Installation Manual

Direct Vent Zero Clearance

Gas Fireplace

natural gas 1700KN

propane gas 1700KP

L2

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in serious

injury, death, or property damage.

Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

▪ Do not try to light any appliance.

DANGER

Hot glass

will cause burns.

Do not touch glass

until cooled.

Never allow children

to touch glass.

▪ Do not touch any electrical switch; do

not use a

▪ Leave the building immediately.

▪ Immediately call your gas supplier from

a neigh

supplier’s instructions.

▪ If you cannot reach your gas supplier,

ll the fi re department.

ca

Installation and service must be

performed by a qualifi ed installer, service

agency or the gas supplier.

A barrier designed to reduce

the risk of burns from the hot

viewing glass is provided with this

appliance and must be installed for

the protection of children and

other at-risk individuals.

ny phone in your building.

bor’s phone. Follow the gas

4008056-01

©2019, Miles Industries Ltd.

This appliance may be installed in an

after-market permanently located,

manufactured (mobile) home where

not prohibited by local codes. This

appliance is only for use with the type

of gas indicated on the rating plate.

This appliance is not convertible for

use with other gases, unless a certifi ed

kit is used.

INSTALLER: Leave this manual with the

appliance.

This manual contains instructions to

install the ENGINE ONLY. A trim kit is

REQUIRED to complete the installation.

A barrier screen is provided with the

trim kit. Refer to the manual supplied

with the trim for installation.

This appliance is a domestic roomheating appliance. It must not be used

for any other purposes such as drying

clothes, etc.

CONSUMER: Retain this manual for

future reference.

Massachusetts:

The piping and fi nal gas connection must be

performed by a licensed plumber or gas fi tter

in the State of Massachusetts. Also, see Carbon

Monoxide Detector requirements in the fi replace

installation manual.

WARNING

This product can expose you to chemicals

including Benzene, which is known to the State

of California to cause cancer and birth defects or

other reproductive harm. For more information

go to www.P65Warnings.ca.gov.

Note: Natural gas, in its original state, contains

Benzene.

This appliance is suitable for

installation in a bedroom or bed

sitting room.

Ce guide est disponible en français sur demande.

Valor Fireplaces

190–2255 Dollarton Highway

North Vancouver, BC, Canada V7H 3B1

T 604.984.3496 F 604.984.0246

valorfi replaces.com

2

The information contained in this manual is believed

to be correct at the time of printing. Miles Industries

Ltd. reserves the right to change or modify any

information or specifi cations without notice. Miles

Industries Ltd. grants no warranty, implied or stated,

for the installation or maintenance of your heater,

and assumes no responsibility for any consequential

damage(s).

© Copyright Miles Industries Ltd., 2019. All rights reserved.

Designed and manufactured for Miles Industries Ltd.

Welcome to Valor

®

This appliance has been professionally installed by:

Dealer Name: ________________________________

Phone:______________________________________

Fireplace Safety ................................................. 4

Specifi cations ..................................................... 6

Kits & Accessories .............................................. 7

Dimensions & Location ..................................... 8

Installation Planning ......................................... 9

Before Installing ............................................................9

Overview ......................................................................10

Mantel Clearances ......................................................11

Framing .........................................................................13

Wall Finish ....................................................................16

Material Specificat ions ..............................................16

Non-Combustible Cement Board ............................16

Avoiding Cracking Wall Finishes ...............................18

Venting .............................................................. 19

Overview ......................................................................19

Co-Axial ....................................................................... 20

Typical Co-axial Venting Components ....................20

Venting Chart ..............................................................21

Restrictor Settings .....................................................22

Horizontal Vent Termination ....................................23

Vertical Vent Termination .........................................24

Co-Linear Conversion ................................................ 25

Installation into existing fireplace cavity ................25

Installation partially into fireplace cavity ...............26

Installation into existing adjacent chimney ...........27

Example of co-linear conversion accessories........28

Installation ....................................................... 29

Appliance Preparation .............................................. 29

Unpack Appliance ......................................................29

Fit Standoffs ................................................................29

Remove Heat Shield ...................................................29

Convert from Top to Rear Outlet (if required) .......30

Fit Appliance into Framing ........................................31

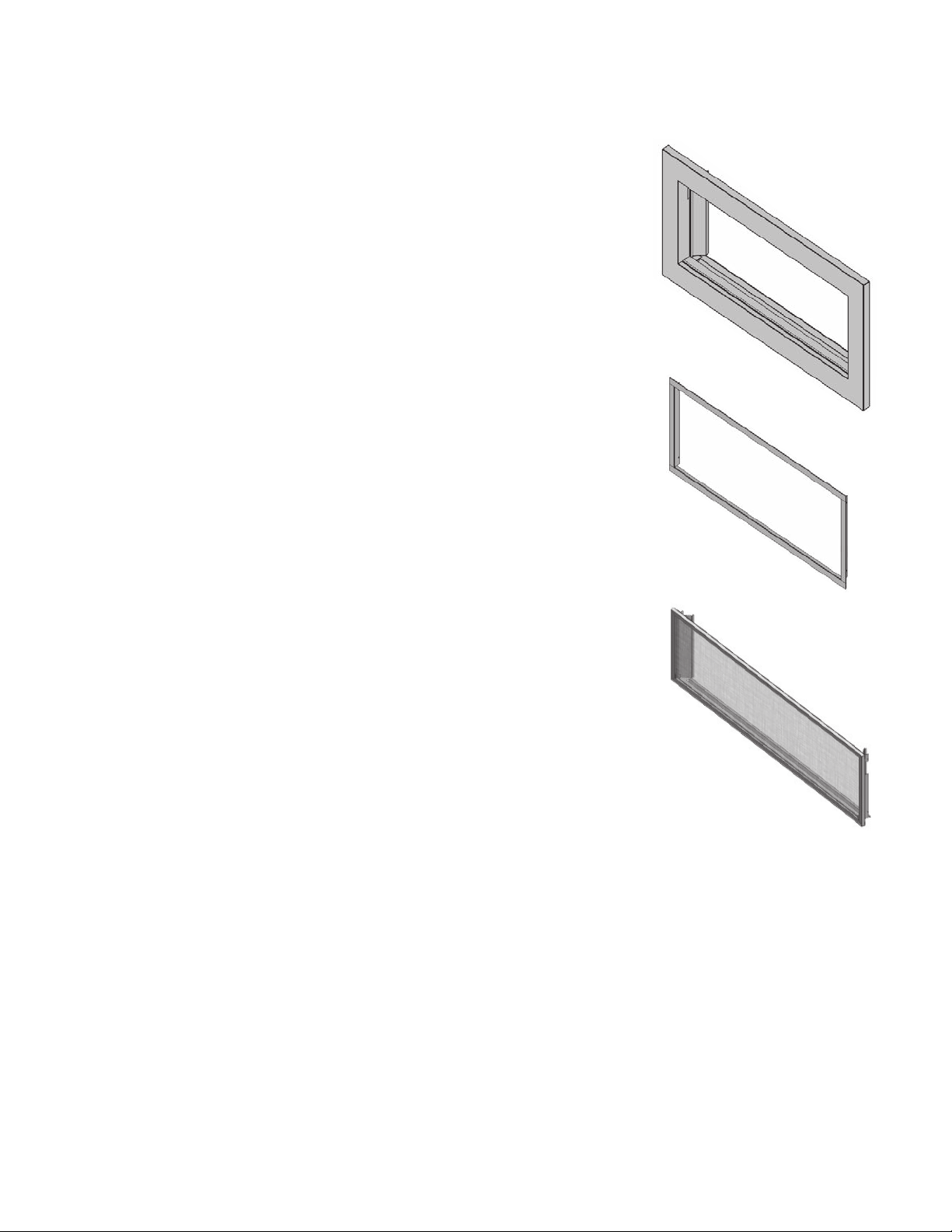

Remove Window ........................................................32

Please read this manual BEFORE

installing and operating this

appliance.

HeatShift™ System—if used .................................... 33

Install HeatShift Take-Off Collars to Appliance .....33

Remove Convection Baffle .......................................33

Electrical Wiring ......................................................... 34

Gas Supply ................................................................... 36

Liners ........................................................................... 38

Fuel Beds ..................................................................... 40

Driftwood Kit 1705DWK ........................................... 40

Decorative Glass Murano 1700DGM.......................43

Rocks & Shale Set 1714RSS ...................................... 44

Split Wood Kit 1700SWK ............................................47

Birch Log Kit 1700BLK ................................................50

Window Re-Installation & Checking ....................... 53

Wall Switch .................................................................. 54

Remote Control Pairing ............................................. 56

Checking Operation and Aeration .......................... 58

Trim & Barrier Screen ................................................ 59

Wiring Diagram ................................................ 60

Approved Venting Components .................... 61

Commonwealth of Massachusetts ............... 63

Appendix A—Lighting Instructions ............... 65

Appendix B—Remote Control Operation .... 66

Appendix C—Wall Switch Operation ............73

Appendix D—HeatShift™System .................. 74

Appendix E—Spare Parts ............................... 94

3

Fireplace Safety

This manual contains very important information about the safe installation and operation of the fi replace. Read and

understand all instructions carefully before installing and operating the fi replace. Failure to follow these instructions

may result in possible fi re hazard and will void the warranty.

Replacement manuals are available by contacting the Valor Customer Service at 1-800-468-2567, or by visiting

valorfi replaces.com.

WARNING: Extremely Hot!

Heat and fl ammability

• Some parts of the fi replace are extremely hot, par-

ticularly the glass windows. Use the barrier screens

provided or a gate to reduce the risk of severe burns.

• The glass windows can exceed 500°F (260°C) at full

capacity.

• Always keep the appliance clear and free from combustible materials, gasoline, and other fl ammable

vapors and liquids.

• Be aware of hot wall surfaces! The walls directly above

the fi replace can get very hot when the fi replace

heats. Although safe, it may reach temperatures in excess of 200ºF (93°C) depending on choice of optional

accessories. Do not touch!

• Be aware of hot hearth/fl oor surfaces! Any projections

directly around the fi replace can get very hot when

the fi replace heats. Although safe, they may reach

temperatures in excess of 200ºF (93°C)depending on

elevation of hearth. Be careful of touching these! Temperature of projection surfaces will be reduced when

barrier screens are installed.

• Some materials or items, although safe, may discolor,

shrink, warp, crack, peel, and so on because of the

heat produced by the fi replace. Avoid placing candles,

paintings, photos and other combustible objects

sensitive to heat or furniture within 36 inches (0.9m)

around the fi replace.

)LUHSODFH

Hearth

Do not put

furniture or other objects

in this space in front of

WKHȴUHSODFH

36” [0.9 m]

• Any safety screen, guard, or barrier removed for servicing an appliance must be replaced prior to operating the appliance.

• Children and adults should be alerted to the hazards

of high surface temperature and should stay away to

avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance. Toddlers,

young children, and others may be susceptible to

accidental contact burns. A physical barrier is recommended if there are at-risk individuals in the house. To

restrict access to a fi replace or stove, install an adjust-

able safety gate to keep toddlers, young children, and

other at-risk individuals out of the room and away

from hot surfaces.

• Due to its high temperatures, the appliance should be

located out of traffi c areas and away from furniture

and draperies.

4

• A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this appliance

and shall be installed for the protection of children

and other at-risk individuals.

• Clothing or fl ammable material should not be placed

on or near the appliance.

Fireplace Safety

Glass windows

WARNING

Do not operate this appliance with the

glass front removed, cracked, or broken.

Replacement of the glass front should

be performed by a licensed or qualified

service person. Do not strike or slam the

glass front.

• The glass front assemblies must be in place and

sealed before the unit can be placed into safe

operation.

• The glass front assemblies must only be replaced as

complete units, as supplied by the fi replace manufac-

turer. No substitute material may be used.

• Do not use abrasive cleaners on the glass front assemblies. Do not attempt to clean the glass when

it is hot.

Intended use

• This appliance is designed and approved as a supplemental heater and provides the potential for most

energy conservation when used while attended. The

use of an alternate primary heat source is advisable.

• This unit is not for use with solid fuel.

• Do not use this heater as a temporary source of heat

during construction.

Installation and Servicing

• Installation and repair should be done by a qualifi ed

service person. The appliance should be inspected

before use and at least annually by a professional

service person. More frequent cleaning might be

required due to excessive lint from carpeting, bedding

material, et cetera. It is imperative that control compartments, burners, and circulating air passageways

of the appliance be kept clean.

Venting

• This unit must be used with a vent system as described in this manual. No other vent system or components may be used.

• Never obstruct the fl ow of combustion and ventilation

air. Keep the front of the appliance clear of all obstacles and materials for servicing and proper operation.

• This gas fi replace and vent assembly must be vented

directly to the outside and must never be attached to

a chimney serving a separate solid fuel burning appliance. Each gas appliance must use a separate vent

system. Common vent systems are prohibited.

WARNING

Side outlets

Ceiling outlet

Front outlet

HeatShift

System:

Do not cover

or place items

in front of or

above outlet(s)!

5

Specifications

Approval & Codes

This appliance is certifi ed to ANSI Z21.88-2017/CSA

2.33-2017 American National Standard / CSA Standard

for Vented Gas Fireplace Heaters for use in Canada

and USA, and to CGA 2.17-91 High Altitude Standard in

Canada. This appliance is for direct vent installations.

This appliance complies with CSA P.4.1-15 Testing

method for measuring annual fi replace effi ciencies.

The installation must conform to local codes or, in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 or the Natural Gas

and Propane Installation Code CAN/CGA-B149.1. Only

qualifi ed licensed or trained personnel should install

this appliance.

This appliance must be electrically grounded in

accordance with local codes, or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70

or the Canadian Electrical Code, CSA C22.1.

Ratings

Model 170 0KN 1700KN

Gas

Altitude (Ft.)*

Input Maximum (Btu/h)

Input Minimum (Btu/h)

Manifold Pressure (in w.c.)

Minimum Supply Pressure (in

w.c.)

Maximum Supply Pressure (in

w.c.)

Main Burner Injector Marking

Pilot Injector Marking

Min. Rate By-Pass Screw

Natural Propane

0-4,500 feet*

36,000 36,000

21,000 22,500

4” 10”

5” 11”

10” 14”

DMS#32 DMS#49

51 3 0

220 160

*High Altitude Installations

Input ratings are shown in BTU per hour and are

certifi ed without deration for elevations up to 4,500

feet (1,370 m) above sea level.

For elevations above 4,500 feet (1,370 m) in USA,

installations must be in accordance with the current

ANSI Z223.1 and/or local codes having jurisdiction.

Heating value of gas in some areas is reduced to

compensate for elevation—consult your local gas

utility to confi rm.

For installations at elevations above 4,500 feet

(1,370 m) in Canada, please consult provincial and/or

local authorities having jurisdiction.

Supply Gas

Heater engine 1700KN uses

natural gas.

Heater engine 1700KP uses

propane gas.

The supply pressure must be

between the limits shown in the Ratings section.

The supply connection is 3/8” NPT male and located on

the left hand side of the fi rebox. A shut-off valve (not

supplied) is required on the supply line to isolate the

unit during service. See Gas Supply Installation section

for details.

X

Conversion Kits

The 1700K are supplied as natural gas or propane

gas and are fi eld convertible between fuels. See

instructions packaged with the conversion kits for

further information.

Electrical

The 1700K are designed to run on battery power and

do not require an electrical power source to operate

as a heater. However, they require electrical power

to operate optional 1595CFKV2 Circulating Fan Kit,

GV60WIFI WiFi Kit or 1270RBK Remote Blower Kit.

HeatShift™System

The 1700K are designed to allow the installation of the

optional HeatShift System, a convection system that

redistributes the warm air fl ow away from the fi replace

opening to a more desirable location using natural

convection, without use of a fan.

The warm air fl ow may be relocated to a position higher

up the wall, out the sidewalls, or even to another room.

The result is much cooler wall temperatures above the

fi replace opening for locating televisions, artwork, etc.

Please note that the framing and mantel clearances

are aff ected by the installation of the HeatShift

System. Refer to “Appendix D—HeatShift™System™” on

page 74 for more information.

Outdoor Conversion Kit

The 1700K models are supplied standard for indoor

applications and may be adapted for installation in

specifi c “outdoor” applications protected from weather

as defi ned in the GV60CKO outdoor conversion kit

manual.

6

Kits & Accessories

Required Kits Information accurate at the time of printing and subject to change

without notice.

Fuel Beds (choose one)

1705DWK Driftwood Kit

1700DGM Decorative Glass Murano Kit

1714RSS Rock & Shale Kit

1700SWK Split Wood Kit

1700BLK Birch Logs Kit

Liners Panels (choose one)

1715FBL Fluted Black Liners

172 5RGL Re fl ective Glass Liners (requires 1725RGL-3 Glass Retainer Kit)

1735LML Limestone Liner Set

1740SSL Stacked Stone Liners

Trims (choose one) Barrier Screen

1730CIK Clean Install Kit - Fine Mesh - REQUIRES HeatShift 4007675

1750v2 Linear 3-1/2” Surrounds 4004221

1775LFB Linear 1” Finishing Trim Black 4005562

Optional Accessories

Information accurate at the time of printing and subject to change

without notice.

Gas Conversion Kits

1700KNGK Conversion to natural gas

1700KPGK Conversion to propane gas

Other Accessories

GV60WIFI WiFi kits - REQUIRES GV60 V-module

GV60CKO Outdoor Fireplace Conversion Kit

1506DRK Additional rocks for Driftwood Kit

1595CFKV2 Circulating Fan Kit - REQUIRES GV60 V-module

1270RBK Remote Blower Kit

LDK HeatShift System Kits (gravity fl ow) - MANDATORY with 1730CIK

Hearth Gate

Hearth gates such as Cardinal’s VersaGate are available at retail stores carrying

safety products for children.

WARNING

HeatShift System MUST be installed on

this appliance when using 1730CIK—Clean

Installation Kit!

WARNING

Optional electrical accessories ARE NOT

ALLOWED when adapting appliance for

outdoor use.

7

i

[

]

p

f

[

]

f

r

Electrical

I

t

G

A

t

Z

6WDQG2V

r

C

r

Li

.

g

ȴ

e

f

t

C

t

H

q

r

t

app

57-3

]

]

6”

]

1

6”

]

[383

18

2”

[470

]

3-3/4”

[9

]

”

[10

m]

8

0

]

3

8

[822

]

8

[8

]

2

[369 m

m]

9-3/8”

[238 m

m]

52” [ 132

]

262

]

1270

B

(

H

p

1270

e

(

Zero Clearance

WR6WDQGRV

DW%DFNDQG6LGHV

Zero Clearance

DWEDFNFRUQHUV

88” [2235 mm]

20-1/2”

[519 mm]

Ze

ro Clearance

DW

EDFNFRUQHUV

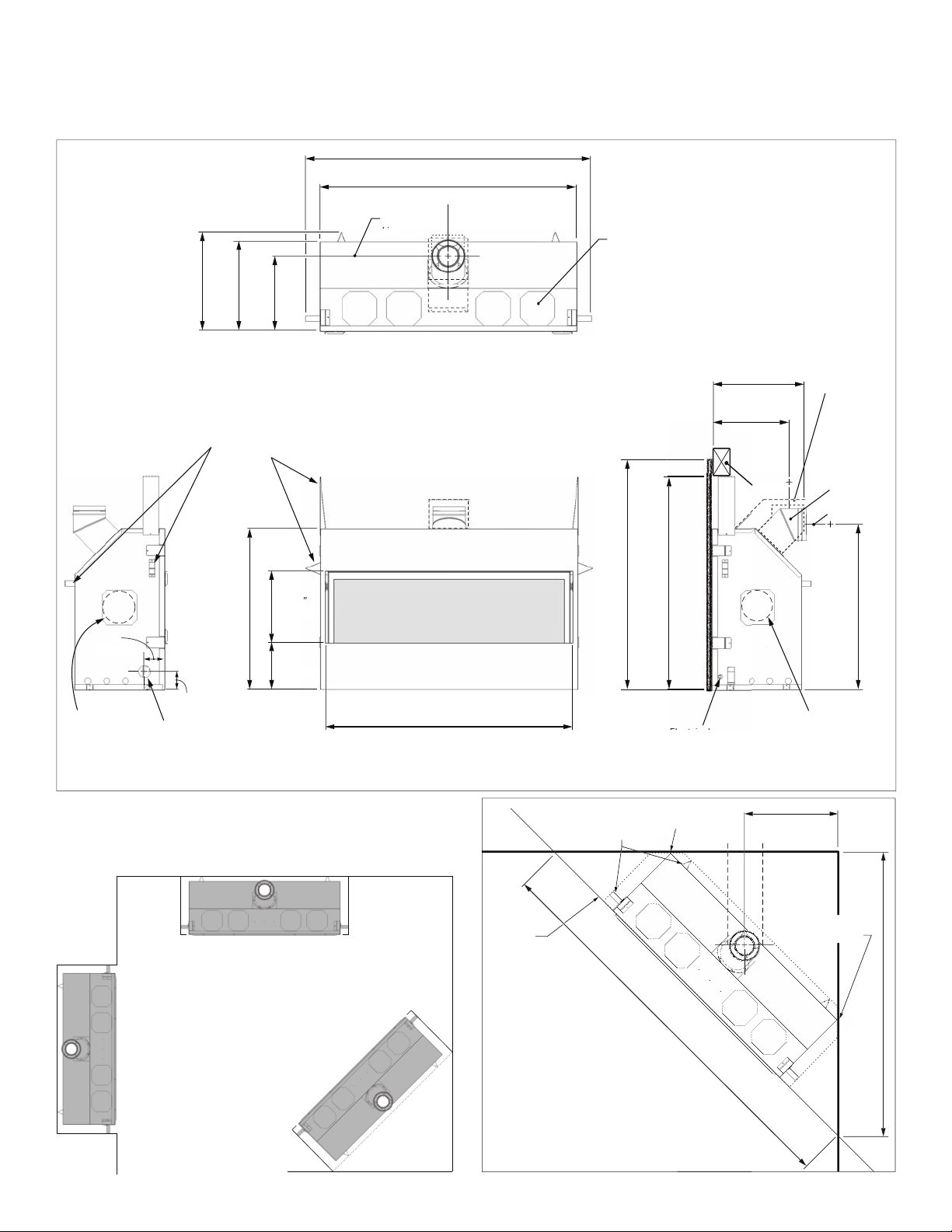

Dimensions & Location

Dimensions

4

2 m

”

-7/

5 mm

5

ero Clearance

457 mm

mm

”

/

-

5-1/1

14-1/

mm

/4” [ 1467 mm

1 mm

ente

ne

Top V iew

eatShift System

outlets (remove

1130 mm

1092 mm

cement board

o

n. 44-1/2”

to to

M

Min. 43”

lates)

heade

underside o

5-1/1

-1/

mm

mm

Heade

eat shield

re

uired fo

rear ven

outlet

lications

6-5/8” dia

Ventin

HOG

convertibl

rom top to

rear outle

enter of ven

41 mm

”

-1/

Blower Kit outlet

remove plate)

Location

8

RBK Remot

5 mm

as Line

ccess Poin

49-11/16” [ 1

mm

nlet Poin

Front ViewLeft Side View Right Side View

Corner Dimensions

RBK Remote

lower Kit outlet

remove plate)

Installation Planning

Caution

Only qualified, licensed, or trained personnel

should install this appliance.

1. YOU NEED TO KNOW FROM THE HOMEOWNER:

• Will optional HeatShift System

• Height of appliance and shelf, if used;

• Thickness and type of wall fi nish around

appliance;

• Trim used

• Other optional accessories used (if any);

• Venting confi guration.

2. Unpack the appliance, removing all items packed

inside and around it. Recycle the packaging.

3. Check that you have everything, using the Pack Content sheet. Also, check that you have:

• Fuel bed (packed separately);

• Liner panels (packed separately);

• Remote Battery and Wall Switch Kit;

• HeatShift System components (if used);

• Gas conversion kit (if necessary);

• Venting accessories;

• Electrical accessories (if used).

4. Carefully read the Installer’s Checklist included with

the fi replace for the installation sequence.

*

;

*

be used;

Before Installing

WARNING

*

HeatShift System MUST be installed on

this appliance when using 1730CIK—Clean

Installation Kit!

9

ndPlate

ept

ard

d

im.730

f

t.

im.

e

ard

.

in

is

Any

k

pag

pg

pg

e p

p

p

age

g

g

g

.

Installation Planning

Overview

Note: This appliance may be installed in outdoor, weather protected environments as defi ned in the GV60CKO

Outdoor Conversion Kit instruction manual.

Mantel—See Mantel & Hearth Clearances

Framing—See Framing Requirements

rrou

ith Barrier Screen

required)

Nar

ow 1” Trim 1775LFB and

wid

r 3-1/2” steel Trim 1750

table, acc

on-combustible finish over

Cement board finishes up to

Not

173 0 C I K in s tal l s befor

wall finishes applied

ver cement board must

be non-combustible.

Combustible mantel are o

rovided they conform to

chart on

additional

cement

behind tr

CIK’s narrow trim

uires HeatShi

imeter of tr

cement

an

11

1/2 inch thick non-combustible cement board –NOT supplied

Supplied as vertical outlet, fi eld convertible to horizontal

outlet. Note - Vertical rise required in vent system

Optional HeatShif t System

outlets (4)—Required with

173 0C IK

170 0 K hea t er

Remote Battery

and Wall Switch Kit

(required) (35-foot wire

length) (supplied)

Remote

Handset

Wall Holder

Electrical

junction box

(not supplied) to

connect power

when using

optional fan, WiFi

Combus tible Floor

Hearth: not required.

If used, must be minimum 4”

below fi replace opening unless

using HeatShift (see “Appendix D—

HeatShift™System” on page 74)

WARNING

Some materials or items, although safe,

may discolor, shrink, warp, crack, peel,

and so on because of the heat produced

by the fireplace. Avoid placing candles,

paintings, photos, and other items

sensitive to heat around the fireplace.

10

Combustible Framing Allowed Beneath Fireplace. When the appliance

is installed directly on carpeting, tile or other combustible material

other than wood fl ooring, the appliance shall be installed on a metal

or wood panel extending the full width and recessed depth of the

appliance.

WARNING

HOT WALL SURFACES! The wall directly

above the fireplace is constructed of noncombustible materials and, although safe,

it may reach temperatures in excess of

200°F (93°C) depending on choice of trims.

Do not touch. Finish wall using materials

suitable for these temperatures.

Installation Planning

Combustible Mantel—Left Side View

NOTE

Use for the optional HeatShift

System affects mantel and hearth

clearances. See HeatShift section in

Appendix D of this manual.

WARNING

HeatShift System MUST be installed

on this appliance when using

1730CIK—Clean Installation Kit!

(from Face of Cement Board)

0 2” 4” 6” 8” 10”12”

Mantel Projection

Mantel Clearances

Ceiling

44”

Mantel

42”

Height

(from

40”

38”

Bottom

of Unit)

24” Min. to Ceiling

Face of 1/2” thick

non-combustible

cement board

Fireplace

Opening

4” minimum to

combustible or

non-combustible hearth

Bottom of Unit

23-7/8”

Do not put

furniture or objects

within 36” (914 mm)

of front of appliance

9-3/8”

11

Installation Planning

Combustible Sidewall / Mantel Leg—Top View

Face of

Finished

Wall

Mantel Clearances

FIREPLACE

Fireplace Opening

49-11/16”

Wall

Min. 4” to

wall or

combustible

mantel leg

12

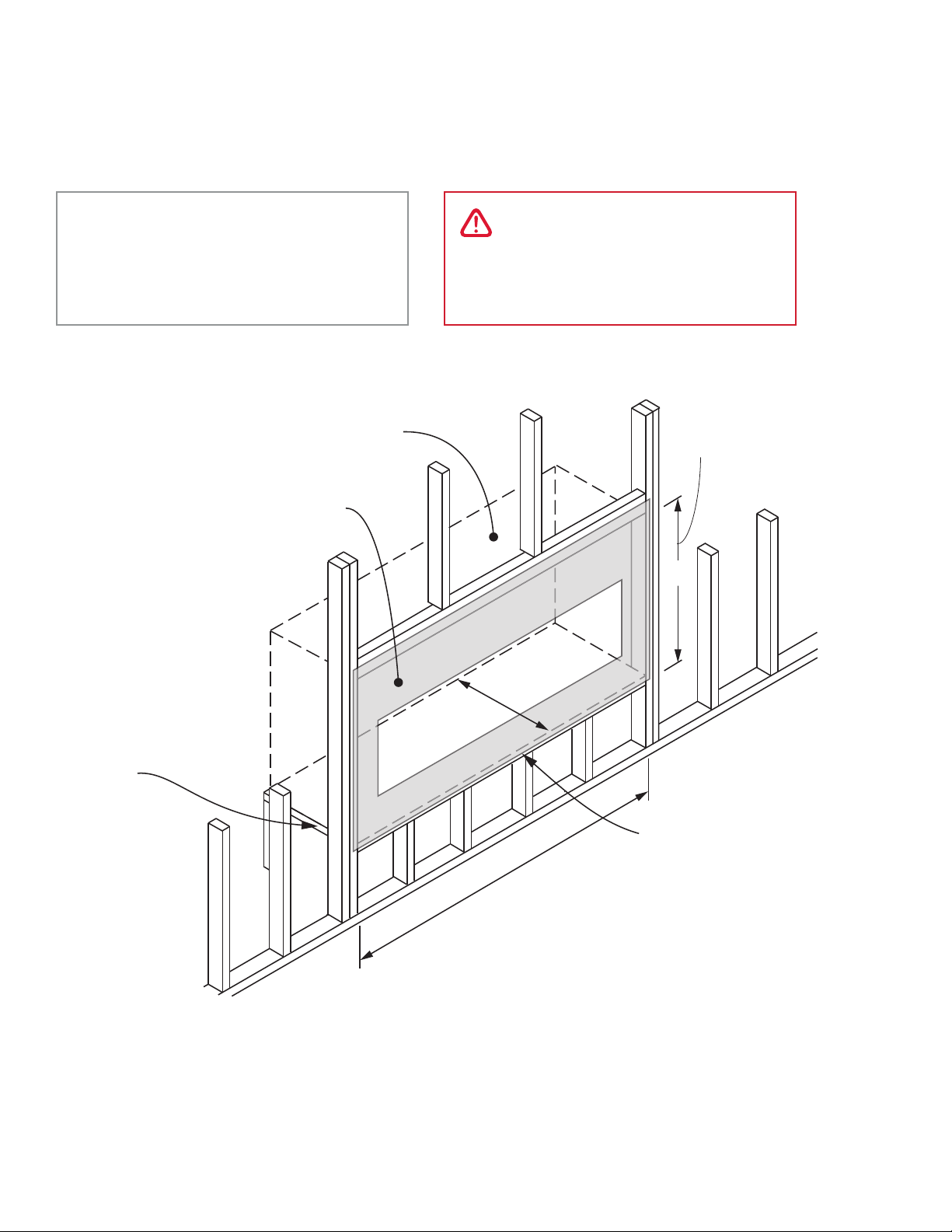

Installation Planning

Framing Dimensions

Framing

NOTE

Use fo the optional HeatShift

System affects mantel and hearth

clearances. See HeatShift section in

Appendix D of this manual.

NOTE: Height of cavity may be

DHFWHGE\YHQWFRQȴJXUDWLRQ

- see page 15

1/2” thick non-combustible

cement board required above,

on each side and below

engine opening (NOT supplied)

NOTE: This unit requires a

solid platform to support it.

Combustible framing allowed

EHQHDWKȴUHSODFH:KHQWKH

appliance is installed directly

on carpeting, tile or other

combustible material other

WKDQZRRGȵRRULQJWKH

appliance shall be installed

on a metal or wood panel

H[WHQGLQJWKHIXOOZLGWK

and recessed depth of the

appliance

WARNING

HeatShift System MUST be installed

on this appliance when using

1730CIK—Clean Installation Kit!

Between underside

of header and bottom

RIȴUHER[

43”

20”

57-3/4”

No hearth required.

If using a hearth,

see page 11.

13

Installation Planning

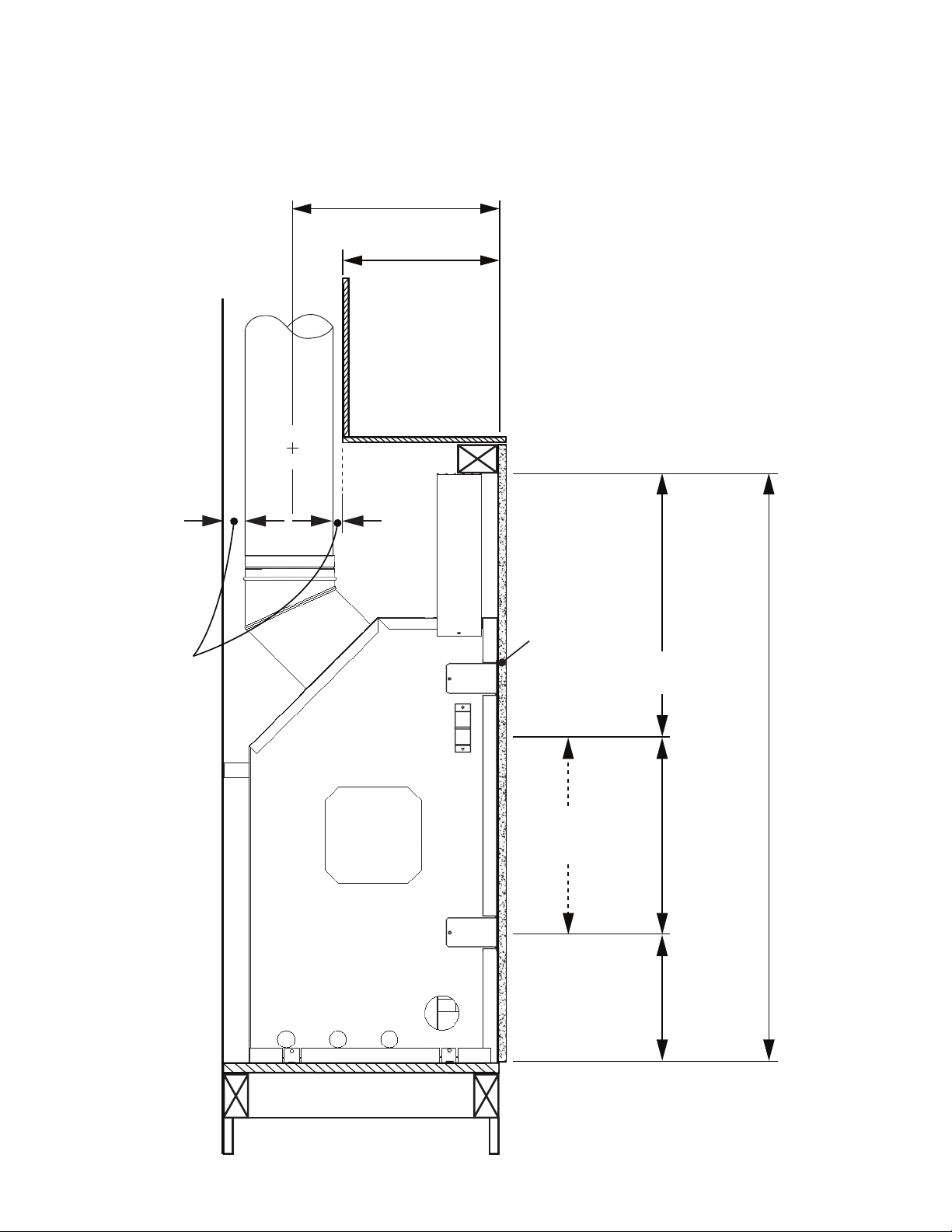

Framing with Partial Shelf—Top Outlet

15-1/16”

[383 mm]

Approx. 10-3/4”

[274 mm]

from back

surface of

ZDOOȴQLVKWR

front surface

of appliance

case w/no

YHQWRVHW

Framing

Min. 1”

[25 mm]

clearance to

combustibles

around

vertical

vent pipe

19-1/4”

ȋWKLFN

non-combustible

Cement Board

Fireplace

Opening

14-1/2”

9-3/8”

[489 mm]

[369 mm]

43” [ 1093 mm] to underside of combustible cavity

[238 mm]

14

PARTIAL SHELF, top outlet

Installation Planning

Venting Considerations—Vertical Takeoff

24” pipe section

Min 1”

[25 mm]

*67-1/2” [ 1715 mm] with 24” vent pipe

Required

clearance

to vertical

37” [940 mm]

stand-o

pipe is

within

space

Fireplace Left Side View

Stand-o

19-1/4”

[489 mm]

14-1/2”

[369 mm]

9-3/8”

[238 mm]

Framing

*Notes—ALL venting considerations

• Dimensions of venting are based on using Dura-Vent elbows. Elbow curve radius

dimensions will vary when using other

brands. In general, other brands have

slightly bigger radius.

• Minimum 24 inches vertical pipe section

required right at unit. Refer to venting chart

on page 30 for allowable horizontal runs.

• 3 inches clearance to combustibles required above horizontal pipe. Slope horizontal pipe upwards 1/4 inch per foot. 1

inch clearance required around sides and

bottom of horizontal pipe and around vertical pipe.

• When calculating eff ective pipe lengths

subtract approximately 1-1/2 inch for pipe

joint - for example, a 12 inches pipe section will add approximately 10-1/2 inches

overall.

43” [ 1093 mm] to underside of combustible cavity

Venting Considerations—Horizontal Takeoff

24” pipe section

*70” [ 1778 mm] with 24” vent pipe

36-1/2” [927 mm]

2-1/2”

[64 mm]

Fireplace Left side view

19-1/4”

[489 mm]

14-1/2”

[369 mm]

9-3/8”

[238 mm]

43” [ 1093 mm] to underside of combustible cavity

15

Installation Planning

Wall Finish

Material Specifi cations

Non-Combustible

Material which will not ignite and burn. Such materials

are those consisting entirely of steel, iron, brick, tile,

concrete, slate, glass or plasters, or any combination

thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in a

Vertical Tube Furnace at 750°C shall be considered

non-combustible materials.

Combustible

Materials made of or surfaced with wood, compressed

paper, plant fi bers, plastics, or other material that

can ignite and burn, whether fl ame proofed or not,

or plastered or unplastered shall be considered

combustible materials.

Minimal coverage area of non-combustible cement board.

Any wall ȴQLVKDSSOLHGWRVKDGHGDUHDPXVWEHQRQFRPEXVWLEOH

Min. 60” [1524 mm]

Non-Combustible Cement Board

The L2 Linear fi replace requires a 1/2” (13mm) thick

non-combustible cement board to be used as a wall

surface immediately surrounding the unit’s opening—

see diagram for minimum coverage.

Extending the cement board well beyond the minimum

shown will help avoid cracking due to diff erential

expansion of materials.

Pre-drill cement board with oversized holes and do

not over-tighten screws to avoid cracking due to heat

expansion.

Standard gypsum wall board may be used beyond the

perimeter of the cement board.

NON-COMBUSTIBLE MATERIALS ONLY

MATÉRIAUX INCOMBUSTIBLES SEULEMENT

READ INSTRUCTIONS

CONSULTEZ LE GUIDE D’INSTALLATION

DD

A

B

Min. 44-1/2” [1130 mm]

C

With 1750 or

inches [mm]

1775 trims

Min. 20-1/2 [521] Min. 20-1/8 [511]

A

14-3/4 [375] 15-13/16 [401]

B

Min. 9-1/4 [235] Min. 8-9/16 [218]

C

Min. 5 [127] Min. 4-1/2 [114]

D

Min. 50 [1270] Min. 51-1/16 [1296]

E

E

NON-COMBUSTIBLE MATERIALS ONLY

NON-COMBUSTIBLE MATERIALS ONLY

READ INSTRUCTIONS

MATÉRIAUX INCOMBUSTIBLES SEULEMENT

CONSULTEZ LE GUIDE D’INSTALLATION

READ INSTRUCTIONS

MATÉRIAUX INCOMBUSTIBLES SEULEMENT

CONSULTEZ LE GUIDE D’INSTALLATION

with 1730CIK kit

Non-combustible

cement board

required thickness:

1/2” [13 mm]

Linear 1700 outline

LQFOXGLQJVWDQGRV

Joints preferred at corners

to prevent cracking

Flush with bottom of unit;

add extra cement board

to overlap framing.

16

Installation Planning

1/4”

(235 mm)

Possible screw loc

(in the designated

ard flush with bo

of heater; add extra

overlapping framing

Non-Combustible Finishing Over Cement

Board

Additional non-combustible material such as tile, etc.,

may be applied over top of the cement board or you

may choose to leave it fi nished clean with no tile, etc.

Be aware that a trim is always required. Finish should

not cover the trims.

1775 and 1750 Trims

Only the 1775 and 1750 style trims will accept tile, etc.

tucked behind them (up to 5/8” thick for the 1775 and

up to 1 inch thick for the 1750).

1730 Trim

1730 trim must be installed BEFORE cement board.

Cement board and fi nishes are applied to the perimeter

of the trim frame. Cement board and fi nished CANNOT

be tucked under this trim.

Wall Finish

Wider trim (1750)

can adjust up to 1”

forward of sur face of

cement board.

Cement board tucks

behind trim.

Narrow trim (1775)

can adjust up to 5/8”

forward of sur face of

cement board.

Cement board tucks

behind trim.

Clean Installation

Kit 1730CIK requires

HeatShift. Cement

board fi nishes up to

perimeter of frame.

Must install

BEFORE cement

board.

17

Installation Planning

Wall Finish

Avoiding Cracking Wall Finishes

We recommend installing the optional HeatShift

System to reduce the wall temperatures and minimize

the possibility of cracking wall fi nishes.

WARNING

HeatShift System MUST be installed on

this appliance when using 1730CIK—Clean

Installation Kit.

If a clean fi nish with no tile, etc. is desired, joints in the

cement board and the transition to gypsum board

will require special attention if future cracking is to be

controlled. Be aware that temperatures on the noncombustible wall surface above the appliance can

exceed 200°F (93°C).

Below are some tips on how to best avoid any cracking:

• Allow materials to dry thoroughly before fi nishing the

wall. Cement board has the ability to absorb up to 30

percent of its weight in water and may shrink as much

as 1/8” over a 48” length when drying from a saturated condition. Running the fi replace for an extended

period before fi nal fi nishing will help drive out mois-

ture.

• Always pre-drill screw holes through cement board

and use screws specifi c for material used.

• Always use mesh tape over joints.

• Always stagger joints in wall board.

• Behind joints, double up studs or use studs “on the

fl at” to add extra support to the joint. Adhesive on

the backside of wall board behind any joints can help

control diff erential movement.

• Use multiple, thinner coats of joint compound and allow to dry thoroughly between coats.

• Ensure framing materials are dry.

• After fi nishing the wall, introduce heat gradually to

slowly dry any excess moisture rather than drying too

fast.

• Avoid notching cement board or tiles around corners

of window opening and instead provide a joint that

intersects the corner.

• Avoid using lage one-piece slab of material with a

cut-out in the middle as a surround for the fi replace.

Expansion above the opening will cause cracking at inside corners. Provide a joint that intersects the inside

corner to avoid cracking.

18

Provide joints

either here or

here

Cracks

Venting

Overview

Top or Rear Outlet

This unit is supplied with a top vent outlet which can

be fi eld-converted to a rear vent outlet. See Appliance

Preparation section for more information.

Vent Material

This unit is approved for installation using

4 x 6-5/8 inches co-axial direct vent pipe and

accessories as listed in the Approved Venting Components

section on pages 61–62 of this manual. Follow the

installation instructions supplied with the individual

venting accessories.

This unit may also be converted to co-linear (1 x 3 in by

1 x 4 in) venting for use in solid-fuel burning fi replaces

and chimneys using adapters and accessories—see list

in the Approved Venting Components section on pages

61–62 of this manual.

Vent Sealing

Seal all outer coaxial pipe and elbow joints, including

sectioned elbow joints, using high quality, high temperature 2 inch wide self-adhesive aluminum foil tape

(Nashua-322-2 brand or similar). Wrap the tape completely around all joints and press fi rmly to seal.

A high temperature black silicone sealant may be used

in the outer joints as a substitute to foil tape.

Ensure all the pipe joints have a minimum of 1¼ inch

overlap.

Tape all joints

(including all

elbow joints)

Wall Thickness

The appliance vent is suitable for penetrating a

combustible wall assembly up to 8 inches in thickness.

A non-combustible wall can be of any thickness up to

the maximum horizontal run of vent pipe allowed for

the particular installation.

Framing Vent in Combustible Walls & Ceilings

When penetrating through combustible walls and

ceilings, frame a minimum of 10 in x 10 in opening and

ensure that the insulation is kept clear of the vent pipe

using either a wall thimble or an attic insulation shield.

Follow the installation instructions supplied with the

individual venting components.

Align the vent center

to the center of the

frame

10” (254 mm)

10” (254 mm)

Important Installer Notice – Weather

Sealing & Vapor Barriers

It is the installer’s responsibility to ensure that vent

installations through exterior walls are caulked and

weatherproofed in such a manner as to:

• Prevent rain water from entering the wall from the

weather side by adequately caulking the outer vent

plate to the exterior wall surface.

• Prevent moisture inside the home from penetrating into the wall structure by ensuring the inside

wall plate is adequately sealed to the inside vapor

barrier.

• Prevent rain water and moisture from entering the

walls by sealing the joints between the outer vent

tube and the inner and outer wall plates.

We recommend the use of a high quality

polyurethane sealant.

All horizontal pipe runs must be graded 1/4 inch per

foot upwards in the direction of the exhaust fl ow. The

fi nal pipe length, when terminating through the wall

may be graded downwards slightly to prevent water

migration.

19

HORIZONTAL

TERMINATION

2-PIECE

WALL THIMBLE

PIPE LENGTH

HORIZONTAL

TERMINATION

2-PIECE

WALL THIMBLE

PIPE

LENGTH

PIPE

LENGTH

PIPE

LENGTH

PIPE

LENGTH

90˚ ELBOW

CEILING

FIRESTOP

ATTIC

FIRESTOP

ATTIC

INSULATION

SHIELD

FLASHING

STORM

COLLAR

VERTICAL

TERMINATION

PIPE

LENGTH

90˚ ELBOW

90˚ ELBOW

Venting

Typical Co-axial Venting Components

Co-Axial

Rear Outlet

20

Top Out l et Top Out l et

Venting

Co-Axial

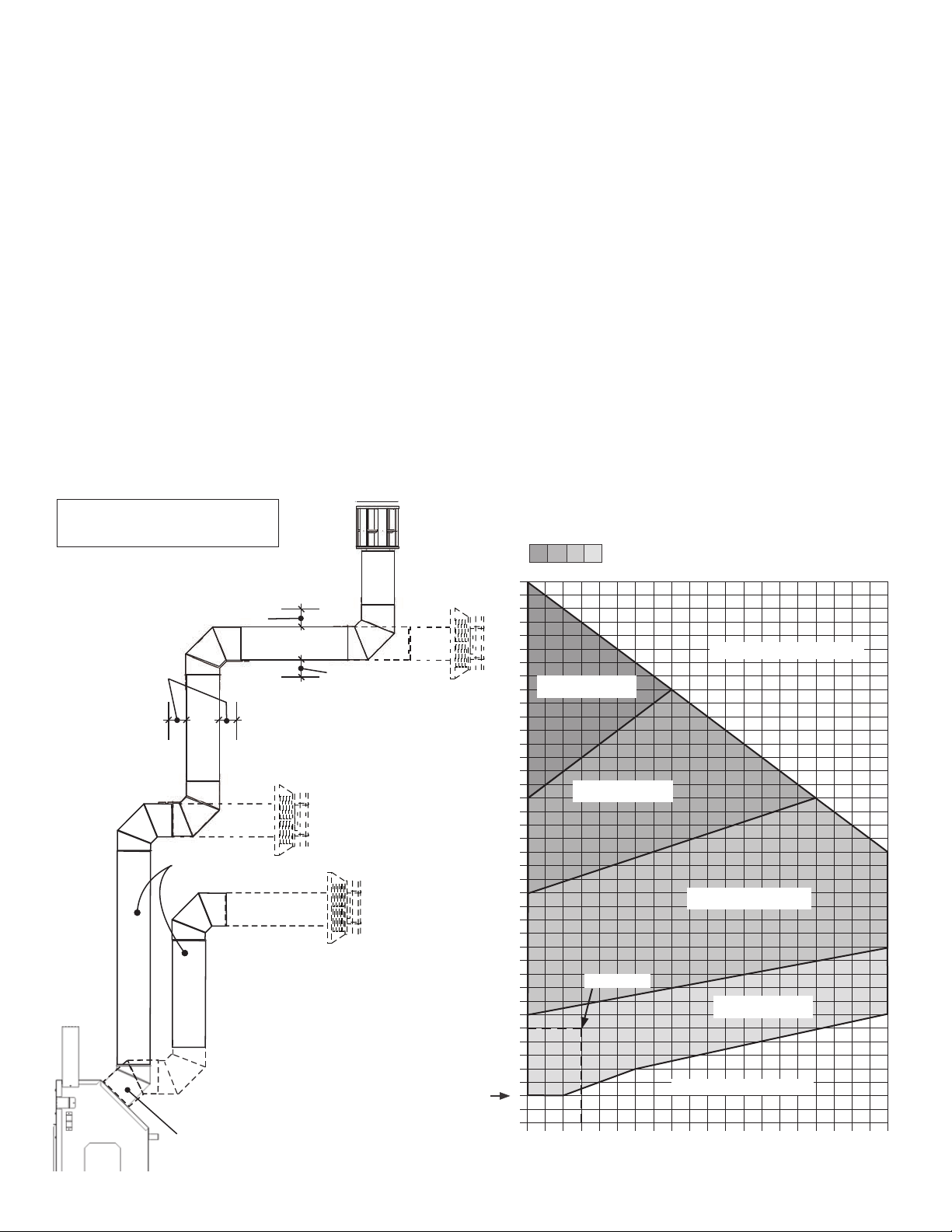

How to Read the Venting Chart

The chart below applies to co-axial roof or wall

termination.

1. A minimum vertical rise of 24 inches is required

directly off the unit or after fi rst elbow, as shown.

2. The total length of the vent pipe cannot exceed

40 feet.

3. The minimum vertical height with roof termination

is 6 feet.

4. Any combination of rise and run can be used as

long as they are within the allowable limits shown

on the chart below.

5. A maximum of 4 x 90 degrees elbows—or

equivalent (2 x 45 degrees = 90 degrees)—can

Venting Chart

4 x 90º ELBOWS MA XIMUM

(or equivalent)

V3

1” min. around

bottom & sides

of horizontal pipe

1” min.

all around

vertical pipe

3” min.

above top of

horizontal pipe

H1

V2

be used. Excludes the 45 degrees take-off elbow

shipped with the appliance.

6. Each 90 degrees elbow installed on the horizontal

plane is equivalent to a 3 feet horizontal pipe;

therefore, 3 feet must be subtracted from allowable

horizontal run. (45 degrees elbow is equivalent to

18 inches horizontal pipe.)

7. All horizontal pipe runs must be graded 1/4 inch per

foot upwards in the direction of the exhaust fl ow.

The fi nal pipe length, when terminating through the

wall may be graded downwards slightly to prevent

water migration.

8. A restrictor adjustment is required for most

installations having a vertical rise—see “Restrictor

Settings” on page 22.

Note: The restrictor is shipped installed at the

exhaust exit of the fi rebox.

Allowable Co-Axial

Vent Confi gurations with

restrictor positions

40

38

36

34

32

Position #5

30

28

NO INSTALLATION

V1

Minimum 24”

pipe section

Example 1

V Value = V1 (2 ’) + V2 (4’ ) + V3 (1’)= 7’

H Value = H1 (2’) = 2 ’

Restrictor position # 1 required

45° elbow take-o

supplied with unit

24” minimum

vertical pipe rise

off unit or after

fi rst elbow

26

24

22

20

18

16

14

VERTICAL RISE (ft)

12

10

8

6

4

2

0

02468101214161820

Position #4

Positions #2/3

Example 1

Position #1

NO INSTALLATION

HORIZONTAL RUN (ft)

21

Venting

Restrictor Settings

The restrictor is located in the roof of the fi rebox

hidden above the top liner panel. Adjust the restrictor

before installation of the top liner panel. Should

subsequent adjustment be required, you will need to

remove the top liner panel—see “Liners” on page 38.

ALL INSTALLATIONS REQUIRE A RESTRICTOR for

improved fl ame picture and performance. This unit is

supplied with a pre-fi tted restrictor having fi ve diff erent

positions or settings. The restrictor is shipped mounted

at the maximum open position which is used for rear

venting with no vertical rise. The level of restriction

required depends on the vertical rise in the venting

system and, to a lesser degree, the horizontal run and

number of elbows.

The amount of restriction is based on laboratory tests.

The ideal restrictor position may vary slightly, especially

when the vent pipe length is near the limits of the

acceptable confi gurations for each type of restrictor.

Co-Axial

Inside fi rebox—roof venting port

The chart on the previous page shows

the vent restrictor required relative to the

length of the vent pipe.

To set the restrictor position:

1. Establish the required position of the

restrictor looking up the venting table

on the previous page.

2. Release the screws (2) on each side of

the restrictor already installed on the

fi rebox roof port.

3. Slide the restrictor in the required position.

4. Tighten the screws.

Position #1 Position #2

Position #3 Position #4

22

Position #5

V

G

A

Min. 72”

Max. 72”

Venting

Co-Axial

Horizontal Vent Termination

Horizontal Vent Termination Location

• The vent terminal must be located on an outside

wall or through the roof.

• This direct vent appliance is designed to operate

when an undisturbed airȵ ow hits the outside vent

terminal from any direction.

• The minimum clearances from this terminal that

must be maintained when located on an outside

wall are shown in ȴ gure below. Any reduction in

these clearances could result in a disruption of the

airȵ ow or a safety hazard. Local codes or regulations

may require greater clearances.

• The vent terminal must not be recessed into a wall

or siding.

• The vent terminal should be positioned where any

snowdrifts will not cover it.

• Sidewall vent terminations require a terminal guard

such as 658TG or 845TG when accessible—within 7’

of ground.

Alcove detail

(open on one

side) Normal

ceiling/soɝ t

clearances

apply.

KEY VENT TERMINAL LOCATIONS - MINIMUM DISTANCES

Inches Cm

A Clearance above grade, verandah, porch, deck or balcony 12 30

B Clearance to window or door that may be opened 12 30

C Clearance to permanently closed window (recommended to prevent condensation on window) 12 30

Vertical clearance to ventilated soɝ t located above the terminal within a horizontal distance of 2 feet (60 cm)

D

from the center-line of the terminal

E Clearance to unventilated soɝ t 12 30

F Clearance to outside corner 12 30

G Clearance to inside corner 12 30

Horizontal clearance to center-line of meter/regulator assembly located within 15 feet (4.6bm) below the

H

terminal

Clearance to service regulator vent outlet

I

J Clearance to non-mechanical air supply inlet to the building or the combustion air inlet to any other appliance 12 30

K Clearance to a mechanical air supply inlet 72 180

Clearance above paved sidewalk or a paved driveway located on public property

Note: A vent must not terminate directly above a sidewalk or paved driveway, which is located bet ween t wo single-

L

family dwellings and serves both dwellings. THIS DOES NOT APPLY to direct vent, non-consdensing appliances in

the Province of Ontario.

Clearance under a verandah, porch, deck or balcony

M

Only permitted if veranda, porch, deck or balcony is fully open on a minimum of 2 sides beneath the ȵ oor

Note: Local codes and regulations may require di erent clearances.

MINIMUM

CLEARANCE

18 4 6

36 90

36 90

84 210

12 30

23

Venting

Vertical Vent Termination

Co-Axial

Roof Pitch

Flat to 7/12 1'

Over 7/12 to

8/12

Over 8/12 to

9/12

Over 9/12 to

10/12

Over 10/12 to

11/ 12

Over 11/12 to

12/12

Over 12/12 to

14/12

Minimum

"H" (feet)

1.5'

2.5’

3.25’

Overhang should not

extend beyond vent if

Horizontal

overhang

2’

Vertical

wall

4’

5’

Roof

ashing

Termination

cap

Min.

18”

Storm

collar

within 48” of

termination cap

Min. 24”

(unvented sot)

Min. 36”

(vented sot)

‘H’

24

Venting

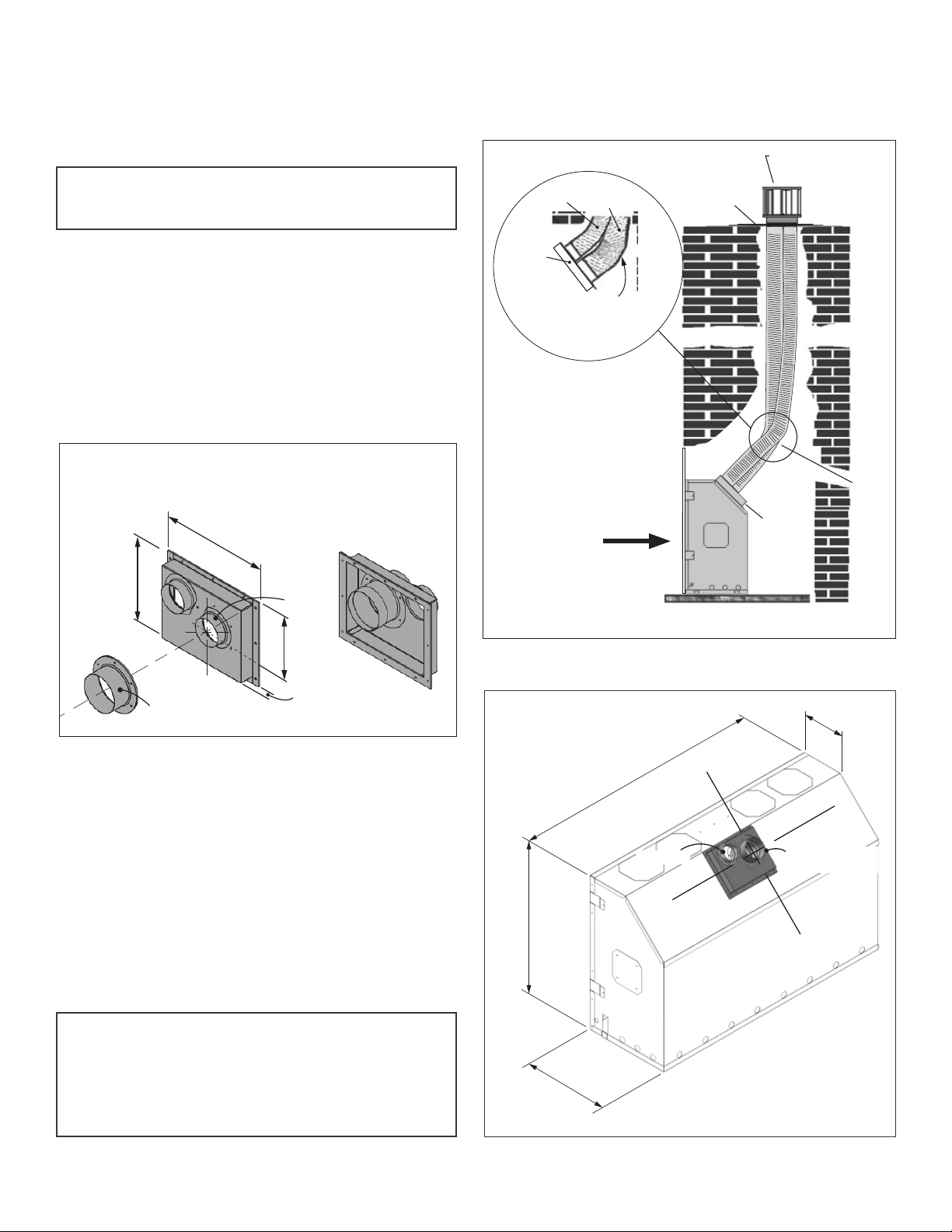

Co-Linear Conversion

Installation into existing fi replace cavity

Note: Co-linear portion of vent system may only be

installed within a solid-fuel burning fi replace and

chimney.

The appliance must not be connected to a chimney fl ue

serving a separate solid-fuel burning appliance.

Requires the Valor Co-Axial to Co-Linear appliance

Adapter 1156CLA, two lengths of 2-ply fl exible chimney

liner both approved for venting gas appliances: one 3”

diameter liner for intake and one 4” diameter liner for

exhaust, a 3 x 4 co-linear termination kit and fl ashing.

Firebox zero clearance standoff s supplied with the heater

may be removed to suit this application.

1156CLA Co-Linear Vent Adapter

FRONT REAR

11-11/16”

9-3/8”

3” exhaust

collar

3” intake

liner

Co-linear

adapter

3” min. bend radius

for intake liner and

4” min. bend radius

for exhaust liner

Any fi nishes

applied

around the

fi replace

must be non-

combustible

4” exhaust

liner

Flashing

Engine

Approved 3 x 4 co-linear

termination

1156

Co-linear

adapter

1 x 3”

intake

liner

and

1 x 4”

exhaust

liner

4”

4” exhaust

collar adapter

1-1/2”

Rules for Co-Linear Venting

• Maximum 40 feet vertical pipe

• Minimum 10 feet vertical

• Maximum off set 8 feet with liners at minimum

45 degrees from horizontal plane

• Restrictor: Not required when using co-linear venting.

Installation

For installation of the adapter to the appliance, see the

instructions supplied with the 1156CLA.

Note: Co-linear fl exible aluminum venting should be

professionally inspected periodically for corrosion

and damage and replaced when necessary. If the

installation does not allow for future inspection or

replacement of the fl exible aluminum venting, then

stainless steel vent liners should be used.

Co-Linear installation into existing fi replace

Dimensions with 1156CLA Co-Linear Adapter

52”

3” intake

32-3/8”

18-1/8”

8-5/8”

4” exhaust collar

on the centerline

25

Venting

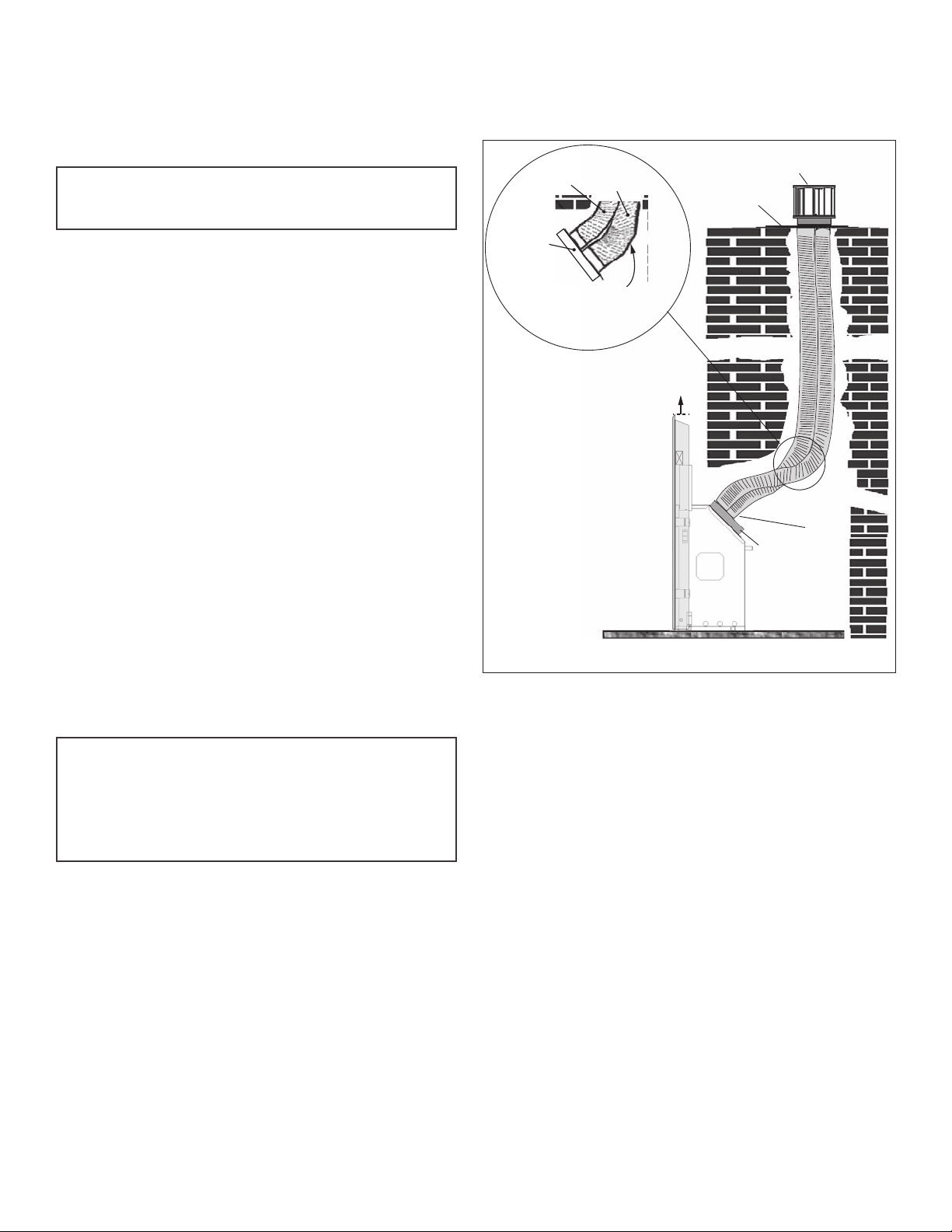

Co-Linear Conversion

Installation partially into fi replace cavity

Note: Co-linear portion of vent system may only be

installed within a solid-fuel burning fi replace and

chimney.

The appliance can be adapted to co-linear applications

using an existing chimney. The appliance must not be

connected to a chimney fl ue serving a separate solid-

fuel burning appliance.

Requires the Valor Co-Axial to Co-Linear appliance

Adapter 1156CLA, 46DVA-GLC34 or equivalent, two

lengths of 2-ply fl exible chimney liner both approved

for venting gas appliances: one 3” diameter liner for

intake and one 4” diameter liner for exhaust, a 3 x 4 colinear termination kit and fl ashing.

The appliance must be fully enclosed while maintaining

clearances to combustibles detailed elsewhere in this

manual.

Rules for Co-Linear Venting

• Maximum 40 feet vertical pipe

• Minimum 10 feet vertical

• Maximum off set 8 feet with liners at minimum

45 degrees from horizontal plane

• Restrictor: Not required when using co-linear venting.

Approved 3 x 4

3” intake

liner

Co-linear

adapter

3” min. bend radius

for intake liner and

4” min. bend radius

for exhaust liner

Co-Linear installation partially into existing fi replace

4” exhaust

liner

Clearances

to combustible

materials listed

elsewhere in this

manual apply

Framed

wall

co-linear termination

Flashing

1156

Co-linear

adapter

Engine

1 x 3”

intake

liner

and

1 x 4”

exhaust

liner

Note: Co-linear fl exible aluminum venting should be

professionally inspected periodically for corrosion

and damage and replaced when necessary. If the

installation does not allow for future inspection or

replacement of the fl exible aluminum venting, then

stainless steel vent liners should be used.

26

Venting

Co-Linear Conversion

Installation into existing adjacent chimney

Note: Co-linear portion of vent system may only be

installed within a solid-fuel burning fi replace and

chimney.

The appliance can be adapted to co-linear applications

using an existing chimney. The appliance must not be

connected to a chimney fl ue serving a separate solid-

fuel burning appliance.

Requires the Co-Axial to Co-Linear appliance Adapter

46DVA-34CLAA or equivalent, two lengths of 2-ply

fl exible chimney liner both approved for venting gas

appliances: one 3” diameter liner for intake and one 4”

diameter liner for exhaust, a 3 x 4 co-linear termination

kit and fl ashing.

The appliance must be fully enclosed while maintaining

clearances to combustibles detailed elsewhere in this

manual.

Approved 3 x 4

co-linear termination

4” exhaust

liner

3” intake

liner

Flashing

Rules for Co-Linear Venting

• Maximum 40 feet vertical pipe

• Minimum 10 feet vertical

• Maximum off set 8 feet with liners at minimum

45 degrees from horizontal plane

• Restrictor: Not required when using co-linear venting.

Note: Co-linear fl exible aluminum venting should be

professionally inspected periodically for corrosion

and damage and replaced when necessary. If the

installation does not allow for future inspection or

replacement of the fl exible aluminum venting, then

stainless steel vent liners should be used.

Approved 3 x 4

4” exhaust

liner

3” intake

liner

co-linear termination

Flashing

3” min. bend radius

for intake liner and

3” min. bend radius

for intake liner and

4” min. bend radius

for exhaust liner

46DVA-34CLAA

or 46DVA-GCL34

Engine

Co-linear

adapter

1 x 3”

intake

liner

and

1 x 4”

exhaust

liner

Clearances

to combustible

materials listed

elsewhere in this

manual apply

Installation using 46DVA-34CLA A Installation using 46DVA-GCL34

Framed

wall

4” min. bend radius

for exhaust liner

Clearances

to combustible

materials listed

elsewhere in this

manual apply

46DVA-GCL34

or 46DVA-34CLAA

Co-linear

Framed

wall

adapter

Max. 12”

1 x 3” intake liner

and

1 x 4” exhaust liner

Engine

27

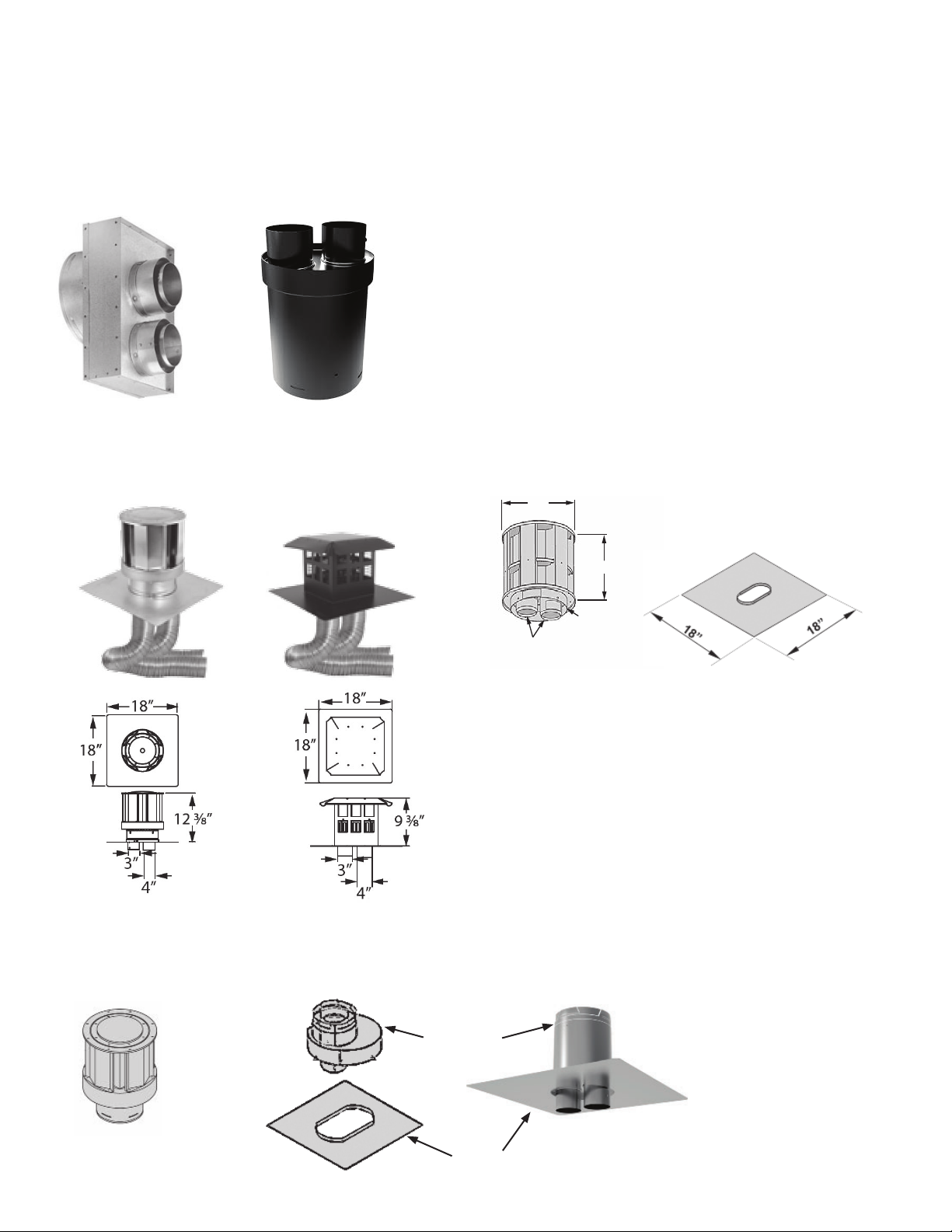

Venting

Example of co-linear conversion accessories

Examples of Co-axial to Co-linear Appliance Adapters

Co-Linear Conversion

46DVA-GCL34

46DVA-34CLAA

Examples of Co-linear Terminal Configurations

10”

10”

7-5/8” dia.

collar

3” Inlet & Exhaust

A 3” - 4”

.

Collars

adapter may be used

for exhaust liner.

Flashing KitCo-Linear Terminal (typical)

Co-linear Termination Kits

Alternate Co-linear to Co-axial Conversion at Terminal

Co-Linear to CoAxial Adapter

With...

Co-axial Terminal Cap

Flashing

28

Installation

Unpack Appliance

Beware of sharp edges! Wear gloves!

1. Remove the cardboard wrapping and the wood pallet from the appliance and discard.

2. Unpack any loose items from around the appliance.

3. Remove the window and set aside in a safe place

to avoid damage—see”Remove Window” on page

32.

4. Verify that you have all the components required for the installation, including:

• approved cement board;

• liners and fuel bed (in separate cartons);

• trim kit with barrier screen;

• venting components and accessories;

• optional HeatShift system if used;

• electrical components if installing optional

decorative light wall switch or blower.

Appliance Preparation

Standoff

Standoff s installed

Fit Standoff s

The standoff s are supplied fl at on the fi rebox sides

and fi xed at one end. Swivel up the fl at standoff s, bend

them as shown and fi x the loose end to the top of the

fi rebox.

Remove Heat Shield

Remove the heat shield from the top of the appliance

case (3 screws). If using a rear outlet, keep the shield

to reinstall after converting the top to rear outlet—see

next subsection. If using the top outlet or the HeatShift

system, discard the shield.

Fold fl at

standoff s

Remove heat shield (3 screws)

29

Installation

Convert from Top to Rear Outlet (if required)

This unit is supplied with a top vent outlet which can

be fi eld-converted to a rear vent outlet.

Please note that the rear outlet requires the installation of the heat shield on top of the heater case as

indicated.

1. Remove the top outlet collar (6 screws).

2. Swivel the collar and install as a rear outlet (6 screws).

3. Reinstall the heat shield to the top of the appliance

case (3 screws).

Appliance Preparation

Remove top outlet (6 screws)

Reinstall heat shield

to top of appliance

(3 screws)

Swivel the outlet so that it

is oriented towards the rear

and reinstall to heater

(6 screws)

30

Rear outlet with required heat shield

Loading...

Loading...