Valor PORTRAIT, PORTRAIT 569 Ledge Front Installation Instructions Manual

PORTRAIT

569 Ledge Front

CSA approved for use with Valor Models 530I Heaters ONLY

INSTALLATION INSTRUCTIONS

!

A barrier designed to reduce the risk of burns from the hot viewing

glass is provided with this appliance and shall be installed

for the protection of children and other at-risk individuals.

Notes: This kit must be installed or serviced by a qualifi ed

installer, service agency or gas supplier. These instructions are to

be used in conjunction with the main installation instructions

for Valor heater model 530I.

The installation of this kit affects the framing and method of

installing the 530 heater.

WARNING

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

INSTALLER

Leave this manual

with the appliance.

CONSUMER

Retain this manual

for future reference.

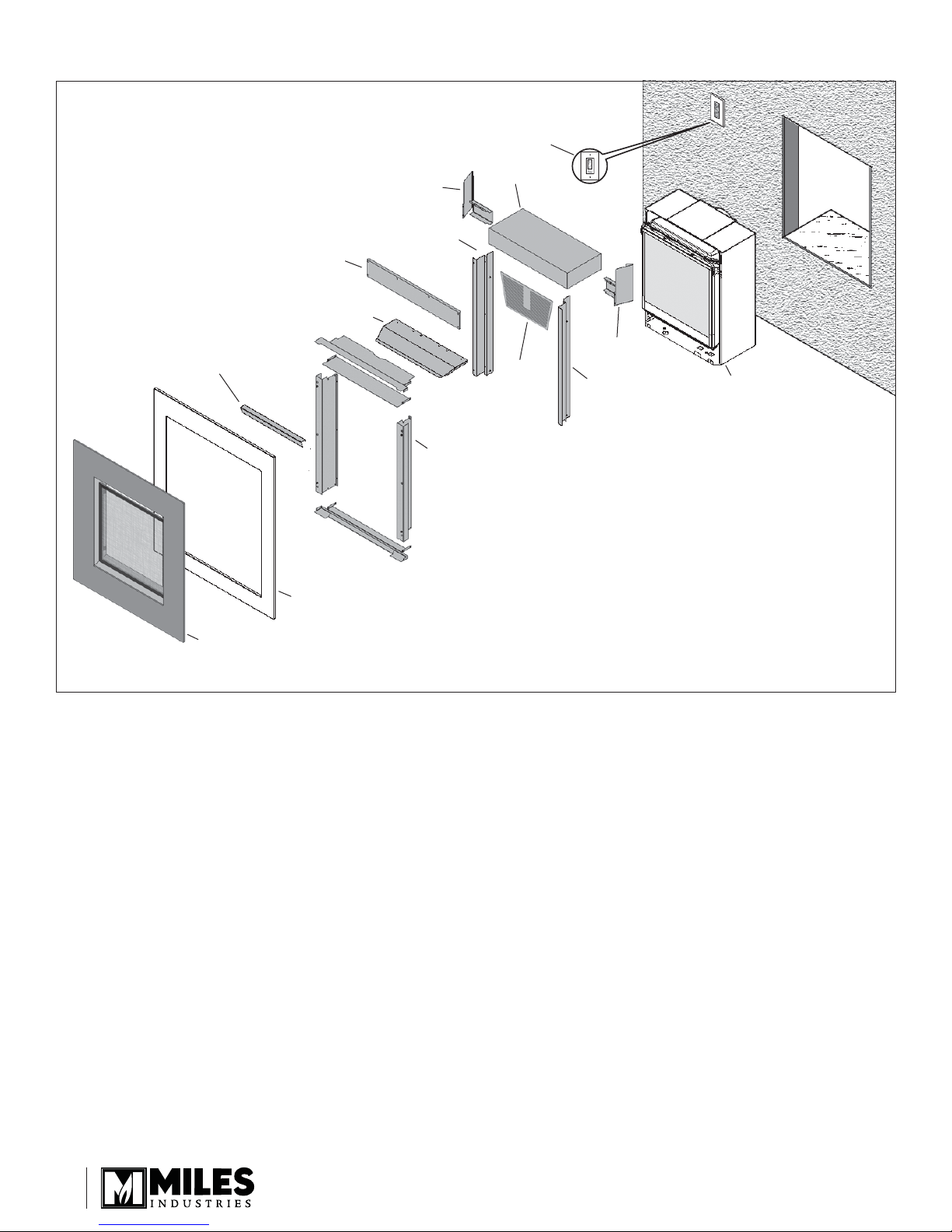

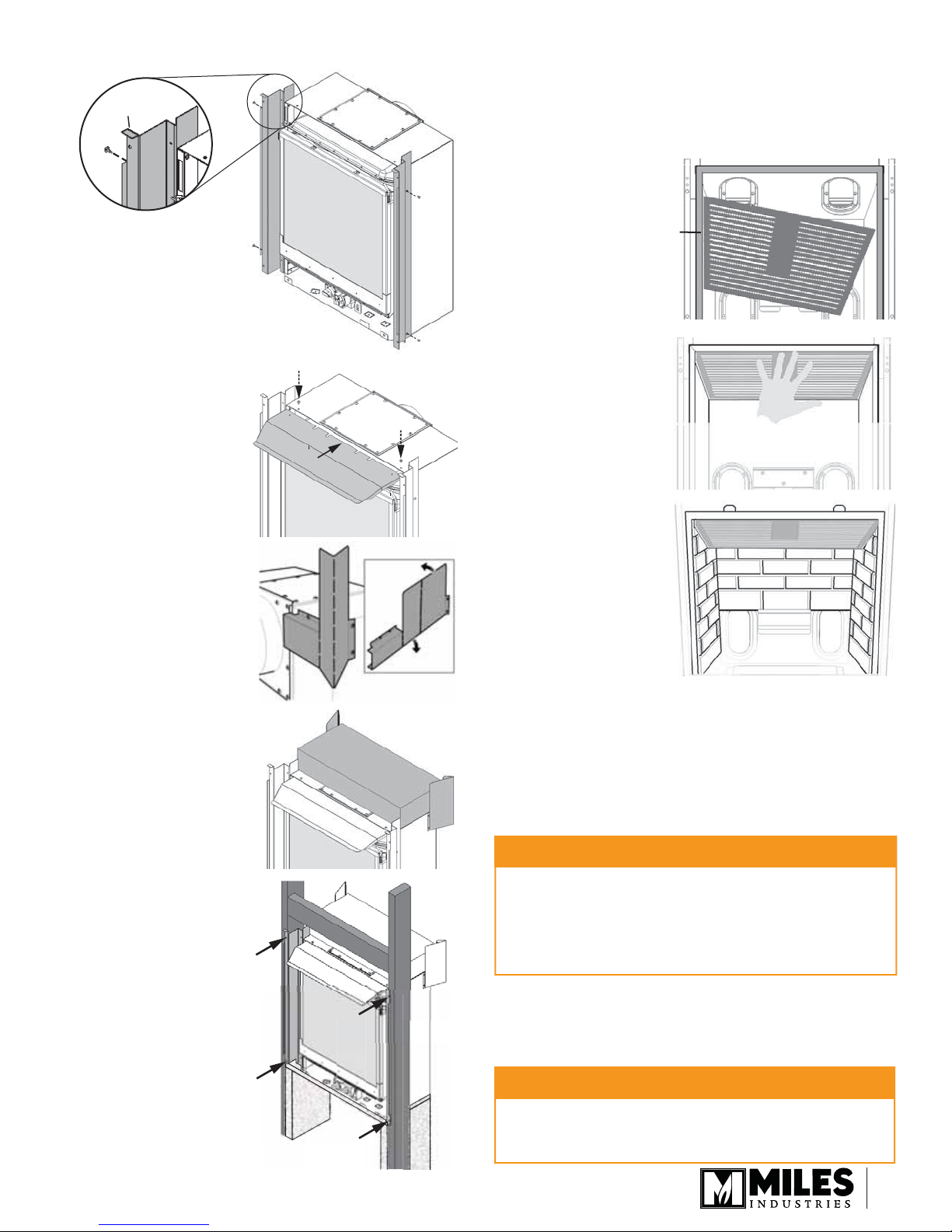

Installation Sequence

1. Frame the cavity.

2. Install the heater with stud brackets, stand-offs, insulation, wall switch

kit, and cement board.

3. Gas fi t and vent heater.

4. Drywall only (no tile, etc.).

5. Assemble and install the mounting frame.

6. Install fi nishing material (tile, etc.). Finish around or under 570 Finishing

Plate if using it.

7. Install the trim panel fi tted with the barrier screen.

4002418-07

© Copyright Miles Industries Ltd., 2013.

Overview

Touch control

wall switch

Window frame cover

Cement board

Convection baffl e

570FPB Finishing Plate

Stand-off

Stud bracket

Mounting

frame

Insulation

Roof

grille

panel

Stand-off

Stud bracket

530 engine

Trim panel —patina, brushed nickel or black—

with barrier screen

(530 engine and 570FPB Finishing Plate sold separately)

2

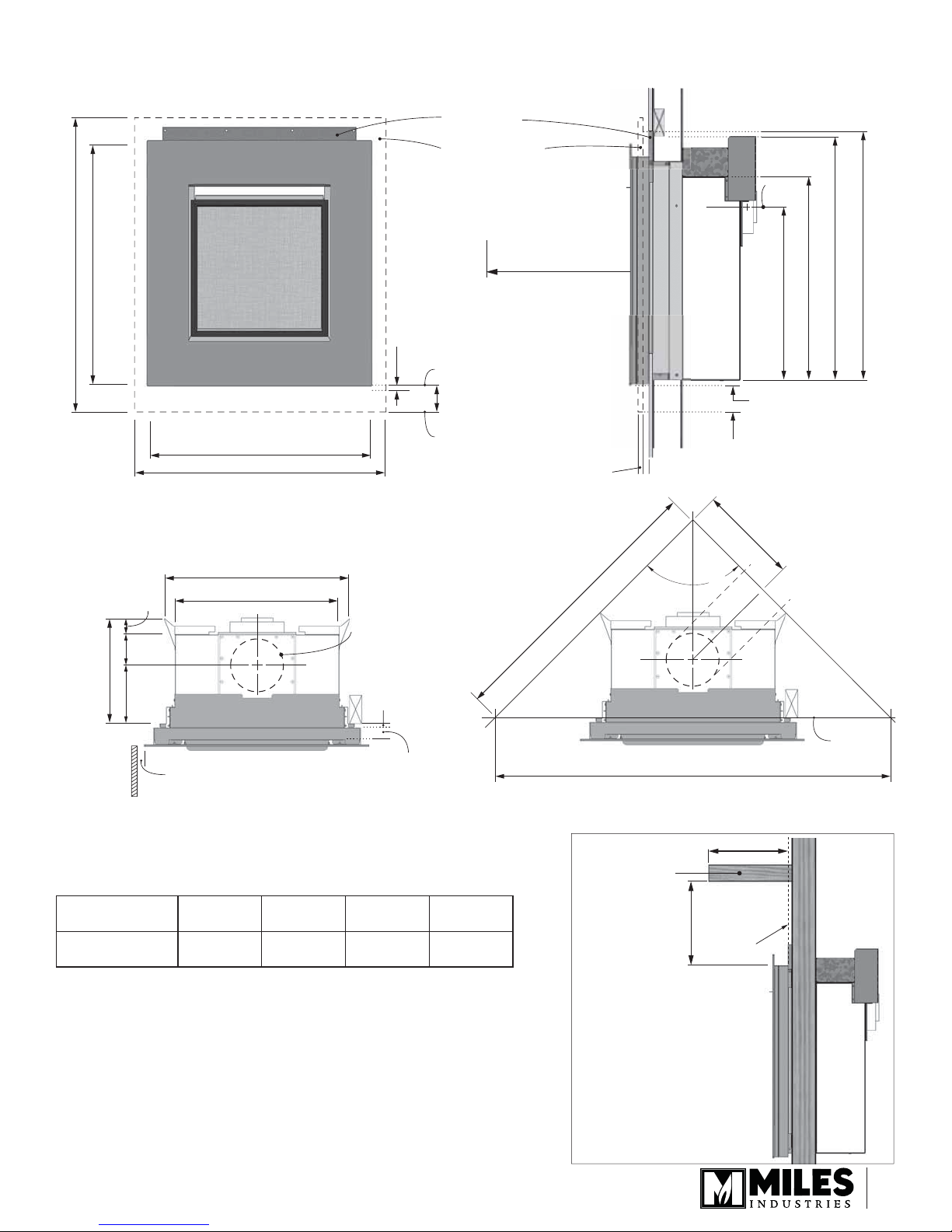

Dimensions & Clearances

30” (762 mm)

36-1/2” (927 mm)

Cement board

570 Finishing Plate

sold separately

1/2” (13 mm) min.

under bottom of

trim for air gap

bottom of trim

Min. 36” (0.9 m) to

combustible materials

center

of vent

21-5/8” (549 mm)

25-1/4” (641 mm)

30-1/4” (768 mm) to header base

31” (787 mm) to cement board top

2”

(51 mm)

12-3/4”

(324 mm)

surface

of wall

nish

to

3-5/8”

(92 mm)

7-1/8”

(181 mm)

2” (51 mm) sidewall

minimum clearance

Mantel Clearances

27-3/8” (696 mm)

31-1/8” (790 mm)

22-1/2” (572 mm)

20” (508 mm)

bottom of 570

570 plate thickness: 1/2” (13 mm)

6-5/8” (168 mm) dia.

cement board

and drywall

thickness:

1/2” (13 mm)

wall nish thickness

over top of drywall:

max 1” (25 mm),

1/2” (13 mm)

when using 570 Plate

3-5/16” (84 mm)

33-15/16” (861.3 mm)

Combustible

4” (102 mm) between

bottom of engine and

bottom of 570 plate

11-15/16”

(302.5 mm)

90°

47-15/16” (1216.9 mm)

mantel

11/16” (17 mm) between

bottom of engine and

bottom of trim

Face of

wall studs

A

Mantel Depth ‘A’

Mantel Height ‘B’

0–6”

(0–152 mm)8”(203 mm)

4”

(102 mm)8”(203 mm)

10”

(254 mm)

10”

(254 mm)

12”

(305 mm)

12”

(305 mm)

Side View

Face of

cement

B

board/

drywall

3

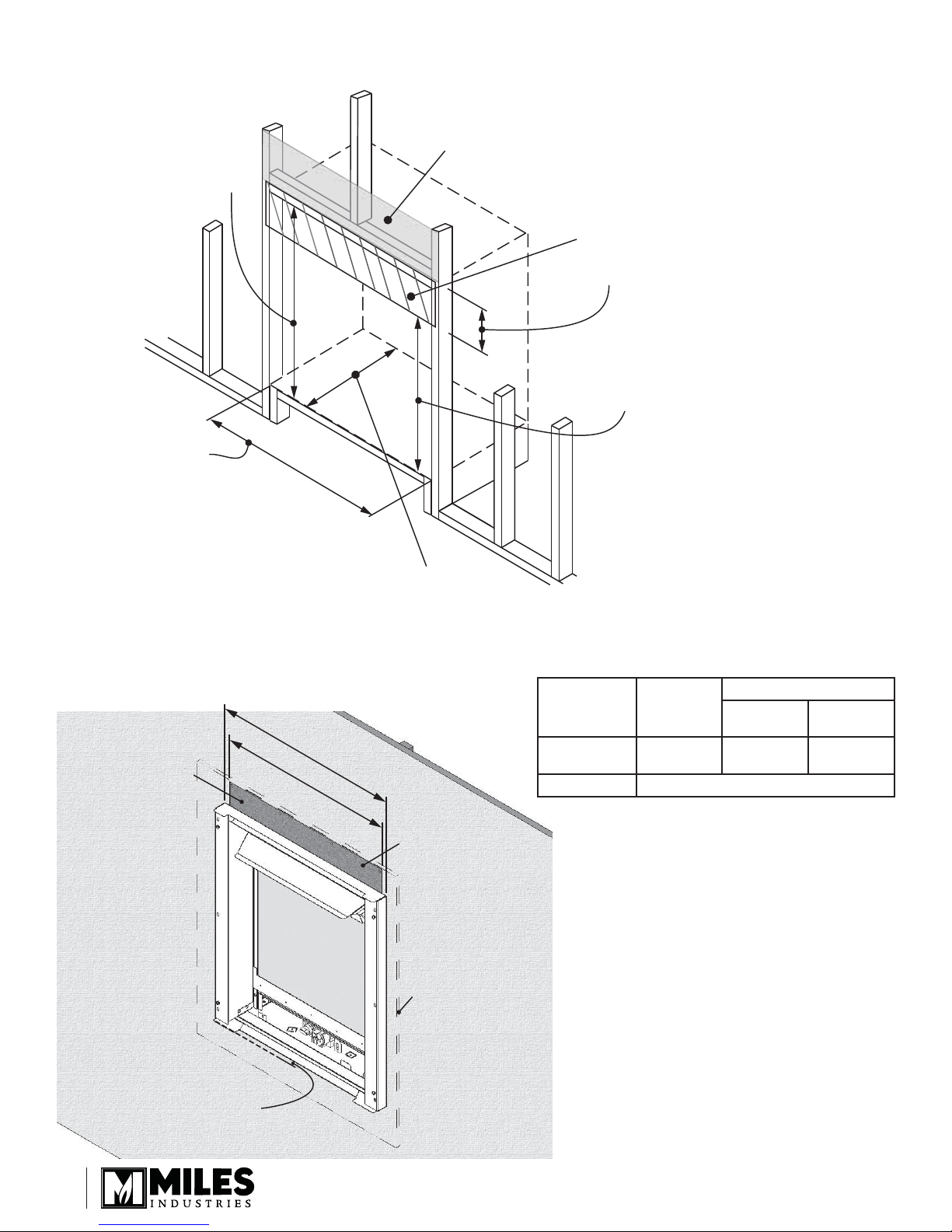

Framing

Wall Finish

30-1/4” (768 mm)

to header

3-5/8” (92 mm)

cement board

supplied

27-3/8” (695 mm) to

cement board

This is the framing

width. Drywall to

23-3/4” (603 mm) wide.

Wall Finish

cement board

drywall

22-1/2” min.

(572 mm)

Minimum 12-3/4” (324 mm)

(Allow extra for rear vent elbow)

25” (635 mm)

23-3/4” (603 mm)

wall nish must be

non-combustible

at top of opening

WALL

FINISH

Tile or fi nish

thickness

Drywall 1/2” (12.7 mm)

no 570

plate

1-1/8”

(30 mm)

with 570 fi nishing plate

tile up to

plate:

1-3/8”

(35 mm)

tile behind

plate:

5/8”

(18 mm)

gap must

remain open

for air ow

4

570 plate outline

Installation

tab at

the top

1. Fit the stud brackets

to the appliance’s

sides (2 screws/

side). Make sure the

horizontal tabs are at

the top.

2. Fit the convection

baffl e to the top of

the appliance case

(2 screws). The

convection baffl e

slips under the top of

the appliance case.

3. Required for

installation

in combustible

construction. Bend

the stand-offs into

shape and fi x them to

the appliance’s case

as indicated (4 screws/

side, pre-fi tted on

engine).

4. Required for

installation in

combustible

construction. Add

insulation pad on the

top of the appliance,

cutting around the pipe

if installing a top vent.

5. Mount the appliance

to the studs with

wood screws (2/side,

not supplied). Make

sure the framing is

leveled.

6. Proceed with the

installation of the

fi rebox, gas fi tting,

venting and so on

as per appliance

instruction manual.

LOGS & ROCKS VERSIONS ONLY. Grille cannot

be used with coal fuel bed version. Install the grille

panel inside the appliance:

a. Insert the grille in the fi rebox by aligning one

of its side edge to the edge of the fi rebox as

indicated.

Grille inserted

parallel to

fi rebox edge

b. Raise the grille up

to cover the top

fi rebox ports

and hold with

one hand.

Note: The port

cover strip

supplied with

the heater is not

required.

c. Place the rear

brick wall. It

should support

the grille. If not,

keep holding it

while you place

the side brick

walls. Refer to

the fi replace

installation manual for more information on

installing the brick walls.

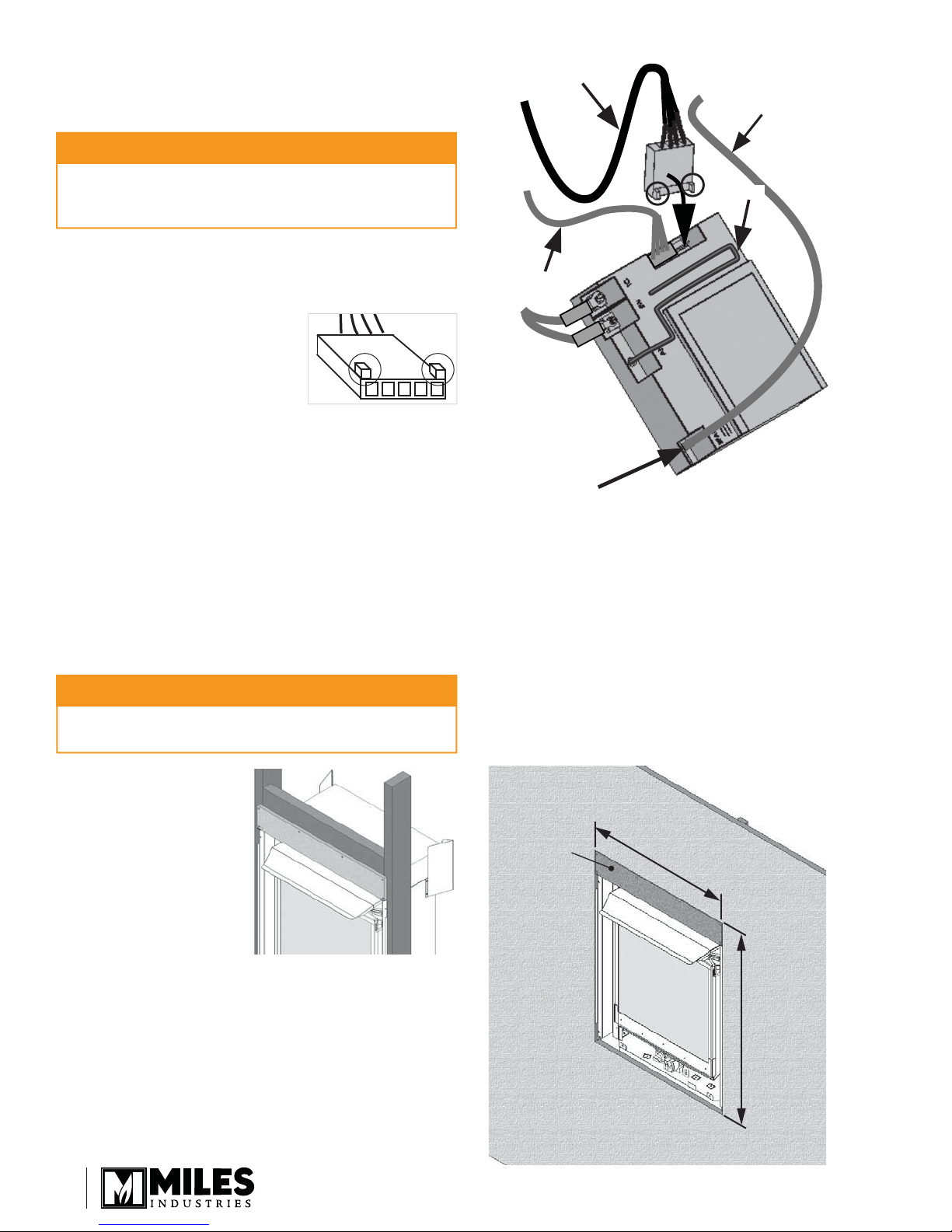

7. Install Touch control wall switch. The wall switch

comes with a 26-foot wire and a cover plate. The

switch is connected to the receiver in the fi replace.

The receiver is located left of the control valve

under the burner module.

CAUTION

DO NOT PUT BATTERIES IN THE REMOTE

CONTROL RECEIVER until the wires are

connected to the burner control unit as shortcircuit could result in the destruction of the

electrical components.

a. Decide where the switch is to be installed. Install

an electrical outlet box (not supplied).

b. Thread the switch wire through an access hole

in the appliance.

CAUTION

Do not run the switch wire over the top of the

fi rebox. Route the wire so it does not contact the

fi rebox.

5

c. Pull out the receiver box. Remove the batteries

from the receiver box if it contains any. You

can remove the ignition wire to improve access

to the receiver.

CAUTION

Wall Switch

Harness

Ignition Wire

DO NOT USE a screwdriver or other metallic object to

remove the batteries from the receiver or the handset!

This could cause a short circuit to the receiver.

d. Take the switch wire and plug it into the

receiver’s connection slot as indicated (the other

slot should already be fi tted with the valve’s wire

harness connector). See diagram at right.

IMPORTANT: The

connection can only be

done one way. Do not

force it or damage the

pins!

e. On the outside of the fi replace, run the switch

wire into the outlet box.

f. Plug the wire into the switch plate and to the

outlet box.

g. Reconnect the ignition wire to the receiver if it

was previously removed.

h. Insert 4 AA batteries in the receiver. Replace the

cover.

i. Test the operation of the wall switch.

j. Fix the wall cover plate to the outlet box.

k. Replace the receiver in its position and as well

as the antenna if deployed.

Antenna

Valve Wire

Harness

Ignition Wire

Connection

(spade type

connector)

Be careful when

removing and

reinstalling: not to

bend or break the

spade connector

CAUTION

To avoid short-circuit to the receiver, position the antenna

so that it DOES NOT TOUCH the ignition wire.

8. Install the cement

board on top of the

appliance. The board

sits on the horizontal

tabs at the top of the

stud brackets.

9. Install the drywall at this point. Although it can be

installed later, the mounting frame for the front will

overlap it.

Wall opening: 23-3/4” (w) x 31” (h)

Note: If tiling, etc. is used overtop of drywall,

complete steps 10, 11, and 12 fi rst as the frame,

once installed, will defi ne where to tile up to.

Cement

board

Drywall opening

23-3/4”

(603 mm)

31”

(787 mm)

6

Loading...

Loading...