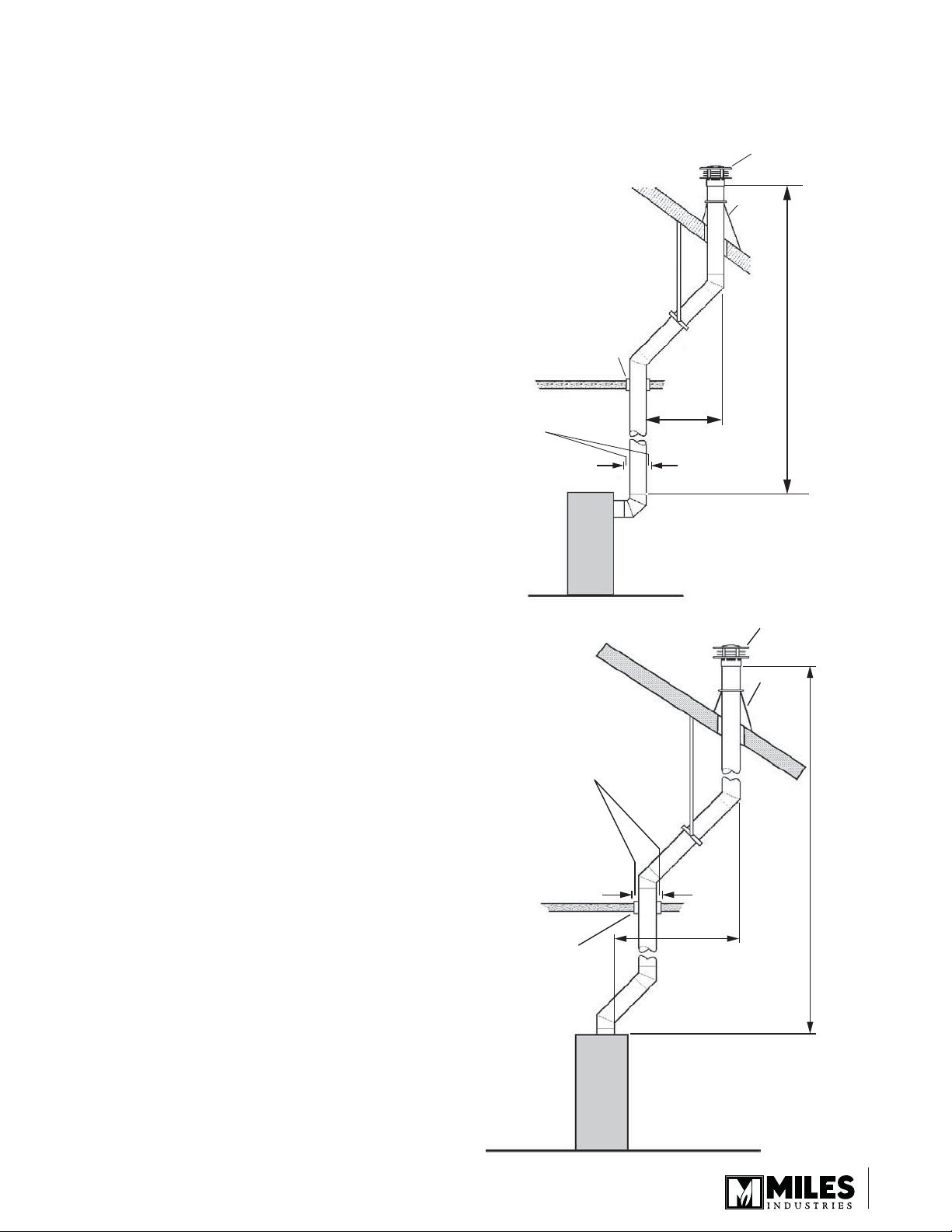

Vertical Termination Venting Confi gurations

See venting accessories list on pages 36–37 for allowable components.

Rear Outlet through Roof (Co-axial Pipe)

• 817VAK Vent Collar Adapter required;

• Maximum two 45° elbows allowed for offsetting;

• Various other ceiling or roof items may be necessary

depending on the particular installation.

1-5/16” (33 mm) min.

clearance to

combustible materials

all around

Ceiling

firestop

4’6”

(137 cm)

max.

Approved vertical

termination cap

Roof

flashing

40’ (12.2 m)

max.

8’ (2.44 m)

min.

Top Outlet through Roof (Co-axial Pipe)

See Conversion to Top Outlet for Solid Direct Vent

Co-axial Piping in Appliance Preparation section for

conversion to top outlet.

• 817VAK Vent Collar Adapter required;

• Maximum offset 4’6”;

• Maximum two 90° elbows allowed for offsetting (or

equivalent: two 45° elbows = one 90° elbow);

• Various other ceiling or roof items may be necessary

depending on the particular installation.

530

engine

1-5/16” (33 mm)

min. clearance

to combustible

materials

all round

Ceiling

firestop

Total offset

4’6”

(137 cm)

max.

Approved

vertical

termination

Roof

flashing

40’ (12.2 m)

max.

8’ (2.44 m)

min.

w/2 x 45˚

elbows

10’ (3 m)

min.

w/2 x 90˚

(or 4 x 45˚)

elbows

530

engine

1313

Loading...

Loading...