LINEAR SERIES

LDK Linear Duct Kits

CSA approved for use with Valor Linear Models 1500J, 1700J & 1800J Heaters ONLY

Installation Instructions

for LDK1, LDK2, LDK3, LDK4, LDK5 & LDK6 Kits

Note: This kit must be installed by a qualifi ed

installer, service agency or gas supplier at

the time of the heater installation. These

instructions are to be used in conjunction with

the fi replace main installation instructions.

Application

This optional convection duct kit redistributes the warm

air fl ow away from the fi replace opening to a more

desirable location using natural convection without

use of a fan. The warm air fl ow may be relocated to

a position higher up the wall, out the sidewalls, or

even to another room. The result is much cooler wall

temperatures above the fi replace opening for locating

televisions, artwork, etc.

The 1595CFK Circulating Fan Kit is not recommended

when installing the LDK Linear Duct Kit.

Any kit, LDK1, LDK3 or LDK4 may be used with any of

the listed model fi replaces.

As a further option, the warm airfl ow may be extracted

away from the duct kit plenum (LDK1 and LDK4 ONLY)

by connecting a 1270RBK Remote Blower Kit to the

duct kit plenum.

This kit is compatible with the “J” series Linear

fi replaces only. Earlier version fi replaces will not accept

the addition of this kit.

Note: These instructions are to be used in conjunction

with instructions supplied with the fi replace.

fi replace requires the removal of the internal

convection baffl e for this system to function

properly—read instructions carefully.

The use of this kit will permit lower mantel clearances

to be used—see page 9. These lower mantel

clearances must only be used when the LDK Duct

system is installed.

Note, the

Approvals

The LDK1, LDK3, LDK4 duct kits are CSA approved

for use only with Valor Linear Series fi replaces listed

above—DO NOT use with any other models.

5-inch diameter duct (not supplied) used with this

kit must be metal and meet requirements of UL-181

Class 1 Air Duct. Flexible aluminum duct is acceptable

provided it meets the UL-181 Class 1 requirements.

Kits

There are 3 kits to choose from:

• LDK1—48” Plenum

• LDK3—14” Plenums (2), includes grilles

• LDK4—38” Plenum

Optional accessories

• LDK2—48” Finishing Frame, to use with LDK1

• LDK5—38” Finishing Frame, to use with LDK4

• LDK6— 5” dia Aluminum 2-ply Flex Kit—

2 x 10’–0” lengths, may be cut to required length

DO NOT cover or place objects in front

of the air outlet(s).

Minimum clearance below the ceiling is 2-1/2”.

Note that staining or streaking may occur on

light colored ceilings due to any dust, etc. in air

fl ow; placing the plenum(s) lower on the wall

will help reduce the possibility of staining or

streaking.

INSTALLER

Leave this manual

with the appliance.

CONSUMER

Retain this manual

for future reference.

WARNING

!

WARNING

!

4005484-02

© Copyright Miles Industries Ltd., 2016.

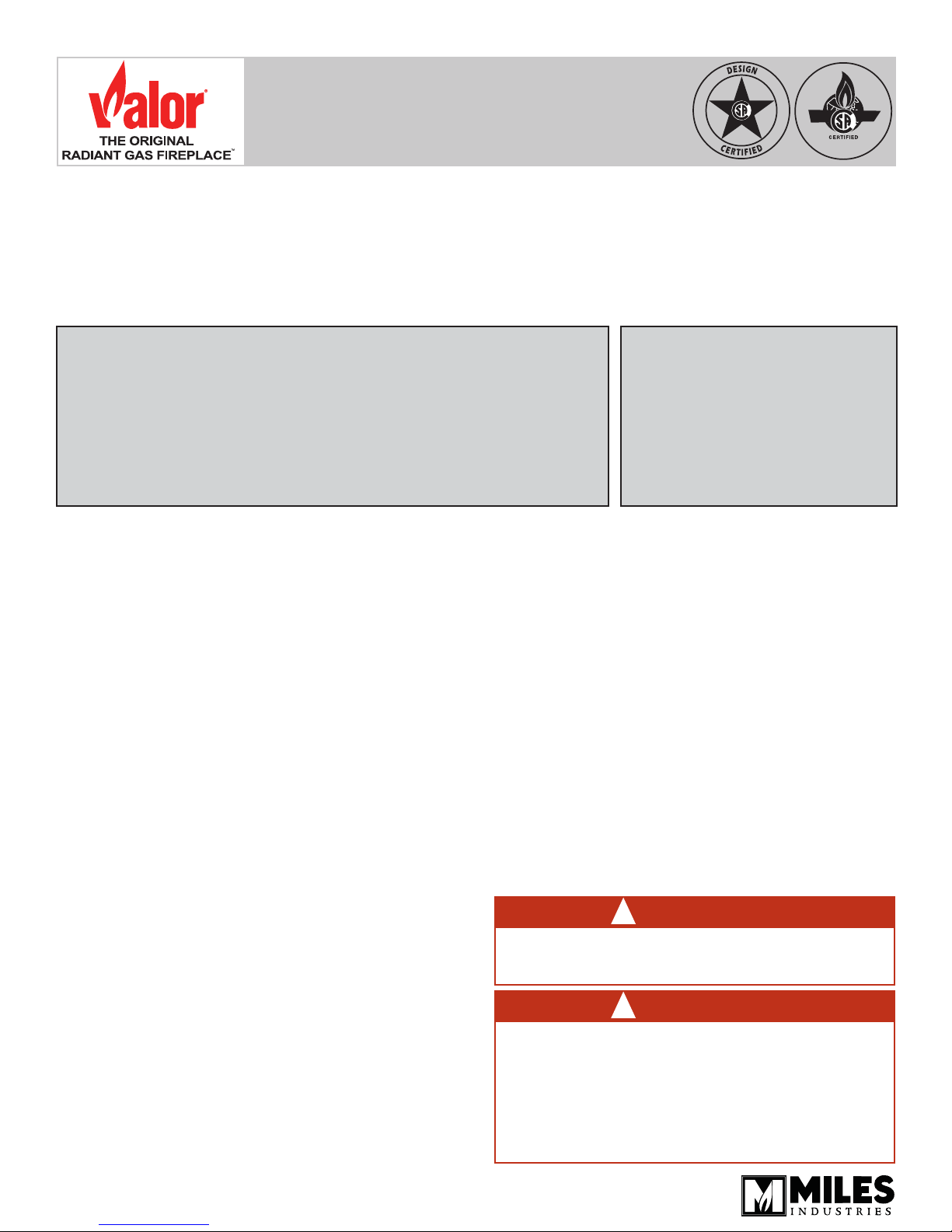

Kits Contents

LDK1

48” x 2”

LDK4

38” x 2”

LDK2 (supplied separately)

48” frame

4 take-off

collars included

LDK3

2 - 14” x 6”

4 take-off

collars included

LDK6

2 - 10’ x 5”

LDK5 (supplied separately)

38” frame

4 take-off

collars included

2 - 14” x 6”

grilles included

2

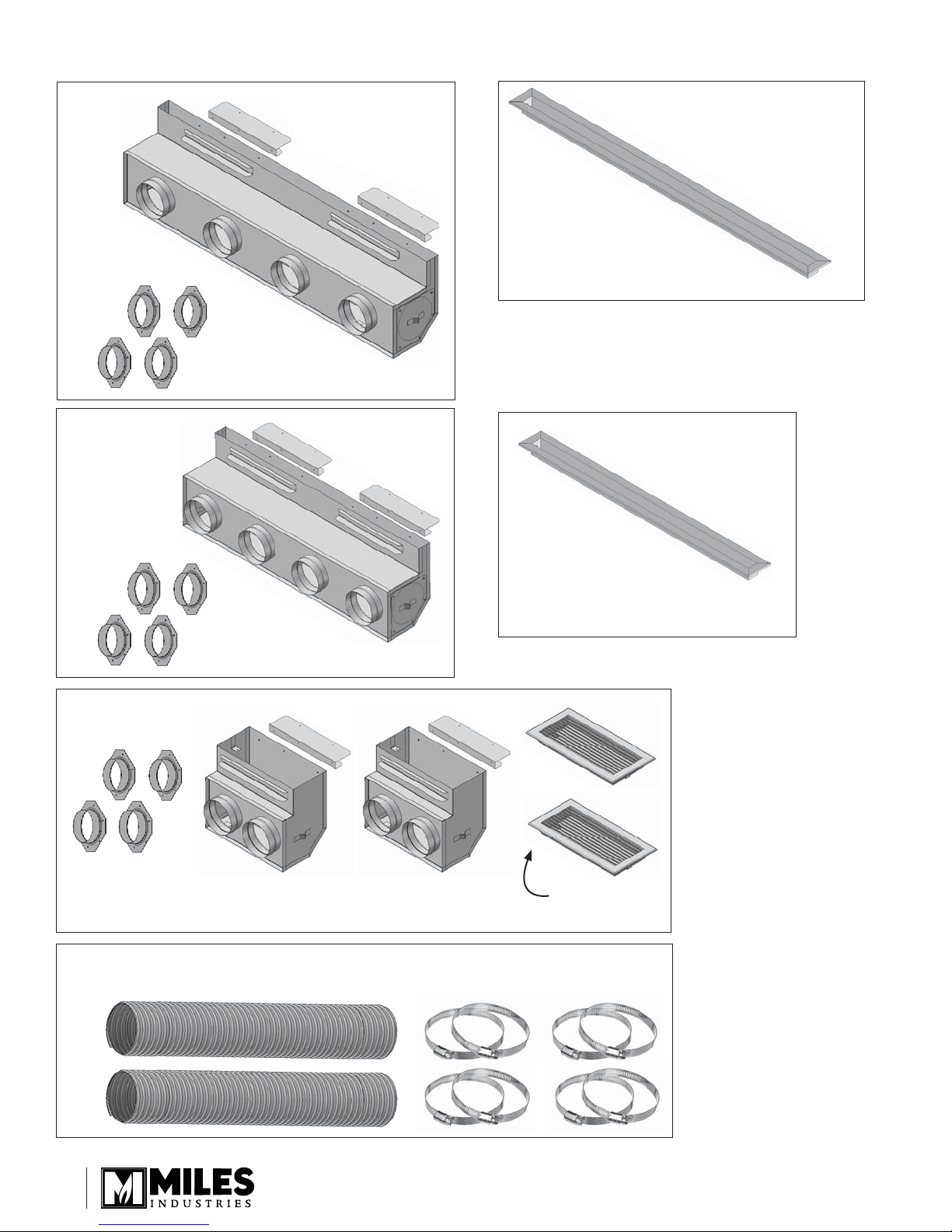

Suggested Confi gurations

WARNING

!

This duct kit is approved for horizontal

discharge ONLY. DO NOT install ple-

num in fl oor or ceiling.

DO NOT DISCHARGE OUTDOORS.

Front wall outlet using LDK1 or LDK4

Rear wall outlet using LDK1 or LDK4

Note: Fireplace vent may confl ict with

plenum. Offset vent around plenum.

Side wall outlets using LDK3

Rear wall outlets using LDK3

Corner installation with front or rear wall outlet

using LDK1, LDK3 or LDK4

3

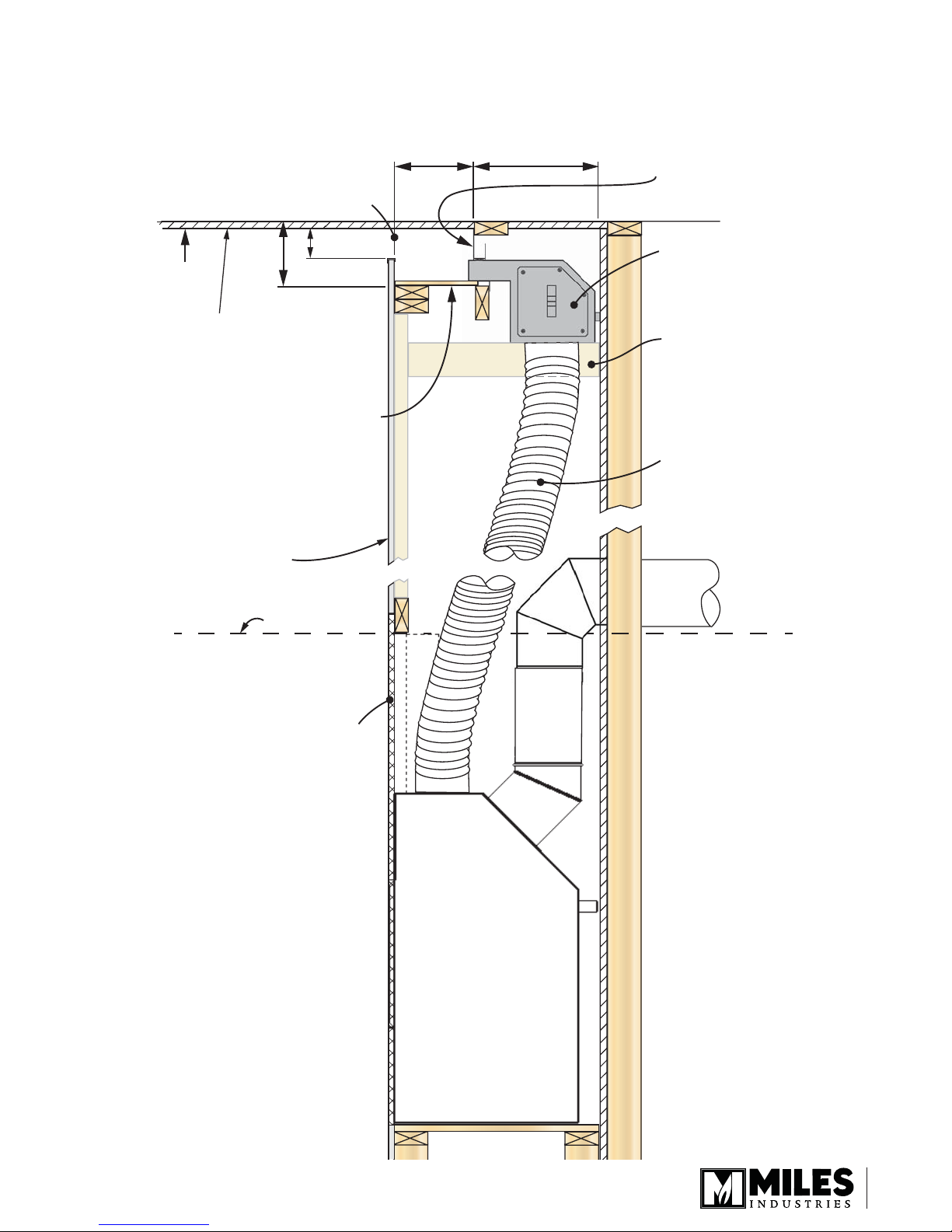

Overview (applies to all kits)

Ceiling

Flexible or rigid,

5” diameter

UL-181, Class 1

Air Duct (4)

(use LDK6 kit

or equivalent)

Min. 1”

clearance to

combustibles

around pipe

Min. 2-1/2”

clearance

to ceiling

8-1/2”

14-1/2”

9-3/8”

Min. 30”, Max. 12’-0”

See table for osets

32-3/8”

Y

Vertical Rise

30” 24”

36” 36”

42” 48”

48” 60”

54” 72”

60” 84”

66” 96”

12’-0” 96” Max.

Max. Allowable

Horizontal

X

Offset

Support horizontal

sections of pipe using

strapping every 24”

5”

Min. bend

+

radius

Top of replace

LDK 1, LDK 3 or LDK 4

8”

Min. bend

radius

+

5”

4

12

DO NOT RUN

pipe horizontal.

Minimum slope 4:12

Min. 2-1/2”

clearance

to ceiling

Min. 1”

clearance to

combustibles

around pipes

Ceiling

Vertical Rise

‘Y’

(Min. 30”

Max. 12’-0”)

Maximum allowable Horizontal Oset

4

‘X’

(oset for take-o

that’s furthest away)

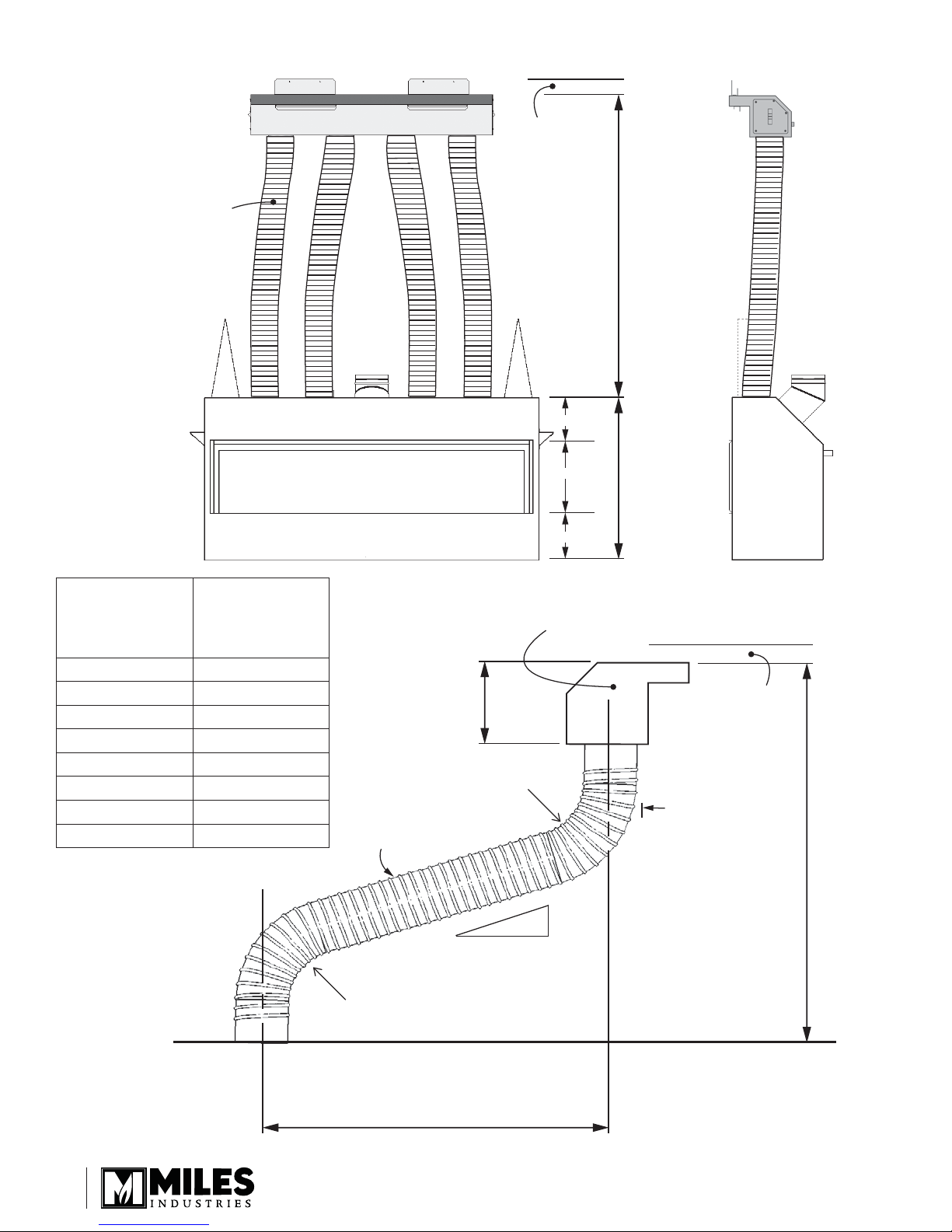

Dimensions

LDK 1

LDK 4

LDK 3

5” dia.

collars (4)

12” LDK 1

5” dia.

collars (4)

48” LDK 1

C

L

12” LDK 1 12” LDK 1

38” LDK 4

C

L

10” LDK 4 10” LDK 4 10” LDK 4

14”

C

1/2” wallboard

11-1/2”

mounting

bracket and

3”

2”

mounting

bracket and

1/2”

stando

3”

1/2”

stando

L

3”

1/2” stando

2”

mounting

bracket and

1/2” stando

1-1/2” stando

8”4”

1/2” wallboard

11-1/2”

mounting

bracket and

1-1/2” stando

8”4”

1/2” wallboard

11-1/2”

mounting

bracket and

1-1/2” stando

1/2”

standos

8”

6” knock-out

each end for

optional

1270RBK

connection

1/2”

standos

8”

6” knock-out

each end for

optional

1270RBK

connection

1/2”

standos

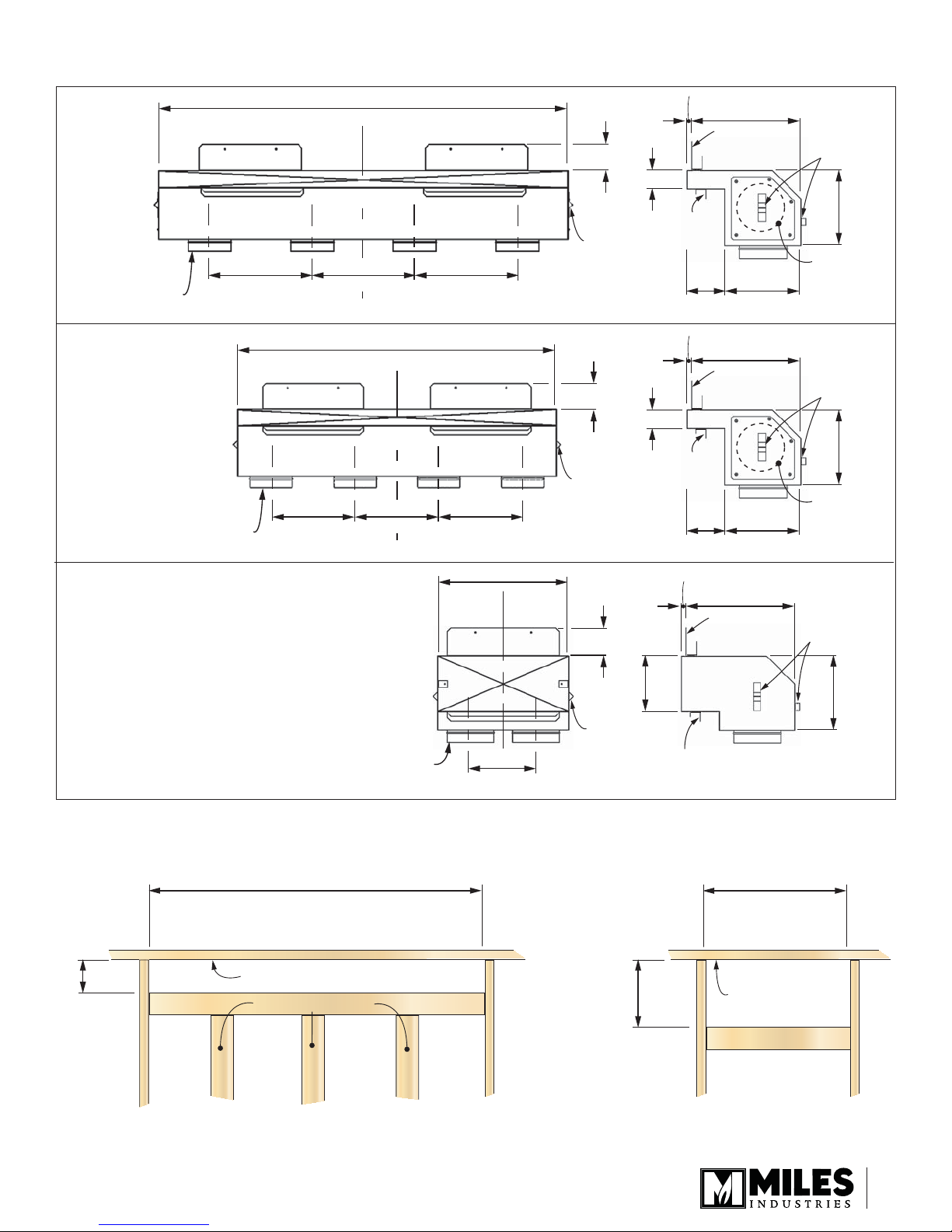

Rough Frame Openings

4”

Min. 1” below nished ceiling

LDK 1 = 49”

LDK 4 = 39”

Framing on edge

5” dia.

collars (2)

6”

1/2”

stando

7”

mounting

bracket and

1/2” stando

8”

LDK 3 = 15”

8”

Min. 1” below

nished ceiling

Framing on edge

LDK 1 & LDK 4 LDK 3

5

Framing and Clearances

Rough Frame Opening

LDK 1 = 49”

LDK 4 = 39”

LDK 3 = 15”

See detail

LDK 1 = 4”

LDK 4 = 4”

LDK 3 = 8”

See Installation

Manual packed

with appliance

for minimum

combustible

cavity dimensions

Rough

Frame

Opening

2 x 4 on edge

2 x 4 on edge

Framing on edge

Min. 1/2”

clearance to

combustibles

at ends

20” min.

LDK 1 & 4

4”

LDK 3

8”

Framing

“on edge”

Framing

“on edge”

Min. 2-1/2” clearance to ceiling

Ceiling

1/2”

Min. 2-1/2” clearance to ceiling

Ceiling

1/2”

1-1/2” min. clearance

to combustibles (top)

1/2” min.

clearance to

combustibles

rear & sides

2 x 4 on edge

to support

plenum.

Maintain 1”

clearance

to pipes

1” min.

clearance to

combustibles

all around pipes

1-1/2” min. clearance

to combustibles (top)

1/2” min.

clearance to

combustibles

rear & sides

1” min.

clearance to

combustibles

all around pipes

6

Alternate Discharge Opening Using Valance Gap At The Top Of Wall

Minimum length

of opening

L1 - 1500 = 40”

L2 - 1700 = 50”

L3 - 1800 = 64”

2-1/2” min.

5-1/2”

Ceiling

Note: Staining or streaking may occur

on light colored ceilings due to any

dust, etc. in air ow. Maximizing the

opening size will help reduce any

staining or streaking.

Discharge cavity requires a base the

entire length of the plenum outlet

as a minimum otherwise beyond

that it may be left open to allow

cavity to ventilate and mix with

discharge air.

Combustible wall

construction

Min. 8” Min. 12”

Space between mounting brackets

may be left open to allow cavity

to ventilate.

LDK 1 & LDK 4 ONLY see clearances on page 6

2 x 4 on edge to support

plenum. Maintain 1”

clearance to pipes.

Min. 1” clearance

around pipes

Top of stand-os

See installation manual packed

with appliance for minimum

combustible cavity dimensions

Non-combustible

cement board

7

Linear Duct Kit LDK 1, LDK 4 with optional 1270RBK Remote Blower Kit

Universal take-o supplied with 1270RBK kit.

Can mount to either end of plenum.

Maximum 1 x 1270RBK kit per plenum.

Note: DO NOT CONNECT 1270RBK directly

See installation instructions packaged

with the LDK Linear Duct Kits

LDK1 or LDK4 plenum

to replace when using LDK Duct Kit;

connect to LDK plenum ONLY as this will

ensure cooler wall temperature whether or

not the 1270 fan is running.

5” dia. piping

Linear 1500J, 1700J or 1800J replaces

8

1270RBK fan unit see diagram for

possible mounting

positions. May be

positioned higher

or lower than

LDK plenum position.

Loading...

Loading...